Adam Equipment PGL User Manual

PGL SERIES

(P.N. 309669326, Revision E, November 2011)

Adam Equipment

© Adam Equipment Company 2011

Easy Reference:

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2011

CONTENTS

2.0

INTRODUCTION...................................................................................3

3.0 SET UP .................................................................................................4

3.1 UNPACKING AND SETTING UP YOUR SCALE.................................................4

3.2 ASSEMBLING THE BALANCE (PGL 203 to PGL 8001).....................................4

3.3 LEVELLING THE BALANCE................................................................................5

3.4 WARM-UP TIME..................................................................................................5

4.0 DISPLAY...............................................................................................7

5.0 KEYPAD ...............................................................................................8

5.1 NUMERIC ENTRY METHOD...............................................................................9

6.0 BASIC OPERATION ...........................................................................10

6.1 INITIALISATION ................................................................................................10

6.2 PASSCODES.....................................................................................................11

6.3 WEIGHING ........................................................................................................11

6.4 WEIGHING UNITS.............................................................................................12

7.0 FUNCTIONS .......................................................................................13

7.1 PARTS COUNTING...........................................................................................13

7.2 PERCENT WEIGHING ......................................................................................14

7.3 CHECK WEIGHING...........................................................................................15

7.4 DENSITY DETERMINATION............................................................................17

8.0 CALIBRATION....................................................................................20

8.1 MANUAL CALIBRATION ...................................................................................20

8.2 AUTOMATIC CALIBRATION.............................................................................21

8.3 CALIBRATION ERRORS...................................................................................21

8.4 CALIBRATION REPORT ...................................................................................22

9.0 RS-232 INTERFACE...........................................................................23

9.1 HARDWARE......................................................................................................23

9.2 STANDARD FORMAT .......................................................................................25

9.3 INPUT COMMANDS USING REMOTE KEYS...................................................25

10.0 BATTERY OPERATION......................................................................27

11.0 ERROR CHECKING ...........................................................................27

12.0 SUPERVISOR MENUS......................................................................28

12.1 ENABLE WEIGHING UNITS .............................................................................28

12.2 ENABLE WEIGHING MODES...........................................................................29

12.3 ENABLE SERIAL INTERFACE PARAMETERS................................................29

12.4 SETUP PARAMETERS .....................................................................................31

12.5 CALIBRATION SETUP ......................................................................................32

12.6 PASSCODES.....................................................................................................33

13.0 SPECIFICATIONS .............................................................................34

14.0 WARRANTY STATEMENT................................................................36

1 | P a g e © Adam Equipment Company 2011

2 | P a g e © Adam Equipment Company 2011

2.0 INTRODUCTION

Thank you for selecting the PGL Balance.

This Instruction Manual will familiarize you with the installation, accessories,

trouble-shooting, after sales service information, general maintenance of the

balance, etc. and will guide you through the various applications.

Please read this Manual thoroughly before starting the operation. If you need any

clarifications, feel free to contact your supplier or Adam Equipment.

PRODUCT OVERVIEW

The PGL balances are ideal for laboratory and general purpose weighing. The

balances can also be used for some advanced weighing functions.

FEATURES:

PGL series

•

Multiple weighing units

•

Capacity tracker

•

Date and time

• Large easy to read LCD display with backlight

• Standard applications include weighing,

check weighing, percentage weighing, parts

counting, and density determination

• Bi-directional RS-232 interface

• Can be configured to print a GLP Compliant

report after each calibration to include the

time, date, balance number and a

verification of the calibration

•

Easy to use, sealed keypad

•

Below balance weighing facility

•

Password protection

•

Security locking point (up to PGL 8001)

•

Robust metal casing

3 | P a g e © Adam Equipment Company 2011

3.0 SET

UP

3.1 UNPACKING AND SETTING UP YOUR SCALE

Remove the balance from the packing by carefully lifting it out of the box. Inside

the box you will find everything needed to start using the balance-

AC adapter

Stainless Steel Top Pan

Draught shield (for mg models only)

This User Manual

3.2 ASSEMBLING

THE BALANCE (PGL 203

TO

PGL

8001)

Locate the balance on a solid surface, free from vibration

Gently place the pan support (if not already fitted) and then the stainless steel

pan on the weighing platform

Gently place the 4 pan supports (if not already fitted) and then the stainless steel

pan on the weighing platform

Place the draught shield frame and the top cover around the pan (PGL 203, 303

models only)

Level the balance using the adjustable feet and spirit level

Connect power to the balance

For best performance, let the balance warm up for 30 minutes and calibrate

before using

4 | P a g e © Adam Equipment Company 2011

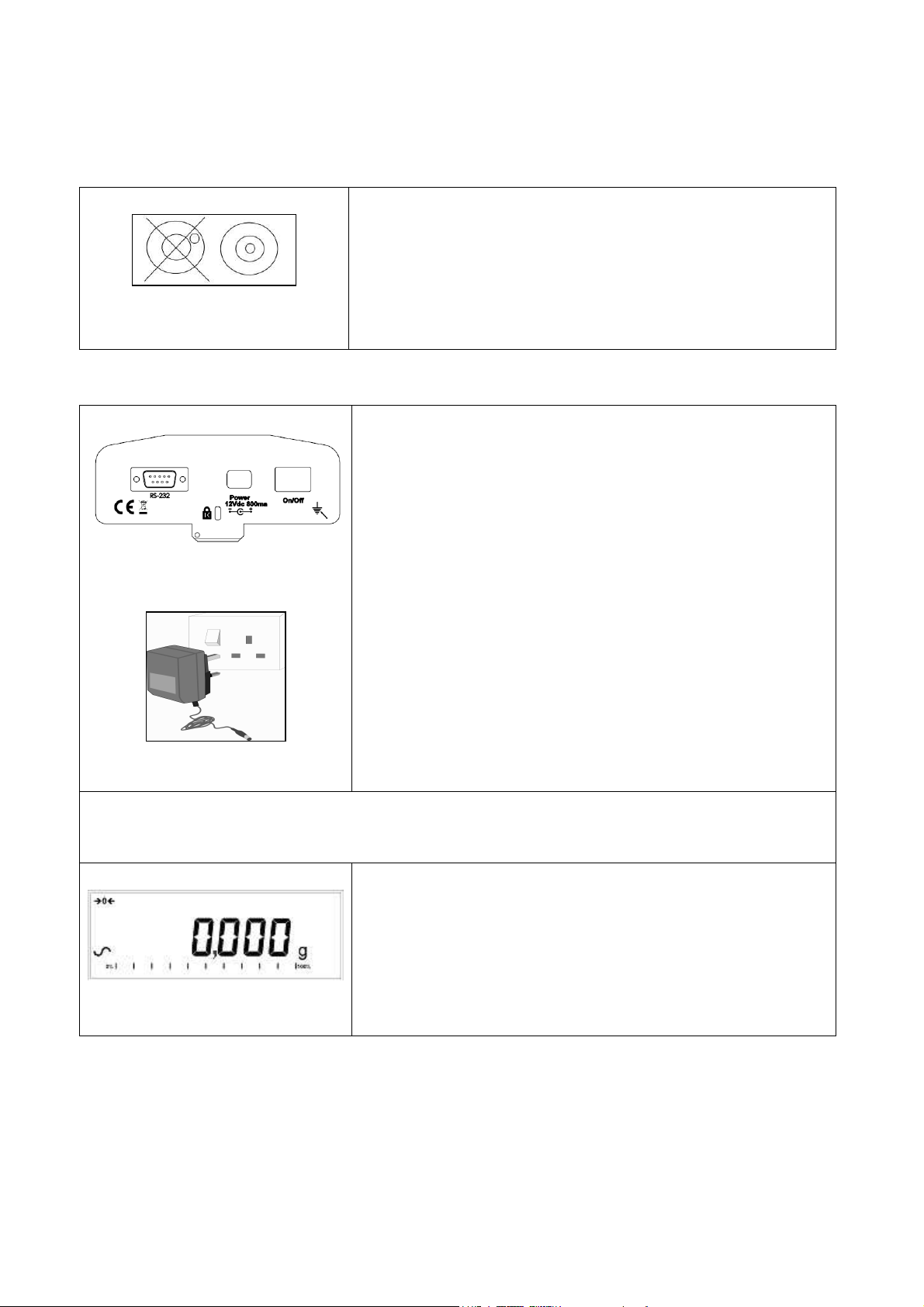

3.3 LEVELLING THE BALANCE

3.4 WARM-UP TIME

After placing the balance in a suitable place, level it

by using the spirit level on the rear of the balance. To

level the balance turn the two adjustable feet at the

rear of the balance until the bubble in the spirit level

is centered.

Attach the power supply cable to the connector on

the rear of the balance. Plug the power supply

module into the mains. The display will indicate the

balance serial number (if set) and the software

revision number followed by the capacity of the

balance. Next the balance will run a self-test by

displaying all segments followed by a symbol

indicating the balance is in busy mode. If the balance

serial number is not set the display will show dashes.

The display will show zeroes accompanied by the

0 symbol.

Before you start weighing, you have to wait for the balance to achieve a stable

internal temperature.

A stable sign ~ is shown when the balance is in

stable condition. It will turn off if the balance is not

stable.

Exact zero is shown when the “0 “ symbol is on

to the left of the display area.

5 | P a g e © Adam Equipment Company 2011

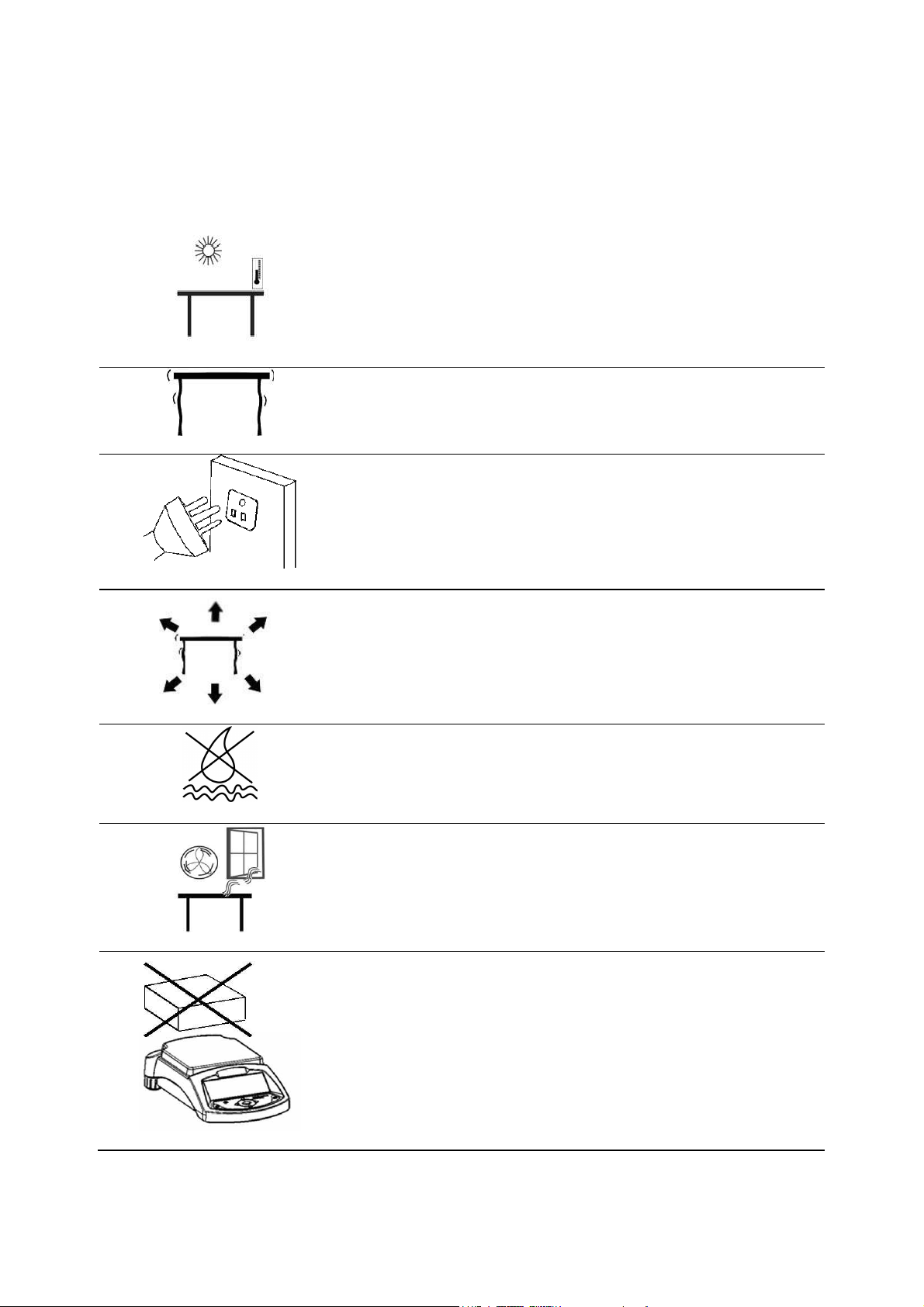

3.5 LOCATING AND PROTECTING YOUR SCALE

In order to keep your scale functioning at its best we suggest that you do the

following:

Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

Make sure the scale is located on a strong table and

free from vibration.

Avoid unstable power sources. Do not use near large

users of electricity such as welding equipment or

large motors. Use only the factory approved power

adapter supplied with the machine.

Keep free from vibration. Do not place near heavy or

vibrating machinery.

Avoid high humidity that might cause condensation.

Keep away from direct contact with water. Do not

spray or immerse the scales in water.

Do not place near open windows, air-conditioning

vents or fans that may cause a draft and unstable

readings.

Keep the scales clean. Do not stack material on the

scale / balance when it is not in use.

6 | P a g e © Adam Equipment Company 2011

4.0 DISPLAY

The LCD has unique symbols to indicate the following:

0

Net

g, kg, ct, oz, lb, ozt, GN, dwt, dr, tl H, tl

T, tl S, MM, T, ti, N, g/cc, Pcs, %, M, and

S

Zero

Stable

Net weight

A bar graph indicating the proportion of the

balance capacity being used by the weight on

the pan

Symbols shown for the units

Not all weighing units are used

Low Battery symbol. On when the battery

voltage is low, signaling the battery should

be recharged.

INDICATORS

“CAL”

“ºC”

“ti”

“Net”

“0%”,

“100%”

7 | P a g e © Adam Equipment Company 2011

When calibration is occurring or is requested

When a temperature is shown

For a time driven calibration

When a net weight is shown

When the capacity tracker is showing percent of maximum range

used

5.0 KEYPAD

The keypad has the following keys to operate the balance.

Keys Primary function Secondary function

To turn the balance to ON or Standby -

[0/T] or [Esc] A combined zero and tare function To escape from setup functions

and modes

[Unit] / or

[Down]

[Mode] / or

[move right]

[Print] / or

[move left]

[Cal] / or [Up] Starts the calibration function

[Setup]/

or [Enter]

-Selects weighing units by cycling

through a set of enabled units

-Scrolls through the options

Enters the Mode Selection Menu To advance a flashing digit by one

Instructs the balance to print data To advance a flashing digit by one

Enters the Setup parameters

(Supervisor Menus)

To decrement or change a

displayed value or scroll through

options backwards

position to the right.

To go back by one step during

setup functions

position to the left

To increase or change a displayed

value or scroll through options

forward

Enters a function or saves a value

while manually entering unit

weight or check weighing limits

8 | P a g e © Adam Equipment Company 2011

5.1 NUMERIC ENTRY METHOD

To set a value when required, use the keys as given below-

- [Up] and [Down] keys to increase or decrease the flashing digit

- [Advance] and [Back] keys to advance or move back the digit

- [Enter] key to accept the value

9 | P a g e © Adam Equipment Company 2011

6.0 BASIC

OPERATION

6.1 INITIALISATION

1) When the balance is first switched on, it will display the balance serial number

(if set), software revision, model capacity and then all segments on the display

will be shown. Overall the time taken is usually 5 -10 seconds.

2) If a passcode has been set, the display will show “PASSCODE” and the main

display will show a zero. In this case you must enter the passcode to continue

using the numeric entry method (see section 5.1). A different passcode may

be set for a Supervisor to weigh or to have access to the selected User menus.

If the passcode has not been set the balance will continue as below.

3) The display will show zero reading along with the zero symbol “→0←” and

the weighing unit last used. If automatic time calibration is enabled the

balance will calibrate after power up and again after the pre-set time interval.

10 | P a g e © Adam Equipment Company 2011

Loading...

Loading...