Adam Equipment

GBK and GFK Series

(

P.N. 9679, Revision C, June 2010)

Software Rev.

V1.17 GK-H scales for Europe

V2.25 EC Approved scale

V3.32 GK scale for USA

V4.07 GK-H scale for USA

V5.32 GK scales for Europe

© Adam Equipment Company 2010

Easy Reference:

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2010

CONTENTS

1. INTRODUCTION......................................................................................3

2. SPECIFICATIONS ...................................................................................4

3. INSTALLATION.......................................................................................9

3.1. UNPACKING ........................................................................................................ 9

3.2. LOCATING ........................................................................................................... 9

3.3 SETTING UP THE SCALES............................................................................... 10

4. KEYPAD ................................................................................................11

5. DISPLAY................................................................................................13

5.1. SYMBOLS AND INDICATORS .......................................................................... 13

6. CALIBRATION COUNTER FOR APPROVED SCALES.......................14

7. BATTERY ..............................................................................................16

8. BACKLIGHT ..........................................................................................16

9. AUTO POWER OFF...............................................................................16

10. OPERATION.......................................................................................17

10.1. ZEROING ........................................................................................................ 17

10.2. TARING........................................................................................................... 17

10.2.1 MANUAL TARE........................................................................................... 17

10.2.2 PRESET TARE (NOT AVAILABLE ON APPROVED SCALES)................. 18

10.3. WEIGHING...................................................................................................... 19

10.4. PARTS COUNTING ........................................................................................ 19

10.5. CHECK-WEIGHING........................................................................................ 22

10.5.1 SETTING UP WHILE WEIGHING ............................................................... 23

10.5.2 SETTING UP WHILE PARTS COUNTING OR % WEIGHING.................... 24

10.6. LIMITS STORING AND RECALLING............................................................. 24

10.7. PERCENT WEIGHING.................................................................................... 26

10.8. ANIMAL (DYNAMIC) WEIGHING................................................................... 29

10.8.1 ANIMAL WEIGHING PROCEDURE............................................................ 30

10.9. ACCUMULATED TOTAL................................................................................ 31

10.9.1 MANUAL ACCUMULATION ....................................................................... 31

10.9.2 AUTOMATIC ACCUMULATION ................................................................. 33

11. RS-232 SPECIFICATION....................................................................34

11.1. INPUT COMMANDS FORMAT....................................................................... 39

12. CALIBRATION....................................................................................40

13. PARAMETER SETTINGS...................................................................41

13.1. CHECK WEIGHING PARAMETERS .............................................................. 41

13.2. RS-232 PARAMETERS .................................................................................. 44

13.3. SCALE PARAMETERS .................................................................................. 46

13.4. PERCENT WEIGHING AND ANIMAL WEIGHING......................................... 48

14. ERROR MESSAGES ..........................................................................49

15. SERVICE PARAMETERS...................................................................51

15.1. ACCESS TO PARAMETERS ......................................................................... 51

15.2. USING “1000” TO ENTER THE SERVICE PARAMETERS........................... 52

16. REPLACEMENT PARTS AND ACCESSORIES.................................57

17. SERVICE INFORMATION ..................................................................58

18. WARRANTY INFORMATION .............................................................59

19. APPENDIX..........................................................................................60

1 | page

© Adam Equipment Company 2010

2 | page

© Adam Equipment Company 2010

1. INTRODUCTION

• The GBK/GFK scales provides an accurate, fast and versatile general

purpose weighing scales with parts counting, percent weighing and

check-weighing functions.

• The GBK/GFK has LEDs to indicate when a weight is below the low limit,

between the limits or above the high limit next to the display. These

can work in conjunction with an audible alarm for check weighing as

well as LCD showing LO, OK and HI.

• The GBK/GFK is supplied with a RS-232 bi-directional interface and real

time clock (RTC).

• The GBK/GFK has a sealed keypad with colour coded membrane

switches and a large easy to read liquid crystal type display (LCD)

supplied with a backlight.

• Includes automatic zero tracking, semi-automatic tare and

accumulation facility that allows the weight to be stored and recalled as

an accumulated total.

• OIML Approved models, GBK/GFK-M, do not allow pounds units, have

calibration controlled by jumpers or passcodes and other limitations as

noted in the manual.

3 | page

© Adam Equipment Company 2010

GBK 260a

GBK 120 /

GBK 60 /

GBK 130a

GBK 70a

GBK 32 /

10g/0.02lb

| P a g e © Adam Equipment Company 2010

GBK 16/

GBK 35a

4

GBK 8 /

GBK 16a

12vDC 800mA UL/CSA adapter for USA

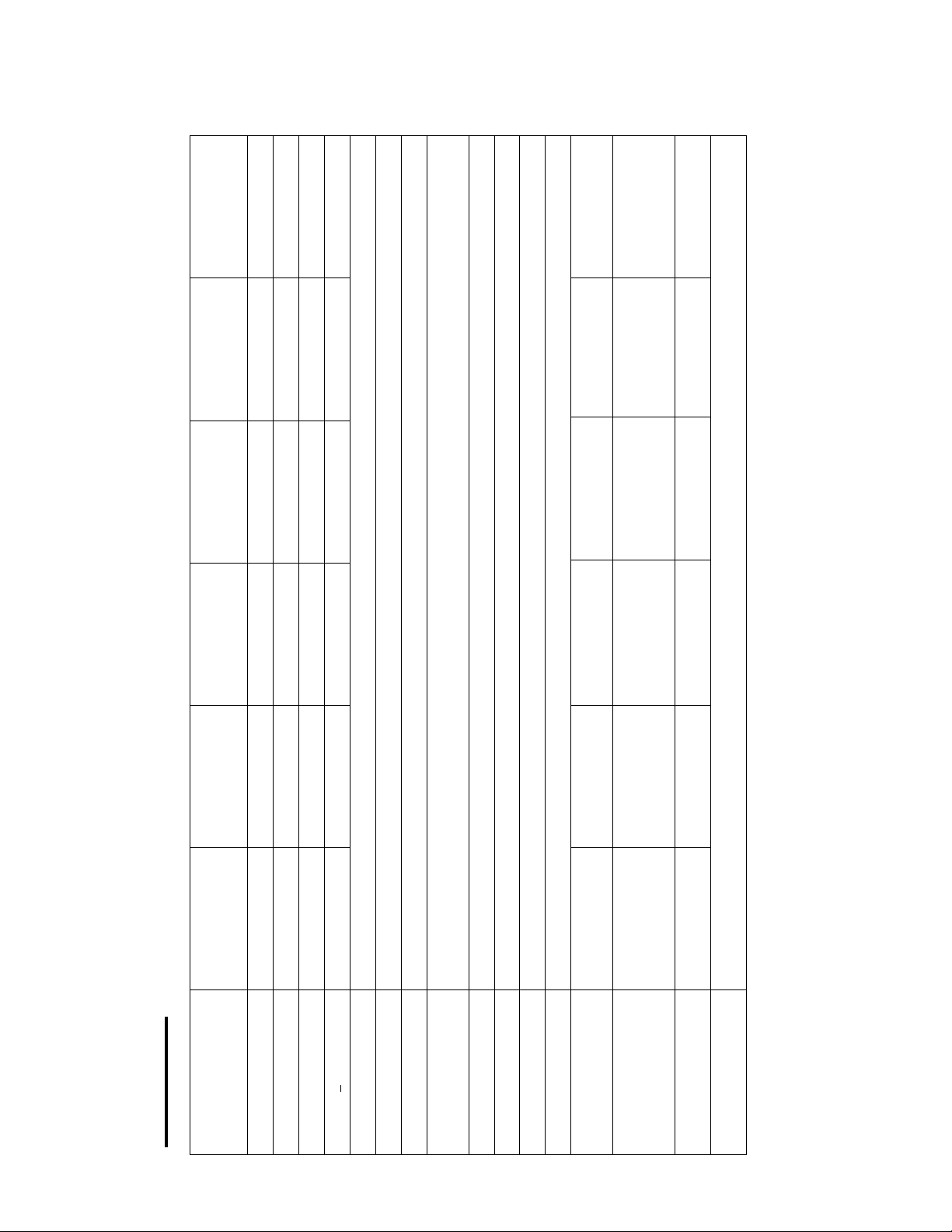

2. SPECIFICATIONS

GBK Models

Model #

Maximum Capacity 8kg/16lb 16kg/35lb 32kg/70lb 60kg/130lb 120kg/260lb

Readability 0.1g/0.0002lb 0.5g/0.001lb 1g/0.002lb 2g/0.005lb 5g/0.01lb

Repeatability (Std Dev) 0.2g/0.0004lb 1g/0.002lb 2g/0.004lb 4g/0.01lb 10g/0.02lb

Linearity + 0.3g/0.0006lb 1g/0.002lb 2g/0.004lb 4g/0.01lb

Units of Measure Grams & Kilograms, XXXa also to have Pounds, Ounces, & Pound/Ounces

Stabilization Time 2-3 Secs

Operating Temperature -10°C to +40°C / +14°F to +104°F

Power Supply 230VAC 50/60Hz. in Europe, Asia and South Africa.

Calibration External

Calibration Mass User Selectable

Display Backlit Green display 25mm with capacity tracker

300mm x 400mm x 32mm / 12” x 15.5” x 1.25”

300mmx 620mm x 860mm for small pillar version, 300 x 820 x 860mm for large pillar

Balance Housing Cast aluminum base, Pantone cool grey painted base, stainless steel grade 304 Top pan, ABS Cool grey indicator housing

Pan Size

Overal Dimensions

(w x d x h)

Net Weight 15kg / 33 Lb 15kg / 33 Lb 15kg / 33 Lb 15kg / 33 Lb 15kg / 33 Lb

Features Weighing/Counting/Checkweighing with LED lights/Percentage/Hold function/RS232

950 mm

GFK330aH

GFK 150H /

GFK 75H /

GFK165aH

GFK 600 /

GFK 1320a

15.7” x 19.7”

400mm x 500mm

400 mm x 675 mm x

15.7” x 26.6” x 37.4”

950 mm

15.7” x 19.7”

400mm x 500mm

400 mm x 675 mm x

15.7” x 26.6” x 37.4”

970 mm

23.6” x 31.5”

600mm x 800mm

600 mm x 925 mm x

23.6” x 36.4” x 37.4”

950 mm

GFK 660a

GFK 300 /

GFK 330a

GFK 150 /

5g / 0.01lb 10g / 0.02lb 20g / 0.05lb 50g / 0.1lb 1g / 0.002lb 2g / 0.005lb

5g / 0.01lb 10g / 0.02lb 20g / 0.05lb 50g / 0.1lb 2g / 0.004lb 4g / 0.01lb

GFK 75 /

75kg / 165lb 150kg / 330lb 300kg / 660lb 600kg / 1320lb 75kg / 165lb 150kg / 330lb

GFK 165a

10g / 0.02lb 20g / 0.04lb 40g / 0.1lb 100g / 0.2lb 3g / 0.006lb 6g / 0.015lb

12vDC 800mA UL/CSA adapter for USA

15.7” x 19.7”

400mm x 500mm

400 mm x 675 mm x

15.7” x 26.6” x 37.4”

950 mm

15.7” x 19.7”

400mm x 500mm

400 mm x 675 mm x

15.7” x 26.6” x 37.4”

950 mm

15.7” x 19.7”

400 mm x 675 mm x

15.7” x 26.6” x 37.4”

| P a g e © Adam Equipment Company 2010

5

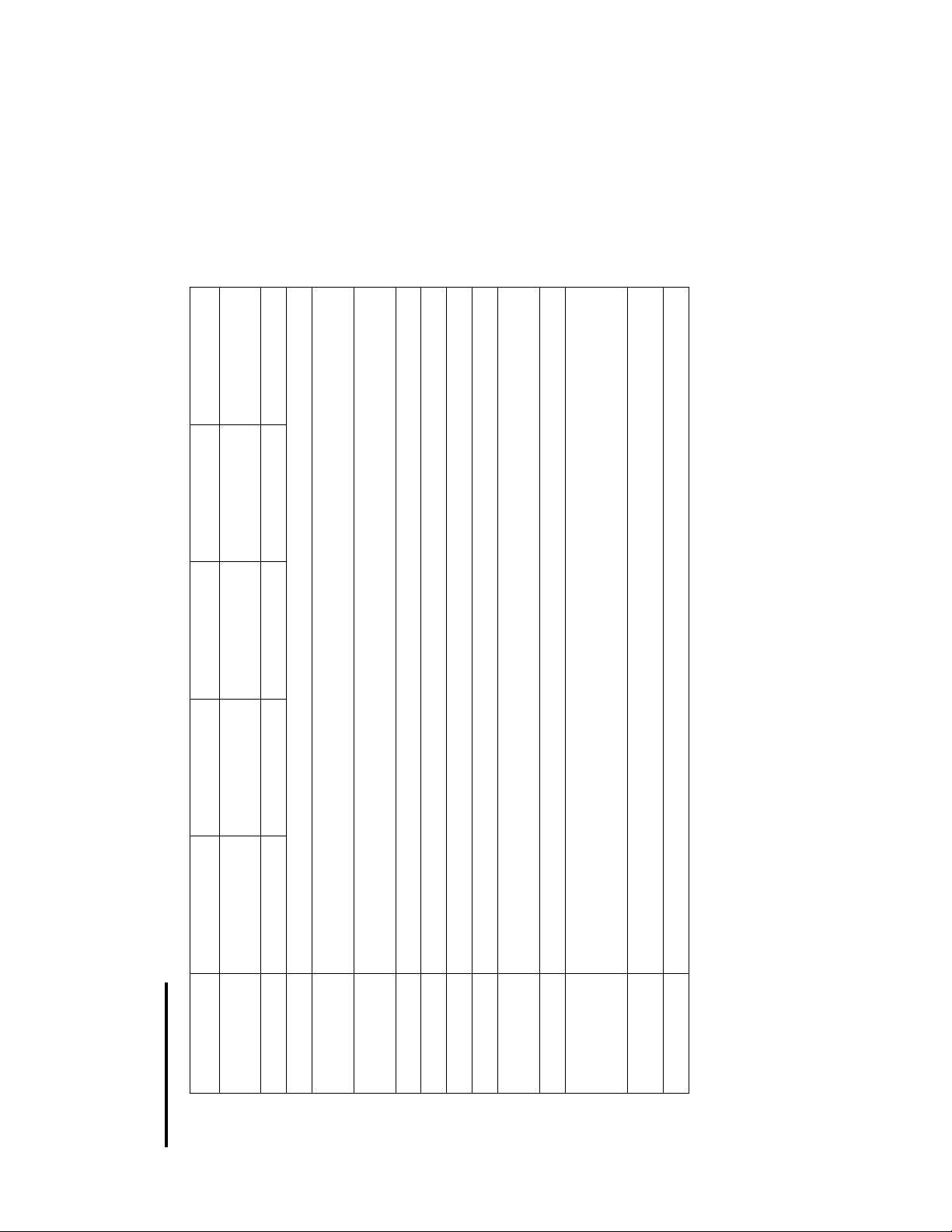

GFK Models

Model #

Maximum Capacity

Readability

Repeatability (Std Dev)

Linearity +

Units of Measure Grams & Kilograms, XXXa also to have Pounds, Ounces, & Pound/Ounces

Stabilization Time 2-3 Secs

Operating Temperature -10°C to +40°C / +14°F to +104°F

Power Supply 230VAC 50/60Hz. in Europe, Asia and South Africa.

Calibration External

Calibration Mass User Selectable

Display Backlit Green display 25mm with capacity tracker

Balance Housing Cast aluminum base, Pantone cool grey painted base, stainless steel grade 304 Top pan, ABS Cool grey indicator housing

Pan Size 400mm x 500mm

Overal Dimensions

(w x d x h)

Net Weight 15kg / 33 Lb 15kg / 33 Lb 15kg / 33 Lb 45 kg / 100 Lb 15kg / 33 Lb 15kg / 33 Lb

Features Weighing/Counting/Checkweighing with LED lights/Percentage/Hold function/RS232

| P a g e © Adam Equipment Company 2010

6

6kg 15kg 30kg 60kg 150kg

GBK 6M GBK 15M GBK 30M GBK 60M GBK 150M

2-3 Secs

-10°C to +40°C / +14°F to +104°F

230VAC 50/60Hz.

External

User Selectable

Backlit Green display 25mm with capacity tracker

Cast Aluminum base, Pantone cool grey painted base, stainless steel grade 304 Top pan, ABS Cool grey indicator

housing

Model #

Maximum

Capacity

Readability 0.002kg 0.005kg 0.01kg 0.02kg 0.05kg

Units of Measure Kilograms only

Stabilization

Time

Operating

Temperature

Power Supply

Calibration

Calibration Mass

Display

Balance Housing

300mmx 620mm x 860mm for small pillar version, 300 x 820 x 860mm for large pillar

15kg / 33 Lb

Weighing/Counting/Checkweighing with LED lights/Percentage/Hold function/RS232

Pan Size 300mm x 400mm x 32mm / 12” x 15.5” x 1.25”

Overal

Dimensions

(w x d x h)

Net Weight

Features

GBK-M Models

| P a g e © Adam Equipment Company 2010

7

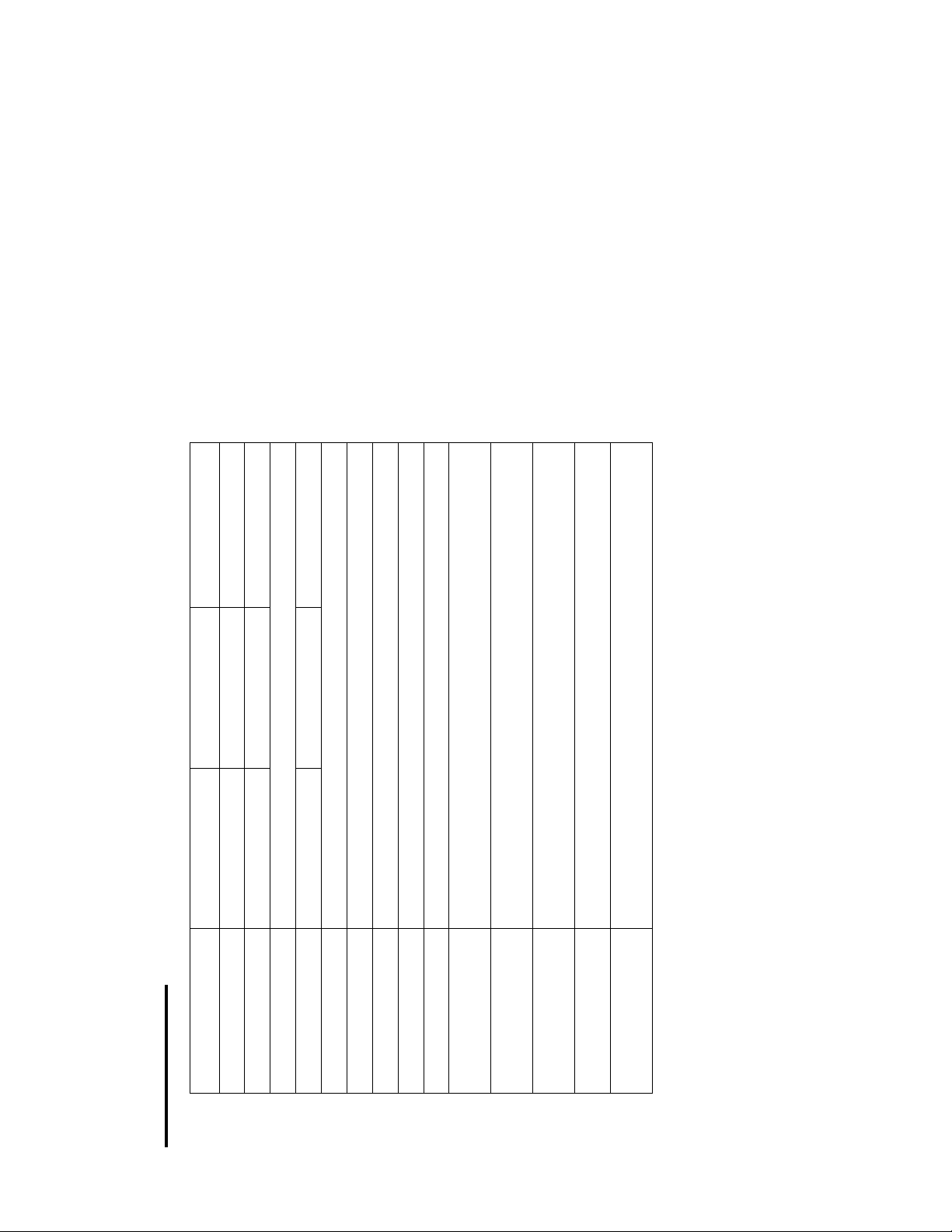

GFK 60M GFK 150M GFK 300M

-10°C to +40°C / +14°F to +104°F

230VAC 50/60Hz.

External

User Selectable

Backlit Green display 25mm with capacity tracker

Cast Aluminum base, Pantone cool grey painted base, stainless steel grade 304

Top pan, ABS Cool grey indicator housing

400 mm x 675 mm x 950 mm

15.7” x 26.6” x 37.4”

400 mm x 675 mm x 950 mm

15.7” x 26.6” x 37.4”

15kg / 33 Lb

Weighing/Counting/Checkweighing with LED lights/Percentage/Hold

function/RS232

Model #

Maximum Capacity 60kg 150kg 300kg

Readability 0.02kg 0.05kg 0.1kg

Units of Measure Kilograms only

Stabilization Time 2-3 Secs 2-3 Secs 2-3 Secs

Operating Temperature

Power Supply

Calibration

Calibration Mass

Display

Balance Housing

Pan Size

Overal Dimensions

(w x d x h)

Net Weight

Features

GFK-M Models

8

| P a g e © Adam Equipment Company 2010

3. INSTALLATION

3.1. UNPACKING

The GBK/GFK scales have already been adjusted to work with a platform and have

been configured for this application. The platform and indicator have been

calibrated as a pair and must be used together .

3.2. LOCATING

• The scales should not be placed in a location that will

reduce the accuracy.

• Avoid extremes of temperature. Do not place in direct

sunlight or near air conditioning vents.

• Avoid unsuitable tables. The table or floor must be rigid

and not vibrate.

• Avoid unstable power sources. Do not use near large

users of electricity such as welding equipment or large

motors.

• Do not place near vibrating machinery.

• Avoid high humidity that might cause condensation.

Avoid direct contact with water. Do not spray or

immerse the scales in water.

• Avoid air movement such as from fans or opening doors.

Do not place near open windows or air-conditioning

vents.

•

Keep the scales clean. Do not stack material on the

scales when they are not in use.

9

| P a g e © Adam Equipment Company 2010

3.3 SETTING UP THE SCALES

• The pillar is attached to the base using a bracket that must be attached

to the base frame first using the 4 bolts supplied. The pillar is secured

to the bracket using 2 sets of screws. The cable from the base to the

indicator module is run through the tube and taken out through the

plastic support at the top. Excess cable can be stored within the tube.

• The GBK/GFK Series comes with a stainless steel platform packed

separately. Place the platform in the base.

• Level the scale by adjusting the four feet. If the scale rocks re-adjust the

feet.

• Attach the indicator module to the pillar by sliding it over the bracket

with the flanges engaged in the groves on the base. Attach the cable

from the base to the connector on the rear of the indicator.

• Attach the power to the indicator. Press the [On/Off] key. The software

revision number will be displayed followed by a self-test showing all

digits before the zero is displayed along with the unit of weight that was

selected last.

• If the scale is an approved version, GBK/GFK..M, and the Calibration

Counter has been enabled (see section 6) the current values will be

displayed. These values should match the values marked on the scale

at the time of verification, if it has been verified.

10

| P a g e © Adam Equipment Company 2010

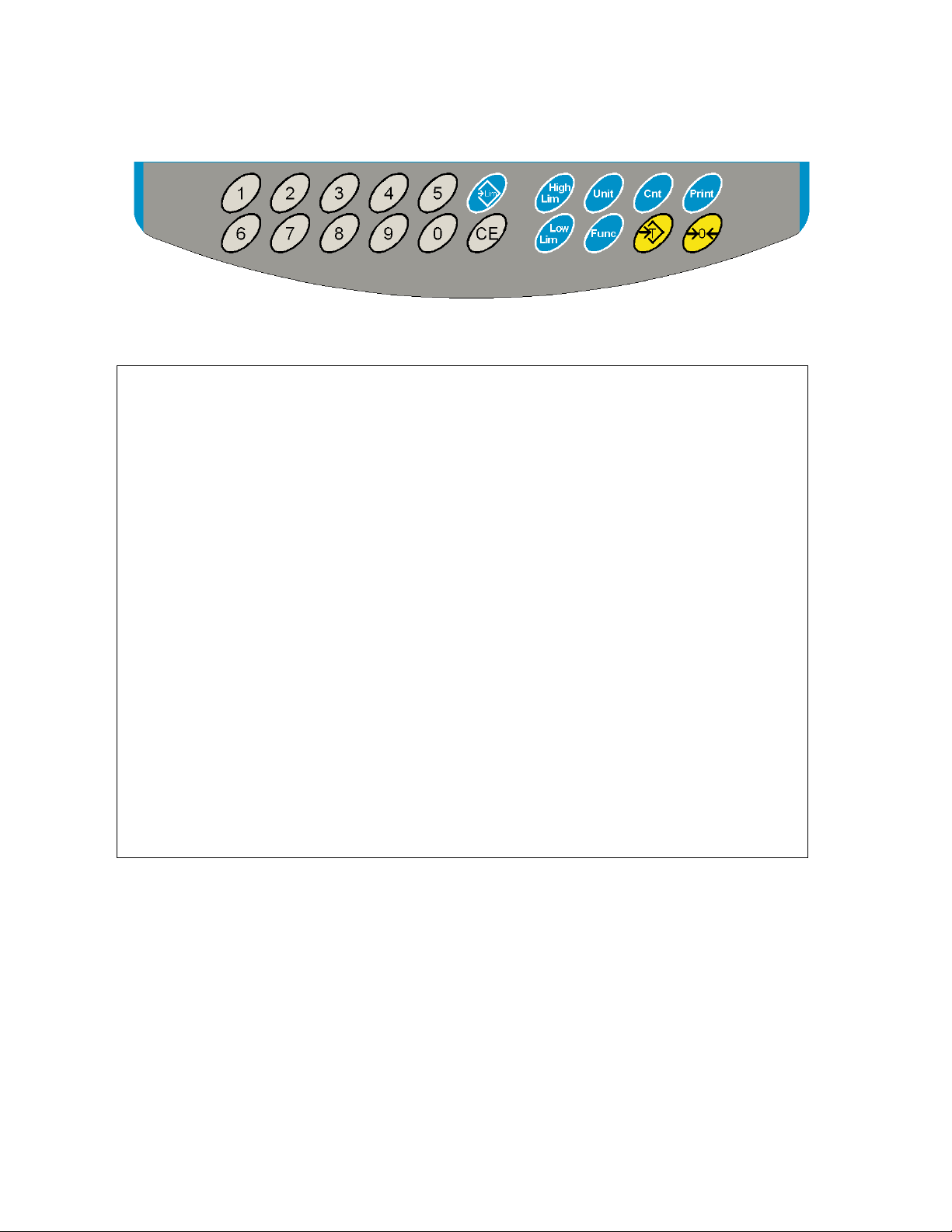

4. KEYPAD

KEYS PRIMARY FUNCTION SECONDARY FUNCTION

[Zero] Sets the zero point for all subsequent

weighing. The display shows zero.

[Tare] It tares the scale and stores the current

weight in memory as a tare value, subtracts

the tare value from the weight and shows

the results. This is the net weight.

[Unit] This is used to select the weighing units

from a preset list of available units.

Escape from any setting menus

Accept the set values

Allows the weight, unit weight, and

count to be seen when parts

counting or to change from weight

to % in percent weighing

11

| P a g e © Adam Equipment Company 2010

[Low

Limit]

&

[High

Limit]

[Lim] It stores and recalls any of 10 preset limits None

[Func] This is used to select percent weighing, RS-

[Count]

It sets the limits for check weighing and

allows setting of either the low limit or the

high limit or both.

232 parameters, Operation of the bar

graph, RTC settings, User ID and Scale ID.

Enter Parts Counting

None

None

None.

[Print] It is used to print the results to a PC or

printer using the RS-232 interface. It also

adds the value to the accumulation memory

if the accumulation function is not

automatic.

[1] to [0]

and [CE]

Allow entering numerical values where

required, setting of limits, tare value, time

and date for example.

None

12

| P a g e © Adam Equipment Company 2010

5. DISPLAY

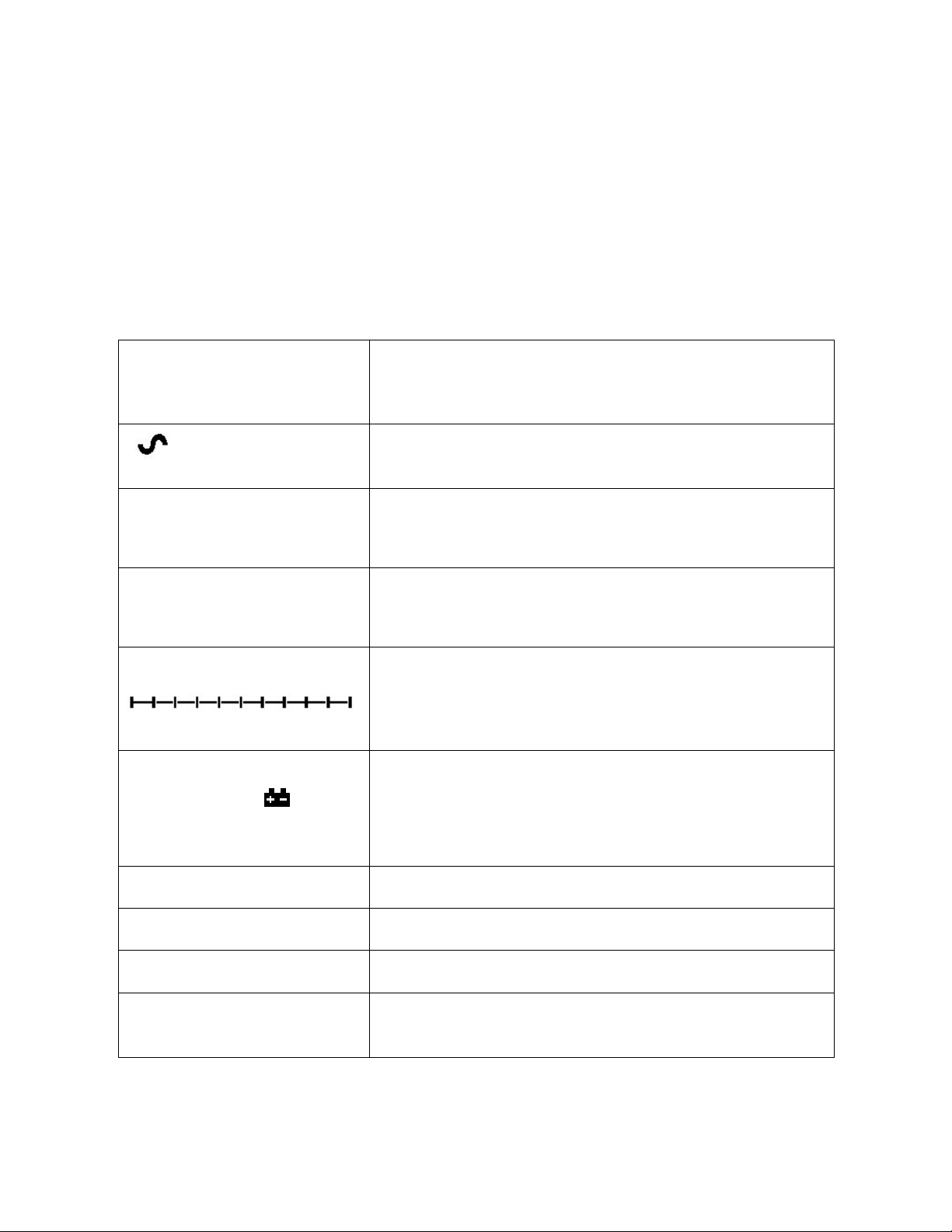

5.1. SYMBOLS AND INDICATORS

The LCD has unique symbols to indicate the following:

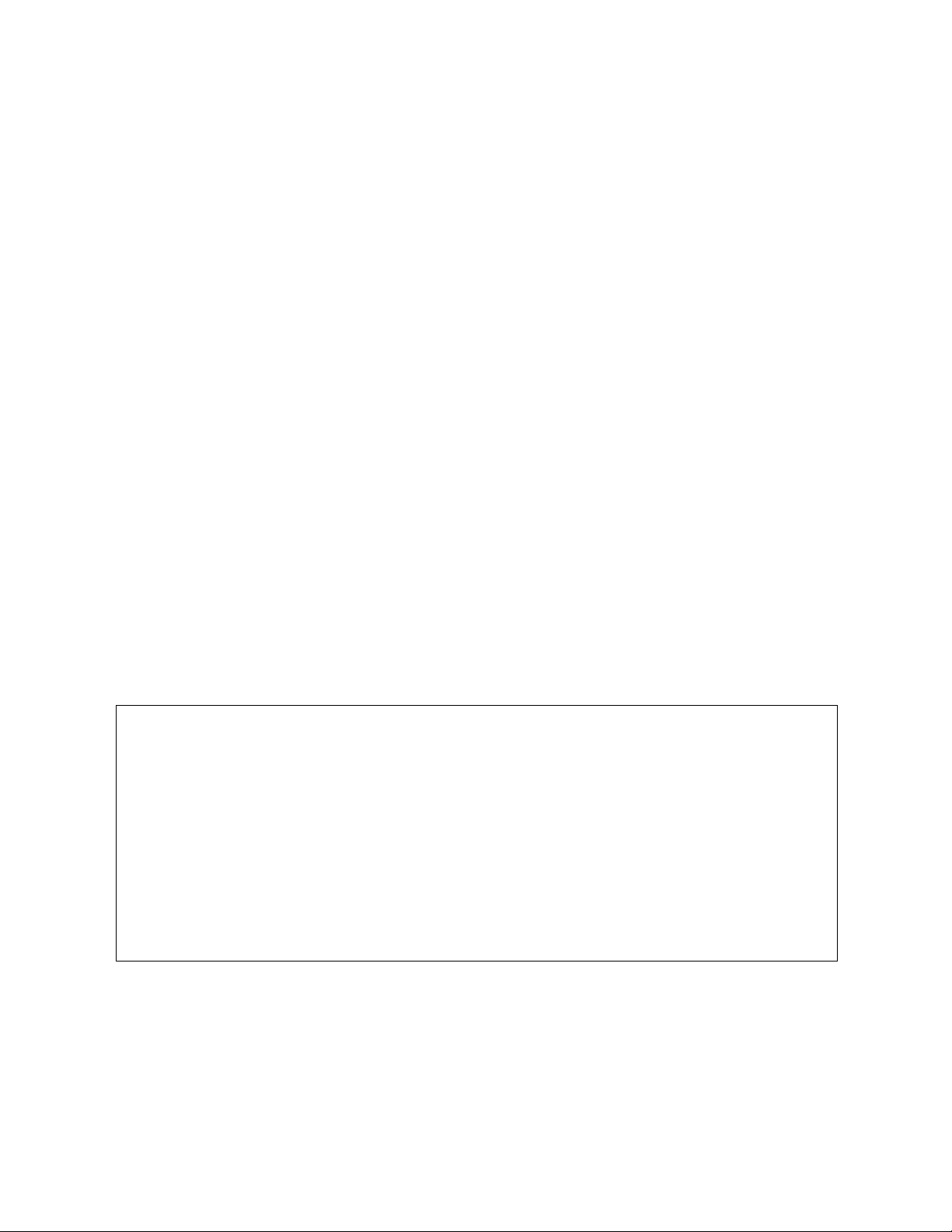

0

Net

kg / lb

bAt LO or

The display is at Zero

The scale is Stable

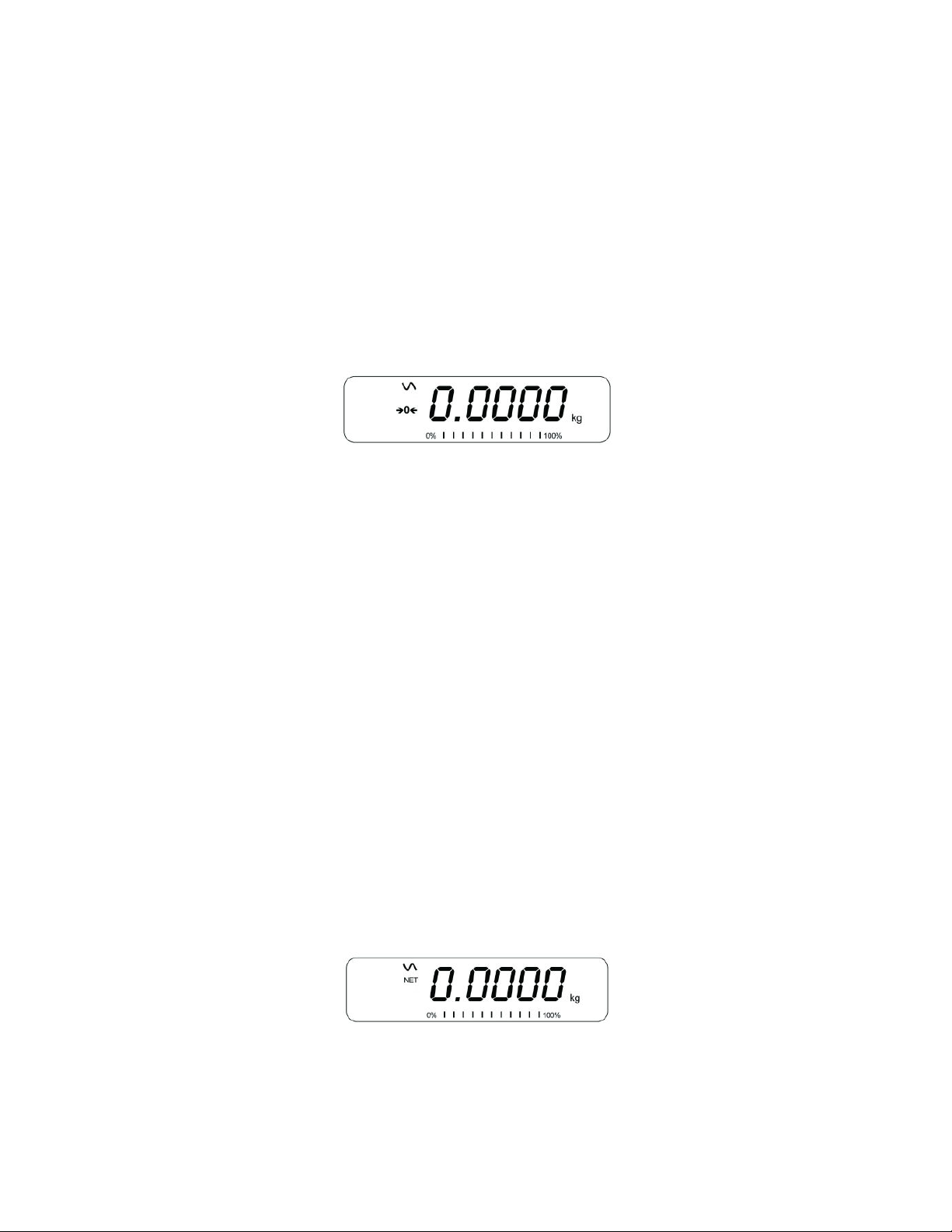

Net weight- The scale has been tared

Symbols shown for the units

Capacity Tracker- A bar graph indicating the proportion of the

scale capacity being used by the weight on the platform

Low battery

%

pcs

HI, OK, LO

:

The scale is in Percent weighing mode

The scale is in Parts counting mode

The scale is in Check weighing mode

The colons “:” are used to separate pounds from ounces and

for the real time clock.

13

| P a g e © Adam Equipment Company 2010

Next to the LCD are a number of LED’s that show when the weight is below, within

or over the limits during check weighing.

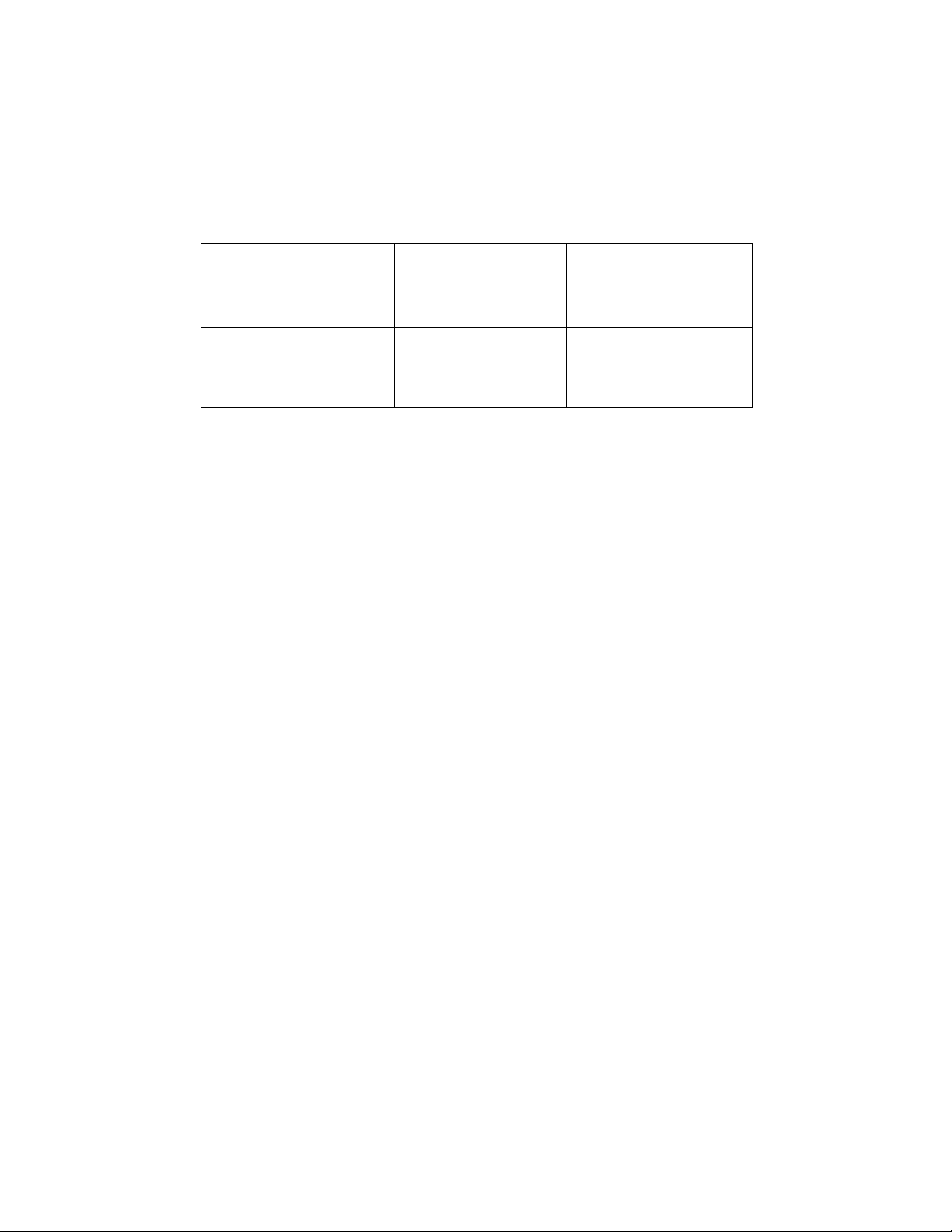

Weight LED LCD

below the low limit Amber LO

Within the limits Green OK

Above the high limit Red HI

NOTE: The LED’s can be set by the user to off, bar, spot or segment mode. See “F3

LED” in section 13.1

The LED can be set to display as a bar, increasing from Low to OK to High, a single

spot increasing from Low, OK to High, or as a single bar that changes colour as the

weight progresses from Low to OK to High.

6. CALIBRATION COUNTER FOR APPROVED SCALES

The approved (GBK/GFK-M Model) scales have the ability to control access to the

calibration or metrology parameters using a passcode to limit access. The

requirements for doing this stipulate the code should be apparent and recorded in a

suitable location on the scale.

In this way if the record of the Calibration or Parameter counters do not agree with

recorded settings the responsible person inspecting the scale can take appropriate

action.

14

| P a g e © Adam Equipment Company 2010

The Counters are incremented any time the calibration section or the Factory

parameters section have been modified.

At power on, the display will show the current software revision number followed

by the message of the Calibration Count “[AL[nt” then a number i.e. “123”. The

number from the counter memory. Then the Parameter Counter message of

“PAr[nt” and probably a different number, i.e. “234”. The counters cannot be

reset to 0, they will increment until the display can no longer hold the values. (1 to

999999). It is expected we will never have more than 1 million calibrations in the

life of the machine.

Each display is held for 1-2 seconds.

The scale will then continue to do the display test and go to normal weighing.

If during the time the counting displays are shown, the user presses the [Tare] key,

the user will be given a message to enter the passcode necessary to calibrate the

scale, “P - - - - “ Enter the code “P0000” to Enter calibration or “P1000” to enter

the parameters, followed by pressing the [Tare] key.

The Calibration access will allow user calibration (See section 15.1) and the

parameter code will allow access to the following parameters. (see section 15.2).

“F4 Int” Initial Zero Range

“F5 rEZ” Re-Zero range

“F6 SCS” Successive Tare Enable

“F7 Cnt” Display ADC counts

“F8 Zem” Zero Mode

“F9 Lvd” Low voltage detection

15

| P a g e © Adam Equipment Company 2010

7. BATTERY

• The scales can be operated from the rechargeable battery, if desired.

The GBK/GFK scales have up to 70 hours battery life before needing to

be recharged if the backlight is disabled and the battery is fully charged.

• When the battery needs charging a symbol on the display will turn on.

The battery should be charged when the symbol is on. The scale will still

operate for a period of time after which it will automatically switch off

to protect the battery.

• To charge the battery, simply plug into the mains power supply. The

scale does not need to be turned on.

• The battery should be charged for 12 hours for full capacity.

• To the right of the display is a LED to indicate the status of battery

charging. When the scale is plugged into the mains power the internal

battery will be charged. If the LED is green the battery is being charged.

If it is red it is nearly discharged and yellow indicates the battery is

increasing the charge level. Continue to charge overnight for a

complete re-charge.

8. BACKLIGHT

The backlight for the LCD can be set by the user to always off, always on or

automatic (on only when the scale is in use or a key is pressed). See setting of the

parameter “S2 bL” in section 13.3.

9. AUTO POWER OFF

The auto power off can be set by the user to disable the feature or to a pre-set time

interval. See setting of the parameter “S3 AoF “ in section 13.3.

16

| P a g e © Adam Equipment Company 2010

10. OPERATION

10.1. ZEROING

• You can press the [Zero] key at any time to set the zero point from

which all other weighing and counting is measured. This will usually be

necessary when the platform is empty. When the zero point is obtained

the display will show the zero indicator.

• The scale has an automatic re-zeroing function to account for minor

drifting or accumulation of material on the platform. However you may

need to press [Zero] to re-zero the scale if small amount of weight is

still shown when the platform is empty.

10.2. TARING

10.2.1 MANUAL TARE

• Zero the scale by pressing [Zero]. The zero indicator will be on. Place a

container on the platform and its weight will be displayed.

• Press [Tare] when the reading is stable. The weight that was displayed

is stored as the tare value and it is subtracted from the display, leaving

zero on the display. The stable and Net indicator will be on.

• As a product is added only the weight of the product will be shown. The

scale could be tared a second time if another type of product was to be

17

| P a g e © Adam Equipment Company 2010

added to the first one. Again only the weight that is added after taring

will be displayed.

NOTE:

When the container is removed a negative value will be shown. If the scale was

tared just before removing the container, this value is the gross weight of the

container plus all products which were removed. The zero indicator will also be on

as the platform is back to the same condition it was when [Zero] was pressed last.

Press [Tare] or [Zero] to remove the tare value and display zero. The Net indicator

will disappear.

10.2.2 PRESET TARE (NOT AVAILABLE ON APPROVED SCALES)

When the scale is at zero with no weight on the platform it is possible to enter a

preset tare.

• Zero the scale by pressing [Zero]. The zero indicator will be on.

• Enter a value using the numeric keys.

• Press [Tare] to tare the scale. The value that was entered is stored as

the tare value and it is subtracted from the display, leaving a negative

number on the display.

18

| P a g e © Adam Equipment Company 2010

10.3. WEIGHING

To determine the weight of a sample, first tare an empty container if used,

then place the sample in the container. The display will show the weight and

the unit of weight currently in use.

To change the weighing unit press the [Unit] key. The only alternative

weighing unit is pounds. This can be enabled by the user in the parameters

section. See section 13.3.

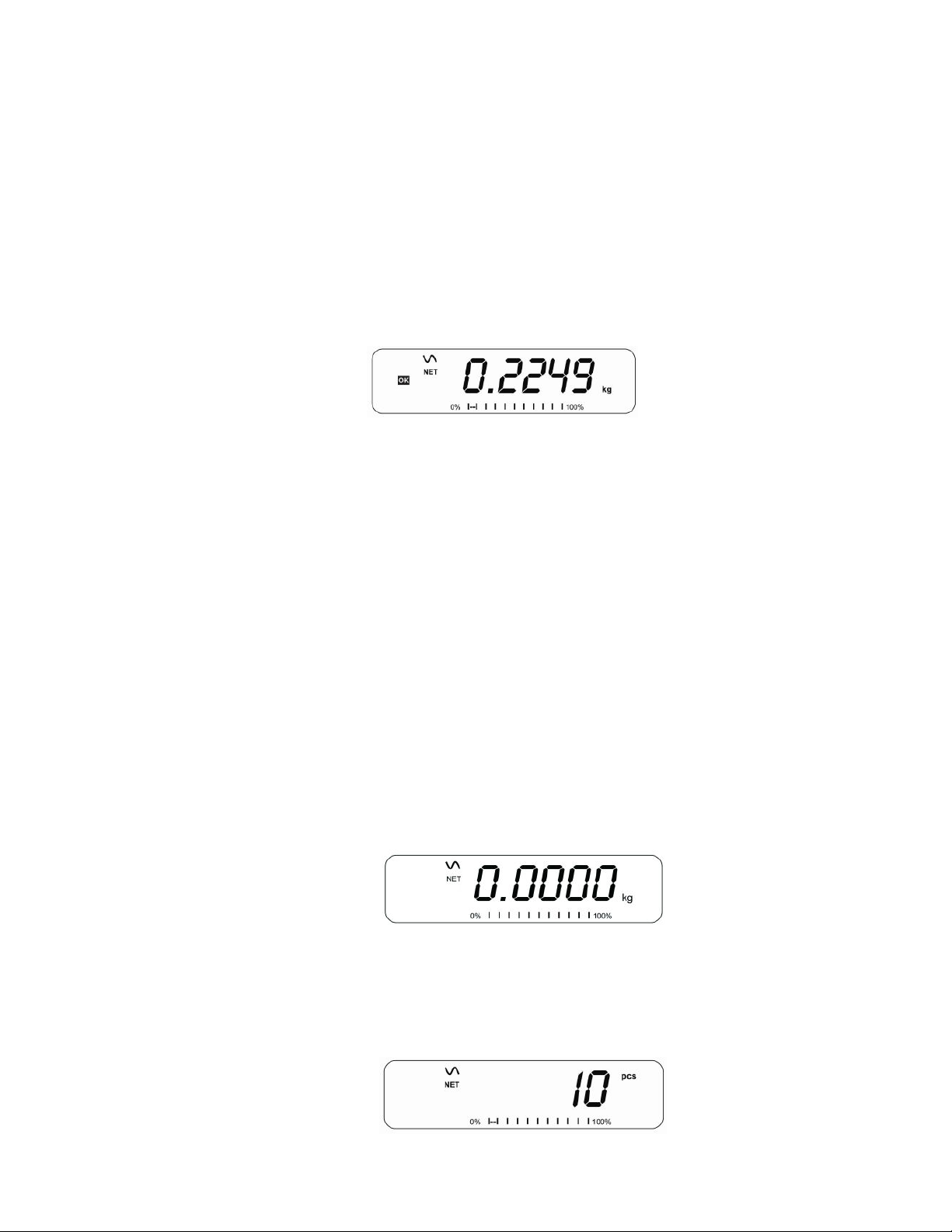

10.4. PARTS COUNTING

The scale can be used to count parts based on the average weight of a sample

weighed. When more parts are added the total number of parts are displayed.

• If a container is to be used, place this container on the platform before

entering parts counting and press [Tare].

• Press [Cnt] to enter the Parts Counting mode. The display will show the

last sample size used. For example, “10 Pcs”.

19

| P a g e © Adam Equipment Company 2010

Loading...

Loading...