Page 1

Installation, Operation and Troubleshooting Instructions

Manual Part No.: P6924700

Rev: 03

Print Date: xx/xx/xx

607 Industrial Way, Eatontown, NJ 07724

Phone: (800) 526- 2807 Fax: (732) 544-0735 Website: www.adamatic.com

For Panera Roll-In Model: AP-51

Adamatic Modular Proofers

Page 2

Proofer Cabinet Installation & Initial Start-Up Checklist

Proper installation is the first step to operation. We recommend that your proofer cabinet be

installed by an authorized Certified Installer. This original checklist is to be signed and returned

to Adamatic with warranty card.

Electrical

❑ Record Voltage to Proofer Cabinet (*recommended 220-240V/60Hz/3Ph)

Voltage Reading: __________________

*For proofer cabinets installed in older facilities, make sure a qualified electrician has confirmed that there are no Delta

or Wild Legs as part of the main power supply. Fluctuating or spiking voltage can destroy electronic components that

will not be covered by warranty.

❑ Record Amperage

Amperage Reading: ________________

Components

❑ Check Fans for Proper Rotation (*fans should be pushing or blowing in outward direction)

❑ Test Light in Proof Box (*if required)

❑ Check Door(s) Operation

- Make sure door(s) are even

- Make sure closer lip properly seats into hook when closing door(s)

- Make sure vertical wiper gasket is tightly mounted to door

- Make sure all door hinges are tightened when satisfied with door placement and operation

- Make sure this is no restriction when closing door(s)

❑ Check Water Solenoid Operation (*solenoid will energize after 10 minutes of pre-heating)

❑ Check Cove Molding & Proper Sealing (*cove molding is to be installed inside cabinet)

Calibration (*if required)

*Note: It is highly recommended that the proofer cabinet be calibrated at 85% humidity. Make sure all Heat &

humidity Monitoring Equipment has been properly calibrated and tested before making adjustments to the proof

cabinet set points! Heat & Humidity Set-Point Viewing & Calibration Instruction follows this checklist.

❑ Compare Proofer Cabinet Temperature with Calibrated Equipment

❑ Compare Proofer Cabinet Humidity with Calibrated Equipment

Instruction

❑ Instruct customer of proper use of proof cabinet

❑ Instruct customer of preventive maintenance & cleaning (i.e. gaskets, vapor check for properly

operating spray nozzle, filter check & change out, etc.)

Installed and Checked by: _________________________________ Date: ___________________

Page 3

1

All units are performance tested and thoroughly inspected prior to shipment. Upon receipt, examine

the exterior of the shipment packaging for any signs of rough handling. If the cabinet is damaged, it

should be noted on the delivery slip or bill of lading and signed. A claim must be filed immediately

against the carrier indicating the extent and estimated cost of damage incurred.

Proper installation is the first step to operation. We recommend that your proofer be installed

by an authorized Certified Installer. An installation checklist is located at the front of manual

and must be checked off and signed by installer of choice. The original checklist is to be

returned with warranty card.

Consider the following when selecting a location for your proofer:

1. Clearance - There must be a minimum clearance of 24” (inches) between the top of the proofer

and the ceiling.

2. Floor Load - The floor on which the cabinet will rest must be free of vibration and suitably strong

enough to support the combined weights of the cabinet plus the maximum product load.

*Note: All pictures show the protective vinyl coat on parts described in this instruction document.

Make sure all vinyl protective coating is removed before installation. Same method of

installation applies to Floorless Proof Boxes with Wall Base Angles only.

T

ools Needed

: Drill with ¼" (inch) Masonry Bit, Tubes of Silicon, Dynabolt Anchors, Screw Driver, & Trowel

1. Find location to assemble proof cabinet. Before assembly, make sure designated floor area and

neighboring wall space is level, clean and free of any obstruction.

2. If supplied, place Stainless Steel Floor on appointed floor space and mark along the edges.

(*Note: Same method of installation applies to Floorless Proof Boxes with Wall Base Angles only!)

3. Remove Stainless Steel Floor and apply beads of Floor Adhesive along the bottom while properly

spreading with Trowel. Make sure the bead is continuous around the edge of Stainless Steel Floor.

4. Seat Stainless Steel Floor over designated floor space and lightly walk on the Floor. Put still weight

on the Stainless Steel Floor so that Adhesive will keep in required contact with Floor beneath (i.e.

weights, boxes with weight, etc).

5. Place Wall Base Angles around the edge of Stainless Steel Floor. Make sure that holes located at

ends of the Wall Base Angles align over the holes in Stainless Steel Floor.

6. Drill Floor Holes through the Wall Base Angles with a 1/4" diameter drill bit for placement of

Concrete Floor Anchors.

●●

Mark drill bit at 1-1/2" (inches) from the end. Drill until mark is aligned with the top of the Stainless

Steel Floor. Do not drill beyond the mark on the drill bit!

●●

Clear concrete dust from holes. (*Note: all debris from drilling must be removed before

installation or Anchors will not work!)

●●

If proof cabinet is mounted on stone or ceramic tile, extend holes and Anchors into concrete

substrate.

FLOOR & WALL BASE ANGLE INSTALLATION

INSTALLATION GUIDELINES

RECEIVING SHIPMENT

Page 4

7. Install Anchors in the holes of Wall Base Angles and set in place.

T

ools Needed : Allen Wrench (*supplied with accessories)

All Proofer Cabinet Panels are joined together by Cam-Locks. Panel sections lock together from inside

the Proofer Cabinet to provide accurate tight joining. Always align top edges and inner face of Panels

as you lock them together.

*Note: From inside Proofer Cabinet, all Cams turn clockwise with exception of inner left hand side of

Header that turns counter-clockwise. All Male Cam direction of turn is marked on required

panels.

3/4” Wide Foam Tape has been provided for Proof Cabinet Panel sealing. Foam Tape should be

placed over Foam Insulation of all Panel Edges with Male Cams. See Figure 1.

Once Foam Tape has been applied to Panel, cut Slit at all Male Cam locations. See Figure 2.

*Note: Only one strip of Foam Tape should be placed in between Panels. This will guarantee proper

Seal and Cam Locking.

Figure 1 Figure 2

CAM-LOCKING PANELS

APPLYING FOAM TAPE

2

Wall Base Angles

Optional Floor with Wall Base Angles Assembled

*Note: Floor shown with vinyl for clarity.

Remove before assembling!

Floor Anchor Placed at

end after checking Corner.

Illustrations show cam-lock panel mechanism from

inside the proofer cabinet.

Page 5

3

Item Part No. Part Description Qty

1 P7900101 10” x 82” Panel, Front Left with Controller 1

2 & 6 P7907401 30.5” x 82” Panel, Side Left Front/Right Rear 2

3 & 7 P7907301 30.5”x 82” Panel, Side Left Rear/ Right Front 2

4 P7905301 37” x 82” Panel, Rear Left 1

5 P7905401 37” x 82” Panel, Rear Right 1

8 P7900801 4” x 82” Panel, Front Right 1

9 P7900901 6” x 60” Panel, Header with Light 1

10 P7901001 34” x 74” Panel, Front Roof 1

11 P7901101 31” x 74” Panel, Rear Roof 1

12 P7903601 Door Assembly, R H with Horizontal Handle 1

13 P7903501 Door Assembly, L H with Horizontal Handle 1

14 P7907501 4-Heater Air Wash Housing Assembly 1

PANEL ASSEMBLY

PANEL ALIGNMENT PINS

A drawing is supplied with all Proofer Cabinets to assure correct placement of Panels. Each Panel is

individually marked with a number to assist with the assembly sequence. An example is shown below.

Silicone has also been provided to fill in Interior and Exterior Seams between Panels after assembly.

*Note: All cams turn clockwise unless label on panel indicates otherwise!

Panel Alignment Pins have been supplied with your Proof Cabinet and are placed on Panel sides with

Male Cams only. Pins support easy alignment and allow Male Cams to properly catch into Female

Cams.

Panel Alignment Pin

Hole for Pin

Pin

Page 6

*Note: All pictures show the protective vinyl coat on parts described in this instruction. Make sure all

vinyl protective coating is removed before installing cove molding.

T

ools Needed: Screw Gun, Rubbing Alcohol, Paper Towels and Measuring Tape

1. Measure Top and Bottom of Proof Box to check for proper alignment. See Figure 1.

Figure 1

2. Wipe down Proof Box Interior Wall Base Angles and Exterior Wall Bottom with Rubbing Alcohol.

See Figure 2 & 2a.

Figure 2 Figure 2a

3. Cut Cove Molding Strip to desired length and miter at corners where needed. Peel Paper from

Adhesive Strip and apply Cove Molding to Proof Box's Interior Wall Base Angles and Exterior Wall

Bottoms. See Figure 3 & 3a.

Figure 3 Figure 3a

4. Install #10 Stainless Steel Self-Tapping Screws into Cove Molding, Interior Wall Base Angles and

Exterior Wall Bottoms. Space Screws approximately 1"(inch) up from bottom of Cove Molding, and

8" to 12" (inches) apart while avoiding Wall Seams. See Figure 4.

Figure 4

5. Repeat process until all Cove Molding is applied completely around the Proof Box's Interior and

Exterior Bottom.

4

APPLYING COVE MOLDING

interior wall base angles

molding with adhesive

Page 7

Tools Needed : Channel Locks, Screw Gun with #2 Phillip Drive, Wire Stripper, Snips (or equivalent)

1. Make sure all Plastic Plug Buttons are placed into Cam-Lock Holes before mounting Air-Wash

System.

2. At top of Air-Wash System, remove 4½"x 4½" Junction Box, Lock Nuts & Reducer Washers from

CPVC Piping. Set aside for later use.

3. Remove Bottom Panel of Air-Wash System by lifting up and away with Mounted Handle. Place

Bottom Panel in secure location to avoid damage. See Figure 1 & 1a.

Figure 1 Figure 1a

4. Move Air-Wash System into Proof Cabinet. Place directly behind Control Panel and in front of First

Left Side Wall Panel.

5. Make sure Heater Wires, Copper Water Line & CPVC Piping are aligned with Holes going through

Front Roof Panel.

6. Put 4½" x 4½" Junction Box on Floor, and place centered inside Air-Wash System (*Note: 4½"x

4½" Junction Box will be used to support Back Panel of Air-Wash System. Make sure it is very

close to Back Panel!). See Figure 2.

Figure 2

7. Carefully lift Air-Wash System and place Heater Wires, Copper Water Line & CPVC Piping

through Holes of Front Roof Panel. Rest bottom of Air-Wash System Back Panel on top of 4½" x

4½" Junction Box for support (*Note: Middle Panel under Fan Panel can also be removed for

easy lift. DO NOT

use Heater Elements to lift!). See Figure 3.

AIR-WASH SYSTEM INSTALLATION

5

Bottom

Panel

Bottom

Panel

Removed

Air-Wash System placed

inside cabinet

4½"x 4½" Junction Box centered

inside of Air-Wash System

Page 8

Figure 3

8. At top of cabinet and left side of Front Roof Panel, place Reducing Washer & Lock Nut over both

CPVC Pipes. Use Channel Locks (or equivalent tool) to tighten until snug. See Figures 4, 4a & 4b.

Figure 4 Figure 4a Figure 4b

9. Starting at top of Proof Cabinet, feed Heat/Humidity Sensor Cable Plug through Copper Water Line

CPVC Piping. (*Note: Can use Finger or 5" Flat Head Screwdriver to feed Cable through if

needed.) See Figures 5 & 5a.

Figure 5 Figure 5a

10.After Heat/Humidity Sensor Cable Plug is placed through CPVC Pipe, feed Plug through 3/4" Hole

located at Upper Right Side of Air-Wash System. (*Note: Picture below shows Air-Wash System

not mounted to Proof Cabinet for visual purposes.) See Figure 6.

Figure 6

Air-Wash System lift

Reducing

Washer &

Lock Nut

applied to

CPVC

4½"x 4½" Junction Box

placed under Back Panel of

Air-Wash System

Heat/Humidity Sensor

Cable Plug fed into

CPVC Piping

Cable fed through Upper

Right Side ¾" Hole or

Air-Wash System

6

Page 9

11. Take ¾" Heyco Bushing from Accessory Kit and cut at one side with Snips (or equivalent). Place

Heat/Humidity Sensor Cable Plug into ¾" Heyco Bushing, and fit ¾" Heyco Bushing to ¾" Hole at

Upper Right Side of Air-Wash System. See Figures 7 & 7a.

Figure 7 Figure 7a

12.Apply Putty in and around Heater Wire & Copper Water Line CPVC Piping. See Figures 8 & 8a.

Figure 8 Figure 8a

13.Remove 4"x 4" Junction Box from bottom of Air-Wash System Back Panel. Take out 1

5

/

16

” Knock

Out from one side of 4"x 4" Junction Box. See Figure 9.

Figure 9

14.Feed Heater Wires and CPVC Pipe through 1

5

/

16

” Knock Out of 4" x 4" Junction Box.

15.Place Lock Nut inside 4" x 4" Junction Box and onto CPVC Threads. Tighten until snug with

Channel Locks (or equivalent tool). See Figure 10 & 10a.

Figure 10 Figure 10a

Cable fed through

¾" Heyco Bushing

¾" Heyco Bushing

fitted flush to

Air-Wash System

Putty placed in and

around CPVC Piping

Removal of 1

5

/

16

”

Knock Out

Tightening Lock Nut

Placing Lock Nut

inside Junction Box

7

Page 10

16.Secure bottom of Air-Wash System by placing three (3) #10 Stainless Steel Self-Drilling Screws.

See Figure 11.

Figure 11

17.To complete Air-Wash System installation, apply Bottom Panel by reversing Step #3.

T

ools Needed

: Phillips Head Screwdriver & Adjustable Wrench

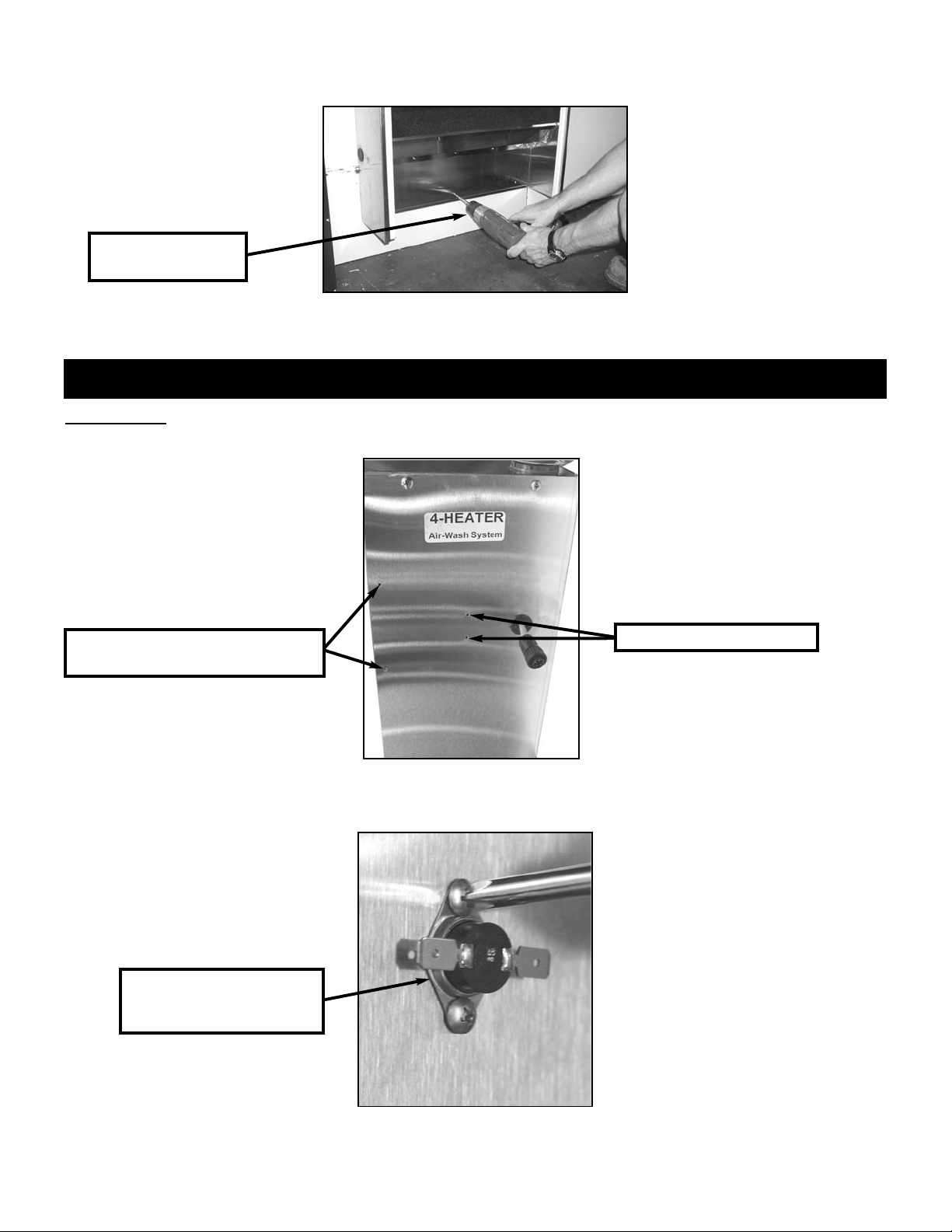

1. Locate Sensor and Klixon Mounting Holes above the Air-Wash System Panel Fans. See Figure 1.

Figure 1

2. Mount Klixon to Air-Wash System Panel. Make sure Metal Disc side of Klixon has contact with Air-

Wash Panel. See Figure 2.

Figure 2

SENSOR / KLIXON ASSEMBLY & INSTALLATION

Placing Three #10

Self-Drilling Screws

Holes for

Heat/Humidity Sensor Bracket

Holes for Mounting Klixon

Klixon shown correctly

mounted to

Air-Wash Panel

8

Page 11

9

3. Mount Sensor Bracket to side of Air-Wash System Panel. See Figure 3.

Figure 3

4. Place and secure Sensor to Sensor Bracket with Screws and Lock Washer Nuts. See Figure 4 &

4a.

Figure 4 Figure 4a

5. Connect Sensor Wires to Klixon, and Heat/Humidty Sensor Cable Plug into Sensor Port. See

Figure 5. (*Note: Refer to page 7 and Figure 7 for Heat/Humidity Sensor Cable Plug)

Figure 5

6. The Sensor and Klixon Assembly is now complete.

Sensor Bracket Mounted

to Air-Wash Panel

Sensor Port

Page 12

Tools Needed : n/a

1. Put PVC Tubing through hole located at bottom of Rear Corner Panel from inside Proofer Cabinet.

2. Place PVC Tubing over Male Barb until flush. See Figure 1 & 1a.

Figure 1 Figure 1a

3. Extend Drain Line to Floor Drain.

T

ools Needed : Drill with Phillips Head Bit

Bumper Guards are to be applied with #10 Self Tapping Screws. All hardware has been supplied with

the accessory kit. Pre-drilled holes are placed on the airwash system panel. Use the Airwash System

Panel Guard as a guide to place additional interior Bumper Guards.

10

DRAIN LINE & RUBBER COUPLING ASSEMBLY

Male Barb

1” (inch) PVC Tubing

BUMPER GUARD ASSEMBLY

Bumper Guards

PVC Tubing Flush

to Male Barb

Page 13

Tools Needed : Drill with Phillips Head Bit

1. Mount 4” x 4” Junction Box at upper right side of Proof Box with supplied Tapping Screws. Apply

Strain Relief with Lock Nut to side of Junction Box closest to Power Module. Refer to “TOP

VIEW” on page 18 for approximate placement. See Figure 1.

Figure 1

2. Take Power Module High Voltage Wires with Ground and put through Flexible Conduit. See

Figure 2.

Figure 2

3. Secure Flexible Conduit into Power Module Strain Relief. See Figure 3 & 3a.

Figure 3 Figure 3a

HIGH VOLTAGE BOX ASSEMBLY

4” x 4”

Junction Box

Lock Nut

Flexible

Conduit

High Voltage Wires

& Ground

Power Module

Strain Relief

Flexible Conduit

Secured Conduit

Plastic Strain

Relief

11

Page 14

4. Take opposite side of Flexible Conduit with exposed High Voltage and Ground Wire; feed

through Strain Relief of 4” x 4” Junction Box. See Figure 4.

Figure 4

5. Secure Flexible Conduit into Strain Relief. Make sure enough High Voltage and Ground Wire to

connect to Main Power Supply High Voltage Wire is available. A Metal Strain Relief has been

supplied for Main Power Supply wire feed. See Figure 5.

Figure 5

“120V Electrical & Relay Box Assembly” “Interior Light Assembly”

Tools Needed : Wire Nuts & Tapping Screws (*supplied with Assembly), Electrical Tape, Drill with Phillips Tip

1. Run Wires from the Interior Light Assembly through the Bottom Hole of Relay Box Assembly

before mounting. See Figure 1.

AP- 51 120V ELECTRICAL /RELAY BOX & INTERIOR LIGHT ASSY

Light Cable

120V Electrical Box

Relay Box

Metal Strain Relief

12

Page 15

Figure 1

2. Mount 120V Relay & Electrical Box in designated locations and secure with supplied #10 Screws.

Make sure Relay Box Bushing is placed into the Hole for Interior Light Wire run. Refer to page 18

“Proofer Top View” and see Figures 2 & 2a below.

Figure 2 Figure 2a

3. Wire the Interior Light, 120V Electrical/Relay Box, and Light Cable according to the Wiring

Diagram. Make sure all Green Wires (Grounds) are properly secured. Ensure that White 14

Gauge Wires are connected with supplied Wire Nut. See Figures 3, 3a & 3b with comments.

Figure 3

“Secure Ground Wires”

Figure 3a

“Connect 14 GA Black Wire with

Insulated Push On Terminal To Open

Relay Terminal”

Figure 3b

“Connect (2) 14 GA White Wires

Together Using Supplied Wire

Nut”

13

Page 16

4. Place Light Cable coming from Relay Box into desginated area on Power Module. See Figure 4.

Figure 4

5. 120V/60Hz/1Ph Electrical Supply should be ran into the 120V Electrical Box by a qualified

electrician in accordance with local electrical codes. Figure 5.

Figure 5

6. Seal Hole between bottom of Relay Box and Roof Panel with Silicone. See Figure 6.

Figure 6

14

Page 17

7. Place Covers on Relay and Electrical Box after all wiring has been completed. See Figures 7 & 7a.

Figure 7 Figure 7a

Place Light Bulb and Globe once wiring of the Interior Light is complete.

T

ools Needed : Drill with Phillips Tip

4 x 4 Junction Box

1. Feed Air Wash System Fan and Heater Wires through Top Left Front Corner of Roof Panel. See

Figure 1.

Figure 1

AIR WASH SYSTEM 4 x 4 JUNCTION BOX, FAN MOTORS, HEATERS

Left Rear Knock Out

Fan & Heater

Wires

INTERIOR LIGHT BULB & GLOBE

15

Page 18

2. Remove left rear Button Knock Out on 4” x 4” Junction Box as shown. Install Bushing and mount

Junction Box using supplied screws. See Figure 2.

Figure 2

Air Wash Heater Connections

3. Remove Right Side Front Knock Out on Junction Box.

4. Install Straight Strain Relief on Black Supply Cable.

5. Insert Black Supply Cable and Straight Strain Relief through Knock Out. Install Lock Nut and tighten.

See Figure 3.

Figure 3

6. Connect Heater Lead “L1” 10 Gauge Wire to Black 10 Gauge Wire using supplied Wire Nut.

7. Connect Heater Lead “L2” 10 Gauge Wire to Red 10 Gauge Wire using Supplied Wire Nut.

16

Knock Out

Strain Relief

Page 19

8. Connect Heater Lead “L3” 10 Gauge Wire to Black 10 Gauge Wire using supplied Wire Nut.

9. Connect Heater Green Grounding Lead to 10 Gauge Green Wire using supplied Green Wire Nut.

Air Wash Fan Motor Connections

10. Remove Right Side Front Knock Out on Junction Box.

11. Install Straight Strain Relief on Gray Fan Cable.

12. Insert Cable and Strain Relief into Knock Out. Install Lock Nut and tighten.

13. Connect Fan Lead Black #14 Gauge Wire to Black #20 Gauge Wire using Supplied Wire Nut.

14. Connect Fan Lead Red #14 Gauge Wire to Red #20 Gauge Wire using supplied Wire Nut.

15. Connect Fan Lead Grounding Green #14 Gauge Wire to Grounding Green #20 Gauge Wire using

supplied Wire Nut.

16. Carefully inspect each Wire Nut connect for proper installation. See Figure 4.

Figure 4

17. Seal Hole for Air Wash Wiring with Silicone. See Figure 5.

Figure 5

18. Carefully place Wires inside of Junction Box and install Cover. See Figure 6 & 6a.

Figure 6 Figure 6a

17

Page 20

“Solenoid & Water Line Assembly”

Tools Needed : Drill with Phillips Tip

1. Plug end of Solenoid Valve Cable into designated area on Power Module. See Figures 1 & 1a.

Figure 1 Figure 1a

2. Feed Water Line Extension Assembly Union Fitting through Heyco Bushing on second Roof

Panel. The Union Fitting will line up with Flare Nut on Air Wash System for proper connection.

Refer to Panera Top View on page 18. See Figures 2 & 2a.

Figure 2 Figure 2a

3. After connecting Union Fitting to Air Wash System, get Solenoid Valve Assembly and connect

Water Line Extension Flare Nut. Mount Solenoid Valve Assembly to Roof Panel by placing Tapping

Screws. See Figures 3 & 3a.

Figure 3 Figure 3a

SOLENOID & WATER LINE EXTENSION ASSEMBLY

18

Solenoid Valve

Cable

Solenoid Valve

Cable

Page 21

19

4. Take Female End of Solenoid Valve Cable and plug onto Solenoid Valve. Secure Female End by

tightening Screw with Flat Head Screwdriver. See Figures 4 & 4a.

Figure 4 Figure 4a

5. After all Proof Box assembly is complete, connect Water Supply Line to Solenoid Assembly. Make

sure that Ball Valve is in “ON” position before putting Proof Box into operation. See Figure 5.

Figure 5

Ball Valve

Water Line Connection Fitting

PANERA AP-51 PROOFER TOP VIEW

Power Module

Main Connection

Utility Box

Main Power Supply

(208-240/60/3)

Electrical Box

(120/60/1)

Relay Box

(120V)

Water Solenoid

Page 22

2

Tools Needed : Drill with Phillips Head Bit

Assemble the Facade on top of the proofer cabinet in the sequence shown below. Use the 5/8” Self

Tapping Screws that have been supplied.

T

ools Needed

: Phillips Head Screwdriver

If Proof Box does not power up and Main Power Supply is good, shut off Main Power and turn Power

Module Disconnect Switch to “OFF” position. Remove 8 Screws at Plate beside Disconnect Switch

and check Circuit Breaker and Fuses. Reverse steps to properly resupply power to Proof Box.

20

TOP FACADE ASSEMBLY

POWER MODULE CABLE CONFIGURATION

POWER MODULE CIRCUIT BREAKER & FUSES

Control Panel

Cable

Fan Motor

Cable

Solenoid

Valve

Cable

Main

Power

Supply

Main Power

Supply To

4x4 Box

Heat/Humidity

Sensor Cable

Proof Cycle

Indicator Light

Cable

Fuses

Disconnect

Removing Plate

Screws

Circuit

Breaker

Switch

1

2

3

5

Item Part No. Part Description

1 P6026500 Grill, Upper Front

2 P6052700 Panel, LH/RH Upper End

3 P6026100 Upper Rear Gusset, RH

4 P6900906 Outer Roof Cover Panel (1ea)

5 P6026201 Upper Rear Gusset, LH

4

Page 23

21

Tools Needed : Soft Mallet (or equivalent)

1. Locate Door Closer Mounting Base on top of Door. See Figure 1.

Figure 1

2. Apply Door Closer to Door Closer Mounting Base by starting with Lip side first. If needed, use a

soft mallet or equivalent to tap Door Closure on to the Mounting Base. See Figure 2, 2a & 2b

Figure 2 Figure 2a Figure 2b

3. Door is now ready to be assembled to the proofer cabinet.

T

ools Needed : Phillips Head Screwdriver

1. Place Hook(s) on front of Cabinet Header. (*Note: The Header is the same panel that supports the

Interior Light) See Figure 1.

Figure 1

Door Closer

Door Closer Mounting

Door Closer Properly Mounted

Lip

DOOR CLOSER ASSEMBLY

DOOR ASSEMBLY

Page 24

2. Locate three (3) Door Hinge Bases on Door Jamb. See Figure 2.

Figure 2

3. Carefully take Door(s) and insert all three (3) Hinge Barrels inside Nylon Cam of Hinge Base. Have

Door(s) open at 90° or more when placing Door(s) on to the Door Jamb. See Figure 3 & 3a.

(Note: If door does not easily drop into nylon cams, remove middle hinge barrel. After top and bottom hinge barrels

have been seated into nylon cams, install middle hinge barrel)

Figure 3 Figure 3a

Hinge Barrel

Hinge Base

Nylon Cam

22

Hinge Base & Cam

Page 25

4. After placement of Door(s), check Closer Lip to make sure it properly seats into Hook when closing

Door(s). Put Hinge Covers on all three (3) Hinges to complete assembly. See Figure 4, Figure 4a

& 4b

Figure 4 Figure 4b

Put on Door Handle(s) with 1/4 x 20 Hex Bolt & Lock Washers and Interior Guard(s) with #10 SelfTapping Screws. (*Note: All Doors are shipped with Mounting Holes for easy assembly!)

Hinge

Hinge Cover

Closer Lip

Hook

23

Closer Lip

Figure 4a

DOOR HANDLE AND GUARD ASSEMBLY

Guard

Door Handle

Page 26

Tools Needed : n/a

1. Discontinue power to cabinet and lift Bottom Front Panel up and away from Air-Wash System. See

Figure 1, 1a & 1b.

Figure 1 Figure 1a Figure 1b

2. Remove Filter and wash in Soap & Water. (*Note: If Filter must be replaced, use one of two

spares that came with Proof Cabinet, or order P/N P7014700). See Figure 2 & 2a.

Figure 2 Figure 2a

3. With Filter removed, clean Drain Pan with clean Sponge or Rag. See Figure 2a.

4. Re-install Filter between Receiving Pockets of Drain Assembly (*Note: Filter closes off entire

opening). See Figure 2 & 2a.

5. Re-install Bottom Front Panel of Air-Wash System by reversing Step #1.

AIR-WASH SYSTEM FILTER & DRAIN PAN CLEANING

24

Filter

Drain Pan

Page 27

Tools Needed : Phillips Head Screwdriver

When adjustment of the Door Gasket seal or alignment is desired, fine-tuning can be accomplished

with the Adjusting Plate (pn 50520104). Check the instructions that follow.

1. Open the door between 90° to 180° and lift the door from the Hinge Brackets (pn 50520103).

2. Slide off the Hinge Cover(s) (pn 50520105) by grasping and pulling in a downward direction.

3. Replace the Door on the Hinge Brackets and close.

4. Locate the Adjusting Plate (pn 50520104) inside of the Hinge Barrel (pn 50520102) of choice.

The Hinge Barrel is placed on the Door itself and attached with at least two Screws (pn 50678801).

5. Loosen the Screws without taking them completely out.

6. Close Door and adjust to the Fascia of the cabinet.

7. Slowly push or pull the door until the Gasket properly aligns and evenly seals to the Cabinet

Fascia.

8. Tighten Screws on the Hinge Barrel.

9. Place Hinge Covers.

There are a couple of Special Feature Shims that assist with the adjustment of Hinged Doors using

the Self-Closing Hinge Assembly (pn 10685101). These items can be used as a second or third option

if additional adjustment is required. Refer to the Shim descriptions below and their purpose.

1. Fascia Shim (pn 05072701) - The Fascia Shim is used to help extend the “Hinge Bracket” (pn

50520103) in a forward direction when the Door Gasket needs to be loosened from or accurately

tightened to the Cabinet Fascia.

DOOR ADJUSTMENT INSTRUCTION

SPECIAL SHIMS FOR HINGED DOOR ADJUSTMENT

25

Page 28

When using this Shim, build-up the Hinge Bracket by inserting one at a time until the forward extension

supports an acceptable Gasket Seal to the Cabinet. Hinge Bracket adjustments can be different from

door to door.

Make sure that the open end of the slot shaped cut-out is always facing towards the Door.

2. Leveling Shim (pn 50538601) - The Leveling Shim is used to raise the Door in and up or down

direction. This part is placed behind the the Hinge Barrel (pn 50520102) with the open ends of the

three slot shaped cut-out’s facing towards the Cabinet. While adjusting the top or bottom Screws

per Hinge Barrel, the Door will go in a specific direction.

a.) Top Hinge Barrel with Leveling Shim - Adjusts the Door in a downward direction.

b.) Bottom Hinge Barrel with Leveling Shim - Adjusts the the Door in an upward direction.

*Note: When inserting and/or adjusting the Leveling Shim, avoid taking the Screws completely out of

the Door. Try to make a gap wide enough to slip the Shim in between the Hinge Barrel and the

Door, then tighten the Screws until the leveling process of the Door is satisfactory and stable.

Removing

Beginning at one corner, pry gasket loose from the retaining strip. Peel remainder of gasket from the

door and discard.

Replacing

Before replacing, be sure the gasket and door are at room temperature. If necessary, soak the

gasket in warm water to make it more pliable. Align new gasket frame on the door retainer strip.

Starting at one corner, press each corner of the gasket into the retainer strip. Once started, the

gasket can be easily inserted around the entire perimeter of the door by simply press rolling into

place.

The Panera AP-51 Proofer Cabinet can hold 6 single racks, or 2 double and 2 Single racks.

After the cabinet has been installed, leveled and cleaned as described, refer to the following checklist

prior to start-up.

Check for proper electrical hook-up.

Check that cabinet is level.

Check drain line to make sure it is free of kinks and restriction.

Cabinet Cleaning

Adamatic recommends periodic internal and exterior cleaning as outlined below. Use non-abrasive

cleaners that do not contain chlorine and a soft cloth or sponge. Do not use steel wool, scrapers, wire

brushes or other harsh items to clean your proofer.

Daily Exterior Cleaning

1. Clean surface with a sponge and cleaning solution.

2. Polish with a soft cloth for stainless steel, wiping with the grain of the metal.

3. Once a week wipe with a film cutting agent to maintain shine and stainless steel finish.

INSTALLATION CHECKLIST

PERIODIC MAINTENANCE

26

DOOR GASKET REPLACEMENT

RACK CAPACITY

Page 29

Weekly Interior Cleaning

1. Turn proofer cabinet “OFF”.

2. Remove loose particles from interior floors, walls and ceiling.

3. Scrub all interior surfaces with warm detergent solution 100 °F - 120°F (38°C - 39°C) and a

nylon bristled brush.

4. Rinse with clear water and allow to air dry.

5. Remove filter and clean. Replace filter if necessary.

6. Turn proofer cabinet “ON”.

All proofers are supplied with a top mounted power module that includes a

"disconnect switch". The disconnect switch is the simplest way to cut off and

restore power to the proofer's working components and control board circuitry.

Common practice is to always disconnect power from the main power

source!

Start-Up

On top of the cabinet, make certain that the main power

module is in the “ON” position (*see above) . Press the

main power “ON/OFF” button on the control panel and a

LED and digital alarm test will take place.

After the testing stage is complete, the controller will recall

all previous settings. (*Note: if cabinet loses power from

main source, previous settings will still be recalled)

At this point, a ten minute pre-heat cycle will begin. The

heat will run at the set temperature for ten minutes prior to

the humidity starting. This allows for the proof box to heat

and warm the interior walls alleviating moisture running to

the floor.

How to Set Temperature & Humidity

As long as the proofer cabinet is “ON”, the control system

will maintain the proofer’s internal temperature and

humidity set points. Temperature and Humidity settings can

be adjusted by using the ×(up) and Ø(down) keys located

on the controller next to the corresponding display.

The internal temperature set point can be adjusted from

40°F to 120°F, and the internal humidity set point from 20%

to 95%. To change the displayed temperature from

Fahrenheit to Celsius or Celsius to Fahrenheit, press both

×(up) and Ø(down) keys at the same time located by the

“SET TEMPERATURE” display.

Setting Timer

The controller has the ability to run up to six timer

programs. To set proofing times, press the ×(up) and

Ø(down) keys next to the “TIME SET” display to choose

from Rack 1 thru 6. When the correct rack number appears,

use the ×(up) and Ø(down) keys next to the “PROOFER

TIME” display to set the amount of time in hours and

minutes that you would want the displayed rack to proof.

27

DISCONNECT SWITCH

“Disconnect Switch”

CONTROL PANEL & HOW IT WORKS

Page 30

To activate the countdown timer, press the start button underneath the proof timer (*when timer is

running, the colon between hours and minutes will flash). To see the time for each rack, press the

×(up) and Ø(down) keys next to “TIME SET” to verify the time left on that numbered rack.

When the time has expired for a particular rack, the buzzer will sound, the lights on the display will

flash as well as the indicator light at the upper right corner of the proofer box. The rack whose time

has expired will show in the time display LED. Hit the “STOP” button to turn off timer. (*Note: when

pressing the “STOP” button, it will only stop the rack displayed in the “TIME SET” LED. The remaining

rack timers will continue to run.)

Viewing Temperature & Humidity Set-Points

To view Heat & Humidity Set-Points while proof cabinet is in normal "ON" state:

(1) Press ×(up) and Ø(down) keys next to "TIME SET" display window in following sequence: ×ØØ

× (2) When in view mode, "SET TEMPERATURE" and "SET HUMIDITY" display windows will

repeatedly flash exact proof cabinet temperature and humidity. (3) To come out of view mode, press

×(up) or Ø(down) key next to "TIME SET" display window and proof cabinet will go back to normal

"ON" state.

Error Codes

Should any error code appear on the display, depress the “MAIN POWER” button on control panel to

“OFF”. Wait 5 minutes and turn proofer cabinet back on. Should error code again appear, call for

service.

Shut-Down

The shut-down is initiated by depressing the power key while in the “ON” state. A dry out stage will

begin consisting of a ten minute period where the fans continue to run and the internal temperature is

held at set point. The humidity will be “OFF” during this period to allow the box to dry out. At the end

of the ten minute dry out cycle, the box will go into a five minute cool down phase to reduce the heat

inside the proofer. At the conclusion of the cool down phase, the box will automatically shut down.

Temperature & Humidity Calibration

*Note: It is highly recommended that the proof cabinet be calibrated at 85% humidity. Make sure all Heat & Humidity

Monitoring Equipment has been properly calibrated and tested before making adjustments to the proof cabinet set points!

(1) If proof cabinet is not "ON", power-up proof cabinet by pressing "ON / OFF" button located at "MAIN

POWER" section of controller. (2) Wait for proof cabinet to complete 7-second diagnostic test. (3) To

enter calibration mode, press ×(up) and Ø(down) keys located next to "TIME SET" display window in

following sequence:

×× ØØ ØØ ××

(4) When in calibration mode, "SET TEMPERATURE" and "SET

HUMIDITY" display windows will repeatedly flash exact proof cabinet temperature and humidity.

(5) Temperature and humidity set-points can now be adjusted (or calibrated) by using press ×(up) and

Ø(down) keys located next to "SET TEMPERATURE" and "SET HUMIDITY" display windows.

(6) When temperature and humidity adjustments are complete, press ×(up) or Ø(down) key next to

"TIME SET" display window to lock-in settings and take proof cabinet back to normal "ON" state.

Adamatic strives to provide excellent customer service along with quality equipment. To help us better

assist you, a serial number and/or model number must be provided when contacting the technical

service or parts department. The data plate is located inside the proofer cabinet on back of the

controller’s corner panel. All serial numbers are recorded and kept indefinitely.

Although common replacement parts have been presented throughout this manual, it is best to contact

Adamatic to confirm the replacement part of choice.

TECHNICAL SERVICE & REPLACEMENT PARTS

28

Page 31

29

TROUBLESHOOTING (*Error Message & Probable Cause Table)

Caution: This information is for Service Technicians! Disconnect Power Supply Prior to Attempting Any Service!

Heater Timeout

Error Code: “ERR 1“

*Sensor calling for

heat more than 60

minutes

High Internal Temp.

Error Code: “ERR 3“

*Sensor finding

internal cabinet

temperature 15ºF than

set point with no

decrease in internal

temperature for more

than 10 minutes

Keypad Error

Error Code: “ERR 5“

*System detected a

depressed key when

power is initially

applied to the unit

Sensor Comm.

Error Code: “ERR 6“

*Sensor Board has

stopped transmitting

data for more than 30

seconds

Thermal Overload

Error Code: “ERR 7“

*Sensor finding a

tripped thermal

overload switch

Sensor Timeout

Error Code: “ERR 8“

*Sensor board not

sending data 35

seconds or more

Most Probable Causes:

1. Proofer Door open

Most Probable Causes:

1. Defective

Temperature Sensor

Most Probable Causes:

1. Someone is

depressing key while

power is being

applied during startup

Most Probable Causes:

1. Sensor Cable has

been disconnected

Most Probable Causes:

1. Thermal Overload

Sensor disconnected

Most Probable Causes:

1. Defective

Sensor Board

2. Heater Power Cable

disconnected

2. Defective Power Triac 2. Defective Keypad 2. Defective Sensor

Board

2. Defective Thermal

Overload Sensor

2. Defective

Sensor Cable

3. L3 (Phase-3) Fuse

tripped or blown

3. Defective

Display Board

3. Defective

Sensor Cable

3. Defective

Temperature Sensor

3. Defective

Interface Cable

4. Defective

Sensor Board

4. Defective

Interface Cable

4. Defective

Interface Cable

4. Defective

Display Board

5. Defective

Interface Cable

5. Defective

Sensor Cable

6. Defective

Sensor Cable

7. Defective

Safety Relay(s)

8. Defective Power Triac

9. Defective

Power Triac Driver

Page 32

30

COMMON REPLACEMENT PARTS

Item # Part # Description

1 P6009700 Fan Motor

2 50185001 Fan Blade

3 50265802 Fan Guard

4 P6099701 Sensor & Klixon Kit

5 P6032500 Heater Safety

6 P6010401 Spray Nozzle, 80°

7 P6010500 Body Spray Adapter

8 P6099501 Power Module

Item # Part # Description

9 P6099501 Power Module

10 P6099801 Flashing Indicator Lamp

11 P6011900 Ball Valve

12 P6011700 Water Solenoid

13 P6030800 Light Housing

14 P6030900 Interior Light Globe

15 P6800036 Controller Assembly

16 P6049200 Filter, 24” x 16” Foam

Item # Part # Description

1 10685101 Hinge Assembly (complete)

2 P6009900 Door Closure

3 P6020501 Door Handle

4 P6009301 Door Gasket, 3-Sided (*not shown)

5 P6009502 Wiper Seal,30” Bottom (*not shown)

6 P6009602 Wiper Seal,60” Side (*not shown)

7 P7903501 Door Assembly, LH Complete

8 P7903601 Door Assembly, RH Complete

Air Wash System

Doors

1

2

3

Item Part No. Description Qty

1 P7906301 Fan Panel Assembly 1

2 P7906401 Electrical Box Assembly 1

3 P6800004 Heater Box Assembly 1

4 P7904101 Chassis Assembly 1

5 P6800023 Front Panel Assembly Lift Off 1

6 P6053000 Front Panel 1

7 P7906201 Drain Pan Assembly 1

8 P6048600 Lower Front Panel 1

9 P6008801 Heater Bracket 1

10 P6008503 Top Panel 1

11 P6008902 Bracket, Spray Nozzle 1

12 P6020601 Carrier Filter 1

13 P6022500 Heat & Humidity Sensor Bracket 1

14 P6024101 Bracket, Bumper Guard 1

15 P6024000 Bumper Guard, Drain 1

16 P6011301 Hairpin Heater 4

17 P6800009 Water Line H Feed Assembly 1

Page 33

31

WIRING DIAGRAM

Page 34

Adamatic Baking Equipment & Sales

607 Industrial Way

Eatontown, NJ 07724

Tel: (800) 526-2807

Fax: (732) 544-0735

Web: www.adamatic.com

Loading...

Loading...