acer AL2002 Service Manual

ACER_LCD_AL2002W_SM061206V0

LCD Color Monitor: T20BNUW-G1

Model Name: ACER AL2002W-Dual

Service Manual

Table of Contents

Important Safety Notice

01. Product Overview---------------------------------------------------------------------------------------02

02. General Requirement----------------------------------------------------------------------------------02

03. Electrica Related Information------------------------------------------------------------------------ 03

04. Flat Panel------------------------------------------------------------------------------------------------ 12

05. Optical Characteristics-------------------------------------------------------------------------------- 14

06. Environmental Requirements------------------------------------------------------------------------ 16

07. RGB settings---------------------------------------------------------------------------------------------17

08. Color grayscale linearity-------------------------------------------------------------------------------17

09. Packing Drawing----------------------------------------------------------------------------------------18

10. Exploded Diagram--------------------------------------------------------------------------------------19

11. Schematics and Layouts-------------------------------------------------------------------------------20

Appendixes:

Appendix-1 Product Matrix

Appendix-2 User s Manual

Appendix-3 Quick Start Guide

Appendix-4 Spare Parts List

-------------------------------------------------------------------------------------01

ACER AL2002W

e

1

Go to cover page

Important Safety Notic

Product Anouncement:

This product is certificated to meet RoHS Directive and Lead-Free produced definition. Using approved critical components only is

recommended when the situation to replace defective parts. Vender assumes no liability express or implied, arising out of any

unauthorized modification of design or replacing non-RoHS parts. Service providers assume all liability.

Qualified Repairability:

Proper service and repair is important to the safe, reliable operation of all series products. The service

providers recommended by vender should being aware of notices listed in this service manual in order to

minimize the risk of personal injury when perform service procedures. Furtermore, the possibile existed

improper repairing method may damage equipment or products. It is recommended that service engineers

should have repairing knowledge, experience, as well as appropriate product training per new model before

performing the service procedures.

NOTICE:

à To avoid electrical shocks, the products should be connect to an authorized power cord, and turn off the master power

switch each time before removing theAC power cord.

à To prevent the product away from water or explosed in extremely high humility environment.

à To ensure the continued reliability of this product, use only original manufacturer’s specified parts.

à To ensure following safty repairing behavior, put the replaced part on the components side of PWBA, not solder side.

à To ensure using a proper screwdriver, follow the torque/force listed in assembly and disassembly

à procedures to unscrew screws.

à Using Lead-Free solder to well mounted the parts.

à The fusion point of Lead-Free solder requested in the degree of 220°C.

2

Go to cover page

1. Product Overview:

This document defines the design and performance requirements for the Liteon standard 20” wide flat panel monitor. The

display element shall be a 20” inch diagonal, WSXGA (1680 x 1050) resolution, TFT-LCD (Thin Film Transistor Liquid Crystal

Display. Video input signals are Analog D-sub and DVI-D Digital with non-interlaced signaling. Power saving function

complies with the DPMS (Display Power Management Standard).

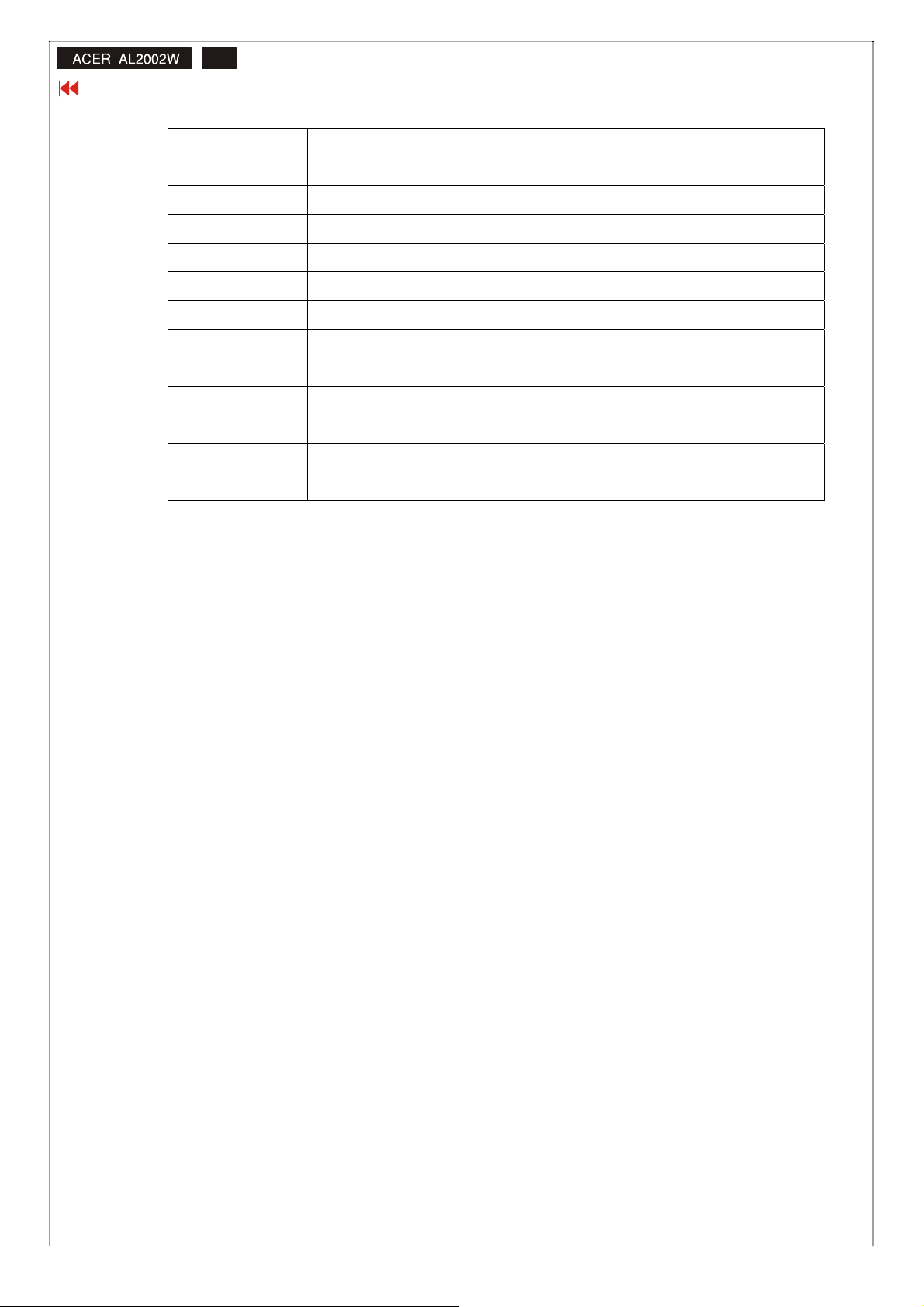

General display parameters

Display Area 20” diagonal, (H)433.44(H)x270.90(V)

Resolution 1680 x 1050 pixels

Display Color Number 16.7M colors(RGB 6-bit+Hi-FRC data)

Display Type a-Si TFT active-matrix

Contrast Ratio 800 : 1 typ.

Brightness 300cd/m2 typ.

Response Time (Ton + Toff) 5 ms typ.

Pixel Pitch 0.258mm x 0.258mm RGB Vertical Stripes

Vertical Viewing 160 degrees typ,

Horizontal Viewing 160 degrees typ,

CR=10

CR=10

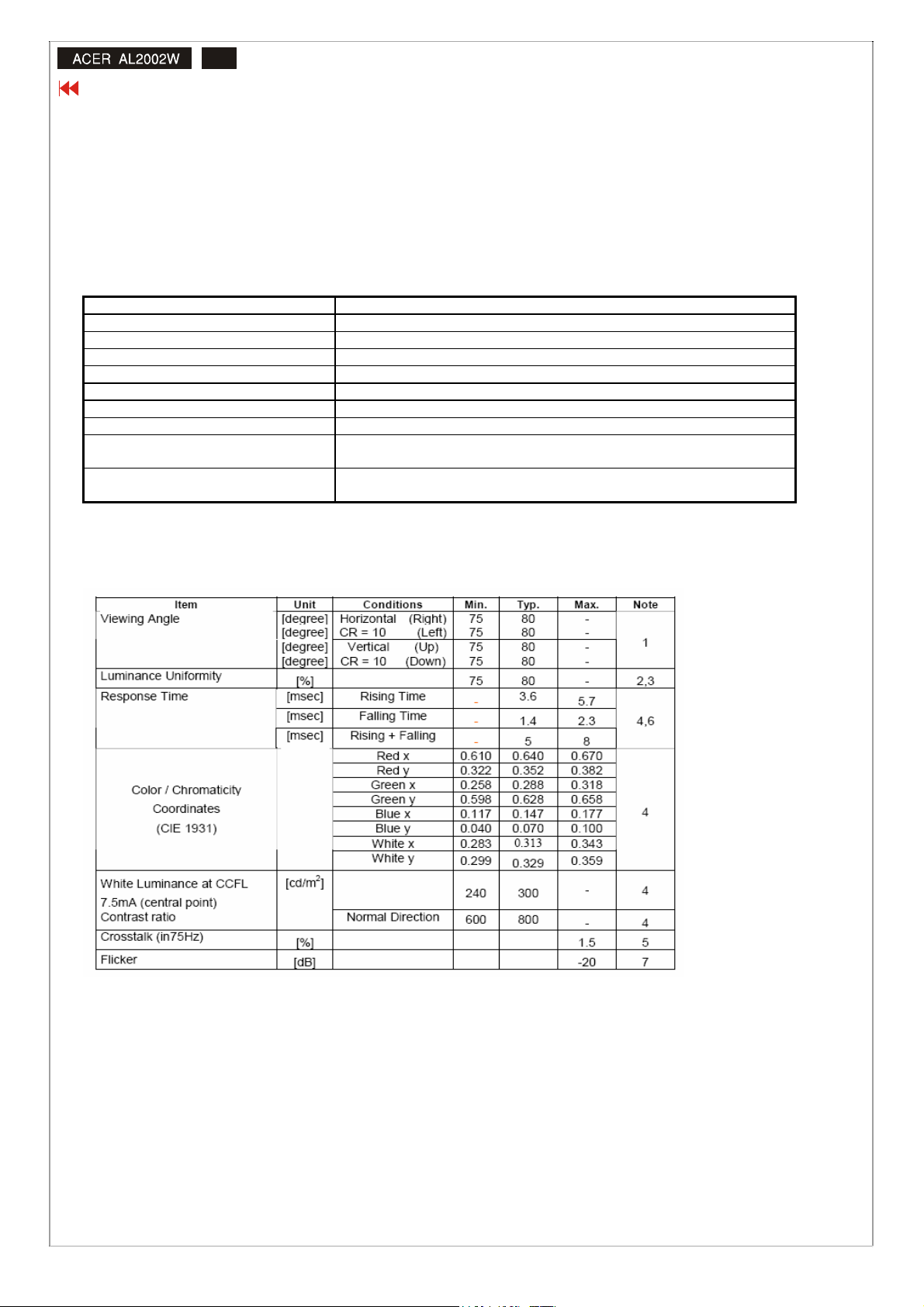

Optical Characteristics

M201EW02 V1

Note: Per panel specification, over the life of the product, variation of parameters specified in panel

specification shall be maintained within reasonable limits. Check supplier quality inspection criteria for

the detail information.

2. GENERAL REQUIREMENTS:

2.1 Test Condition

Brightness level at max & contrast level at default full white pattern test mode following spec. Warm up more than 30

min, ambient light < 1 Lux, Luminance meter CA210 or BM7 or compatible equipment.

3

Go to cover page

2.2 Test Equipment

The reference signal source is a calibrated Chroma 2326 or Quantum 801GD video generator. The use of other signal

generators during qualification and production is acceptable provided the product complies with this specification.

3. ELECTRICAL RELATED INFORMATION:

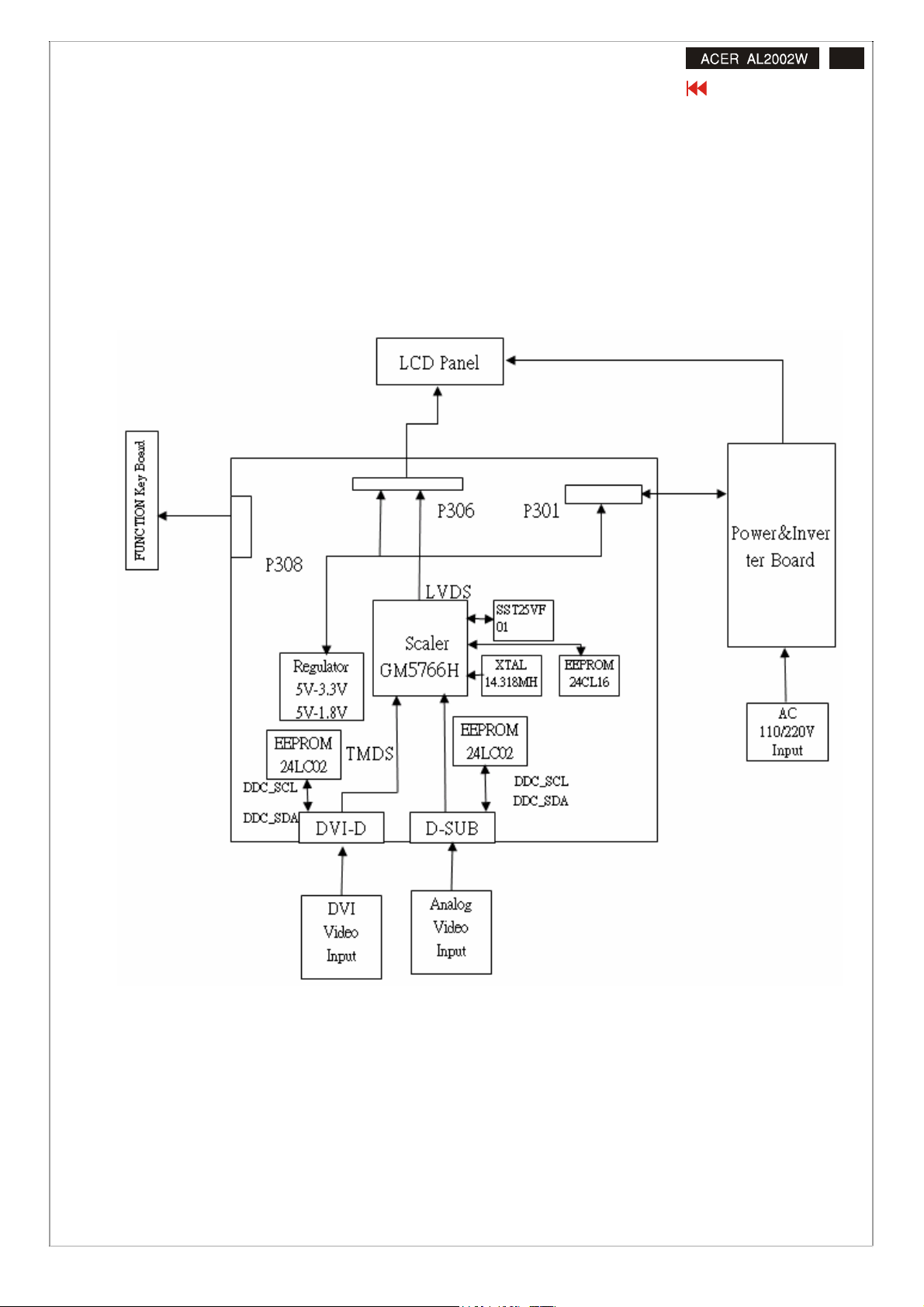

This section describes the electrical requirement of the monitor. The block diagram in Figure 1 illustrates the various electrical

sub-system.

3.1. Product Block Diagram

The LCD monitor will contain an interface board, a Power / Inverter board, and a function key board. The interface block

will house the flat panel control logic, brightness control logic, and DC-DC conversion to supply the appropriate power to

the whole board and LCD panel, and transmitting LVDS signals into LCD Module to drive the LCD display circuit. The

inverter block will drive the four dual CCFLs (Cold Cathode fluorescent Tube). The power block will provide the DC power

to interface board and LCD panel. The function key block will provides the OSD control signal, power ON/OFF and LED

indicator to the interface board.

4

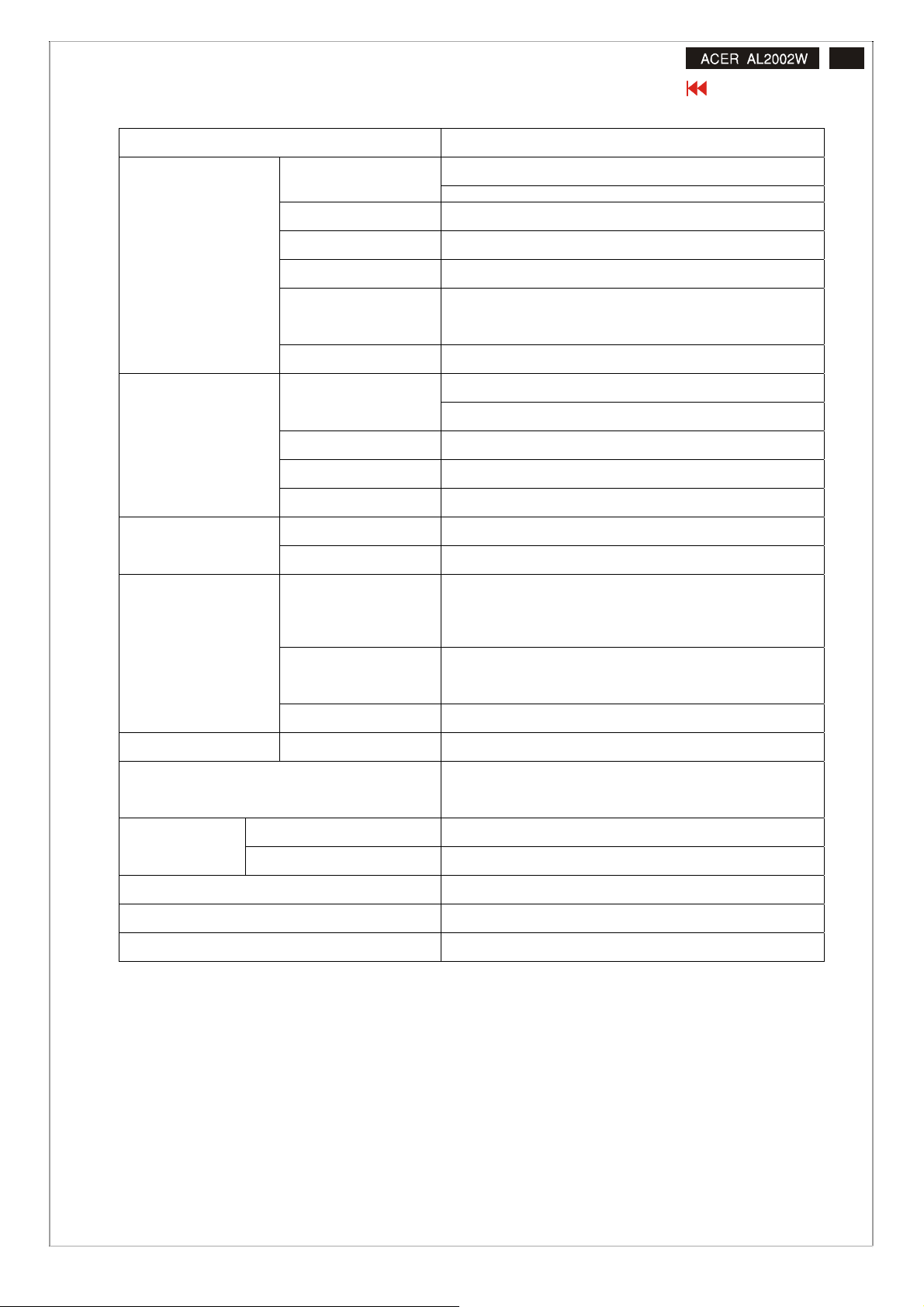

3.2. Product Specification

Analog Signal Input

Digital Signal Input

Connectors

Go to cover page

ITEM SPEC

Frequency Ranges

Max Pixel clock 205MHz

RGB Input Level 0.7Vp-p

RGB Input Impedance 75Ω

Sync Input Signal

Sync Input Impedance 50Ω

Frequency Ranges

Max Pixel clock 165MHz

DVI Input Level 150mV Vp≦ -p 1560mV ≦

DVI Input Impedance Input Impedance 100Ω per pair

AC power AC 100V ~ AC 220V ± 10% 50/60Hz, 3 pin AC power cord

Input connectors D-SUB 15 pin, DVI-D

H 30kHz ~ 81kHz

V 56Hz ~ 76Hz

Separate SYNC, Composite Sync or Sync on Green are

supported

H 30kHz ~ 81kHz

V 56Hz ~ 76Hz

Power Consumption

User’s Control Front Panel Buttons POWER, MENU, SELECT, + , -

Dimming control range

(max-min/max) x 100%

Timing

Plug and Play VESA DDC2B

Power Saving DPMS

Input Signal Counter tolerance H ±1kHz, V ±1 Hz

3.3. Interface Connectors

3.3.1. Power Connector and Cables

AC IN 90~264V

Normal Operation

Standby, Suspend,

Active Off

Power Off < 1W @ (90VAC~240VAC)

Factory 11 Pre-Defined

User 15

49W Max

< 2W

35% typical

The AC inlet connector shall have an IEC/CEE-22 type male power receptacle for connection to mains power.

The power cord, exact type to be supplied in the appropriate Option Kit, shall be black have length of 1.8

0.05 meters.

5

Go to cover page

3.3.2. Signal Connectors and Cable

The analog signal cable shall be black and 1800 mini-meters, the digital signal cable shall be black and 1800

mini-meters, At the end of the analog cable shall be a molded-over, shielded, triple row, 15 position and blue

color D subminiature connector. At the end of the digital cable shall be a molded-over, shielded, triple row, 24

position, white color DVI-D connector. The CPU connection shall have captive screw locks, which will be

adequate for hand tightening. The monitor connection may use small screws.

3.3.3. Connector Pin Assignment

A. DSUB

Pin Signal Pin Signal Pin Signal

B. DVI-D (Digital TMDS) Connector

Pin Signal Pin Signal Pin Signal

1 Red-Video 6 Red-GND 11 GND

2 Green-Video 7 Green-GND 12 DDC-SDL

3 Blue-Video 8 Blue-GND 13 H-SYNC

4 GND 9 + 5V 14 V-SYNC

5 Self Test 10 DDC-GND 15 DDC-SCL

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 0-

2 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data GND 11 TMDS Data GND 19 TMDS Data GND

4 NC 12 NC 20 NC

5 NC 13 NC 21 NC

6 DDC Clock 14 + 5V Power 22 TMDS Clock GND

7 DDC Data 15 Self Test 23 TMDS Clock +

8 NC 16 Hot Plug Detect 24 TMDS Clock -

C. Power Board Connector

Pin Signal

1 5.2V

2 5.2V

3 5.2V

4 5.2V

5 GND

6 GND

7 GND

8 GND

9 BKLT-EN

10 BKLT-ADJ

6

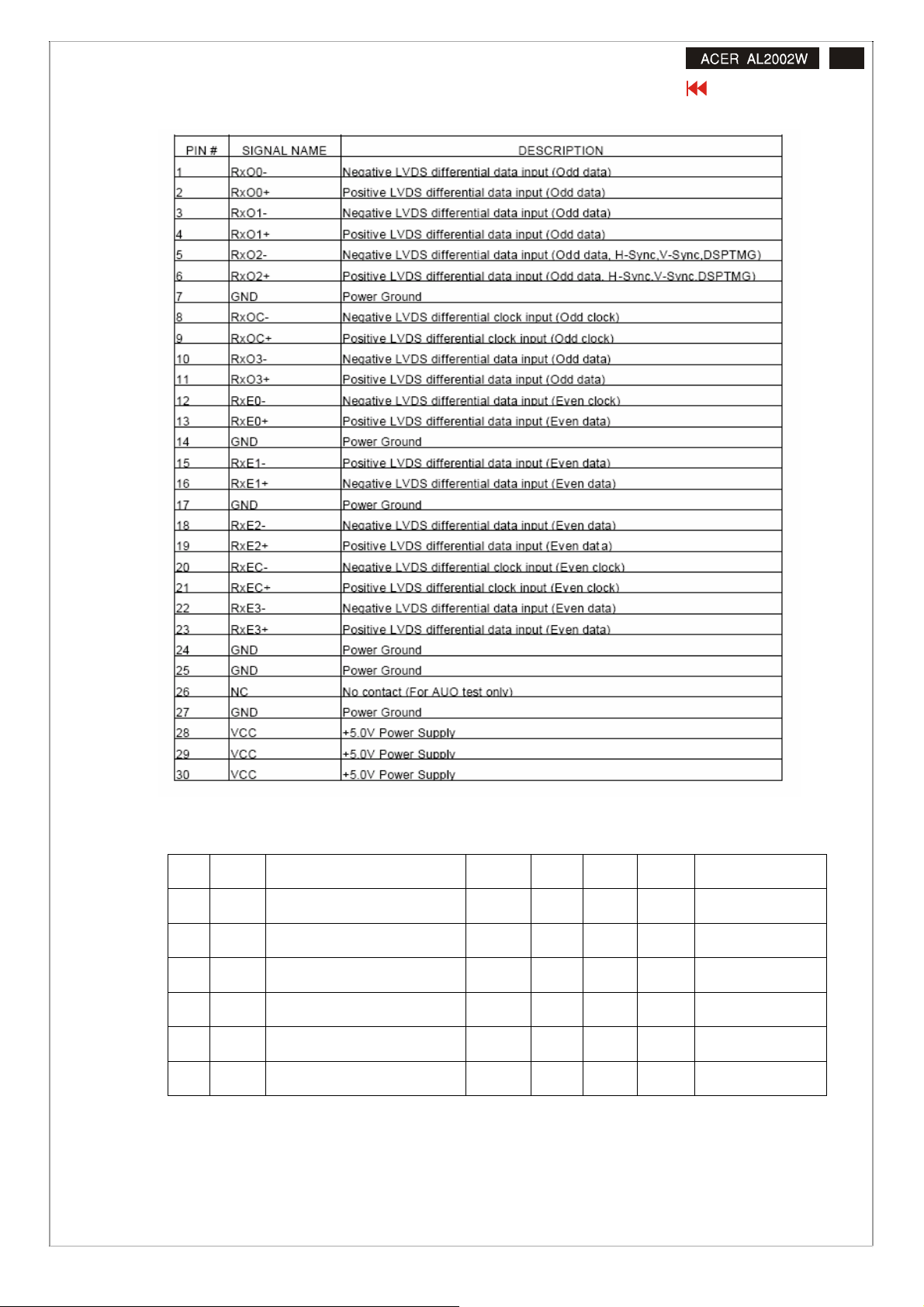

D. Flat Panel Connector

Go to cover page

3.4. Input Signals (Analog RGB Signal Input):

3.4.1. Video Input Signal Ranges

No. Symbol Item Min Normal Max Unit Remark

1 Fh Horizontal Frequency 30 81 kHz Minimum range

2 Fv Vertical Frequency 56 76 Hz Minimum range

3 Fclk Locked Pixel Clock Frequency 165 MHz

4 Vih Hi Level Input 2.0 5.0 V Note 1)

5 Vil Low Level Input 0 0.8 V Note 1)

6 Video RGB Analog Video Level 0.0 0.735 V 75Ω to Ground

Note : 2.2kΩ to Ground, Schmitt-Triggers Input, Supported 3.3V device H & V sync. Output.

7

Go to cover page

3.4.2. Video Signal Amplitudes

The three video inputs consist of Red, Green, and Blue signals, each with its own coaxial cable terminated at

the monitor. These video signals are analog levels, where 0V corresponds to black, and 735 mV is the

maximum signal amplitude for the respective color, when each signal is terminated by a nominal 75.0 ohm. For

a given monitor luminance levels are measured using this defined video amplitude driving a monitor meeting

the termination requirements. The signal amplitude is not to be readjusted to compensate for variations in

termination impedance.

3.4.3. Video Signal Termination Impedance

This analog video signal termination shall be 75 ohm +/- 2% which shall be resistive with a negligible reactive

component.

3.4.4. Synchronization (Sync) Signals

The Horizontal Sync (HS) TTL signal is used to initiate the display of a horizontal line. HS may be either active

high or active low, depending upon the timing. The Vertical Sync (VS) TTL signal is used to initiate the display

of a new frame. VS may be either active high or active low, depending on the timing.

3.4.5. Sync Signal Levels

The monitor must accept sync signals from both 3.3 and 5 volt TTL logic families. The inputs shall sense a logic

0 when the input is 0.8 volt or less and shall sense a logic 1 when the input is 2.0 volts or greater. In addition to

these level requirements, there shall also be a minimum of 0.3 volt hysteresis provided for noise immunity

(typically by using a Schmitt Trigger input). That is, the input level at which the monitor actually detects a logic 0

shall be at least 0.3 volt lower than the level at which it actually detects a logic 1. If the monitor sync processing

circuits are designed around the 3.3 volt logic family, then the sync inputs must be 5 volt tolerant.

3.4.6. Sync Signal Loading

TTL input loading shall be equivalent to one TTL input load. When logic 0 is asserted by a sync input, the

maximum current source from any single monitor sync input to the driver is 1.6 mA. When logic 1 is asserted,

the maximum current source from the driver to any single monitor sync input is 400mA.

3.4.7. Abnormal Signal Immunity

The monitor shall not be damaged by improper sync timing, pulse duration, or absence of sync, or abnormal

input signal amplitude (video and/ or sync too large or too small), or any other anomalous behavior of a

graphics card video generator when changing modes, or when any combination of input signals is removed or

replaced. Additionally, under these conditions, the monitor shall not cause damage to the driving source.

8

Go to cover page

3.5. Interface Boards (Digital TMDS Input)

3.5.1. The interface board will house the Panel-Link receiver , and transmitting TTL level signals into LCD Module to

driver the LCD display circuit.

3.5.2. Video Signal Amplitudes

This video inputs consist of TX 0 ±, TX 1 ±, TX 2 ± and CLK ± signals, each with its own shielded twisted pair.

These video signals are digital levels, when each signal pair is terminated by a normal 100 ohms .The panel-Link

signal transmitting over the cable is based on 3V DC offset with ± 0.5V amplitude.

3.5.3. Video Signal Termination Impedance

This panel link signal termination shall be 100Ω per pair which shall be resistive with a negligible reactive

component.

3.5.4. Signal Connector (DVI-D 24 pin)

This signal cable connector shall be white color, molded – over and shielded twisted pair cable with 50Ω

impedance per line or 100Ω ±10% per differential pair. The cable shall be 2000 mini-meters long.

3.6. User Controls and Indicators:

3.6.1. Power On / Off Switch

The monitor shall have a power control switch visible and accessible on the front of the monitor.

The switch shall have no effect on the operation of the AC / DC converter. Instead, it shall interrupt the DC

supply to the monitor.

3.6.2. Power Indicator LED

The monitor shall make use of a LED type indicator located on the front of the monitor. The LED color shall

indicate the power states as given in Table below.

Power-ON Mode : Green

Power Saving Mode : Amber

3.6.3. On-Screen Display

The On Screen Display system shall be used, controlled by a select button (SELECT), a menu button (MENU),

LED Color

a plus (+) button and a minus (-) button. If the buttons remain untouched for OSD turn off time while displaying

a menu, the firmware shall save the current adjustments and exit. Also, if the video controller changes video

mode while the OSD is active, the current settings shall be saved immediately, the OSD turned off, and the new

mode is displayed.

A. Menu Operation

Pressing the MENU button the first time brings up the first menu level. The (MENU) button is used to enter

and exit the OSD menu. Pressing the MENU button brings up the second menu level for the item selected.

9

Go to cover page

B. OSD Controls

Brightness Backlight Luminance of the LCD panel is adjusted.

Contrast A gain of R,G and B signal is adjusted.

Color Temperature 9300K, 8200K, 7500, 6500K, 5000K And User settings.

Auto Adjust Clock system auto adjustment, about under 5 sec.

Left/Right The indication screen is horizontally moved right and left (1 pixel pitch)

Up/Down The indication screen is vertically moved up and down (1 pixel pitch)

Pixel Clock The ratio of dividing frequency of the dot clock is adjusted.

Phase The phase of dot clock is adjusted.

OSD Language Select the language used for the OSD menu from between English, French, Italian,

Recall Defaults All data copy from factory shipment data.

OSD Position The OSD indication position can be selected.

3.7. Monitor Modes and Timing Capability:

Item Description

Deutsch, Spanish, Japan, Simple Chinese and Traditional Chinese.

3.7.1. Format and Timing

The monitor shall synchronize with any vertical frequency from 56 to 76 Hz, and with any horizontal frequency

from 30 to 81 KHz. If the input frequency is beyond the specified range, the monitor shall display a warning

screen indicating that the input frequency is out of range. Under no circumstances shall any combination of

input signals cause any damage to the monitor.

3.7.2. Factory Assigned Display Modes

There are 11 factory pre-set frequency video modes. These modes have a factory pre-set for all characteristics

affecting front-of-screen performance. When the system is powered-on, previously stored screen

parameters for a pre-defined mode will be recalled if the operating mode is one of those stored in memory. If

the operating mode is not one of those stored in memory, the monitor CPU will select the PRESET timing for a

mode that is the next lowest in horizontal scanning frequency to the mode being currently used. The screen

parameters may be adjusted by the use of the front bezel controls and then may be saved as a user defined

mode. The monitor shall include all the preset video timings shown in the following page.

3.7.3. Mode Recognition Pull-in

The monitor shall recognize preset modes within a range of +,- 1KHz whichever is less for horizontal ; and

within +,- 1Hz for vertical.

3.7.4. User Display Modes

In addition to the factory pre-set video modes, provisions shall be made to store up to 15 user modes. If the

current mode is a user mode, the monitor shall select its previously stored settings. If the user alters a setting,

the new setting will be stored in the same user mode. The user modes are not affected by the pre-set

command. If the input signal requires a new user mode, storage of the new format is automatically performed

during user adjustment of the display (if required).

10

Go to cover page

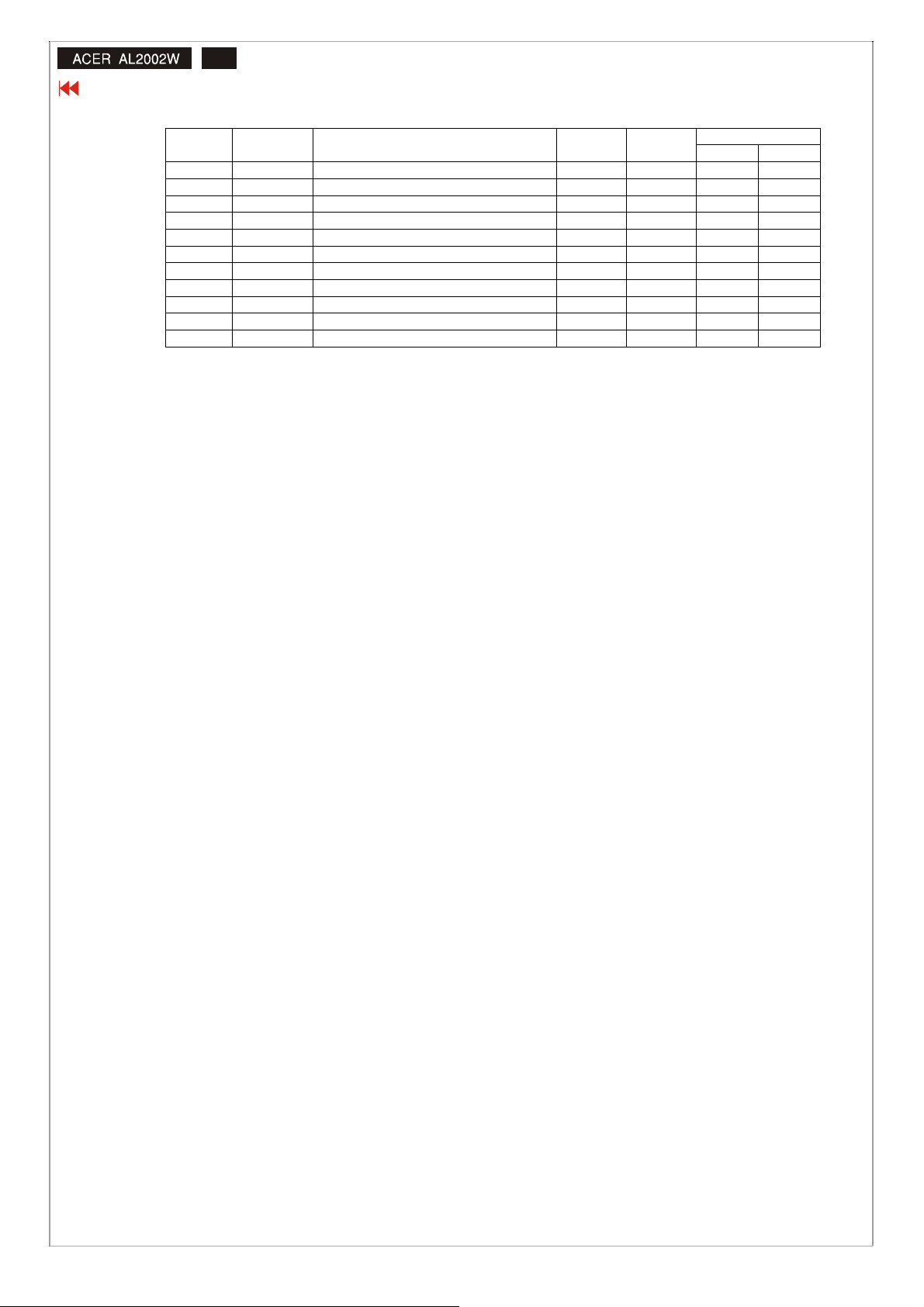

Preset Timing Chart

No

NOTE: (1)76Hz FV: monitor can display but doesn’t guarantee.≦

(2) FH>=85KHz, or Fv>=80Hz: Power Save (OSD warning invalid mode).

3.8. Controller Requirements

3.8.1. General Requirements

The monitor shall include a controller capable of converting the analog RGB signal from a standard WSXGA

resolution video controller in the CPU to a signal which can be displayed on the panel. The controller will

Chroma

Timing

1 102 VGA 720 x 400 70Hz 31.47 28.322 - +

2 103 VGA 640 x 480 60Hz 31.47 25.175 - 3 109 VESA 640 x 480 75Hz 37.5 31.5 - 4 116 VESA 800 x 600 60Hz 37.88 40 + +

5 110 VESA 800 x 600 75Hz 46.88 49.5 + +

6 118 VESA 1024 x 768 60Hz 48.36 65 - 7 141 VESA 1024 x 768 75Hz 60.02 78.75 + +

8 126 MAC 1152 x 864 75Hz 67.5 108 + +

9 179 SXGA 1280 x 1024 60Hz 64 108 + +

10 131 SXGA 1280 x 1024 75Hz 80 135 + +

11 333 WSXGA 1680 x 1050 60Hz 65.3 146.25 - +

Timing Modes, FV(Hz)

FH Pixel Rate Sync Polarity

(KHz) (MHz) H V

include a PLL, A/D converters, and other circuitry necessary to perform its function. The PLL shall be stable

enough to ensure that a static image from the CPU is placed in the same physical location on the flat panel in

each frame.

3.8.2. Video Stretching

The monitor shall contain provisions to “stretch” the video signal, so that an input signal from the computer in

any resolution smaller than 1680 x 1050 is automatically expanded to fill the entire screen.

3.8.3. Panel Timing and Interface

The controller supplied with the monitor shall control all panel timing. This controller shall adequately insulate

the monitor from the computer, so that no possible combination of input signals from the computer shall

cause damage to the flat panel or any other component of the monitor. The LCD panel interface shall support

the TFT standard.

3.9. DC - AC Inverter Requirements:

The frequencies used by the DC - AC inverter used to power the backlight shall be chosen so as to prevent any

noticeable effects on the flat panel (such as a rolling effect).

3.10. Power Supply Requirements

The AC to DC converter power supply for the monitor shall be an integrated power supply. This power supply shall

have an IEC receptacle for mains power input and provide sufficient power for the monitor, the backlight assembly

and the “Dell Sound bar”, and shall meet all requirements specified in Table 2.

11

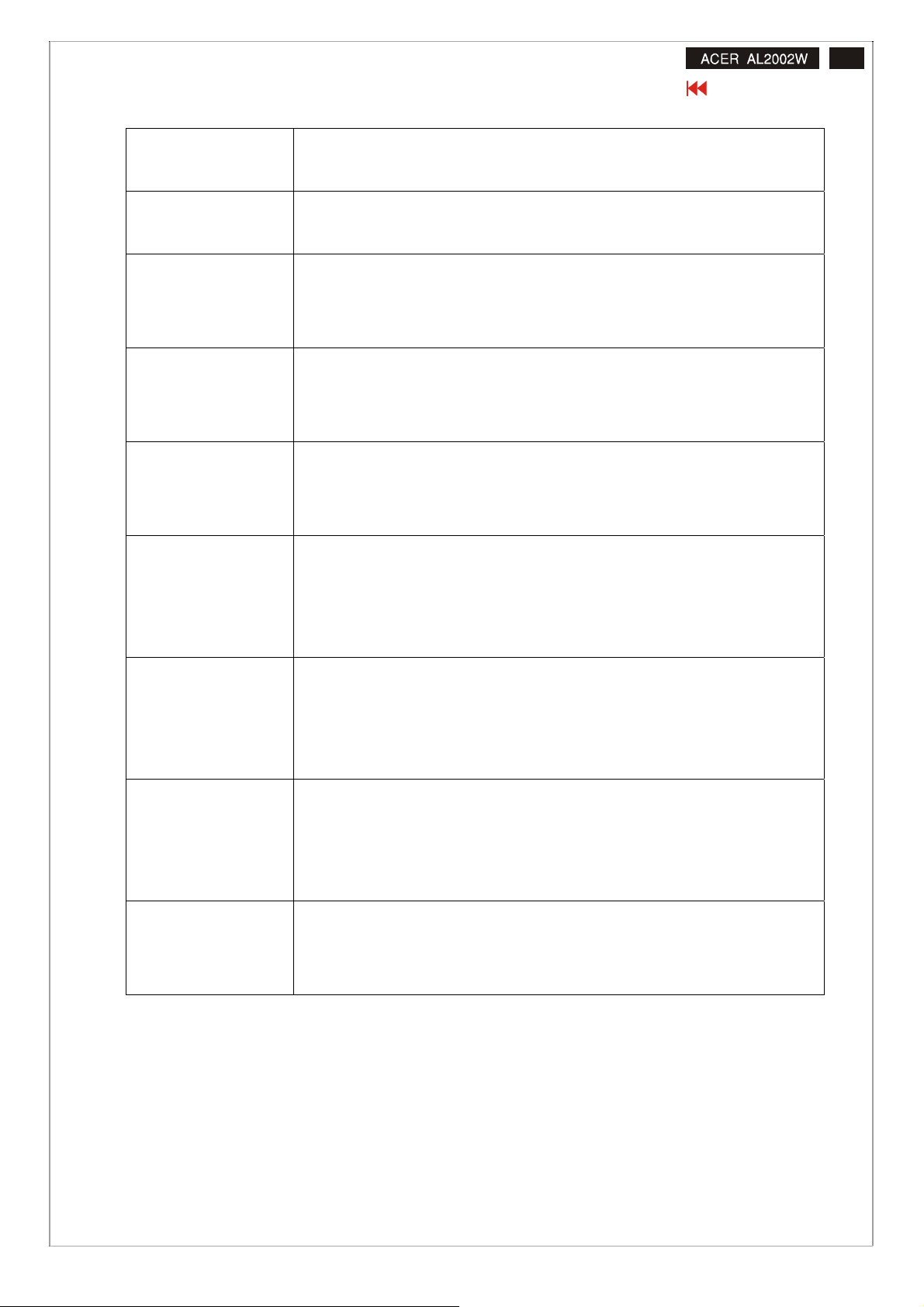

Table 2. AC TO DC Converter Requirements

Input Voltage Range

Input Frequency Range

Power Consumption

Line Fuse

Initial Cold Start

The operating range shall be from 90 to 132 and 195 to 240 VAC sinusoidal for all

models specified.

Input power frequency range shall be from 47.5 to 63Hz over the specified input

voltage range.

Power consumption for the monitor shall be less than 49W over the specified voltage

and frequency ranges. In power off mode the power consumption will be less than

1W (at 90VAC~240VAC).

The AC input shall be fused and become electrically open as a result on an unsafe

current level. The fuse may not be user replaceable.

The power supply shall start and function properly when under full load, with worst

case conditions of input voltage, input frequency, operating temperature, and cold

backlight lamps.

Go to cover page

Inrush Current

Hot Start Cycle

Under Voltage

Line Transient

3.11. Display Communications Channel

The inrush current must be limited to 42A when operated at 120VAC, and 80A when

operated at 220VAC. In - rush current is measured at an ambient temperature of 25°

C, with the unit temperature stabilized in the power - off

The power supply shall not be damaged when switched ON for one second and OFF

for one second for seven consecutive times after operating for one hour at full load,

25°C, and nominal input line voltage.

The power supply shall contain protection circuitry such that the application of an

input voltage below the minimum specified in this table shall not cause damage to

the power supply unit nor cause failure of the input

The power supply shall operate within IEC 801-4 (±1KV) and IEC 801 -5 (±2KV) for

the domestic U.S. Version. The UPS power supply shall operate and comply with CE

mark.

The monitor assembly shall provide a display communications channel that conforms to VESA DDC2B hardware

requirements. This configuration shall contain the 256-byte EDID file as specified by VESA E-EDID Standard. The

monitor contains a separate EEProm for each video input to store EDID information. Once the EDID is programmed

there is a write protection that is enabled so that the EEPROM cannot be overwritten.

12

Go to cover page

4. FLAT PANEL:

4.1. General Requirements

The panel used as the display device shall be a WSXGA resolution, 20” diagonal, TFT-LCD.

4.2. Panel Timings

The controller included with the monitor shall translate all video timings from the CPU that meet the timing

requirements listed in Panel specification into timings appropriate for the panel. Under no circumstances may the

controller supply the panel with timings that may result in damage. The controller shall insulate the panel from the

CPU, so that the panel shall always be driven per its own specification regardless of the timings being sent from the

CPU.

4.3. Polarizer Hardness

The outer face of the front polarizer panel shall be covered with a coating with a 3H hardness value, Haze 44%

(AMLCD).

4.4. Backlight Requirements

4.4.1. General Requirements

The backlight assembly shall be designed to support field replacement at the customer site or authorized service

center. The lamps shall have a continuous operating life of at least 50,000 hours at 25oC. The operating life is

defined as having ended when the illumination of light has reached 50% of the initial value. The lamps shall

extend a sufficient amount from the edge of the light guide that sputtering over the life of the lamps shall not

cause degradation of the luminance uniformity (such as non-illuminated bands along the edges of the display).

4.4.2. Lamps Startup Time

The backlight lamps shall start within 3 sec. of the time the monitor power switch is pressed or the monitor is

restarted from a power - down mode .The starting time shall stay below 3 sec. for the minimum expected life of

the lamps.

Test conditions are as follows:

Ambient Light ---------------------- < 1.0 lux.

Temperature-------------------------- 10oC

Inactive Time ----------------------- > 24 hours

4.5. Defects:

4.5.1. Visual Inspection

The LCD panel shall be inspected with all pixels set to white, black, red, green, and blue. The color variation,

brightness variation, and overall appearance must not be perceived as poor quality by Lite - On. Areas and / or

parameters considered questionable shall be subjected to detailed measurements.

13

4.5.2. Display Degradation

Over the life of the product, variation of the parameters specified in Panel specification shall be maintained

within reasonable limits. The panel must not exhibit any significant defects while in operation (excluding the

CCFL operation). This does not in any way change the warranty given by the panel manufacturer.

4.5.3. Light Leakage

Except for the active display area, there shall be no light emission visible from any angle from any other part of

the display. For this test, the ambient illumination will follow the panel specification 300 to 700 lux.

4.5.4. Allowable Defects

No cosmetic defects are allowed except those specified below. The conditions of visual inspections are as

follows:

; Viewing distance is to be approximately 35cm.

; Ambient illumination is to be 300 to 500 lux.

; Viewing angle range shall be 160 degrees Horizontal and 160 degrees vertical typically.(AMLCD)

Go to cover page

; Defects not apparent within one minute shall be ignored.

4.5.5. Defect Terminology

Below table is the descriptive terms used in classifying defects.

Dark Spots/Lines Spots or lines that appear dark in the display patterns and are usually the result

of contamination. Defects do not vary in size or intensity (contrast) when contrast

voltage is varied. Contrast variation can be achieved through the use of varying

gray shade patterns.

Bright Spots/Lines Spots or lines appear light in the display patterns. Defects do not vary in size or

intensity (contrast) when contrast voltage is varied. Contrast variation can be

achieved through the use of varying gray shade patterns.

Polarizer Scratch When the unit lights, lines appear light (white) with display patterns dark and do

not vary in size. Physical damage to the polarizer does not damage the glass.

Polarizer Dent When the unit lights, spots appear light (white) with display patterns dark and do

not vary in size. Physical damage to the polarizer that does not damage the

glass.

Rubbing Line Horizontal or diagonal lines that appear gray with the display patterns dark and

may have resulted from an “ out of control “ rubbing process on the polyimide or

“ waves “ on the BEFs or prism sheets .

Newton Ring The “rainbow” effect caused by non-uniform cell thickness.

Mottling When the unit lights, variation / non – uniformity (splotchiness) appears light

(white) with the display and might vary in size.

Dim Line When the unit lights, line(s) in the minor (vertical) or major (horizontal) axis

appear dim, but not completely on or off.

Cross Lines Off When the unit lights , lines in both the minor and major axis do not appear.

Bright / Dark Dot A sub - pixel (R, G, B dot) stuck off / on (electrical).

14

Go to cover page

4.5.6. Smudges, Streaks and Smears

When viewing the panel oriented so as to maximize reflected light, there shall be no visible smudging,

streaking, smearing or other non-uniformity from contaminants, fingerprints, or defects in any of the visible

surfaces. This is independent of whether the unit is operating or off.

4.5.7. LCD Inspection

Put LCD panel on inspection table and illuminate the panel with a daylight fluorescent lamp located above the

panel surface such that the luminance at the LCD panel is between 1000 lux. and 1500 lux. Defect limits are

given as following.

Smaller of (L+W)/2 or L/20 + 2W

< 0.1mm Non countable N / A

0.1mm - 0.3mm 10 15mm

0.31mm - 0.5mm 10 15mm

0.51mm - 1.25mm 5 15mm

1.26mm - 2.5mm 3 25.4mm

2.51mm - 0.3mm 3 25.4mm

Greater than 3.75mm None Not applicable

Average Diameter

Acceptable Number Minimum Separation

Allowable distance between spots of two sizes is the minimum separation number for the smaller spot.

Therefore, if there are two spots, 1.30mm and 0.4mm in diameter, they must be at least 15mm apart.

Note: Per panel specification, over the life of the product, variation of parameters specified in

Panel specification shall be maintained within reasonable limits. Check supplier quality

inspection criteria for the detail information.

5. Optical Characteristics:

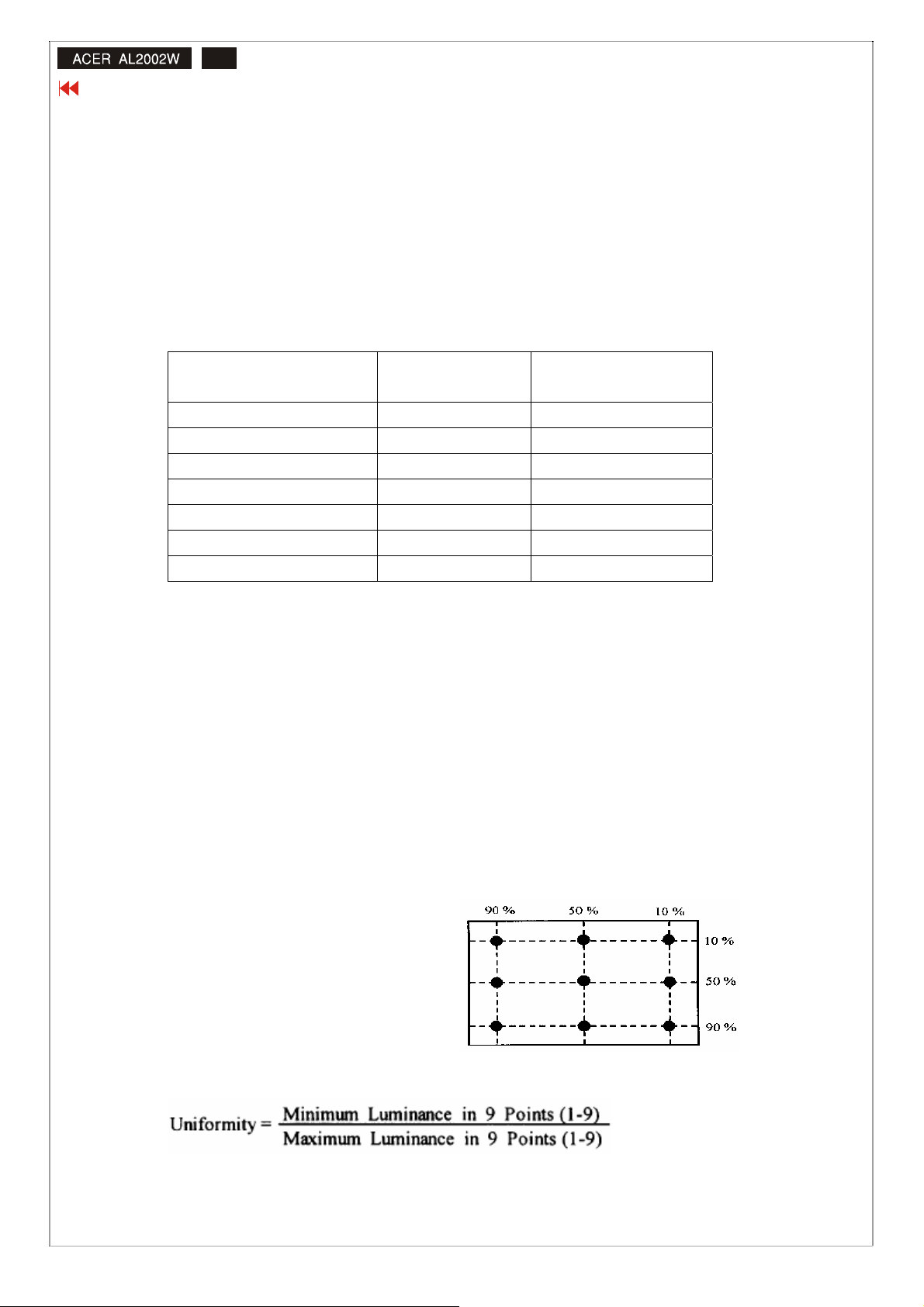

5.1. Brightness uniformity

The uniformity is determined by using a photometer (CA-210) to measure the 9 points luminance in front of monitor

after at least 30 minutes warm up. It shall be test at 1680x1050/60Hz mode and full white square pattern with contrast

and brightness in default value. The values specified are at an approximate distance 20 cm from the LCD surface and

at 0 viewing angle.

5.1.1. The 9 test points are defined as the right

photo.

5.1.2. The brightness uniformity is calculated as below :

Brightness uniformity 75≧ %

15

5.2. Contrast ratio (CR)

The contrast ratio is determined by using a photometer (CA-210) to measure the maximum and minimum luminance in

front of monitor after at least 30 minutes warm up. It shall be test at 1680x1050/60Hz mode and full white/full black

square pattern with contrast/brightness in default value. The values specified are at an approximate distance 20 cm

from the LCD surface and at 0 viewing angle. The contrast ratio is calculated as below:

CR = (Max. full white luminance) / (Max. full black luminance)

CR = 800: 1(typ)

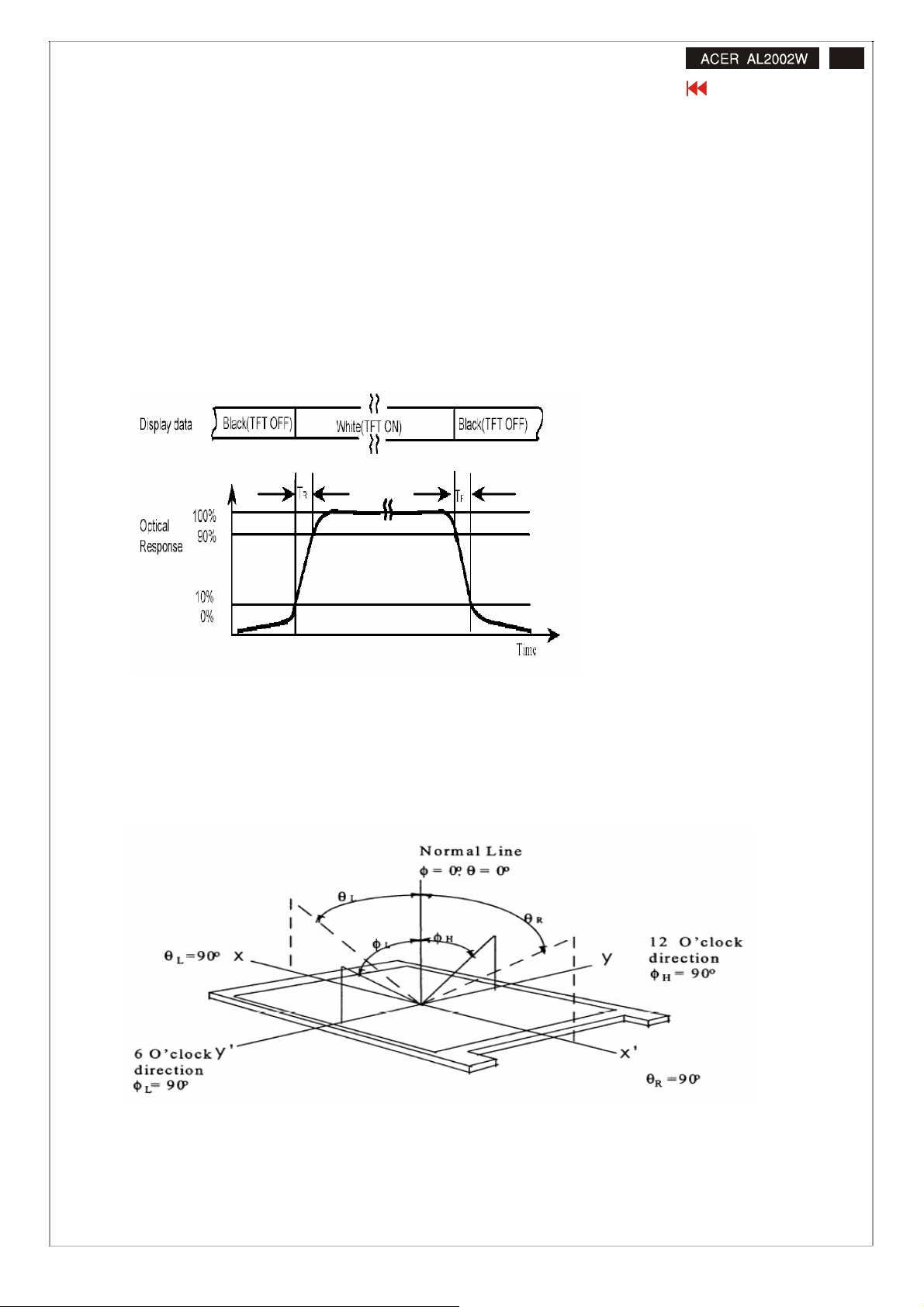

5.3. Response time

The response time is defined as below:

Go to cover page

Tr + Tf: 5 msec typ.

5.4. Viewing angles

The viewing angles are measured at CR=10 as below:

Horizontal Left: 80 degrees typ. (M201EW02 V1);

Right: 80 degrees typ. (M201EW02 V1);

Vertical Up: 80 degrees typ. (M201EW02 V1);

Down: 80 degrees typ. (M201EW02 V1);

16

Go to cover page

5.5. Chromaticity

The color chromaticity is measured by a photometer (CA-210) at 1680x1050/60Hz mode and full white square pattern

with contrast/brightness in default value. The x and y co-ordinates for 9300K, 8200K, 7500K, 6500K and 5000K. Preset

mode shall be as below:

9300K Preset : 0.253 x 0.313 ; 0.268 y 0.328≦≦ ≦≦

7500K Preset : 0.269 x 0.3≦≦ 29 ; 0.285 y 0.3≦≦ 45

6500K Preset : 0.283 x 0.343 ; 0.299 y 0.359≦≦ ≦≦

5000K Preset: 0.314 x 0.≦≦ 375 ; 0.329 y 0.3≦≦ 89

8200K Preset: 0.262 x 0.≦≦ 322 ; 0.277 y 0.3≦≦ 37

5.6. Brightness

The uniformity is determined by using a photometer (CA-210) to measure luminance on the center of screen after at

least 30 minutes warm up. It shall be test at 1680x1050/60Hz mode and full white square pattern with contrast at

default and brightness at max conditions. The values specified are at an approximate distance 20 cm from the LCD

surface and at 0 viewing angle. The brightness at 6500K Preset mode shall be 240 cd/m² min. (M201EW02 V1)

Note: Per panel specification, over the life of the product, variation of parameters specification Panel

specification shall be maintained within reasonable limits. Check supplier quality inspection

criteria for the detail information.

6. Environmental Requirements:

6.1. Temperature Ranges

Operating Temperature (guaranteed functional performance): 0oC to 50oC

Operating Temperature (guaranteed optical performance): 5oC to 35oC

Shipping Temperature: -20oC to 60oC

Storage Temperature: -20oC to 60oC

6.2. Humidity

Operating (non-condensing) : 10% to 80%

Shipping (non-condensing) : 5% to 90%

Storage (non-condensing) : 5% to 90%

6.3. Altitude

Operating 0 to +12,000 feet [3,658m].

Equivalent to 14.7 to 10.1 psia.

Shipping (Non-Operating) 0 to +40,000 feet [12,192m].

Equivalent to 14.7 to 4.4 psia.

17

6.4. Vibration Test Procedure

6.4.1. Vibration System. Perform in accordance with Liteon Spec.

6.4.2. Fixturing. The packaged product shall be secured to the vibration table to prevent the package from moving off

the vibration surface during test.

6.4.3. Test Axes. The packaged product shall undergo random profile vibration on all six (6) surfaces for a duration of

30 minutes per surface.

6.4.4. Random Vibration Spectrum. The total random vibration spectrum energy shall be 1.15 Grms and follow

spectrum specified below.

Random Vibration Spectrum Break Points

Frequency (Hz) PSD , G

1 0.0001

4 0.01

100 0.01

200 0.001

6.4.5. Acceptance Criteria. The package and its contents should be inspected and evaluated for failure against the

2

/Hz

Go to cover page

Acceptance Criteria. Ref. Section 4.0 Packaged Product Testing.

7. RGB settings

The red, green and blue areas shall be measured at a digital input signal full white square pattern at 1680x1050,

fH=65.3kHz/fV=60Hz mode with default color temperature setting (Normal Preset = 6500K). The u´ and v´ co-ordinates for

R, G and B shall be setting as follows:

Red u´ 0.411, v´ 0.503≧≧

Green u´ 0.140, v´ 0.548≦≧

Blue u´ 0.200, v´ 0.224≦≦

8. Color grayscale linearity

The co-ordinates of color grayscale shall be measured at a digital input signal full grayscale square pattern at 640x480,

fH=31.5 kHz/fV=60Hz mode with default color temperature setting (Normal Preset = 6500K). The measured u´ and v´

co-ordinates at grayscale 255,225,195,165,135,105 should meet the spec. as follows :

Δu´v´= ((u´max–u´min)² + (v´max–v´min)²)½ 0.02≦

Loading...

Loading...