Page 1

Document 482394

Model XMSF

Direct Drive Supply Fan

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electrical Code (CEC) in

Canada.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than the maximum

cataloged fan rpm. Adjustments to fan speed

significantly affects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces, or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open blower access doors while the fan is

running.

DANGER

Always disconnect power before working on or near

a unit. Use appropriate lockout tagout procedures to

prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

Direct Drive Supply Fan 1

Page 2

Table of Contents

General

Receiving ..................................3

Handling ...................................3

Unpacking ...............................3

Storage

Indoor ..................................3

Outdoor .................................3

Inspection and Maintenance .................3

Removing from Storage ....................3

Installation

Outdoor Unit Mounting

Standard Curb ............................4

Electrical Wiring

Optional Exhaust Fan Starter ................5

Line Voltage ..............................5

Pre-Start-Up

Checklist

Tool List .................................6

Motor Identification ........................6

Pre-Start-Up Checklist .....................6

Start-Up

Checklist

Start-Up Checklist .........................7

Maintenance

General

Filters ...................................8

Fan Wheels ..............................8

Motors ..................................8

Reference

Vari-Green

Vari-Green Motor Features ..................9

1/2 HP and 1 HP Motors ....................9

2 HP Motors ............................10

Variable Frequency Drives (VFD) ...............11

VFD Features ............................11

Changing the VFD Access Level .............11

Operation ...............................11

Changing VFD Speed Settings ..............11

Maintenance Log .................... Backcover

Our Commitment .....................Backcover

®

Motors

Direct Drive Supply Fan2

Page 3

General

Receiving

This product may have been subject to road salt during

transit. If so, immediately wash off all visible white

reside from all exterior surfaces. Upon receiving the

product, check to ensure all line items are accounted

for by referencing the delivery receipt or packing list.

Inspect each crate or carton for shipping damage before

accepting delivery. Alert the carrier if any damage is

detected,

make notation of damage (or shortage of items) on the

delivery receipt and all copies of the bill of lading should

be countersigned by the delivering carrier. If damaged,

immediately contact your manufacturer’s representative.

Any physical damage to the unit after acceptance is not

the responsibility of the manufacturer.

do not refuse shipment

. The customer shall

Handling

Units are to be rigged and moved by the lifting brackets

provided or by the skid when a forklift is used. Location

of brackets varies by model and size. Handle in such

a manner as to keep from scratching or chipping the

coating. Damaged finish may reduce ability of unit to

resist corrosion.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Units designed for outdoor

applications may be stored outdoors. All accessories

must be stored indoors in a clean, dry atmosphere.

Indoor

Maintain temperatures evenly to prevent condensation.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

avoid condensation, allow cold parts to reach room

temperature. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off

the floor. Clearance should be provided to permit air

circulation and space for inspection.

Outdoor

The fan should be placed on a level surface to prevent

water from leaking into the unit. The unit should be

elevated so that it is above water and snow levels.

Ensure sufficient support to prevent unit from settling

into soft ground. Locate parts far enough apart to

permit air circulation, sunlight, and space for periodic

inspection. To minimize water accumulation, place all

unit parts on blocking supports so that rain water will

run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lint-free

cloths. Polish any remaining rust from surface with

crocus cloth or fine emery paper and oil. Do not destroy

the continuity of the surfaces. Wipe thoroughly clean

with Tectyl

hard to reach internal surfaces or for occasional use,

consider using Tectyl® 511M Rust Preventive, WD-40®

or the equivalent.

®

506 (Ashland Inc.) or the equivalent. For

Removing from Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion, until the equipment goes

into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base, and accessories for

tightness.

2. Rotate the fan wheel(s) by hand and assure no parts

are rubbing.

Direct Drive Supply Fan 3

Page 4

Installation

Sealant

Ductwork

Lifting Area

(4 places)

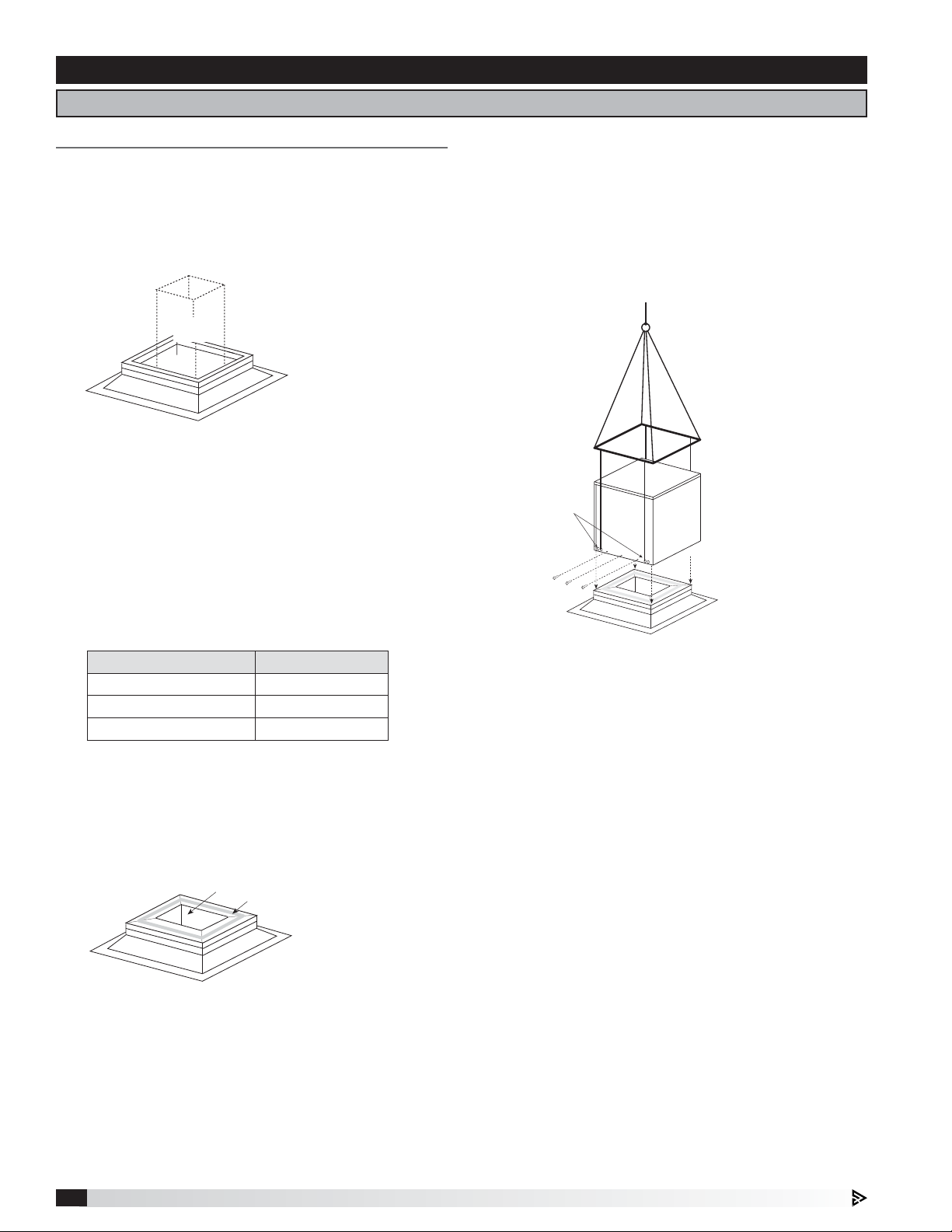

Outdoor Unit Mounting

Standard Curb

1. Install Curb

Position curb on the roof (reference the CAPS submittal

for placement in relation to the unit). Verify that unit is

level, shim if necessary. Attach curb to roof and flash

into place using appropriate methods.

Supply

Ductwork

by Others

2. Install Ductwork

Good duct practices should be followed for all

ductwork. All ductwork should be installed in

accordance with SMACNA and AMCA guidelines,

NFPA96 and all local codes. Reference the CAPS

submittal for ductwork sizes.

The use of a duct adapter is recommended on a

downblast (DB) arrangement to align the ductwork with

the supply unit. The duct adapter is only a guide and is

not to be used as a support for the ductwork.

4. Install Unit

Use a crane and a set of spreader bars hooked to the

factory lifting lugs to lift and center the unit on the curb.

The use of all lifting lugs and a set of spreader bars is

mandatory when lifting the unit.

Fasten the unit to the curb using appropriate methods.

The installer is responsible for determining appropriate

support and fastening methods to ensure compliance

with all applicable codes.

Model Duct Size

XMSF-P113-H10 13x13

XMSF-P115-H20 15x15

XMSF-P117-H30 17x17

3. Apply Sealant

Apply an appropriate sealant around the perimeter of

the curb and duct adapter(s) to isolate fan vibration and

prevent water penetration.

Direct Drive Supply Fan4

Page 5

Installation

Electrical Wiring

Before connecting power to the unit, read and

understand the following instructions and wiring

diagrams. Complete wiring diagrams are attached on

the inside of the control center door(s).

All wiring should be done in accordance with the latest

edition of the National Electric Code ANSI/NFPA70

and any local codes that may apply. In Canada, wiring

should be done in accordance with the Canadian

Electrical Code.

The equipment must be properly grounded. Any

wiring running through the unit in the airstream must

be protected by metal conduit, metal clad cable or

raceways.

If replacement wire is required, it must have a

temperature rating of at least 105ºC.

High voltage electrical input is needed for this

equipment. This work should be performed by a

qualified electrician.

Any wiring deviations may result in personal injury or

property damage. Manufacturer is not responsible for

any damage to, or failure of the unit caused by incorrect

final wiring.

Manufacturer’s standard control voltage is 24VAC.

Control wire resistance should not exceed 0.75ohms

(approximately 285 feet total length for 14gauge wire;

455 feet total length for 12gauge wire). If the resistance

exceeds 0.75 ohms, an industrial-style plug-in relay

should be wired in place of the remote switch. The relay

must be rated for at least 5 amps and have a 24VAC

coil. Failure to comply with these guidelines may cause

motor starters to chatter or not pull in, resulting in

contactor failures and/or motor failures.

Optional Exhaust Fan Starter

1. Verify Exhaust Fan Compatibility

Compare the voltage, frequency, and phase on the unit

label with the exhaust fan label. Additionally, compare

the exhaust HP on the unit label with the exhaust fan

label. The unit has been sized to provide power for the

exhaust fan and all values must match.

2. Determine the Size of the Exhaust Fan Power

Lines

Size the exhaust fan power lines appropriately per the

exhaust fan voltage, and amps.

3. Connect power to the Exhaust Fan

Connect the power lines to the exhaust fan disconnect

switch. The electrical supply line must conform to local

and national electrical codes. Electrical wires must be

located so as not to rub on moving components.

Line Voltage

1. Determine the Size of the Main Power Lines

The unit’s nameplate states the voltage and the unit’s

MCA. The main power lines to the unit should be sized

accordingly.

CONFORMS TO UL STD 705

58310

VOLTS

MCA

SUPPLY MOTOR

SUPPLY MOTOR LOCKED ROTOR CODE

EXHAUST MOTOR#1

EXHAUST MOTOR#2

SUITABLE FOR OUTDOOR USE

FOR GENERAL VENTILATION USE ONLY

DO NOT USE TO EXHAUST DIRT, DUST, GREASE

2. Install Solid State Speed Controller

If the unit was supplied with a ship loose solid state

speed controller, it must be installed to control the fan

RPM.

NOTE: Units with VG or VFD in the model name or units

with a control center do not require a field installed solid

state speed controller.

3. Connect the Main Power

Connect the main power lines to the disconnect switch.

The electrical supply must be compatible with the fan

motor with regards to voltage, phase, and amperage

capacity. Moreover, the electrical supply line must

be properly fused and conform to local and national

electrical codes. Electrical wires must be located so as

not to rub on moving components.

NOTE: If fan motor is not thermally protected, remote

overload protection must be installed having the

adequate rating as to voltage, frequency horsepower,

and full load current per phase.

POWER VENTILATORS

PHASE

HP

HP

HP

OR LINT-LADEN AIR

HZ

MOP

AMPS

AMPS

AMPS

695066

Direct Drive Supply Fan 5

Page 6

Pre-Start-Up

Checklist

Tool List

• Voltage Meter (with wire probes)

• Amperage Meter

• Tachometer

WARNING

Disconnect and lock-out all power and gas before

performing any maintenance or service to the unit.

Failure to due so could result in serious injury or death

and damage to equipment.

WARNING

Check the housing, blower, and ductwork for any

foreign objects before running the blower.

Motor Identification

Check the metal nameplate located near the disconnect

for the model number.

Suffix of the model number will identify the motor type

that is referenced in the Start-Up, Checklist, Start-Up

Checklist sections:

• XMSF-P1##-H## (no suffix) - refer to PSC motor

with solid state speed control

• XMSF-P1##-H##-VG - refer to Vari-Green® motor

• XMSF-P1##-H##-VFD - refers to Variable

Frequency Drive (VFD) controlled motor

Pre-Start-Up Checklist

1. Check Fasteners for Tightness

Check fasteners, set screws and locking collars on the

fan, motor base and accessories for tightness.

2. Check the Voltage

Before starting the unit, compare the supplied voltage,

hertz and phase with the unit and motor nameplate

information.

3. Check Wheel Overlap

Wheel position is preset and the unit is tested at the

factory. Movement may occur during shipment and

realignment may be necessary. Wheel and inlet cone

overlap can be adjusted by loosening the setscrews in

the wheel and moving the wheel to the desired position.

Model Overlap

XMSF-P113-H10

1/4 in.XMSF-P115-H20

XMSF-P117-H30

Overlap

A

Radial

Gap

Wheel

Inlet

Cone

4. Wheel Rotation

Rotate the wheel by hand

and make sure the wheel

does not rub on any parts.

Verify wheel rotation by

momentarily energizing the

unit. Rotation should be

clockwise as shown below

and correspond to the

rotation decal on the unit.

Motor Type _______________

Check fastener tightness

Check Supply Voltage L1 - L2 _________ Amps

L2 - L3 _________ Amps

L1 - L3 _________ Amps

Check Wheel Overlap

Wheel Rotation

Direct Drive Supply Fan6

e

s

i

w

k

c

o

l

C

Page 7

Start-Up

Checklist

Start-Up Checklist

1. Set Fan and Motor RPM

Motors with either solid state speed control or

Vari-Green motor must be field balanced to the

design fan RPM.

PSC Motor with Solid State Speed Control

(XMSF-P1XX-HXX)

To adjust the speed of a motor with solid state speed

control, adjust the speed controller dial until the fan is

at its design fan RPM. The speed controller is shipped

loose on units without a control center and is factory

mounted and wired on units with a control center.

Vari-Green Motor (XMSF-P1XX-HXX-VG)

To adjust the speed of a Vari-Green motor, adjust the

built-in potentiometer on the motor. To increase the

speed, rotate the dial clockwise. To decrease the speed,

rotate the dial counterclockwise.

VFD Controlled Motor (XMSF-P1XX-HXX-VFD)

The VFD will be factory programed for the design

fan RPM. If VFD adjustments are required please see

the Variable Frequency Drive section for additional

information.

2. Check for Vibration

Check for unusual noise, or vibration. Excessive

vibration may be experienced during initial start-up.

Left unchecked, it can cause a multitude of problems,

including structural and/or component failure.

Generally, fan vibration and noise is transmitted to other

parts of the building by the ductwork. To minimize this

undesirable effect, the use of heavy canvas connectors

is recommended.

3. Motor Check

Measure the motor’s voltage, and amps. Compare to

the specifications. Motor amps can be reduced by

lowering the fan and motor RPM

4. Air Volume Measurement and Check

Measure the unit’s air volume (cfm) and compare it

with its rated air volume. If air volume does not match

the rated air volume, adjust the fan and motor RPM as

necessary. The most accurate method for measuring

the air volume is a pitot traverse method downstream of

the blower. Other methods can be used, but should be

proven and accurate.

Unit Model Number ________________________________

Unit Serial Number _________________________________

(e.g. 10111000)

Start-Up Date _____________________________________

Start-Up Personnel Name __________________________

Start-Up Company _________________________________

Phone Number ____________________________________

(e.g. XMSF-P113-H10)

Start-Up Blower Checklist

Check line voltage L1-L2 _______________

L2-L3 _______________

L1-L3 _______________

Check blower rotation

Check for vibration

Supply fan RPM _____________ RPM

Motor nameplate amps _____________ Amps

Actual motor L1 _____________ Amps

L2 _____________ Amps

L3 _____________ Amps

Actual CFM delivered _____________ CFM

Direct Drive Supply Fan 7

Page 8

Maintenance

General

Filters

Filter maintenance is generally limited to cleaning and

replacement.

If aluminum mesh filters are installed, they can be

washed in warm soapy water.

An adhesive spray can be added to aluminum mesh

filters to increase their efficiency.

If disposable filters are installed, they can be checked

by holding up to a light source. If light cannot pass

through the filter, it should be replaced.

When reinstalling filters, be sure to install them with the

airflow in the correct direction. An airflow direction arrow

is located on the side of the filters.

Replacement filters should be from the same

manufacturer and the same size as the original filters

provided with the unit.

Model Filter Size Filter Qty

XMSF-H10 19x19x1 2

XMSF-H20 21x21x1 2

XMSF-H30 24x24x1 2

Motors

Motor maintenance is generally limited to cleaning and

lubrication (where applicable).

Cleaning should be limited to exterior surfaces only.

Removing dust and grease build-up on the motor

assures proper motor cooling.

Motors supplied with grease fittings should be

greased in accordance with the manufacturer’s

recommendations.

Do not allow water or solvents to enter the motor or

bearings. Motors and bearings should never be sprayed

with steam, water or solvents.

Greasing motors is only intended when fittings are

provided. Many motors are permanently lubricated,

requiring no additional lubrication.

Fan Wheels

Wheels require little attention when moving clean air.

Occasionally oil and dust may accumulate on the wheel

causing imbalance. When this occurs, the wheel and

housing should be cleaned to assure proper operation.

Direct Drive Supply Fan8

Page 9

Reference

Vari-Green® Motors

Vari-Green® Motor Features

The Vari-Green motor is an electronically commutated

(EC) motor that uses AC input power and internally

converts it to a DC power supply which provides built-in

control of motor speed down to 20% of design RPM.

Soft Start

All motors feature soft start technology which eliminates

inrush current at start-up. The motors will reliably start

at any speed setting

Overload Protection

If the motor becomes overloaded, it will automatically

reduce its speed until it is no longer overloaded. This

means that the motor will never operate in the “service

factor” which is possible with many AC motors. The

motor and control are electrically protected with

lightning surge protection.

1/2 HP and 1 HP Motors

These motors have both a potentiometer dial on the

motor for speed adjustment and the ability to accept a

0-10 VDC signal for remote speed control.

Electrical Wiring

The motor is

prewired at

the factory

and cannot be

changed inside

the motor.

Connect singlephase power

at the voltage

listed on the

nameplate. If

remote control

is desired,

connect the

0-10 VDC and

24V signal for

remote speed control.

Operation

There is a 4 second delay between the application of

power and the motor starting. Motor speed is controlled

as follows:

0-10V (RED)

24V (BLACK)

COM (WHITE)

UNIT DISCONNECT

115/208/230/277 VAC INPUT

TO MATCH MOTOR NAMEPLATE

Dial on Motor

A small screwdriver can

be used to make speed

adjustments. To increase speed,

rotate the dial clockwise. To

decrease speed, rotate the dial

counterclockwise. There is no

need to connect the control

wires.

Speed

Adjustment Dial

0-10 VDC Signal

The dial on the motor will act as a maximum speed

limiter. During start-up this should be adjusted for rated

air volume.

24 VAC/DC power is required to control the motor

with a 0-10 VDC signal. Without the 24 VAC/DC power

the motor will be controlled by the dial on the motor.

The motor will consume 0.7VA at 24 VAC or 25mA at

24VDC.

From 0-1.9V the motor will be off. From 2-10V the motor

will operate.

A low voltage wiring harness is needed to supply the

0-10V signal to the motor. This harness is available from

the factory if conversion is necessary.

Direct Drive Supply Fan 9

Page 10

Reference

Vari-Green® Motors

2 HP Motors

These motors have both a potentiometer dial on the

motor for speed adjustment and the ability to accept a

0-10 VDC signal for remote speed control.

Electrical Wiring

All high and low voltage wiring connections are made

inside the motor control box at the factory. Normally,

there is no reason to enter the control box of the motor.

If there is a need to enter the control box, disconnect

power and wait at least five minutes to allow the

capacitors to discharge.

The motor is prewired at the factory and cannot be

changed inside the motor. Connect single-phase power

at the voltage listed on the nameplate. If remote control

is desired connect the 0-10 VDC signal for remote

speed control. Inside the control motor control box

wiring will be dependent on the selected operation:

Dial on Motor - the dial

is factory-wired into the

low voltage terminal block

inside the control box.

The wires are connected

as shown.

Dial on motor connection inside control box

If the motor needs to be tested before the 0-10 VDC

signal is available, a jumper can be placed between

terminals 1 and 2. This will force the motor to run at full

speed.

Operation

There will be up to a 30 second delay between the

application of power and the motor starting. The motor

will “rock” back and forth upon startup as part of its

normal operation.

Dial on Motor

Turn the dial with your fingers to adjust. To increase the

speed, rotate the dial clockwise. To decrease the speed,

rotate the dial counterclockwise. Turning the dial fully

counterclockwise will turn the motor off.

0-10 VDC signal

From 0-1.9 V the motor will be off. From 2-10V

the motor will operate. 10V will correspond to the

nameplate motor RPM, regardless of the position of the

dial on the motor.

0-10 VDC Signal - a two-wire

pigtail is factory-wired into the

low voltage terminal block.

The wires are connected

as shown.

0-10 VDC signal connection inside control box

Direct Drive Supply Fan10

Page 11

Reference

Variable Frequency Drives (VFD)

VFD Features

The factory installed wired and programmed VFD is

used to control the speed of the fan as either a constant

speed, multi-speed or modulating speed control. A

Yaskawa model J1000 VFD will be located in the unit

control center. This section contains basic information

on operation and changing VFD speed settings. For

more detailed information including fault codes see the

Yaskawa VFD manual. For additional information on

wiring please refer to the unit specific wiring diagram

located inside the unit control center.

MA MB MCACAMAC+VA1SCS5S4S3S2S1

J1000

Changing the VFD Access Level

With factory default settings, the VFD will be configured

to restrict access to the majority of the VFD parameters.

To view or change any of these parameters, change the

access level (A1-01) to 2. This will allow access to the all

VFD parameters.

Operation

VFDs will be configured from the factory to operate in

one of three modes:

Constant Speed

The VFD will control the motor to operate at constant

speed. The VFD will run at Frequency Reference 1 (D1-

01). The factory default setting is unit specific for design

fan RPM.

Changing VFD Speed Settings

Before making any changes, ensure the drive is stopped

and the access level (A1-01) is set to 2.

Maximum and Minimum Frequency Limits

Maximum frequency will be indicated by a label on the

unit.

Minimum recommended frequency is 18 Hz.

SUPPLY FAN

MAX FREQUENCY

Constant Speed and Multi-Speed

Maximum speed – Change frequency reference 1 (D1-

01) to the desired frequency. If the desired frequency

is greater than 60Hz, adjust the max output frequency

(E1-04) to the desired frequency first.

Minimum speed (multi-speed only) – Change frequency

reference 3 (D1-03) to the desired frequency.

Modulating

Maximum Speed (Desired frequency ≥ 60Hz) – Change

the upper reference (D2-01) and the terminal A1 gain

(H3-03) to 100%. Adjust the max output frequency (E1-

04) to the desired frequency.

Maximum Speed (Desired frequency <60Hz) - Change

the upper reference (D2-01) and the terminal A1 gain

(H3-03) to desired % of 60 Hz (i.e. for 48 Hz set to

80%).

Minimum Speed – Change the lower reference (D2-02)

and the terminal A1 bias (H3-04) to the desired % of 60

Hz (i.e. for 24 Hz set to 40%)

XX

PRD ORDER

Hz

695064

Multi-Speed

Digital contact closures (by others) command the VFD

to run at multiple speed settings:

• Open – VFD runs at frequency reference 1 (D1-01).

Factory default is unit specific for design fan RPM.

• SC to S5 – VFD runs at frequency reference 3 (D1-03).

Factory default is unit specific for one-half design fan

RPM.

Modulating

A 0-10 VDC signal wired in the field by others varies the

speed of the fan. 10V results in design fan RPM and

0V results in one-half design fan RPM, per the factory

default settings.

Direct Drive Supply Fan 11

Page 12

Reference

Maintenance Log

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Our Commitment

Our Commitment

As a result of our commitment to continuous improvement, Accurex reserves the right to change specifications

without notice.

Product warranties can be found online at accurex.com, either on the specific product page or in the Warranty

section of the website at Accurex.com/Resources/Warranty.

P.O. Box 410 Schofield, WI 54476

Phone: 800.333.1400 • Fax: 715.241.6191

Parts: 800.355.5354 • accurex.com

12

482394 • XMSF Direct Drive Supply Fan , Rev. 1, March 2017 © 2017 Accurex, LLC12

Loading...

Loading...