Page 1

Document 470404

Model XM

Utility Distribution System

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

UL Listed to UL 891

General Safety Information

Only qualified personnel should install and service this system. Personnel should have a clear understanding of these

instructions and all applicable local and national building and fire codes.

DANGER

Always disconnect lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

DANGER

Pour écarter les risques d’incendie, de choc électrique

ou de blessure grave, veiller à toujours débrancher,

verrouiller et étiqueter la source de courant avant

l’installation ou l’entretien.

NOTE

Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), and the

latest edition of the National Fire Protection Agency

Standard for Ventilation Control and Fire Protection

of Commercial Cooking Operations (NFPA 96). Follow

the Canadian Electrical Code and ULC-S650 if

installing this product in Canada.

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury

or death. Read the installation, operating, and

maintenance instructions thoroughly before installing

or servicing this equipment.

Les poses, réglages, modifications, entretiens et

réparations incorrects peuvent provoquer des dégâts

matériels, des blessures ou la mort. Bien lire les

instructions de pose, d’utilisation et d’entretien avant

l’installation ou l’entretien de ce matériel.

WARNING

AVERTISSEMENT

Utility Distribution System 1

Page 2

Table of Contents

Receiving, Handling and Storage ............... 2

Product Overview ............................ 3

Unit Configuration ........................... 4

Option and Accessory Descriptions ............. 5

Installation

Uncrating ................................. 6

Mounting and Securing. . . . . . . . . . . . . . . . . . . . . . 6

Plumbing ................................. 7

Electrical ................................7-8

Main Incoming Service ...................... 8

Control Power ............................. 8

Fire System Integration ...................... 8

Hose Installation Instructions ................. 9

Start-Up

Testing ................................... 9

Fire Fuel Shut-Off, optional ................... 10

Overcurrent Protection, optional ............... 10

Operation ................................. 11

Troubleshooting ............................ 11

Our Commitment ........................... 12

Receiving

Upon receiving the equipment, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file a

claim with the final carrier. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts. Confirmation of shipment(s)

must be limited to only items on the bill of lading. Any

physical damage to the unit or missing parts found after

acceptance is not the responsibility of the manufacturer.

Handling

Move the unit slowly and carefully using the forklift

pockets on either end. Be sure to completely support

the entire unit length when moving. Do not lay the

crated unit on its side.

Storage

Units are protected against damaged during shipment.

If the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage.

The ideal environment for storage of the UDS and

accessories is indoors, above grade in a clean, dry

atmosphere that is sealed from the elements. Store unit

standing up; do not lay the unit on its side.

Utility Distribution System2

Page 3

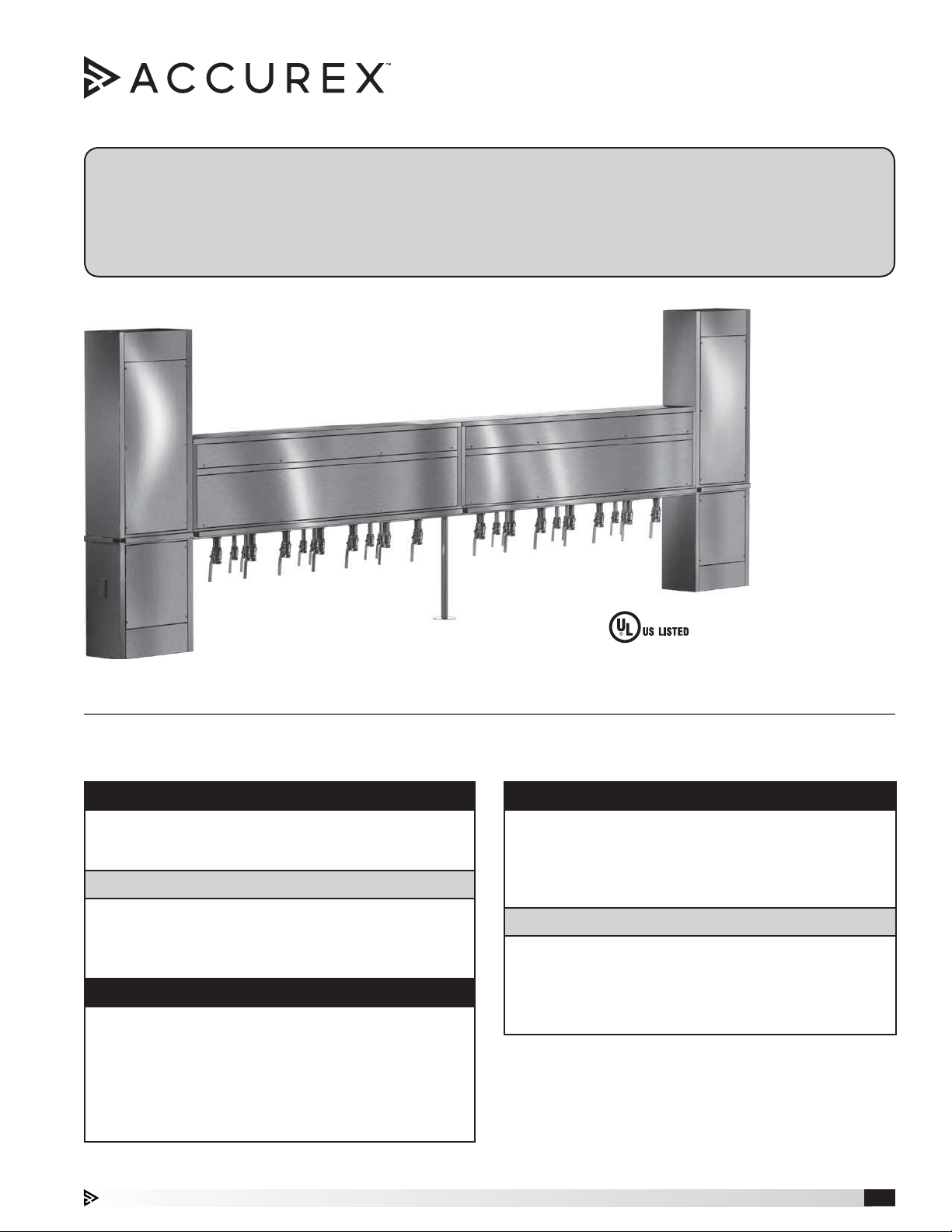

Product Overview

2

Panel Board

Breaker System

4

5

Electrical Option

1

3

6

7

4

NOTE

Utility Distribution System, or UDS, are a highly configurable and customizable product. Some instances in this

manual may make references to features which may or may not be present on your equipment. Please consult

your submittal and electrical drawings which are also provided to determine which portions of this manual apply.

1. Utility Chase – Horizontal component that is

connected between the two (2) vertical risers. This

brings the utilities to the cooking equipment in a

clean convenient way.

2. Utility Riser – Vertical components that house major

utilities, control center, fire fuel shut-off, and field

connections.

3. Pedestal (optional) – Supporting component for the

chase under the field joint(s) at the chase when the

UDS has reached a predetermined length.

4. Access Panels – Doors on the UDS that allow

access for installation or maintenance.

5. Electrical Section of Chase – All electrical (typically

wire bus or bus bar) is fed through this portion of the

utility chase. This portion is intentionally closed off

to the plumbing section of the utility chase. Electrical

sections are accessible through removable panels.

6. Plumbing Section of Chase – All plumbing (typically

includes gas, hot water, and cold water) is fed

through this portion of the utility chase. This portion

is intentionally closed off to the electrical section of

the utility chase. Plumbing sections are accessible

through removable panels.

7. Bumper Strip - Bump out strips mounted about

waist-high on the UDS to prevent cooking equipment

that is not fastened to the floor from hitting and

damaging the UDS.

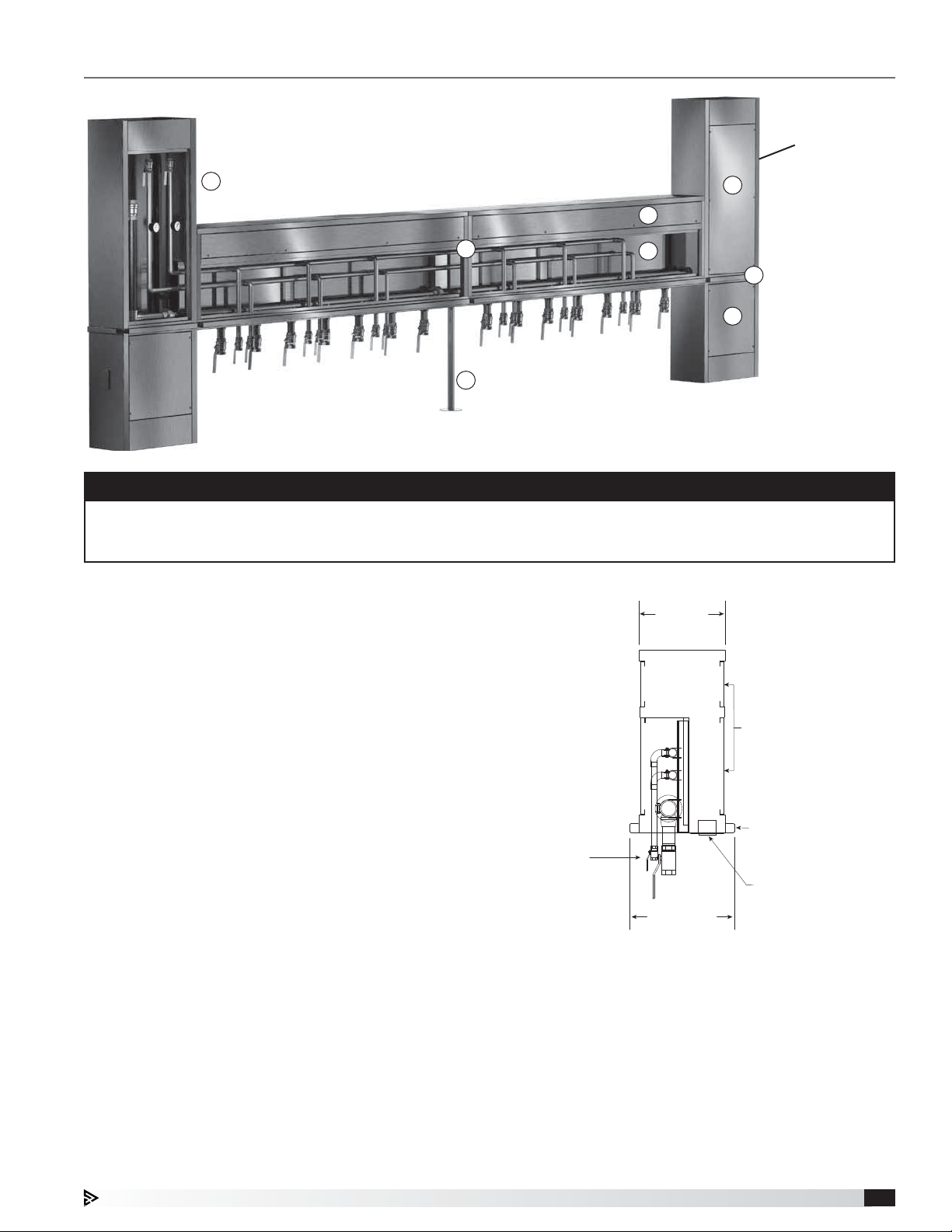

Gas and Water

Plumbing Drops with

Equipment Shutoff

Per Customer Request

Typical Section View Through

Typically

12 inches

16 Gauge Stainless Steel

Removable Panels

(Both Sides on Island UDS)

Full-Length

Bumper Guards

(Both Sides on Island UDS)

Receptable Plates

Typically

14.6 inches

Utility Distribution System 3

Page 4

Unit Configuration

Utility Distribution System

XM W V - GHC - 132

UDS Style

C - Chase

I - Island

O - Overhead

P - Electric Pole

U - Utility Column

W - Wall

Electrical Services

B - Buss Bar

H - Point of Use with Receptacles

N - None

R - Receptacle(s) Only

V - Panelboard with Receptacles

1. Manufacturer

a. Model XM, Modular FlexConnect™ Utility

Distribution System Series

2. Style

a. (W) Wall – Mounted up against a wall with

appliances on one side only; no bumper or

electrical outlets on opposite side of utility chase (if

provided with electrical service).

b. (I) Island – Appliances on both sides; bumper and

electrical outlets on both sides of utility chase (if

provided with electrical service).

3. Electrical

a. (V) Panelboard – Electrical service panelboard

in either the right or left most riser. Typically,

this includes a shunt trip or under-voltage main

breaker and individual branch breaker(s) for

each equipment receptacle. Breakers, wiring,

and receptacles are all provided by the factory.

20A convenience outlets are provided on both

left and right riser ends. Equipment receptacles

are fastened in the specified location under the

horizontal chase.

b. (H) Point-of-Use – Incoming electrical service riser

is located on the left or right most riser. Typically,

this includes a shunt trip or under-voltage main

breaker in the riser. Individual branch breakers

for each piece of equipment are located in the

horizontal chase directly inline with the equipment

receptacle. 20A convenience outlets are provided

on both left and right riser ends.

c. (R) Receptacles Only – Unit shall include

equipment receptacles fastened in the specified

location under the horizontal chase. 20A

convenience outlets are provided on both left

and right riser ends. All wiring and/or conduit is

provided by others in the field.

Unit Length

Overall unit length in inches

Piped Services

1 to 4 characters depending upon plumbing services

A - Compressed Air

C - Cold Water

D - Drain and Vent

F - Filtered Water

G - Gas

H - Hot Water

L - Chilled Water

S - Steam/Condensate Return

4. Gas

a. (G) Gas Manifold – Either a single service through

one riser, or a looped service through both risers

is provided. Gas line is fed through the plumbing

section of the utility chase by the factory, with

gas drops every 12 inches. Typically, these are

provided with quarter turn ball valve disconnects if

used for specific appliances.

5. Water

a. (H) Hot Water – Either 3/4 or 1 inch hot water

manifold is fed through the plumbing section of

the utility chase by the factory with drops every

24inches. Typically, these are provided with

quarter turn ball valve disconnects if used for

specific appliances.

b. (C) Cold Water – Either 3/4 or 1 inch cold water

manifold is fed through the plumbing section of

the utility chase by the factory with drops every

24inches. Typically, these are provided with

quarter turn ball valve disconnects if used for

specific appliances.

6. Length

a. Length – Total length of the UDS, including risers

and utility chase by the factory.

Utility Distribution System4

Page 5

Option and Accessory Descriptions

Chilled Water Line – Additional plumbing manifold to

provide chilled water. This manifold will be insulated.

Compressed Air Line – Additional plumbing manifold

to provide compressed air.

E-Stop Emergency Shut Off – Button provided to shut

off electricity (and gas, depending on gas valve type) to

the cooking equipment.

Equipment Cord Set – Combination cord and plug

assembly that can be provided to wire into an appliance

and be plugged into the UDS.

Equipment Hoses – Flexible hoses with steel mesh

covers and quick disconnects for cooking equipment.

Fill Faucet – UDS mounted pot filler, typically used to fill

commercial kettles with water.

Filler Panel between Risers – Stainless steel paneling

to close off the area above and below the horizontal

chase.

Filtered Cold Water – Option that includes water

filter(s) within the UDS to filter contaminants out of the

cold water supply. This may be required for certain

appliances like combination ovens and steamers.

Gas Reset – Manual reset button and indicator light.

Gasketed Construction – Gasketing provided to cover

all stainless steel edges within the UDS.

Ground Fault Protection – Receptacles and breakers

with added electrical components to protect people

from line to ground electrocution.

Hose Reel – A retractable hose reel to keep a pre-rinse

spray valve assembly in a tight, contained space on the

UDS.

Looped Gas – Configuration where gas manifold is fed

from one riser, through the chase, and out the other

riser. This provides more balanced gas supply, and is

sometimes necessary with systems that need to deliver

a large amount gas for the cooking line up.

Main Breaker with Shunt Trip – Main breaker designed

to trip during a fire or if the emergency stop button is

pressed. This is standard with UDS configured with

either point-of-use or panel board electrical service.

Main Breaker with Undervoltage Trip – Available

upon special design request, this breaker is designed

to trip upon a loss or dip in control voltage. This may be

required per a local code or jurisdiction.

Make-Up Air through UDS – UDS designed with

supply collars and perforation below the horizontal

chase to provide dedicated make-up air for the kitchen

hoods around the UDS.

Peak Top on Chase – Option to include a peaked

chase top to help prevent grease from building up on

the top of the chase.

Pin and Sleeve Receptacles and Plugs – Special

type of twist-to-lock receptacle and plug that provides

a durable, fused interlock in wet and corrosive

environments.

Prison Package – For kitchens within a prison, it

is important that the system is built without any

components that could be removed and used as a

weapon. For the UDS, this typically incorporates tamper

proof fasteners, gasketed construction, and while-inuse receptacle covers.

Restraining Cables – Cable that attaches from the UDS

to the movable appliance. This helps prevent appliances

with gas and other plumbing connections from being

pulled too far away and damaging the hoses. Length of

the restraining cables need to be shorter than the length

of the plumbing hoses.

Riser Extensions – Riser extensions paneling that

extends from the top of the riser to the top of the hood

or hood enclosure panels.

Riser Extension from top

of riser to top of hood or

enclosure panels

Slim Line Unit – UDS that is 8 inches wide or narrower,

instead of the standard 12 inch width.

Status Lights – Status lights provided by each branch

circuit breaker to indicate power.

Steam/Condensate Return – Additional plumbing

manifold to provide steam/condensate return for

steamers and other types of cooking equipment.

Super Swivel – Equipment hoses designed with

a swivel adapter to prevent damage to the hose if

equipment is moved frequently.

Twist Lock Receptacles – Receptacles designed to

slip together then twist to lock into place. This keeps

the plug and receptacle from pulling apart; also waterresistant.

UDS Mounted Hood Controls – Hood and fan controls,

from fan switches to systems including motor starters or

variable frequency drives can be built into the UDS.

Uninterruptable Power Supply (UPS) – Power supply

for the control circuit within a UDS that is able to “ride

through” any temporary building power outages.

NOTE

Other options are available. For more information,

contact your local manufacturer’s representative.

Utility Distribution System 5

Page 6

Installation

Uncrating

Use caution when uncrating the UDS. Depending on

the configuration, switches and indicator lights may be

provided and protrude from the unit, use caution when

moving the unit or moving equipment around the unit.

Mounting and Securing

1. Refer to drawings and equipment layout to

determine the orientation of the UDS. Unit

orientation is important as the unit is typically

configured with drop locations specific to an initial

set and order of appliances.

2. Gently lift the unit off of the pallet and position into

place. If the UDS is broken into multiple sections, lift

each section into place.

3. Remove all access panels on raceway, riser and

pedestal to reveal internal plumbing, electrical, and

internal flanges.

4. Once sections are in position, join field joints (if

any) between sections by bolting internal flanges

together and applying NSF approved silicone caulk

(GE SCS-1009, or equivalent) over seams. Caulk is

not provided.

Chase Sections

bolt together with

(9) 5/16 inch bolt and nuts

(typically 3 top, 3 back and 3 front)

8. If a kitchen hood or hoods is/are intended to be

mounted on either side of the UDS, hang and level

the hood(s) at this time. Make sure the hood is

mounted at the specific height shown in the drawing

provided.

9. Adjust riser collar(s) if supplied and as necessary

by loosening nuts on weld studs inside riser collars,

adjusting as necessary, and re-tightening nuts.

Loosen (2) 1/4-20 nuts inside of

risers (on opposite corners) to

adjust collars. Tighten nuts when

collar is in appropriate position.

Collar slides up

and down when

fasteners are

loosened.

10. If applicable, make connections between the hood

and hood controls to the utility distribution system.

Once the fire system has been installed, tested, and

armed, wire the fire system into the UDS as well.

11. Once all electrical connections have been

completed on the hood, and all electrical and

plumbing services have been connected to the

UDS, install all filler panels and enclosure panels (if

provided) between the hoods and above the hood

and UDS.

Bottom

Filler Panel

End Filler Panel

(Each End)

5. If applicable, drill holes through unit as shown

on the drawing and secure properly to wall. This

typically is required for systems that are not

provided with risers.

6. If applicable, fasten risers to the floor.

Fasten UDS to floor

using pre-drilled holes

Bottom

of Riser

FASTENERS PROVIDED BY OTHERS

on bottom flanges.

7. Complete all plumbing and electrical installation

procedures. Reference drawing, and see pages 7

and 8.

Utility Distribution System6

Page 7

Plumbing

1. If system has field joint(s), plumbing must be

connected at the joint(s) before attaching main

service. Connect corresponding pipes by aligning

unions and tightening securely.

NOTE

Do not force the threaded connections or pull sections

together by tightening the plumbing fittings.

Field Jointed Chase

Threaded unions at field joint.

Staggered for accessibility.

2. Connect all plumbing stub-ins to the main lines.

Provide all necessary nipples, couplers, unions, etc.

to make neat and proper connections.

3. Connect all hose assemblies (if provided) to the

appropriate equipment as shown on the drawing.

Provide all necessary L’s and nipples to make neat

and proper appearance. (Please see hose installation

instructions on page 9).

4. During testing, check all plumbing for leaks and

tighten as required.

5. Replace all access panels.

NOTE

This equipment is to be installed with adequate

backflow protection to comply with federal, state or

local codes having jurisdiction.

Electrical

1. If system has field joint(s), wiring must be

interconnected at the joint(s) before attaching main

service.

a. If provided with bus bar, connect the

corresponding bus bars together with the brass

bolts and nuts provided.

b. If provided with wire bus, connect number-

matched wires from one section to the other

using the corresponding terminal blocks

provided.

Field Jointed Chase

Connections beyond field joint

are number-matched, then

folded back for shipment.

2. Connect the electrical service(s) to the system as

follows:

a. Attach main service wires to the corresponding

terminals on the main breaker and neutral bar.

b. Connect all control wiring as shown in the

electrical drawing provided with the unit.

Additional information is shown on page 8.

c. Check and tighten connections if necessary.

d. Connect all cord assemblies to the appropriate

equipment as shown on submittal drawing. Cut

cord assemblies if necessary to make a neat

appearance.

e. Test the electrical systems for proper operation.

f. Replace all access panels.

Utility Distribution System 7

Page 8

Electrical, continued

NOTE

All field wiring of electrical equipment must be done to

meet all NEC and local electrical codes.

The extent of field wiring required will depend on the

configuration of the UDS. A few options are broken

out in the next portion of this manual. Reference the

UDS electrical drawings provided with the unit for more

specific wiring details.

Main Incoming Service

UDS appliance power is typically provided from

120/208/3 and/or 460/3 60Hz power from the building

directly to the main breaker(s) within the electrical riser

from above. Service size should be shown on the UDS

drawing.

• 120/208V/3PH to main breaker, neutral lug, and

grounding bar

• 460V/3PH to main breaker and grounding bar

Control Power

The UDS needs a power source to operate all control

components. This source must come from a separate,

non-shunted breaker from the building; the power must

remain constant, even during the event of a fire.

• 120VAC, 10 amp circuit to terminals H and N

120V/1PH/60HZ

from 10A REMOTE BREAKER

L1

N

NH

from REMOTE BREAKER

*

GROUND BAR

from REMOTE BREAKER

120/208V/3PH/60HZ

L2

L1

H

HH

CBM1

208V

SERVICE A

MAIN BREAKER

460V/3PH/60HZ

L2

L1

H

HH

L3

L3

N

NEUTRAL LUG

Fire System Integration

A dedicated fire system microswitch or dry SPDT set

of fire contacts needs to be wired to the UDS. During a

fire, this will shut off fuel to the cooking equipment per

NFPA 96.

• Common on microswitch to terminal C1

• Normally-closed to terminal NC1

• Normally-open to terminal NO1

120V/1PH/10A

to FIRE SYSTEM MICROSWITCH

FS1

NC

NO

NONC

C

*

GROUND BAR

Utility Distribution System8

CBM3

460V

SERVICE B

MAIN BREAKER

Page 9

Hose Installation Instructions

1. Check sizes and quantity of hose assemblies as

shown on the drawing.

2. Make sure all plumbing 1/4 turn ball valves are in the

off position. When the handle is in-line with the pipe,

the valve is in the “on” position. When the handle is

at a right angle to the pipe, it is in the “off” position.

3. Connect all hose assemblies to the appropriate

equipment as shown on the drawing. Provide and

install necessary plumbing fittings to present a neat

appearance and to ensure that the hose assemblies

do not touch floor. To connect hoses to quick

disconnects, pull back sleeve, and push plug into

socket. To disconnect, pull back sleeve, unlocking

the coupling.

4. To ensure proper installation and minimal wear of

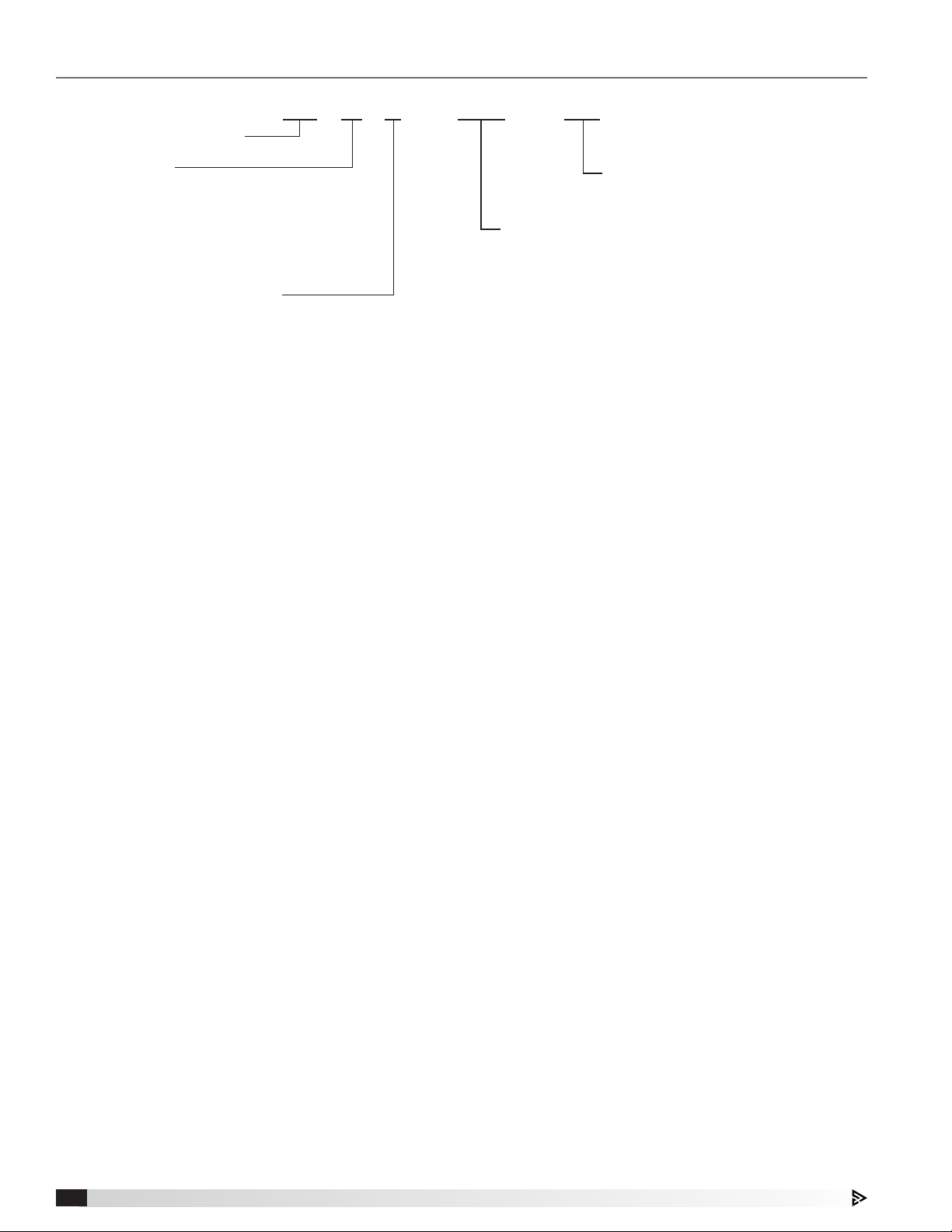

hoses, follow the examples shown below:

Do not offset

couplings. This

creates torsional

twisting and

undue strain

causing

premature

failure.

Allowing a sharp

bend strains and

twists the metal

hose to a point

of early failure at

the coupling.

Couplings and hose

should be installed

in the same plane

as shown.

This is the correct way

to install metal hose

for vertical traverse.

Note the single natural

loop.

Start-Up

Testing

1. After installation has been completed, including

plumbing and electrical connections, replace all

access panels in the electrical chase.

2. Make sure all breakers (including the main) are in

the off position.

3. Make sure all service and appliance ball valves are

closed.

4. Slowly open the cold water main supply ball valve

(if provided). Check for leaks between the main

ball valve and appliance ball valves. Once check is

complete, close the main supply valve.

5. Repeat step 4 for hot water and steam valves (if

provided), as well as any other plumbing valves

except for gas (if provided).

6. Turn on main service circuit breakers.

7. Turn on each branch breaker and check the status

lights (if provided) and GFCI receptacles connected

to each breaker. Continue with all branch breakers.

8. Slowly open the gas main supply ball valve until fully

open (if provided). If equipped with an electric gas

valve, press the RESET button on the fire fuel shut

off panel to allow gas to flow to the appliance ball

valves. Check for leaks.

9. At this point, hook up all equipment (plug and

cordsets, plumbing hoses). Refer to Hose

Installation Instructions found on this page.

10. Open all appliance ball valves.

11. With everything on, test appliances for proper

operation and look for any leaks.

12. If provided, test fire fuel shut-off (see page 10 for fire

fuel shut off operation).

Closing in the

diameter at the

coupling creates

double bends

causing work

fatigue failure

of fittings.

Maintain the minimum

or larger bending

diameter between

the couplings for

longest life.

Utility Distribution System 9

Page 10

Fire Fuel Shut-Off (optional)

Overcurrent Protection (optional)

Sequence of Operation

GAS "ON"

RESET

E-STOP

ALARM

after the fire system is returned to the cocked (armed)

position under normal operating conditions, the button

marked gas reset must be pressed to allow gas to flow

to all gas operated equipment. A “GAS ON” pilot light

will illuminate when gas is allowed to flow to all gas

operated equipment.

1. Electricity

Actuation of the fire system will trip

all circuit breakers equipped with

the fire-fuel shut off feature and deenergize the corresponding outlets.

Typically, this occurs only on the main

service shunt trip breaker(s) in the

UDS electrical riser. If equipped, the

audible alarm in the UDS will sound.

After the fire system is returned to the

cocked (armed) position under normal

operating conditions, these circuit

breakers will remain de-energized

until manually reset.

2. Gas

Actuation of the fire system will stop

all gas flow to the gas operated

equipment. If equipped, the audible

alarm in the UDS will sound. If the

UDS is supplied with a mechanical

gas valve, after the fire system is

returned to the cocked (armed)

position under normal operating

conditions, gas will flow to all gas

operated equipment. If the UDS is

supplied with an electric gas valve,

Testing

1. Turn all individual equipment controls to the OFF

position before attempting to connect or disconnect

any cord and plug assembly. After the cord and plug

assembly is connected, equipment may be turned

ON.

2. When the circuit breaker is in the OFF position,

the receptacle operation indicator light will not

be illuminated. To energize the outlet, turn the

circuit breaker to the ON position. The receptacle

operation indicator light will turn ON.

3. To test the connection plate, turn the circuit breaker

to the ON position and press the PUSH TO TEST

button. The circuit breaker will automatically turn to

the OFF position and the outlet will be de-energized.

4. Turn the circuit breaker back to the ON position and

the outlet will be energized. The equipment is now

ready for operation.

Current Sensor Adjustment

NOTE

Ground fault nuisance tripping may occur on certain

pieces of equipment. If this situation occurs, follow

these steps

1. Turn off ALL main services to raceway.

2. Carefully remove the screws securing the access

panel.

3. Locate the ground fault sensing relay and adjust the

potentiometer slightly clockwise.

4. Carefully replace the access panel and tighten

securely.

5. Test the circuit breaker and appliance.

IMPORTANT

After the gas has been reset, all pilot lights must be

re-lit. Failing to re-light pilots will cause gas to flow

into the kitchen.

Emergency Stop

Depressing the emergency stop switch will trip the main

shunt trip breaker(s), and stop all gas flow to the gas

operated equipment (if provided with an electric gas

valve). To reset, pull this emergency stop switch out,

then press the RESET button. The main circuit breaker

must then be reset (turned to the OFF, then to the ON

position) to re-energize the outlets.

IMPORTANT

After the gas has been reset, all pilot lights must be

re-lit. Failing to re-light pilots will cause gas to flow

into the kitchen.

Utility Distribution System10

NOTE

If intermittent tripping continues, contact the factory

for further instruction.

Page 11

Operation

Under normal operation, appliances should remain powered unless:

a. a fire or fire test occurs, or

b. the emergency stop is pressed.

If provided with fan or light controls, buttons to control the lights and/or fans will be provided. Pressing these

buttons will operate hood lights and fans. For more information, reference the drawings provided with the UDS.

Troubleshooting

Problem: Main breaker trips.

Has the main breaker been reset properly? Turn the main breaker completely off, then into the on position.

Is the breaker too small? Check the breaker size and service load and consult the UDS drawings.

Faulty wiring? Check the wiring and fire microswitch wiring.

Faulty breaker Replace main circuit breaker

Problem: Branch breaker trips.

Has the branch breaker been reset properly? Turn the branch breaker completely off, then into the on position.

Current sensor needs adjustment. If UDS is supplied with over current protection, the sensor in the raceway may

need adjustment. See page 10 for instruction on adjusting current sensor.

Problem: Main breaker will not reset.

Fire system in fire position Fire system must be reset.

Fire system microswitch is not connected Connect fire microswitch to UDS. See UDS drawings for details.

Problem: Electric gas valve will not open.

Is the system in fire condition? Check fire microswitch connections and fire system status.

Problem: Water and/or gas is not working.

Are the manual shut off valves in the

service risers on?

Are the appliance quick disconnects

attached?

Check valves to see if they are on.

Check quick disconnects behind appliances for proper installation.

Utility Distribution System 11

Page 12

Our Commitment

Our Commitment

As a result of our commitment to continuous improvement, Accurex reserves the right to change specifications

without notice.

Product warranties can be found online at accurex.com, either on the specific product page or in the Warranty

section of the website at Accurex.com/Resources/Warranty.

P.O. Box 410 Schofield, WI 54476

Phone: 800.333.1400 • Fax: 715.241.6191

Parts: 800.355.5354 • accurex.com

12

470404 • UDS Model XM, Rev. 2, July 2018 © 2018 Accurex, LLC12

Loading...

Loading...