Page 1

Part #

Waterwash Hoods

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

Waterwash Hoods

Page 2

TABLE OF CONTENTS

How To Use This Manual .................................................................... 4

Receiving and Handling ..................................................................... 4

Storage .................................................................................. 4

Waterwash System Function ................................................................. 4

Waterwash Components..................................................................... 5

Typical Installation ......................................................................... 5

Continuous Capture Plenum ........................................................... 8

Double Island Style Hood ............................................................. 9

U Channel Strips..................................................................... 9

Ductwork.......................................................................... 10

Installation Instructions for the External Supply Plenums.......................................... 11

Installation Instructions for the Backsupply Plenum BSP.......................................... 13

Installing the Supply Duct Collar ....................................................... 13

Hanging the Backsupply Unit ......................................................... 13

Hanging the Hood .................................................................. 14

Air Diffusers ....................................................................... 14

Enclosure Panel Installation Instructions.......................................................15

Filler Panel Installation Instructions ........................................................... 16

End Skirt Installation Instructions............................................................. 17

Backsplash Panel Installation Instructions ..................................................... 18

Duct Collar Installation Instructions for XB, XW, XK and XX Series Hoods ............................ 20

Plumbing ................................................................................ 21

Electrical Connections ..................................................................... 23

Electrical Wiring .................................................................... 23

Startup, 24/7 Timer, Pump Settings, Detergent Operation .................................. 25

Daily Operation of Waterwash Hood....................................................27

Sequence of Operation ............................................................28-29

Balancing the Kitchen Exhaust............................................................... 31

Short Circuit Hoods ................................................................. 34

2

2

October 2010

Page 3

TABLE OF CONTENTS CONT’D

Field Wiring for Ansul Snap-Action Switch ..................................................... 35

Overall Wiring Plan View .................................................................... 36

Wiring for Hood Switch Panels............................................................... 37

Circuit Diagram ........................................................................... 38

Waterwash Control Panel .................................................................39-44

Maintenance ............................................................................. 45

Troubleshooting Guide ...................................................................45-49

Replacement Parts/Kits ..................................................................50-51

Waterwash Start-up Checklist .............................................................52-53

Notes for Maintenance Checks ............................................................54-55

Warranty ................................................................................ 56

October 2010

3

3

Page 4

HOW TO USE THIS MANUAL

Read and save these instructions. This manual is designed to assist qualified field service, operating and

maintenance personnel with the installation, operation, and maintenance of Accurex canopy type kitchen hoods

and accessories.

Procedures described in this manual should be followed in the order they appear, with attention to all safety and

caution statements.

RECEIVING, HANDLING & STORAGE:

Upon receiving the equipment, check for both obvious and hidden damage. If damage is found, record all

necessary information on the bill of lading and file a claim with the final carrier. Check also to be sure that all

parts of the shipment, including accessories, are accounted for.

If a kitchen hood must be stored prior to installation, (or for any long period) it must be protected from dirt and

moisture. Indoor storage is recommended. For outdoor storage, cover the hood with a tarp to keep it clean, dry,

and protected from UV (Ultra Violet) radiation damage.

NOTE: The kitchen hood is shipped with a plastic film attached to the surface. The film is to protect the panels

from minor scratches during handling and shipment. This film must be removed prior to assembling the system.

When the system is operating, the film will melt and bake on to the surface. Once the film is removed caution

should be used in handling the parts.

Improper storage which results in damage to the unit will void the warranty.

WATERWASH SYSTEM FUNCTIONS:

Accurex waterwash hoods are designed for three primary functions:

1) Capture and contain the effluent produced by the cooking process.

2) Remove grease and other contaminants from the airstream with a series of extraction baffles.

3) Wash the baffles and other surfaces within the exhaust plenum to remove contaminants.

NOTE: The functions listed above require the control center to be wired to the exhaust fan and plumbed.

Normal Exhaust Operation and Contaminant Collection:

The system’s exhaust fan is manually controlled by a push-button switch (Start Fan) located on the face of the

waterwash control station. The exhaust system operates until the Stop Fan/Start Wash push-button switch is

pressed.

Optional Continuous Cold Water Mist:

The optional continuous cold water mist is controlled by the same push-button switch (Start Fan). With this

option, all hoods with this option are sprayed continuously when the fan is on. This feature acts as a spark

arrestor for solid fuel applications, as per NFPA 96, Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations. This does not have to be all hoods - can be just the solid fuel hoods.

Cleaning Cycle:

A factory programmed controller triggers the waterwash function when the exhaust fans are shut down at the

end of each day’s cooking operations. A pressurized spray of hot water and detergent cleans the hood in a

timed cycle. When the cleaning cycle is complete, the controller runs the exhaust fans briefly to remove steam

from the exhaust system. The controller then automatically resets itself. If the kitchen is closed for a day, the

wash cycle will skip as long as the start fan button has not been pushed.

For multiple hoods totalling over 20 ft. 0 in. in length, systems are designed to wash each hood or group of

hoods sequentially. (Hoods totalling up to 20 ft.0 in. in length can be washed as a single unit.)

4

4

October 2010

Page 5

Fire Mode (Optional):

The waterwash system also provides water spray for the exhaust plenum when the system is in fire mode. This

is in addition to the hood’s automatic fire suppression system. When the fire suppression system discharges,

it activates the waterwash system (without the detergent) and the optional continuous cold water mist to spray

water within the exhaust plenum and turns on the fan circuit. The system will shut off when the fire protection

system is reset. It can also be shut off manually by turning off the water flow in the waterwash control station.

Exhaust fan will be on, Supply fan off

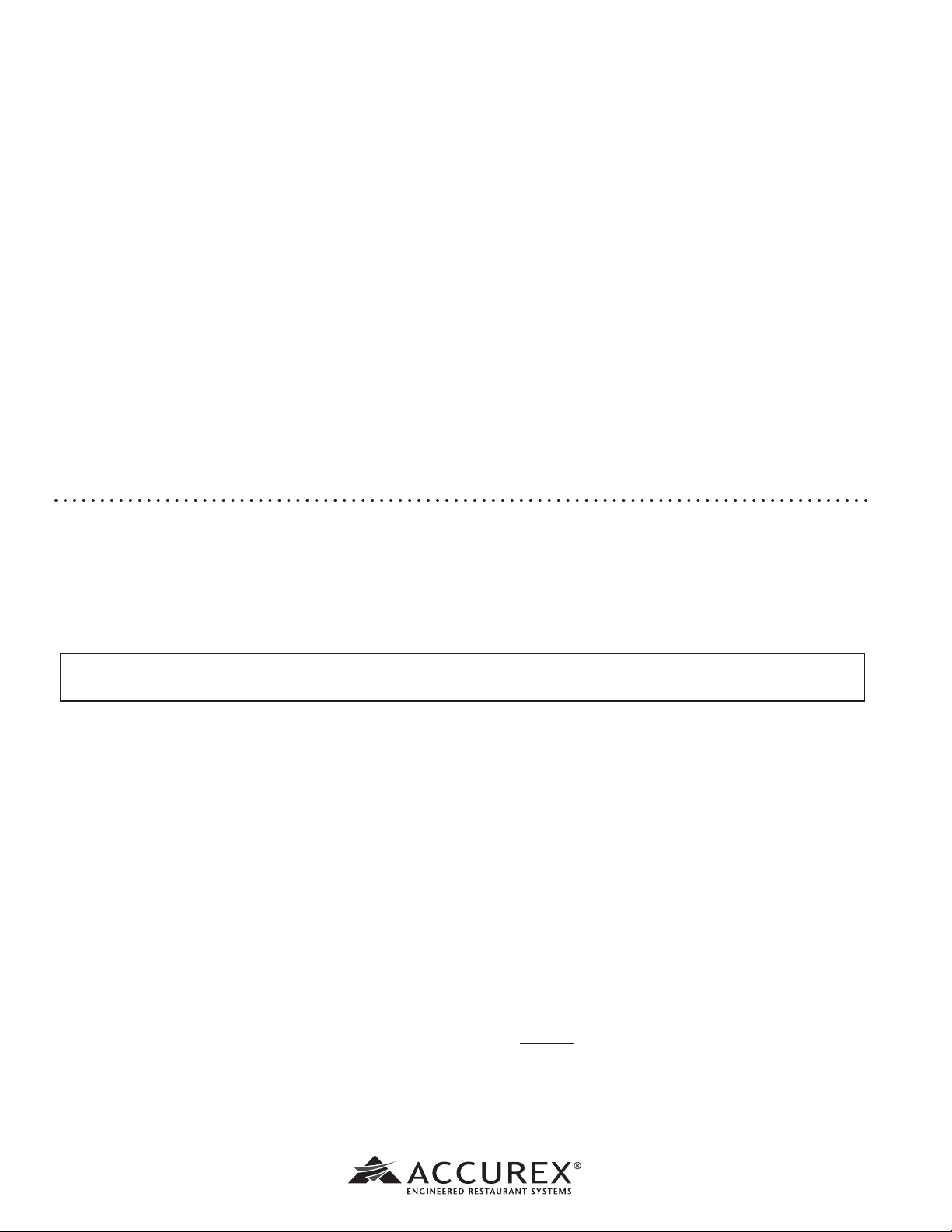

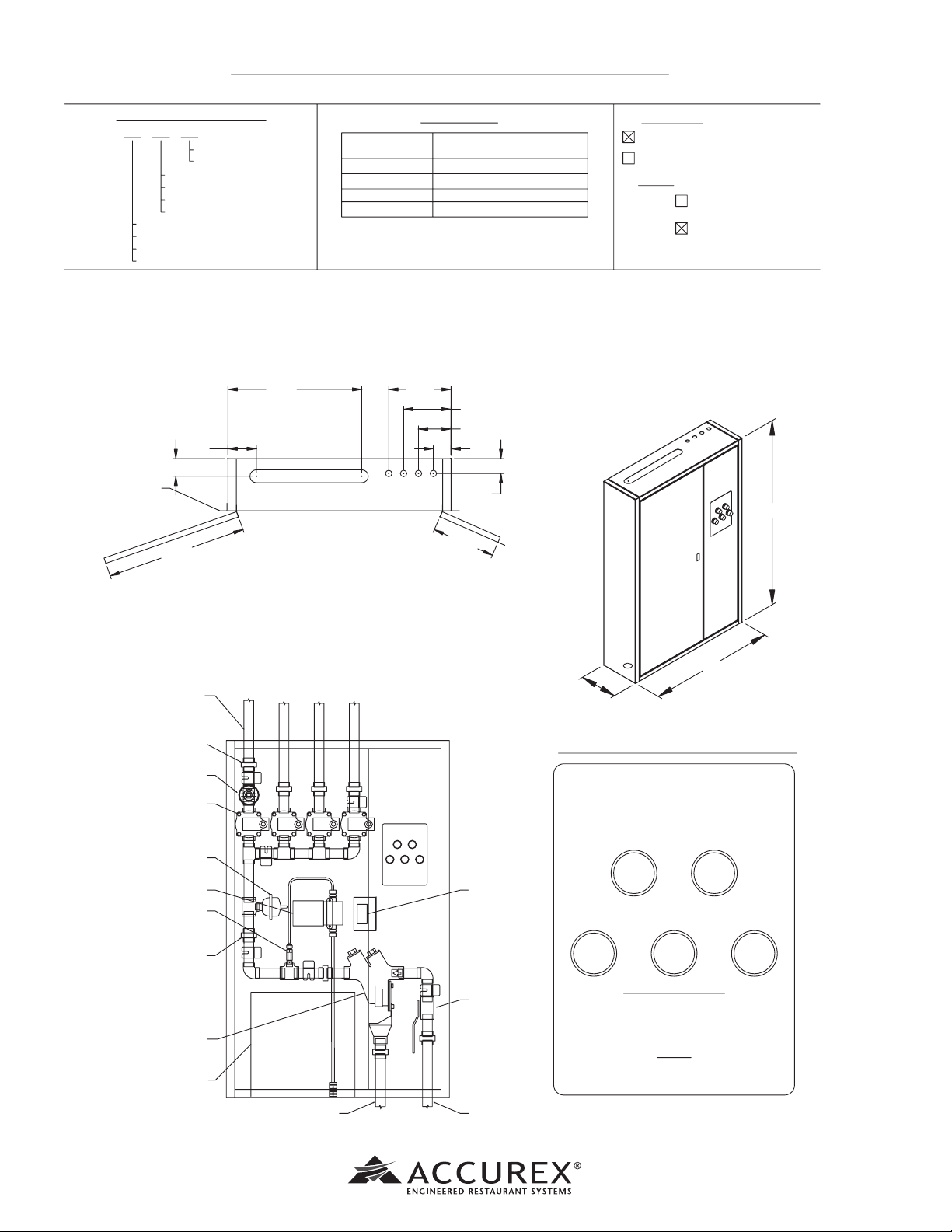

Typical Installation:

Fig. 1

Vacuum Breaker

Detergent Line

Wiring to:

115 VAC 20 AMP service

Fire Sup. System NC Switch

Fan Control Center

Opt. Solenoid Valve

for Seq. Wash

Optional Continuous Cold

Water Mist Supply Line

Hot Water/Detergent to Hood

Detergent Check Valve

Internal components of hood

and control station are factory

piped and wired. All external

piping and wiring is by others.

Exhaust Duct Collar

Waterwash Hood

Junction Box Hood Lights

Hot Water Supply

to Control Station

October 2010

Waterwash

Control Station

Optional

Cold Water Supply

to Control Station

Drain Pipe

The system shown includes

a vacuum breaker for

backflow prevention. Some

state plumbing codes

require a reduced pressure

backflow preventer. See

page 7 for detailed control

panel layouts of each type.

5

5

Page 6

SYSTEM COMPONENTS:

Hood:

The hood is shipped from the factory prepiped and ready to install. All waterwash components within the hood

are complete and ready for connection to hot water, electrical sources, the sanitary sewer drain and optional

cold water. All piping to and from the waterwash control station and the hood is by others. Wiring from the

control panel to the hood (for lights) is by others. All plumbing and wiring must conform to plumbing and

electrical codes. See Figure 1(previous page) for typical installation and location of electrical and plumbing

components.

Duct collars are also mounted at the factory unless requested otherwise.

Waterwash Control Station:

The waterwash control station contains all of the water and electrical controls in two separate compartments.

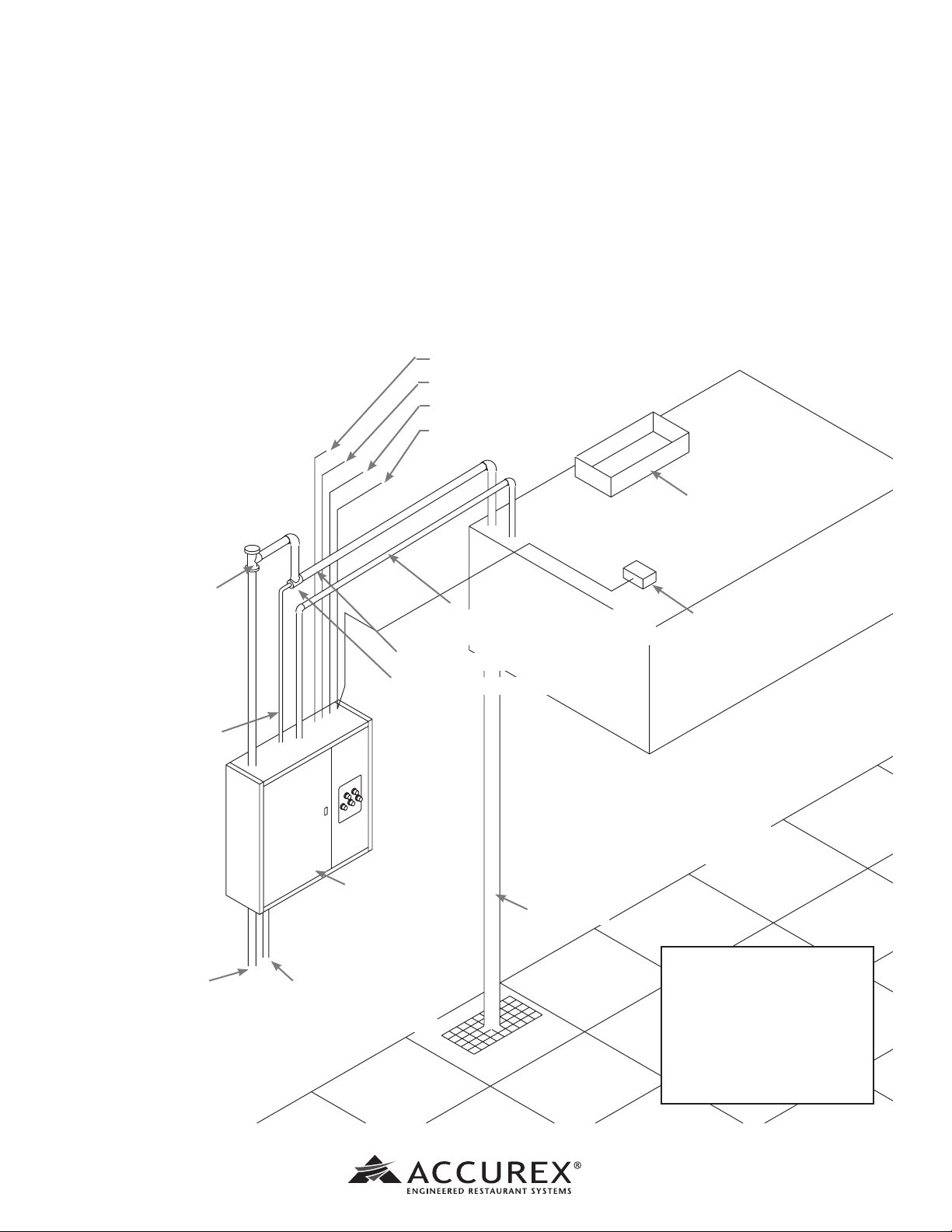

(See Figs. 2, 3, 4, 5, 6 & 7). The electrical side includes all electrical components, connections, and on/off

switches. These switches are illuminated and are mounted on the face of the cabinet. The water side includes

hot water connections, pressure/temperature gauges, the detergent reservoir and pump, water hammer arrestor,

the water solenoid valves, and optional continuous cold water mist piping.

Vacuum Breaker (shipped loose for field installation):

The vacuum breaker is installed at the highest point in the system’s piping to prevent backflow when there is no

water pressure to the hood. It must be installed a minimum of 6 in. above the hood water supply line

(See Figs. 2, 3 & 4).

Reduced Pressure Backflow Preventer - RPBP (shipped loose for field installation):

Where building codes require a reduced pressure backflow preventer, it will be provided in lieu of a vacuum

breaker when ordered. The reduced pressure backflow preventer is installed beneath the control panel (See

Fig. 5, 6 & 7). May by ordered mounted in 48 in. tall cabinet.

Detergent Pump-Related Components (shipped loose for field installation—installed

in RPBP systems. See page 42 ):

•Detergentlinecheckvalve

•Detergenttube(1/4in.I.D.,3/8in.O.D.)

Optional Features:

24 Hour / 7 Day Timer:

This feature allows the cleaning cycle to begin at any preset time after the fans are shut down, rather than

immediately after. This allows time, for instance, for completion of dishwashing to avoid a shortage of hot water.

Fans must be turned OFF just as with the standard cleaning cycle. Maximum six start times.

Multiple Hoods Sequenced Wash:

Where more than one hood must be washed, the control station is set up to wash each hood individually in a

prescribed sequence. This ensures that there will be adequate hot water for all hoods. Individual water solenoid

valves are provided for each hood to be washed in a multiple sequence. Maximum five sequences.

(Sequence solenoid valves are shipped loose for systems with vacuum breakers or optional continuous

cold water mist. They are mounted in the control station for standard systems with reduced pressure

backflow preventers.)

Low Detergent Indicator Light:

A sensor and indicator light are available to alert the operator when the detergent tank requires filling.

Continuous Cold Water Mist:

This feature continuously sprays a fine water mist in the exhaust plenum of the hood. The continuous cold water

mist is controlled by the same push button switch as the fan.

6

6

October 2010

Page 7

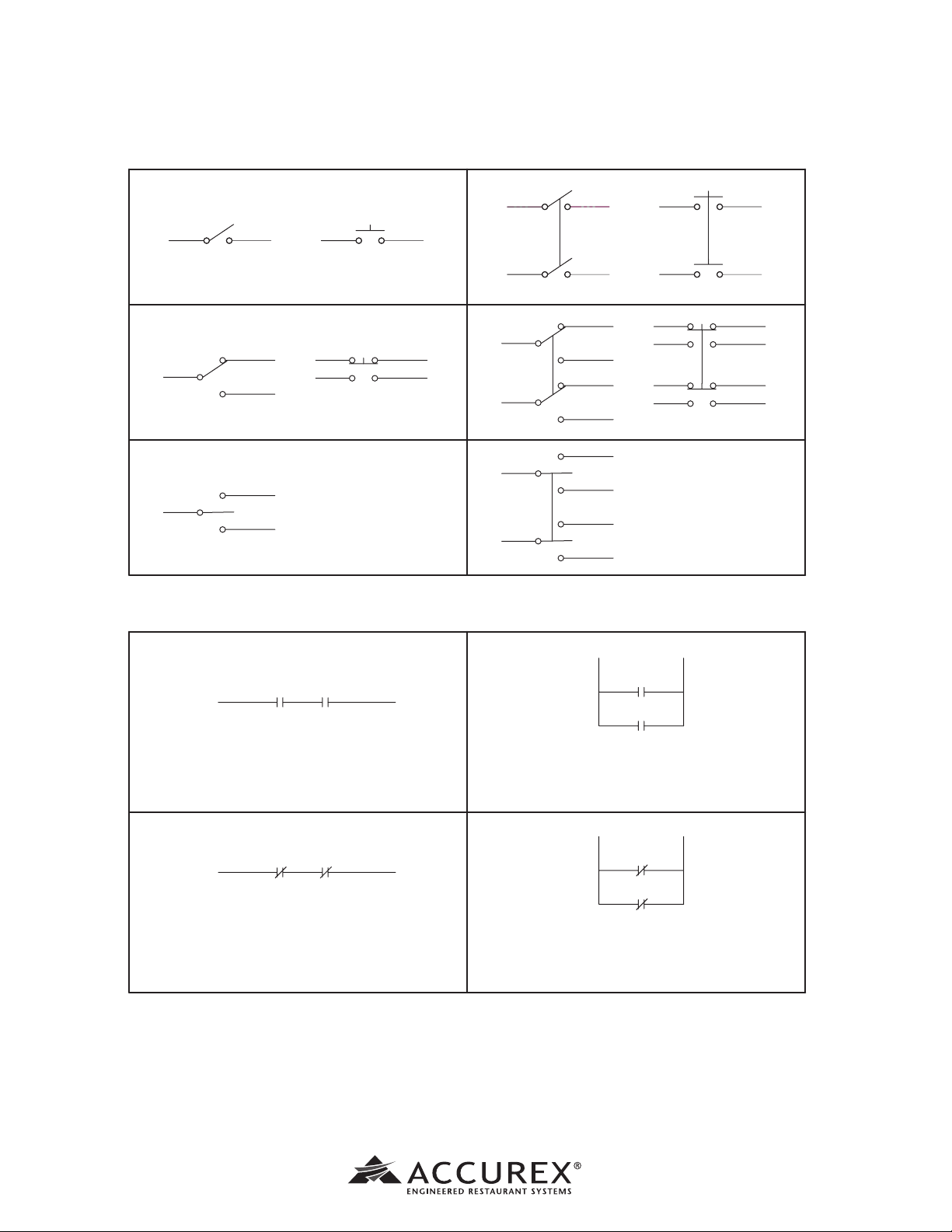

Fig. 2 Std. Piping with Vacuum Breakers

To Hood

3/4 in. or 1 in.

Piping

Connection

by

Others

Optional Low

Detergent

Indicator Light

Fire Mode

Indicator Light

Hood Lights

Stop Fan/Start Wash Switch

Hot Water Inlet

Start Fan

Switch

Fig. 5 Std. Piping with Reduced Pressure

Backflow Preventer

Disconnect

Switches

Field Wiring

Terminal Strip

Fan Relay

Optional 24

Hour Timer

Fuse Block

Factory Wiring

Terminal Strip

Programmable

Piping by

Controller

others

Vacuum Breaker

Detergent

Check Valve

Union

Detergent

Pump

Water

Solenoid Valve

Water Hammer

Arrestor

Pressure and

Temperature

Gauge

6 in.

Fig. 3 Optional

Piping for

Sequence Wash

Water Solenoid

Valve(s)

To Hood

3/4 in. or 1 in. Connection

6 in.

To Hood 3/8

in. Connection

Solenoid Valve

Pressure

Gauge

Detergent

Injection Point

Pressure

Reducing Valve

and Strainer

Hand Valve

Reduced Pressure

Backflow Preventer

Fig. 6 Optional

Piping for

Water

Sequence Wash

Solenoid

Valve(s)

To Hood

3/4 in. or 1 in. Connection

Hand Valve

Detergent Tank

Fig. 4 Piping with Vacuum Breakers and

Optional Continuous Cold Water Mist

October 2010

Cold Water Inlet

Detergent

Line Strainer

Fig. 7 Piping with Reduced Pressure

Backflow Preventer and Optional

Continuous Cold Water Mist

7

7

Page 8

2. RAISE ALL HOODS INTO APPROPRIATE LOCATION

AND

SUPPO

RT PER CONSTRUCTION PLAN

S.

3. FASTEN TOP ANGLES TOGETHER USING 1/4 in. BOLTS & NUTS (BY OTHERS

).

4. FASTEN HOODS TOGETHER USING U-CLIPS, 1/4 in. BOLT

S

5. CAULK ALL SEAMS AS NECESSARY

.

& CAP NUTS AS INDICATED

.

1. REMOVE SUPPORT ANGLE ON OPEN END PANEL

.

H

OOD

ACO

RN N

UT

BOL

T

U-CLIP

CAULK

H

OOD

RN N

UT

BOL

T

-CLI

P

AUL

K

Front

1

/2 in. threaded rod by

Note: If a utility distribution system (UDS) is part of the kitchen package, allow adequate room for it before

mounting hood(s) and welding ductwork. Check construction documents.

Fig. 8

INSTALLATION

NOTE: If you have a Backsupply

Plenum (BSP), this must be

installed before the hood. Please

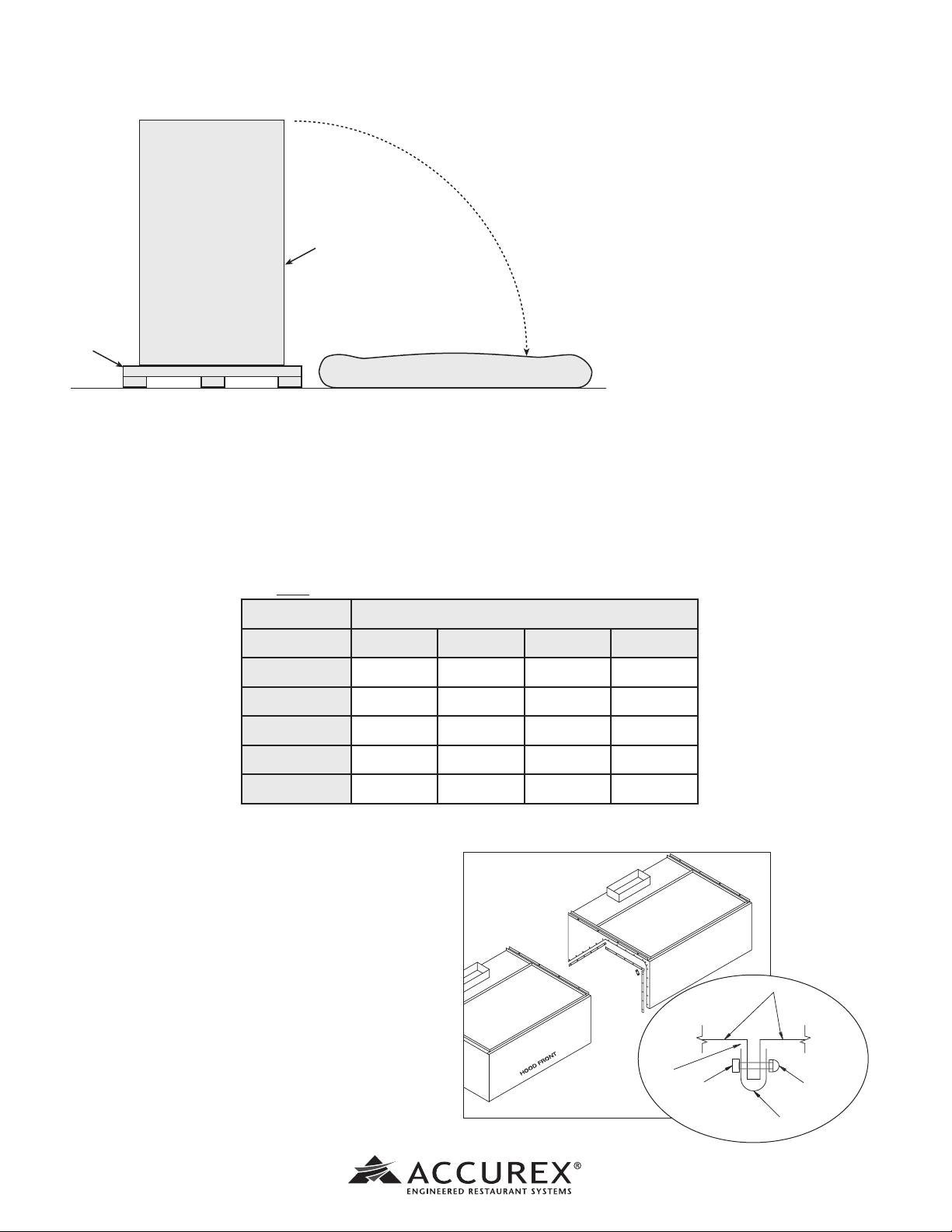

Bottom

Pallet

Protective Material

Carefully remove the packing crate. Place some protective material on the floor next to the crate to avoid

damaging the hood as it is tipped on its side. (See Fig. 8) Tip the hood carefully onto the protective material.

If you have filler panels, install them now. Please see page 16. If you have integral filler panels, no

additional installation is needed.

Insert 1Ú2 in. diameter threaded rod (by others) into hanger brackets on hood top. (Fig. 9, Pg. 10) Check the

engineering drawings for proper hood height above finished floor. Accurex recommends that the hoods be hung

6 feet 6 inches above the finished floor. Raise and hang hood from adequate roof or ceiling supports. All hanger

brackets must be used and hood must be properly supported while lifting to prevent damage or distortion to the

hood. The hood must be hung level to or slightly pitched toward the grease drain.

Hood Model Width (in feet)

see Page 13.

For Wall/Single Island Style Hoods,

prior to installation, check with

local authorities having jurisdiction

on clearances to combustible

surfaces, etc.

With the hood still inside its

packing crate, position the unit

beneath its installation location.

Wall Canopy 4 4.5 5 5.5

XWEW 53 lbs/ft. 56 lbs/ft. 59 lbs/ft. 62 lbs/ft.

XWFW 60 lbs/ft. 60 lbs/ft. 62 lbs/ft. NA

XWAW NA 60 lbs/ft. 65 lbs/ft. 70 lbs/ft.

XWCW NA 65 lbs/ft. 70 lbs/ft. 75 lbs/ft.

XWSW 60 lbs/ft. 65 lbs/ft. 70 lbs/ft. 75 lbs/ft.

For double island hoods, multiply the weight by two.

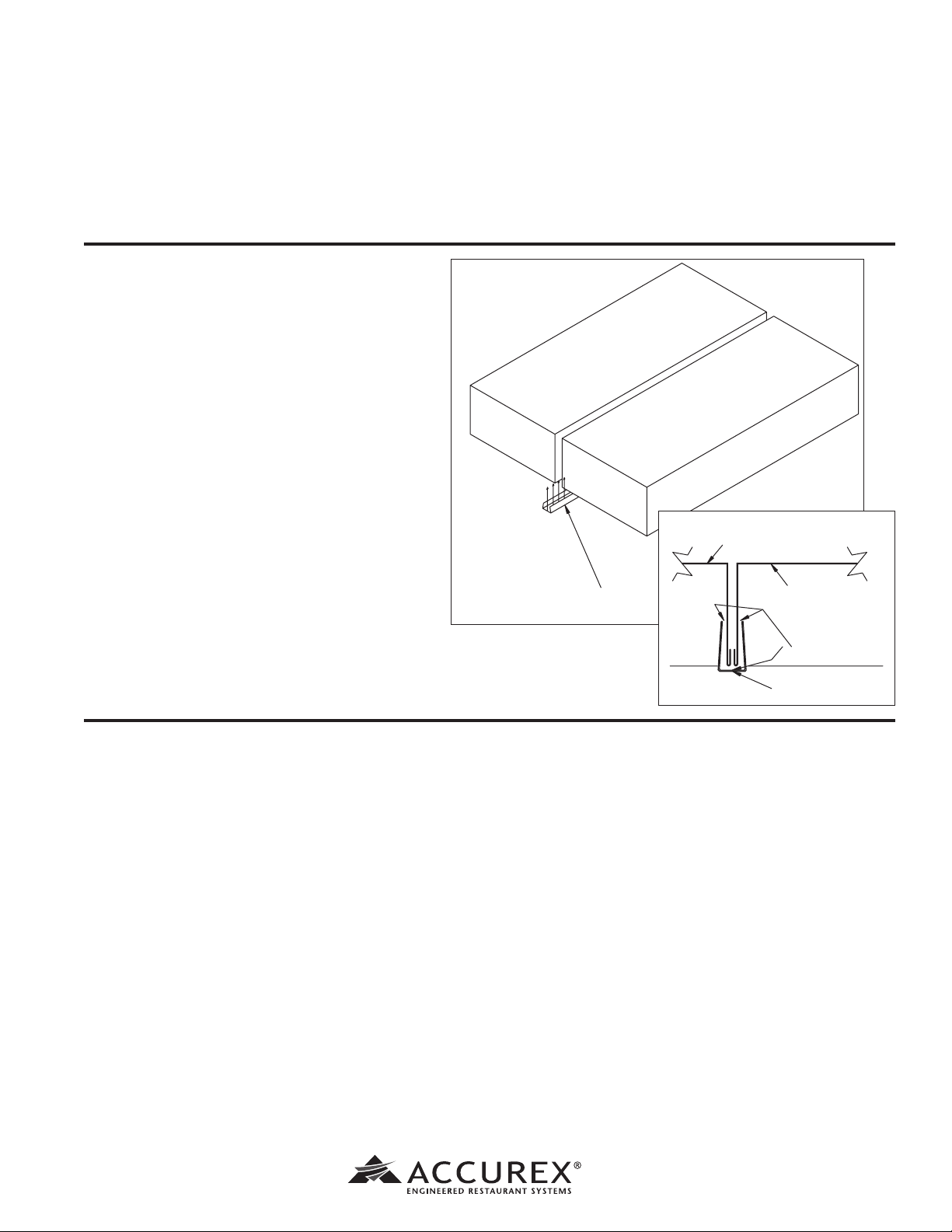

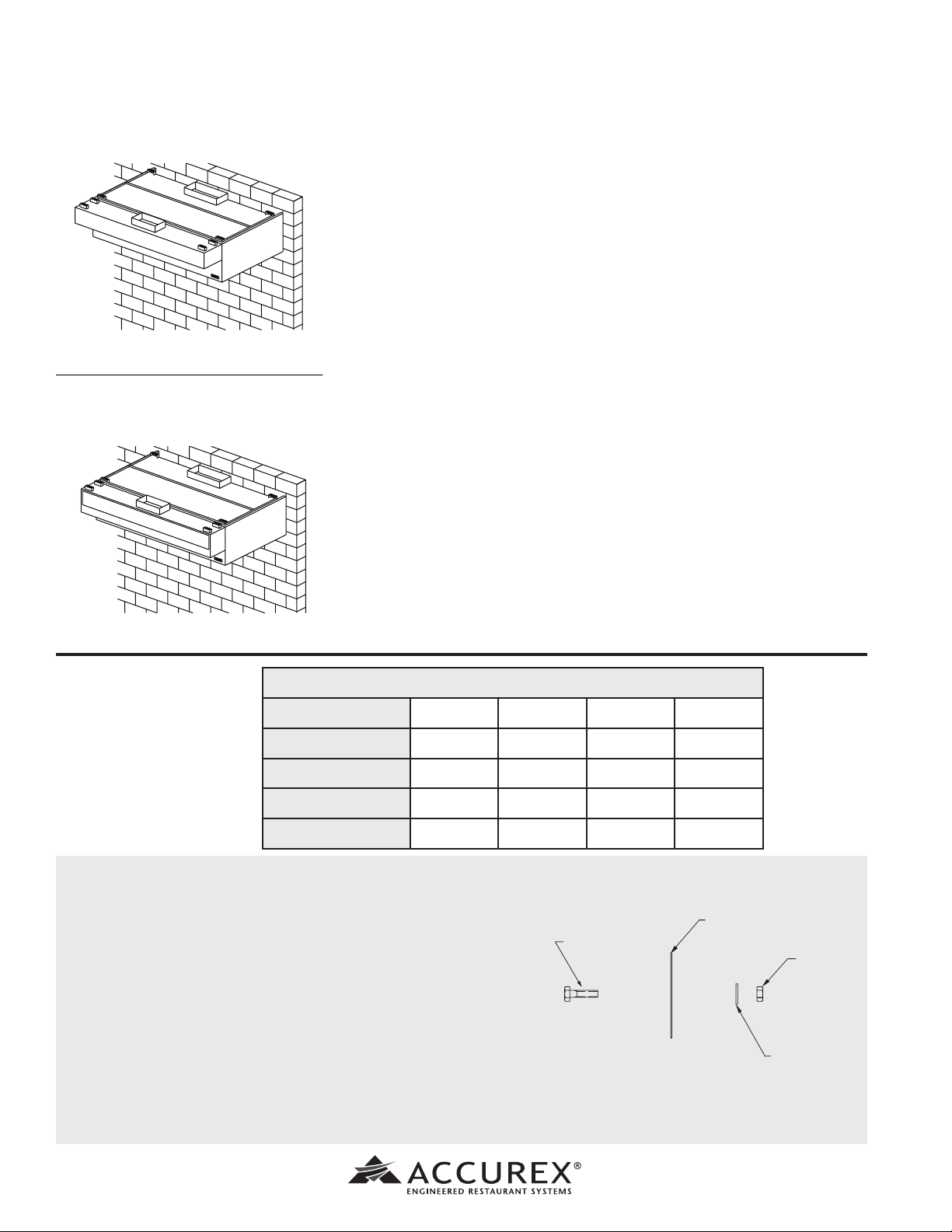

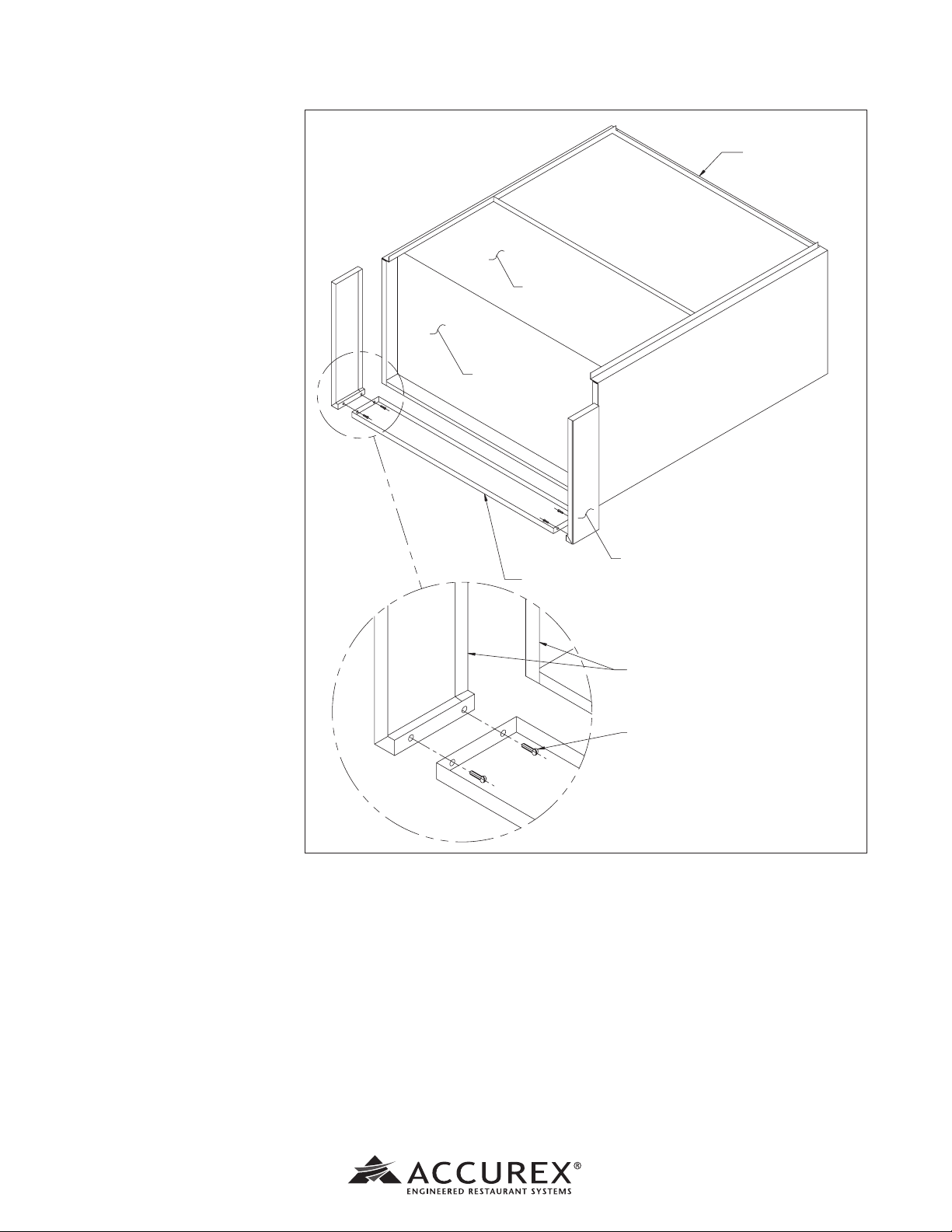

Continuous Capture Plenum Hoods

Remove the support angles on the open end panels.

(See Fig. 8A) Use the installation procedure described

above, for single island hoods to install and level both

hoods. After leveling, secure the hoods together by

tack welding and/or bolting the top angles. Fasten the

hoods together using u-clips and bolts. (See Fig. 8B)

Caulk this joint with NSF approved silicone caulk (GE

SCS-1009 or its equivalent). The caulk is not provided.

Fig. 8A

Fig. 8B

8

8

October 2010

Page 9

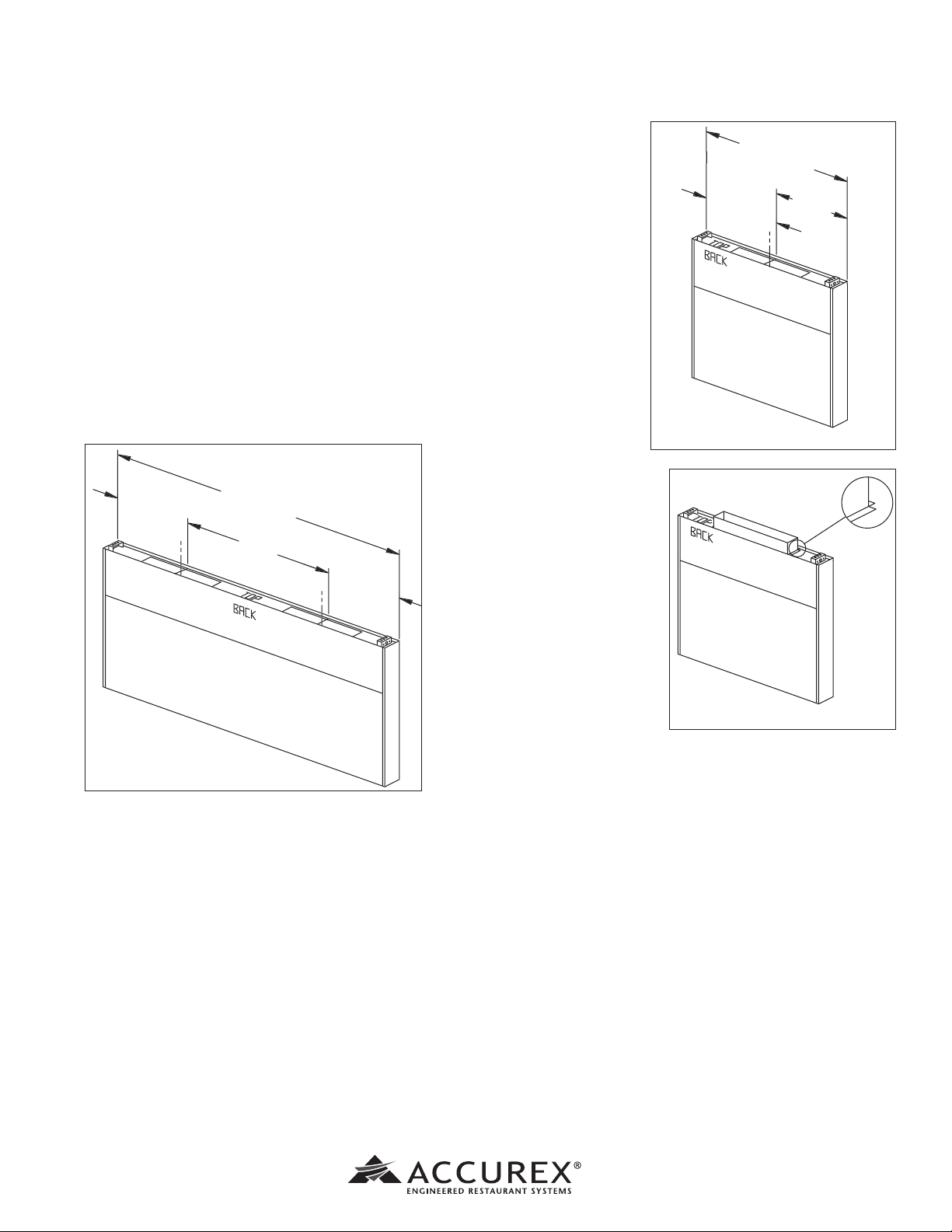

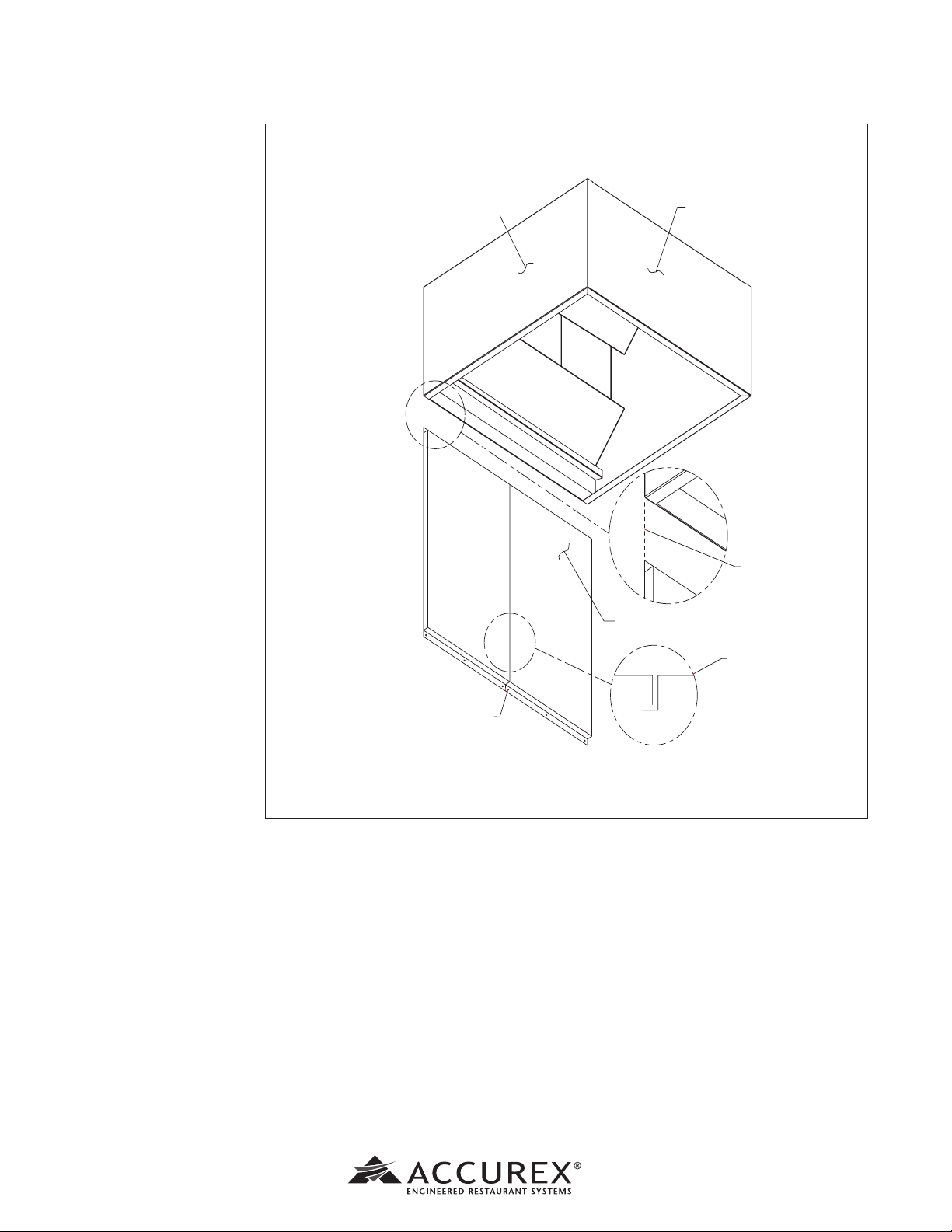

Double Island Style Hoods

HOOD FRONT

ITEM-1B

DOUBLE ISLAND

CLIP

ITEM-1A

HOOD FRONT

ITEM-1B

DOUBLE ISLAND

ITEM-1A

Before hanging the hoods, please verify the hood marks to make sure the correct hood is

hung on the correct side.

A double island hood is created by installing two wall style hoods back to back. Use the installation procedure

described on page 8, for single island hoods to install and level both hoods. After leveling, secure the hoods

together by tack welding and/or bolting the rear mounting brackets. Caulk this joint with NSF approved silicone

caulk (GE SCS-1009 or its equivalent). The caulk is not provided.

Installing U Channel Trim Strip

1. After the hood is hung in position

and leveled, apply caulk to the

inside edge of the double island clip

(see detail).

2. Position and install the clip by

tapping into position along clip

(friction fit).

3. Caulk edges to seal out grease and

allow for ease of cleaning. Caulk with

NSF approved silicone caulk (GE SCS-

1009 or its equivalent). The caulk is not

provided.

HOOD-1A

HOOD-1B

SILICONE CAULK

(GE SCS 1009)

DOUBLE ISLAND

CLIP

Note: The installation of the canopy hoods shall be in accordance with NFPA 96 (latest edition), Removal of

Smoke and Grease-laden Vapors from Commercial Cooking Equipment.

See separate instructions for proper installation of enclosure panels, backsplash panels, and end skirts when

provided. Please see Pages 15 -19 for the installation instructions.

After the hood is installed, remove all protective plastic.

Note: Accurex does not recommend walking or standing on the hood top as damage can result. If you must walk

on the hood top, protect the hood with additional support or planks for flooring.

October 2010

9

9

Page 10

DUCTWORK

1

/2 in. threaded rod by

others

Exhaust

Fig. 9

As specified in NFPA 96, Ch. 7.5 (latest

edition), exhaust duct systems must be

constructed in the following manner:

Materials. Ducts shall be constructed

of and supported by carbon steel not

less than 1.37mm (.054 in.) (No. 16 MSG)

Fig. 2

in thickness or stainless steel not less

than 1.09mm (0.043 in.) (No. 18 MSG) in

thickness.

Front

Installation: All seams, joints, penetrations, and duct to hood collar connections shall have a liquid tight

external weld. If you have an Automatic Fire Damper please refer to that manual for installation

instructions.

Supply

Supply ductwork (where applicable) should be connected to the hood in a manner approved by the local code

authorities.

Note: For hoods with fire dampers in the exhaust and supply duct collars, an access panel for cleaning and

inspection shall be provided in the duct. This panel shall be as close to the hood as possible and not exceed 18

inches from any hood damper.

For proper installation of duct collars when they are shipped unattached, see page 20.

10

10

October 2010

Page 11

INSTALLATION INSTRUCTIONS FOR EXTERNAL SUPPLY PLENUMS

HANGER BRACKET

END VIEW

THREADED ROD

HOOD

ATTACH HANGING CLIP TO

HOOD STANDING SEAM WITH

THE SUPPLIED "C" CLAMPS

(OPTIONAL: DRILL AND BOLT A

1/4-20 SS BOLT THROUGH

THE CLIP AND HOOD STANDING

SEAM)

HANGING METHODS FOR SUPPLY PLENUMS

ASP, FSP AND VSP

TOP VIEW

HOOD

TOP VIEW

SUPPLY PLENUM

2 CLIPS ARE NEEDED

3 CLIPS ARE NEEDED

FOR PLENUMS > 96"

FOR PLENUMS <= 96"

THE THIRD CLIP IS LOCATED

IN THE CENTER OF THE PLENUM

LENGTH

THREADED ROD

OPTION #3

OPTION #1

ON THE END OF THE HOOD

HANGING CLIP COULD BE 23.5" FROM

END IF THERE IS A UTILITY CABINET

OPTION #1

OPTION #1

THE HOOD AND IS MOUNTED TO THE ASP

HOOD UP CANTILEVERS OVER THE END OF

THE UNI-STRUT (U-CHANNEL) THAT HOLDS THE

HANGER BRACKETS

OPTION #2

OPTION #2

UNI-STRUT SUPPLIED BY OTHERS

OPTION #1 = HANGING CLIP

OPTION #2 = UNI-STRUT

OPTION #3 = THREADED ROD

OPTIONAL UTILITY CABINET

SUPPLIED BY OTHERS

ASP, FSP, VSP

11.5

23.5

END VIEW

THREADED ROD

HOOD

ATTACH HANGING CLIP TO

HOOD STANDING SEAM WITH

THE SUPPLIED "C" CLAMPS

(OPTIONAL: DRILL AND BOLT A

1/4-20 SS BOLT THROUGH

THE CLIP AND HOOD STANDING

SEAM)

HANGING METHODS FOR SUPPLY PLENUMS

ASP, FSP AND VSP

TOP VIEW

HOOD

2 CLIPS ARE NEEDED

3 CLIPS ARE NEEDED

FOR PLENUMS > 96"

FOR PLENUMS <= 96"

THE THIRD CLIP IS LOCATED

IN THE CENTER OF THE PLENUM

LENGTH

THREADED ROD

OPTION #3

OPTION #1

OPTION #1

THE HOOD AND IS MOUNTED TO THE ASP

HOOD UP CANTILEVERS OVER THE END OF

THE UNI-STRUT (U-CHANNEL) THAT HOLDS THE

HANGER BRACKETS

OPTION #2

OPTION #2

UNI-STRUT SUPPLIED BY OTHERS

OPTION #1 = HANGING CLIP

OPTION #2 = UNI-STRUT

OPTION #3 = THREADED ROD

OPTIONAL UTILITY CABINET

SUPPLIED BY OTHERS

ASP, FSP, VSP

11.5

USING THE SUPPLY PLENUM CLIP or UNI STRUT

OPTION #1

HANGING CLIP COULD BE 23.5" FROM

END IF THERE IS A UTILITY CABINET

ON THE END OF THE HOOD

OPTIONAL UTILITY CABINET

11.5

23.5

OPTION #2

UNI-STRUT SUPPLIED BY OTHERS

TOP VIEW

HOOD

OPTION #1

FOR PLENUMS <= 96"

2 CLIPS ARE NEEDED

FOR PLENUMS > 96"

3 CLIPS ARE NEEDED

THE THIRD CLIP IS LOCATED

IN THE CENTER OF THE PLENUM

LENGTH

OPTION #1

ATTACH HANGING CLIP TO

HOOD STANDING SEAM WITH

THE SUPPLIED "C" CLAMPS

(OPTIONAL: DRILL AND BOLT A

1/4-20 SS BOLT THROUGH

THE CLIP AND HOOD STANDING

SEAM)

TOP VIEW

SUPPLY PLENUM

HANGER BRACKET

Using the Supply Plenum Clip

1. Bolt the hanging clip to the supply

plenum - 2 clips are needed for plenums

less than 96 in. long and 3 for plenums

greater than 96 in. The third clip is

located in the center of the plenum

length. If there is a utility cabinet, the

hanging clip should be 23.5 in. from the

end to the hood.

2. Using the C-Clamps provided, clamp the

supply plenum hanging clip to the hood

standing seam. Option: Drill and bolt a

1/4-20 SS bolt through the clip and hood

standing seam.

"C" CLAMP

HOOD FRONT

HOOD STANDING SEAM

HANGING CLIP BOLTED TO PLENUM SHELL

HANGING CLIP

SUPPLY PLENUM SHELL

OPTION #1

HANGING CLIP

October 2010

Supply Plenum Clip

Using the UNI-STRUT

1. The uni-strut (supplied by

others) that holds the hood up

cantilevers over the end of the

hood and is mounted to the

supply plenum hanger brackets.

11

11

Page 12

INSTALLATION INSTRUCTIONS FOR EXTERNAL SUPPLY PLENUMS

BACKSUPPLY BACKSHELF HOODBACKSUPPLY CANOPY STYLE HOODBACKSUPPLY CANOPY STYLE HOOD

ATTACHED AIR CURTAIN CANOPY STYLE HOOD ATTACHED AIR CURTAIN CANOPY STYLE HOOD

BACKSUPPLY BACKSHELF HOODBACKSUPPLY CANOPY STYLE HOODBACKSUPPLY CANOPY STYLE HOOD

1/4 in.

SS NUT

1/4 - 20 UNC - 2A

SS BOLT

SS FLAT WASHER

HOOD

HOLE SIZE 9/32 in.

USING A THREADED ROD

Installing External Supply Plenum

1. Insert 1Ú2 in. diameter threaded rod (by others) into

hanger brackets on the supply plenum top. Raise and

hang the external supply plenum from adequate roof or

ceiling supports.

2. The external supply plenum should be resting lightly

against the hood. The hood is used to position the plenum

only, it is not intended to support the plenum. All hanger

brackets must be used and the plenum must be properly

supported while lifting to prevent damage or distortion.

ASP - Air Curtain Supply Plenum

The supply plenum must be hung level to operate properly.

(Optional fastening of supply plenum to hood - see

directions below)

3. It is recommended that caulk be applied at the mating

seams and surfaces of the plenum, the hood, and the wall.

If the supply plenum is next to a wall, you will also need to

caulk around the surface next to the wall. Caulk the joints

with NSF approved silicone caulk (GE SCS-1009, or its

equivalent). The caulk is not provided.

Installing the Supply Duct Collar to the Plenum

1. Place the duct collar(s) over the opening, fastening with

tack welds at 1 in. to 2 in. intervals, or sheet metal screws

at 3 in. to 6 in. intervals.

VSP - Variable Supply Plenum

SUPPLY PLENUM WEIGHTS

Hood Height 24 in. 24 in. 30 in. 30 in.

Hanging Height 78 in. 84 in. 78 in. 84 in.

ASP 9.5 lbs/ft. 11.7 lbs/ft. 11.7 lbs/ft. 13.9 lbs/ft.

VSP 16.5 lbs/ft. 18.7 lbs/ft. 18.7 lbs/ft. 20.9 lbs/ft.

BSP 42 lbs/ft. 42.2 lbs/ft. 42.2 lbs/ft. 44.4 lbs/ft.

Using the UL Listed Fastener Provided

1. Drill a 9/32 in. hole for the 1/4 in. bolt from the inside of the

supply plenum to inside the hood. Fasteners are to be located

max. 6 in. from the end of the hood with max. spacing

between bolts 36 in.

DO NOT include utility cabinets or fillers when figuring bolt

placement.

DO NOT bolt the supply plenum to a fire/utility cabinet.

2. Push bolt through hole, using the washer and nut.

3. Hand tighten, then use a wrench until fully tightened. Caulk

around bolts from inside of hood as necessary.

12

12

October 2010

Page 13

TEP

2

W (MODULE WIDTH

)

W

/2

W

/4

W

/4

TEP

1

IF MODULE > 6 ft.

)

4 in. TO 6 in

.

FASTEN WITH SCREWS, OR TACK WELDS EVER

Y

PLACE THE DUCT COLLAR OVER THE OPENING

,

TEP

2

INSTALLATION INSTRUCTIONS FOR THE BACKSUPPLY PLENUM BSP

W (MODULE WIDTH

)

W

/2

W

/2

W

/2

(MODULE WIDTH

)

W

W

/4

W

/4

TEP

1

IF MODULE > 6 ft.

)

IF MODULE < 6 ft.

)

TEP

1

4 in. TO 6 in

.

FASTEN WITH SCREWS, OR TACK WELD

S

Y

PLACE THE DUCT COLLAR OVER THE OPENING

,

TEP

2

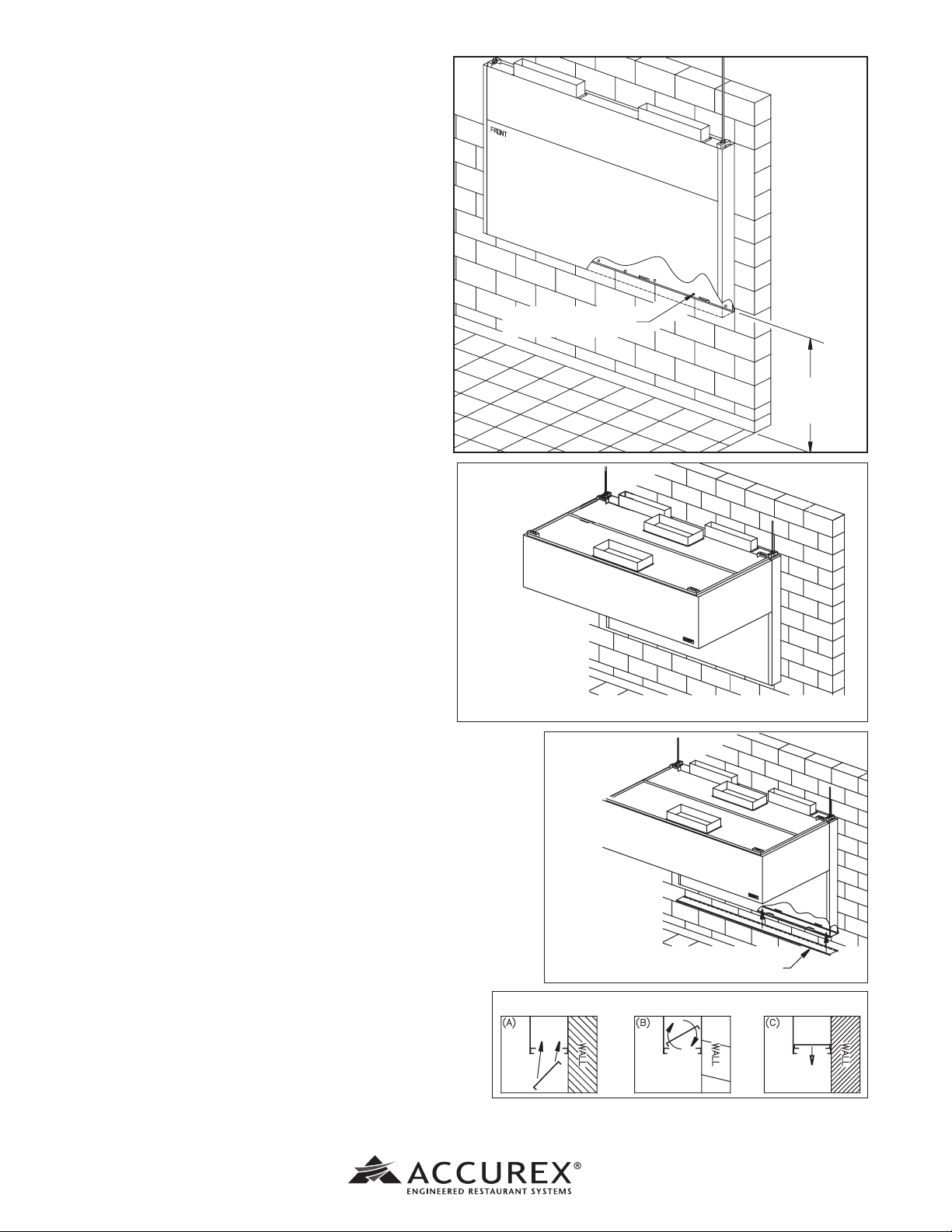

Installing the Supply Duct Collar

1. Find the center of the Backsupply Plenum.

2. If the Backsupply Plenum is less than 9 ft. 10 in. wide, cut opening at

the suggested location, centering the opening over the center of the

backsupply Plenum. (see Fig. 10A)

3. If the Backsupply Plenum is greater than 9 ft. 10 in. wide, divide the

width of the backsupply by four. This will give you the center of each

half. Cut openings at the suggested location, centering the duct collar

over the center measurement of each half. (see Fig. 10B)

4. Place the duct collar(s) over the opening, fastening with screws or tack

welds every four to six inches. (see Fig. 11)

Fig. 10A

Fig. 10B

• The4in.highduct

collar is to be attached

to the backsupply.

Fig. 11

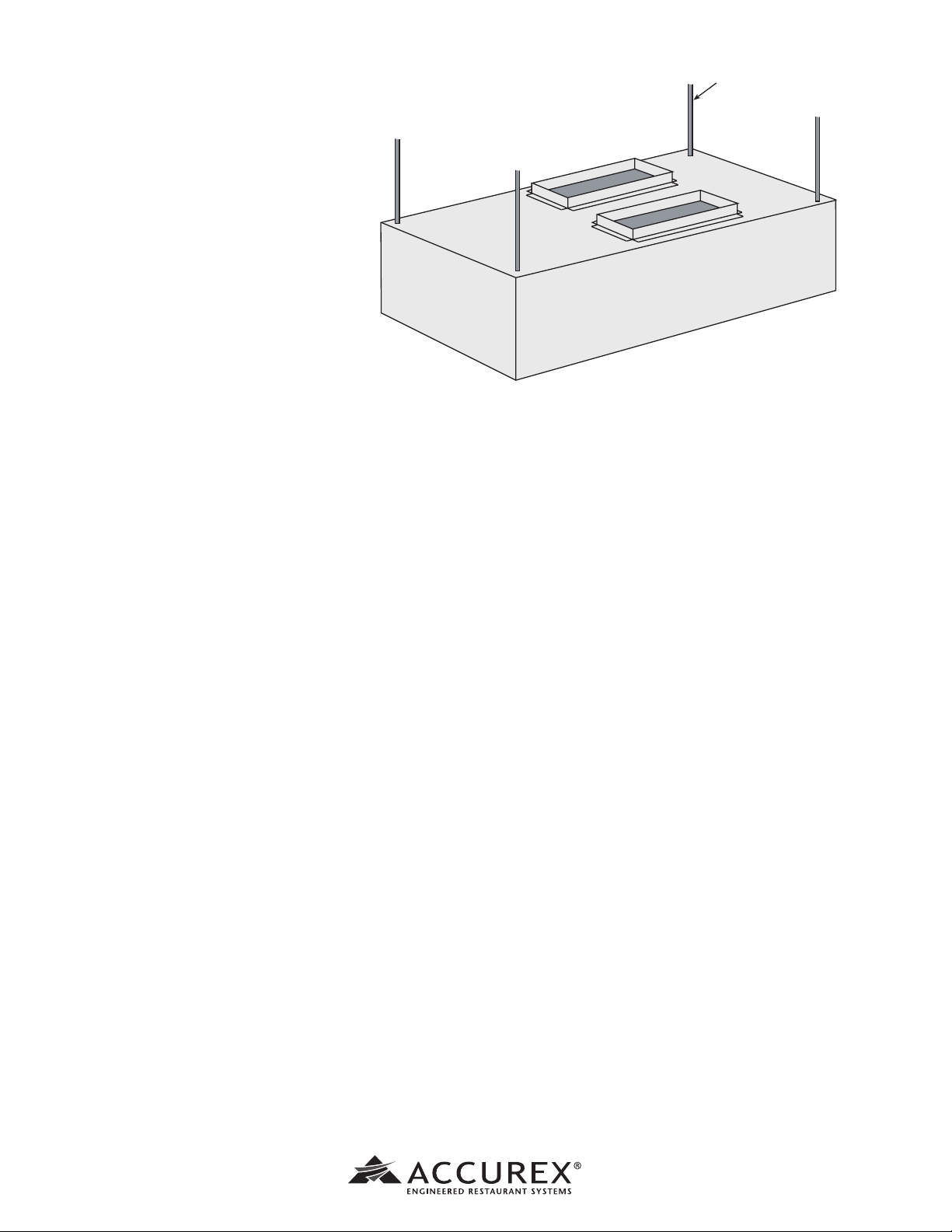

Hanging the Backsupply Plenum

5. Hang the Backsupply Plenum from the ceiling.

(The Backsupply Plenum needs to be mounted 31.25 in. above the floor (based upon a canopy hood that will

be hung at 6 ft. 6 in. above the finished floor. This is measured from the lowest rear edge of the Backsupply

Plenum to the finished floor. Leave 6 to 10 inches of space below the plenum for access to the air diffusers.)

6. Fasten the Backsupply to the wall, going through the lower Backsupply wall. (See Fig. 12)

• These fasteners are to help maintain the location of the Backsupply, and are not intended to hold the weight

of the Backsupply Unit.

• The fasteners should not interfere with the removable air diffusers.

• The 31.25 in. height is based upon the canopy hood hanging height of 78 in. from the finished floor to the

bottom of the hood.

October 2010

13

13

Page 14

STEP 3

Furnished by Others

0.500 in. Threaded &

0.500 in. Threaded Nuts

(Furnished by Others)

Hanger Bracket Detail

1) Hang Backsupply Modules from the

ceiling (the example shows the module

being supported with threaded rod)

The backsupply is to be 31.25 in. from the

floor. This is measured from the lowest

rear edge of the backsupply module to the

finished floor.

2) Fasten backsupply to wall through the

lower backsupply wall. These fasteners

are to help maintain location of the

backsupply, and are NOT intended to hold

any weight of the unit. Fasteners should

not interfere with the removable air diffuser.

31.25 in.

Critical

Dimension

Fasteners holding the

backsupply to the wall

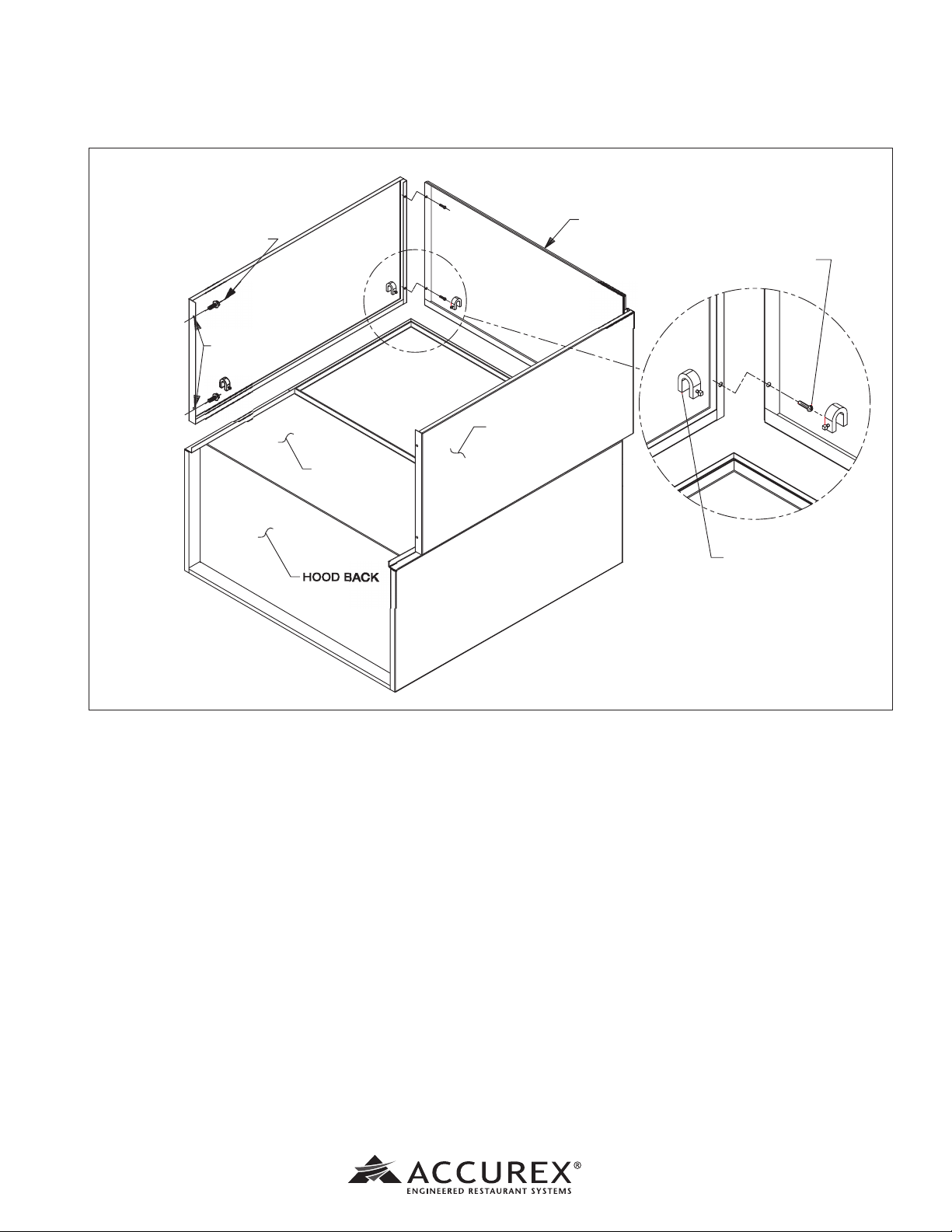

Hanging the Hood

HANG THE H

OOD

INSTRUCTIONS, THE HOOD MAY BE FASTENED TO THE BACKSUPPLY

.

5. CONNECT REMAINING DUCTWORK FOR THE BACKSUPPLY AND TH

E

HOOD. CAULK IS RECOMMENDED TO BE APPLIED AT THE MATIN

G

4. LIFT THE HOOD; POSITION IT SO THE TOP OF TH

E

HOOD IS LEVEL WITH THE TOP OF THE BACKSUPPLY; AFTE

R

THE HOOD IS HUNG FROM THE CEILING AS PER IT'S INSTALLATI

ON

1. THE HOOD IS TO BE HUNG AS PER THE HOODS INSTALLATI

ON

HOULD BE CONNECTED BEFORE THE HOOD IS HUN

G.

3. DUCTWORK FOR THE BACKSUPPLY; IF IT WILL NOT INTERFERE

,

2. BEFORE THE HOOD IS HUNG THE BACKSUPPLY MUST BE SECURE

D

INSTRUCTIONS AND THE FOLLOWIN

G.

PROPERLY, AS DESCRIBED IN "STEP 3 in

.

TEP

4

STEP 5

Air Diffusers

(A) Insert the air diffusers at an angle from the bottom.

(B) Rotate the diffusers so the forms are downward.

(C) Rest the diffuser on the internal angles.

Canopy Style Hood

Removable Air Diffusers

Before hanging the hood according to the hood

installation instructions, please check the following:

1. Make sure the Backsupply Plenum is properly

secured, as described in steps 5 and 6, page 13.

2. If the ductwork for the Backsupply will not

interfere with the hood installation, it should be

connected now.

3. Any filler panels should be attached to the hood

before the hood installation. See page 16 for

instructions.

4. For Canopy Hoods: Lift the hood, and position

it so the filler panels are resting lightly on the

top outside edges of the Backsupply. The

Backsupply is used to position the hood only,

it is not intended to hold any hood weight. (See

Fig. 13)

5. Connect the remaining ductwork for the

Backsupply and the hood. It is recommended

that caulk be applied at the mating seams and

surfaces of the Backsupply, the hood, and the

wall.

Fig. 12

Air Diffusers

The air diffusers, located at the bottom of the backsupply

(See Fig. 14), will need to be cleaned as often as the

application dictates. Inspect periodically to determine the

cleaning schedule.

1. To clean the air diffusers, unfasten the screws. Remove

the air diffusers from the Backsupply Unit, and wash in

the sink or dishwasher.

2. Insert the air diffusers at an angle from the bottom, and

rotate so the forms are downward. Rest the diffuser on

the internal angles. (See Fig. 15)

3. Refasten with the stainless steel screws.

Return to Page 8.

14

14

Fig. 13

Fig. 14

Fig. 15

October 2010

Page 15

OSURE

OP

OSURE

S

L

E

.

H

S

ENCLOSURE PANEL INSTALLATION INSTRUCTIONS

Before installing the enclosure panels, make sure the hood is hung in position with all the ductwork attached

and electrical connections completed.

FRONT ENCL

FASTENERS TO WAL

BY OTHER

3/8 IN. DIA

HOL

ND ENCL

HOOD T

PANE

5/16 IN. BOLTS WIT

NUTS AND WASHER

LAMP

Fig. 16

1. Position the end enclosure panels on the hood, and clamp into place with clamps provided or tack weld the

panels into place (see Fig 16).

2. Fasten the end enclosure panels to the wall, method depends on wall construction. (fasteners are not

provided)

If the hood is a double island, bolt the end enclosure panels together. (fasteners are not provided)

3. Position the front enclosure panel(s) on the hood, and bolt to the end enclosure panels with the 5/16 in.

bolts provided in the hardware package.

4. Tack weld or clamp the front enclosure panel(s) to the hood. If clamps are used, they must be positioned

4 inches from the ends, and in the center of the front enclosure panel.

5. To allow for ease of cleaning, caulk the external seams with NSF Approved silicone caulk (GE SCS-1009, or

its equivalent). The caulk is not provided.

6. Installation instructions may not be applicable for concrete ceilings.

Return to Page 9.

October 2010

15

15

Page 16

OO

G

L

H

S

CK

FILLER PANEL INSTALLATION INSTRUCTIONS

1. Uncrate the hood and

lay it on the floor with

protective material

between the hood and the

floor (See Fig. 8, page 8).

2. Bolt the filler panels

together with 5/16 in. bolts

provided in the hardware

package.

3. Position the filler panels to

the hood back, and tack

weld them into place (see

Fig. 17).

4. To allow for ease of

cleaning, caulk the

external seams with NSF

approved silicone caulk

(GE SCS-1009, or its

equivalent). The caulk is

not provided.

Fig. 17

H

HOOD

HOOD

D

Return to Page 8.

HT FILLER PANE

RI

TACKWELDED TO HOOD BA

5/16 IN. X 3/4 IN. BOLTS WIT

WASHERS & NUT

16

16

October 2010

Page 17

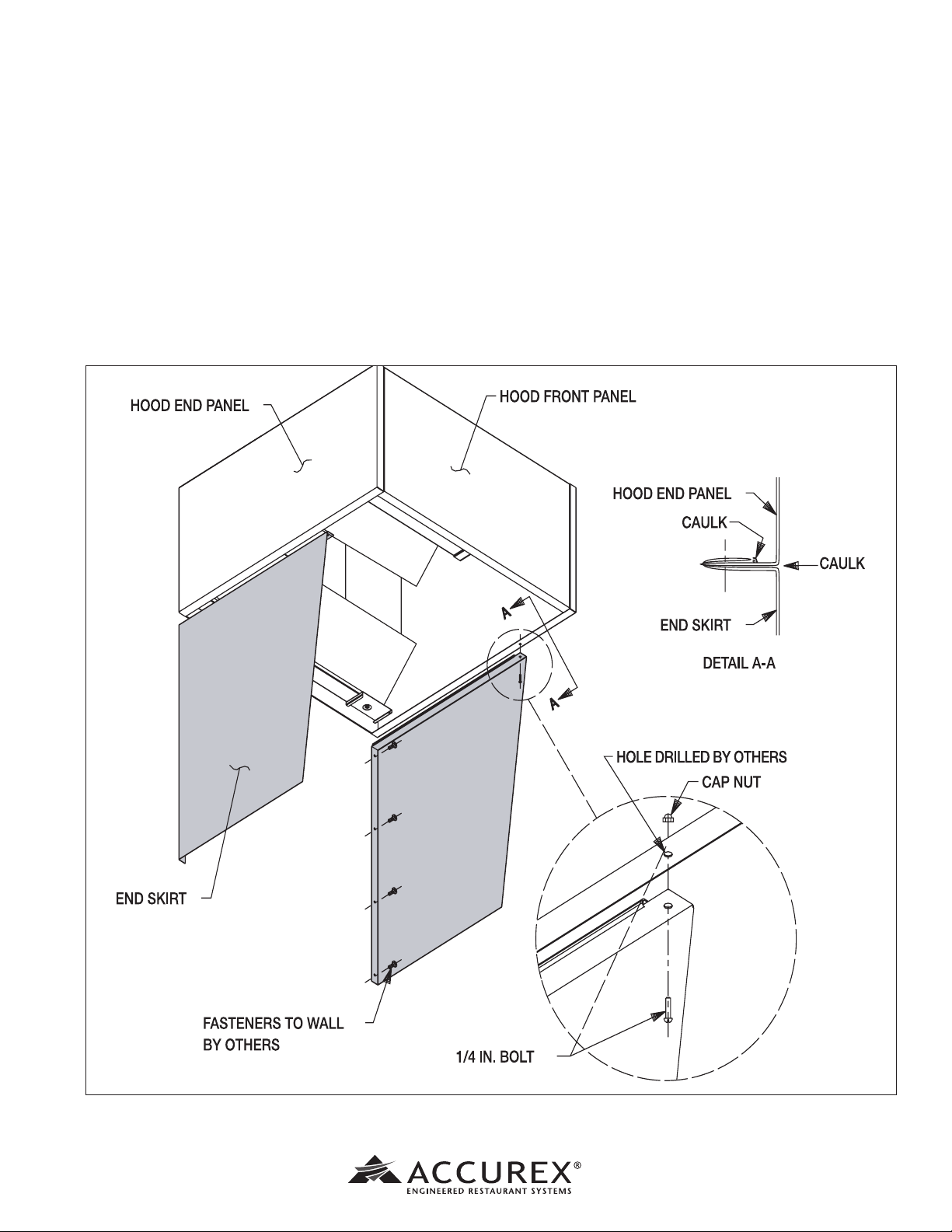

END SKIRT INSTALLATION INSTRUCTIONS

1. After the hood is hung in position, slide the hemmed form on top of the end skirt onto the end panels of the

hood.

2. Drill a hole in the hood end panel to line up with the hole in the end skirt. Attach the end skirt with a 1/4 in.

bolt and cap nut to the inside of the hood, or tack weld the end skirt to the hood.

3. Position the end skirt against the wall and attach. The method depends on the wall construction. (fasteners

for this are not provided)

4. Caulk the internal joint formed by the end skirt and the hood end panel with NSF approved silicone caulk

(GE SCS-1009 or its equivalent). The caulk is not provided.

5. To allow for ease in cleaning, also caulk all the external seams.

Return to Page 9.

Fig. 18

October 2010

17

17

Page 18

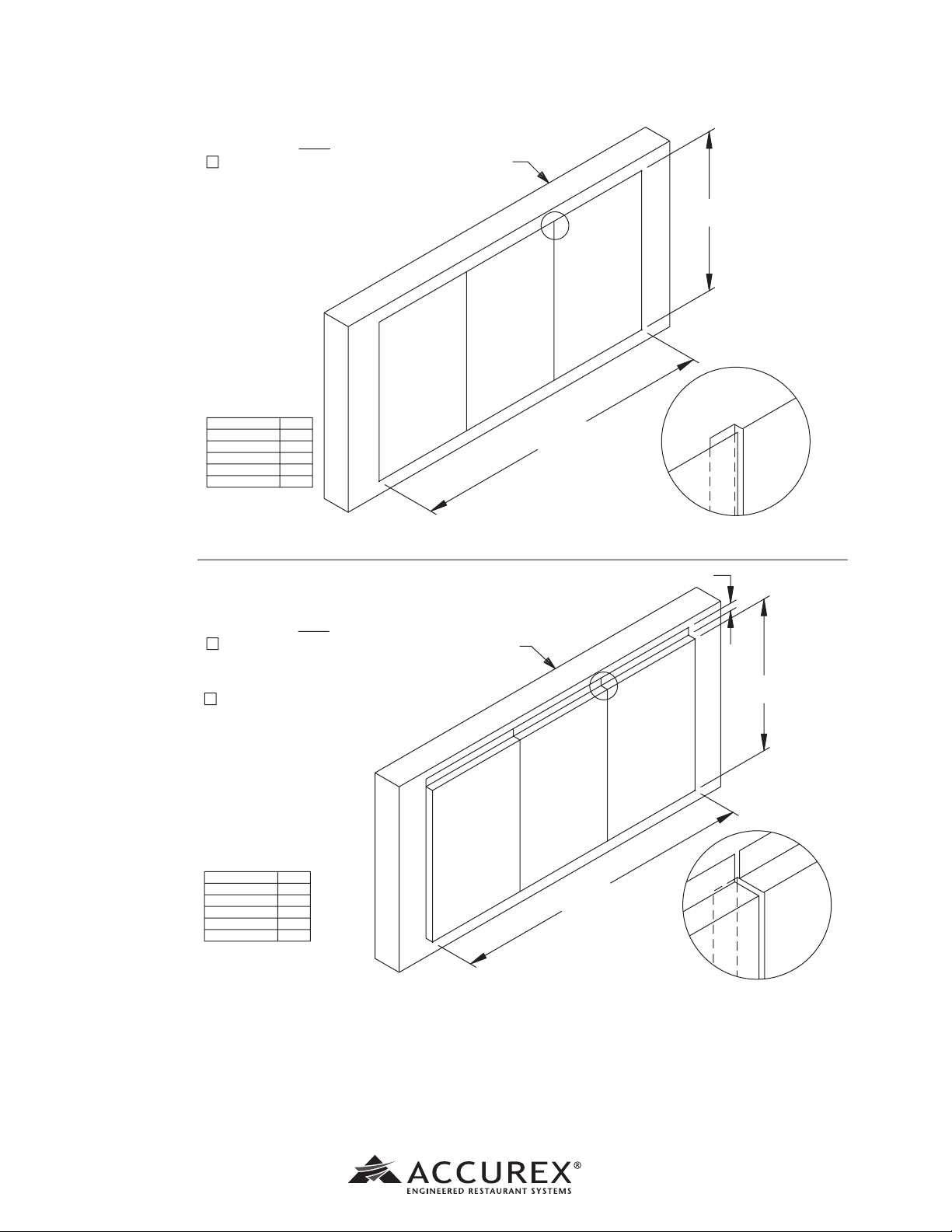

BACKSPLASH PANEL INSTALLATION INSTRUCTIONS

HOLES SHOULD BE SPACED TO

ADEQUATELY SECURE THE PANEL

TO THE WALL STUDS (HOLE SPACING

AND FASTENERS PROVIDED BY OT HERS)

BACKSPLASH PANEL

HOOD END PANEL

HOOD FRONT PANEL

SLIDE FLANGE

BEHIND BACK

OF THE HOOD

SECTION VIEW

OF BACKSPLASH

PANEL OVERLAP

1. After the hood is

hung in position, slide

the flat flange of the

backsplash panel

behind the back of the

hood.

Note: If the backsplash

panel length is greater

than 46 in., it will be

shipped in multiple

pieces.

2. After the backsplash

panel has been

positioned, drill holes

in the panel and fasten

to the wall. (fasteners

provided by others)

Note: The holes

should be spaced to

adequately secure the

panel to the wall.

3. Caulk the joints

between the hood and

the backsplash panel

with NSF approved

silicone caulk (GE

SCS-1009, or its

equivalent). The caulk

is not provided.

Fig. 19

4. Caulk the joint

between the

backsplash panels

when multiple panels

are required, with NSF

approved silicone

caulk (GE SCS-1009,

or its equivalent). The

caulk is not provided.

Return to page 9

18

18

October 2010

Page 19

FLAT BACKSPLASH PANEL

MATERIAL GA.

(S) STAINLESS

WALL

HEIGHT

LENGTH

<=48

>48<=94

>94<=141

>141<=188

>188<=235

QTY

1

2

3

4

5

LENGTH

NOTE: PANELS UP TO 48 INCHES WIDE SHIPPED IN 1 PIECE, OVER 48 INCHES IN MULT IPLE PIECES.

1.000

INSULATED BACKSPLASH PANEL

MATERIAL GA.

(S) STAINLESS

INSULATION

1 IN.

WALL

HEIGHT

October 2010

LENGTH

<=46

>46<=91

>91<=136

>136<=181

>181<=226

QTY

1

2

3

4

5

NOTE: PANELS UP TO 46 INCHES WIDE SHIPPED IN 1 PIECE,

OVER 46 INCHES IN MULTIPLE PIECES.

LENGTH

19

19

Page 20

DUCT COLLAR INSTALLATION INSTRUCTIONS

O

NTINUOUS LIQUID TIGHT WEL

D TO HOO

D.

EXHAUST

DUCT CONNECTION IS TO B

E

CONNECTION

EXHAUST

DUC

T

1" TO 2" TACKS OR SHEET METAL SCREWS AT 3" TO

6" SPACING TO HOO

D.

S

UPPLY

DUCT CONNECTION TO BE TACK WELDED WITH

C

ONNECTIO

N

S

UPPLY

DUC

T

PPL

Y

PPL

Y

HAMBE

R

HOOD

INSULATE

D

PPLY PLEN

UM

EXHA

UST

APTURE

FOR XB, XW, XK, XX, & XG SERIES HOODS

1. The exhaust duct

connection needs to be

located within 48 in. from

the center of the hood

length to the center of

the duct connection.

(see Fig. 20A)

2. The exhaust duct

connection is to be a

continuous liquid tight

weld. Weld with a non-

ferrous filler wire,

such as silicon bronze

or stainless steel

filler wire. Protect all

stainless steel areas

from weld splatter.

3. The supply duct

connection is tack

welded at 1 in. to 2 in.

intervals, or sheet metal

screws at 3 in. to 6 in.

spacing to the hood.

(see Fig. 20B)

8.00

Top View of the Hood

Hangar Bracket

Exhaust Plenum

Supply Plenum

Hood Length

Duct Cut Out Area

Front of Hood

3.00

10.00

Hood Width

16.00

3.00

8.00

Fig. 20A

4. The deflector is centered

under the supply duct

collar. (see Fig. 20C)

5. For hoods that are

insulated, the edges of

the insulation need to

be taped after the hole

is cut, (the insulation

tape is to be provided by

others).

6. On combination hoods,

make sure the fire

damper is located over

the internal supply

chamber. (see Fig. 20D)

Return to page 9.

Fig. 20B

Fig. 20C

Note: UL listed hood

DEFLECTOR TO BE PLACED CENTERED

UNDER THE SUPPLY DUCT COLLAR

Fig. 20D

assembly to be used

only with Accurex

Fan Corp. labeled

subassembly for

exhaust hood without

exhaust damper part

Number DC.

20

20

October 2010

Page 21

Plumbing

Mounting the Control Station:

The control station can be either surface mounted or recessed mounted within the wall. For recessed mounts,

provisions must also be made for piping and electrical wiring within the wall. Holes are provided in the top and

bottom of the control station for piping and wiring. Use four holes provided in the back of the cabinet to attach it

to the wall.

A trim ring is available as an option for recessed mounting of the panels.

Plumbing:

All plumbing must be done according to all applicable national and local building codes.

1) Waterwash Engineering Specifications:

Control Panel

Size

1 3/4 inch 0 ft. - 10 ft. 2.5 gal.

2 1 inch 10 ft 1in. - 20 ft. 0 in. 2.5 gal.

Plumbing Size Hood Length

Detergent Tank

Capacity

Hot Water Requirements

Water Pressure - 40 to 60 psi

Water Temperature - 140°F to 180°F

Average Water Consumption - 1.25 GPM per lineal foot of hood (2.5 GPM for double islands).

Hot Water Flow

Hood Number Water Flow in GPM

Length of Nozzles @40psi @60 psi

4 ft. 0 in. 12 4.8 6.0

4 ft. 6 in. 14 5.6 7.0

5 ft. 6 in. 16 6.4 8.0

6 ft. 0 in. 18 7.2 9.0

7 ft. 0 in. 20 8.0 10.0

7 ft. 6 in. 22 8.8 11.0

8 ft. 6 in. 24 9.6 12.0

9 ft. 0 in. 26 10.4 13.0

10 ft. 0 in. 28 11.2 14.0

10 ft. 6 in. 30 12.0 15.0

11 ft. 6 in. 32 12.8 16.0

12 ft. 0 in. 34 13.6 17.0

13 ft. 0 in. 36 14.4 18.0

13 ft. 6 in. 38 15.2 19.0

14 ft. 6 in. 40 16.0 20.0

15 ft. 0 in. 42 16.8 21.0

16 ft. 0 in. 44 17.6 22.0

NOTES: For hood lengths not listed above, use the data for the next smaller hood length listed.

For hoods that are washed together, or for groups of sequenced hoods, determine the number of gallons

per minute required by each hood from the table above and add those values for the total gallons per minute

required for the group of hoods.

October 2010

21

21

Page 22

Plumbing & Electrical

2) Optional Continuous Cold Water Mist Engineering Specifications:

Minimum

Control Panel

Pipe Size

3/4 in. 50 ft. or less 1/2 in. 4 gpm 3/8 in.

3/4 in. 100 ft. or less 3/4 in. 8 gpm 3/8 in.

Cold Water Requirements

Water Supply 30-60 psi

Average water consumption 0.1 gpm per linear foot of hood

Set pressure reducing valve to 25 psi on the gauge in the cabinet when running.

3) Water Supply to Cabinet:

Connect hot water supply to waterwash pipe fitting at bottom of control station. Connect cold water supply

to optional continuous cold water mist pipe fitting at bottom of control station. The water requirements to the

cabinet are detailed in the Engineering Specifications.

Optional Reduced Pressure Backflow Preventer:

Water solenoid valves and detergent line are factory-mounted inside the control panel (See Fig. 5, 6 & 7, page

7). The reduced pressure backflow preventer and strainer (provided) must be field piped in the supply line before

the control panel. The backflow preventer relief valve must also be piped to a drain.

Total Hood

Length

Cabinet to

Hood Pipe Size

by others

Maximum

Water Usage

Hood

Pipe Size

4) Control Cabinet to Hood Plumbing:

The waterwash plumbing requires 3/4 in. or 1 in. pipe (by others) depending on the length of hood in each

washing sequence. The optional continuous cold water mist plumbing requires 1/2 in. to 3/4 in. pipe (by others)

depending on the total length of hood. Only reduce to 3/8 in. at the hood connection.

See the Engineer Specifications for information on the pipe size required.

For Systems with a Vacuum Breaker:

Piping from control station to hood includes a detergent line and a vacuum breaker. The vacuum breaker must

be installed at the highest point in the system (and a minimum of 6 in. above the hood water supply line). The

detergent line joins the supply line downstream from the vacuum breaker as shown in Fig. 2, 3 & 4, page 7.

Where optional solenoid valves are used in systems with multiple hood sequence washing, additional piping

must be installed downstream from the vacuum breaker. Hot water/detergent supply pipe connects to hood piping at top rear corner of hood.

5) Drain Connection:

Install hood drain pipe at bottom rear corner of hood as shown in Fig. 1. A 2 inch NPT female fitting is provided.

A grease trap is recommended in the drain to avoid clogging the sanitary sewer. If a RPBP is shipped with the

control panel, an air gap assembly may be required and will need to be plumbed to a sanitary sewer. See drawing on page 42 of the drawing diagram section of this manual.

22

22

October 2010

Page 23

Electrical

B. Electrical Wiring:

All wiring must be done according to NEC (National Electrical Code NFPA #70) and local building codes.

A terminal block is provided in the electrical compartment of the waterwash control station for all wiring

connections. (See Figs. 21 & 22 on page 24. See also separate wiring diagram.)

NOTE: The waterwash control station must be wired to the exhaust fan controls and optionally

to the hood’s fire protection system.

Wiring to waterwash control station is 115 VAC, 20 AMP separately fused service.

Wiring from waterwash control station to fan control center is configured as a normally-open dry contact.

However, it can be configured by others to provide 115 VAC, 1 AMP (max) control power to the fan control

center. If the fans are controlled by a building management system, it may be necessary to reprogram the

control panels PLC to eliminate having to push the start fan & start wash buttons to initiate a wash cycle. A

24-hour timer is then required to initiate the wash cycle.

Wire hood light switch to junction box on top of hood.

Wire waterwash control station terminals to fire suppression system microswitch in the Fire Suppression Control

Cabinet (a normally-closed dry contact switch). If this switch or jumper is not installed, the waterwash system

will operate in fire mode continuously. (This is not required but will provide added protection during a fire and

the control panel is shipped with a jumper between terminals 5 & 6 which must be removed when connecting to

the fire system micro-switch)

For optional sequence washing of multiple hoods, use one of the following:

A) Controls with vacuum breakers (See Fig. 2, 3 & 4, page 7)

B) Controls with backflow preventers with waterwash only (See Fig. 5, page 7)

C) Controls with optional continuous cold water mist and backflow preventer (See Fig. 6 & 7, page 7)

October 2010

23

23

Page 24

Electrical

TERMINAL STRIP IN GREENHECK MODEL

KSU

UPPLSUPPLYFAN CONTROL CENTER

Electrical Service

ELECTRICAL SER VICE

FOR WA TER

for Waterwash

CONTROL

Control Station

120/60/1

120/60/1

L1 NG

L1 N G

12 345678 9101112131514

Terminal Strip in Accurex

MUA Control Center

R

3

RG

N.C. FIRE CONT AC T

N.C. Fire Contact

N.C. FIRE SYSTEM SWITC H

N.C. Fire System Contact

NEUTRA

NEUTRA

Neutral

Neutral

Fig. 21 Typical Field Wiring for

Waterwash Control Station to

Accurex MUA Control Center

SEE WATER W ASH CONTROL

See Waterwash Control Station

Wiring Diagram for Exact Layout

WIRING DIAGRAM FOR EXACT LAYOUT

120/60/1 to Hood Lights

120/60/1 TO HOOD LIGHTS

SEQUENCE

Sequence

SEQUENCE

Sequence

SEQUENCE

Sequence

SEQUENCE

Sequence

SEQUENCE

Sequence

120/60/1 to Optional

Remote Solenoid

120/60/1 TO OPTIONAL

Valves for Sequence

REMOTE

Washing

VA LV ES FO R

WA SHIN

Motor Circuit Control Voltage

MOTOR CIRCUIT CONTROL

L1 N G

N.C Fire

N.C. FIRE

CONTACT

Contact

Electrical Service

ELECTRICAL SERVICE

for Waterwash

FOR WATER

CONTROL

Control Station

120/60/1

120/60/1

L1

L1 N G

NG

Fig. 22 Typical Field Wiring

for Waterwash Control

GNL1

SUPPLY POWER FOR FAN

Supply Power for Fan Motors

Station to Field Furnished Fan

Controls

L2

L1

L3

L1L2L3

OL

T3

T1

T2

T1

T3

T2

Supply

Motor

N.C. FIRE SYSTEM SWITCH

N.C. Fire System Contact

NEUTRA

NEUTRA

Neutral

Neutral

O.L.O.L.

L2

L3

L1

L1

L2 L3

All Components and

ALL COMPONENTS

WIRING BY OTHERS

Wiring By Others

T3

T1

T2

T1OLT2

T3

Exhaust

Motor

SEE WATER WASH CONTROL

See Waterwash Control Station

WIRING DIAGRAM FOR EXACT LAYOUT

Wiring Diagram for Exact Layout

120/60/1 to Hood Lights

120/60/1 TO HOOD LIGHTS

Sequence

SEQUENCE

SEQUENCE

Sequence

SEQUENCE

Sequence

SEQUENCE

Sequence

SEQUENCE

Sequence

120/60/1 to Optional

Remote Solenoid

120/60/1 TO OPTIONAL

Valves for Sequence

REMOTE

VALVES FOR

Washing

WASHIN

24

24

12 345678910 11 12 13 1514

Terminal Strip in Accurex Waterwash Control Station

TERMINAL STRIP IN GREENHECK WATER WASH CONTROL PANEL

October 2010

Page 25

Instructions for programming the

Waterwash Control Panel (WWCP)

24-hour or 7-day timer

If your waterwash control panel included a timer, either 24-hour or 7-day, it will need to be

programmed prior to kitchen start-up. The timer was shipped with a 3-year battery installed

and was tested before leaving the factory.

The function of the timer is to start the hood wash sequence after all cooking and dish

washing operations have ended for the day, so that all available hot water may be used in

washing the hood baffles.

The daily sequence of operations is:

1. Press the “Start Fan” button at the beginning of the day to start the fans.

2. Press the “Stop Fan / Start Wash” button at the end of the day to stop the fans.

A. This will initiate the wash timing delay

B. To wash the hood immediately, press the “Stop Fan / Start Wash” button a second time.

3. After all wash sequences have been completed, the WWCP will reset for the next day’s operation.

Programming Instructions:

1. Remove the clear plastic cover over the 6 buttons by gently lifting out at the top.

2. Press the “MODE” button until “CLK” is displayed in the upper left corner.

3. Press the “DAY” button until the correct day is shown at the bottom of the display.

4. Press the “H+” and “M+” buttons to set the correct time. “AM” or “PM” is shown at the left side of the

display.

5. Press the “MODE” button once. “PRG” should be displayed.

A. On the right side of the screen should be a “1” and “ON”. This is the first program.

There are 6 available to use. Normally only one is used for 24-hour timing and the other 5 can be used

for 7-day timing.

B. With 24 hour timing, the wash cycle will start the same time everyday.

6. Press the “DAY” button until the correct day or days appear at the bottom of the display. Use “MO TU WE

TH FR SA SU” for 24 hour timing.

7. Press the “H+” and “M+” buttons to set the time the wash is to start.

8. Press the “ON/OFF EVENT” button once. “OFF” and “1” should be on the right of the display.

9. Set the off time to be 5 minutes after the on time for this program.

10. If using as a 7-day timer, use the “ON/OFF EVENT” button and repeat steps 6-9 to set the other programs

as needed.

11. Press the “MODE” button once. “AUTO” should be displayed.

12. Replace the clear plastic cover over the buttons.

13. The hood may also be manually washed any time the fans are off by pressing the clear plastic button

cover. “ON” should appear on the right side of the display.

October 2010

25

25

Page 26

Waterwash Timing Adjustment for PLCs:

(PU214 & CPU224)

SEQUENCE OF WASH OPERATIONS

15 SEC. COLD WATER PURGE (OPTIONAL 30 SEC.)

4 MIN. WASH (OPTIONAL 0 TO 10 MIN.)

30 SEC. DETERGENT PURGE (OPTIONAL 1 MIN.)

Fig. 23A

15 MIN. SEQUENCE DELAY (OPT. 0 TO 45 MIN.)

1 MIN. DRAIN DOWN (OPTIONAL 10 MIN.)

1 MIN. DRY (FANS ON) (OPTIONAL 10 MIN.)

SIEMENS

SIMATIC

S7-200

SF

RUN

STOP

OPTIONAL FIELD INSTALLED

JUMPERS FOR ADDITIONAL TIME

24V FROM OUTPUT 0.2

OR OTHER ALWAYS "HOT"

24V ELECTRICAL SOURCE

MAIN

FANS

SEQ. 1

SEQ. 2

FAN ON

OFF / WASH

FIRE

TIMER

2L*0.30.20.10.01L

0.4

SEQ. 3

SEQ. 5

SEQ. 4

PROGRAMMABLE

CONTROLLER

+15 SEC. COLD

+30 SEC. DET.

+9 MIN. DRIP

+9 MIN. DRY

2M

4. ADDING 120V JUMPERS WILL:

5. RECONNECT POWER.

L1N1.11.00.73L*0.60.5

OUTPUTS

CPU 224

FIRE

AC/DC/RLY

PUMP

SUPPLY

RUN

TERM

STOP

10

SEQ.

WASH

DELAY

TIME

INPUTS

L+M1.51.41.31.21.11.00.70.60.50.40.30.20.10.01M

TERM. 0.4 - ADD 15 SECONDS TO COLD WATER PURGE

TERM. 0.5 - ADD 30 SECONDS TO DETERGENT PURGE

TERM. 0.6 - ADD 9 MINUTES TO DRAIN DOWN TIME

TERM. 0.7 - ADD 9 MINUTES TO FAN ON DRY TIME

1. DISCONNECT POWER BEFORE SERVICING.

WASH TIME

4 MIN.

0

POTENTIOMETERS:

2. WITH A SMALL SCREDRIVER

AJDUST TO THE DESIRED SETTING.

DO NOT FORCE SCREW PAST ITS STOPS.

3. NEW SETTING WILL TAKE EFFECT

WHEN POWER IS REAPPLIED.

7 MIN.

10 MIN.

SEQ. DELAY

0

20 MIN.

60 MIN.

40 MIN.

DETERGENT PUMP:

For proper operation of the detergent pump and wash system, hot water pressure must be between 40 PSI

(min.) and 60 PSI (max.). The water temperature range is 140°F to 180°F.

Water pressure, water temperature, grease accumulation, wash cycle length, wash cycle frequency, and the

type and amount of detergent used can influence cleaning effectiveness. In very heavy cooking operations,

additional washes may be necessary. The wash time can also be increased to a maximum of 10 minutes; the

wash time is factory set at four minutes. Consult Fig. 23A to change the wash time. If this is not effective,

manual cleaning may be necessary (hand scrubbing, steam cleaning or pressure washing).

Adjusting Detergent Pump Output Rate

Adjustment of the detergent flow may be necessary. Pump must be OFF.

Use the following formula to determine proper pump setting: (Adjust pump setting as needed for proper

cleaning.)

0.3 oz./min. x Hood Length = Pump Setting The minimum pump setting is #2.

Pump

Setting

0 1 2 3 4 5 6

Oz./min. 0 1.35 2.7 4.05 5.4 6.75 8.1

Record Original Pump Setting at Start-up for Future Reference

Pump Setting = __________________

1. Knob

6

2. Wing

Nut

5

4

3

2

1

0

5. Screw

Adjust the Detergent Injectors Output:

3. Pointer

4. Yolk

To calculate the number of washes a full detergent

tank will deliver for a specific application, use these

formulas:

1) Pump setting (oz. per min.) x Wash Length (4.0 min. std.)

= Oz. per wash

2) 320 oz. Tank Capacity = Number of Washes per Tank

Oz. per Wash

26

26

1) With the pump and detergent injector off

hold adjustment knob(1) and loosen

wing nut.

2) Turn adjustment knob until the pointer

(3) indicates the desired setting. Six is

the maximum; zero is the minimum.

3) While still holding adjustment knob,

tighten wing nut.

Fig. 23B

October 2010

Page 27

Detergent Requirements

The detergent brand SC-5 (by 2010 Products) is recommended by Accurex for use in the waterwash system.

For normal use in Accurex waterwash hood systems, use SC-5 full strength or as suggested by supplier. This

product is biodegradable, non-caustic, and safe for kitchen staff to use. It can also be diluted with one part SC-5

to one part water for cleaning hood exterior surfaces. To eliminate grease from drains, TDW Bio-Enzyme Grease

Treatment is recommended. This product contains no harsh chemicals, removing grease, fats, and oils with

bacteria and enzymes in a detergent base. Both SC-5 and TDW are manufactured by 2010 Products, Inc., Food

Service Division, Salem, Oregon 97303. For details and ordering information, call 800-286-2010.

Preventive Maintenance

The following practices will prolong the life of the detergent pump:

•Avoidspillingdetergentontheexteriorofthepump.

•Cleanthedetergenttankatleasteverysixmonths.

•Cleanthedetergentlinestraineratleasteverysixmonths.

•Checktightnessofallfittingsperiodically.

•Keepdetergenttankfilled.

The detergent pump motor has sealed bearings which do not require lubrication.

INITIAL SYSTEM START UP:

1. Check electrical power (see wiring diagram page 24, Figs. 21 & 22)

Correct supply voltage

Proper connections to fire suppression system

Proper connections to fan control center

Proper connections to optional remote solenoid valves

2. Adjust the detergent injector’s output (See page 26, Fig 23B)

3. Add detergent to the detergent tank in the cabinet (See page 7, Fig. 4)

4. Flush the piping:

Remove last nozzle from the waterwash piping and from the optional continuous cold water

mist piping in the hood. With the cabinet doors closed press the “Start Fan” button. After

sufficient time press the “Stop Fan/Start Wash” button twice. After sufficient time open the

cabinet doors and replace the nozzles. Clean all strainers in water lines.

5. Close the cabinet doors and press the “Start Fan” button

- Check exhaust and supply air volumes with a pitot traverse or equivalent method

(see page 32 for equivalent method)

- Verify optional continuous cold water mist is spraying

- Set the pressure reducing valve on the optional continuous cold water mist to 25 psi on the

gauge provided.

6. Press the “Stop Fan/Start Wash” button. (Press twice if there is a 24- hour timer)

- Verify the waterwash sequence of operation (page 28, Fig. 24).

- During the wash cycle verify the flow of water. Verify the pressure and temperature on the gauge

provided meets the Engineering Specifications (see page 21).

- During detergent pump cycle verify that it is pumping.

Start up checklist available in the appendix.

DAILY OPERATION OF THE WATERWASH HOOD:

Pressing the Start Fan switch will start the exhaust fans, supply fans, and optional continuous cold water mist.

This can be done at any time, including during wash cycle operations. The only exception is during fire mode.

(See Fig 24).

Pressing the Stop Fan/Start Wash switch shuts down the fans, shuts down the optional continuous cold water

mist, and starts the wash cycle. If the system has a 24 hour timer, the wash cycle will begin at the set time. To

start the wash cycle independently of the timer, press the Start Fan/Start Wash switch a second time. When the

wash is completed, the system will then automatically reset itself.

If the fans are controlled by a building management system (BMS), the steps above still apply unless a special

program is requested to by-pass having to initiate the wash cycle by pushing the stop fan/start wash button.

October 2010

27

27

Page 28

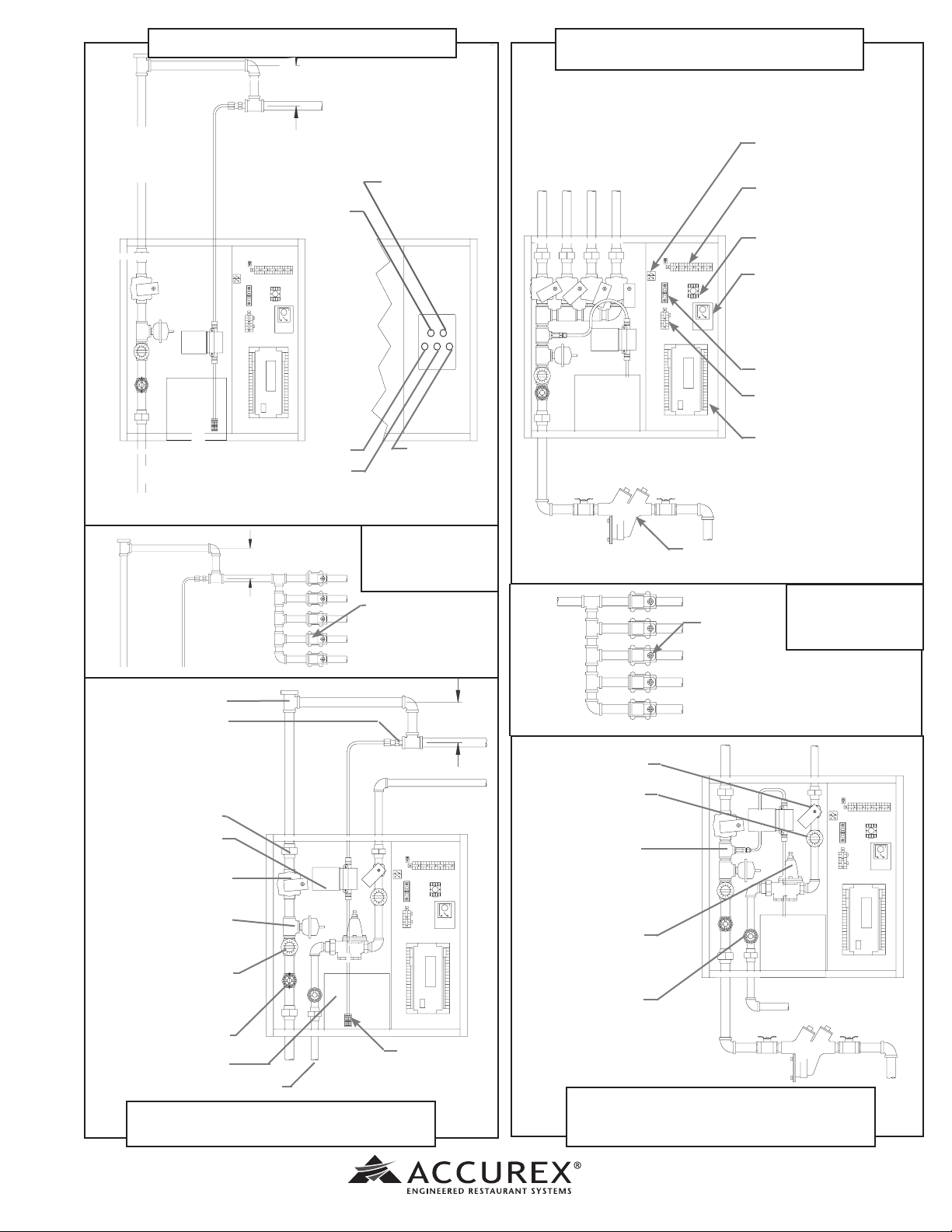

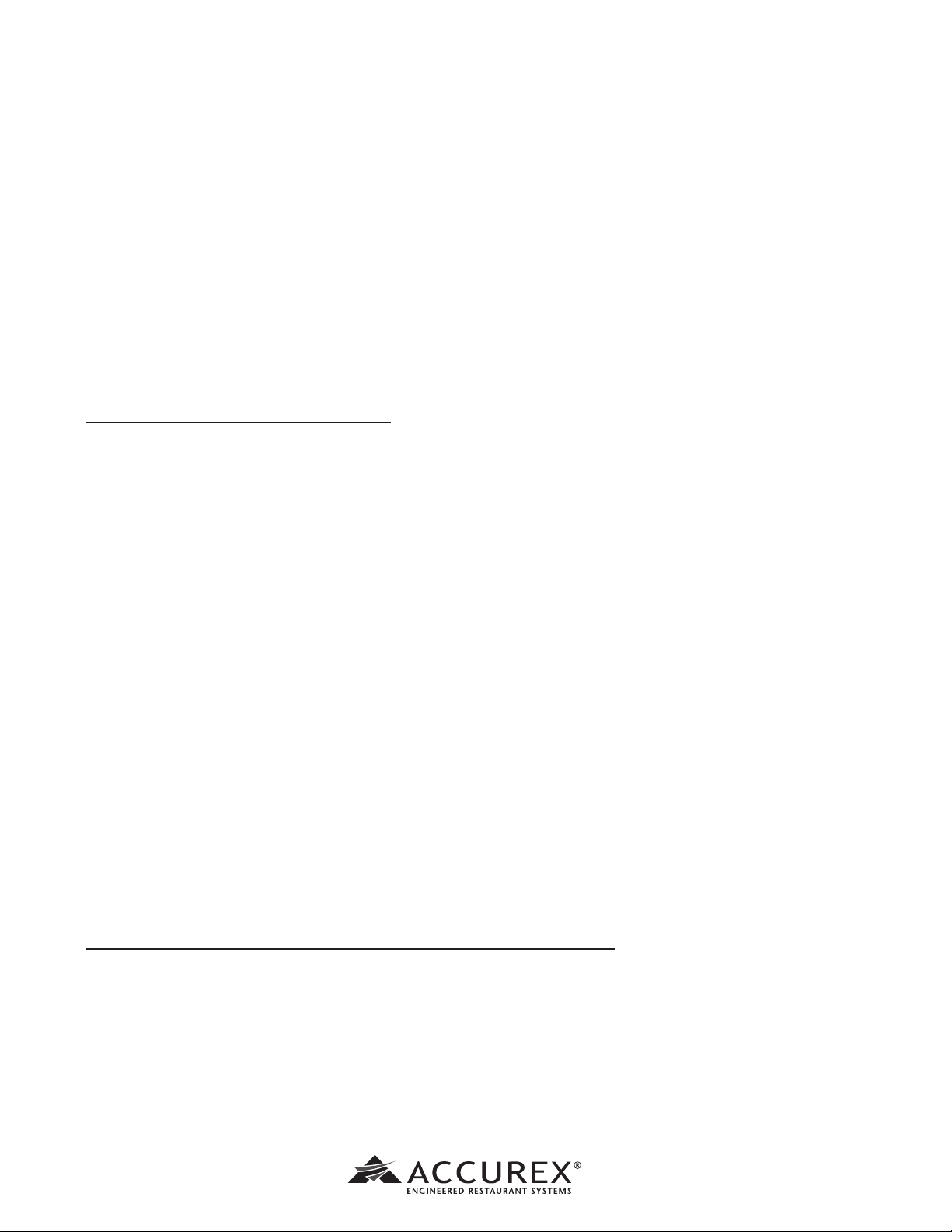

Fig. 24

YES

Do you

Want to

Bypass the

24 Hour Timer?

START

Push Start Fan Button

Exhaust Fan, Supply Fan and Optional

Continuous Cold Water Mist will start

for the normal Cooking Operation.

Start Fan Light ON

Push Stop Fans/Start Wash Button

Exhaust Fan, Supply Fan and Optional

Continuous Cold Water Mist will stop

and allow the wash cycle to initiate.

Start Fan Light OFF

Sequence of Operation

Exhaust Plenum Drip Dry (1 min.)

Allows excess water

to drain from hood.

Stop Fan/Start Wash Light OFF

Exhaust, Supply Fans and Optional

Continuous Cold Water Mist Activate

(1 min.) to exhaust heat and steam

built up in hood. Start Fan Light ON

Dry

Cycle

NO

24 Hour Timer

The Wash Cycle Will Begin at the

Preset Time.

To Bypass the 24 Hour Timer

Press the Stop Fan/Start Wash

Button a Second Time.

Sequence Wash Delay To Allow

Water Heater to Regenerate.

Factory set at 15 Min.

Consult page 26 to Change Delay.

Wash

Cycle

Does the

YES

system have

the 24 Hour Timer

Option?

NO

Cold Water Purge (15 sec.)

Water Solenoid Valve Opens o Allow

Cold Water to be Purged from the

Hot Water line.

Stop Fan/Start Wash Light ON.

Detergent Pump Activates

Detergent will be injected into the

Water solenoid valve remains open

pump stops to allow detergent to

water line

Detergent Pump Stops

Pump run time is factory set

at 4 Minutes. Consult page 26

to change pump run time.

Water Solenoid Valve Closes

for 30 sec. after the detergent

be purged from the line.

Exhaust, Supply Fans and Optional

Continuous Cold Water Mist shut

Fans Stop

down. Start Fan Light OFF.

END

Override

Hoods Automatic Fire Suppression System Activates

N.C. Contacts Open -One to activate waterwash system

fire mode, the other to disconnect the supply fan

Waterwash System Enters Fire Mode

Waterwash and Continuous Cold Water Mist Spray Water in

Hood Plenum. The Fan Circuit is activated. All Lights ON

Are Manual

Shut-off

valves going

to be used?

NO

Fire Mode

YES

Manually Shut-off Water

with Hand Valves

Water Flow Stops

28

28

NO

Is this a single

hood or the last

hood to wash in

a sequence wash

system?

YES

Reset Hoods Automatic Fire

Suppression System

N.C. Contacts Close

Open All Waterwash Hand

Valves

Return to Normal

Reset Hoods Automatic Fire

Suppression System

N.C. Contacts Close

October 2010

Page 29

Accurex Waterwash Sequence of Operations

Siemens PLC S7-200, CPU 214 & CPU 224

The intent of the waterwash control panel(WWCP) is to control the operation of the fans and will start the wash

cycle upon fan shutdown. If hooked up properly, the fans will be off during wash cycles. If the exhaust fan is

being controlled by something other than the WWCP, this panel will still function. To start the wash cycle, you

must still press the “Start Fan” and “Stop Fan/Start Wash” buttons. Washing will either start immediately or

when the 24 hour timer is tripped. A fan interlock should be installed by others to keep the exhaust fan(s) from

sucking water up into the duct(s).

1. Off Mode - At the beginning of a day the following PLC lights will be lit:

Run - Should always be on

I 0.2 - Signal from fire system. Loss of this signal will initiate “FIRE” mode.

I 0.3 - Signal from wash timer (only on at time set on timer). If no timer, this will always be lit.

2. Cooking Mode - Press “Start Fan” button. The following PLC lights will be lit:

Run

I 0.2

I 0.3 - Signal from wash timer (only on at time set on timer). If no timer, this will always be lit.

Q 0.0 - Fans. Combined switching. This will control both exhaust and supply fans. Fan control relay

should be energized. Fans should be on. Optional “Cold Water Spray” solenoid should be

energized and water spraying along entire length of exhaust plenum.

Q 0.7 - Supply fan, not wired from factory. Use this if separate switching is required. Supply fan will

shut down or turn off during a fire.

3. Stop Mode - Press “Stop Fan, Start Wash” button. The fans and optional cold water spray will stop. If there

is a 24 hour or 7 day timer, the wash cycle will start at the time set on the timer. If there is no timer, the wash

cycle starts immediately. To bypass the timer and start the wash cycle immediately, you can either press the

“Start Wash” button a second time or manually trip the timer. The following PLC lights will be lit if not in wash

mode:

Run

I 0.2

I 0.3 - Signal from wash timer (only on at time set on timer). If no timer, this will always be lit.

4. Wash Mode - Sequence of Operations:

15 seconds cold water purge from piping. Detergent requires hot water.

(Optional 30 seconds)

4 minutes wash with detergent. (Optional 0 – 10 minutes)

30 seconds detergent purge to remove detergent from piping.

(Optional 1 minute)

15 minutes sequence delay to allow water heater to recover.

(Optional 0 – 45 minutes)

Repeat the above for each sequence until the last sequence is completed.

1 minute drain down to remove the majority of water from hood.

(Optional 10 minutes)

1 minute fans on to remove steam and moisture from hood.

(Optional 10 minutes)

PLC resets itself for the next days’ operation.

October 2010

29

29

Page 30

The “Start Fan” and “Stop Fan / Start Wash” buttons must be pushed everyday for PLC to be reset.

Each sequence can wash up to the following combined hood lengths.

10 feet with 3Ú4 in. piping,

20 feet with 1 in. piping,

30 feet with 11Ú4 in. piping and

45 feet with 11Ú2 in. piping.

The following PLC lights will be lit during wash mode:

Run

I 0.2

I 0.3 - Signal from wash timer (only on at time set on timer). If no timer, this will always be lit.

Q 0.1 - main wash solenoid valve stays on for entire wash sequence

Q 0.2 thru Q 0.6 – wash sequence solenoid valves

Q 1.0 - detergent pump on during each wash sequence

I 1.5 - last sequence indicator on during last sequence (CPU 214 only)

Q 0.0 & Q 0.7 - fans on at end of last sequence

Water requirements:

Water temperature – 140 to 180 degrees Fahrenheit

Water pressure – 40 to 60 PSI

Average water usage – 1.1 GPM per linear foot of hood (@ 40 PSI)

Detergent requirements: SC-5 from 2010 Products or X-701 from ZEP manufacturing.

5. Fire Mode. Exhaust fan should be on. Supply fan should be off. Water should be spraying in each exhaust

plenum. The following PLC lights will be lit:

Run

I 1.5 - last sequence indicator (CPU 214 only)

I 0.3 - Signal from wash timer (only on at time set on timer). If no timer, this will always be lit.

Q 0.0 - fans on

Q 0.1 - main solenoid valve on

Q 0.2 - sequence 1 solenoid valve on

Q 0.3 - sequence 2 solenoid valve on

Q 0.0 - sequence 3 solenoid valve on

Q 0.5 - sequence 4 solenoid valve on

Q 0.6 - sequence 5 solenoid valve on

Q 1.0 - detergent pump on

Q 1.1 - fire mode light on

30

30

October 2010

Page 31

BALANCING THE KITCHEN EXHAUST SYSTEM

A. To determine the proper dining room air balance:

1. Refer to engineering drawings to determine total exhaust CFM from dining areas. (Exhaust fans, heating

and air conditioning units, restrooms, etc.)

2. Determine the total CFM of make-up air supplied to dining area.

3. Subtract #1 from #2 above. If the result is a negative number, a negative pressure is present in the dining

area. In this case, kitchen exhaust odors could be drawn from the kitchen to the dining area. Therefore,

exhaust or supply air should be adjusted to provide a slight positive pressure in the dining area.

B. To determine proper kitchen air balance:

1. Refer to engineering drawings to determine total exhaust from the kitchen area. (Exhaust hoods,

dishwasher hoods, etc.)

2. Determine total CFM of make-up air supplied to kitchen area. (Make-up air hoods, heating and air

conditioning units, etc.)

3. Subtract #1 from #2 above. The result should be a negative number. If the result is a positive number, a

positive pressure is present in the kitchen area. Kitchen odors could be forced into the dining area. Also,

a positively balanced kitchen area can adversely affect the performance of the exhaust hood.

Caution: According to NFPA 96, Ch. 8-3 Replacement Air : Replacement air quantity shall be adequate to prevent

negative pressures in the commercial cooking areas from exceeding 4.98kPa (.02 in. water column).

October 2010

31

31

Page 32

Measuring Hood Exhaust Volume:

A digital 2-3/4 in. rotating vane anemometer can be used to measure exhaust CFM when the more accurate

pilot traverse is not available. Accuracy of the rotating vane anamometer has been tested at + 15%.

Measuring Velocity and Calculating Volume

1. Turn off all cooking equipment and hood supply fan (if applicable).

2. Remove the deflector panel on short circuit hoods.

3. Place the anemometer head in the hood exhaust airstream as shown in Fig. 25. It must be

placed in the slot as close to the back wall of the hood as possible and at a 90° angle to it.

4. Take measurements at 8 in. intervals along the entire length of the hood.

5. Calculate the average slot velocity.

6. Calculate the CFM per lineal foot by dividing the average velocity by a conversion factor of 3.9.

7. Calculate the hood’s exhaust volume by multiplying the CFM per lineal foot by the length of the hood.

Example:

1. Measured slot velocities in FPM for a hood 4 ft.-0 in.

920 937 924 935 927 925

Fig. 25

Exhaust

Airflow

Digital Rotating

Vane Anemometer

2. Average slot velocity = (Sum of velocity readings)

(Number of readings)

= 920 + 937 + 924 + 935 + 927 + 925 = 5568 = 928 FPM

6 6

3. CFM per lineal foot = Average velocity in FPM

3.9

= 928 = 238 CFM/lineal foot

3.9

4. Hood exhaust volume = (CFM/lineal foot) x (hood length)

= 238 x 4 = 952 CFM

32

32

October 2010

Page 33

Supply (If Applicable):

Example for Perforated Face Supply

1. Hood set up

If the make-up air unit has a temperature control, it should be used to keep the supply air a the desired room

discharge air temperature.

2. Measure Velocities

Divide the perforated face panel into a grid of equal areas, each approximately 4 in. square.

Measure the velocity at the center of each grid area. A digital 2 3/4 in. rotating vane anemometer or

equivalent is suggested. The center of the anemometer should be held tight to the face of the panel, and

parallel to the filter. Both squareness and distance are important for accuracy. Calculate the average

velocity of the panel.

3. Measure the length, height, and width of the perforated face panel.

4. Calculate the perforated face panel volume in CFM by using the following formula:

Volume = Avg. Velocity * Length (in.) * Height (in.) * .005

5. Calculate the system’s volume by repeating the process for the remaining panels and adding the individual

panel volumes together.

Example: GWFW Hood with (3) 28 in. Perforated Panels

260 250 255 260 250 255 265

• MeasuredvelocitiesinFPMforoneperforatedpanel

• AverageVelocity= Sum of Velocity Readings

Number of Readings

= 260+250+ ... +290+295 = 270.7 FPM

28

• Measure = 28in.longperforatedpanelsx16in.high

Length and Height

• Volumefor = 0.005x(AverageVelocity) x(Length)x(Height)

one panel = 0.005 x 270.7 x 28 x 16 in. = 606.4 CFM

• TotalSystem = (Panel1Volume) +(Panel2Volume) + (Panel3Volume)

Volume = 606.4 + 614.3 + 593.8 = 1814.5 CFM

270 275 270 280 265 265 270

290 285 280 280 275 290 295

285 275 280 260 270 265 260

October 2010

33

33

Page 34

TESTING HOOD AIR VOLUME

Short Circuit Hoods

Supply

All cooking equipment should be off. The hood exhaust

should also be off.

1. Measuring Velocities

• Velocitymeasurementsshouldbemadewith

a digital 2-3/4 in. rotating vane anemometer

or its equivalent.

• Onevelocitymeasurementshouldbetaken

for every 8 in. of short circuit opening length,

starting tight against one edge of the

opening, and finishing tight against the other

edge. The anemometer should be placed at

the bottom edge of the opening, flush with

the bottom lip as shown in Fig. 26. Both

squareness and placement are important for

accuracy.

2. Calculate the average slot velocity.

3. Calculate the CFM per linear foot by dividing the

average velocity by a conversion factor of 5.52.

Fig. 26

4. Calculate the hoods exhaust volume by

multiplying the CFM per linear foot by the total

hood length.

Example: 4 ft. short circuit hood (36 in. short circuit opening).

1. Number of Readings = 36 in. / 8 in. => 6 readings

2. Average Slot Velocity = (Sum of Velocity Readings)

(Number of Readings)

= 786 + 900 + 1126 + 1048 + 1111 + 1115 = 6086 = 1014 FPM

6 6

3 . CFM per Linear Foot = Average Slot Velocity in FPM = 1014 = 184 CFM / Linear Foot

5.52 5.52

4. Hood Supply Volume = (CFM/Linear Foot) x (Total Hood Length in Feet)

= 184 x 4 = 736 CFM

34

34

October 2010

Page 35

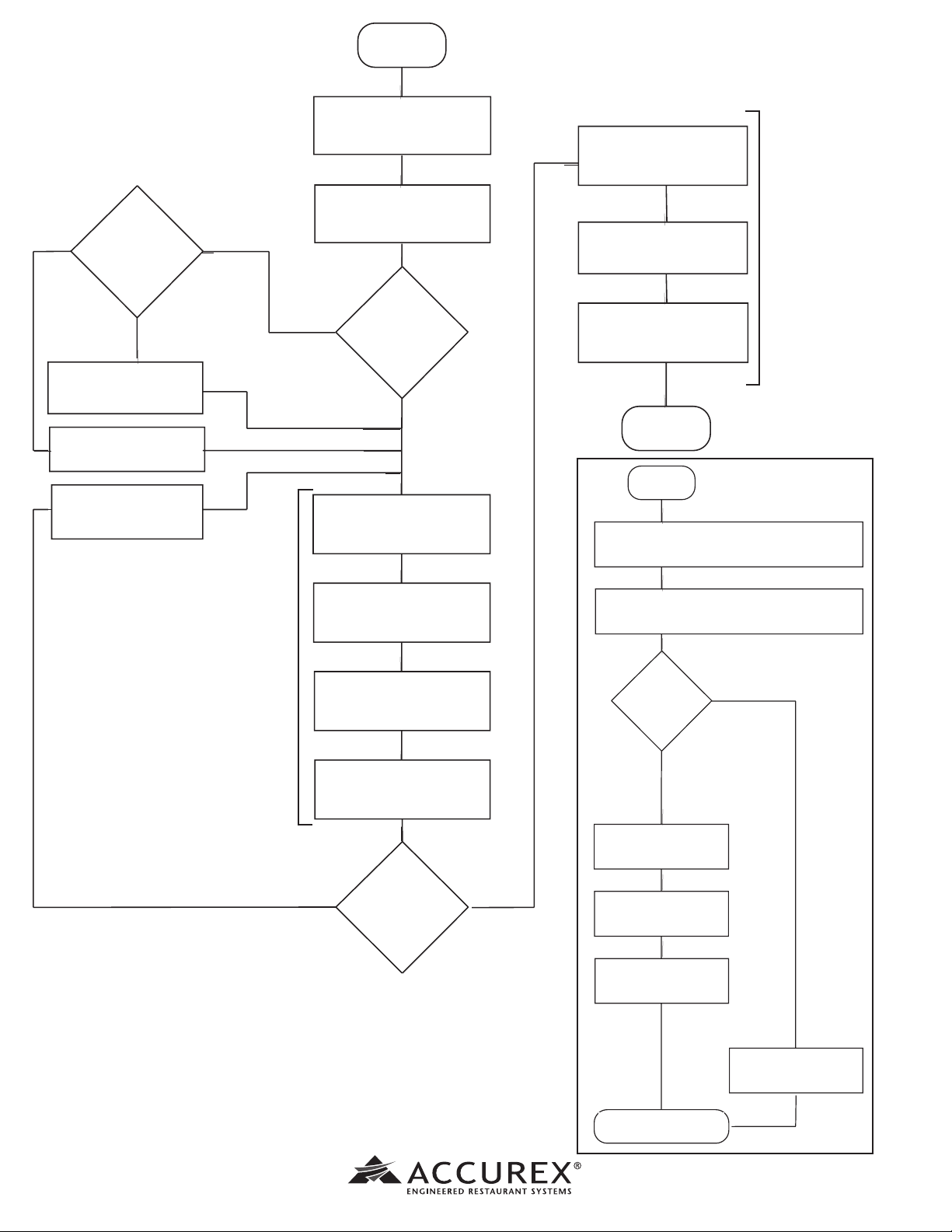

Field Wiring for the Ansul or Amerex Snap-Action Switch

Option A

Relay Part NO. 14702

* K1a and K1b are N.O. when K1 is de-energized

Manual Reset Relay

Part NO. 14702

K1*

N.O.

K1a

K1b

N.O.

Push Button

Switch

Gas Valve

See Note 3

1

2

3

5

6

7

8

L1

110V/60HZ

Black

Red

Brown

L2

Snap-Action Switch

Part NO. 423878

Option B

Relay Part NO. 426151

Ansul Snap-Action Switch

(switch contacts shown with Ansul

Automan in the cocked position)

Snap-Action Switch

Part NO. 423878

Black

Red

Brown

L2 Neutral

L1 Hot

110 VAC/60HZ

5

4

3

2

1

GND

Screw

Power

Indicator

Reset

A

B

Relay Coil

Manual Reset Relay

(Part NO. 426151)

Electrical Rating

1/3 HP, 10 AMP, 120 VAC

1/2 HP, 10 AMP, 240 VAC

13 AMP, 28 VDC

Gas Valve

See Note 3

6

9

3

4

7

1

2 Snap-Action Switches Provided by Greenheck may be

wired as shown.

4 Typical Examples Shown

Power to cooking

equipment