Page 1

Document 482584

Grease Trapper ESP™

Kitchen Exhaust Pollution Control System

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

Grease Trapper ESP™

The Grease Trapper ESP™ is a pre-engineered electrostatic precipitator

type pollution control unit with integral exhaust fan (available without

exhaust fan as an option). The unit is designed to remove grease and

smoke particles as well as odor from the kitchen exhaust airstream.

This installation manual covers procedures for receiving, installing, and

maintaining the unit.

For additional instructions and maintenance information on the integral

exhaust fan, when applicable, refer to the fan nameplate to determine

model type and visit accurex.com to download the corresponding manual.

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

DANGER

Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

To reduce the risk of fire, electric shock, and injury be

sure to follow the cautions below:

• Before servicing, make sure the unit is properly

grounded.

• When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

• Do not operate this unit in an explosive atmosphere.

• Keep all flammable materials (such as gasoline)

away from the unit.

• Do not use flammable cleaner on or near the unit.

• The unit should be inspected frequently and the

unit and cells should be manually cleaned at proper

intervals to prevent a fire.

• Operating temperatures of the airstream should not

exceed 130°F.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. The rotation of the fan wheel is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

3. Fan motor must be securely and adequately

grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan rpm. Adjustments to fan speed

significantly affects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the wires to kink or come in contact

with oil, grease, hot surfaces or chemicals. Replace

immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

8. The precipitator contains safety electrical interlock

switches at all maintenance access doors. Do not

attempt to defeat these interlocks.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 1

Page 2

Receiving

Upon receiving the product, check to make sure all

items are accounted for by referencing items shown

on the packing list. Inspect each crate for shipping

damage before accepting delivery. Notify the carrier if

any damage is noticed. The carrier will make a notation

on the delivery receipt acknowledging any damage

to the product. All damage should be noted on all the

copies of the bill of lading which is countersigned by

the delivering carrier. A Carrier Inspection Report should

be filled out by the carrier upon arrival and filed with

the Traffic Department. If damaged upon arrival, file

claim with carrier. Any physical damage to the unit after

acceptance is not the responsibility of manufacturer.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the packing list. Remove all other shipping/

packing materials including fan tie down straps.

Handling

Units are to be rigged and moved by the lifting brackets

provided or by the skid when a forklift is used. Location

of brackets varies by model and size. Handle in such

a manner as to keep from scratching or chipping the

coating. Damaged finish may reduce ability of unit to

resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Temperatures should

be evenly maintained between 30°F (-1°C) and

110°F (43°C) (wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories (including the main control panel and the

keypad/touchscreen user interface) must be stored

indoors in a clean, dry atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts, allow cold parts to reach

room temperature. To dry parts and packages use a

portable electric heater to get rid of any moisture build

up. Leave coverings loose to permit air circulation and

to allow for periodic inspection.

OUTDOOR

Units designed for outdoor applications may be stored

outdoors, if absolutely necessary. Roads or aisles for

portable cranes and hauling equipment are needed.

The unit should be placed on a level surface to prevent

water from leaking into it. The unit should be elevated

on an adequate number of wooden blocks so that it is

above water and snow levels and has enough blocking

to prevent it from settling into soft ground. Locate parts

far enough apart to permit air circulation, sunlight,

and space for periodic inspection. To minimize water

accumulation, place all unit parts on blocking supports

so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

NOTE

The main electrical panel, if stored, shall be stored

indoors only in a dry environment protected from the

elements.

Inspection & Maintenance during Storage

While in storage, inspect equipment once per month.

Keep a record of inspection and maintenance

performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every three

months, the fan motor should be energized. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lintfree cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Wipe thoroughly

clean with Tectyl

For hard to reach internal surfaces or for occasional

use, consider using Tectyl® 511M Rust Preventive or

WD-40® or the equivalent.

®

506 (Ashland Inc.) or the equivalent.

Removing from Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion, until the equipment goes

into operation. Prior to installing the unit and system

components, inspect the unit assembly to make sure it

is in working order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base, and accessories for

tightness.

2. Rotate the fan wheel(s), where applicable, by hand

and assure no parts are rubbing.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System2

Page 3

Table of Contents

Grease Trapper ESP System Function . . . . . . .3

System Components

Unit Body . . . . . . . . . . . . . . . . . . . . . . .4

ESP Cells . . . . . . . . . . . . . . . . . . . . . . .4

Impingement Filters / Mist Eliminator / Filters /

Carbon Trays . . . . . . . . . . . . . . . . . . . . .4

Component Quantities . . . . . . . . . . . . . . . .4

Remote Mounted Detergent Dispenser. . . . . . . .4

Remote Mounted System Control Panel . . . . . . .5

Fire Cabinet . . . . . . . . . . . . . . . . . . . . . .5

PCU Field Assembly

Unit Modules . . . . . . . . . . . . . . . . . . . . .5

Terminal Enclosure . . . . . . . . . . . . . . . . . .6

Attaching Fan . . . . . . . . . . . . . . . . . . . . .6

Installation

Rigging and Placing Equipment . . . . . . . . . . .7

Ductwork Connections . . . . . . . . . . . . . . . .7

Cells and Carbon Trays . . . . . . . . . . . . . . . .7

Plumbing Connections

Detergent Dispenser . . . . . . . . . . . . . . . . .8

Wash Manifolds . . . . . . . . . . . . . . . . . . . .9

Electrical . . . . . . . . . . . . . . . . . . . . . . .9

Fire System

Ansul® . . . . . . . . . . . . . . . . . . . . . . . 10

Initial System Start-Up . . . . . . . . . . . . . . . 11

Sequence of Operation

Normal . . . . . . . . . . . . . . . . . . . . . . . 11

Wash . . . . . . . . . . . . . . . . . . . . . . . . 12

Controller Setup and Tutorial . . . . . . . . . 13-14

A.

B. Input/Output . . . . . . . . . . . . . . . . . 15

C.

D. Manufacturer . . . . . . . . . . . . . . . . 21

Keypad Navigation . . . . . . . . . . . . . . . . . 22

Touch Screen Navigation . . . . . . . . . . . 23-26

Variable Frequency Drive Information . . . . 27-28

BMS Points List . . . . . . . . . . . . . . . . . . . 29

Maintenance . . . . . . . . . . . . . . . . . . 30-31

Unit Layout . . . . . . . . . . . . . . . . . . . . . 31

Field Wiring Diagrams . . . . . . . . . . . . . 32-33

Wash Water Plumbing Schematic

Drain Line Plumbing . . . . . . . . . . . . . . . . 34

Detergent Dispenser Assembly . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . 35

Maintenance Log . . . . . . . . . . . . . .Backcover

Our Commitment . . . . . . . . . . . . . .Backcover

Clock. . . . . . . . . . . . . . . . . . . . . 15

Service. . . . . . . . . . . . . . . . . . 16-21

Grease Trapper ESP

System Function

Grease Trapper ESP is an electrostatic precipitator

pollution control unit (PCU), with an additional carbon

filtration module designed for two specific functions:

• Remove smoke/grease particles from kitchen exhaust

• Remove odor from kitchen exhaust

NOTE

• Grease Trapper ESP must be connected to a listed

exhaust hood assembly and must be installed in

accordance with local building codes, NFPA 96

and NEC.

• The unit must be installed with a minimum 12 inch

clearance to combustible materials on top of unit

and six inches on the sides and bottom.

A mechanical impingement pre-filter removes large

airborne particles from the incoming airstream prior to

reaching the ionizer cell. The permanent electrostatic

collector section removes grease and smoke particles

from the airstream using a high voltage ionizer cell(s).

The ionizer imparts a positive charge on the grease and

smoke particles as they pass. These particles are then

repelled by positively charged plates and collected on

negatively charged plates. Upon completion of each

cooking day, a wash sequence is initiated for the selfcleaning function of the electrostatic cell via the remote

mounted control panel. The mesh mist eliminator filter

prevents wash water from entering the carbon filtration

section(s) of the unit.

NOTE

Do not use this unit for applications with high

concentrations of water vapor, or other matter, that

is highly conductive if condensed in the airstream.

Heavy water vapor can causing continuous electrical

shorting within the ESP cells, which does not allow

the unit to collect cooking particulate and perform

asdesigned.

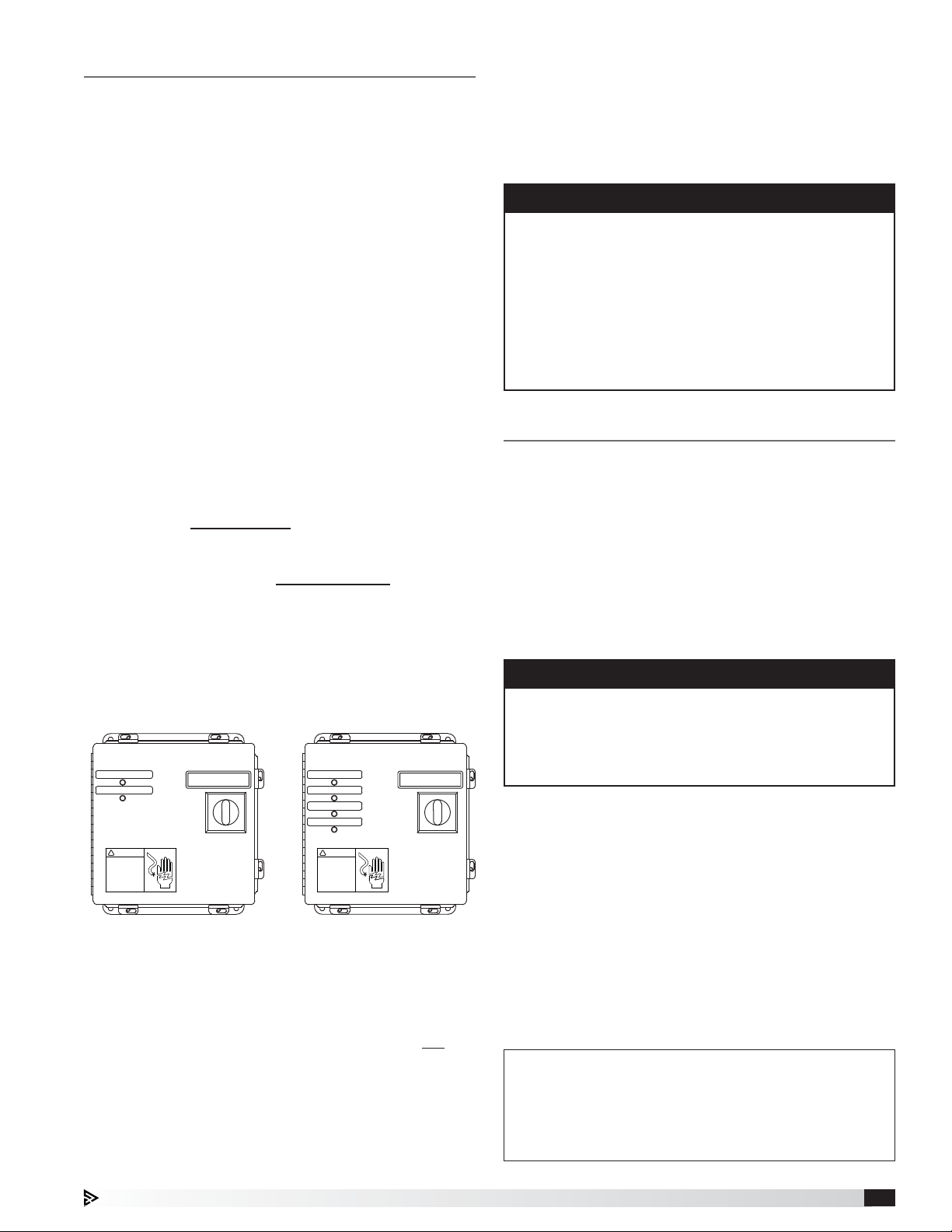

There are two configuration options for the Grease

Trapper ESP PCU’s. The standard unit will have two

ESP modules and one carbon filtration section for use

with light, medium and heavy duty cooking. For solid

fuel applications which will contain a greater quantity

of grease, smoke and odors, the solid fuel unit should

be selected. The solid fuel unit will contain three ESP

modules and two carbon filtration modules.

NOTE

This unit should NOT be installed in applications

where incoming airstream at the inlet of the unit is

capable of exceeding 130°F.

NOTE

Grease Trapper ESP is designed to remove submicron, airborne particulate generated from cooking

processes. This system is NOT INTENDED to

eliminate regular hood and ductwork cleaning and

service. Improper care and maintenance of this

system and associated hoods and ductwork may

present a fire hazard.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 3

Page 4

System Components

NOTE

The installation criteria for each of the system

components shown below should be considered

when selecting a site for install. For further detail on

installing the components, refer to the INSTALLATION

section on page 7.

Unit Body

The unit body is shipped on a mounting rails ready for

installation. If the unit was ordered with an exhaust fan,

typically the fan will also be mounted on the same set

of rails as part of the PCU assembly. Unless specified

and built for outdoor use, the PCU must be mounted

indoors and be protected from weather. The unit should

be easily accessible for service personnel. (1) One-inch

water supply line and (1) two-inch waste water drain line

is required at the unit for the system’s wash function.

Power packs (power supply boxes) are attached to

hinged cell access doors of the cabinet assembly which

are wired to the terminal enclosure (disconnect box)

mounted to the rail below. High voltage feed-through

pins safely transfer voltage from power supply to the

cells located inside the unit. Power supplies are selfprotecting against overloads (which can be caused

by contaminant build up that leads to short circuits in

ionizer and collector sections) and are self regulating

from AC input voltage variations from 108 - 264 VAC.

Impingement Filters / Mist Eliminator

Filters / Carbon Trays

Impingement filters and mist eliminator filters will ship

installed in the unit. Carbon trays will ship in a separate

container. Filter quantities for each stage are based on

unit size.

Each carbon filter is a 20 x 20 x 2 inch, 12 lbs, and

contains coconut shell carbon, standard. Max designed

velocity across each filter is 90 ft/min.

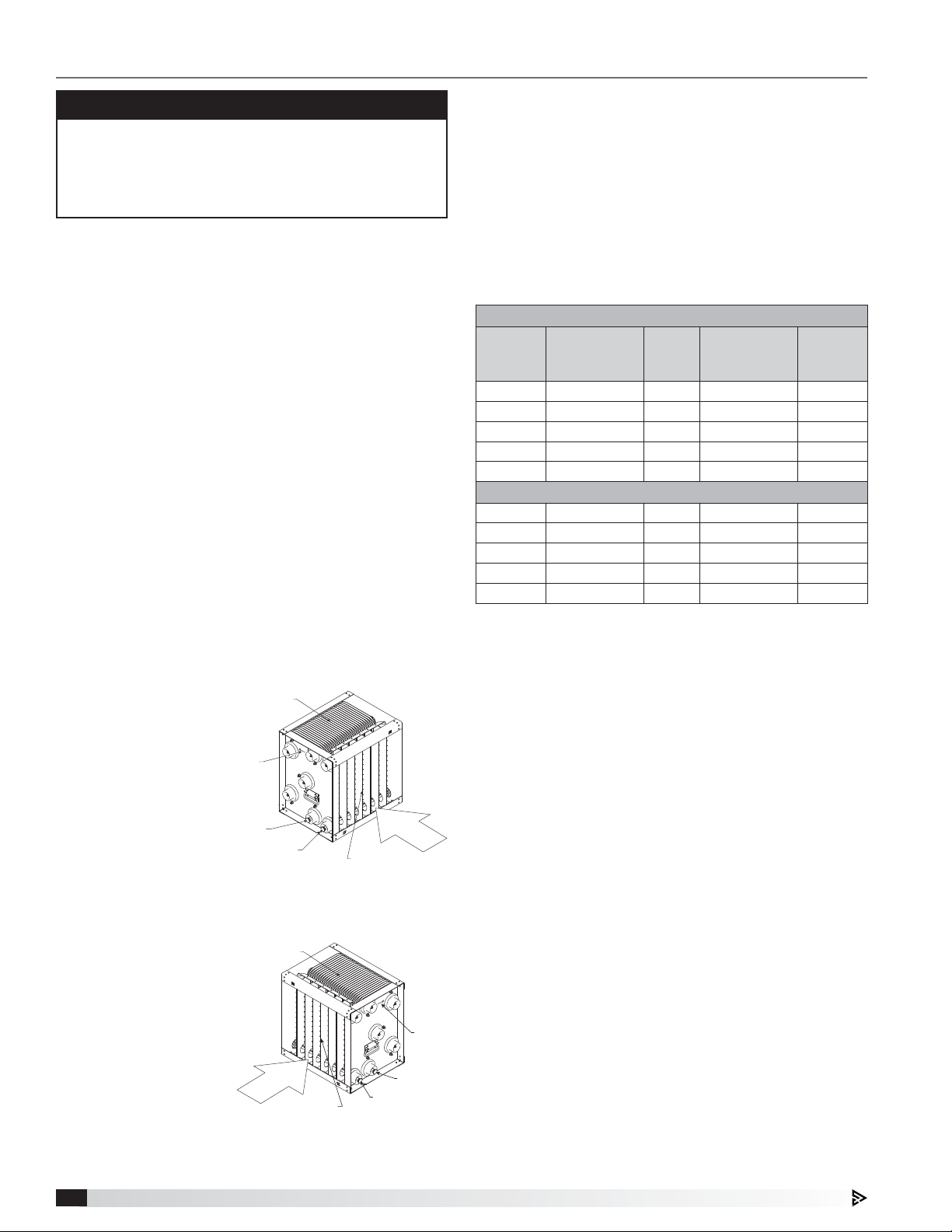

Component Quantities

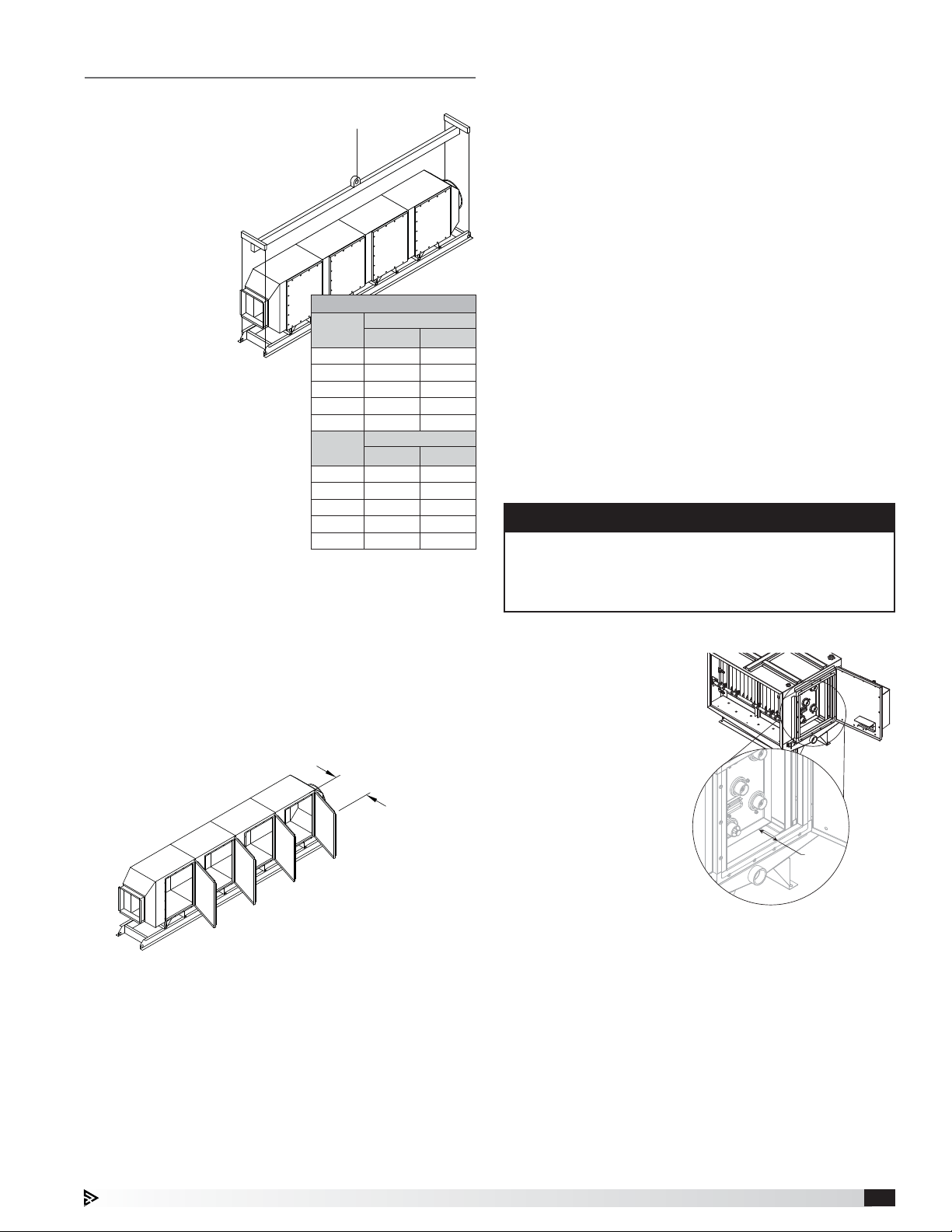

STANDARD UNIT

Housing

Size

15 121 6

30 2 4 2 12

45 3 6 3 18

60 4 8 4 24

90 6 12 6 36

Impingement

Filter

ESP

Cell

Mist Eliminator

Filter

SOLID FUEL UNIT

15 1 3 1 12

30 2 6 2 24

45 3 9 3 36

60 4 12 4 48

90 6 18 6 72

2" Deep

Carbon

Trays

ESP Cells

ESP cells will ship in separate crate to protect them

during shipping. Cell quantities for each stage are based

on unit size.

Cells have an ionizer

section and collector

section. Ionizer section

includes spiked

ionizer plates that are

charged with 12,000

VDC. Collector section

includes alternating

plates between ground

(0 VDC) and 6,000VDC

potential. Cells are fed voltage through high voltage

feed-through pins that are insulated from the unit

housing. These pins

contact brass plungers

located on the side

of the cell near the

bottom. If a module has

multiple cells, power is

passed from cell to cell

through these brass

plungers coming into

contact with the pins on

nextcell.

The total current to both the ionizer section and

collector section is below 6 mA.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System4

Collector Section

Stamped

Airflow

Direction

Indicator

Collector

Brass Plunger

Ionizer

Brass Plunger

Airflow

Ionizer Section

Left Hand Access Unit Cell

Collector Section

Airflow

Ionizer

Ionizer Section

Brass Plunger

Right Hand Access Unit Cell

Stamped

Airflow

Direction

Indicator

Collector

Brass Plunger

Remote Mounted Detergent Dispenser

A 30 gallon remote mounted detergent dispenser

equipped with 1/2 hp pump is included as part of the

electrostatic collector self-wash system. Solenoid

valves, pressure gauge, ball valve, ystrainer, and

backflow preventer are to be provided by others.

The detergent dispenser must be mounted indoors

on a solid, level foundation, as close to the cabinet

assembly as possible, and in a freeze protected location

accessible to maintenance personnel. The 1/2 inch

line from the detergent dispenser must be connected

to the water supply line prior to the precipitator. Refer

to the PLUMBING section for details on plumbing

connections.

Page 5

System Components - continued

Remote Mounted System Control Panel

The 115 VAC system control panel fed from a 30A

building breaker allows the user to interface with the

unit and controls operation, as well as monitors wash

and other functions. Field wiring connects the system

control panel to the terminal enclosures on the unit,

and works in conjunction with the unit’s power supplies

and high voltage ESP cells. The system control panel

is designed to be mounted indoors (NEMA-1) in an

area easily accessible to daily operational staff. Allow

adequate room from the face of the panels for door

swing clearance and servicing.

Fire Cabinet

The fire cabinet should be mounted as close to the

Pollution Control Unit as possible, typically within 5 feet.

Unless the fire cabinet was provided with an outdoor

cabinet and heater, the cabinet should be mounted

indoors and must be kept above freezing.

3. After rails and modules have been moved to desired

location, the modules and rails can be reassembled.

Control boxes, access doors, filters,

and ESP cells must be removed

before welding modules together

Each module is

attached to the rails

with (4) 5/16-inch fasteners

1/8

Liquid Tight

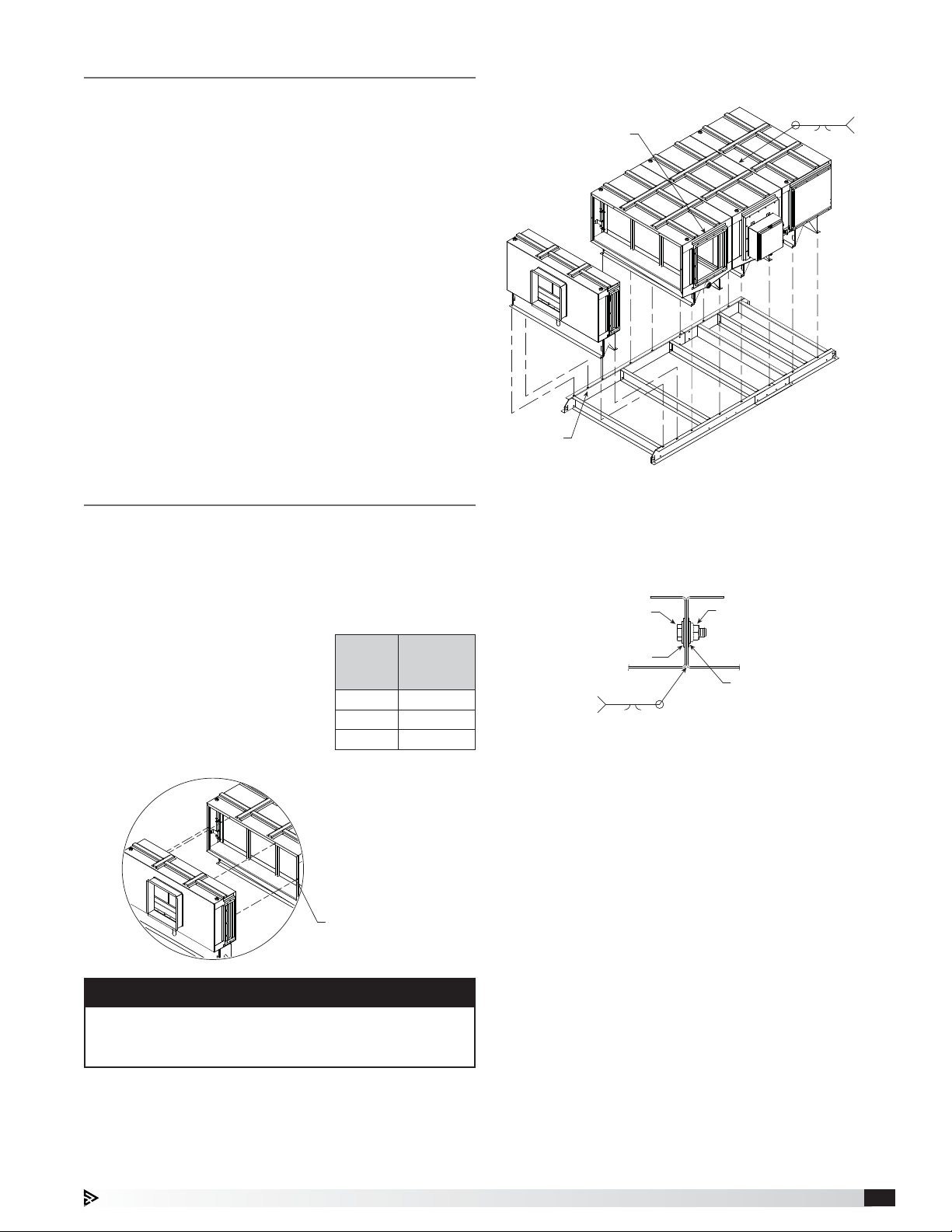

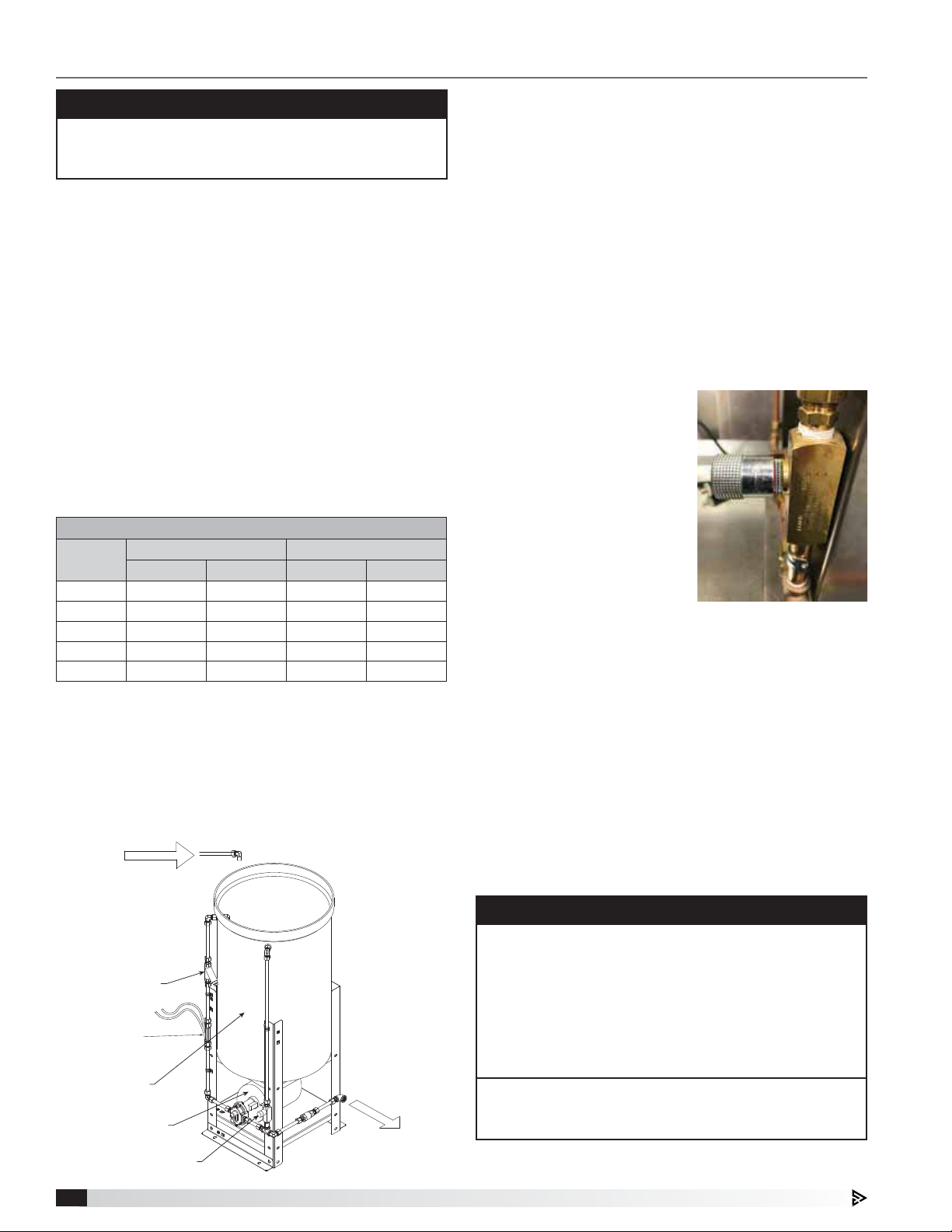

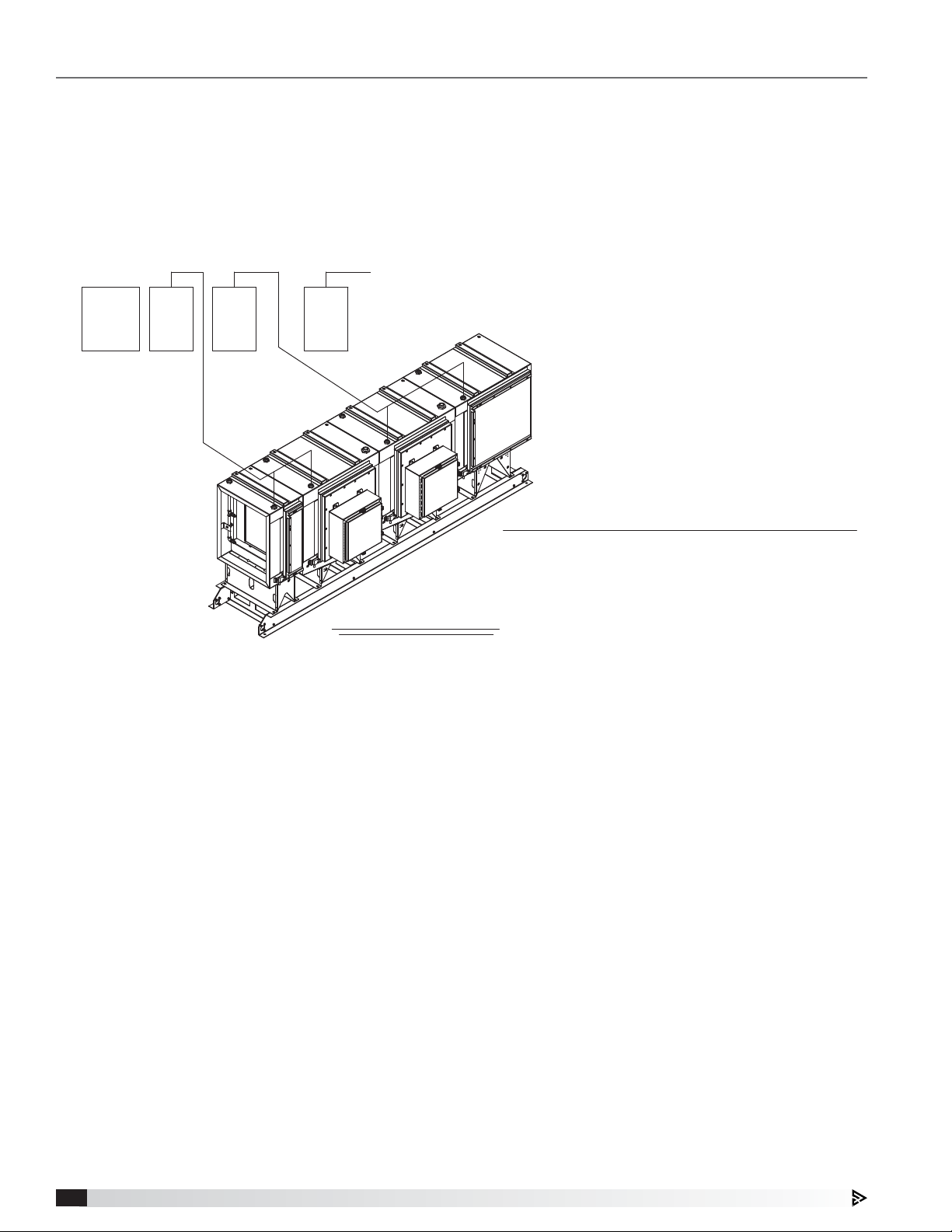

PCU Field Assembly - if applicable

If unit is shipped in sections, each section will need to

be welded in the field.

Unit Modules

1. Remove (4) 5/16 inch mechanical fasteners that

attach each module to the rails.

2. Remove 5/16 inch mechanical

fasteners that attach each

module to the next adjacent

module. PCU housing size

can be found in the model

number on tag on side of unit.

Housing

Size

15 3

30, 45 4

60, 90 6

Each module is attached

to the adjacent module

with 5/16-inch fasteners

Number of

Mechanical

Fasteners

4. It is recommended to reattach the fasteners from

step 2 to properly align the modules with each other,

but fasteners are not required when the modules are

welded together from the outside.

INTERIOR OF MODULES

5/16 inch X 1 inch SS bolt

PN# 417205

SS washer with neoprene gasket

Liquid Tight

PN# 417246

1/8

EXTERIOR OF MODULES

5/16 inch SS hex nut

PN# 415576

SS washer with neoprene gasket

PN# 417246

5. Make sure all control boxes, access doors, filters

and cells are removed from the modules before

welding modules together.

6. Fully weld modules together on all four sides on the

outside of the unit. Welds must be liquid tight.

NOTE

Doors will have to be opened and/or removed to

access fasteners inside of modules. A 1/2 inch socket

is required to remove door bolts.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 5

Page 6

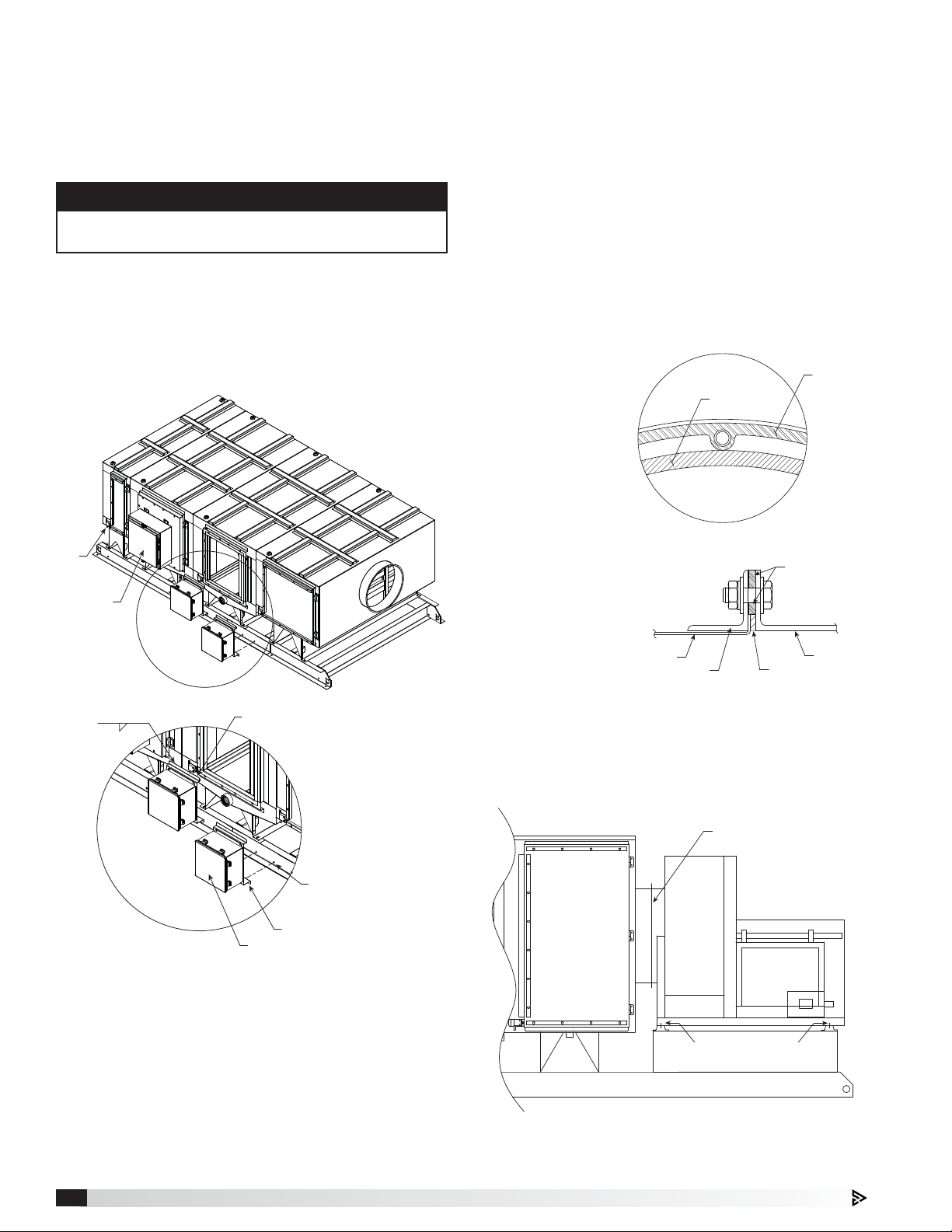

Terminal Enclosure

1/2 inch silicone gasket

1. The bottom of each terminal enclosure mount needs

to be attached to the rail with (2) 5/16 inch fasteners

(provided by factory).

2. The top of each terminal enclosure mount needs to

be welded to the side of the modules.

NOTE

Be sure terminal enclosures do not block module

drains or doors.

3. Refer to wiring diagram provided with the unit

control panel for more information. Limit switches

(mounted on each module) need to be wired to

terminal enclosures.

4. Plugs on power pack enclosure (ESP modules only)

need to be plugged into the terminal enclosures.

Limit

switch

Power pack

enclosure

1/8 2-3.5

Weld top of terminal enclosure

mount to modules

Attaching Fan

The ESP fan is shipped bolted to unit body and rails. If

the unit was requested to be disassembled in the field,

the unit body-to-fan connection has not been sealed.

1. To disassemble in the field, remove mechanical

fasteners that attach the companion flange and fan

to the unit body.

2. Remove mechanical fasteners that attach the fan to

the isolators on the rails.

After fan and unit body have been moved to desired

location, the fan can be sealed and reattached to

the unit body and rails.

3. To seal the fan to unit body connection, apply fire

rated caulk (3M Fire Barrier Sealant CP25WP+ or

equivalent) to

fan inlet flange.

Make sure to

apply caulk

1/2 inch

silicone gasket

around each bolt

hole. Caulk to be

located outside

of silicon gasket

Seam on gasket to be

located on side of unit

mounted during

step 4.

4. Attach 1/2 inch silicone gasket around fan inlet

flange. Silicone gasket

to be located inside

of caulk applied

in step 3 (seam

of gasket to be

located on the

side of unit).

Transition collar

Companion flange

5. To reassemble locate fan on isolators on rails.

6. Reattach fasteners for companion flange removed in

step 1.

7. Reattach fasteners attaching fan to isolators

removed in step 2.

Liberally apply

fire caulk to

outside portion

of companion

flange and

around each

individual

bolt hole

Fire rated caulk

Fan

Fasteners attaching fan to ESP

transition are evenly spaced

around fan inlet

Connect bottom of terminal

mounting bracket to rails with

(2) 5/16 inch fasteners each

(provided by others)

Terminal enclosure mount

Terminal enclosure

Fasteners attach the fan to

the isolators on each corner

of the fan

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System6

Page 7

Installation

4 inches

Rigging and Placing Equipment

1. The unit is furnished with lifting lugs

at the four corners. For corner

weights, reference the unit’s

submittal drawings.

2. Use a crane and a

set of spreader

bars hooked to

all four factory

lifting lugs to lift

the unit.

3. Field weight will

vary depending

upon final

selections

such as fan

type, accessories, etc.

Approximate weights are

shown in the table.

4. The unit can be positioned

on a base or roof deck

suitable for this purpose.

5. The unit must be anchored

to its base/roof deck.

6. Alternatively, the unit may be suspended from

an adequate overhead structure, using suitable

undercarriage or hanging rods (by others). If

suspended a cradle or support structure must be

provided by others to support unit from bottom. All

hanger brackets/lifting lugs must be used to ensure

proper support. The unit must also be hung level to

ensure proper operation.

7. A service clearance of 36 inches must be provided

on the access door side of the unit.

8. A minimum 12inch clearance must be maintained

between the top and 6 inches on each side and

bottom of this unit and any combustible material.

Approximate Weight

Housing

Housing

STANDARD UNIT

Size

15 1410 641

30 1710 777

45 2120 964

60 2765 1257

90 3315 1507

Size

15 1860 845

30 2295 1043

45 2860 1300

60 3660 1664

90 4390 1995

36 inches

lbs kg

SOLID FUEL UNIT

lbs kg

Ductwork Connections

Ductwork must conform to IMC and SMACNA guidelines.

All factory-built grease duct needs to be constructed

in accordance with ANSI/UL 1978 and should be

manufactured and installed in accordance with their

listing.

All field-built grease ductwork must be constructed in

the following manner per NFPA 96, unless otherwise

specified by the local authority having jurisdiction (AHJ):

Materials - Ducts shall be constructed of and supported

by carbon steel not less than 1.37 mm (0.054 in.) (No.

16 MSG) in thickness or stainless steel not less than

1.09mm (0.043 in.) (No. 18 MSG) in thickness.

Installation - All seams, joints, penetrations, and duct-

to-hood collar connections shall have a liquid-tight

external weld.

Units intended for indoor mounting have an outlet

mounting flange provided on the outlet of the fan. Outlet

ductwork from the exhaust fan is required to be per the

above mentioned methods unless otherwise specified by

the local authority having jurisdiction (AHJ).

NOTE

Ductwork should be properly insulated to prevent

formation of condensation through temperature

change. Condensation that occurs in ductwork will

short circuit ionizing-collecting cells.

Cells and Carbon Trays

Open ESP cell and carbon

tray access doors using

1/2inch socket wrench to

remove all bolts.

Insert cells into the ESP

module(s) in the unit,

making sure the brass

plungers are on the

bottom facing towards

you and the airflow arrow

stamped on each cell is

pointing towards the fan.

ESP cells should be pushed

in by the one next in the row.

For example, the second cell pushes the first cell,

third cell pushes the second, etc. The last cell installed

should be no more than 4 inches (±1/8inch) from the

edge of the cell to the edge of the frame.

Insert carbon trays into the carbon module(s) in the unit.

Make sure trays are inserted where gasketing material is

orientated on the left and right hand side, NOT the top

and bottom, so there is a seal against the filter next to

them.

After all cells and filters are properly installed, refasten

unit doors. Torque the bolts to 60-70 in-lbs. Bolts should

be started by hand prior to using an impact driver or

socket.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 7

Page 8

Plumbing Connections

NOTE

All water piping exposed to freezing temperatures

must be trace heated and insulated to prevent

damage to the unit.

Once all system components are installed, plumbing

connections for the system can be made. It is

recommended that plumbing connections be done prior

to making electrical connections.

From the building, a 1-inch (refer to drawings) hot

water line is required for connecting the wash system.

Recommended water temperature is 140-180°F at 40

psi pressure. Make sure water pressure does not exceed

50 psi. Refer to the chart for information on water and

detergent quantity requirements. Install the quarter

turn ball valve (by others) at the incoming water source

to allow the water to be turned off for servicing. Next,

install the strainer (by others), backflow preventer (by

others), pressure gauge (by others), and 24 VAC solenoid

valve (by others) respectively. Locate these items along

the incoming water line in a location convenient for

inspection/servicing.

Approximate Water and Detergent Used per Wash Cycle (gallons)*

Housing

Size

15 70 1 105 2

30 140 1 210 2

45 210 2 315 4

60 220 2 330 4

90 330 2 495 4

Water usage numbers shown above are assuming factory default

wash cycle times. Actual water and detergent required may be

different based on the cooking load, appliance type, and cooking

frequency/time.

*Assuming 40 psi water pressure

STANDARD UNIT SOLID FUEL UNIT

Water Detergent Water Detergent

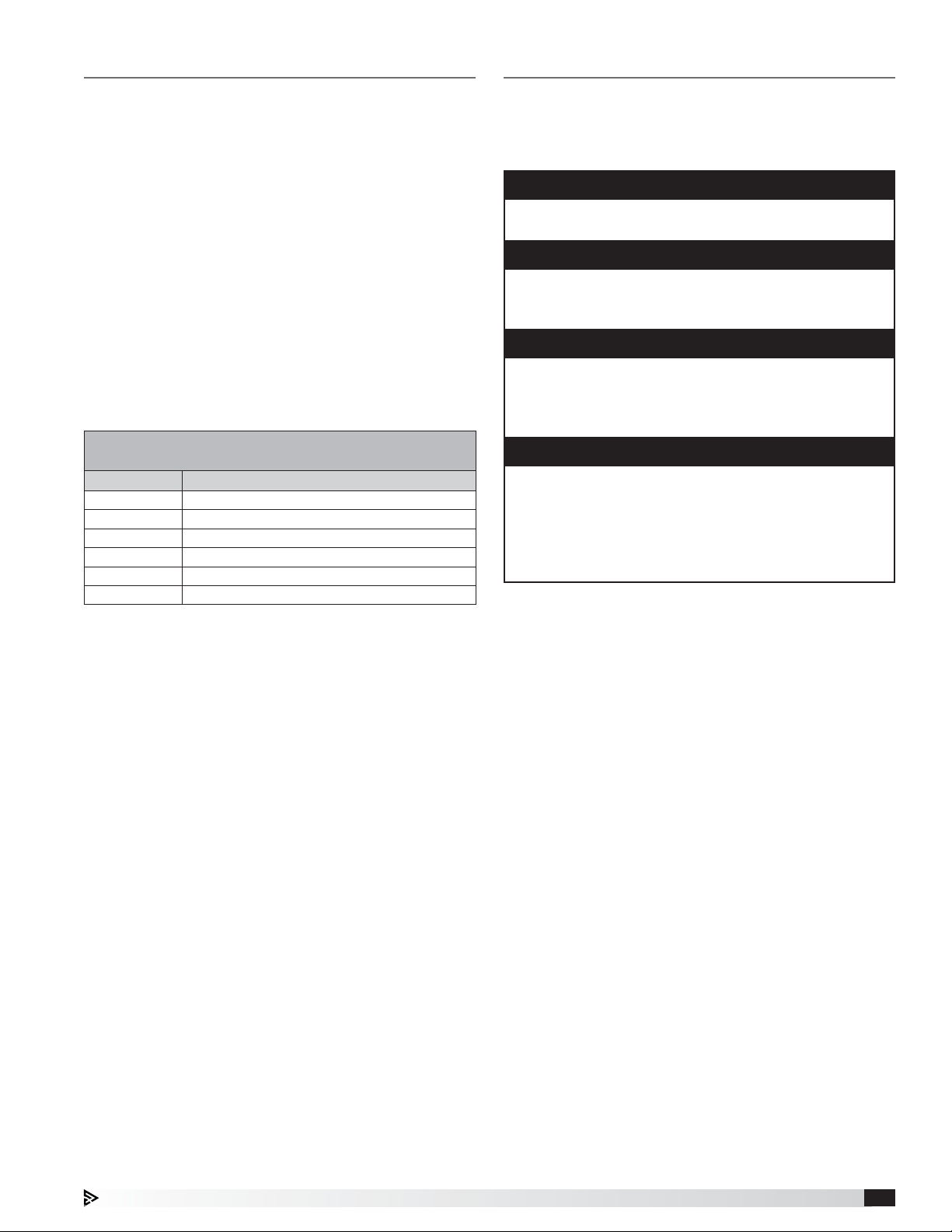

Detergent Dispenser

The detergent dispenser supplies detergent to the wash

system during the WASH mode.

1/2-inch

Hot Water

Fill Line

(Recommended

To Make It

Easier For

Detergent

Dillution)

Y-strainer

With Sediment Trap

Detergent

Flow Switch

Detergent Tank

Detergent Pump

1/2-inch

Detergent

Injection

Line (Connect

To 1-inch

Water Line)

When the unit is washing and the wash sequence is

calling for detergent, a pump housed underneath the

detergent tank pumps the detergent into the hot water

line. A Y-strainer is responsible for removing debris

and sediment from reaching the pump. A flow switch

determines if detergent is flowing when detergent is

being injected (if the flow switch doesn't close within

a time period upon detergent pump running, this will

trigger a low detergent fault). A detergent flow valve is

responsible for diverting some detergent back into the

tank. Turning the flow valve knob clockwise (closing

the valve) will force more detergent into the hot water

line and to the unit during a wash. Turning the flow

valve knob counter-clockwise (opening the valve) will

force more detergent back into the tank during a wash.

A series of colored rings on the flow control valve

indicate how opened/closed

the valve currently is. This can

be adjusted as needed based

on the detergent required for

the wash cycle, but should

start with setting the valve so

that the red ring is visible,

(see Flow Valve image) which

should equate to roughly

0.6GPM. Adjustments to the

flow control setting should be

done in small increments over

a period of several wash cycles.

Flow Valve

This flow valve may be locked into place by a black

hex head set screw located on the bottom of the flow

valve, just below the adjustable knob. Loosen the set

screw before making an adjustment using a 2-mm

Allenwrench.

From the pump located on the base of the detergent

dispenser, connect a 1/2-inch piping connection for

the detergent supply to the 1-inch water supply line.

A quarter turn ball valve (by others) can be installed

on this line if necessary for servicing. The connection

of the 1/2-inch detergent supply line to the 1-inch

water supply line should be made within 10 feet of the

cabinetassembly.

NOTE

Upon the system detecting no detergent flow for

the detergent alarm delay time, the system will go

into a low detergent alarm and the detergent pump

will be immediately shut off. The low detergent fault

can be manually reset (see page 14 for details), or it

will automatically reset if detergent flow is detected

upon the next wash cycle when detergent injection is

takingplace.

Pump should be located as close to unit as possible,

on same floor. Maximum distance recommended from

detergent pump to unit is 10 feet.

Detergent Flow Valve

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System8

Page 9

Plumbing Connections - continued

Electrical

Wash Manifolds

The unit is supplied with 1-inch wash headers located

at the top of each ESP module. Connect the hot water

supply line to the wash headers at the top of the

ESP module. Bring a 2-inch waste water drain piping

connection with P trap to the drain pipe on the side of

the ESP module. The trap drain line water column for

the drain should be sized for the total system resistance

plus 1 in. wg.

For more information, refer to the plumbing schematic

located on page 34.

The Grease Trapper ESP PCU will be supplied with

a detergent tank and pump and connection headers

on each module. All other plumbing components and

piping will be provided by others. Follow all applicable

plumbing codes and best practices when installing

system.

Required Plumbing Components

(Provided by Others)

Quantity Item Description

3 Ball Valve

1 Y Strainer

2 Backflow Preventer or Check Valve

1 Pressure Gauge

4 24 VAC Solenoid Valves - Standard Unit

5 24 VAC Solenoid Valves - Solid Fuel Unit

Once all system components are installed, electrical

connections for the system can be made. It is

recommended that plumbing connections be done prior

to making electrical connections.

CAUTION

RISK OF ELECTRIC SHOCK. All wiring to be done by

qualified personnel only.

NOTE

All wiring must be done according to the equipment

data plate information, NEC (National Electrical Code

NFPA 70), and local codes.

NOTE

All wiring must be permanently installed in conduit.

Under no circumstances should extension cords be

used to connect the source of electrical supply to the

equipment.

NOTE

An earth ground must be provided to the unit

assembly housing and main control panel. If shipped

loose for remote mounting, terminal enclosures must

be provided with earth ground. The detergent pump

motor and solenoid valve must also be appropriately

grounded.

The Grease Trapper ESP PCU will require additional field

wiring for proper installation. The main control panel

will be shipped loose and is designed to be mounted

indoors. A typical field wiring diagram is shown on page

32. Refer to the unit specific wiring diagram located on

the inside of the door of the system control panel for

unit specific wiring that is required.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 9

Page 10

Fire System

The Pollution Control Unit (PCU) is furnished with factory pre-piped fire suppression nozzles. Field connection, tanks,

controls, fusible link detectors, and commissioning is provided and installed, based on specifications at time of

order. The Authority Having Jurisdiction (AHJ) may require additional protection.

The fire system must be installed and operational to maintain the UL Listing of the unit. Refer to the drawings below

for information on field piping the fire system to the unit. The release and tanks should be mounted no more than

5feet away from the PCU unit.

ANSUL

To duct nozzles

(duct nozzles by Distributor)

RELEASE

TANK TANK TANK

FIRE SYSTEM DISTRIBUTOR / FIRE SYSTEM INSTALLER:

There are two quik-seals on each module. Connection to

only one of the quik-seals on each module is required.

Multiple quik-seals are provided for situations where

there are obstructions to the connection point.

TYPICAL DRAWING

• Do not install fire piping in front of doors on module. Must have 36 inches of clearance.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System10

Page 11

Initial System Start-Up

1. Verify unit is installed properly and all field water

and electrical connections have been made.

2. Check that all ESP cells have been installed

properly. There is a directional arrow that indicates

the direction of the proper airflow. If cells are not

installed in the proper direction, the unit will not

operate correctly.

3. Close and properly fasten the doors on the unit to

ensure the door limit switches are closed.

4. Turn on electrical power to control cabinet and

exhaust fan.

5. Turn on fan disconnect.

6. Turn on the disconnect switch on the PCU terminal

enclosures to energize the power packs.

7. Press the fan button on the user interface to start

the fan. The green indicator lights on the terminal

enclosure(s) should illuminate indicating the power

supply is powering cells. Some electrical arcing

(audible snapping and cracking) is normal at

initial power up as leftover debris in the duct and

unit may occasionally get caught inside the cells.

When the ionizer section on an ESP cell is arcing,

the green indicator light on the terminal box will

shut off, and the red indicator light will illuminate

temporarily. When the collector section of an

ESP cell is arcing, the green indicator light on the

terminal box will shut off, and both the red and

green indicator lights will remain off temporarily.

Arcing should subside after a short period of

time. If arcing continues, reference page 35 for

troubleshooting assistance.

POWER SUPPLY OFF/FAULT

POWER SUPPLY ON

!

DANGER

High

Voltage

Housing Size

15, 30, 45

DO NOT REMOVE THIS PANEL

Unless electrical switch is in the OFF position.

Failure to do so will damage switch.

ON

OFF

POWER SUPPLY OFF/FAULT

POWER SUPPLY ON

POWER SUPPLY OFF/FAULT

POWER SUPPLY ON

!

DANGER

High

Voltage

Housing Size

60, 90

DO NOT REMOVE THIS PANEL

Unless electrical switch is in the OFF position.

Failure to do so will damage switch.

ON

OFF

• RED indicates an ionizer fault within a cell

• GREEN indicates normal operation

• NO LIGHTS indicates power supply is off OR

collector fault within a cell

8. The indicating lights on the terminal enclosure(s)

will indicate status of the power supplies. Terminal

enclosure indicator lights will remain off unless fan

is running.

9. Check for alarms on the system controller. Correct

any alarms that may be displayed (See page 14

fordetails).

10. System should now be ready for operation.

NOTE

As a safety precaution, the system will only operate

in the NORMAL mode when the access doors of

the unit are completely closed and the terminal box

disconnect switch is in the ON position.

If the plunger of the safety switch on all of the doors

is not fully depressed, the red FAULT light on the

main controller (PLC) will illuminate and the unit will

not start. Do not attempt to operate the unit with the

access doors open or bypass the safety.

Sequence of Operation

The operation of the Grease Trapper ESP system falls

into two main categories:

1. NORMAL: System collects smoke and grease

particulate from the airstream.

The unit can be started by pressing the fan button on

the user interface or by closing the remote run contact

(terminals RE-1A and RE-1B). The remote run command

is a contact that can be wired to the kitchen control

panel, timeclock, or any other contact closure desired to

call for the system to run.

NOTE

BOTH the keypad fan button needs to be disengaged

AND the remote run contact needs to be open in

order for the fan to shut off. A call for the fan to run

will not allow for a wash to start, which will prevent

the cells from being cleaned.

During normal operation, as the grease enters the

unit, it will pass through an impingement filter that is

designed to remove the large grease particles. After

passing through the impingement filter, it will enter the

ESP module(s) which will remove the grease particles

and smoke from the airstream through a process

of electrostatic precipitation. Upon leaving the ESP

modules, the air then passes through a mist eliminator

filter which stops water from entering the carbon filters

during the wash down process and also helps protect

the carbon filter section from grease build-up. The air

then enters the carbon filtration section which removes

the odors from the airstream.

Normal Mode

• Exhaust Fan - Running

• Terminal Enclosure Indicator Lights - Green

• Main Solenoid Valve - Closed

• Detergent Pump - Off

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 11

Page 12

Sequence of Operation - continued

2. WASH: System goes through cycles to clean and

dry dirty ionizing-collecting cells

The wash cycle is recommended to be performed

daily on the unit and uses an automated wash down

sequence to remove the grease that has been collected

on the ESP cells. The length of time and frequency of

washing will be determined by the grease load in the

airstream. The times shown are the factory settings but

can be adjusted as needed based on site conditions.

The wash cycle can be started three different ways:

1. User presses the wash button on the keypad or

touch screen.

2. An external wash contact is closed (terminals WS-1A

and WS-1B).

3. The controller can be set up to wash the unit

automatically based on a schedule set up on the

controller.

The wash sequence will wash each ESP module using

the steps below. For units with multiple ESP modules,

the wash sequence will repeat itself for each module

with the exception of the drip dry and fan dry sequence.

The drip dry and fan dry portion will start once all of the

modules have completed washing and are used to dry

the entire unit before placing it back into service.

Wash Override: The wash sequence can be stopped

by pressing the wash button on the user interface. This

will cancel the wash sequence and return the PCU to

normal operation. When calling for a wash or during the

wash sequence if the fan is turned on either by the fan

button, remote fan enable contact, or the fire system is

activated the wash sequence will stop and the exhaust

fan will turn on.

Pre-Soak

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Open

• Detergent Pump - Off

• Time - 3 minutes

Detergent

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Open

• Detergent Pump - On

• Time - 30 seconds (Housing sizes 15 and 30)

1 minute (Housing sizes 45, 60 and 90)

Rinse

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Open

• Detergent Pump - Off

• Time - 4 minutes

Detergent

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Open

• Detergent Pump - On

• Time - 30 seconds (Housing sizes 15 and 30)

1 minute (Housing sizes 45, 60 and 90)

Soak

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Closed

• Detergent Pump - Off

• Time - 3 minutes

Rinse

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Open

• Detergent Pump - Off

• Time - 4 minutes

Drip Dry

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• ESP Module Solenoid Valve - Closed

• Detergent Pump - Off

• Time - 1 minute

Fan Dry

• Exhaust Fan - On

• Terminal Box Indicator Lights - Off

• ESP Module Solenoid Valve - Closed

• Detergent Pump - Off

• Time - 90 minutes

Soak

• Exhaust Fan - Off

• Terminal Box Indicator Lights - Off

• Main and ESP Module Solenoid Valve - Off

• Detergent Pump - Off

• Time - 3 minutes

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System12

Page 13

Controller Setup and Tutorial

The user can access the main menu by pressing the

button.

Within the programmable logic controller, factory set

points can be modified to configure the system for

specific functions if necessary. All parameters are

shown in this section.

Some of the menus require the user to enter a password

in order to enter the menu. The service password is

1000 and is entered by pressing the

number and to advance the cursor, press the button.

Escape Allows the user to exit the current menu, jumping to the Main Menu.

to change the

Keypad Navigation

The DDC controller is located in the unit control panel.

The face of the controller has six buttons, allowing the

user to view unit conditions and alter parameters. The

DDC controller is pre-programmed with easy to use

menus.

!

Ì

To change the display contrast, hold the Alarm

Program

and arrows.

If equipped, the keypad user interface connects via a

factory-provided RJ-25 cable to the J10 port on the

controller.

Information regarding most of the settings within the

Controller U1 are provided in this Installation, Operation

and Maintenance Manual.

buttons simultaneously while pressing the

and

Up | Down

!

Ì

Exhaust 1 Setpoints

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

Current Temp: 70.0°F

Exhaust 1 Setpoints

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

Current Temp: 70.0°F

Alarm

Enter

Program Pressing the Program button allows the user to enter the Main Program Menu.

The arrow buttons allow the user to scroll through different screens and adjust

parameters.

Button will blink red, indicating an alarm condition. Press to review current alarms. To

review previous alarms, access the DATA LOGGER in the alarm menu.

A. In screens with adjustable parameters, pressing the Enter button moves the cursor

from the upper left corner of the screen to the parameter. The arrow buttons can then

be used to adjust the parameter.

B. To move to the next parameter on the same screen, press the Enter button.

C. To save the change, press the Enter button until the cursor moves back to the upper

left corner of the screen.

Example of Parameter Adjustment

Once you enter into a menu that has adjustable parameters, the cursor always

begins in the upper left corner of the display and will be blinking. Press the

button to move the cursor down for parameter adjustment.

Once the cursor has reached the desired parameter, press the buttons to

adjust the value.

Exhaust 1 Setpoints

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

Current Temp: 70.0°F

When satisfied with the adjustment, press the button to save the parameter.

When finished, make certain the cursor is in the upper left corner. If the

cursor is not in the upper left corner, the changes will not be saved. The

cursor must be in the upper left corner to enable screen advancement.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 13

Page 14

Main Menu Overview

If the PCU panel is configured with a touch screen, the controller will revert back to a PCU status loop. This loop

includes several screens to view the operating conditions of the unit. If configured, scroll through the menu screens

by using

appear for every system.

buttons. Screens with a dashed line border are dependent upon the configuration and may not

PCU Exhaust Fan

Exhaust: On

Speed: XXX%

System Status:

***

!

button will flash red on the controller and the keypad (if connected).

Ì

Ì

If an alarm occurs, the

Alarms

Press DOWN to review current

alarm(s).

Press ESC to exit.

Press ALARM to reset.

ALARM

***

Exhaust Fan Alarm

Check exhaust fan starter

No active alarm

Press ENTER key

to access ALARM

HISTORY log.

or VFD.

Alarms

PCU STATUS :

This screen will display the status of the PCU exhaust fan as well as display fan

speed.

Example of Alarms

To navigate to the alarm menu, press the

scroll through any current alarms. Once the problem causing the alarm has been

corrected, all alarms except low detergent will automatically clear. Pressing the

!

button will clear the low detergent fault if it needs to be manually cleared. If the

alarm cannot be cleared, the cause of the alarm has not been fixed.

This is an example of an exhaust fan fault.

This screen appears if there are no active alarms.

To view all saved alarms, press the button to enter the DATA LOGGER. For

more information, see the Data Logger menu.

!

button once. Press the

Ì

button to

Alarm Alarm Description

Low Detergent No detergent flow or empty detergent tank*

Fan Fault Failure of the exhaust fan

PCU Door Fault One of the doors to the unit is open

Power Supply Failure Power supply has failed

Fire Detected Indicates fire in either the kitchen or PCU unit

*Depending on the software version for the controller provided with your specific system, the low detergent

alarm may have to be cleared manually. If your system requires you to clear the fault manually, fill the

detergent tank with the 1:1 detergent/water mix, then clear the alarm from the system from the user interface.

If your system automatically clears low detergent faults, fill the detergent tank with 1:1 detergent/water mix,

and the fault will be cleared upon the next wash cycle.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System14

Page 15

A. Clock

The Clock menu allows the user to view and alter the time and date. The user can

also adjust the daylight savings time setting.

Clock

02:00:00PM 01/01/18

Date: MM/DD/YY

Hour: 15:30

Day: Monday

Clock

DST: Enable

Transition time: 60min

Start: LAST SUNDAY

in MARCH at 2.00

End: LAST SUNDAY

in OCTOBER at 3.00

Holiday Configuration

Number: 4

Wash and fan schedules will

not operate during holidays.

Holiday X

1: 0/ 0 - 0/ 0

2: 0/ 0 - 0/ 0

3: 0/ 0 - 0/ 0

4: 0/ 0 - 0/ 0

THE CLOCK SCREEN ALLOWS THE USER TO ADJUST THE TIME AND DATE.

The time/date will not be adjustable on the controller if the user interface is the

touch screen.

THIS SCREEN ALLOWS THE USER TO ADJUST DAYLIGHT SAVINGS TIME SETTING.

The Daylight Savings time feature can be adjusted to meet the current daylight

savings time requirements.

THIS SCREEN ALLOWS THE USER TO ADD AND ADJUST HOLIDAY TIMES.

The user can add up to 16 holidays. Adding holidays will prevent the wash and fan

scheduler controlling the wash/fan during the days selected.

B. Input/Output

Analog Input

Fan Speed (AIN1)

Input Ch: B001 0.0%

Digital Input

On / Off (DIN1)

DI 1 Status: Open

Relay Output

Exhaust Relay (DOUT1)

Relay 1 Status: OFF

Analog Output

Fan Speed (AOUT1)

Output: 5.00vdc

The Input/Output menu allows the user to quickly view the status of the controller

inputs and outputs.

To manually control I/O values, go to the Service menu > Service settings >

I/O Manual Control.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize the input shown. See unit wiring diagram for your

specific configuration.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize the input shown. See unit wiring diagram for your

specific configuration.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize the output shown. See unit wiring diagram for your

specific configuration.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize the output shown. See unit wiring diagram for your

specific configuration.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 15

Page 16

C. Service

The Service menu allows the user to access several sub-menus regarding controller

information, controller overrides, operating hours, BMS configuration, I/O manual

management and wash settings. By accessing the BMS Configuration sub-menu,

the user can adjust BMS protocol settings. (BACnet®, LonWorks®, Modbus)

C. Service

a. System Information

Information

Accurex, LLC.

Version: 1.0.006

Date 07/19/19

Bios: 6.27 09/07/04

Boot: 5.00 09/07/04

C. Service

b. Power Supply

Power Supply Settings 1

Power Supply Operating

Signal Voltage

Pass1: 3.0vdc (12.0kV)

Pass2: 3.0vdc (12.0kV)

Pass3: 3.0vdc (12.0kV)

Power Supply Settings 2

Power supply initial reset

attempts before alarm: 10

The System Information sub-menu displays information about the controller and

the program loaded on the controller.

THIS SCREEN SHOWS VERSION, BOOT AND BIOS INFORMATION. BIOS AND BOOT PERTAIN

TO THE CONTROLLER’S FIRMWARE AND OPERATING SYSTEM.

The Power Supply sub-menu allows the user to view and adjust the power supply

settings.

THIS SCREEN ALLOWS THE USER TO ADJUST OUTPUT SIGNAL POWER TO THE POWER

SUPPLIES AND THE CORRESPONDING KV OUTPUT.

This should only be adjusted on factory advisement only. Default is 3.0vdc (12kV).

THIS SCREEN ALLOWS THE USER TO ADJUST POWER SUPPLY RESET ATTE MP TS UPON A

FAULT BEFORE ENTERING ALARM.

Default is 10 attempts.

Power Supply Settings 3

Power supply alarm

reset delay: 10 minutes

C. Service

c. Wash Settings

Wash Settings 1

Pre-Soak: 180 sec

Detergent: 60 sec

Soak: 180 sec

Rinse: 240 sec

Dry: 60 min

Drain Time: 60 sec

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System16

THIS SCREEN ALLOWS THE USER TO ADJUST POWER SUPPLY RESET DELAY AFTER A

POWER SUPPLY ALARM HAS OCCURRED.

Default is 10 minutes.

The Wash Settings sub-menu allows the user to view and adjust the wash times.

THIS SCREEN ALLOWS THE USER TO ADJUST SETTINGS FOR A UNIT WAS H. DEFAULT

TIMES ARE PROVIDED ON PAGE 12 OF THIS MANUAL.

Pre-Soak: Time for spraying cell(s) with water.

Detergent: Time for spraying cell(s) with water with detergent injected into the

water line.

Soak: Time to allow the cells to soak (water and detergent stop).

Rinse: Time for spraying the cell(s) with water to remove debris and detergent.

Dry: Time for turning on the fan after a wash to dry out the cells.

Drain: This time begins simultaneously with the dry time. During this drain time,

the drain solenoid valve will open allowing any excess water in the main line to

drain.

Page 17

Wash Settings 2

Auto Wash: Yes

Auto Wash Time: 2:00am

Days/Week

Mo Tu Wd Th Fr Sa Su

THIS SCREEN ALLOWS THE USER TO ADJUST SETTINGS REGARDING THE AUTO WASH

FEATURE WHICH STARTS A WASH AUTOMATICALLY AT A SPECIFIC TIME A DAY.

Auto Wash: Enable or disable the auto wash feature.

Auto Wash Time: Adjust the time of day the wash will start. Note the wash will

only begin if the fan is not on.

Days/Week: Adjust which days per week the auto wash should occur. Black

(filled in) boxes indicate enabled for that day, white (open) boxes indicate disabled

for that day.

Last Washes

Last Complete Wash

00:00:00am 00/00/00

Last Aborted Wash

00:00:00am 00/00/00

Reason: None

THIS SCREEN ALLOWS THE USER TO VIEW LAST COMPLETED SUCCESSFUL WASH CYCLE,

LAST WASH CYCLE THAT WAS STOPPED SHORT, AND THE REASON WHY THE LAST WASH

CYCLE WAS STOPPED SHORT.

Last Complete Wash: Date and time stamp of last completed, successful wash

cycle.

Last Aborted Wash: Date and time stamp when last wash cycle was stopped.

Reason: Reason for the last wash cycle stopping short OR prevented from

starting. Reasons can include:

a. Keypad Wash Bn – Wash button on keypad was pressed, stopping the wash

cycle

b. Open Unit Door – Door on unit body was left open or opened during the wash

cycle

c. Keypad Fan Run – Fan button on keypad was pressed before the wash cycle

was attempted to start, or pressed while the wash cycle was in process,

overriding the fan to turn on and therefore stopping the wash cycle

d. DI Fan Run – Digital input (Fan On/Off, Digital Input 1) was detected as closed

before wash cycle was attempted to start, or closed while the wash cycle was

in process, overriding the fan to turn on and therefore stopping the wash cycle

e. Program Change – If wash control is disabled in the factory settings, this will

stop a wash from completing

f. Fire Active – If kitchen fire is detected, it will prevent a wash from occurring or

stop a wash from completing

Wash Log History

Press ENTER key to

access log history of

completed washes.

Clear Wash Log History

This will clear the wash log

history.

Continue? NO

THIS SCREEN ALLOWS THE USER TO VIEW LAST COMPLETED SUCCESSFUL WASH

CYCLES, PROVIDED WITH A DATE AND TIME STAMP.

Pressing enter will bring up the successful wash log history. Pressing up/down

arrows will cycle through each successful wash date/time stamp. The log only

records successfully completed wash cycles. All aborted wash cycles will not be

recorded.

NOTE

The log is capable of logging up to 100 washes. Once

100 is reached, the program will overwrite the oldest

wash date/time stamp logged.

THIS SCREEN ALLOWS USER TO CLEAR THE WASH LOG HISTORY. PRESSING ENTER TO

NAVIGATE DOWN TO “NO”, AND CHANGING TO “YES” ON THIS SCREEN WILL CLEAR ALL

RECORDED SUCCESSFUL WASH CYCLE DATE/TIME STAMPS.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 17

Page 18

Low Det Settings 1

Washes during low detergent

alarm: 0

Last wash on low det:

00:00:00am 00/00/00

Reset Det Count: OFF

THIS SCREEN ALLOWS USER TO VIEW LOW DETERGENT INFORMATION RECORDED WITH

WASH SYSTEM.

Washes during low detergent alarm: Counts number of times wash cycle was

completed during a low detergent alarm.

Last wash on low detergent: Date and time stamp when last wash cycle was

stopped short OR prevented from starting.

Reset detergent count: Changing this from “OFF” to “ON” will change the count

for “Washes during low detergent alarm” back to 0.

Low Det Settings 2

Det Alm Delay: 15s

Wash Settings 3

ESP cell power supply

delay time after wash

cycle is aborted: 90 min

Test Wash Setup

Pre-Soak: 10 sec

Detergent: 10 sec

Soak: 10 sec

Rinse: 10 sec

Dry: 1 min

Drain: 10 sec

Start Test Wash? NO

THIS SCREEN ALLOWS THE USER TO ADJUST THE DELAY TIME TO INITIATE A LOW

DETERGENT FAULT AFTER DETECTING NO DETERGENT FLOW.

Default is 15 seconds.

THIS SCREEN ALLOWS THE USER TO ADJUST THE DELAY TIME BEFORE CELLS CAN BE

POWERED AGAIN IF A WASH CYCLE IS STOPPED PREMATURELY.

Default setting is 90 minutes.

THIS SCREEN ALLOWS THE USER TO ADJUST SETTINGS FOR A UNIT TEST WAS H AND

ALSO START A TEST WASH. TEST WASH ES ALLOW FOR EXPEDITED SEQUENCE TIMES TO

QUICKLY MONITOR A FULL WASH SEQUENCE. CHANGING “NO” TO “YES” WILL START

A TEST WASH. DURING A TEST WASH, PRESS THE BACK BUTTON TO ABORT THE TEST

WASH SEQUENCE.

C. Service

d. BMS Configuration

BMS Configuration

Protocol: BACnet MSTP

BACnet Plugin? YES

MODBUS SETUP

Address: 1

Baudrate 9600

The BMS Configuration sub-menu allows the user to view and alter BMS protocol

settings. If the BMS protocol is BACnet or Modbus, additional screens allow

further configuration. See below for details. To access the BMS Configuration

sub-menu, enter the service password (Default=1000).

THIS SCREEN ALLOWS THE USER TO SELECT THE BMS PROTOCOL. ALL BMS

PROTOCOLS REQUIRE A COMMUNICATIONS CARD INSTALLED IN THE SERIAL CARD

PORT, LOCATED ON THE FACE OF THE CONTROLLER.

If the protocol is BACnet MSTP or BACnet IP/Eth, the user can change common

BACnet parameters via the controller. The BACnet Plugin must be set to YES.

THIS SCREEN ALLOWS THE USER TO ADJUST MODBUS PAR AMETERS.

This screen only appears if the selected BMS protocol is set to Modbus.

The address is the Modbus address of the card installed in the SERIAL CARD port

located on the face of the controller. (Factory Default = 1).

The Baud Rate should be set to the BMS baud rate. (Factory Default = 9600).

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System18

Page 19

MSTP SETUP

Instance: 77000

Baudrate 38400

MAC Addr: 0

MaxMasters: 127

MaxInfoFrames: 20

THIS SCREEN ALLOWS THE USER TO ADJUST BACNET MSTP PARAMETERS.

This screen only appears if the selected BMS protocol is set to BACnet MSTP and

BACnet Plugin = YES.

If a BACnet MSTP card has been installed, the default parameters can be changed

via the controller display. Factory settings are shown in the screen to the left.

To view current parameters:

BACnet Read/Write

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Configuration menu and view BACnet Read/Write screen.

Function: Read

Update? Yes

*Cycle unit power to confirm

write command.

3. Change Function to Read and Update? to YES.

Current BACnet MSTP parameters should now be displayed in the BACnet MSTP

SETUP screen. If all values appear to be zeros, consult the factory. (Make sure you

have allowed several minutes for the controller to initialize).

Values may appear to be zero prior to setting the Function to READ.

To change BACnet MSTP parameters:

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Configuration menu and view MSTP SETUP screen.

3. Move cursor to desired parameter by pressing the

4. Once desired parameters have been entered, go to BACnet Read/Write

5. Reboot the controller by cycling power to the unit. Allow several minutes for

6. View MSTP parameters. If changed values did not save, contact the factory.

buttons. Press

to select the parameter to change. Press the buttons to adjust the

parameter. Press to save adjusted value.

screen. Change Function to Write and Update? to YES.

the controller to initialize.

TCP/IP SETUP

Instance: 77000

IP set by: DHCP

IP: 128.2.104.134

Subnet: 255.255.000.000

Gatewy: 128.2.0.12

THIS SCREEN ALLOWS THE USER TO ADJUST BACNET IP PARAM ETER S.

This screen only appears if the selected BMS protocol is set to BACnet IP/Eth and

BACnet Plugin = YES.

If a BACnet IP card has been installed, the default parameters can be changed

via the controller display. The card is in DHCP mode from the factory. Once

communication is established, the user can enter static IP parameters.

TCP/IP SETUP

To view current parameters:

1. Power on controller and allow several minutes to initialize.

DNS 1: 192.168.001.001

DNS 2: 192.168.001.001

Type: IP

2. Go to BMS Configuration menu and view BACnet Read/Write screen.

3. Change Function to Read and Update? to YES.

Current BACnet IP parameters should now be displayed in the BACnet TCP/IP

SETUP screen. If all values appear to be zeros, consult the factory. (Make sure you

have allowed several minutes for the controller to initialize).

*Values may appear to be zero prior to setting the Function to READ.

BACnet Read/Write

To change BACnet TCP/IP parameters:

1. Power on the controller and allow several minutes to initialize.

Function: Read

Update? Yes

*Cycle unit power to confirm

write command.

2. Go to BMS Configuration menu and view TCP/IP SETUP screen.

3. Move cursor to desired parameter by pressing the

4. Once desired parameters have been entered, go to BACnet Read/Write

5. Reboot the controller by cycling power to the unit. Allow several minutes for

6. View TCP/IP parameters. If changed values did not save, contact the factory.

buttons. Press

to select the parameter to change. Press the buttons to adjust the

parameter. Press to save adjusted value.

screen. Change Function to Write and Update? to YES.

the controller to initialize.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 19

Page 20

C. Service

e. Service Settings

a. Fan Operation

b. I/O Manual Control

c. Sensor Calibration

d. User Save/Restore

e. Alarm History Reset

The Service Settings sub-menu allows the user to adjust fan operation settings,

set a fan on/off schedule, manually enable/disable input and outputs, calibrate

sensors, create or restore user settings and the alarm history log.

C. Service

e. Service Settings

a. Fan Operation

Auto Fan Off Settings

Auto Fan Off? No

Run Hours: 8 hours

Note: This will only shut the

fan off if the fan was powered

on by the keypad (NOT DI)

Fan Scheduling

Fan On: NO

8:00am

Fan Off: NO

10:00pm

Days/Week

Mo Tu Wd Th Fr Sa Su

The Fan Operation sub-menu allows the user to adjust fan settings.

THIS SCREEN ALLOWS THE USER TO ADJUST SETTINGS REGARDING THE AUTO OFF

FEATURE WHICH STOPS THE FAN IF STARTED FROM THE USER INTERFACE AFTER A

SPECIFIC AMOUNT OF TIME.

Auto Fan Off?: Enable or disable the auto fan off feature. (Default is No).

Run Hours: Adjust fan run time before the fan automatically shuts off. (Default =

8hours).

THIS SCREEN ALLOWS THE USER TO SET A FA N ON/OFF SCHEDULE FOR THE WEEK.

Fan On: Enable or disable the fan turning on at a specific time. Time can be

adjusted below for fan on setting. (Default is NO, with 8:00am start time).

Fan Off: Enable or disable the fan turning off at a specific time. Time can be

adjusted below for fan off setting. (Default is NO, with 10:00pm start time).

Days/Week: Adjust which days per week the auto wash should occur. Black

(filled in) boxes indicate enabled for that day, white (open) boxes indicate disabled

for that day.

C. Service

e. Service Settings

b. I/O Manual Control

Analog Input

PS1 Status (AIN 4)

Manual Control B004:OFF

Manual Position 0.0

Value 2.50vdc

Digital Input

On / Off (DIN 1)

Manual DI 1: OFF

Manual Position: CLOSED

DI 1 Status: Open

In I/O Manual Control, the user will be able to adjust inputs/outputs.

NOTE: The manual adjustment of these input and/or outputs should only be

adjusted in the event of troubleshooting. We suggest these parameters only be

changed with the advice of factory personnel.

Manual Control: Allows the user to override the analog input for troubleshooting.

Manual Position: The value to force the input to when in an override state.

Value: The current value of the analog input.

Manual DI: Allows the user to override the digital input for troubleshooting.

Manual Position: The value to force the input to when in an override state.

Status: The current value of the digital input.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System20

Page 21

Relay Output

Exhaust Relay (DOUT 1)

Manual Relay 1: OFF

Manual Position OFF

Relay 1 Status: OFF

Manual Relay: Allows the user to override the relay output for troubleshooting.

Manual Position: The value to force the output to when in an override state.

Status: The current value of the relay output.

Analog Output 1

Fan Speed (AOUT 1)

Mode: Auto

Manual Value 0.00vdc

Output: 0.00vdc

C. Service

e. Service Settings

c. Sensor Calibration

Analog Input

Fan Speed (AIN1)

Input B01

Offset 0.0

Value 100.0

C. Service

e. Service Settings

d. User Save/Restore

Mode: Allows the user to override the analog output for troubleshooting.

Manual Value: The value to force the output to when in an override state.

Output: The current value of the analog output.

In Sensor Calibration, the user will be able to adjust analog inputs offsets.

Offset: This adjustable value can be used to calibrate the input with an offset

value. (Factory Default = 0.0)

Value: This is the current value of the input. (Offset adjustment is added).

Similar screens are available for the remaining analog inputs.

In User Save/Restore mode, the user will be able to save and restore the default

parameters stored in memory.

User Save/Restore

Save? No

Restore? No

Enable Auto Save: Yes

C. Service

e. Service Settings

e. Alarm History Reset

Alarm History Reset

This will clear the

alarm history.

Continue? NO

D. Manufacturer

If the user would like to save their settings, move the cursor to the SAVE position

and change to YES. This will save all of the current parameters into memory as

Service Settings. If the user would like to restore to these values at some point

in the future, moving the cursor to the RESTORE position and selecting ON, will

restore the controller to the user-saved defaults.

THIS SCREEN ALLOWS THE USER TO CLEAR THE ALARM FROM MEMORY.

If the user would like to clear the alarm log, move the cursor to the OFF position

and change to YES.

The Manufacturer menu allows the user to access several sub-menus regarding

controller configuration, I/O configuration, factory settings, controller initialization

pages, and factory save/restore pages. These changes are to be completed under

factory advisement only!

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System 21

Page 22

Keypad Navigation

SYSTEM FAULT

SYSTEM FAULT

FAN WASH

MENU

MENU

NAV

NAV

When ‘BUTTON(S)’ are mentioned in the description below, we are referring to the ‘squares’ on the keypad.

The following information details the Daily Operations of the Grease Trapper ESP keypad buttons and their functions.

FAN - Momentarily pressing the ‘FAN’ button will turn

on the PCU unit. If the fan is on, the background behind

‘FAN’ text will be dark. To turn the system off, press the

‘FAN’ button.

WASH - Momentarily pressing the ‘WASH’ button will

start the automatic washdown sequence. If the wash

sequence is in process, the background behind ‘WASH’

text will be dark. To cancel the wash sequence, press

the ‘WASH’ button.

MORE, if equipped - Momentarily pressing the ‘MORE’

button will navigate to an additional screen

BACK, if equipped - Momentarily pressing ‘BACK’

button will navigate to the previous screen.

Display functionality and control:

To change the display contrast, hold the buttons next

to the Alarm

while pressing the buttons next to the

!

and Program icons simultaneously

Ì

and arrows.

The down arrow will make the screen lighter and the up

arrow will make the screen darker.

Upon any alarm, the ‘SYSTEM FAULT’ red LED light on

the face of the keypad starts flashing. Once all alarms

are corrected and any low detergent alarm is manually

reset, this LED will stop flashing and no longer be

illuminated.

Through the middle of the screen, system status

messages will be displayed as a reference. These

system statuses will include:

• Current alarms

• Power Supply Status

• Exhaust Fan Status

• Wash Sequence

The keypad also includes indicators next to the buttons

that correspond to the buttons on the controller. These

can be used to navigate through the controller using the

keypad. To access the main menu, simply press and

hold the button next to the Program

icon for five

seconds or until the screen changes to the main menu.

Grease Trapper ESP™ Kitchen Exhaust Pollution Control System22

Page 23

AM

ON/O

ON/O

DO

ORS

S

US

WAS

S

US

S

US

S

USANS

US

PO

T

I

G

E

Touch Screen Navigation

N

ON/O

ON/O

I

S

US

Y

S

US

DO

ORS

S

S

S

US

S

US

GREASE TRAPPER ESP MAIN PAGE 10:11

REASE TRAPPER ESP MAIN PAG

DETERGEN

FAN

STATUS

TAT

POWER SUPPLY 6 ON

WER SUPPLY 6 ON

FAN

AN

ON/OFF

FF

POWER SUPPLY

POWERSUPPLY

STATUS

WASH

WASH

ON/OFF

FF

DOOR SAFETY

AFETY

STATUS

TAT

TAT

WASH

STATUS

TAT

DETERGENT

INDICATOR

NDICATOR

H

10:11 AM

FIRE

STATUS

TAT

FIRE STATUS INDICATOR – green indicates

normal operation and red indicates a fire has

FIRE

STATUS

TAT

been detected.

HELP – displays a help menu and navigation

tips.

ESP WASH STATUS - navigates to a screen

IRE

showing wash status and countdown timers.

ESP Wash Status Indicators: As the system

is in the wash mode, the indicators will

change colors based on the state of washing.

Green indicates the mode of operation.

Momentarily press or tap to access the menu or enable

or disable the action of the associated icon. All icons

surrounded by blue are momentary push buttons.