Page 1

Document 481488

Auto Scrubber

Auto-Cleaning Hood

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and all applicable local and national building

and fire codes. Personnel should be aware of general

safety precautions. SMACNA guidelines should be

followed for hanging and supporting the hood. If more

information is needed, contact a licensed professional

engineer before moving forward.

DANGER

Always disconnect power before working on or near a

unit. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

NOTE

Follow all local electrical, plumbing and safety codes,

as well as the National Electrical Code (NEC) and the

latest edition of the National Fire Protection Agency

Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations, (NFPA 96). Follow

the Canadian Electrical Code (CEC) and ULC-S650 if

installing this product in Canada.

Receiving

Upon receiving the product, check to ensure all items

are accounted for by referencing the delivery receipt or

packing list. Inspect each crate or carton for shipping

damage before accepting delivery. Alert the carrier

of any damage detected. The customer will make

a notation of damage (or shortage of items) on the

delivery receipt and all copies of the bill of lading which

is countersigned by the delivering carrier. If damaged,

immediately contact your Accurex Representative. Any

physical damage to the unit after acceptance is not the

responsibility of Accurex, LLC.

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited

to only items on the bill of lading. Filters are shipped

on a separate skid in their original packaging. Do not

remove factory packaging or install filters until just prior

to commissioning. Remove all other shipping/packing

materials.

Handling

Units are to be rigged and moved by the lifting brackets

provided or by the skid when a forklift is used. Location

of brackets varies by model and size. Handle in such

a manner as to keep from scratching or denting.

Damaged finish may reduce ability of unit to resist

corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage.

The ideal environment for storage of the hood and

accessories is indoors, above grade in a clean, dry

atmosphere that is sealed from the elements. While in

storage, inspect equipment routinely. If any moisture,

dirt or other accumulations are found on the hood or

any of the parts, the source should be located and

eliminated.

Removing from Storage

As equipment is removed from storage to be installed

in their final location, it should be protected and

maintained as outlined in the Handling section above.

Auto Scrubber 1

Page 2

Table of Contents

Auto Scrubber Hood Function

General Safety Information . . . . . . . . . . . . . . 1

Receiving/Unpacking/Handling . . . . . . . . . . . 1

Storage/Removing from Storage . . . . . . . . . . 1

Auto Scrubber Hood Function . . . . . . . . . . . . . 2

System Components

Hood. . . . . . . . . . . . . . . . . . . . . . . . . 3

Auto Scrubber Control Panel . . . . . . . . . . . . 3

Backflow Preventer . . . . . . . . . . . . . . . . . 3

User Interface . . . . . . . . . . . . . . . . . . . . 3

Hood Weights . . . . . . . . . . . . . . . . . . . . . 3

Supply Plenum Weights and Dimensions . . . . . . . 4

Prior to Installation . . . . . . . . . . . . . . . . . . . 5

Unpacking . . . . . . . . . . . . . . . . . . . . . . . 5

Hood Installation Overview . . . . . . . . . . . . . 6-7

Filler Panel Installation . . . . . . . . . . . . . . . . . 7

Clearance Reduction Method . . . . . . . . . . . . 7-8

Top Clearance Reduction Options . . . . . . . . . 7

Back and Front Clearance Reduction Options . . . 8

End Clearance Reduction Method . . . . . . . . . 8

Installing Duct Collars

Exhaust Duct Collars . . . . . . . . . . . . . . . . 8

Supply Duct Collars to the Plenum . . . . . . . . . 8

Installing Back Supply Plenum . . . . . . . . . . . . 9

Ductwork

Exhaust/Supply . . . . . . . . . . . . . . . . . . . 9

Continuous Capture Plenum Hoods . . . . . . . . . . 9

Installing Front/Side External Supply Plenums . . . .10

Uni-Strut . . . . . . . . . . . . . . . . . . . . . . .10

Hanger Brackets and Threaded Rod . . . . . . . .10

Supply Duct Collar . . . . . . . . . . . . . . . . .10

Installing Backsplash / Side Splash Panels . . . . . .11

Installing End Skirts . . . . . . . . . . . . . . . . . .12

Plumbing

Connections . . . . . . . . . . . . . . . . . . . . .13

Detergent Tank Installation . . . . . . . . . . . . .13

Detergent Requirements . . . . . . . . . . . . . .13

Preventative Maintenance . . . . . . . . . . . . . .13

Typical Plumbing Connection Layout . . . . . . . .14

Electrical Connections

Wiring . . . . . . . . . . . . . . . . . . . . . .15-16

Typical Electrical Connection Layout . . . . . . . .17

Installing Ceiling Enclosure Panels . . . . . . . . . .18

Double Island Canopy Style Hoods . . . . . . . . . .18

Initial System Start-Up . . . . . . . . . . . . . . . . .19

System Operation

Fan Operation . . . . . . . . . . . . . . . . . . . .19

Hood Light Operation . . . . . . . . . . . . . . . .19

Wash Operation . . . . . . . . . . . . . . . . . . .20

Wash Sequence of Operation . . . . . . . . . . . 21-22

Airflow Testing Procedure . . . . . . . . . . . . . . .23

Additional Wiring Schematics

Ansul® and Amerex® Wiring Plan View . . . . . .24

Maintenance

Filters and Capture Tank . . . . . . . . . . . . . .25

Auto Scrubber Start-Up Checklist . . . . . . . . . . .26

Troubleshooting . . . . . . . . . . . . . . . . . . 27-29

Replacement Parts. . . . . . . . . . . . . . . . . . .30

Maintenance Log. . . . . . . . . . . . . . . . . . . .31

Our Commitment. . . . . . . . . . . . . . . Backcover

Accurex’s Auto Scrubber hoods are designed for three

primary functions:

• Capture and contain the effluent produced by the

cooking process.

• Remove grease and other contaminants from the

airstream with either one or multiple stages of

mechanical filters.

• Wash the filters and other surfaces within the exhaust

plenum to remove contaminants.

NOTE

The wash sequence of the hood is not designed for

fire suppression and will not engage in the event of

afire.

NOTE

For information on the complete wash cycle, please

refer to the Wash Sequence of Operation, pages 21

and 22.

Auto Scrubber2

Page 3

System Components Hood Weights

Hood

The hood is shipped from the factory pre-piped and

ready to install. All wash components within the hood

are complete and ready for connection to hot water,

sanitary sewer drain and the electrical sources. If the

Auto Scrubber Control Panel is mounted on the hood,

wiring from the control panel to the hood lights, valves

and sensors is completed by Accurex. All field plumbing

and wiring must conform to plumbing and electrical

codes.

Auto Scrubber Control Panel (ASCP)

The control cabinet contains the water and electrical

components, including the Programmable Logic

Controller (PLC), that controls

the wash sequencing and

operations. The control

cabinet also includes the

detergent reservoir, detergent

pump, and other water piping.

NOTE

Filters are shipped loose with the hood and installed

in the field. To install the filters, perform the sequence

of steps outlined on page 25 in reverse.

Backflow Preventer

A backflow preventer will be shipped loose with the

ASCP and will need to be installed in-line with the hot

water supply to the ASCP to prevent detergent from

back-feeding into the building water supply. Plumbing

instructions begin on page 13.

Hood Weights

Hood Width

inches (cm)

48

(121.92)

51

(129.54)

54

(137.16)

57

(144.78)

60

(152.40)

63

(160.02)

66

(167.64)

69

(175.26)

72

(182.88)

4 feet

lbs. (kg)

244

(110.7)

250

(113.4)

256

(116.1)

262

(118.8)

268

(121.6)

274

(124.3)

280

(127.0)

286

(129.7)

292

(132.4)

Length

8 feet

lbs. (kg)

398

(135.2)

404

(183.3)

410

(186.0)

416

(188.7)

422

(191.4)

428

(194.1)

434

(196.9)

440

(199.6)

446

(202.3)

12 feet

lbs. (kg)

553

(250.8)

559

(253.6)

565

(256.3)

571

(259.0)

577

(261.7)

583

(264.4)

594

(269.4)

600

(272.2)

606

(274.9)

CAUTION

To ensure proper structural support, all hanger

brackets must be used for hanging the hood.

16 feet

lbs. (kg)

707

(320.7)

713

(323.4)

719

(326.1)

725

(328.9)

731

(331.6)

737

(334.3)

743

(337.0)

749

(339.7)

755

(342.5)

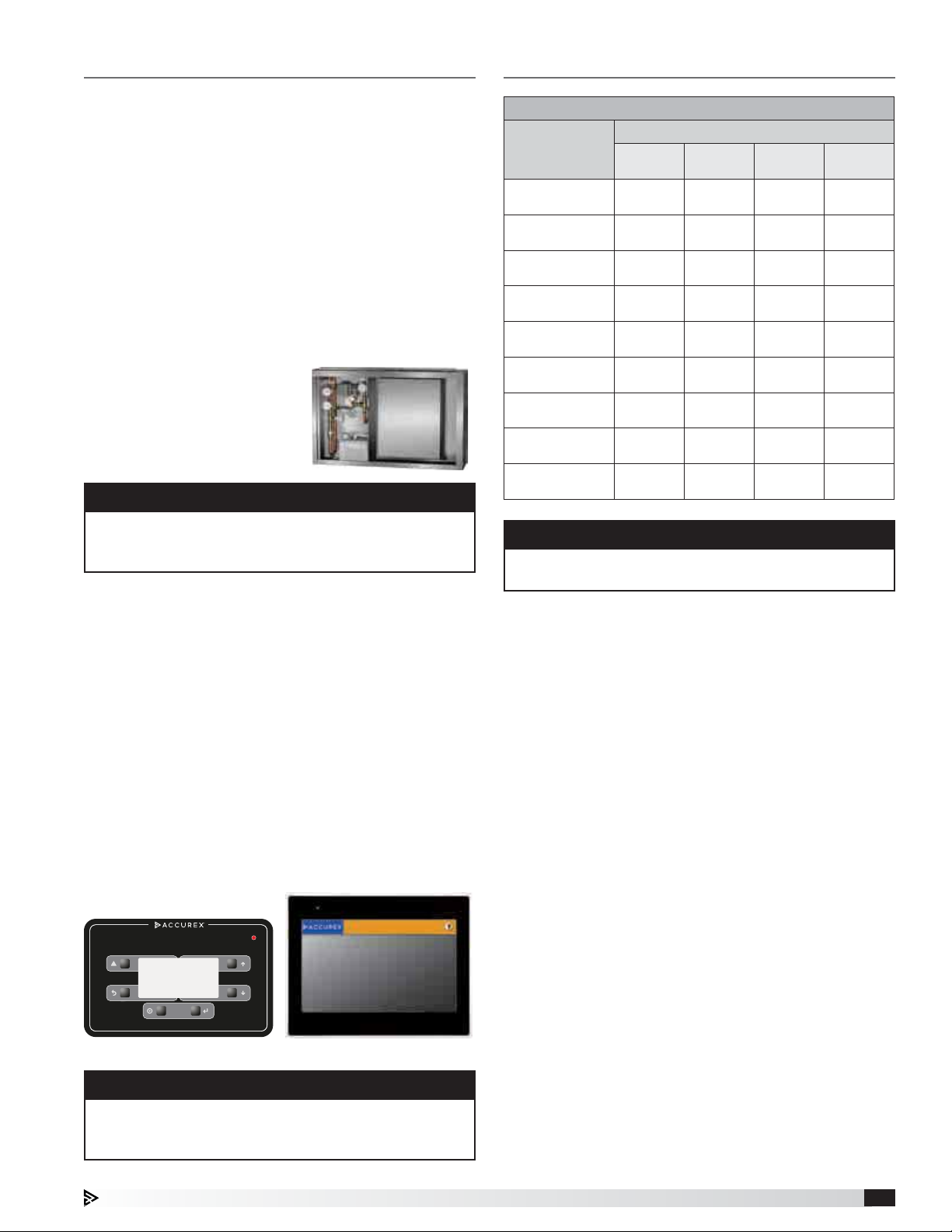

User Interface

The user interface will be either a keypad with LCD

screen or touch screen. It can be mounted on the Auto

Scrubber control cabinet, hood or shipped loose for

remote mounting. It will provide a WASH button (WASH

ON/OFF with touch screen), and a means of turning

on/off hood fans and lights, if applicable. It also includes

system alarm notifications to alert of any faults on the

system, such as a low detergent alarm.

SYSTEM FAULT

MENU

NAV

Keypad Touch Screen

NOTE

For detailed information on the Auto Scrubber Control

Panel (ASCP), please refer to the Accurex website,

www.accurex.com

Auto Scrubber 3

Page 4

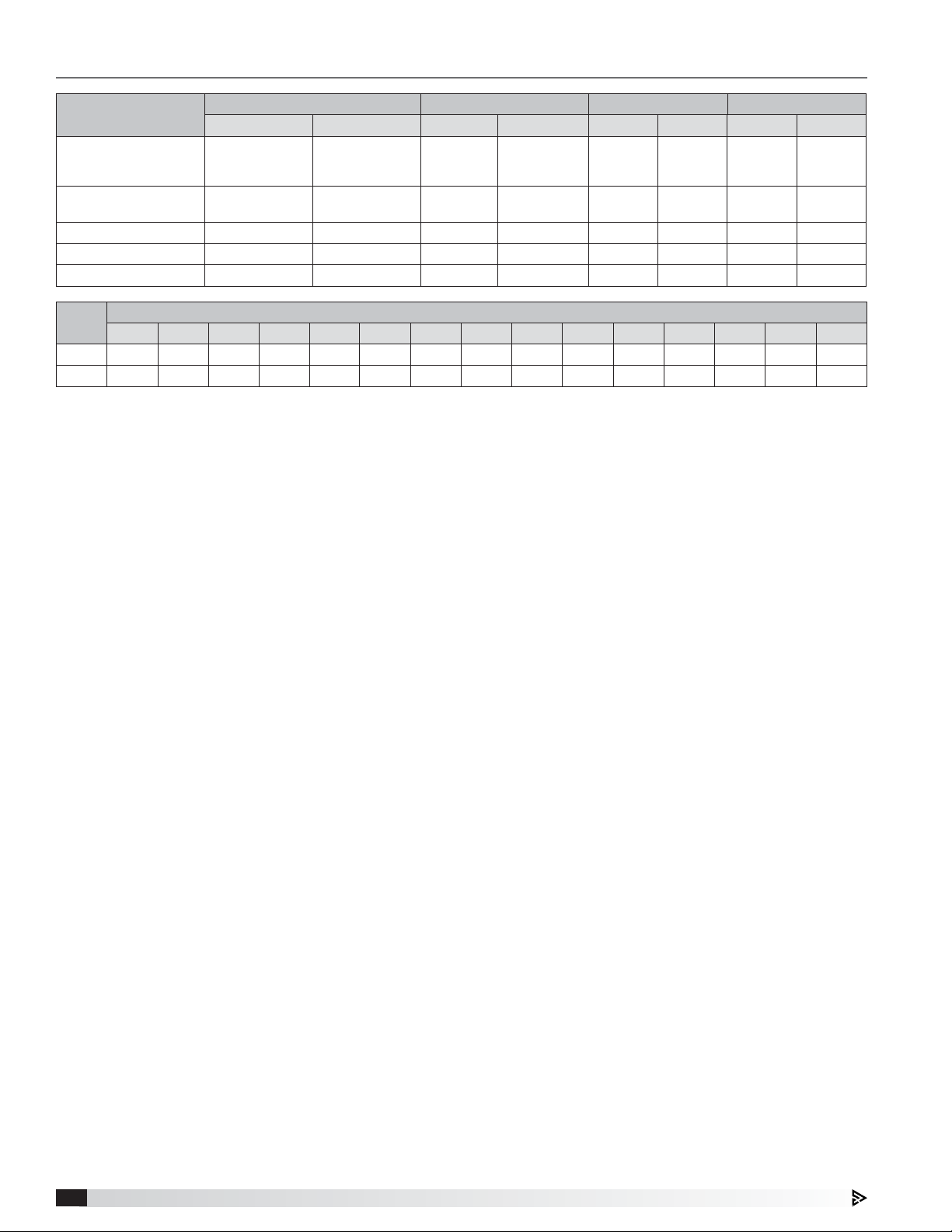

Supply Plenum Weights and Dimensions

External Supply

Plenum Type

Air Curtain Supply (ASP)

Split Air Curtain Supply

(Split ASP)

lbs/ft kg/m in. mm in. mm ft. m

Refer to Air Curtain

Supply Plenum

Weight Table

15.5 23.07 24 609.6 10 254.0 3 to 16 .91 to 4.88

Weight Width Height Length per section

Refer Air Curtain

Supply Plenum

Weight Table

10 to 24 254.0 to 609.6 10 254.0 3 to 16 .91 to 4.88

Back Supply (BSP) 35.0 52.09 6 152.4 Variable Variable 3 to 16 .91 to 4.88

Horizontal Supply (HSP) 14.0 20.83 12 304.8 18 457.2 3 to 16 .91 to 4.88

Variable Supply (VSP) 16.0 23.81 12 304.8 18 457.2 3 to 16 .91 to 4.88

Weight

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Air Curtain Supply Plenum Width (inches)

lbs/ft 8.3 8.6 8.9 9.2 9.5 9.8 10.1 10.4 10.7 11.1 11.3 11.6 11.9 12.2 12.5

kg/m 12.35 12.80 13.24 13.69 14.14 14.58 15.03 15.48 15.92 16.52 16.82 17.26 17.71 18.16 18.60

Auto Scrubber4

Page 5

Prior to Installation

Unpacking

Prior to installation, check with the Authorities Having

Jurisdiction (AHJ) on clearance requirements to

structures surrounding the hood and other equipment.

Verify there is enough space to safely lift the hood up

into its operating position and enough clearance around

the hood for components like fire system connections,

hood lights, hood control components, plumbing

connections, etc. Consider access for servicing the

equipment and the different components when locating

the hood.

The UL label located on the end panel on the inside of

the hood will provide pertinent information regarding the

hood installation. Information includes:

• Allowable cooking surface temperatures of the

cooking equipment

• Front and side overhang requirements

• Minimum exhaust airflow requirements

• Hood lights load information and restrictions

• Filter information

• Fire damper fusible link replacement information, if

applicable

Carefully remove the top of the crate and set aside all

accessories in the crate such as backsplash panels,

control packages, and boxes with loose parts. When

removing the hood from the crate, place protective

material on the floor next to the crate to avoid damaging

the hood.

Lift the hood only by utilizing the hanger brackets. Make

sure the hood weight is evenly distributed. Slowly lift

the hood out of the crate and place on the protective

material.

NOTE

If using straps, the straps should not interfere with

plumbing on the top of the hood in an effort to prevent

internal piping damage which could cause future

leaks.

Top of Hood

Pallet

Protective Material

Auto Scrubber 5

Page 6

Hood Installation Overview

It is recommended that the protective plastic sheeting

remain on the hood until fully installed to better protect

the product from scratching and marking. Once

removed, use stainless steel polish, such as BlueAway

or equivalent, to clean the hood and/or remove marks

or discoloration. Be sure to wipe with the grain and not

against it.

1. If the hood is provided with filler panels, shipped

loose, install them now. See page 7, Filler Panel

Installation. Filler panels may be integral to the

hood, which requires no additional installation.

2. If the hood is equipped with Clearance Reduction

Methods, refer to pages 7 and 8 for special

considerations with hanging the hood.

3. If the hood is provided with hood/duct sensors or

thermostats that were shipped loose, install them

now. See the Installation and Operations guide

provided with the control panel.

4. If the hood was provided with either exhaust

collars or supply collars that have shipped loose,

it is recommended that the exhaust and supply

openings are cut and collars are attached now,

prior to hanging the hood. See Installing Duct

Collars on page 8.

5 If the hood is provided with a back supply plenum

(BSP) install it now. See page 9, Installing the Back

Supply Plenum.

6. If possible, connect (weld) exhaust duct to the

hood while on the floor, unless it prohibits the hood

from being raised into place. For information on

ductwork, see page 9, Ductwork.

7. At this point, drill holes in the building structural

support system or utilize uni-strut to match up with

the hanger bracket holes. Then slowly and evenly

raise the hood into position and insert 1/2-inch

(12.7mm) diameter threaded rod (provided by

others) between the hanger brackets and structure.

The hood hanging height requirements are given on

the UL label. Typical canopy hood hanging height

will be 80inches (198.12cm) off the finished floor.

NOTE

If the hood is supplied with ceiling enclosure panels,

the height of the enclosures will typically be the

distance from the ceiling to the top of the hood. Use

this dimension to find the hood’s hanging height off of

the floor.

For questions regarding the supporting structure and

its integrity, either the contractor or structural engineer

needs to be consulted.

NOTE

All hanger brackets MUST be used and the hood must

be properly supported while lifting to prevent damage

or distortion to the hood.

NOTE

Ensure the hood is hung evenly to prevent drainage

problems. Provide adequate support so that the hood

does not move in a manner that is unacceptable to

the Authorities Having Jurisdiction (AHJ).

WARNING

When mounting the hood or any components against

the hood, never puncture or drill into the canopy

unless otherwise instructed in this manual. Doing so

will void the hood listing and warranty.

8. If the hood was provided in sections with the

continuous capture option, once each hood

section is hung, install this option now. See page 9,

Continuous Capture Plenum Hoods.

9. If the hood was provided with any front or side

external supply plenums (other than the back

supply plenum), install these now. See page 10,

Installing Front/Side External Supply Plenums.

10. Install the remainder of both the exhaust and

supply ductwork. For further guidelines see page 9,

Ductwork.

11. If the hood is provided with any backsplash/

sidesplash panels, install them now. See page 11,

Installing Backsplash Panels.

12. If the hood is provided with any end skirts, install

them now. See page 12, Installing End Skirts.

13. This is a Type I hood and it requires a fire

suppression system. Once the hood(s) and

ductwork are fully installed, appliance(s) are in

place and walls are complete, the fire system

should be completed.

If the hood is provided with a full factory-

coordinated fire suppression system installation,

the certified fire system installer should be

contacted at this time to complete the final

hookups, testing and system certification based

upon manufacturer’s specification and local fire

codes.

If the hood is equipped with pre-piping only, and/

or does not include fire suppression, it is the

responsibility of a certified fire system installer

to install, test and certify the system based upon

manufacturer’s specification and local fire codes.

14. The Auto Scrubber Control Panel (ASCP), if

shipped loose, will need to be installed at this time.

Once mounted, plumbing and electrical wiring

will need to be completed by the jobsite plumber

and electrician. Typical site wiring responsibilities

include wiring hood temperature sensors, hood

lights, hood sequencing valves, fire suppression

micro-switches, and fans (if applicable) to the

control panel. Hood plumbing details are given on

page 13-14, and hood electrical wiring details are

provided on page 15-17.

Auto Scrubber6

Page 7

Hood Installation Overview, continued

Clearance Reduction Methods

15. If the hood is provided with enclosure panels,

install them now. See page 18, Installing Enclosure

Panels.

16. Install the rest of the hood accessories provided.

This may include grease filters or condensate

hood baffles, grease cups, light bulbs (provided by

others unless LED tube style), light globes, and trim

strips.

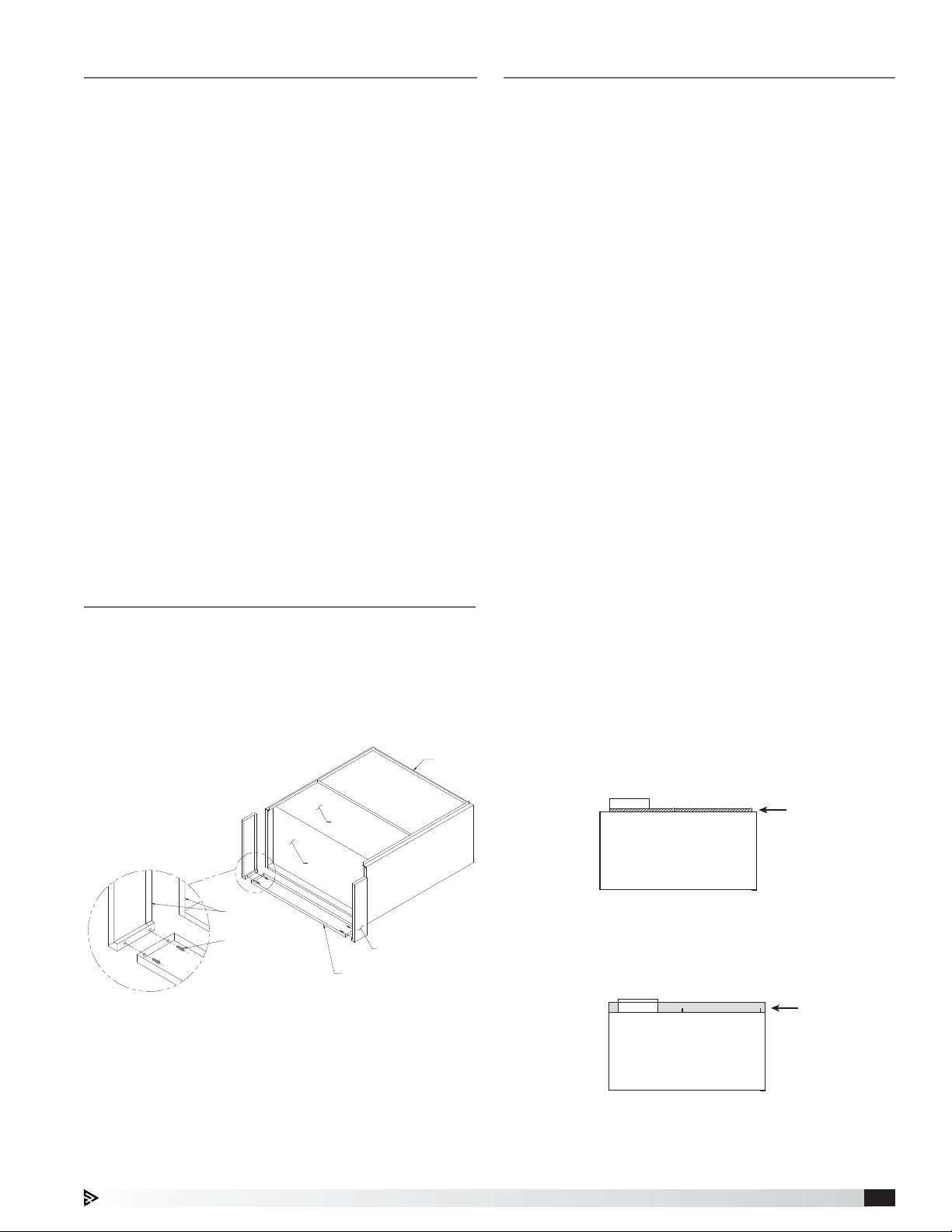

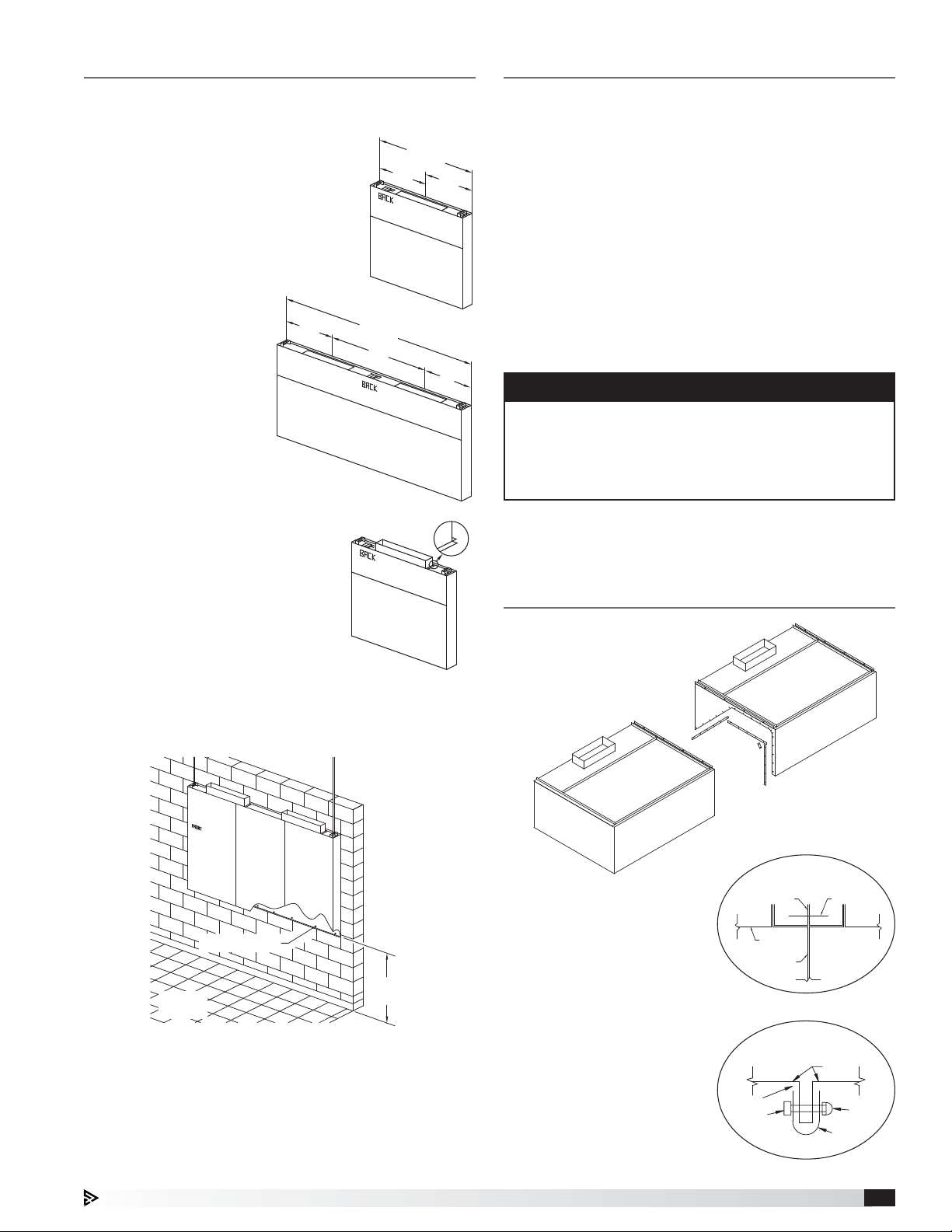

Filler Panel Installation

1. Uncrate the hood and lay it on the floor with

protective material between the hood and the floor.

2. Bolt the filler panels together with 5/16 in. bolts

provided in the hardware package.

3. Position the filler panels to the hood back, and tack-

weld them into place.

HOOD

Clearance reduction methods have been evaluated and

tested and are listed by UL (Underwriters Laboratory).

The method of test was derived from the UL 710 test

standard.

The hood may be installed with zero clearance to

combustible materials if constructed in the following

manner.

1. One inch (2.54 cm) thick layer of insulation of Owens

Corning

®

Type 475, Johns Manville Type 475, IIG®

MinWool-1200® Flexible Batt, or Knauf Insulation

Type EI 475.

2. Insulation must be held securely in place. Pins that

are welded or secured with an adhesive may be

used.

3. A backsplash panel must be attached to the wall

(insulated or uninsulated).

To comply with the UL Listing, the cooking appliances

must be as follows:

• Maximum surface temperature is 700°F (371°C)

• Appliances are located at least 3 in. (7.62 cm) from

the rear wall

• Appliances are at least 40 in. (101.6 cm) below the

bottom front edge of the hood

The hood may be installed with 3 in. (7.62 cm) clearance

to limited combustible materials per NFPA 96 if

constructed in one of the following methods:

• 3 in. (7.62 cm) rear uninsulated stand-off

• 3 in. (7.62 cm) top enclosure panel system

• 3 in. (7.62 cm) end uninsulated stand-off

Top Clearance Reduction Options

One inch (2.54 cm) layer of insulation installed on top

of the hood (optional) meets zero inch requirements for

clearance to combustible surfaces as outlined under the

clearance reductions methods.

HOOD

HOOD

TACK-WELDED TO

HOOD BACK

5/16 IN. X 3/4 IN. BOLTS

WITH WASHERS & NUTS

RIGHT FILLER PANEL

BOTTOM FILLER PANEL

4. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk (GE

SCS1009, or its equivalent). The caulk is not

provided.

Three inches (7.62cm) uninsulated airspace installed on

top of hood (optional) meets NFPA 96 requirements for

clearance to limited combustible surfaces.

Auto Scrubber 7

Page 8

Back and Front Clearance

Reduction Options

One inch (2.54 cm) layer of insulation in 3 in. (7.62cm)

back stand-off meets zero inch requirements for

clearance to combustible surfaces as outlined under the

clearance reduction methods.

Three inches (7.62 cm) uninsulated back stand-off

meets NFPA 96 requirements for clearance to limited

combustible surfaces.

One inch (2.54 cm) layer of insulation factory-installed

on the front of the hood (optional) meets zero inch

requirements for clearance to combustible surfaces.

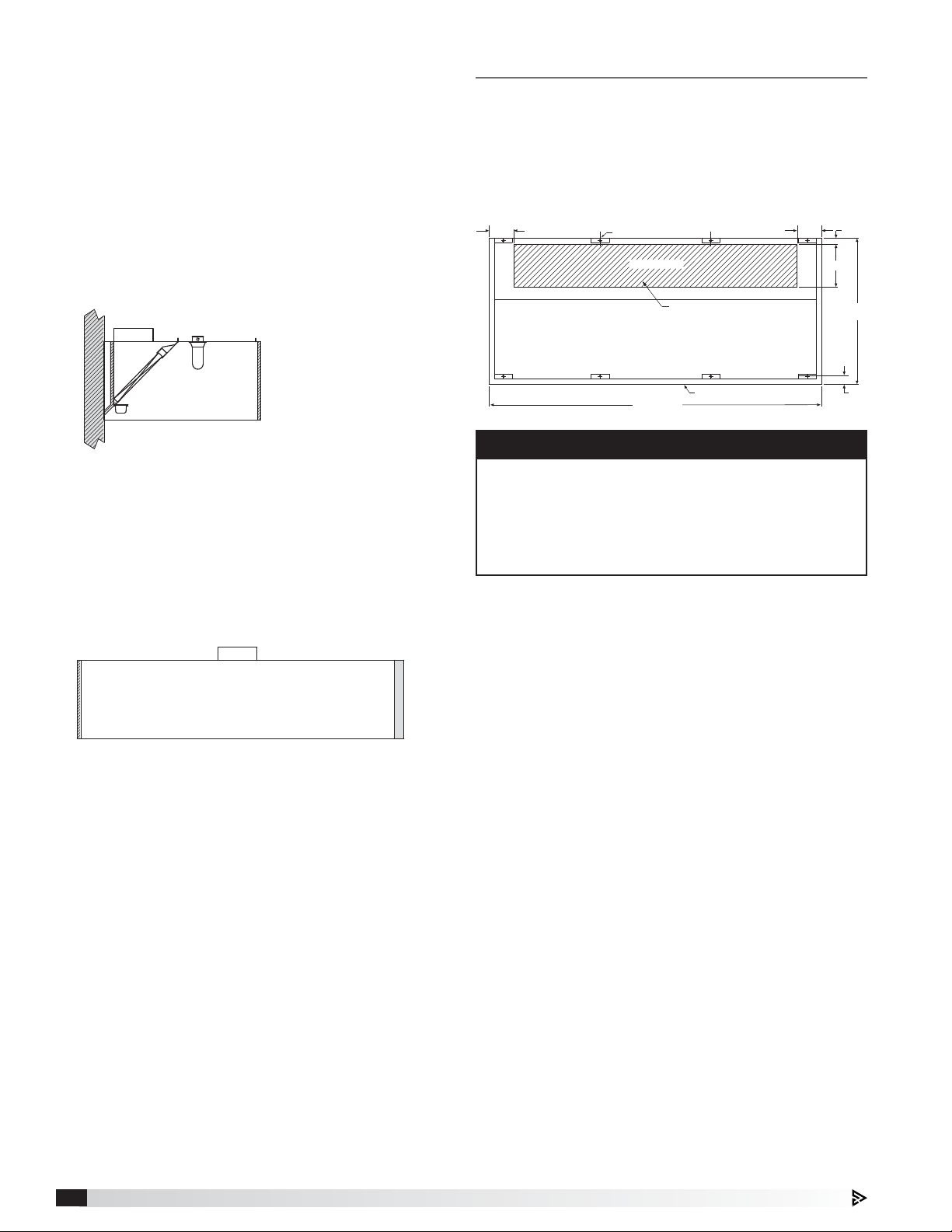

Installing Duct Collars

Exhaust Duct Collars

1. The exhaust duct connection needs to be located

within 48 in. (121.92 cm) from the center of the hood

length to the center of the duct connection and

within shaded area as shown.

Top View of the Hood

8 in.

Hanger Bracket

Exhaust Plenum

Duct cut out area

8 in.

14 in.

3 in.

Hood

Width

End Clearance Reduction Options

One inch (2.54 cm) layer of insulation factory-installed

on the end of the hood (optional) meets zero inch

requirements for clearance to combustible surfaces

under the clearance reduction methods.

Three inches (7.62 cm) uninsulated airspace installed on

end of hood (optional). Meets NFPA 96 requirements for

clearance to limited combustible surfaces.

Hood Length

Front of hood

NOTE

An 8x8x4-inch enclosure and sequencing solenoid

valves will be mounted on top of the Auto Scrubber

hood near the right or left-hand side. Avoid

interference with these items by keeping the exhaust

collars 20 inches from the end of the hood where

these components are mounted.

2. The exhaust duct connection is to be a continuous

liquid-tight weld. Weld with a non-ferrous filler wire,

such as silicon bronze or stainless steel filler wire.

Protect all stainless steel areas from weld splatter.

Supply Duct Collars to the Plenum

Place the duct collar(s) over the opening, fastening

with tack-welds at 1 to 2 in. (2.54 to 5.08 cm) intervals,

or sheet metal screws at 3 to 6 in. (7.62 to 15.24 cm)

intervals.

3 in.

Auto Scrubber8

Page 9

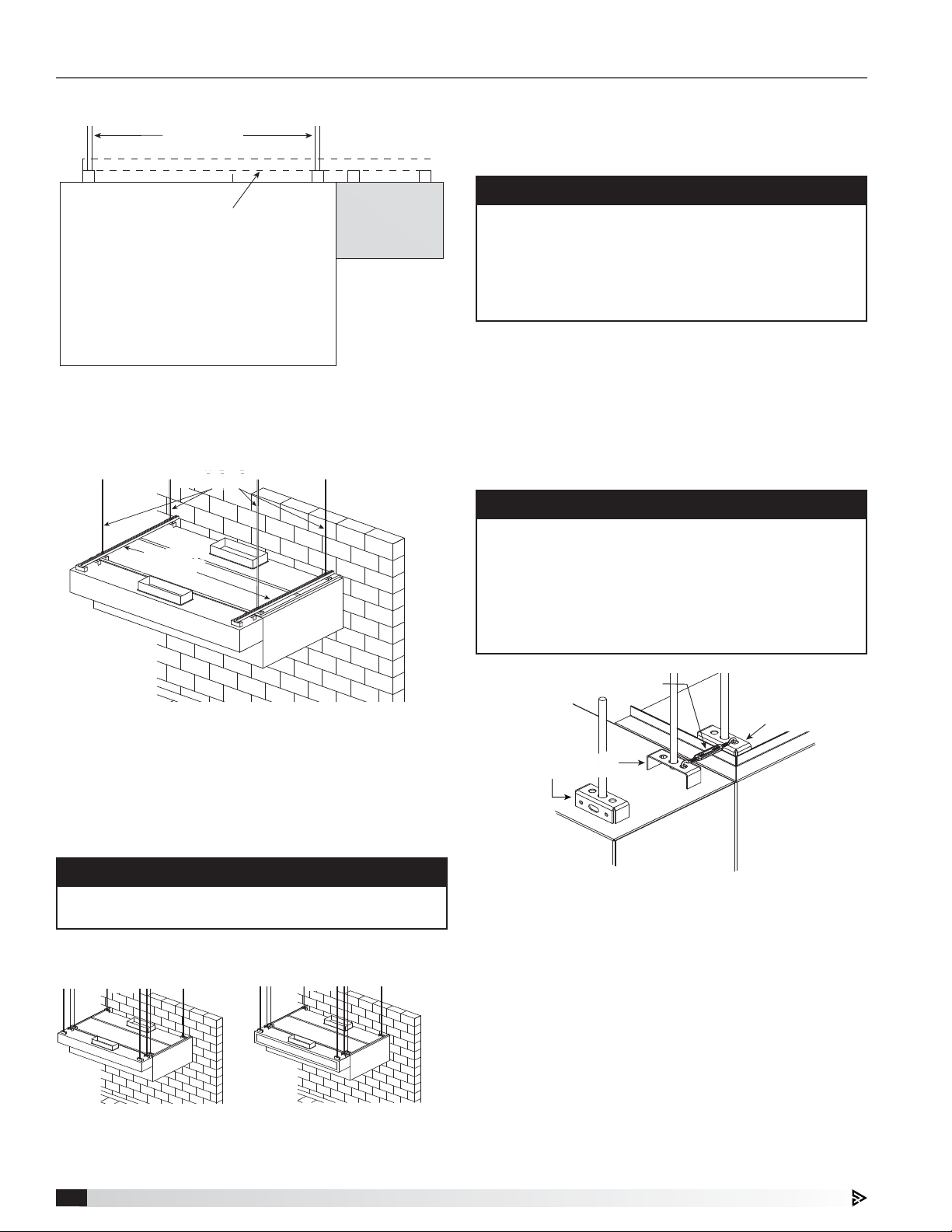

Installing the Back Supply Plenum

BOLT OR WELD

HOOD TOP

HOOD END

SUPPORT ANGLES

CAULK

BOLT

U-CLIP

HOOD

ACORN

NUT

2. RAIS

AND

3. FAST

4. FAST

5. CAU

& CAP

1. REM

HOOD FRONT

HOOD FRONT

REMOVE

SUPPORT

ANGLES ON

THE OPEN

END PANEL

Ductwork

Install the Supply Duct Collar

1. Find the center of the back supply plenum.

2. If the back supply plenum is to have

one opening, cut the opening such

that it is centered at L /2 from the

plenum end. (Fig.1)

3. If the back supply plenum is to have

two openings, cut openings such

that they are centered at L /4 from

each end of the plenum.

(Fig. 2)

4. Place the duct

L/4

collar(s) over the

opening(s), fastening

with screws or

tack-welds every

4 to 6 in. (10.16 to

15.24cm). (Fig. 3)

Hang the Plenum

Fig. 2

5. Hang the back

supply plenum

from the ceiling.

The back supply plenum

needs to be mounted 31.25in.

(79.375 cm) above the finished

floor. This is measured from

the lowest rear edge of the

back supply plenum to the

finished floor. (Fig. 4)

Hang using threaded rod

placed through the hanger brackets.

6. Fasten the back supply to the wall, going through the

lower back supply wall.

L (MODULE LENGTH)

L/2

Fig. 1

L (MODULE LENGTH)

L/2

Fig. 3

L/2

L/4

Exhaust - As specified in NFPA 96, Ch. 7.5 (latest

edition), exhaust duct systems must be constructed in

the following manner:

Materials: Ducts shall be constructed of and supported

by carbon steel not less than 1.37 mm (0.054 in.) (No.

16 MSG) in thickness, or stainless steel not less than

1.09 mm (0.043 in.) (No. 18 MSG) in thickness.

Installation: All seams, joints, penetrations, and duct to

hood collar connections shall have a liquid-tight external

weld. If you have an automatic fire damper, please refer

to that manual for installation instructions now.

Supply - Supply ductwork (where applicable) should

be connected to the hood in a manner approved by the

local code authorities.

NOTE

For hoods with fire dampers in the exhaust and

supply duct collars, an access panel for cleaning and

inspection shall be provided in the duct. This panel

shall be as close to the hood as possible but should

not exceed 18 in. (45.72 cm).

For proper installation of duct collars when they are

shipped unattached, see page 8.

Continuous Capture Plenum Hoods

1. Remove the support angles

provided for support during

shipping on the open

end panels. Install

and level both

hoods.

FASTENERS HOLDING THE

BACKSUPPLY TO THE WALL

31.25 INCH

CRITICAL

Fig. 4

DIMENSION

• These fasteners are to help maintain the location of

the back supply, and are not intended to hold the

weight of the back supply unit.

• The fasteners should not interfere with the

removable air diffusers.

2. After leveling, secure the

hoods together by tackwelding and/or bolting the

angles that are located at

the top of the hoods along

its width (Fig. 5).

3. Next, fasten the hoods

together at its inside

plenum profile using

u-clips and bolts (Fig.6).

Caulk this joint with NSF

Approved silicone caulk

(GE SCS1009 or its

equivalent). The caulk is

not provided.

Fig. 5

Fig. 6

Auto Scrubber 9

Page 10

Installing Front/Side External Supply Plenums

Using Uni-strut

THREADED ROD

SUPPLIED BY OTHERS

UNI-STRUT (U-CHANNEL)

SUPPLIED BY OTHERS

END VIEW

HOOD

The uni-strut (supplied by others) supporting the hood

may be cantilevered over the end of the hood. Utilizing

the external supply plenum’s hanger brackets, securely

fasten to the uni-strut.

THREADED

THREADED

ROD

ROD

UNI-STRUT

UNI-STRUT

(U-CHANNEL)

(U-CHANNEL)

EXTERNAL

SUPPLY

PLENUM

1. Insert 1/2 in. (12.7 mm) diameter threaded rod (by

others) into hanger brackets on the external supply

plenum top. Raise and hang the external supply

plenum from adequate roof or ceiling supports.

NOTE

Ensure the external supply plenum is installed

flush with the hood front and is plumb and level by

adjusting the threaded rod(s). There should be no gap

between the bottom of the external supply plenum

and the hood after installation and adjustments are

completed.

2. The external supply plenum should be resting

lightly against the hood. The hood is only used to

position the plenum; it is not intended to support the

plenum. All hanger brackets on the external supply

plenum must be used and the plenum must be

properly supported while lifting to prevent damage or

distortion. The external supply plenum must be level

to operate properly.

NOTE

After hanging, secure the external supply plenum to

the hood (or to another external supply plenum) using

the supplied turnbuckle(s). Use caution tensioning the

turnbuckle. Too much tension may cause the bottom

of the external supply plenum to pull away from the

hood or cause the face of the hood to become

deformed.

Air Curtain Supply (ASP)

Horizontal Supply Plenum (HSP)

Variable Supply Plenum (VSP)

Mounted with uni-strut and threaded rod

When using uni-strut (supplied by others), it must be

bolted to the hood and external supply plenum hanger

brackets.

NOTE

The uni-strut needs to be the full length of the hood

and the external supply plenum.

Using Hanger Brackets and Threaded Rod

Air Curtain

Supply Plenum (ASP)

Horizontal Supply Plenum (HSP)

Variable Supply Plenum (VSP)

TURNBUCKLE

TURNBUCKLE

HOOD HANGER

HOOD HANGER

BRACKET

BRACKET

EXTERNAL

EXTERNAL

SUPPLY PLENUM

SUPPLY PLENUM

HANGER BRACKET

HANGER BRACKET

HOOD

EXTERNAL

SUPPLY

PLENUM

3. It is recommended that caulk be applied at the

mating seams and surfaces of the external supply

plenum, the hood, and the wall. If the external supply

plenum is next to a wall, you will need to caulk

around the surface next to the wall. Caulk the joints

with NSF Approved silicone caulk (GE SCS1009, or

its equivalent). The caulk is not provided.

Installing the Supply Duct Collar to

thePlenum

Place the duct collar(s) over the opening, fastening

with tack-welds at 1 to 2 in. (2.54 to 5.08 cm) intervals,

or sheet metal screws at 3 to 6 in. (7.62 to 15.24 cm)

intervals.

Auto Scrubber10

Page 11

Installing Backsplash/Sidesplash Panels

Flat Backsplash/Sidesplash Panel

Material: Stainless

NOTE

• Panel length up to 47.25 inches (1200.15mm) wide

ship in one piece; panel lengths over 47.25inches

(1200.15mm) ship in multiple pieces when panel

height is <66 inches (1674.4 mm) or >80inches

(2032mm).

• Panel length up to 48 inches (1219.2 mm) wide

ship in one piece; panel lengths over 48inches

(1219.2mm) ship in multiple pieces when panel

height is ≥66 inches (1676.4 mm) or ≤80 inches

(2032 mm).

Insulated Backsplash/Sidesplash Panel

Material: Stainless

Insulation: 1 in. (25.4 mm)

Panels up to 45 in. (1143 mm) wide ship in one piece;

over 45 in. (1143 mm) in multiple pieces.

HOOD END PANEL

1 IN. (25.4 MM)

WALL

HEIGHT

LENGTH

NOTE

HOOD FRONT PANEL

1. After hood is hung into position, slide the flat flange

of the backsplash/sidesplash panel behind the

back/side of the hood. If the hood is provided with

flat backsplash/sidesplash panels, divider bars will

be provided. Install divider bars between panels

as shown in the flat backsplash/sidesplash panel

section view.

2. After the panels and dividers have been positioned,

drill holes in the panel and fasten to the wall.

(Fasteners provided by others). The holes should be

spaced to adequately secure the panel to the wall.

3. Caulk the joints between the hood and the panel

with NSF Approved silicone caulk (GE SCS1009 or

its equivalent). Caulk provided by others.

4. Caulk the joint between the panels when multiple

insulated panels are required with NSF Approved

(GE SCS1009 or its equivalent). Caulk provided by

others.

SLIDE FLANGE

BEHIND BACK

OF THE HOOD

BACKSPLASH PANEL

SECTION VIEW

OF BACKSPLASH

PANEL OVERLAP

Auto Scrubber 11

Page 12

Installing End Skirts

1. After the hood is hung in position, line up the top of

the end skirt with the end panels of the hood.

2. Drill a hole in the hood end panel to line up with

the hole in the end skirt. Attach the end skirt with a

1/4in. bolt and cap nut to the inside of the hood, or

tack-weld the end skirt to the hood.

3. Position the end skirt against the wall and attach.

The method depends on the wall construction.

(Fasteners provided by others).

4. Caulk the internal joint formed by the end skirt and

the hood end panel with NSF Approved silicone

caulk (GE SCS1009 or its equivalent). The caulk is

not provided.

5. To allow for ease in cleaning, also caulk all the

external seams.

HOLE DRILLED

BY INSTALLER

1/4 INCH BOLT AND CAP NUT

SUPPLIED BY MANUFACTURER

FULL END SKIRT

ATTACH TO WALL

FASTENERS BY OTHERS

HEMMED EDGE

Auto Scrubber12

Page 13

Plumbing Connections

TOP VIEW OF AUTO SCRUBBER CONTROL PANEL (ASCP)

4

5

FRONT VIEW OF AUTO SCRUBBER CONTROL PANEL (ASCP)

22

8

1. Electrical Control Cabinet 5. Hot Water Inlet Connection

2. Detergent Pump 6. Cold Water Outlet Connection to Hood

3. Detergent Tank 7. Cold Water Inlet Connection

4. Hot Water Outlet Connection to Hood 8. Inlet Valve

1. Install the factory

6

1

7

1

3

FROM 1 INCH

HOT WATER SUPPLY

provided backflow

preventer (shipped

loose) and drain

TO ASCP 1 INCH

HOT WATER INLET

connection per

local codes.

Backflow Preventer

2. Bring 1-inch hot water supply line to the backflow

preventer.

3. Plumb 1-inch line from outlet of backflow preventer

to the hot water inlet in the control cabinet.

4. If the cabinet is remote mounted, connect the hot

water outlet on the controls cabinet to the hot water

inlet on the top of the hood.

5. If system is configured for cold water mist, bring

0.75-inch water piping to the cold water mist inlet in

the control cabinet.

6. If the cabinet is remote mounted and the system

is configured for cold water mist, connect the cold

water mist outlet on the controls cabinet to each

hood with a cold water mist solenoid valve

7. Plumb 2-inch drain on each hood to grease trap

(floor).

NOTE

• Hot water temperature should be 140°F.

• While the hood is washing, water pressure in the

control panel should be between 40 and 70 PSI.

• Cold mist water pressure should be between 20

and 40 PSI.

Detergent Tank Installation

The detergent tank is located in the plumbing section

of the ASCP. The tank provided can hold up to

2.5gallons of detergent. It will need to be checked

periodically depending on detergent use and filled with

the recommended chemical detergent. The tank is also

equipped with a float that will trigger an alarm to warn

the user when detergent is low.

Steps for removal and installation of the detergent tank

are as follows:

Removal:

1. Disconnect the two float switch wires at the quick

connect electrical fittings.

2. Remove the 1/4-inch detergent line that enters the

tank thru the screw on cap.

3. Lift out the detergent tank from the utility cabinet.

4. Unscrew the 63 mm cap from the tank; this will

remove the float assembly.

5. Fill the tank with the approved detergent.

Install:

1. Install the 63 mm cap and float assembly into the

detergent tank.

2. Lift the detergent tank back into the utility cabinet.

3. Install the 1/4-inch detergent line thru the hole in the

63 mm cap.

4. Connect the two float switch wires at the quick

connect electrical fittings.

Detergent Requirements

Detergent model X-701 manufactured by ZEP, Inc., is

recommended by Accurex for use in the wash system.

This product is biodegradable, non-caustic, and safe

for kitchen staff to use. If X-701 detergent is not used,

the cleanliness of the exhaust plenum and filters cannot

beguaranteed.

NOTE

• X-701 is manufactured by ZEP, Inc., Atlanta, GA,

USA. For details and ordering information, call

1-800-371-6858.

• If washed once a day, the 2.5 gallon detergent tank

will last approximately 24 to 30 days depending on

filter type.

Preventative Maintenance

The following practices will prolong the life of the

detergent pump:

• Keep detergent tank filled.

• Avoid spilling detergent on the exterior of the pump.

• Clean the detergent tank at least every six months.

• Clean the detergent line strainer at least every six

months.

• Check tightness of all fittings periodically.

The detergent pump motor has sealed bearings which

do not require lubrication.

Auto Scrubber 13

Page 14

Typical Plumbing Connection Layout

Building

Water

Supply

DD

Backflow Preventer

Provided by Accurex; field installed

Drain required for backflow preventer

Plumbing connections made here

C

B

BAA

C

E

E

First Auto

Scrubber Hood

Auto Scrubber Control Panel

(ASCP)

Plumbing Key

Hot Water Piping

Cold Water Piping

HOT WATER CONNECTIONS:

A 1-inch hot water supply from building to Backflow Preventer

B 1-inch hot water piping from Backflow Preventer to control cabinet

C 1-inch hot water piping from control cabinet to hood(s)

COLD WATER CONNECTIONS, optional with continuous cold water mist

D 3/4-inch cold water supply from building to control cabinet

E 3/4 inch cold water piping from control cabinet to hood(s)

DRAIN CONNECTIONS FROM AUTO SCRUBBER HOOD(S):

F 2-inch male NPT connection to building drain with grease trap (one per hood section)

FF

Each additional

Auto Scrubber Hood

(if applicable)

F

F

Auto Scrubber14

Page 15

Electrical Connections

NOTE

All wiring of electrical equipment must be done to

meet NEC and local codes.

NOTE

It is recommended that shielded wire be used for all

low voltage connections (24V or less) to prevent signal

interference with other high voltage circuits.

WARNING

All 115 VAC field wiring (or higher) must be high

temperature rated and must be routed through hard

or flex conduit. All low voltage field wiring should be

plenum rated if not routed through conduit. All field

wiring should not come in contact with the surface of

the hood.

This section will provide some field wiring information

for connections directly to the hood. For all other wiring

connection requirements for the Auto Scrubber Control

Panel (ASCP), please refer to both the Auto Scrubber

Control Panel Installation, Operation and Maintenance

manual and the job specific wiring diagram located on

the inside door of the control cabinet.

Hood Lights

If the hood is provided with lights, a junction box will be

located on top of the hood for field connections. Use

minimum 14 AWG copper wire. Light bulbs will not be

provided (unless equipped with LED tube style fixtures).

For incandescent or compact fixtures, standard light

bulbs up to 100 watts may be used.

• 115 VAC, power for hood lights, one per light circuit

(Terminals H1, N1 | H2, N2 | H3, N3 | H4, N4)

• 115 VAC, power to lights, one per light circuit

(Terminals B1, W1 | B2, W2 | B3, W3 | B4, W4)

EACH CANOPY LIGHTING CIRCUIT MUST NOT EXCEED 15A TOTAL CURRENT

LIGHT CIRCUIT 1: 115 VAC, 15 AMPS FROM BREAKER

R__

11

H1 W1B1

14

HOOD LIGHT

RELAY 1

HOOD LIGHT(S)

WH 14GABK 14GA BK 14GA

G

N1

Keypad - if equipped

• Connect factory provided cable from back of keypad

to CAREL® PCO5+ controller (Terminal J10)

CONNECT FACTORY PROVIDED RJ25 CABLE

TO J10 ON PCO5+ AND BACK OF KEYPAD

PCO5+ J10 KEYPAD

35 Foot Cable Provided

75 or 150 Foot Cable is Optional

Touch Screen - if equipped

Power Wiring

• Connect factory provided 2-wire cable from Vari-Flow

(Terminals TS24, TSC) to touch screen

(Terminals G, GO)

Control Wiring

• Connect factory provided 3-wire cable from Vari-Flow

(Terminals -, +, GND) to touch screen

(Terminals -, +, GND)

POWER WIRING

TOUCH

TS24

TSC

SCREEN

GO

G

CONTROL WIRING

TOUCH

-

+

GND

J25 (BMS2)

SCREEN

-

+

GND

LIGHT CIRCUIT 2: 115 VAC, 15 AMPS FROM BREAKER

R__

11

BK 14GA

H2 B2 N2W2

LIGHT CIRCUIT 3: 115 VAC, 15 AMPS FROM BREAKER

BK 14GA BK 14GA

H3 B3 N3W3

LIGHT CIRCUIT 4: 115 VAC, 15 AMPS FROM BREAKER

BK 14GA BK 14GA

H4 B4 N4W4

14

HOOD LIGHT

RELAY 2

R__

11

14

HOOD LIGHT

RELAY 3

R__

11

14

HOOD LIGHT

RELAY 4

WH 14GABK 14GA

HOOD LIGHT(S)

WH 14GA

HOOD LIGHT(S)

WH 14GA

HOOD LIGHT(S)

CAUTION

For multiple hood systems that have more than 14

lights total, incandescent or fluorescent, the hood

lights must be wired to multiple circuits. Each circuit

must have less than 14 lights total.

Auto Scrubber 15

Page 16

Electrical Connections, continued

Solenoids and Temperature Sensors

Each Auto Scrubber hood will include an 8x8x4

enclosure factory wired to the hood solenoids and

sensors. If the Auto Scrubber Control Panel (ASCP) is

not mounted on the hood, the field will need to wire

from the 8x8x4 enclosure back to the ASCP. The hood

sensors and solenoids are low voltage, therefore,

18gauge stranded wire is recommended. The two wires

of each hood sensor are not polarity sensitive.

The wiring diagram provided with the ASCP will display

a table showing which sensors/solenoids connect to

each hood. If more than one hood is being controlled,

be sure that the appropriate sensor/solenoid is wired to

the appropriate terminals as depicted on this diagram.

Wash Hood Solenoids

• Wire between control panel terminal WO-_A and

hood j-box terminal WO-_A

• Wire between control panel terminal WO-_B and

hood j-box terminal WO-_B

• Wire between control panel terminal 24C and hood

j-box terminal 24C

• Wire between control panel terminal GND and hood

j-box terminal GND

Wash Hood Temp Sensor 1 – if equipped

• Wire between control panel terminal T_-A and hood

j-box terminal T_-A

• Wire between control panel terminal T_-B and hood

j-box terminal T_-B

Wash Hood Temp Sensor 2 – if equipped

• Wire between control panel terminal T_-A and hood

j-box terminal T_-A

• Wire between control panel terminal T_-B and hood

j-box terminal T_-B

MAIN

CONTROL

WO-_A

WO-_B

J-BOX

HOOD #_

WO-_A

WO-_B

WASH SOL _

SV_

WASH SOL _

SV_

NOTE

The resistive temperature detectors (RTD), or sensor

probes, should not be exposed to direct flame. The

RTD’s are rated up to 250°F.

CAUTION

Exposing the sensor to direct flame may render the

sensor inoperable and will void the warranty.

24C

GND

T_-A

T_-B

T_-A

T_-B

Auto Scrubber16

24C

GND

T_-A

T_-B

T_-A

T_-B

T_

T_

Page 17

Typical Electrical Connection Layout

Electrical connections made in here

A

A

Building

Breaker

Panel

(by others)

Wiring Key

High Voltage (115V)

Low Voltage (24V)

B

B

C

C

D

D

E

E

Auto Scrubber Control Panel

(ASCP)

SYSTEM FAULT

or

MENU

FF

NAV

User Interface

(Keypad or Touch Screen)

G

G

H

H

I

I

First Auto

Scrubber Hood

G

G

H

H

I

I

Each additional

Auto Scrubber Hood

(if applicable)

J

J

Exhaust Fan(s)

NOTE: Exhaust fan wiring will

depend on type of exhaust fan

A 115/1, 15A Circuit (Control Power)

B 115/1, 15A Circuit (Light Power)

C Input Power for Exhaust Fan(s) (if applicable)

D Input Power for Supply Fan(s) (if applicable)

E Input Power for Supply Fan(s) Controls (if applicable)

F Control Wiring to User Interface (Keypad or Touch Screen)

Cable(s) provided by Accurex

G Power to Hood Lights

H Control Wiring to Wash Solenoids

I Control Wiring to Temperature Sensors

J Output Power to Exhaust Fan(s) (if applicable)

K Output Power to Supply Fan(s) (if applicable)

L Control Wiring to Supply Fan(s) (if applicable)

KLK

L

Supply Fan

NOTE: Supply fan wiring will

depend on type of supply fan

Auto Scrubber 17

Page 18

DOUBLE ISLAND CLIP

Installing Ceiling Enclosure Panels

Double Island Canopy Style Hoods

Before installing the enclosure panels, make sure

the hood is hung in position with all the ductwork

attached and all fire system and electrical connections

completed.

1. Position the end enclosure panels on the hood, and

clamp into place with clamps provided or tack-weld

the panels into place.

2. Fasten the end enclosure panels to the wall; method

depends on wall construction. (Fasteners provided

by others).

If the hood is a double island, bolt the end enclosure

panels together. (Fasteners provided by others).

3. Position the front enclosure panel(s) on the hood,

and bolt to the end enclosure panels with the 5/16 in.

bolts provided in the hardware package.

4. Tack-weld or clamp the front enclosure panel(s)

to the hood. If clamps are used, they must be

positioned 4in. (10.16 cm) from the ends and in the

center of the front enclosure panel.

5. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk

(GE SCS1009, or its equivalent). The caulk is not

provided.

NOTE

Before hanging the hoods, please verify the hood

marks to ensure the correct hood is hung on the

correct side.

A double island hood is created by installing two

wall style hoods back to back. Use the installation

procedure described for single island canopy hoods;

install and level both hoods. After leveling, secure the

hoods together by tack-welding and/or bolting the rear

mounting brackets together. Double island hoods may

also be provided with a U-Channel to seal the seam

between the two hoods.

Installing U-Channel Strip

1. After the hood is hung in position and leveled, apply

caulk to the inside edge of the double island clip.

2. Position and install the clip by tapping into position

along clip (friction fit).

3. Caulk edges to seal out grease and allow for ease

of cleaning. Caulk with NSF Approved silicone caulk

(GE SCS1009 or its equivalent). The caulk is not

provided.

NOTE

Installation instructions may not be applicable for

concrete ceilings.

BOLT PANELS TOGETHER

WITH 5/16 INCH BOLTS

SUPPLIED BY MANUFACTURER

CLAMP PANELS TO HOOD

STANDING SEAM WITH HARDWARE

SUPPLIED BY MANUFACTURER

END ENSLOSURE

PANEL

HOOD TOP

FRONT ENCLOSURE PANEL

END ENSLOSURE

PANEL

ITEM-1B

ITEM-1A

HOOD FRONT

HOOD-1A

HOOD-1B

SILICONE CAULK

(GE SCS1009)

DOUBLE ISLAND CLIP

ATTACH TO WALL

FASTENERS BY OTHERS

HOOD BACK

Auto Scrubber18

Page 19

Initial System Start-Up

System Operation

1. Clean the control cabinet of any debris that may

have entered the cabinet during installation.

2. Add detergent to the detergent tank in the cabinet.

3. Turn power on to the hood and control cabinet and

fans (if applicable).

4. Check electrical power is correct for hood controls,

lights (if applicable) and fans (if applicable).

5. Confirm the CAREL controller is operational; display

should be illuminated.

6. If the system is controlling fans, turn the fans on via

the user interface. Check fan rotation and confirm

exhaust and supply air volumes are correct (per

design). After this has been completed, turn the

fans off.

7. Turn on water supply.

8. Prime the detergent pump. On the CAREL

controller, navigate to Service > Wash Settings >

“Prime Detergent Pump” menu screen. Changing

“OFF” to “ON” will start the detergent pump.

Monitor the detergent

line and press the ESC

key once the detergent

reaches the hot water

line. This will stop the

detergent pump.

Prime Detergent Pump

Prime the detergent

pump? OFF

Change NO to YES to

start detergent pump.

9. If the filter access doors are not installed, install

them now. Instructions for installing filters and

access doors can be found on page 25.

NOTE

Ensure the access doors are installed before starting

any wash cycles. Running a wash cycle without the

doors in place will result in water spraying on the

cooking line-up/area below the hood.

10. Run a test wash. On the CAREL controller,

navigate to Service > Wash Settings > Hood Test

Wash Setup menu

screen. Adjust the

times as necessary on

the screen; change NO

to YES. A test wash

will start.

While the hood is washing, ensure water is not leaking

through the edges of the access doors or anywhere

else in the exhaust plenum. Ensure the grease drain and

trap are not plugged, or kitchen flooding may occur.

Water pressure while the hood is washing should

be between 40 and 70 PSI. Monitor the inlet pressure

and temperature gauge in the ASCP through one wash

cycle.

At any time, the test wash can be aborted by pressing

the ESC key.

Hood Test Wash Setup

Seq Time: 30s

Seq Det Time: 10s

Drip Dry Time: 10s

Fan Dry Time: 15s

Start Test Wash? NO

NOTE

The information given in this section provides basic

instructions for operating the user interface provided

with the Auto Scrubber Control Panel (ASCP). For

more detailed information regarding the operation of

the control panel, as well as all electrical and plumbing

requirements, please reference the Auto Scrubber

control panel Installation, Maintenance and Operation

Manual. This manual will ship with the control package

and can also be found on accurex.com

Fan Operation (if equipped)

If the hood system is equipped with fan control, start/

stop the fans exhausting and supplying the hoods from

the user interface.

KEYPAD - Press the button next to the “ALL HOODS”

text on the keypad to start/stop all of the hoods. If the

keypad has a button labeled “HOODS”, pressing this

button will navigate to a set of screens where the user

can individually start/stop different fans.

TOUCH SCREEN - Press the “ALL HOODS ON/OFF”

icon on the touch screen to start/stop all of the hoods.

If the touch screen has a icon labeled “INDIVIDUAL

HOOD SYSTEMS ON/OFF”, pressing this will navigate

to a screen where the user can individually start/stop

different fans.

Hood Light Operation (if equipped)

If the hood system is equipped with light control, turn

on/off the hood lights from the user interface.

KEYPAD - Press the button next to “ALL LIGHTS” text

on the keypad to will turn on/off all hood lights. If the

keypad has a button labeled “LIGHTS”, pressing this

button will navigate to a set of screens where the user

can individually start/stop different hood light circuits.

TOUCH SCREEN - Press the “ALL LIGHTS ON/OFF”

icon on the touch screen to turn on/off all hood lights. If

the touch screen has a icon labeled “INDIVIDUAL LIGHT

ON/OFF”, pressing this will navigate to a screen where

the user can individually turn on/off different hood light

circuits.

Auto Scrubber 19

Page 20

Wash Operation (if equipped)

A hood wash can be initiated through a number of

different options.

Wash by Button (Factory default = ON): A wash can

be initiated through pressing either the “WASH” button

(if equipped with a keypad) or by pressing “WASH ON/

OFF” icon (if equipped with a touch screen).

Wash by Digital Input (Factory default = OFF): A wash

can be initiated through engaging a configured digital

input on controller. For the correct terminals to wire this

digital input, please reference the Auto Scrubber Control

Panel wiring diagram.

Wash by BMS Interface (Factory default = OFF): A

wash can be initiated through engaging a BMS read/

write point. Point lists can be found in the Auto

Scrubber Control Panel IOM.

Wash by Scheduler (Factory default = OFF): A wash

can be initiated daily at a specific time. If this option

is enabled, this time can be field adjusted within the

controller and touch screen, if equipped.

Wash by Auto Start (Factory default = ON): Each

individual hood can be washed after that hood’s fan(s)

has been running for a pre-determined time (factory

default is 8 hours). This time setting and the maximum

allowable auto start washes can be field adjusted within

the controller and touch screen, if equipped.

A fan exhausting an Auto Scrubber hood cannot be

controlled by the user (turned on and off) while that Auto

Scrubber hood is washing. If multiple Auto Scrubber

hoods are employed, a fan linked to an Auto Scrubber

hood which is not currently washing can be controlled

by the user (turned on and off) as normal.

NOTE

Duct sumps may be controlled by this Auto Scrubber

system. A duct sump is a grease reservoir installed in

low points of grease duct which also requires routine

wash downs.

When duct sumps are washing, fans cannot run, unless:

• A kitchen fire is detected

• A sensor linked to any Auto Scrubber hood fails, or

any temperature sensor exceeds the temperature

interlock on setpoint

• If the Auto Scrubber control panel is equipped with no

fan controls (ASCP-W) and the fan input is triggered

NOTE

Auto Start will only enable to Auto Scrubber hoods. It

cannot be used to engage duct sump washes.

With exception to the Auto Start option, when a wash

cycle has been initialized the Auto Scrubber hoods will

be washed in order starting with Auto Scrubber hood 1.

If duct sumps are also connected to this system, they

will be washed in order after the Auto Scrubber hoods

have been washed.

A wash cycle can be stopped at any time by pressing

the “WASH” button (if equipped with a keypad) or by the

“WASH ON/OFF” icon (if equipped with a touch screen).

An Auto Scrubber hood will be prevented, or abort

operating in the wash cycle, should one of the following

events occur:

• A kitchen fire alarm is detected.

• A sensor linked to the Auto Scrubber hood fails.

• The option to disable a wash during temperature

interlock is on (factory defaulted on) and a sensor

linked to the Auto Scrubber hood exceeds the

temperature interlock on setpoint.

• If the Auto Scrubber control panel is equipped

with no fan controls (ASCP-W) and the fan input is

triggered.

Auto Scrubber20

Page 21

Wash Sequence of Operation

NOTE

The previously stated items regarding ending a wash cycle/skipping a hood wash still apply. Please use this in

conjunction with the information found in System Operation section found on pages 19 and 20.

WASH CYCLE ENABLED

• by User Interface Wash Button

• by Digital Input

• by BMS Interface

• by Scheduler

Hood Pre-Wash Delay

Pre-Soak

Solenoid 1 Opens

Pre-Soak Spray Time

Solenoid 1 Closes

Soak Time

Wash Top of Filters

Solenoid 1 Opens

Top of Filters

Wash Time

Solenoid 1 Closes

Between Sequence

Delay

Wash Bottom of Filters

Solenoid 2 Opens

Bottom of Filters

Wash Time

Delay for 30 seconds

Detergent pump ON

Pre-Soak Detergent

Injection Time

Detergent pump OFF

Delay for 5 seconds

Detergent pump ON

Top Wash Detergent

Injection TIme

Detergent pump OFF

Delay for 5 seconds

Detergent pump ON

Start next Auto Scrubber

Hood Wash

Start Sump Washes

Turn off all fan(s)

Sump Pre-Wash Delay

Sump Solenoid Opens

Wash Sump

Sump Wash

Time

Sump Solenoid Closes

Another Sump

available to be

washed?

NO

YES

Delay for 5 seconds

Detergent pump ON

Sump Detergent

Injection Time

Detergent pump OFF

Between Sump

Delay

Solenoid 2 Closes

Drip Dry Time

Fan Dry Enable

ON (Default)

Fans controlling Auto

Scrubber Hood ON

Fan Dry Time

Fans controlling Auto

Scrubber Hood OFF

Bottom Wash Detergent

Detergent pump OFF

OFF

WASH CYCLE COMPLETED

Injection TIme

Another

Auto Scrubber

hood available to

be washed

Sumps available

to be washed?

WASH CYCLE COMPLETED

NO

YES

NO

Auto Scrubber 21

Page 22

Wash Sequence of Operation, continued

HOOD WASH ENABLED BY

AUTO START FEATURE

• Auto Scrubber hood fans have

been running for minimum time

(Default = 480 minutes) and have

been shut off

Hood Pre-Wash Delay

Pre-Soak

Solenoid 1 Opens

Pre-Soak Spray Time

Solenoid 1 Closes

Soak Time

Wash Top of Filters

Solenoid 1 Opens

Top of Filters Wash Time

Solenoid 1 Closes

Between Sequence Delay

Wash Bottom of Filters

Solenoid 2 Opens

Bottom of Filters

Wash Time

Solenoid 2 Closes

Drip Dry Time

Fan Dry

Delay for 30 seconds

Detergent pump ON

Pre-Soak Detergent

Injection Time

Detergent pump OFF

Delay for 5 seconds

Detergent pump ON

Top Wash Detergent

Injection Time

Detergent pump OFF

Delay for 5 seconds

Detergent pump ON

Bottom Wash Detergent

Detergent pump OFF

OFF

AUTO START HOOD WASH

Injection Time

COMPLETED

Wash Cycle Factory Default Times

Time (seconds) Based on Filter Type

Wash Cycle

Stage

Pre-Wash Delay 10 10

Pre-Soak Spray 60 60

Pre-Soak Detergent 30 30

Soak 60 60

Top Wash 120 350

Top Wash Detergent 60 150

Between Sequence

Delay

Bottom Wash 120 240

Bottom Wash

Detergent

Drip Dry 60 60

Fan Dry 120 120

The wash times are based on filter cleaning tests

using filters coated heavily with oil and then bakedon using high temperatures. Actual required cleaning

times will vary based on cooking equipment, fuel

type, cooking frequency, and the food prepared. The

table shown above should be used as a starting point.

After a few weeks, the field can make adjustments as

necessary based on the cleanliness of the filters upon

removal/inspection (see Maintenance on page 25).

Baffle

Grease-X-Tractor™

Energy Recovery

-5 -5

60 60

NOTE

Grease Grabber™

Fans controlling Auto

Scrubber Hood ON

Fan Dry Time

Fans controlling Auto

Scrubber Hood OFF

Auto Scrubber22

ON (Default)

Page 23

Airflow Testing Procedure

After the appropriate number of readings have been

taken from the inlet slot of the hood, an average reading

can be calculated by summing the velocity readings and

dividing the total value by the number of readings taken.

Short Ridge Meter Components

For measuring exhaust airflow rates (cubic feet per

minute = CFM), use a short ridge meter to measure

velocities along the inlet slot of the hood. To ensure

accurate data, all appliances should be on. Multiple

locations need to be tested as outlined below to ensure

an accurate reading.

To take velocity

readings along the

length of the hood, the

short ridge meter must

be evenly spaced along

the length of each door

to provide two readings

per door. Vertical

Hood Length

48 to 69 inches 2

70 to 109 inches 4

110 to 139 inches 6

140 to 174 inches 8

175 to 192 inches 10

Number of Test

Locations

placement of the short

ridge meter along the inlet slot is shown.

Average Velocity =

Sum of Velocity Readings

Number of Readings

Next calculate the total hood airflow volume (CFM) by

using the following equation:

Hood CFM = [(Length of Hood in inches x 3.398) x

(Average inlet slot velocity x 3.06)] 144

NOTE

The constants 3.398 and 3.6 are factory derived for

use with the Auto Scrubber hood.

Calculation Example:

Four (4) inlet slot velocity readings (minimum)

Hood Length

Test Location

(left to right; in inches)

Velocity Reading (fpm)

6 274869

224 242 228 236

Average Velocity (FPM) =

(224 + 242 + 228 + 236) 4 = 233 FPM

Hood Exhaust Rate (CFM) =

[(96 x 3.398) x (233 x 3.6)] 144 = 1900 CFM

96 inches

Auto Scrubber 23

Page 24

Additional Wiring Schematics

Ansul® Wiring Plan View

Snap-Action Switches may be wired as shown.

Typical examples shown.

Equipment

NO

115 VAC

N

NC

Alarms

NO

NC

Fans

Electric gas valve - If reset relay is

used, see option A or B at right.

Mechanical gas shut off valve does not

require electrical connection.

NO

Input

NC

Power to cooking

equipment

Shunt Trip Breaker

Input

Voltage Free

Contacts for

Building Alarm(s)

Amerex® Wiring Plan View

Power Source

PRM

Microswitch

Installer provided Junction Boxes

Basic Wiring Diagram

Red (Common)

Yellow (N.O)

Microswitch

Power Source

Black (N.C.)

NOTE: Do not use yellow wire on miroswitch in normal

installation. The yellow wire is to be used only for extinguisher

alarm, lights, circuits, etc.

Manual Reset Relay

Manual Reset Relay

Electric Gas Valve

Gas Valve

NO

NC

If prohibited by local codes, do not shut down

exhaust fans with this method of wiring.

Manual Reset Relay

Part No. 426151

AB

Relay Coil

6

9

3

4

7

1

Electrical Rating

1/3 HP, 10 AMP, 115 VAC

1/2 HP, 10 AMP, 240 VAC

13 AMP, 28 VDC

Reset

115 VAC

N

Power

Indicator

GND

Screw

Input

Manual Switch

Black

Red

Brown

5

4

3

2

1

Gas Valve

See Note 3

Power to

fan(s)

Fan Starter

Ansul Snap-Action Switch

Part No. 423878

Switch contacts shown with Ansul

Automan in the cocked position

115 VAC/60Hz

L2 Neutral

L1 Hot

Basic Wiring Diagram

Manual Reset Relay

Red (Common)

Yellow (N.O)

Microswitch

NOTES:

1. Denotes field installation

2. Denotes factory installation

3. GAS VALVE: UL Listed electronically-operated safety valve for natural or LP Gas as needed of

appropriate pressures and temperature rating, 115V/60 Hz or Amerex gas valves,

PN 12870, 12871, 12872, 12873, 12874, 12875 and 12876.

4. K1a and K1b are N.0. when K1 is de-energized.

120V/60HZ

Black (N.C.)

L1

L2

K1b

Current Draw Max:

8A Resistive

8A Inductive

115 VAC

K1

Ka

Push Button Switch

Gas Valve

(see note 3)

Note:

1. Denotes eld installation.

2. Denotes factory installation.

3. Gas Valves: “UL Listed electrically- operated safety valve for natural or LP gas

as needed, of appropriate pressure and temperature rating, 115V/60Hz”

or Ansul gas valves.

4. Do not use black wire on snap-action switch in normal installation. Black

wire may only be used for extraneous alarm, light circuits, etc.

Auto Scrubber24

Page 25

Maintenance

Filters

The first or primary stage (baffle or Grease-X-Tractor™)

filters and second stage (Grease Grabber™) bead filters

(if applicable) need to be inspected one week after start

up, then once every two weeks to make certain the

filters are positioned correctly (no gaps between filters)

and that the wash system is adequately cleaning the

filters.

To inspect the filters, remove all access doors. Each

door is held in place with two cammed latch handles.

Turn the handles and remove the doors.

Image 1

Once the doors are removed the filters can be removed.

If the hood contains second stage filters, these will also

need to be removed. While holding the handles of the

filter, push the filter up and lift the bottom of the filter out

of its track. Then pull the filter out of the hood.

3, 4 and 5. Repeat this for all the second stage filters.

Images 1 and 2.

Image 2

Images

Capture Tank

The interior surfaces of the hood capture tank should be

wiped down weekly.

Image 3 Image 4

Once the second stage

filters are out, (

Image 5)

the first stage filters can

be removed in the same

Image 5

manner.

Image 6.

Depending on the equipment

under the hood, it might be

easier to remove the filters

from the left or right side.

In that case, slide the filters

Image 6

towards the end that allows

for easier removal.

After inspection, insert the filters back into the hood.

Primary filters go in first, then the second stage filters (if

applicable). After installing all the filters, make sure the

filters are positioned correctly in the hood. There should

be no gaps between the filters.

If for some reason the filters don’t seem to be getting

adequately cleaned, or if the filters appear damaged,

consult the factory.

Auto Scrubber 25

Page 26

Auto Scrubber Start-Up Checklist

Check boxes when item has been verified and reviewed

with customer.

Hook-Up

Electrical Connections

• Confirm all electrical connections are made per Auto

Scrubber Control Panel (ASCP) wiring diagram.

• Turn on all hood, light and fan power (if

applicable).

• Check voltages on incoming lines to confirm

these are correct.

Plumbing Connections

• Plumb 1-inch hot water piping to backflow

preventer, then from backflow preventer to inlet hot

water connection in control cabinet.

• Plumb 0.75-inch cold water piping to inlet cold

water mist connection in controls cabinet (if

applicable).

• Plumb water connections from controls cabinet to

each hood.

• Plumb 0.75-inch cold water piping to cold water

mist connection in controls cabinet (if applicable).

Detergent

• Detergent tank filled with proper detergent.

• Low detergent tubing and strainer should be at the

bottom of the detergent tank.

• Prime detergent pump.

Miscellaneous

Fire Mode Test

• Trip fire system microswitch. Confirm fan/light

operation (if applicable) and wash stopping when in

fire mode.

• Alarm message should appear on user interface and

main controller.

Low Detergent Mode

• If removing the float from the tank, the user interface

and controller should display a low detergent alarm.

Replacing the float in the tank (filled with detergent),

the low detergent alarm should disappear.

Hood Access

• Confirm the hood access panels fit tightly to prevent

water from spraying out of the exhaust plenum onto

appliances.

Cleaning

• Is the hood cleaning properly? If not, refer to

troubleshooting guide on pages 25 through 27.

Start-Up

Test Fan/Light Control Modes (if applicable)

• Confirm fan operation/rotation when enabled/

disabled by user interface.

• Confirm hood light operation when enabled/disabled

by user interface.

Run Test Wash

• Test wash instructions on page 20.

• Confirm solenoids and detergent pump are engaging

correctly based upon sequence of operation found

on pages 21 and 22.

_________ Record hot water pressure during wash.

Should be between 40-70 PSI

_________ Record cold water mist water pressure, if

equipped. Should be between 20-40 PSI

_________ Record hot water temperature during

wash. Should be 140°F

• Adjust water pressure if needed using throttling

valve. For cold water mist only.

Auto Scrubber26

Page 27

Troubleshooting

Problem: Exhaust fan is not operating or is not operating at design levels.

Is the fan receiving power? Replace fuses, reset circuit breakers, check disconnect.

Is the belt loose or broken? Replace or tighten belt.

Is the fan rotating in correct direction? Have the electrician correctly wire the fan.

Is the make-up air operating?

Does the airflow need to be increased? Adjust or replace pulleys to increase fan RPM, install a larger motor.

Does the fan vibrate?

Problem: Hood is full of smoke. There is smoke coming out of the edges of the hood.

Is the fan operating at design levels? See exhaust fan troubleshooting section.

Is the fan correctly sized?

Are the filters in good condition? Clean filters, replace damaged filters, properly position filters.

Is there sufficient make-up air?

(Kitchen should be in a slight negative

but not excessive. Check to see if there

is a strong draft through an open door).

Does the current cooking equipment match

the original design?

Are there multiple hoods on one fan?

Are there closed dampers in the duct? Open dampers.

Is the ductwork complex or to small? Change to a higher static fan, modify the ductwork.

Is the ductwork obstructed? Clear obstruction.

Problems with make-up air may interfere with the exhaust fan. Check the

manufacturer’s installation manual.

Clean the fan wheel/blade, replace fan wheel if damaged, check for loose bolts,

check for broken or damaged components, check for rags and other foreign

objects.

Refer to test and balance report, design specifications and fan curves; have an

electrician check the motor amperage; try removing the filter temporarily to see

if capture improves. (Make sure to replace filter to prevent risk of fire!); switch to

different filters with lower static pressure.

Check make-up air unit. Increase make-up air.

Make-up air should be evenly distributed throughout the kitchen.

Adjust or replace fan to match the cooking equipment load.

One hood may be over exhausting and the other hood not drawing enough.

Restrict second hood to help problem hood.

Problem: Smoke blows away before reaching the bottom of the hood.

Are there cooling fans directed at the hood

or cooking equipment?

Are there ceiling diffusers directing air at

the hood?

Are there open windows or doors? Close windows and doors.

Are there cross drafts or other drafts in the

kitchen?

Is the hood near a main walkway?

Are there pass-thru windows near

the hood?

Is the make-up air entering through an

attached plenum?

Turn off or redirect fans.

Move diffusers to more neutral area or replace with a diffuser that directs air away

from the hood.

Find source of the draft and eliminate, add side skirts to hood (test with

cardboard; use stainless for permanent side skirts); increase the amount of

overhang on the spillage side; add a 6 in. (152.4 mm) lip around the base of the

hood (test with cardboard; use stainless for permanent side skirts); make-up air

should be spread out evenly through the kitchen.

Add side skirts to hood (test with cardboard first); increase the amount of

overhang on spillage side.

Adjust amount and locations of make-up air to eliminate drafts through the passthru windows.

Try turning off or reducing the amount of make-up air; block off portions of the

supply to direct air away from the problem area (test with cardboard).

Auto Scrubber 27

Page 28

Troubleshooting

Problem: Pilot lights are being blown out or cooking equipment is being cooled by make-up air.

Try turning off or reducing the amount of make-up air; block off portions of the

Are there drafts from make-up air?

Problem: Cold air can be felt by the cook at the hood.

Is the make-up air entering through an

attached plenum?

Problem: The kitchen gets hot.

Is the hood capturing?

Is the make-up air entering through an

attached plenum?

Problem: Cooking odors in the dining area.

Is the hood capturing?

Is there a draft through doors between the

kitchen and dining area?

supply to direct air away from the problem area (test with cardboard first); remove

any obstructions in front of supply that directs air toward cooking equipment.

Try turning off or reducing the amount of make-up air; heat the supply air.

Hood is not drawing enough air, see sections on fan performance and hood

capture.

Try turning off or reducing the amount of make-up air; cool the supply air.

Hood is not drawing enough air, see sections above on fan performance and

hood capture.

Decrease make-up air in the kitchen; increase exhaust air through hood.

Problem: Grease is running off the hood.

Is there grease on top of the hood? Exhaust duct is not correctly welded.

Is the caulk missing or damaged? Clean problem area and recaulk.