PAPER SHREDDER

S16

ILLUSTRATED

PARTS LIST

AND

SERVICE INSTRUCTIONS

Acco Service Division,

Halesowen Industrial Estate, Hereward Rise, Halesowen, West Midlands B62 8AN

Telephone 0845 658 6600 Fax 0121 501 3991

DEM Page 1 of 43 FEBRUARY 07

CONTENTS

HEADING PAGE No

ILLUSTRATED PARTS LIST INDEX 3

SERVICE INSTRUCTIONS INDEX 4

PREFACE 5

INSTALLATION 17

MODEL SPECIFICATION 38

WIRING DIAGRAMS 39 TO 42

AMENDMENT RECORD 43

DEM Page 2 of 43 FEBRUARY 07

PAPER SHREDDER INDEX

S16

ILLUSTRATED PARTS LIST

SECTION INDEX

1

2 CASING ASSEMBLY 8 & 9 2

3 CUTTING HEAD 10 & 11 2

4 BIN ASSEMBLY 12 & 13 2

5 ELECTRICS 14 - 16 2

FRAME AND COVER PANELS ASSEMBLY

PAPER SHREDDER INDEX

S16

PAGE No ISSUE NO

6 & 7

2

DEM Page 3 of 43 FEBRUARY 07

SERVICE INSTRUCTIONS

SECTION INDEX

1 INSTALLATION AND SAFETY 17 2

2 LUBRICATION OF CUTTING HEAD 18 2

3 FEED CHUTE REMOVAL AND REPLACEMENT 19 2

4 REMOVAL OF CASING 20 & 21 2

5 CUTTING HEAD ADJUSTMENT 22 2

6 REPLACING DRIVE BELT 23 2

7 REPLACING CUTTING HEAD 24 2

8 REPLACING GEARBOX 25 & 26 2

9 CUTTERS AND STRIPPER REPLACEMENT 27 2

10 MOTOR REPLACEMENT 28 2

11 SWITCH PANEL REPLACEMENT 29 2

12 ELECTRONIC ADJUSTMENTS (REED

13 ELECTRONIC ADJUSTMENTS (SENSING COIL) 32 2

14 PCB REPLACEMEMT (REED SWITCHES) 33 2

SWITCHES)

15 PCB REPLACEMENT (SENSING COIL) 34 2

16 CONTACTOR REPLACEMENT 35 2

17 HINGED GATE SAFETY REPLACEMENT 36 2

18 BIN FULL SWITCH REPLACEMENT 37 2

PAGE No ISSUE NO.

30 & 31 2

19 FACTORY POTENTIOMETER SETTINGS 38 2

19 SPECIFICATION 38 2

20 WIRING DIAGRAMS 39 TO 42 2

PAPER SHREDDER INDEX

DEM Page 4 of 43 FEBRUARY 07

S16

PREFACE

SERVICE PREPARATION

This manual provides the instructions for the replacement of all the components that may become worn or

damaged during normal usage of the machine.

“Illustrated Parts Lists”

with supporting diagrams to show the location of the components.

“Service Instructions”

with supporting pictorial diagrams for added clarity

WARNING

1. Check the machine RATING PLATE DETAILS are compatible with the electrical mains supply.

2. Disconnect the electrical mains supply before removing any covers.

3. The machine MUST

NOTE: THE ELECTRIC MOTOR IS PROTECTED BY AN AUTOMATIC THERMAL OVERLOAD CUT-OUT

Product Testing after Servicing or Repair.

IMPORTANT. If any electrical component has been changed, an electrical connection broken and

remade, or any wiring disturbed, the product being repaired or serviced must be flash tested or PAT

tested. This test must be carried before a product is handed back or returned to the customer or

returned to stock. The test must be appropriate for the machine being repaired. E.g. double insulated

or earthed. A competent person should conduct the test and keep a log of all machines tested, the

serial number of the machine, the details of the test, the test results and the date the test was carried

out.

- For each machine give full details of the replacement part numbers

- For each machine give the recommended servicing procedure

have a sound Electrical Earth Connection.

ILLUSTRATED PARTS LIST

DEM Page 5 of 43 FEBRUARY 07

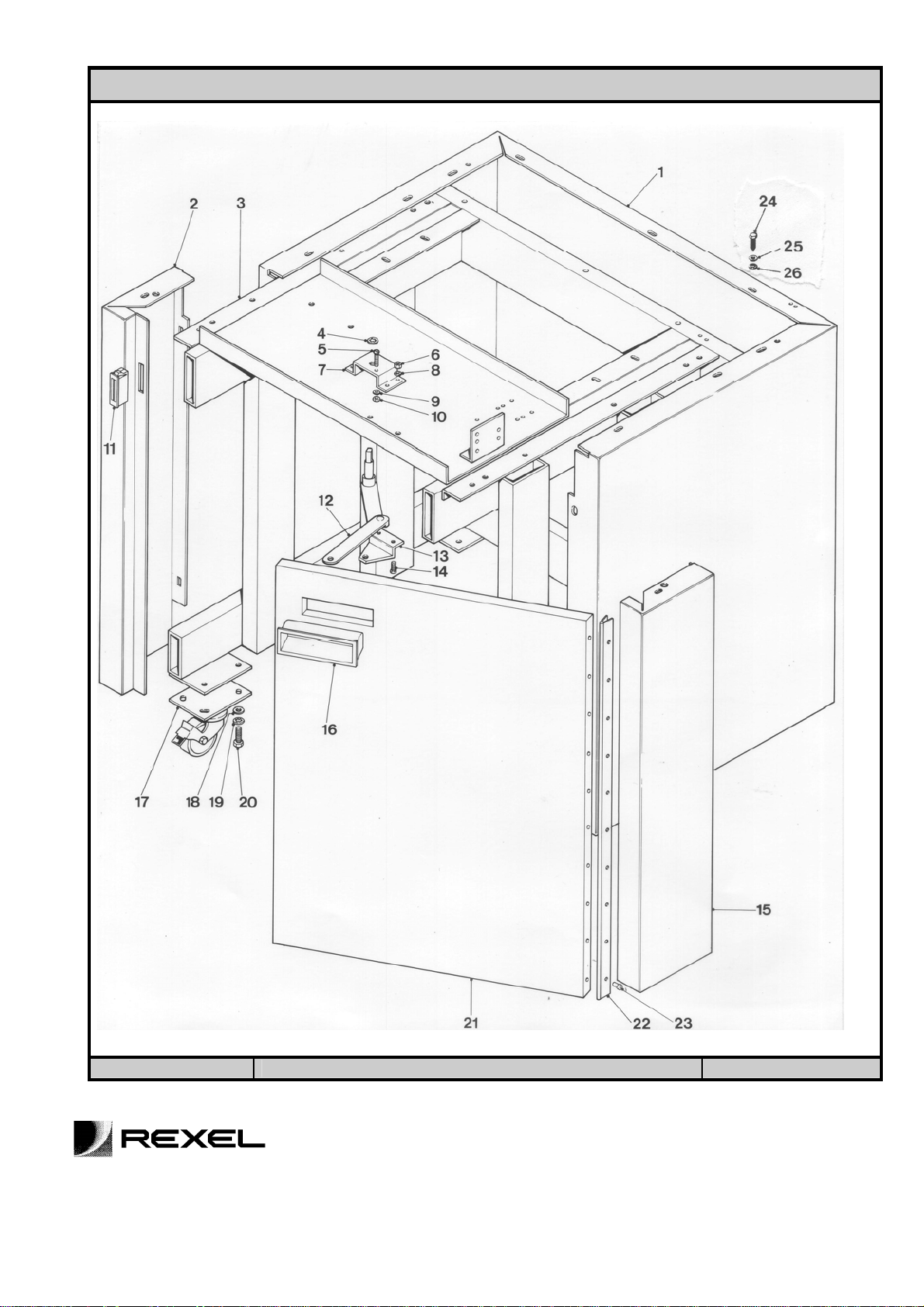

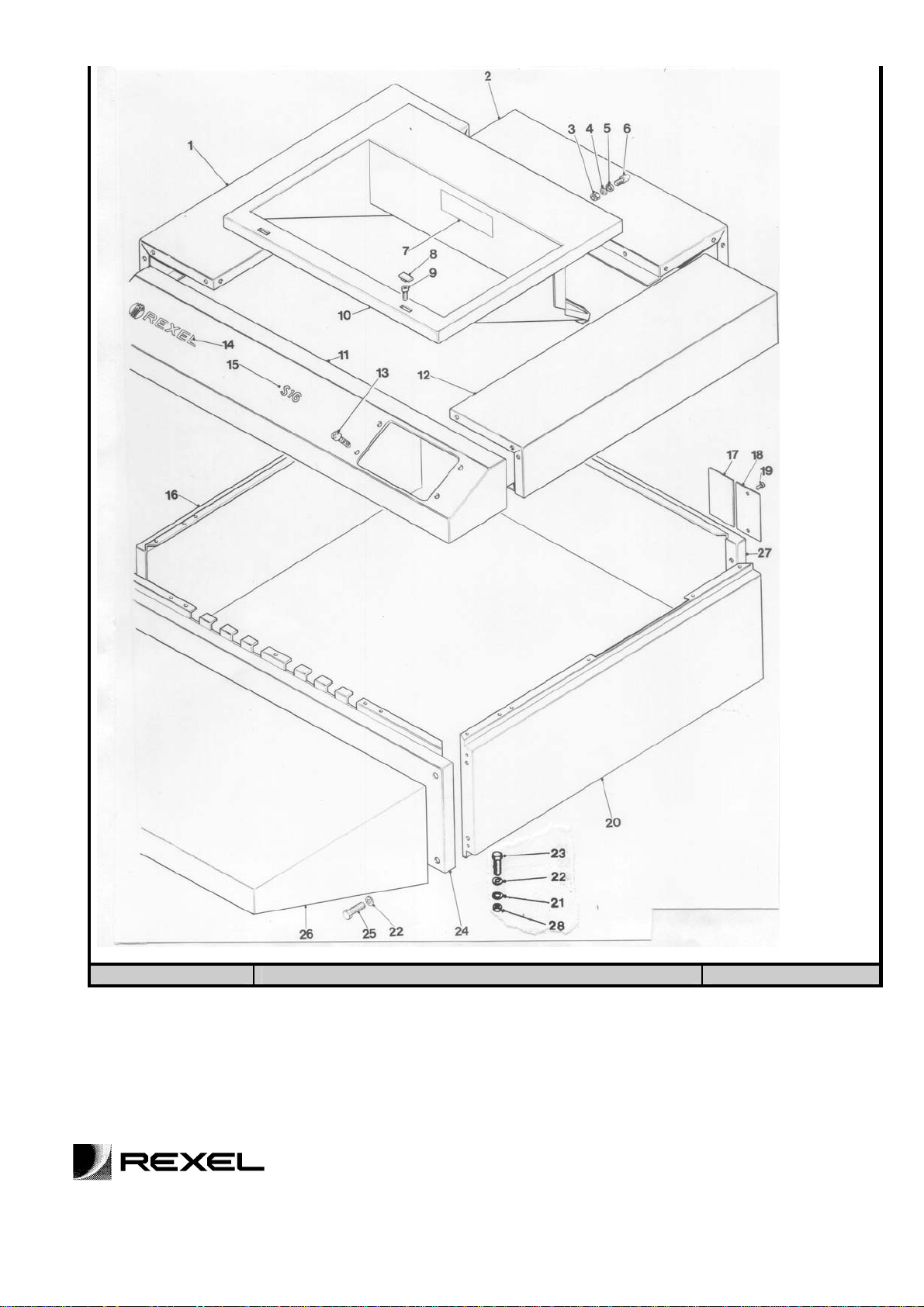

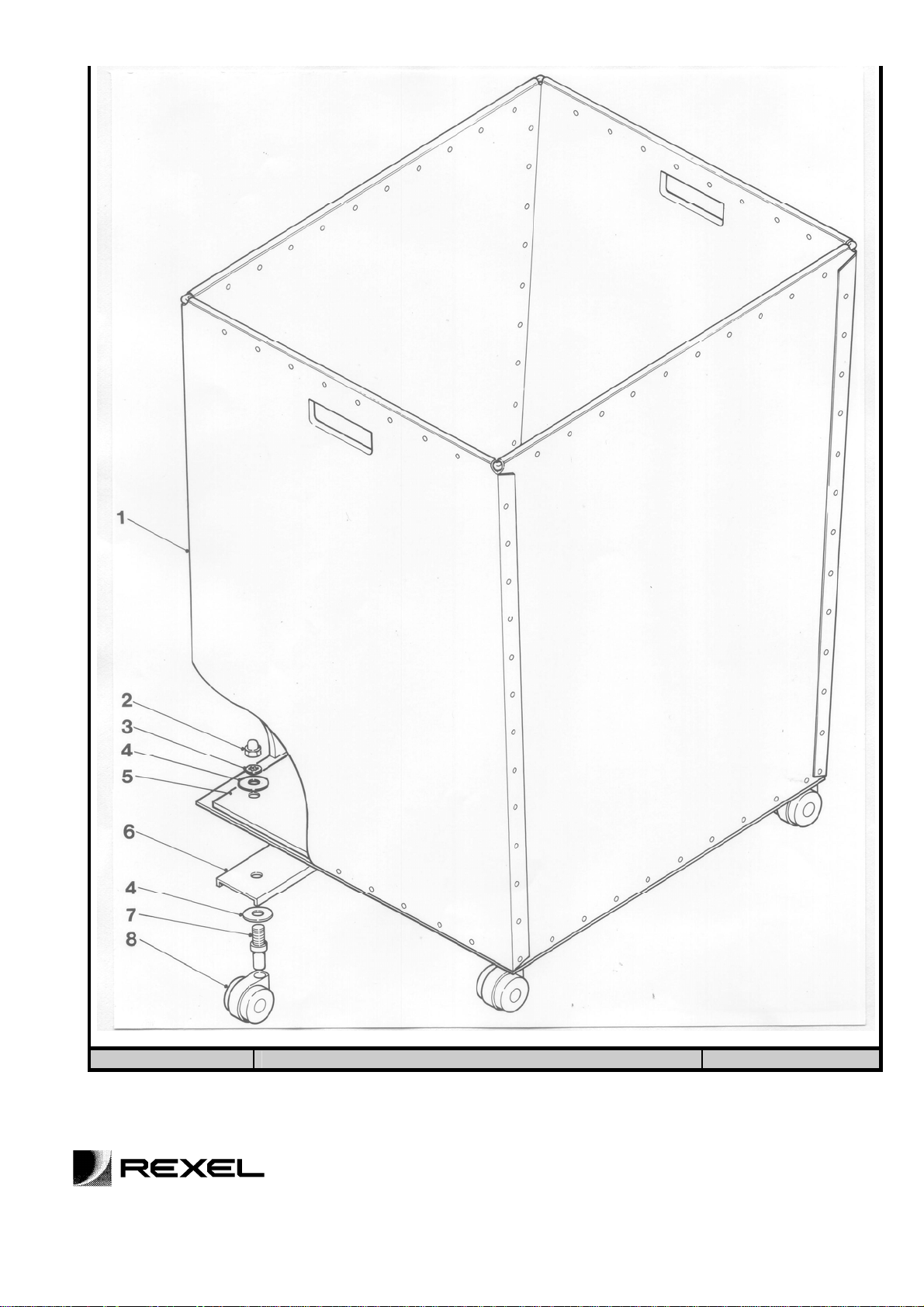

PAPER SHREDDER S16 SECTION 1

FRAME & COVER PANELS ASSEMBLY

NO PART NO DESCRIPTION QTY COMMENTS

1 25384 REAR COVER PANEL 1

2 25400 LH FRONT COVER PANEL ASSY 1

3 A25065 FRAME ASSEMBLY 1

4 TRU67 GRIP RING 1

5 SCM43 M3 X 20 POZI PAN SCREW 2

6 NM8 M5 NUT 4

7 25238 SAFETY SWITCH BRACKET 1

8 SHK3 M5 SHAKEPROOF WASHER 8

9 SHK1 M3 SHAKEPROOF WASHER 4

10 NM7 M3 NUT 2

11 SL23-12 DOOR CATCH MAGNET 1

12 25418 LINKAGE ASSEMBLY 1

13 25244 LINKAGE BRACKET 1

14 SCM40 M5 X 12 POZI HEAD SCREW 4

15 D25398 RH FRONT COVER PANEL ASSY 1

16 SL18-281 HANDLE 1

17 SL18-184 LOCKING CASTOR 2

SL18-297 NON-LOCKING CASTOR 2

18 PLN5 M8 PLAIN WASHER 16

19 SHK5 M8 SHAKEPROOF WASHER 16

20 SCM38 M8 x 16 HEX HEAD SCREW 16

21 D25402 DOOR ASSEMBLY 1

22 25419 HINGE 1

23 RTS37 POP RIVET 20

24 SCM15 M6 x 12 SCREW HEX HEAD 11

25 PLN4 M6 PLAIN WASHER 11

26 SHK4 M6 SHAKEPROOF WASHER 11

ISSUE 2

PAPER SHREDDER S16 SECTION 1

ILLUSTRATED PARTS LIST

DEM Page 6 of 43 FEBRUARY 07

FRAME & COVER PANELS ASSEMBLY

ISSUE 2

PAPER SHREDDER S16 SECTION 2

ILLUSTRATED PARTS LIST

CASING ASSEMBLY

DEM Page 7 of 43 FEBRUARY 07

NO PART

DESCRIPTION QTY COMMENTS

NO

25467 TOP COVER ASSY COMPLETE 1 Consists of Item Nos.

1 25397 SIDE PANEL UPPER CASE LH 1

2 25396 REAR PANEL UPPER CASE 1

3 NM8 M5 HEXAGON NUT 2

4 SHK3 M5 SHAKEPROOF WASHER 2

5 PLN3 M5 PLAIN WASHER 2

6 39019 LOCATING PEG 2

7 D000309 OILING/WARNING DECAL 1

8 45659 PLASTIC CAP 2

9 SCM122 M5 x 20 SOCKET CAP SCREW 2

10 A25434 FEED CHUTE 1

11 25394 FACIA PANEL 1

12 25080 SIDE PANEL UPPER CASE RH 1

13 SCM81? M4 x 12 COUNTERSUNK RAISED

HEAD SCREW

14 1000748 REXEL LOGO DECAL 1

15 D000238? FACIA DECAL 1

16 25072 SIDE PANEL CASE LH 1

17 D000157 ? INSTRUCTION DECAL 1

18 RPS16 RATING PLATE 1

19 RTS19 POP RIVET 2

20 25073 SIDE PANEL CASE RH 1

21 PLN4 M6 PLAIN WASHER 4

22 SHK4 M6 SHAKEPROOF WASHER 8

23 SCM13? M6 x 40 HEXAGON HEAD SCREW 4

24 25143 FRONT PANEL CASE S/W ASSY 1

25 SCM31 M6 x 30 HEXAGON HEAD SCREW 4

26 25094 FEED SHELF 1

27 25075 REAR PANEL 1

28 NM5 M6 HEXAGONAL NUT 4

ISSUE 2

PAPER SHREDDER S16 SECTION 2

ILLUSTRATED PARTS LIST

CASING ASSEMBLY

4

DEM Page 8 of 43 FEBRUARY 07

ISSUE 2

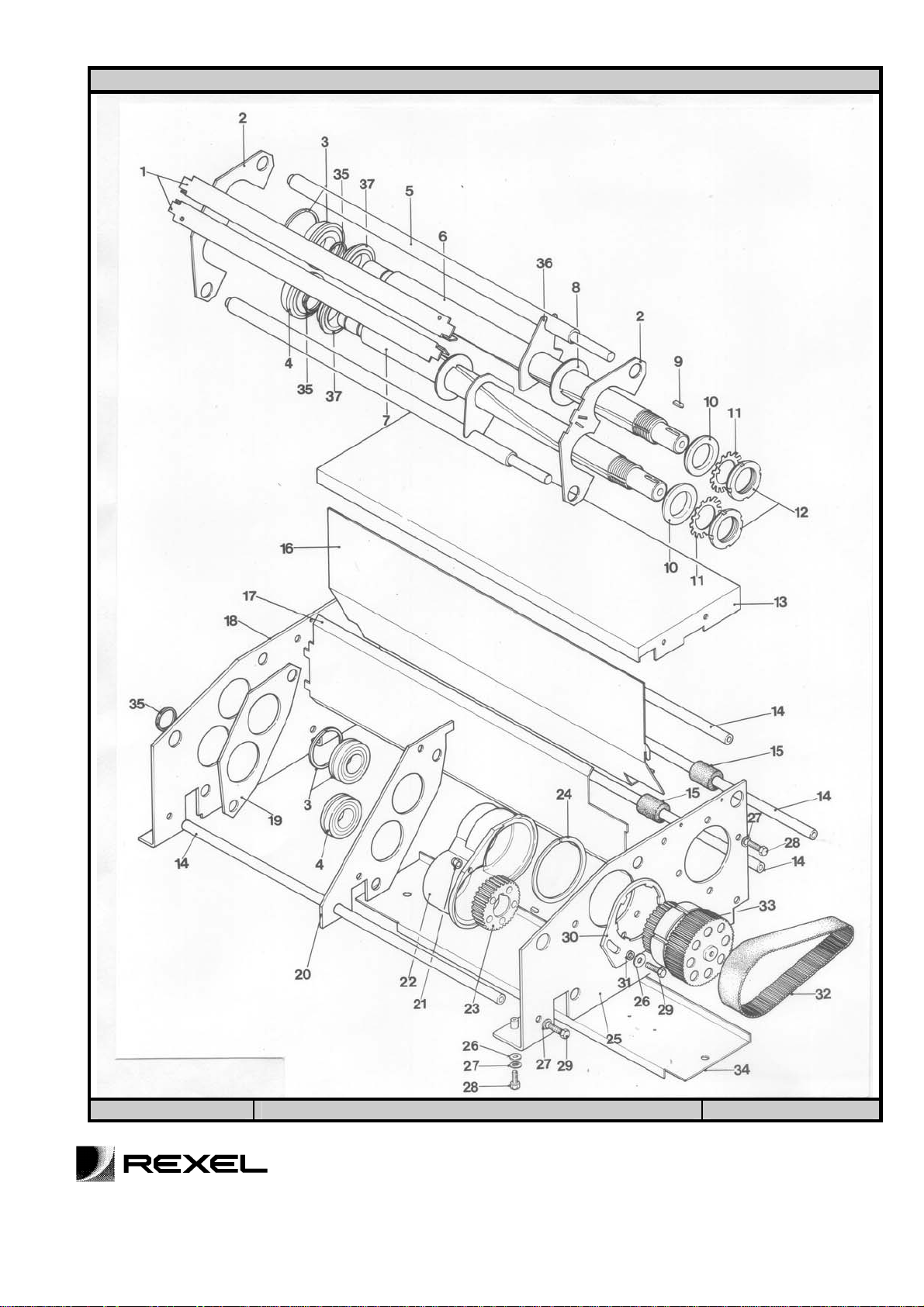

PAPER SHREDDER S16 SECTION 3

ILLUSTRATED PARTS LIST

CUTTING HEAD

DEM Page 9 of 43 FEBRUARY 07

NO PART

DESCRIPTION QTY COMMENTS

NO

25449 CUTTING HEAD COMPLETE 1 Comprising Item Nos.

1 D25435 INFEED EXTENSION 1 2

2 D25440 PAPER GUIDE 2 UP TO S/N 661559

3

4 BR15 BEARING 2

5 D25443 STRIPPER BAR 2

6 D25445 CUTTER DRIVE SHAFT 1

7 D25446 CUTTER DRIVEN SHAFT 1

8 D25437 CUTTER 268

9 KEY31? KEY 8 x 7 x 18 (ROUND ONE END) 2

10 D25444 COLLAR 2

11 TAB5 TAB WASHER 40 2

12 NM29 NUT NOTCHED M40 x 1.5 2

13 D25436 MOT O R DUST COVER 1

14 45966 TIE ROD 4

15 45535 SUPPORT BUSH 2 NOLONGER FITTED

16 D25427 BIN FULL FLAP 1

17 D25448 DEFLECTOR PLATE 1

18 A25429 SIDE PLATE LH ASSEMBLY 1 COMPRISING

19 D25439BI STRIPPER LOCATION PLATE LH 1

20 D25438 STRIPPER LOCATION PLATE RH 1

21 NM22 NUT NYLOC M8 2

22 D25442 GEARBOX COVER 1

23 45737 2ndSTAGE PLANET CARRIER 1

24 TRU84 GEAR CASING CIRCLIP 1

25 A25428 SIDE PLATE RH ASSEMBLY 1 COMPRISING

26 PLN5/L WASHER PLAIN 6

27 SHK5 SHAKEPROOF WASHER 16

28 SCM32 M8 x 20 HEX HEAD SCREW 8

29 SCM38 M8 x 16 HEX HEAD SCREW 10

30 45541 DE-JAM KICK PLATE 1

31 45539BI SPACER 2

32 SL22-82 BELT 1

33 45667 GEARBOX COMPLETE 1

34 D25441 REAR HEAD SUPPORT PANEL 1

35 TRU70 CIRCLIPS 3

36 D45973 STRIPPERS 268

37 45585 COLLARS 2

D25454

BR22

PAPER GUIDE

BEARING C/W SNAP RING

2

2

FROM S/N 661559

ISSUE 2

PAPER SHREDDER S16 SECTION 3

ILLUSTRATED PARTS LIST

DEM Page 10 of 43 FEBRUARY 07

CUTTING HEAD

ISSUE 2

PAPER SHREDDER S16 SECTION 4

ILLUSTRATED PARTS LIST

BIN ASSEMBLY

DEM Page 11 of 43 FEBRUARY 07

NO PART

DESCRIPTION QTY COMMENTS

NO

1 25386 FIBRE BIN 1

2 D-NUT36 M8 DOME NUT 4

3 SHK5 M8 SHAKEPROOF WASHER 4

4 PLN27 WASHER LARGE 8

5 25452 BASE REINFORCEMENT 1

6 25413 BASE STIFFENER 2

7 SL18-344 CASTOR STEM INSERT (M8 x 15) 4

8 SL18-345 CASTOR 4

ISSUE 2

PAPER SHREDDER S16 SECTION 4

ILLUSTRATED PARTS LIST

BIN ASSEMBLY

DEM Page 12 of 43 FEBRUARY 07

ISSUE 2

PAPER SHREDDER S16 SECTION 5

ILLUSTRATED PARTS LIST

ELECTRICS

DEM Page 13 of 43 FEBRUARY 07

NO PART

DESCRIPTION QTY COMMENTS

NO

25455 SWITCH/CONTROL UNIT

COMPLETE

1 NM7 NUT M3 2

2 SKH1 SHAKEPROOF WASHER 6

3 SL8-107 MICROSWITCH 1

4 SCM78 SCREW M3 x 16mm POZI PAN 4

5 SL6-33 CAPACITOR 90-112uF 1 TO S/N 690498

6 NM5 NUT M6 2

7 SHK4 SHAKEPROOF WASHER 2

8 PLN4 PLAIN WASHER 2

9 SCM87 SCREW M6 x 16mm 2

10 SL6-22 CAPACITOR 16uF 1 TO S/N 930900

SL6-53 CAPACITOR 15uF 1 FROM S/N 930900

11 PEG6 PIN 30 x 5mm 1

12 SL26-10 MOTOR FAN 1

13 SL20-255 MOTOR 600W 220-240V 1 C/W CAPACITORS (2) UP TO S/N 690498

SL20-265 MOTOR 600W 220-240V 50Hz 1 FROM S/N 690498 TO S/N 930900

SL20-309 MOTOR 600W 220-240V 50Hz 1 FROM S/N 930900

14 SHK6 SHAKEPROOF WASHER M8 4

15 SCM38 SCREW M8 x 16mm HEX HEAD 4

16 KEY 1 KEY 5 x 5 x 40mm 1

17 SCM27 SOCKET SET SCREW M5 x 10mm 1

18 45621 MOTOR PULLEY 1

19 SL9-11 6-WAY TERMINAL BLOCK 1 T O S/N 930900

20 SCM43 SCREW M3 x 20mm POZI PAN 2 TO S/N 930900

21 NM13 NUT M3 PILLAR TYPE 4 TO S/N 930900

22 SL5-67 CONTACTOR 2 TO S/N 930900

SL5-80 CONTACTOR 115V 2

23 NM8 M5 NUT 8 TO S/N 930900

24 SHK3 SHAKEPROOF WASHER M5 8 TO S/N 930900

25 PLN3 PLAIN WASHER M5 8 TO S/N 930900

26 23516 INSULATION - SAFETY SWITCH 1

27 SL8-72 SAFETY SWITCH 1

28 SCM6? M4 x 30mm POZI PAN SCREW 2

29 SCR559B 2BA x 1” BRASS SCREW 1

30 X1466 INSULATION 2 TO S/N 930900

31 SL9-19 16A TERMINAL BLOCK 1 TO S/N 930900

32 SL5-69 MECHANICAL INTERLOCK 1 TO S/N 930900?

33 V2132/1 EARTH TAG 1 TO S/N 930900

34 NUT 42B 2BA BRASS NUT 3

35 SL17-41 SHELL CLAMP 4 T O S/N 930900

36 PLN3B 2BA PLAIN BRASS WASHER 3

37 SL17-131? BAR CLAMP 2

38 SHK2? SHAKEPROOF WASHER M4 1

39 NM3? M4 NUT 1

40 SL4-28 CABLE 1 T O S/N 930900

SL4-29 CABLE 115V 1 T O S/N 930900

41 SL17-112 SELF-ADHESIVE CABLE CLIP 3 TO S/N 930900

SL17-111 SELF-ADHESIVE CABLE CLIP 3 FROM S/N 930900

42 SL17-126 CABLE ENTRY CLAMP 1 TO S/N 930900

43 SL17-127 ENTRY CLAMP BUSH 1 TO S/N 930900

44 SCM22 SCREW M6 x 20mm HEX HEAD 1 TO S/N 930900

ISSUE 2

PAPER SHREDDER S16 SECTION 5

ILLUSTRATED PARTS LIST

ELECTRICS

1

DEM Page 14 of 43 FEBRUARY 07

ISSUE 2

PAPER SHREDDER S16 SECTION 5

ILLUSTRATED PARTS

LIST

ELECTRICS

DEM Page 15 of 43 FEBRUARY 07

NO PART

DESCRIPTION QTY COMMENTS

NO

45 D000200 CONTROL PANEL DECAL 1 T O S/N 930900

1000728 S16 SWITCH DECAL 1 FROM S/N 930900

46 SL10-45 RED NEON INDICATOR LIGHT 1

SL10-62 RED NEON LIGHT 115V 1

47 SL10-46 RED LED INDICATOR LIGHT 1 TO S/N 930900

48 SL8-117 EMERGENCY STOP SWITCH 1

49 SCM81 M4 x 12mm COUNTERSUNK

RAISED HEAD SCREW

50 25350 SWITCH BRACKET S/W ASSY 1

51 SL17-147 SWITCH PANEL 1 TO 23/12/94

SL17-242 SWITCH PCB 1 FROM 2/1/95 TO S/N 930900

SL17-319 SWITCH PCB 1 FROM S/N 930900

52 SL8-118 SWITCH MOUNTING CONNECTOR 1

53 SL8-119 DP CONTACTOR BLOCK 1

54 W142 WIRING KIT 1 TO S/N 930900

W159 WIRING KIT 115V 1

WD283 WIRING DIAGRAM 1 TO S/N 930900

WD294 WIRING DIAGRAM 1 FROM S/N 930900

55 SL17-143 PCB LUG SUPPORT 4

56 25290 PCB BRACKET S/W ASSEMBLY 1 TO S/N 930900

SL17-320 PCB PILLAR 1 FROM S/N 930900

SL17-321 PCB PILLAR 3 FROM S/N 930900

57 SL17-182 CONTROL PCB 1 TO 23/12/94

SL17-243 CONTROL PCB 1 FROM 2/1/95 TO S/N 930900

SL17-238 CONTROL PCB 115V 1

SL17-318 CONTROL LED PCB 1 FROM S/N 930900

58 SL18-198 CABLE CLAMP 2

59 SCR543 NO.6 x ¼” POZI PAN (TYPE Z) 2

60 1000880 INLET SOCKET BRACKET 1 FROM S/N 930900 (NOT SHOWN)

61 SL12-51 APPLIANCE INLET SOCKET 1 FROM S/N 930900 (NOT SHOWN)

62 SL15-22 10 AMP FUSE SEMI DELAY 1 FROM S/N 930900 (NOT SHOWN)

63 1000762 SAFETY CICUIT 1 FROM S/N 930900 (NOT SHOWN)

4

ISSUE 2

PAPER SHREDDER S16 SECTION 1

SERVICE INSTRUCTIONS

DEM Page 16 of 43 FEBRUARY 07

INSTALLATION NOTES

POWER SUPPLY

Check that the details marked on the machine rating plate conform with the electrical mains supply.

Single phase power supply operation - 115v. 1ph. 60Hz

240v. 1ph. 50Hz

This machine must be earthed.

SAFETY PRECAUTIONS

1. Before ‘testing’ or ‘using’ the machine, the locking castor wheels MUST be securely locked in the

LOCKED POSITION; this is achieved by depressing the locking levers on the two castor wheels

at the front of the machine. When the castor wheels are securely locked the machine is prevented

from moving on the floor in the event of the paper cutters becoming jammed.

2. DISCONNECT the electrical mains supply plug from its socket before commencing any services.

3. PAT TEST after any servicing.

NOTE: THE ELECTRIC MOTOR IS PROTECTED BY AN AUTOMATIC OVERLOAD CUTOUT.

PAPER SHREDDER S16 SECTION 2

SERVICE INSTRUCTIONS

DEM Page 17 of 43 FEBRUARY 07

LUBRICATION OF CUTTING HEAD

To avoid a build-up of paper dust, the cutting head should be cleaned thoroughly on a regular basis

followed by the application of a small amount of shredder oil to lubricate the cutters. Oil penetration

can be assisted by running the machine in reverse and forward modes alternatively.

When the machine is used regularly it is recommended that cleaning and oiling is carried out at

weekly intervals.

At six monthly intervals chains, sprockets and gears should be cleaned and re-coated with Rexel

Shredder Oil.

DEM Page 18 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 3

SERVICE INSTRUCTIONS

FEED CHUTE REMOVAL AND REPLACEMENT

1. Remove the two plastic screw covers (1, fig. 1) by prising upwards with s screwdriver.

2. Remove the two set screws (2, fig. 1), lift front of feed chute, slide forward to unplug at the rear

and lift free.

3. Assemble in reverse sequence.

4. NOTE: if replacing feed chute the two plugs (3, fig.1) can be removed and refitted to a new feed

chute by removal of nuts and washers (4,5,6, fig.1).

DEM Page 19 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 4

SERVICE INSTRUCTIONS

REMOVAL OF CASING

1. Remove the four screws (1, fig. 2), securing the operating switches assembly to facia

panel.

2. Lower the switch assembly to the inside of the machine.

3. Open the hinged door and withdraw the waste bin (1, fig.3).

4. Remove the four nuts and washers (1, fig.4) securing the casing to the frame assembly.

These are situated within the main frame, upper section.

PAPER SHREDDER S16 SECTION 4

SERVICE INSTRUCTIONS

5. Remove the casing from the main frame assembly (2, fig.4).

6. Assemble in reverse sequence.

DEM Page 20 of 43 FEBRUARY 07

DEM Page 21 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 5

CUTTING HEAD ADJUSTMENT

Ensure that machine is disconnected from the electricity supply.

Too much clearance between adjacent cutters can cause incorrect shredding.

To rectify:-

1. Remove the casing (section 2 page 4).

2. Prose open locking washers on both shafts on the gearbox end.

3. Tighten locknuts equally to a finger tight position using a ‘C’ spanner or by pushing on

notches with a screwdriver.

SERVICE INSTRUCTIONS

4. Peen over locking tabs on to locknuts to secure in position.

5. Run amchine and test for quality of cut.

6. If cut quality is unacceptable repeat stages 2-5 and tighten lock nuts equally in one notch

steps until an accceptable quality of cut is obtained.

7. Refit casing and test operation.

DEM Page 22 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 6

SERVICE INSTRUCTIONS

REPLACING DRIVE BELT

1. Remove the casing (section 2, page 4).

2. NOTE: The gearbox pulley and motor drive are on fixed centres. To remove belt, slaken

socket set screw securing motor pulley and wind belt off gearbox pulley as shown (fig. 5).

3. to fit replacement belt, position motor pulley half way onto motor shaft. Fit belt and ‘wind’

onto gearbox pulley.

4. Align motor pulley with gearbox and secure with grub screw.

5. Refit cover and test.

DEM Page 23 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 7

SERVICE INSTRUCTIONS

REPLACING CUTTING HEAD

1. Remove the casing (section 2, page 4).

2. Remove the motor dust cover and lift out the bin full flap.

3. Note and disconnect motor wires from the rear terminal block, capacitor and earth screw.

Disconnect the wires from the bin full switch.

4. Remove the drive belt (section 2, page 6) and motor (section 2, page 12).

5. Unscrew 4 cutting head fixing screws and lift out the cutting head assembly. NOTE: 4

holes are provided in the sideplates for lifting with a hoist if required.

6. Replace the new cutting head assembly and reassemble in the reverse sequence.

7. Test the operation and adjust the cutter tension if necessary.

DEM Page 24 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 8

SERVICE INSTRUCTIONS

REPLACING GEARBOX

1. Remove the cutting head unit (section 2 page 7), drive belt (section 2 page 6), and motor

(section 2 page 10).

2. Support the cutting head with the gearbox uppermost and remove the screws securing the

de-jam plate, gearbox cover and tie rods. Lift away the side plate and gearbox assembly.

(Fig 6)

3. Remove the circlip securing the gearbox and withdraw the gearbox from the side frame.

Retain the de-jam plate.

4. On separation of the gearbox, part of the gear train may remain in the gearbox position.

Remove the gears and clean gearbox cover.

NOTE: Examine the shaft bearings and 1/1 gears for wear and replace if required.

5. Should the gears have become dislodged from the replacement gearbox position the

centre dowel gear as shown (fig. 7) into drive pulley, locate the centre dowel and engage

assembled 1st stage gear. Pack with LM2 grease. Engage the assembled 2nd stage

planet gear carrier with the 1st stage drive gear.

Restrain the gear carrier and rotate the drive pulley to seat the gears.

6. Align the de-jam plate with the gear casing and secure with the new circlip to the side

frame.

7. Offer the side frame assembly to the gearbox cover and rotate the drive pulley to locate

the gears.

8. Locate the de-jam plate with the gearbox mounting holes and secure.

9. Reassemble the remaining components in the reverse sequence.

DEM Page 25 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 8

SERVICE INSTRUCTIONS

REPLACING GEARBOX CONT’D

DEM Page 26 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 9

SERVICE INSTRUCTIONS

CUTTERS AND STRIPPER REPLACEMENT

1. Remove the cutting head (section 2, page 7) and gearbox and sideframe assembly

(section 2 page 8).

2. Remove the 1/1 gears and gearbox cover assembly.

3. Prise open the locking washers and unscrew the locknuts on both shafts. Remove the

collars from both shafts and lift away the paper guide plate and infeed extensions.

4. NOTE

: The assembly order of cutter s and stripper and remove cutters and strippers as

required.

5. Reassemble the new cutters and stripper onto the shafts in the original order of assembly

(i.e in stacks of 4 components).

6. Reassemble the cutting head and test the operation.

7. Adjust the cutter clearance (section 2 page ) as necessary to give a good quality cut.

DEM Page 27 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 10

SERVICE INSTRUCTIONS

MOTOR REPLACEMENT

1. Remove the casing (section 2 page 4), the motor dust guard and the bin full flap.

2. Remove the drive belt and motor pulley (section 2 page 6).

3. Note the wiring connections and disconnect the motor wires from the terminal block,

capacitor and the motor earth screw.

4. Remove the screws securing the motor to the side frame.

5. Lift away the motor and fit the replacement, ensuring that the details on the motor rating

plate are correct for the machine.

6. Reconnect motor wires as originally fitted and reassemble the machine.

7. Run the machine and test the operation.

NOTE: Should the motor operate in reverse on test, interchange the black and

red motor wires.

DEM Page 28 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 11

SERVICE INSTRUCTIONS

SWITCH PANEL REPLACEMENT

1. Remove the casing (section 2 page 4).

2. Disconnect the ten way ribbon plug from the PCB (1, fig.9).

3. Note the wiring connections and disconnect the four wires (2, fig.9) from the emergency

stop switch.

4. Replace with the new switch panel and reconnect the wires as originally fitted (refer to

WD221, fig.9A).

5. Reassemble the machine in the reverse sequence.

6. Run the machine and test the operation.

DEM Page 29 of 43 FEBRUARY 07

Fig 9

Fig 9a

PAPER SHREDDER S16 SECTION 12

SERVICE INSTRUCTIONS

ELECTRONIC ADJUSTMENTS (REED SWITCHES)

Two sensors are mounted on the printed circuit board (PCB) 91, fig.11), each of which

comprise a coil supported on a terminal block and encircling a reed switch. One sensor

detects the high current present in the event of a phase failure, the other detecting the high

current drawn when the motor stalls due to the jamming of the cutting head. The magnetic

field from the coils operates the reed switches that form part of the logic circuit controlling the

contactors which directly switch the motor. (Warning: the glass encapsulated reed switch is

fragile). In the event of a phase failure, the machine will cease to operate, and the control

‘STOP’ button will illuminate.

When jamming occurs, after a short pause, the motor will automatically reverse momentarily

and then stop, the unshredded paper having been returned to the feed chute. The

illuminated controls will now indicate the ‘STOP’ mode. Manual reverse can be obtained by

pressing the reverse button on the control panel to give momentary reverse and then stop.

The waste container door is linked to a safety switch which is connected in the logic circuit

and when open also reverts the machine to the ‘[STOP’ mode. This condition is indicated by

an illumination on the switch control panel/

A ‘Fail-Safe’ circuit is incorporated within the logic circuit to detect any interruption in the

power supply which causes the machine to suddenly cease working. When the power

supply is restored the machine will automatically be re-set into the ‘STOP’ mode.

Machine not cutting required number of sheets

to establish whether the fault is mechanical or electrical both sensors on the PCB should be

temporarily short circuited as in fig.10. The machine should now be checked on mechanical

setting for maximum number of sheets cut and, if satisfactory, will indicate that the fault is

electronic, and adjustment is required. During the test avoid stalling the motor for a

prolonged period. If the maximum cut is not satisfactory, the problem is mechanical.

Adjustment

Revert the sensor connections to the original circuit before proceeding. Correct adjustment is

attained by slackening the terminal block securing screw(1,fig 11) and slightly rotating the

block to adjust the position of the coil relative to the reed switch (2, fig 11). Adjustment of the

coil towards either end of the switch will increase the quantity of sheets cut. Returning the

coil towards the centre decreases the quantity. When the coil is set, tighten the terminal

block securing screw.

This is the only adjustment on the PCB, should any other problems be encountered with the

electronics the complete PCB should be replaced.

ELECTRONIC ADJUSTMENTS (REED SWITCHES) CONT’D

DEM Page 30 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION12

PAPER SHREDDER S16 SECTION 13

SERVICE INSTRUCTIONS

SERVICE INSTRUCTIONS

ELECTRONIC ADJUSTMENTS (SENSING COILS)

DEM Page 31 of 43 FEBRUARY 07

The sensor is mounted on the printed circuit board (PCB) (fig 11b) and detects the high

current drawn when the motor stalls due to the cutting head jamming. The magnetic field of

the wire passing through the coil is sensed by the coil and operates the potentiometer, which

forms part of the logic circuit controlling the contactors which switch the motor.

When jamming occurs, after a short pause, the motor will automatically reverse momentarily

and then stop; the unshredded paper having been returned to the feed chute. The

illuminated controls will now indicate the “STOP” mode. Manual reverse can be obtained by

pressing the reverse button on the control panel to give momentary reverse and then stop.

The waste container door is linked to a safety switch which is connected in the logic circuit

and when open also reverts the machine to the “STOP” mode. This condition is indicated by

an illuminated on the switch control panel.

A “Fail-Safe” circuit is incorporated within the logic circuit, to detect any interruption in the

power supply that may cause the machine to suddenly cease working. When the power

supply is restored the machine will automatically be reset into the “STOP” mode.

Machine Not Cutting the Required Number of Sheets

Each machine is set at the factory to achieve the cutting of the maximum number of sheets.

The electrical control is achieved by setting the potentiometer on the PCB (fig 11b). The

electrical setting is checked using the 2-pin test plug located by the potentiometer and

checking the electrical resistance (ohms); compare the value with the factory setting value.

N.B. The setting screw located on the top of the potentiometer is used to achieve adjustment

if necessary. Turning the screw clockwise will increase the maximum number of sheets cut.

Should any other problems be encountered with the electronics, the complete PCB should be

replaced.

PAPER SHREDDER S16 SECTION 14

SERVICE INSTRUCTIONS

DEM Page 32 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 15

PRINTED CIRCUIT BOARD REPLACEMENT – REED SWITCH

1. Remove casing (ref section 3)

2. Note wiring connections and disconnect the two wires from the terminal block on the

PCB (1, fig 12).

3. Disconnect the 8-way plug (2, fig 12) and the 10-way ribbon plug (3, fig 12) from the

PCB.

4. Remove the PCB from its support and replace with the new board.

5. Reconnect wires and plugs as originally fitted (refer to wiring diagram).

6. Reassemble machine in reverse sequence. Carry out PAT test, run machine and test

operation.

SERVICE INSTRUCTIONS

DEM Page 33 of 43 FEBRUARY 07

PRINTED CIRCUIT BOARD REPLACEMENT – SENSING

COIL

1. Remove casing (ref section 3)

2. Note wiring connections and disconnect at the (7 Connectors) terminal block on the

PCB

3. Disconnect the 10-way ribbon plug from the PCB.

4. Disconnect the Over Current Wire from the Auto Reset Switch and remove from the

centre of the Over Current Coil.

5. Remove the PCB from its support and replace with the new board.

6. Reconnect wires and plugs as originally fitted (refer to wiring diagrams).

7. Reassemble the machine in the reverse sequence. Carry out PAT test, run the

machine and test the operation.

PAPER SHREDDER S16 SECTION 16

SERVICE INSTRUCTIONS

CONTACTOR REPLACEMENT

DEM Page 34 of 43 FEBRUARY 07

1. Remove casing (ref section 3).

2. Note wiring connections and disconnect all wires from

contactor(s) to be replaced (1, fig 13).

3. Remove the eight screws, nuts and washers (2, fig 13) securing both contactors to the

main frame.

4. Remove the mechanical interlock clips from between the two contactors using pliers,

separate the contactors and remove the mechanical interlock unit (3,fig 13).

5. Replace the contactor(s) as required and reassemble the mechanical interlock and

clips.

6. Reconnect wiring as originally fitted (refer to wiring diagrams).

7. Reassemble machine in reverse sequence. Run machine and test for operation.

PAPER SHREDDER S16 SECTION 17

SERVICE INSTRUCTIONS

DEM Page 35 of 43 FEBRUARY 07

HINGED GATE SAFETY SWITCH REPLACEMENT

1. Remove casing (section 3).

2. Remove the four screws, nuts and washers (1, fig 14) securing the switch bracket to

the main frame.

3. Remove the switch and bracket assembly ( 2, fig 14) and also the shaft support

bracket (3, fig 14).

4. Separate the switch and insulating cover from the bracket by removing the two screws

and nuts (4, fig 14).

5. Disconnect the leads from the switch.

6. Replace with new switch and connect the wiring.

7. Assemble in reverse sequence and test operation.

PAPER SHREDDER S16 SECTION 18

SERVICE INSTRUCTIONS

DEM Page 36 of 43 FEBRUARY 07

BIN FULL SWITCH REPLACEMENT

1. Remove casing (section 3).

2. Disconnect switch from the switch located on the left hand side frame.

3. Remove the two screws securing switch and insulating cover to bracket.

4. Replace with the new switch and reconnect the wiring. Test operation.

5. Assemble in reverse sequence.

DEM Page 37 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 19

FACTORY POTENTIOMETER SETTINGS

All machines are set in the factory to achieve the maximum number of sheets

cut by adjusting the potentiometer to the value shown below.

Individual machines may require adjustment to suit the site conditions, by either

increasing or decreasing the resistance value as required.

MACHINE

SUPPLY RESISTANCE (k ohm)

S16 230V 50HZ 950

S16 115V 60Hz 500-600

These values are for reference only and are not intended to represent the

values required by an individual machine site.

SPECIFICATION

MODEL S16

Power Supply 220-240V 50 Hz

Height 1170 mm

Width 735 mm

Depth

With shelf

Weight 140Kg

Motor Power 600W

Particle Size 6 mm Strip

Speed 12 m/min

Max Sheets (A4 70gsm) 40

660 mm

980 mm

Dimensions of Waste Container (HxDxW) 715 x 510 x 600 mm

Waste Container Capacity 0.205 m3

DEM Page 38 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 20

WIRING DIAGRAMS

Wiring Diagram 115V with Sensing Coil

DEM Page 39 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 20 CONT’D

WIRING DIAGRAMS

Wiring Diagram 220-240V with Sensing Coil

( From 2/1/95 S/N 690488 To S/N 930900)

DEM Page 40 of 43 FEBRUARY 07

PAPER SHREDDER S16 SECTION 20 CONT’D

WIRING DIAGRAMS

Wiring Diagram 220-240V with Reed Switch

(To 23/12/94 S/N 690488)

PAPER SHREDDER S16 SECTION 20 CONT’D

DEM Page 41 of 43 FEBRUARY 07

SERVICE INSTRUCTIONS

WIRING DIAGRAMS

Wiring Diagram 220-240V

( From S/N 930900)

DEM Page 42 of 43 FEBRUARY 07

PAPER SHREDDER S16

AMENDMENT RECORD SHEET

ISSUE

NO

DECRIPTION SERIAL

NO

CARO NO

1 Original - 2 PCB with sensing coil and new motor 690488

3 LED PCB and new motor 930900

DEM Page 43 of 43 FEBRUARY 07

Loading...

Loading...