Page 1

Actuator Sizing

Actuator Sizing

Because the actuator sizing is so critical to the proper

operation and life of a ball valve, we have chosen

not to publish torque values. Misinterpretation of

manual torque data can lead to undersizing, while

misinterpretation of factored torque values can

mislead as to ease of manual operation.

Furthermore, types of service conditions can

signifi cantly alter standard torque requirements.

Balon valves facilitate ease of use, and we will be

glad to provide sizing information upon request

through one of our fi eld representatives or from our

Oklahoma City headquarters.

Standards and Speci cations

Balon utilizes the following standards in the

manufacture of ball valves. It should be noted that

not all styles, confi gurations and materials used in

Balon valves meet all of these standards in their

entirety.

API. . . . . . . . . . . . . (American Petroleum Institute)

API-6FA. . . . . . . . . Fire Test For Resilient-Seated Valves

API 5B . . . . . . . . . . Inspection Of Threads

API-6D. . . . . . . . . . Pipeline Valves, End Closures,

Connectors And Swivels.

API-Q1. . . . . . . . . . Quality Programs

API-594 . . . . . . . . . Wafer Check Valves

ANSI . . . . . . . . . . . (American National Standard Institute)

ANSI-B. . . . . . . . . . 16.5 - Pipe Flanges And Flanged Fittings

ANSI-B. . . . . . . . . . 16.10 - Face-To-Face End-To-End

Dimensions

ANSI-B. . . . . . . . . . 16.42 Ductile Iron Pipe Flanges And

Flanged Fittings

ANSI-B. . . . . . . . . . 16.34 - Valves - Flanged End,

. . . . . . . . . . . . . . . . Threaded And Butt Weld

ANSI-B. . . . . . . . . . (B1.20.1) - Pipe Threads General

Purpose (Inch)

The user therefore, should specify a given standard

if there is a need to assure total compliance with a

given standard.

MSS . . . . . . . . . . . . (Manufacturers Standardization Society)

MSS-SP6 . . . . . . . . Standard Finishes For Contact Faces Of

Pipe Flanges And Connection End

Flanges Of Valves And Fittings

MSS-SP25. . . . . . . Standard Marking System For Valves, Fittings,

Flanges And Fittings

MSS-SP72. . . . . . . Ball Valves With Flanged Or Butt

Welding Ends For General Service

MSS-SP82. . . . . . . Valve Pressure Test Methods

MSS-SP84. . . . . . . Steel Valves - Socket Welding And Threaded

Ends

NACE MR-01-75. . .Sulfi de Stress Cracking, Resistant

Metallic Material For Oil Field Equipment (NACE

Materials Are Optional And Must Be Specifi ed

On Purchase Orders)

Standards & Specifi cations

ABC

Different by Philosophy, Better by Design

Page 2

g

theckouou

gh

h

ovovovov

atatat

l

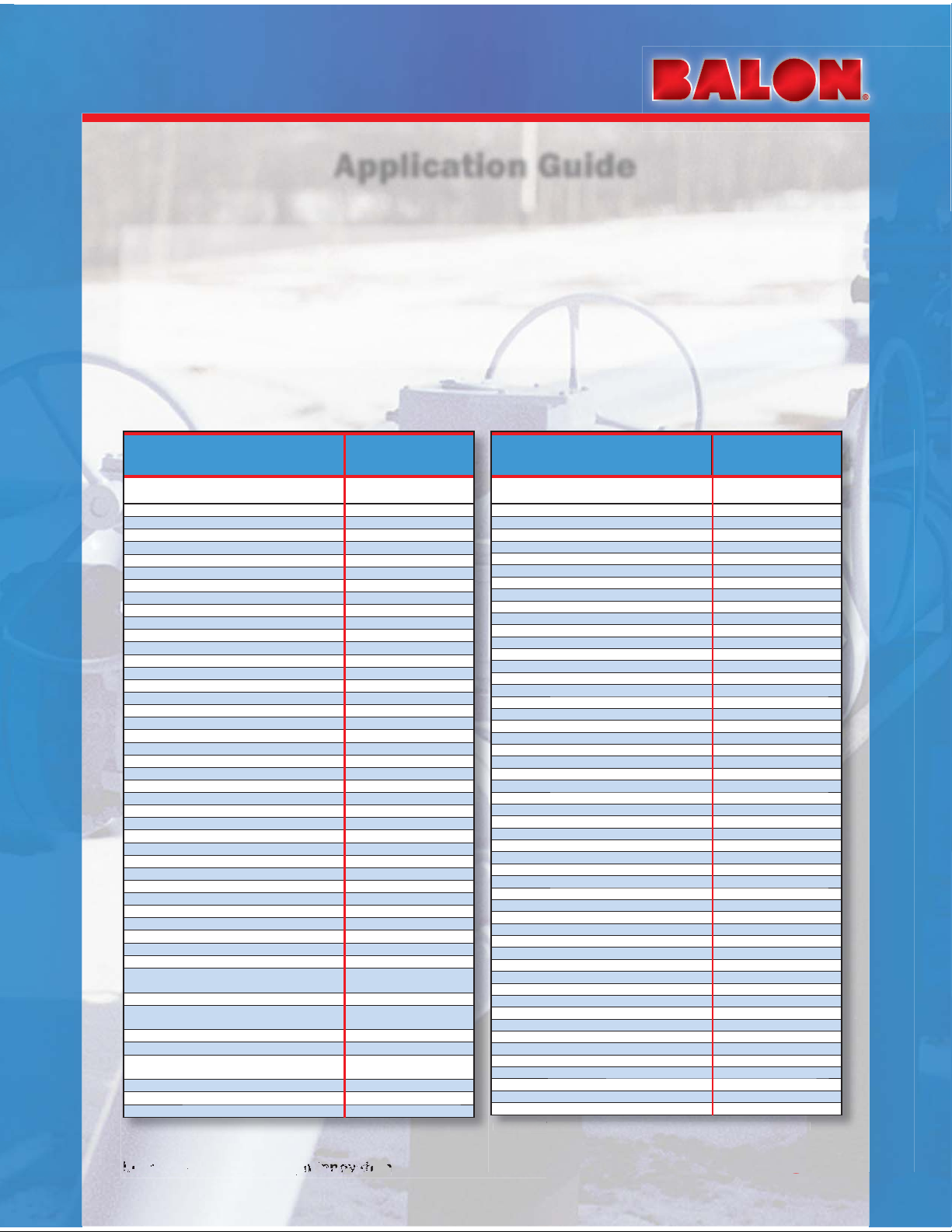

Application Guide

Application Guide

This Balon “Media and Application Guide” provides assistance to the engineer in selecting the best material

for a particular service. The fi nal selection of materials however, requires the judgement of the user because it

may be necessary to sacrifi ce certain physical properties of a material to take better advantage of others.

Information contained in the following chart is believed to be reliable and is intended to be used by trained

personnel at their own discretion and risk. Due to many factors which affect the rate of corrosion, we

suggest that fi nal acceptability be established by test under actual operating conditions.

Ratings are based on media at ambient temperatures except as noted.

E - Excellent G - Good F - Fair U - Unsatisfactory BLANK - Insuffi cient Data

Application Guide

VALV E

MATERIAL

Carbon

Media *

Air E E E E E E E

Alcohols G G E E E F E

Amines (conc.) E E E U U E E

Ammonia, Anhydrous E G E F U E E

- Aqueous E E E F U G E

- Solutions G G E F U G E

Benzene or Benzol G G E U E E E

Brines F F G E E E E

Bunker Oils (Fuels) G G E E E E E

Butane E E E E E E E

Carbolic Acid (Phenol) U U G U G U E

Carbon Dioxide, Dry E F E G G G E

Carbonic Acid U U G G E E E

Carbon Tetrachloride, Dry F F E U E E E

-Wet U U G U E E E

Carbonated Water G G E E E G E

Crude Oil, Sweet E E E E E E E

- Sour G G E F G G E

Diethylamine (DEA) E E E U U E E

Diesel Fuels E E E E E E E

Dowtherm A and E G G E U E E E

Drilling Mud G G E E E E E

Ethane E E E E E E E

Ethylene E E E U E E E

Ethylene Glycol G G G E E G E

Fuel Oil G G E E E E E

Gas, Manufactured G G G E E E E

- Natural G G E E E E E

- Odorizers G G E U E G E

- Sour G G E F E E E

Gasoline, Leaded E G E G E E E

- Unleaded E G E F E E E

- Aviation E G E G E E E

- Motor E G E F E E E

Glycols G G G E E G E

Heptane E E E E E E E

Hexane E E E E E E E

Hydraulic Oil

- Petroleum Base E E E E E E E

- Phosphate Base E E E U E E E

Hydrocloric Acid

-Air Free U U U F E U E

Hydrofl oric Acid U U U U U U F

Hydrogen Gas G G E E E E E

Hydrogen Sulfi de,

Dry(Conc.)

Wet(Conc.) F U G U F E E

Illuminating Gas E E E E E E

Iso-Octane E G E E E E E

Ductile

Steel

Iron

GGE FFEE

SEAT AND SEAL

MATERIAL

316

Buna-N Viton Nylon TFE

SS

VALV E

MATERIAL

Carbon

Media *

Isopropyl Alcohol G G G G E G E

- Ether E G E G U E E

JP-4 Fuel E E E E E E E

JP-5 Fuel E E E E E E E

JP-6 Fuel E E E E E E E

Kerosene G G E E E E E

Liquifi ed Pet. Gas (LPG) G G G E E E E

Lubricating Oil E E E E E E E

Mercaptan (Conc.) G G E F E G E

Methane E E E E E E E

Muratic Acid U U U G E U E

Naphtha G G E G E E E

Naphthalene E G E U E E E

Natural Gas E E E E E E E

Nitrogen E E E E E E E

Oil, Animal E E E E E E

- Cottonseed F F G E E E E

- Fish G G E E E E E

- Fuel G G E E E E E

- Lube E E E E E E E

- Mineral G G E E E E E

- Petroleum, Refi ned E G E E E E E

Oil-Water Mixtures E E E E E E E

Parafi n G G E G E E E

Pentane G G E U E E E

Producer Gas G G G E E E E

Propane E E E E E E E

Propyl Alcohol E E E E E E E

Propylene Glycol E E E E E F E

Sea Water U U E E E E E

Sodium Acetate G G G G U G E

- Hydroxide, Cold, 20% E E E G G E E

- Hydroxide, Hot, 20% F F G G G G E

- Hydroxide, Cold, 50% G G G F F F F

- Hydroxide, Hot, 50% G G G U F U F

- Hydroxide, Cold, 70% F F G U F F

- Hydroxide, Hot, 70% G F G U F U

Steam (212˚ F) E E E U U U E

Stoddard Solvent G G G E E G E

Sulfur Dioxide (Dry) G G E U U F E

Sulfuric Acid, 0-7% F F G F E G E

- 20% U U F U E U E

- 50% U U U U E U E

- 100% U U U U E U E

Toluene or Toluol E E E U E E E

Water, Distilled, Aerated U U E E G E E

- Fresh F F E E E E E

- Sea U U E E E E E

Wax Emulsions E G E E E E E

Waxes E E E E E E E

Xylene, Dry E E E U E E E

* Consul t Oklahom a City offi ce for c ompatibi lity of Alu minum Bro nze Material

ahoma City offi ce for compatibility of Aluminum Bronze Material

onsult Ok

Steel

Ductile

Iron

SEAT AND SEAL

MATERIAL

316

Buna-N Viton Nylon TFE

SS

ABCLeading the Pack Through Innovation

Page 3

°

°

Seat Pressure Ratings

Seat Pressure & Temperature Ratings

NYLON / ACETAL / PEEK

4000

3000

2000

1800

1600

1400

1200

1000

PSI - VALVE CLOSED

800

PRESSURE DIFFERENTIAL

600

ACETAL

NYLON

PEEK

400

200

0

100° 200° 300° 400° 500

220° 350°

TEMP. F°

TEFLON*

2200

2000

1800

1600

1400

1200

1000

PSI - VALVE CLOSED

PRESSURE DIFFERENTIAL

1/4" Full - 2" Reduced

2" Full - 3" Reduced

3" Full - 4" Reduced

800

4" Full - 6" Reduced

600

400

Seat Pressure & Temperature Ratings

6" Full - 8" Reduced

200

0

ABC

100° 200° 300° 400° 500

250°

TEMP. F° * Reg. DuPont

Safety Is No Accident, We Do It by Design.

Loading...

Loading...