Page 1

2

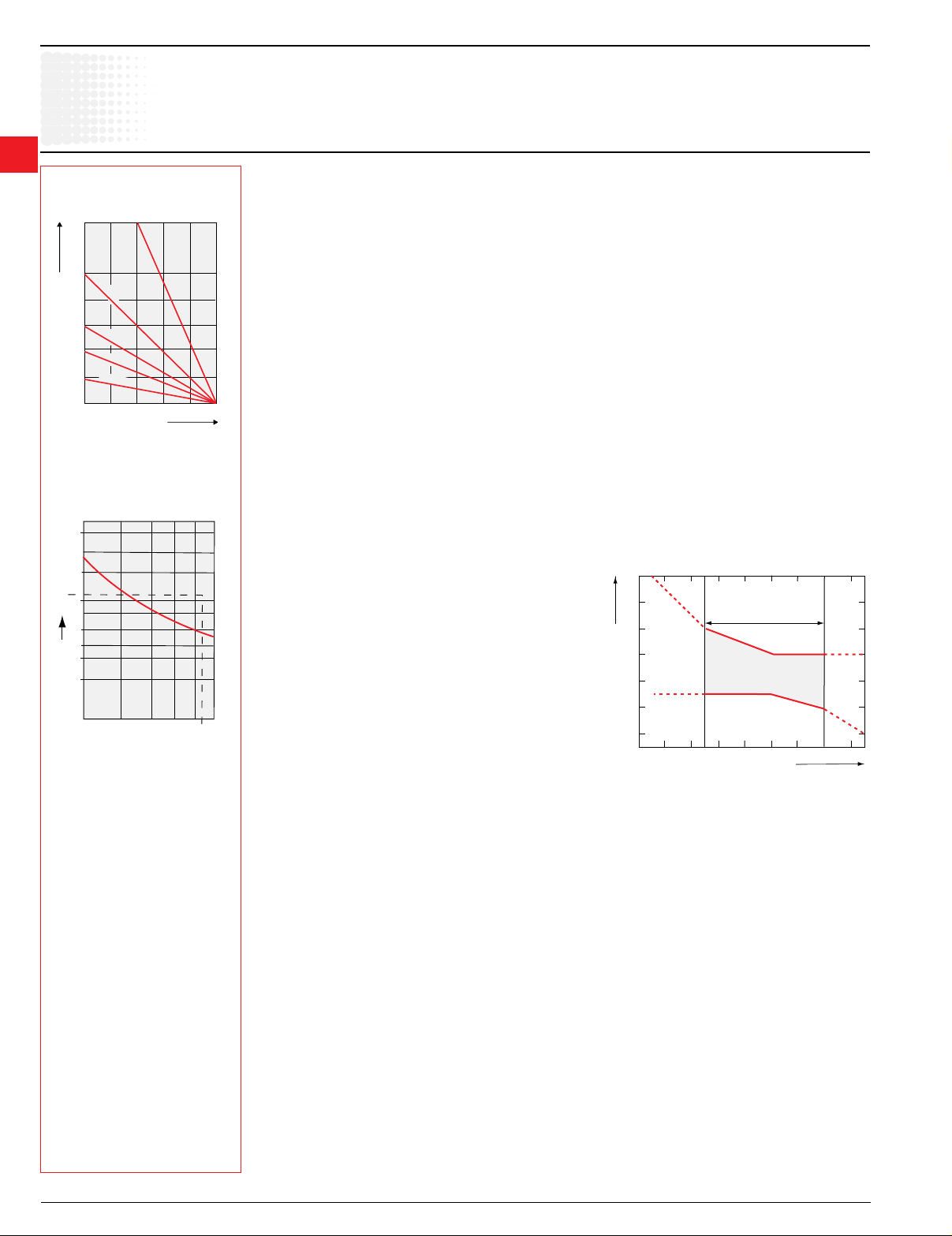

0 20 40 60 80 100(%)

Closing time

0

20

40

60

80

100

120

140

Switching frequency

(ops/h)

ta = 0.5s

ta = 1s

ta = 1.5s

ta = 3s

ta = 3.5s

Intermittent duty

Ambient temperature

compensation limits

according to IEC 947-4-1

No tripping

Multiple of the setting current

Tripping

Ambient temperature

-20 -10 0 10 20 30 40 50

0.9

1.0

1.1

1.2

1.3

1.4

1.5

40

20

11

10

6

4

3

2

1

3 4 5

6 7

7.4

8

[s]

Multiple of the setting current

Tripping time

Thermal

Overload

relays

Switching frequency

in relation to load factor.

ta:

motor starting time.

Technical data

TA25DU – TA450DU

Switchingfrequency:

To avoid untimely tripping, TA and T thermal O/L relays have been designed to withstand roughly 15 switching operations

per hour with an approximately equal distribution between working and rest cycles.

In these conditions, the motor starting time must not exceed 1 second and the starting current must be lower than or equal

to 6 times the motor I

For intermittent operations, the diagram opposite species relay operating limits.

Example: Motor starting time: 1 sec.

Load factor: 40 %

Switching frequency: 60 ops./h according to diagram

For a higher number of operations and for load variations (e.g. frequent starting and braking), it is advisable to use

CUSTORAPID

For motors subject to particularly severe operating conditions (e.g. locked rotor) it is advisable to use protection combined

with a thermal O/L relay and the CUSTORAPID

Protection of motors with long starting time

See electronic overload relay section, pages 2.21 - 2.32.

Mounting position

On a support at an angle of ± 30° in relation to the vertical plane (standard position).

Other mounting positions possible, except mounting on a horizontal plane (in this case the tripping

mechanism would be located above the bimetals).

SpecialversionforEExemotors

Consult factory.

n

®

protection.

.

®

system.

Tripping limits at ambient temperatures varying by + 20°C

Ambient temperature compensation

Thermal O/L relays are compensated against ambient temperature

variations by a compensation bimetal which is sensitive to the

ambient temperature.

Thermal O/L relays are designed to operate between – 5 °C and

+40 °C in compliance with standard IEC 947-4-1. For a wider range

of –25° C to +55 °C consult the graph opposite.

Example:tripping at – 25 °C. Tripping takes place before 1.5 times

the setting current.

Resetting:TA25DU – TA450 DU thermal O/L relays have convertible

manual/automatic resetting.

Delivery:in manual resetting mode.

TA thermal O/L relay cold-state

tripping characteristics

2.10 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Page 2

Technical data

A1

A2

TA25DU – TA80DU

Thermal

Overload

relays

Types TA25DU TA42DU TA75DU TA80DU

Standards:

(international, European)

Rated insulation voltage Ui V 690

according to IEC 947-4-1

Rated impulse withstand voltage U

according to IEC 947-4-1

Permissible ambient temperature

– for storage °C –40 to +70

– for operation °C –25 to +55 with temperature compensation (maximum values: see page 2.9)

Climatic withstand DIN 50017 Humidity in alternate climate KFW, 30 cycles

Mounting positions On a support at an angle of ±30° in relation to the vertical plane (standard position). Other positions

possible except mounting on a horizontal plane (in this case the tripping mechanism

would be located above the bimetals).

Shock withstand shock duration ms 15

at nominal Ie

Critical direction

of shocks A1, A2 multiples of g 12

Resistance to vibrations

(±1 mm, 50 Hz) multiples of g 8

Mounting – on contactor Latching below the contactor, screw xing on main terminals

– separate with DB - kit Using screws: 2 x M4 or 35 mm EN 50022

Terminals and cross-sectional areas TA25DU setting ranges:

for main conductors (motor side) from 0.1-0.16A 24-32 A

• screw terminal to 18-25A

– with cable clamp M4 –

– via tunnel connector – M5 M6 M6 M6

– at type for lug or bar – – – – –

• conductor cross-sectional area

– rigid solid or rigid stranded mm2 2 x 1.5 - 6 1 x 10 1 x 2.5 - 35 or 2 x 2.5 x 16

– exible with cable end mm2 2 x 1.5 - 4 2 x 0.75- 6 1 x 2.5 - 25 or 2 x 2.5 x 10

– recommended bars mm – – – – –

Terminals and cross-sectional area

for auxiliary conductors

• screw terminal (screw size)

– with cable clamp M 3.5

• conductor cross-sectional area

– rigid solid or rigid stranded 2 x mm2 0.75 - 4

– exible with cable end 2 x mm2 0.75 - 2.5

Degree of protection All the terminals are protected against direct contact according to All the terminals are

VDE 0106/Part. 100. (without additional terminal shrouds) protected against direct

direct contact according to

VDE0106/part 100 (with

additional terminal shrouds

for the main terminals

kV 6

imp

IEC 947-4-1, EN 60947-4-1

2

Pole Technical Characteristics

Types TA25 TA42 TA75 TA80 TA10 TA200 TA450

DU DU DU DU DU DU DU

Number of poles 3

Setting ranges see page 2.6

Tripping class according to IEC 947-4-1, EN 60947-1 10 A

Rated operational frequencies Hz 0 - 400 50/60

Max. switching frequency Up to 15 starts/h or 60 starts/h with 40 % on-load factor when neither

without untimely tripping the starting current of 6 x In nor the starting time 1 s are exceeded.

Resistance per phase in mΩ

and heat dissipation in W see page 2.13

Low Voltage Products & Systems 2.11

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Page 3

Technical data

A1

A2

Thermal

Overload

relays

2

Types TA110DU TA200DU TA450DU

Standards:

(international, European)

Rated insulation voltage Ui V 690 1000

according to IEC 947-4-1

Rated impulse withstand voltage U

according to IEC 947-4-1

Permissible ambient temperature

– for storage °C –40 to +70

– for operation °C –25 to +55 with temperature compensation (maximum values: see page 2.9)

Climatic withstand DIN 50017 Humidity in alternate climate KFW, 30 cycles

Mounting positions On a support at an angle of ±30° in relation to the vertical plane (standard position). Other positions

possible except mounting on a horizontal plane (in this case the tripping mechanism would

be located above the bimetals).

Shock withstand shock duration ms 15

at nominal Ie

Critical direction

of shocks A1, A2 multiples of g 12

Resistance to vibrations

(±1 mm, 50 Hz) multiples of g 8

Mounting – on contactor

– separate with DB - kit

Terminals and cross-sectional areas

for main conductors (motor side)

• screw terminal

– with cable clamp – – –

– via tunnel connector HC, M8 – –

– at type for lug or bar – M10 M10

• conductor cross-sectional area

– rigid solid or rigid stranded

– exible with cable end

– recommended bars

Terminals and cross-sectional area

for auxiliary conductors

• screw terminal (screw size)

– with cable clamp M 3.5

• conductor cross-sectional area

– rigid solid or rigid stranded 2 x

– exible with cable end 2 x

Degree of protection All the terminals are protected against direct contact according to

VDE 0106/Part. 100. (with additional terminal shrouds)

TA110DU – TA450DU

IEC 947-4-1, EN 60947-4-1

kV 6 8

imp

4 x M5 screws

2

mm

16 – 35 25 – 120 2 x 240

2

mm

16 – 35 25 – 95 2 x 240

mm 12 x 3 20 x 4 20 x 4...5

2

mm

0.75 - 4

2

mm

0.75 - 2.5

TechnicalcharacteristicsofauxiliarycontactsforthermalO/Lrelays:TA25DU to TA450DU

Auxiliary contacts normally closed N.C. normally open N.O.

Terminal marking 95-96 97-98

Rated operational voltage Ue VAC 500 500

Conventional thermal current (in free air) Ith A 10 6

Rated operational current Ie, AC-15

up to 240 V A 3.0 1.5

up to 440 V A 1.9 0.95

up to 500 V A 1.0 0.75

Rated operational current I

up to 250 V A 0.12 0.04

Protection against short circuits

gG (gl) fuses (according to IEC 269) A 10 6

S 271/S 281circuit-breaker A k3 k1

Maximum potential difference VAC 500 500

between N.C. and N.O. auxiliary contacts VDC 440 440

2.12 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

DC-13

e

Page 4

Technical data

M3~M3~M3~M

3~

SPEM

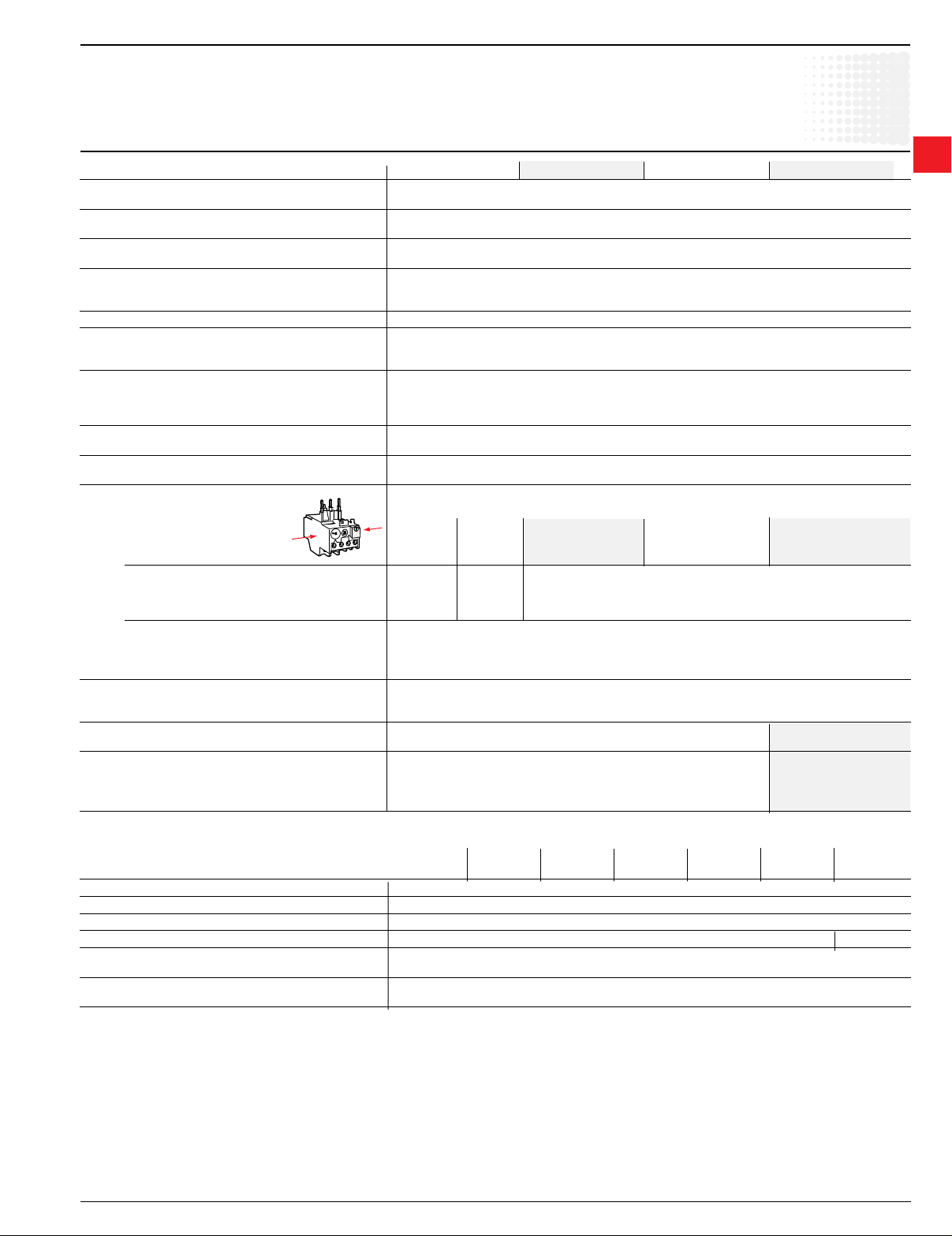

Motor protection; Choice of protective device

Motor Protection — general

It is very important to choose an adequate protective device for the safety of the motor during operation and for its durability.

The efciency of protection methods varies according to the application. The overview below will help you to choose.

There is no general rule and we are available to advise you for special applications and especially in the case of difcult starting.

Protective devices and efficiency

Protectioninrelationtocurrent: Protectioninrelationtotemperature:

Thermal

Overload

relays

2

Fuses Protective relay with Motor protection Motor protection

phase fault protection via CUSTORAPID

thermistor

®

via SPEM electronic

relay

Causes of dangerous overloads for the motor windings

1 Overload with current ❑ ● ● ●

1.2 times the nominal current

2 S1-S8 nominal duties ❑ ■ ● ●

according to IEC 34-I

3 Operation with starting, ❑ ■ ● ●

braking, reversal in operating direction

4 Operation with starting ❑ ■ ● ●

rate at > 15 cycles/hour

5 Locked rotor ■ ● ■ for motors with ●

special rotor

6 Overloads due to phase failure ❑ ● ● ●

7 Network undervoltage or overvoltage ❑ ● ● ●

8 Fluctuation of network frequency ❑ ● ●❑

9 Ambient temperature too high ❑ ● ●❑

10 Overheating due to external ❑ ❑ ●❑

cause (i.e. overheating of bearings)

11 Motor cooling disturbed ❑ ❑ ●❑

12 Undercurrent protection

on drop in load

13 Protection of asymmetry:

wrong phase direction

rotation or asymmetrical load

14 Earth fault protection

15 Automatic disconnection for

auxiliary load fault

Protectionefciency:

❑ unsuitable

■ very average efciency

● perfectly efcient

Low Voltage Products & Systems 2.13

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Note:Fuses

Fuses do not protect motors against overloads. They are only used to protect installations and lines against short circuits.

To ensure efcient protection of a motor against short circuits, it is advisable to use aM type fuses in association with thermal

OLR relays.

For the selection of fuses or circuit-breakers, refer to the indications given in this catalogue concerning contactors on the one

hand and thermal O/L relays on the other.

In general, fuse protection for direct-on-line starting must be sized as follows:

– aM fuses: choose the fuse rating immediately above the full load value of the motor current.

– gG (gI) fuses: determine the fuse rating immediately above the motor current value and choose the next highest fuse rating.

Page 5

Technical data

Thermal

Overload

relays

2

Resistance and Joule losses per phase, short circuit protection

Resistance and Joule losses per phase

Short circuit protection

Joule losses

Setting range Resistance per phase at

current per phase max. setting

from – to

A A mΩ W

TA25DU

0.1 – 0.16 85850 2.2

0.16 – 0.25 85150 2.2

0.25 – 0.4 13750 2.2

0.4 – 0.63 5370 2.2

0.63 – 1.0 2190 2.2

1.0 – 1.4 1120 2.2

1.3 – 1.8 670 2.2

1.7 – 2.4 383 2.2

2.2 – 3.1 229 2.2

2.8 – 4.0 137 2.2

3.5 – 5.0 87.5 2.2

4.5 – 6.5 61 2.2

6.0 – 8.5 30.4 2.2

7.5 – 11 18.2 2.2

10 – 14 11.2 2.2

13 – 19 6.3 2.3

18 – 25 4.7 2.9

24 – 32 3.2 3.3

TA42DU

18 – 25 5.5 3.43

22 – 32 2.89 2.91

29 – 42 1.84 3.24

TA75DU

18 – 25 5.5 3.43

22 – 32 2.89 2.91

29 – 42 1.84 3.24

36 – 52 1.3 3.51

45 – 63 0.936 3.72

60 – 80 0.615 3.94

TA80DU

29 – 42 1.84 3.24

36 – 52 1.3 3.51

45 – 63 0.936 3.72

60 – 80 0.615 3.94

Joule losses

Setting range Resistance per phase at

current per phase max. setting

from – to

A A mΩ W

TA110DU

80 – 110 0.378 3.78

TA200DU

100 – 135 0.318 5.79

110 – 150 0.255 5.74

130 – 175 0.214 6.55

150 – 200 0.182 7.28

TA450DU

130 – 185 — 2.5

165 – 235 — 2.5

220 – 310 — 2.5

2.14 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Page 6

Tripping time

Minutes

Tripping current

in multiples of the setting current

Seconds

120

100

80

60

40

40

20

20

10

10

8

868

6

4

4

2

2

1

1

0.8 1 2 3 4 5 6 7 8 9 101.2 1.5

from warm state

from cold state

3 Phases

3 Phases

2 Phases

2 Phases

Tripping time

Minutes

Tripping current

in multiples of the setting current

Seconds

120

100

80

60

40

40

20

20

10

10

8

868

6

4

4

2

2

1

1

0.8 1 2 3 4 5 6 7 8 9 101.2 1.5

from warm state

from cold state

3 Phases

3 Phases

2 Phases

2 Phases

Tripping time

Minutes

Tripping current

in multiples of the setting current

Seconds

120

100

80

60

40

40

20

20

10

10

8

868

6

4

4

2

2

1

1

0.8 1 2 3 4 5 6 7 8 9 101.2 1.5

from warm state

from cold state

3 Phases

3 Phases

2 Phases

2 Phases

6

8

0.8 1 1.2 1.5 2 3 4 5 6 7 8 9 10

1

2

4

8

10

20

40

1

2

4

6

10

20

40

60

80

100

120

from warm state

from cold state

3 Phases

3 Phases

2 Phases

2 Phases

Tripping time

Minutes

Tripping current

in multiples of the setting current

Seconds

6

8

0.8 1 1.2 1.5 2 3 4 5 6 7 8 9 10

Tripping current

as multiple of setting current

1

2

4

8

10

20

40

1

2

4

6

10

20

40

60

80

100

120

Triping time

minutes

seconds

from warm state

from cold state

2 Phase

3 Phase

2 Phase

3 Phase

Technical data

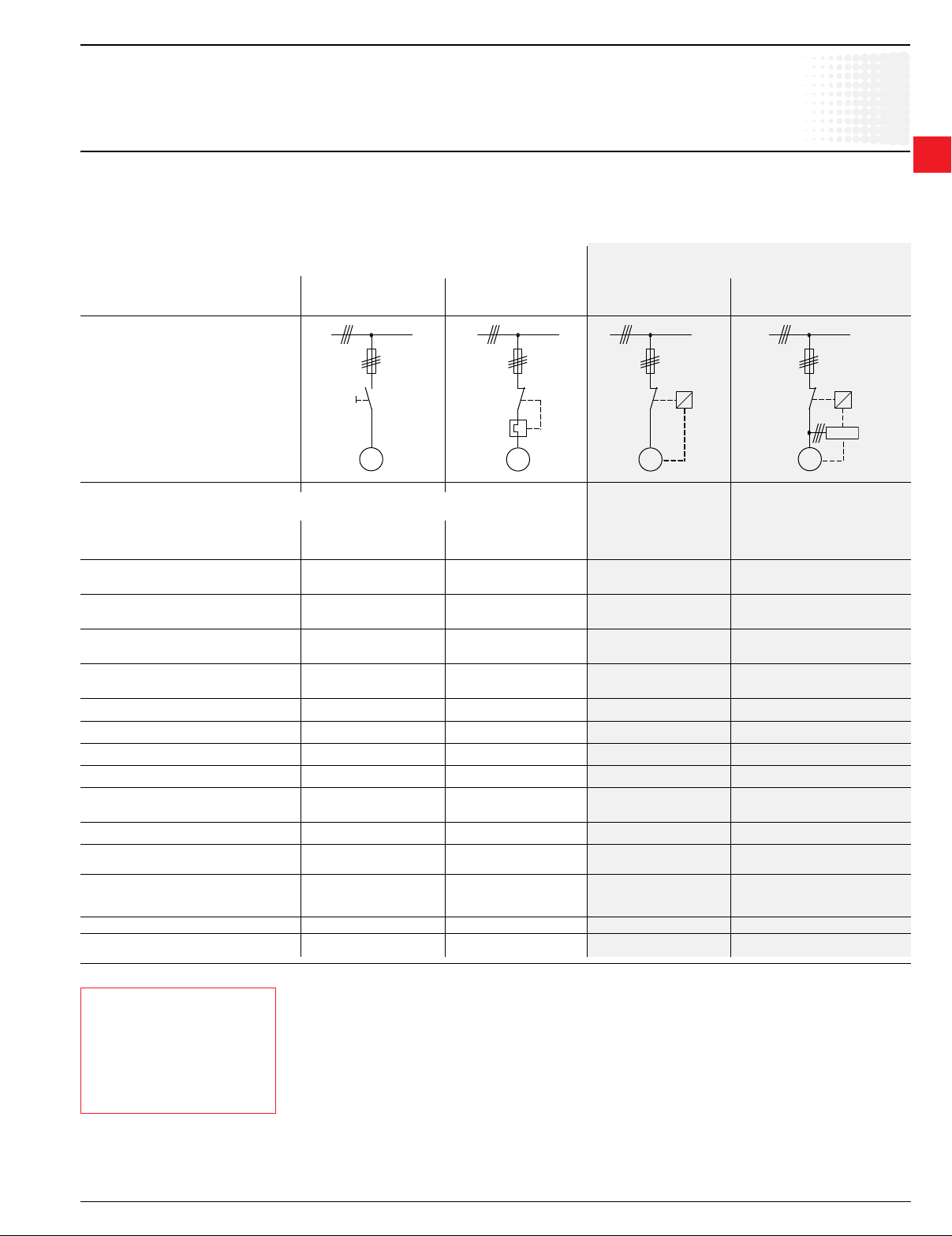

Tripping curves

Overload

relays

TA25DU TA75DU TA110DU/SU TA450DU

TA-DU thermal O/L relays are 3-pole with manual or automatic resetting mode selection.

The resetting button can also be used for stopping.

Built-in auxiliary contacts are physically separate and, consequently, can be used in different circuits (control circuit/indication circuit).

Each relay is temperature compensated and ensures phase failure protection.

Protective relays up to size TA75DU are protected against direct contact via the front face. Terminal shrouds are available for TA200DU to TA450DU size relays.

The connecting terminals are delivered in open position with (+,-) pozidriv screws and screwdriver guidance. It is advisable to tighten unused terminal screws.

Thermal O/L relay tripping curves

TA25DU TA42DU, TA75DU and TA80DU TA110DU

(tripping class 10A) (tripping class 10A) (tripping class 10A)

Thermal

2

TA200DU TA450DU

(tripping class 10A) (tripping class 10A)

Low Voltage Products & Systems 2.15

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Loading...

Loading...