ABB Thermal Overload relays Catalog Page

Thermal overload relays

Type TA

Class 10

Class 20

Thermal

Overload

relays

2

Thermal

Overload relays

Description

• Available for starter construction with

A Line contactors and separate panel

mounting

• Designed for close couple mounting

• Separate base mounting available for all

overload relays

• Class 10 adjustable overload relays are

standard with all ABB Line starters

• Reset can also be adjusted to function as a

stop button

• Screwdriver guide holes

• All terminal screws are available from the

front

• UL File No: E48139

Tripping classes of the thermal overload relays

Standard classes in IEC 947-4-1 are classes: 10 A, 10, 20, 30. The tripping class indicates

according to IEC 947-4-1 the maximum tripping time in seconds under specied conditions of

test at 7.2 times the setting current and species tripping and non tripping times for 1.5 and 7.2

times the setting current. Mostly used class is 10 A.

Abstract from IEC 947-4-1

Tripping class 10 A 10 20 30

Max. tripping time

at 1.5 x setting current (s) 120 240 480 720

(warm state)

Tripping time at

7.2 x setting current (s) 2 – 10 4 – 10 6 – 20 9 – 30

(cold state)

At 1.05 x setting current no tripping

• CSA File No: LR98336

• Trip indication

• Remote trip and reset option available

• Single phase and phase unbalance protection

• Isolated alarm circuit (N.O.) contact

• Ambient compensation:

-25°C to +55°C (-13

• Manual test

• Manual or automatic reset

• Factory calibrated and tested

• Wide adjustment range

o

F to +131oF)

Low Voltage Products & Systems 2.1

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Description

Thermal

Overload

relays

2

TA thermal overload relays are used with A Line contactors for the protection of

motors having a nominal voltage of up to 600VAC max per UL/CSA (690VAC and

800VDC per IEC).

Product range

• Standardrelays:

Types: TA25DU, TA42DU, TA75DU, TA80DU, TA110DU, TA200DU and TA450DU

– TA25 to TA110 and TA200 are directly connected in the motor circuit.

– TA450DU relays are fed through a linear type transformer

• Specialconstruction

Thermal overload relays with different certications and approvals.

Relays for protection EEx e motors.

Construction and function

• General

Thermal O/L relays and their accessories meet UL, CSA and most other important

international standards (IEC), European standards (EN) and the most important

national standards (DIN-VDE, NFC-UTE, BS, etc.). They meet the certication

and approval directives required throughout the world.

Thermal overload relays are 3 pole. The motor current ows through their bimetals

(1 per phase) which are indirectly heated. Under the effect of the heating, the

bimetals bend, cause the relay to trip and the position of the auxiliary contacts to

change.

The relay setting range is graduated in amps. In compliance with international and

national standards, the setting current is the motor nominal current and not the

tripping current (no tripping at 1.05 x setting current, tripping at 1.2 times setting

current).

The tripping curves (cold or warm starting, 3 phases and 2 phases) are shown on

page 2.14.

The relays are built to be self protecting in the event of an overload until the short

circuit protection device is activated.

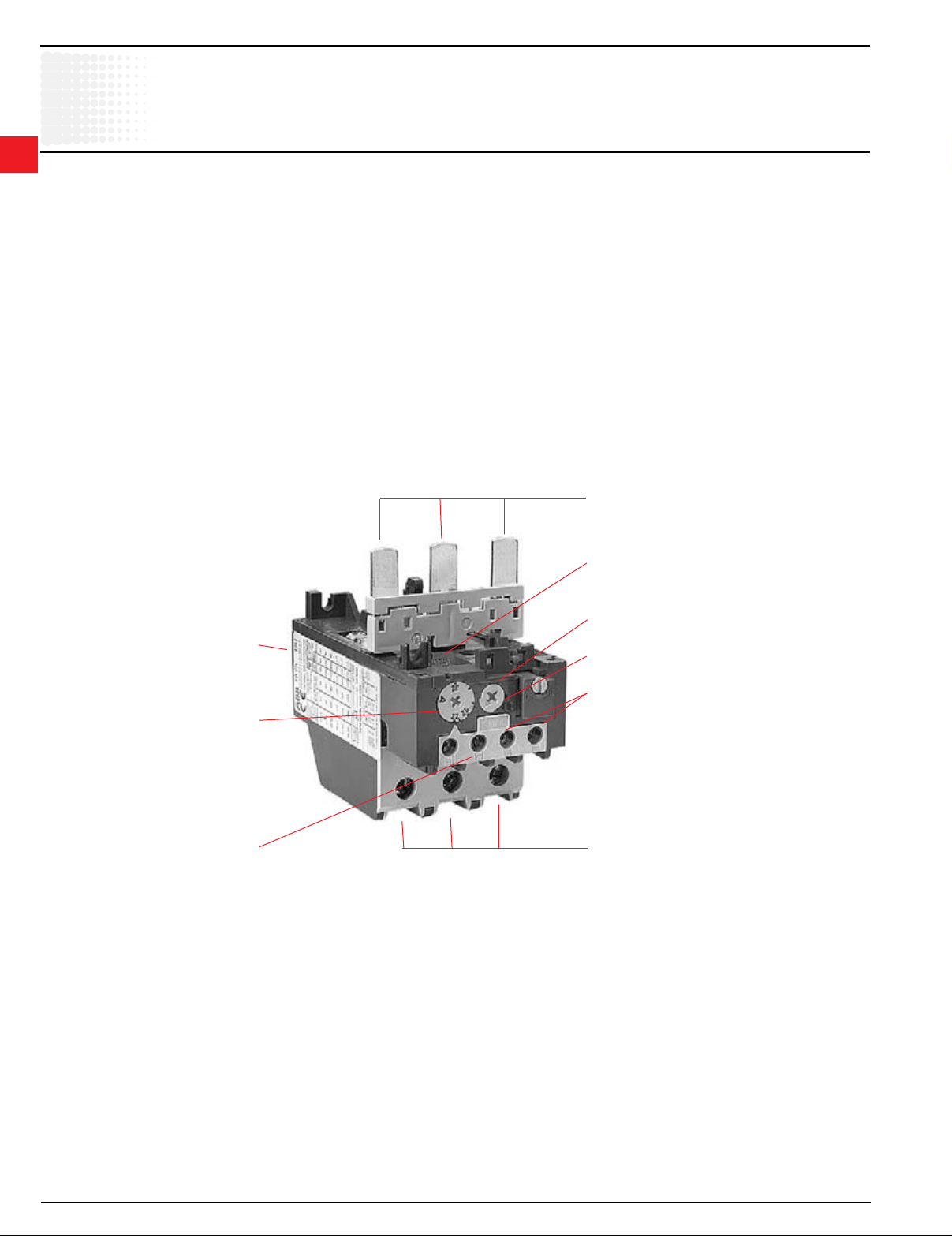

Terminals L1, L3, L5

Frame size

TA....DU

Amp setting range

Signaling contact, (97, 98)

Manual test

Manual or automatic reset

Trip indication light

Tripping contact (95, 96)

Terminals T1, T2, T3

2.2 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Loading...

Loading...