Page 1

—

1SFC132057M0201

Softstarters Type PSE18...PSE370

Installation and commissioning manual

Page 2

This manual belongs to:

__________________________________________

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201

2

Page 3

Installation and Commissioning Manual

ABB Softstarters PSE18...PSE370

1 General

This is the Installation and Commissioning Manual for Softstarters Type

PSE18…PSE370.

Document number: 1SFC132057M0201

Revision: G

Issue date: 2018-11-20

Data subject to change without notice.

We reserve all rights to this document, even in the event that a patent is issued

and a different commercial proprietary right is registered. Improper use, in particular reproduction and dissemination to third parties, is not permitted.

This document has been carefully checked. If the user nevertheless detects any

errors, he is kindly asked to notify us as soon as possible.

The data contained in this manual is intended solely for the product description and is not to be deemed to be a statement of guaranteed properties. In the

interests of our customers, we constantly seek to ensure that our products are

developed to the latest technological standards.

As a result, there may be some differences between the softstarter and the information in this manual.

Author’s address:

ABB AB

Control Products

SE-721 61 Västerås, Sweden

Telephone: +46 (0) 21 32 07 00

www.new.abb.com/lowvoltage/products/softstarters

www.abb.com/drives

© Copyright 2018. All rights reserved. Specifi cation subject to changes without notice.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 3

Page 4

2 Safety

This chapter describes warning and information signs used in this manual, which

the user should pay attention to.

The softstarter shall be installed by authorized personnel only.

This manual is a part of the PSE Softstarter and should always be accessible to

personnel working with this product.

The manual shall always be read through before performing any installation or

commissioning tasks.

2.1 Use of signs warning and information

Warning!

Warning symbol indicates the presence of hazardous voltage which

could result in personal injury.

Warning!

General warning symbol indicates the presence of a hazard which could

result in personal injury and damage to equipment or property.

Information

Information sign alerts the reader to pertinent facts and conditions.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201

4

Page 5

Chapter

1 Introduction ............................................ 7

2 Quickstart ............................................... 11

3 Description ............................................. 15

4 Mounting ................................................ 27

5 Connection ............................................. 31

6 Human-Machine Interface (HMI) .............. 45

7 Functions and confi guration .................... 55

8 Fieldbus communication ......................... 79

9 Maintenance ........................................... 81

10 Troubleshooting ...................................... 83

11 Wiring diagrams ...................................... 95

12 Index ...................................................... 99

Customer feedback report ............................... 102

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 5

Page 6

Notes

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201

6

Page 7

Chapter 1 Introduction

Documentation for PSE18...PSE370 softstarter .......................................... 8

Installation and Commissioning Manual ...................................................... 8

Intended audience ................................................................................. 9

General ............................................................................................. 9

Requirements .................................................................................... 9

Revision notes and other documents ..................................................... 9

Acronyms and abbreviations .................................................................. 9

Explanation of concepts ......................................................................... 10

Cyber Security Legal Disclaimer .................................................................. 10

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 7 Chapter 1

Page 8

Chapter 1 Introduction

1.1 Documentation for PSE18...PSE370 softstarter

For the Softstarter Type PSE18...PSE370, the following manuals are available:

1SFC132059M9901 (User manual short form, printed)

1SFC132057M0201 (English version, PDF-fi le)

1.2 Installation and Commissioning Manual

This manual contains instructions on how to install, commission and maintain the

softstarter. The manual covers procedures for mechanical and electrical installation, and installation of communication devices. It also covers energizing, setting,

and confi guration and verifying settings.

For brief information see Softstarters Type PSE18...PSE370 User Manual short

form, containing the same languages as the Installation and Commissioning

Manual. Softstarters Type PSE18...PSE370 User Manual short form has document ID 1SFC132059M9901.

For quickest possible start, read Chapter 2 Quickstart or go to the short form

manual (1SFC132059M9901).

A complete compilation of ABB’s softstarters can be found in Main catalogue

Softstarters, document ID 1SFC132012C0201.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M02018 Chapter 1

Page 9

1.2.1 Intended audience

1.2.1.1 General

The installation and commissioning manual is intended for the installation, commissioning, and maintenance personnel responsible for getting the softstarter into

normal service and out of service.

1.2.1.2 Requirements

The installation personnel must have a basic knowledge in handling electric equipment. The commissioning and maintenance personnel must be well experienced

in using this kind of equipment.

1.2.2 Revision notes and other documents

For latest information on revisions and other documents related to the PSE Softstarters, please check

www.new.abb.com/low-voltage/products/softstarters

www.abb.com/drives

1.2.3 Acronyms and abbreviations

The acronyms and abbreviations described in table 1.1 are used in this manual.

Table 1.1

Acronym/ abbreviation

BP By-pass

DOL Direct-on-line

EOL Electronic overload protection for the Motor

FB Fieldbus

FBP FieldBusPlug

HMI Human-Machine Interface

I

e

IT Information Technology

LCD Liquid Crystal Display

LED Light Emitting Diode

PCB Printed Circuit Board

PLC Programmable Logic Controller

PTC Positive Temperature Coeffi cient

RTU Remote Terminal Unit

SC Short Circuit

SCR Silicon Controlled Rectifi er ( thyristor)

TOR Top of Ramp ( full voltage/ Full-On)

U

c

U

e

U

s

Description

Rated operational current

Rated control circuit voltage *

Rated operational voltage *

Rated control supply voltage *

*) For defi nition see IEC 60947-1 edition 5.0

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 9 Chapter 1

Page 10

1.2.4 Explanation of concepts

The setting of current Ie is the setting for the rated operational current (main current) of the motor.

Ue = Rated operational voltage on the motor’s operational current (three phase

main voltage feeding the motor).

Us = Rated control supply voltage, feeding the electronics in the softstarter.

Uc = Rated control voltage, used for controlling the softstarter.

1.3 Cyber Security Legal Disclaimer

This product is designed to be connected to and to communicate information and

data via a communication interface. It is Customer’s sole responsibility to provide

and continuously ensure a secure connection between the product and Customer

network or any other network (as the case may be). Customer shall establish and

maintain any appropriate measures (such as but not limited to the installation of

fi rewalls, application of authentication measures, encryption of data, installation of

anti-virus programs, etc) to protect the product, the network, its system and the

interface against any kind of security breaches, unauthorized access, interference,

intrusion, leakage and/or theft of data or information.

ABB Ltd and its affi liates are not liable for damages and/or losses related to such

security breaches, any unauthorized access, interference, intrusion, leakage and/

or theft of data or information.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020110 Chapter 1

Page 11

Chapter 2 Quickstart

Quickstart ................................................................................................... 12

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 11 Chapter 2

Page 12

Ready Run

A

Protection

B

Fault

Chapter 2 Quickstart

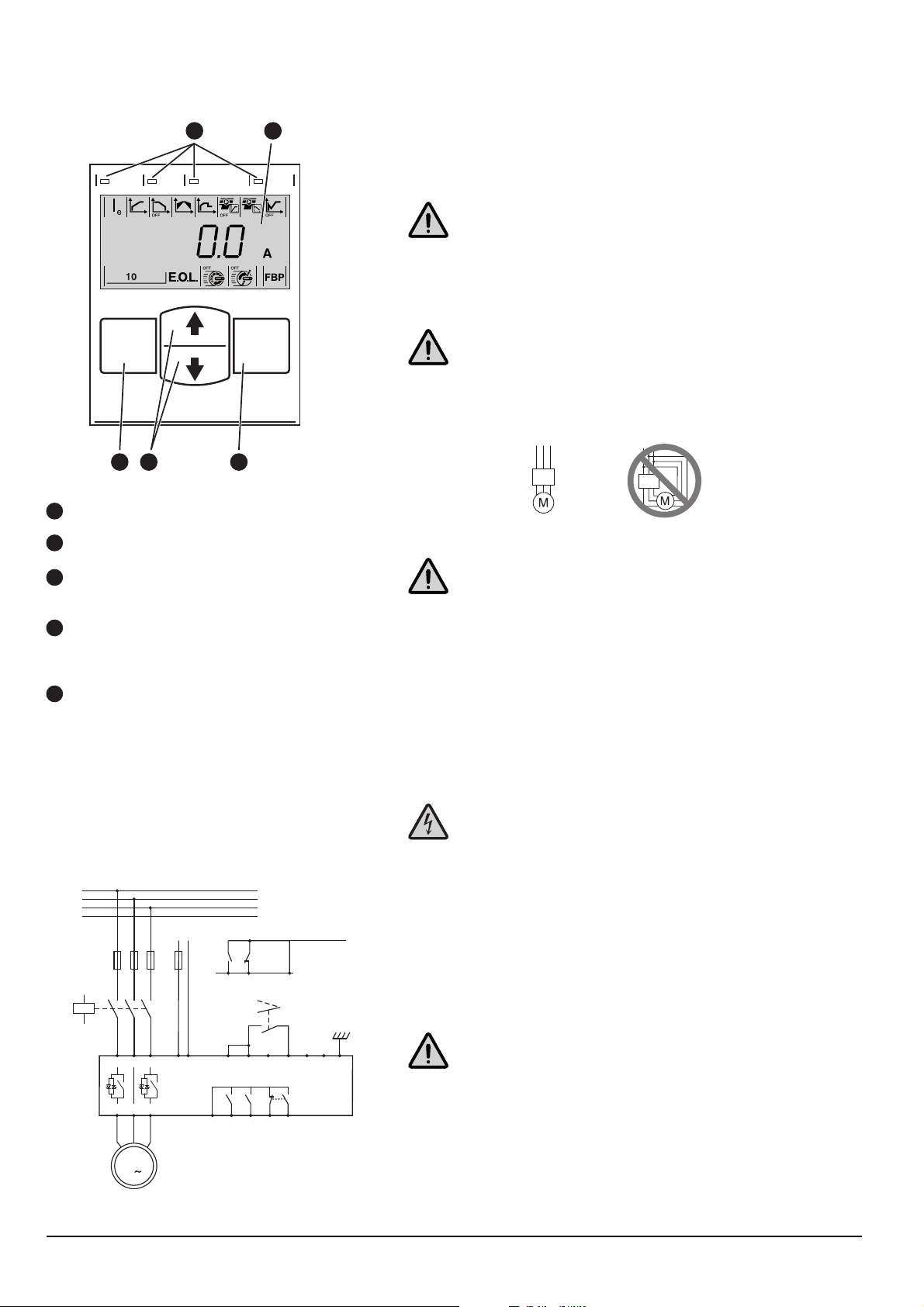

This chapter is a short guide on how to connect, confi gure and start the

softstarter in the easiest way.

This product has been carefully manufactured and tested but there is a

risk that damage can occur from abnormal handling during transportation.

Therefore, the procedure below should be followed during initial installation:

Warning!

Mounting, electrical connection and settings of the softstarter shall

be made in accordance with existing laws and regulations and be

performed by authorized personnel.

Exit

Select

Reset

C DE

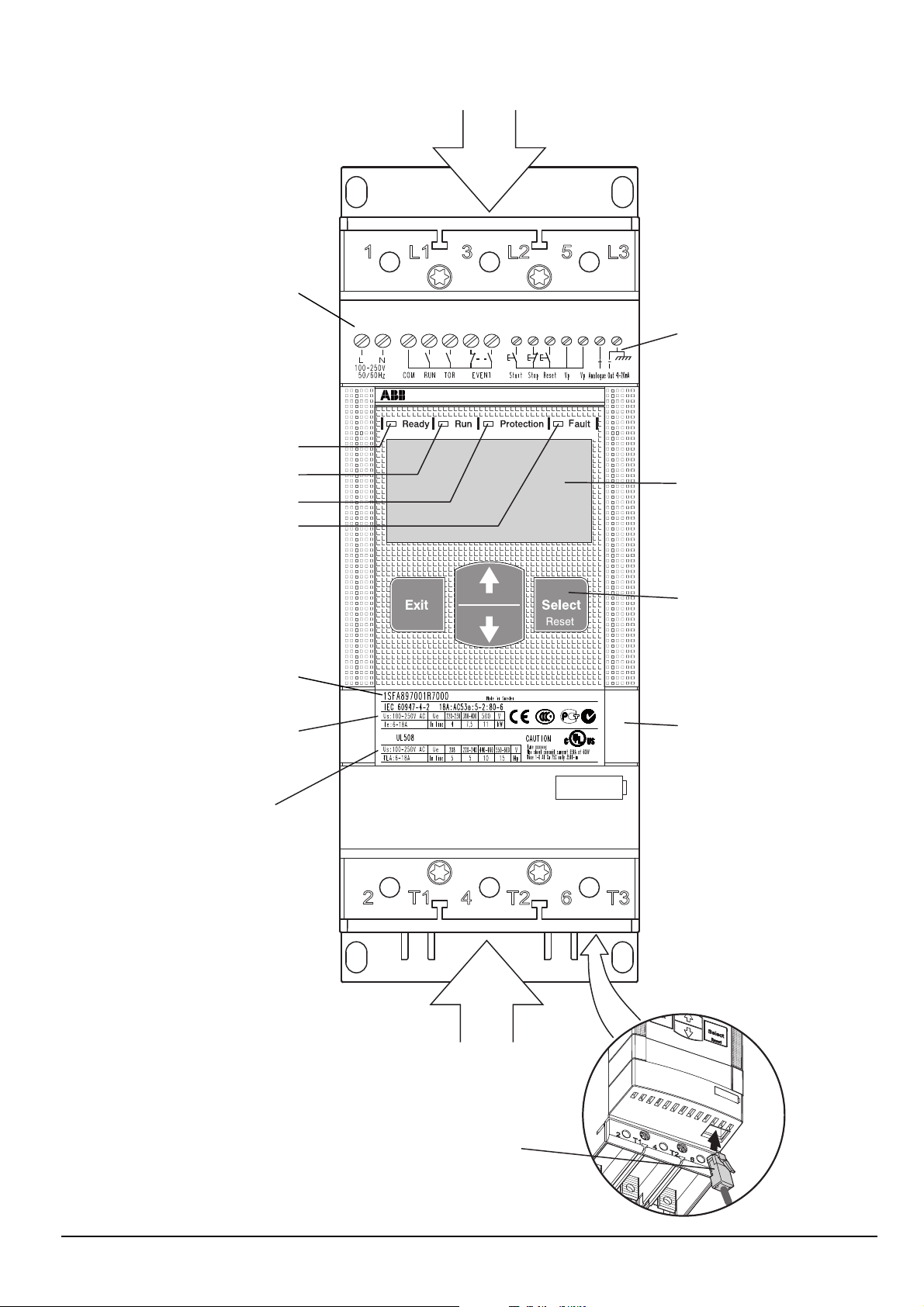

Figure 2.1:

LED status indicators.

A

B

LCD display with backlight.

Exit key for cancelling parameter edits and

C

moving up one menu level.

Select/Reset key for changing and storing

D

parameter values, moving down one menu

level, and to reset tripping events.

E

Navigation keys for navigating the menu and

changing parameter values. Flashing numbers

or text shown in the display indicates that the

menu/value can be changed or scrolled.

1SFC132235F0001

Warning!

Connecting Softstarters PSE18...PSE370 Inside Delta will cause damage to the equipment, and there is a risk of death or serious injury.

PSE

1SFC132265F0001

In Line Inside Delta

PSE

1SFC132263F0001

Warning!

Before connecting the PSE18...PSE170 to operational voltage(Ue) for

the fi rst time, the supply voltage(Us) must be connected and turned

on to ensure the bypass relay is switched to open position. This is

necessary to avoid unintentional starting of the equipment during the

connection.

1. Be aware of the ambient temperature. Derating is required above 40 °C

(104 °F). See chapter 3.6.

2. Mount the softstarter according to Chapter 4 Mounting.

L1

L2

L3

N

LN

Start Stop

KM1

1L1 3L2 5L3

2T1 4T2 6T3

U

V

12 1489

W

89

Start

Stop

Run

TOR Fault

NC NO

67

543

11

11

1210 13

M

3

Figure 2.2: Example connection of PSE Softstarter

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020112 Chapter 2

Warning!

Hazardous voltage. Will cause death or serious injury. Turn off and

lock out all power supplying this device before starting work on this

equipment.

3. Connect the terminals 1 L1, 3 L2 and 5 L3 to the operational voltage on the

power supply line side.

4. Connect the terminals 2T1, 4T2 and 6T3 to the motor.

Warning!

Capacitors for power factor compensation are not allowed between

the softstarter and the motor, since this can cause current peaks

which can damage the thyristors in the softstarter. If such capacitors are to be used, they should be connected on the line side of the

softstarter.

1SFC132237F0001

Page 13

5. Connect control supply voltage to terminals 1 and 2 (100-250 V 50/60 Hz).

Exit

Select

Reset

B

Exit

Exit

Select

Reset

C

Select

Reset

D

6. Connect the functional earth to terminal 14, with an earthing point close to

the softstarter.

The earthing is not a protective earth, it is a functional earth. The earthing

cable should be as short as possible. Maximum length 0.5 m. The earthing

cable should be connected to the mounting plate, which should also be

earthed.

7. Connect the start, stop and other control circuits including the analog out to

the terminals, 8, 9, 10, 11, 12, 13 if needed. This section is using an internal

24 V DC. Do not feed with any external voltage.

Select

Reset

A

Exit

Select

Reset

Warning!

Do not connect an external voltage to the control terminals 8, 9, 10,

11, 12, 13 and 14. Failure to observe the above may damage the softstarter and the warranty may no longer be valid.

8. Connect terminals 3, 4, 5, 6 and 7 when using the signal output relays. These

are potential free contacts for maximum 250 V AC, 1,5 A AC-15. Make sure

you are using the same voltage level within this terminal section.

1SFC132268F0001

Figure 2.3:

Confi guration of the parameter Rated Current.

A

If disabled, press any key to activate the light

in the display. Enter the application setting by

pressing the Select key a second time.

B

Press select again to enable editing of the Ie

parameter. This is indicated by a fl ashing value.

Increase or decrease the value by pressing the

C

Up or Down keys repeatedly. Holding the key

down will speed up the change. Press the Exit

key to abort change.

D

When the rated current of the motor is

reached, press the Select key again to save.

If needed, continue to set other parameters

according to the application following the

same procedure.

Press the Exit key to return to the top level.

Warning!

The same external voltage (maximum 24 V DC or maximum 250 V

AC) must be connected to the output relay terminals 3, 4, 5, 6 and 7.

Failure to observe the above may damage the softstarter and the warranty may no longer be valid.

9. Switch ON the control supply voltage Us, terminals 1 and 2.

10. Continue to confi gure parameter Ie as described in fi gure 2.3. Complete

information about confi guration is available in Chapter 6 Human-Machine

Interface (HMI) and Chapter 7 Functions and confi guration.

11. Switch ON the operational voltage Ue. The green “Ready” LED will turn solid.

12. Give start command to the softstarter.

Warning!

Depending on the two phase control, a connected motor terminal

always carries live hazardous voltage. Do not touch terminals when

voltage is applied. Output terminals will have live voltage even when

the device is OFF. This can cause death or serious injury.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 13 Chapter 2

Page 14

This page is intentionally left blank.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020114 Chapter 2

Page 15

Chapter 3 Description

Overview .................................................................................................... 16

Markings and connections .......................................................................... 17

Type designation ......................................................................................... 18

Documentation ........................................................................................... 18

Environmental infl uence .............................................................................. 18

Specifi cations ............................................................................................. 18

Technical data ............................................................................................ 19

General .................................................................................................. 19

Weights .................................................................................................. 19

PSE Softstarter types ............................................................................. 20

IEC information ...................................................................................... 21

information .............................................................................. 21

Dimensions ............................................................................................ 22

Drilling plan ............................................................................................ 24

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 15 Chapter 3

Page 16

Chapter 3 Description

This chapter describes the PSE Softstarter in general, specifi cations as well as

available accessories and spare parts.

L1

L2 L3

M

Figure 3.1: Integrated By-pass. Controlled

phases 1 and 3 (L1 and L3).

3.1 Overview

The PSE Softstarter is a microprocessor-based softstarter designed with the latest

technology for soft starting and soft stopping of three-phase squirrel cage motors.

The softstarter has several advanced features as standard.

• Integrated by-pass in phases L1 and L3, see fi gure 3.1.

• Thyristors are used on phases L1 and L3 for controlling the motor voltage.

1SFC132253F0001

• Select between voltage ramp or torque control during start and stop.

• Motor protection, as well as underload and locked rotor protection.

The keypad on the front is designed to be as user-friendly as possible, with a clear

display showing icons.

The PSE Softstarter can be controlled in two ways:

• Hardwire inputs control

• Fieldbus communication interface

Only one type of control method can be enabled simultaneously. Default selection

is hardwire inputs control.

The integrated fans for cooling are operated only during ramping ( start/stop) and

when the temperature of the heat sink is high. The temperature is monitored by a

thermistor mounted on the heat sink.

Phase L2 is directly connected to the motor, see fi gure 3.1.

Figure 3.2: Torque control is offered as standard

with the PSE softstarter.

Check that you have the correct product in regards to operational voltage, control

supply voltage and rated motor data. See chapter 3.3 Type designation.

The PSE18...PSE370 Softstarters operates over wide voltage ranges.

• Rated operational voltage 208 - 600 V AC

• Rated control supply voltage 100 - 250 V AC

Warning!

The product should only be used within the specifi ed ratings.

Be aware of the ambient temperature and altitude above sea level. Derating

is required above 40 °C (104 °F) and above 1000 m (3281 ft).

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020116 Chapter 3

Page 17

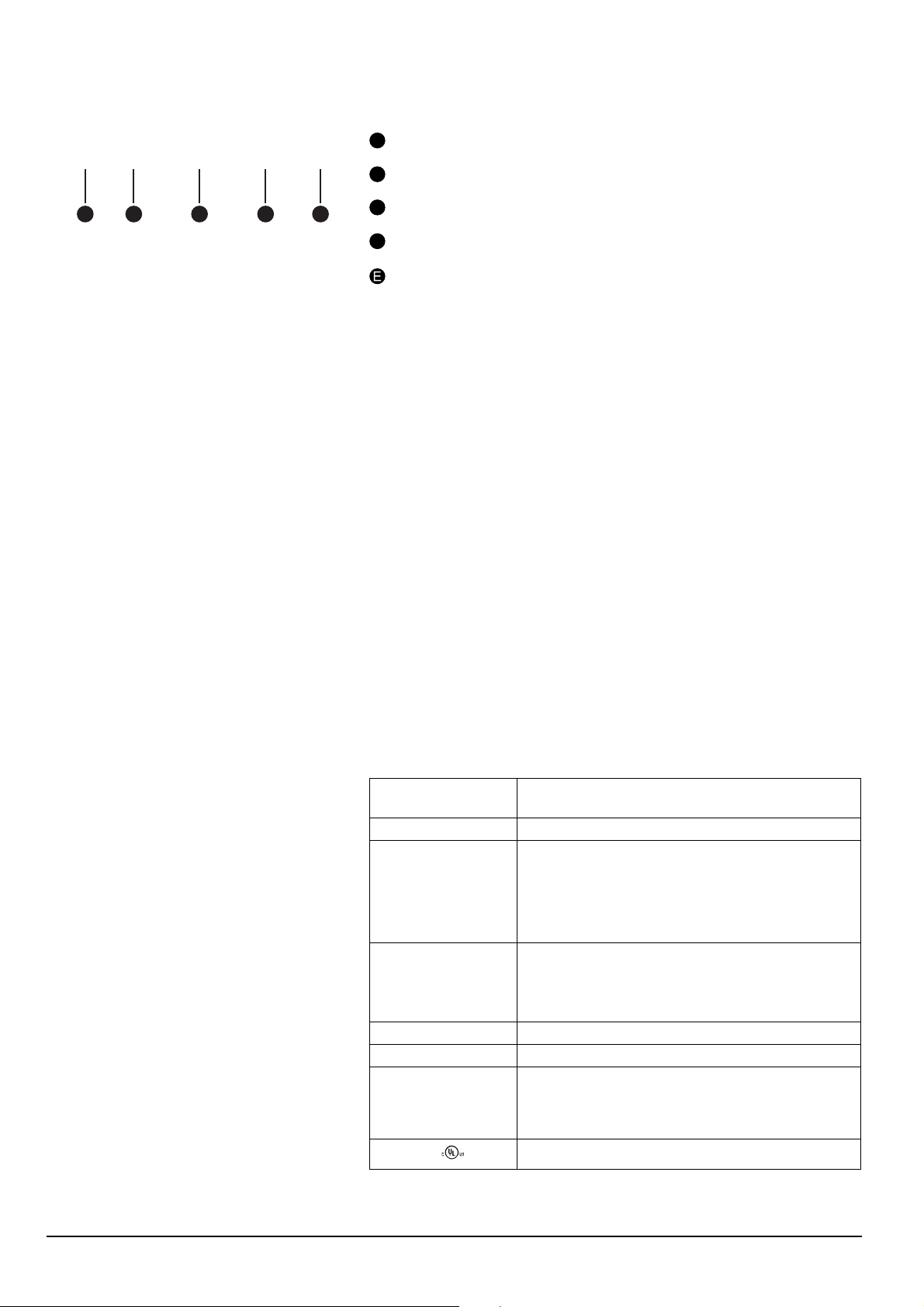

3.2 Markings and connections

Line side connection

Supply voltage U

Green

Green

Yellow

Red

Order code

Technical data according

to IEC 947-4-2

s

81 2 3 4 5 6 7 9 10 11 12 13 14

Terminal marking of

control circuits

PSE 18-600-70

Display

Keypad

Fieldbus connection

Technical data

according to UL 508

and CSA-C22.2 No. 14-05

Figure 3.3: Markings and connections

1SFC132238F0001

Motor side connection

External Keypad connection

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 17 Chapter 3

Page 18

PSE18 - 600 - 70 - 1

A

B

C

D E

3.3 Type designation

Type designation to be found on the softstarters front. See fi gure 3.4.

A

Softstarter type: PSE

B

Current rating: 18 = 18 A

C

Operational voltage: 600 = 208 - 600 V 50/60 Hz

Control supply voltage: 70 = 100 - 250 V 50/60 Hz

D

Figure 3.4: Type designation

Design code (PSE210...PSE370 only)

3.4 Documentation

Documentation such as brochures, catalogs, certifi cates, and drawings included

can be found at:

www.new.abb.com/lowvoltage/products/softstarters.

3.5 Environmental infl uence

The product is designed to minimize the environmental effects during manufacturing and use of the product. Most of the materials used, are of recycle type, and

shall be handled and recycled according to existing laws.

Further information regarding used material and recycling of the product can be

found at:

www.new.abb.com/low-voltage/products/softstarters

www.abb.com/drives

3.6 Specifi cations

Table 3.1

Degree of protection

( Operational circuit)

Operating position Vertical at ±

Ambient temperature Storage. -40 oC to + 70 oC (-40 oF to 158 oF)

Altitude 1000 m (3281 ft.) above sea level without derating.

Pollution degree 3

Relative humidity 5-95% (non-condensing)

Standards IEC 60947-1

Standards

IP 00

o

30

o

Operation: -25

derating.

o

C to + 60 oC (104 oF to 140 oF) with derating 0.6

+ 40

o

C (0.6% / 1,8 oF).

% /1

1000-4000 m (3281 - 13123 ft.) above sea level with

derating

0.67 % per 100 m above 1000 m

IEC 60947-4-2

EN 60947-1

EN 60947-4-2

UL 508, CSA C22.2 No 14-10

C to + 40 oC (-13 oF to 104 oF) without

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020118 Chapter 3

Page 19

3.7 Technical data

3.7.1 General

Table 3.2

General data

Rated insulation voltage, U

Rated operational voltage, U

Rated control supply voltage, U

Voltage tolerance +10% to -15%

Frequency tolerance

Rated impulse withstand voltage 6 kV operational circuit

Number of controlled phases 2

Inputs Start, stop, reset

Analog out 4-20 mA

Cooling system Fan

Rated form Form 1

Rated duty Uninterrupted

EMC

Recommended fuse

Supply circuit

Communication protocols, Internal

Modbus RTU

i

e

600 V

208-600 V 50 / 60 Hz

100 - 250 V 50 / 60 Hz

s

±

5%

/ 4 kV control supply circuit

IEC 60947-4-2 Class A

Lloyd’s Register (2002)

6A Delayed

MCB use characteristics

DeviceNet with fi eldbus plug/Profi bus

DP with fi eldbus plug/ Modbus RTU with

fi eldbus plug

1

1

This product has been designed for environment A. Use of this product in environmentB

may cause unwanted electromagnetic disturbances in which case the user may be

required to take adequate mitigation measures.

3.7.2 Weights

Table 3.3

Type Weight in kg Weight in lbs

PSE18...PSE60 2.4 5.3

PSE72...PSE105 2.5 5.5

PSE142...PSE170 4.2 9.2

PSE210 9.5 20.9

PSE250...PSE370 10.9 24.0

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 19 Chapter 3

Page 20

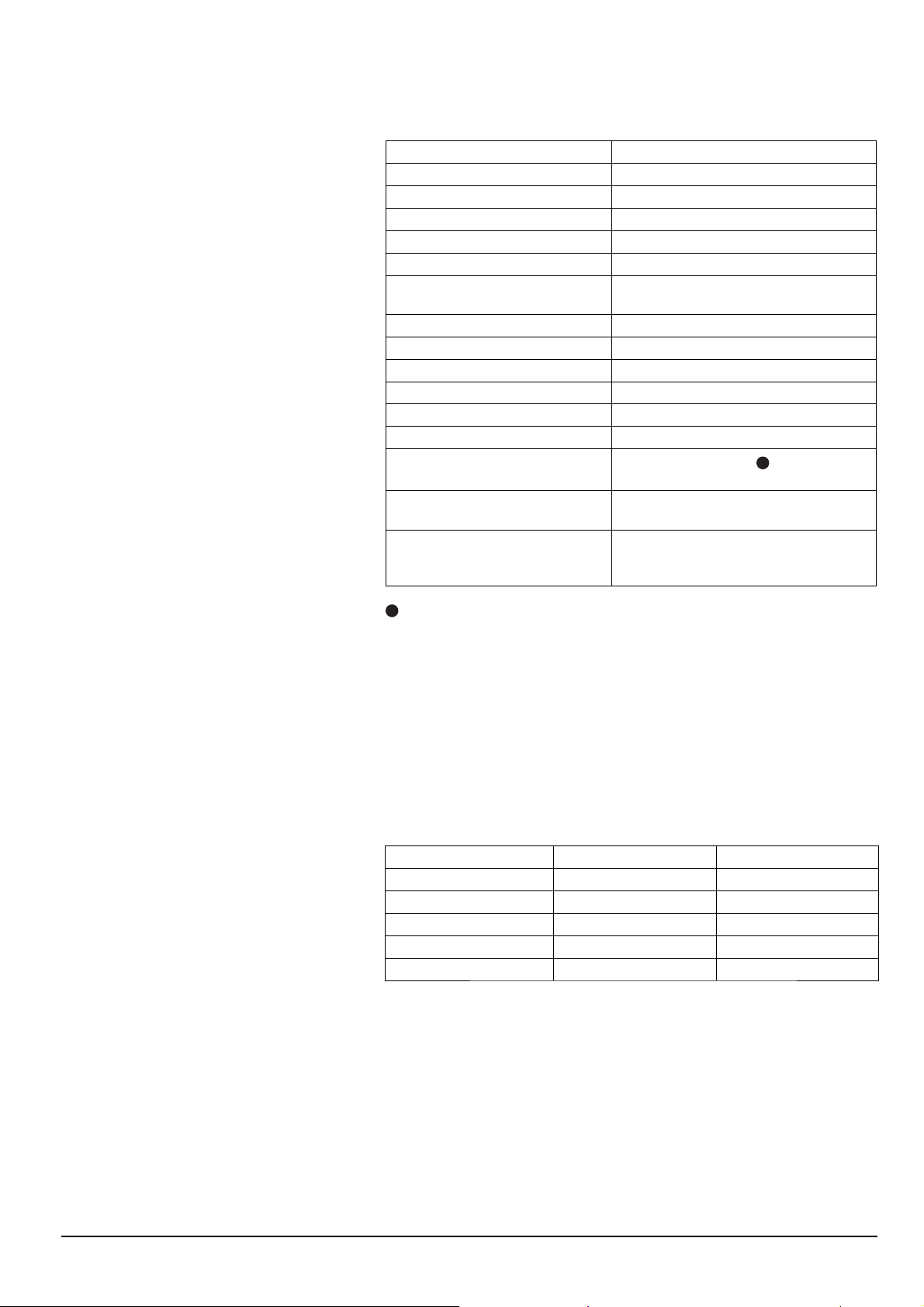

3.7.3 PSE Softstarter types

Table 3.4

t ≤ + 40 oC (104 oF)

IEC

220-

240 V

Softstarter

type

PSE18 18 4 7.5 11 18 5 5 10 15

PSE25 25 5.5 11 15 25 7.5 7.5 15 20

PSE30 30 7.5 15 18.5 28 7.5 10 20 25

PSE37 37 9 18.5 22 34 10 10 25 30

PSE45 45 11 22 30 42 10 15 30 40

Ie (A)

P (kW)

380400 V

P (kW)

500 V

P (kW) FLA (A)

208 V

P (HP)

220240 V

P (HP)

440480 V

P (HP)

550600 V

P (HP)

PSE60 60 15 30 37 60 20 20 40 50

PSE72 72 18.5 37 45 68 20 25 50 60

PSE85 85 22 45 55 80 25 30 60 75

PSE105 106 30 55 75 104 30 40 75 100

PSE142 143 40 75 90 130 40 50 100 125

PSE170 171 45 90 110 169 60 60 125 150

PSE210 210 59 110 132 192 60 75 150 200

PSE250 250 75 132 180 248 75 100 200 250

PSE300 300 90 160 200 302 100 100 250 300

PSE370 370 110 200 250 361 125 150 300 350

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020120 Chapter 3

Page 21

3.7.4 IEC information

For more information see: https://applications.it.abb.com/SOC/Motor

3.7.5 information

For more information see: https://applications.it.abb.com/SOC/Motor

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 21 Chapter 3

Page 22

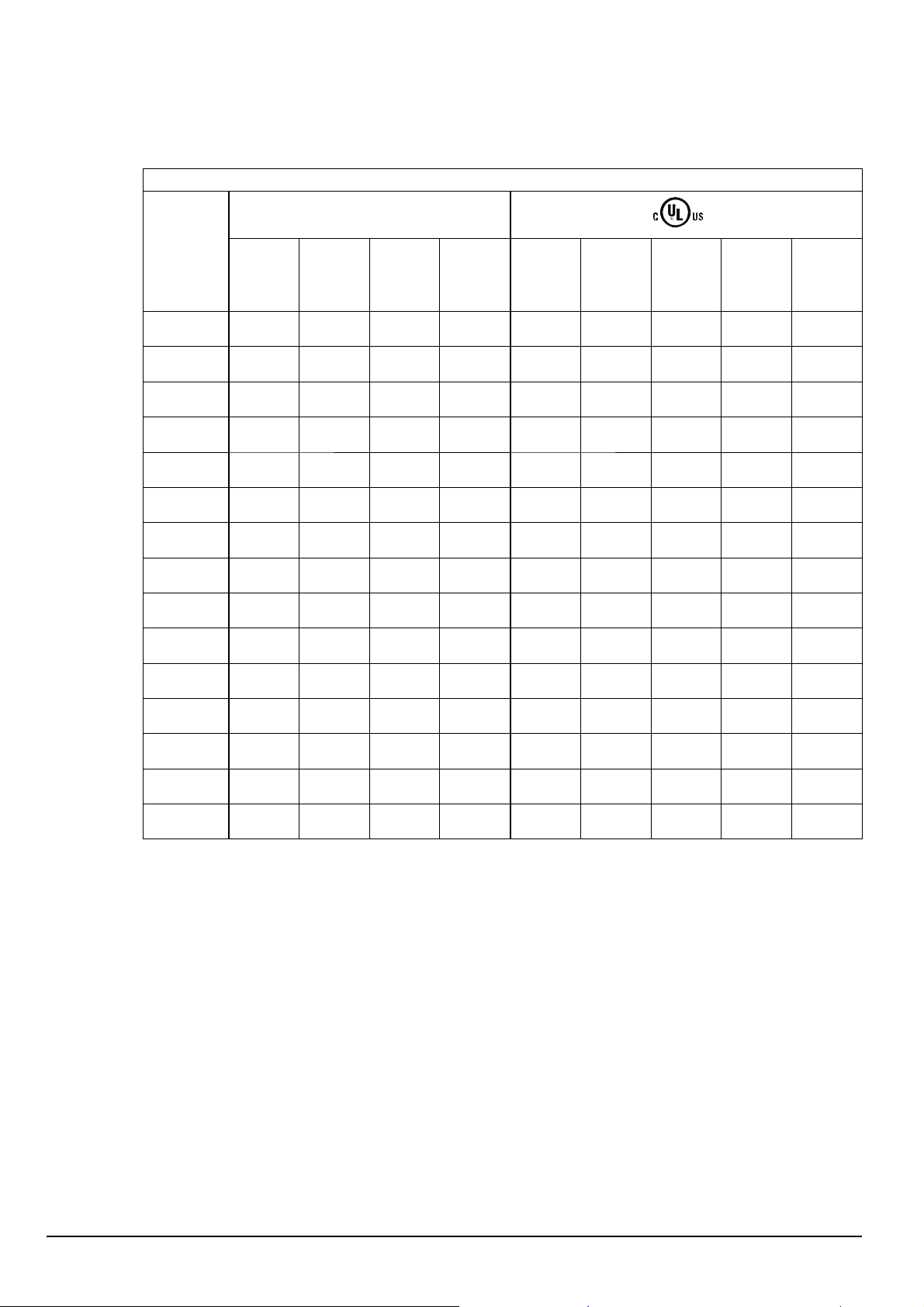

3.7.6 Dimensions

Dimensions PSE18...PSE105

6 mm (0.24 in)

6,5 mm (0.26 in)

230 mm (9.06 in)

80 mm (3.14 in)

PSE 18-600-70

245 mm (9.65 in)

188 mm (7.40 in) 28 mm (1.12 in)

30 mm (1.18 in)

185,5 mm (7.30 in)

90 mm (3.54 in) 3 mm (0.12 in)

13 mm (0.51 in)

90 mm (3.54 in)

3 mm (0.12 in)

7 mm (0.28 in)

278 mm (10.94 in)

Dimensions PSE142...PSE170

6,5 mm (0.26 in)

37 mm (1.46 in)

PSE142-600-70

221 mm (8.70 in)

295 mm (11.61 in)

5 mm (0.20 in)

219,5 mm (8.64 in)

3 mm (0.12 in)

35 mm (1.38 in)

113,5 mm (4.47 in)

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020122 Chapter 3

130 mm (5.12 in)

109,5 mm (4.31 in)

1SFC132260F0001

17,5 mm (0.69 in)

Page 23

163.5 mm (6.44 in)

6.5 mm (0.26 in)

8.2 mm (0.32 in)

Dimensions PSE210...PSE370

39 mm (1.54 in)

418 mm (16.46 in)

43.75 mm (1.72 in)

379 mm (14.92 in)

43.75 mm (1.72 in)

435 mm (17.13 in)

236.5 mm (9.31 in)

125.5 mm (4.94 in) 5 mm (0.20 in)

190 mm (7.48 in)

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 23 Chapter 3

Page 24

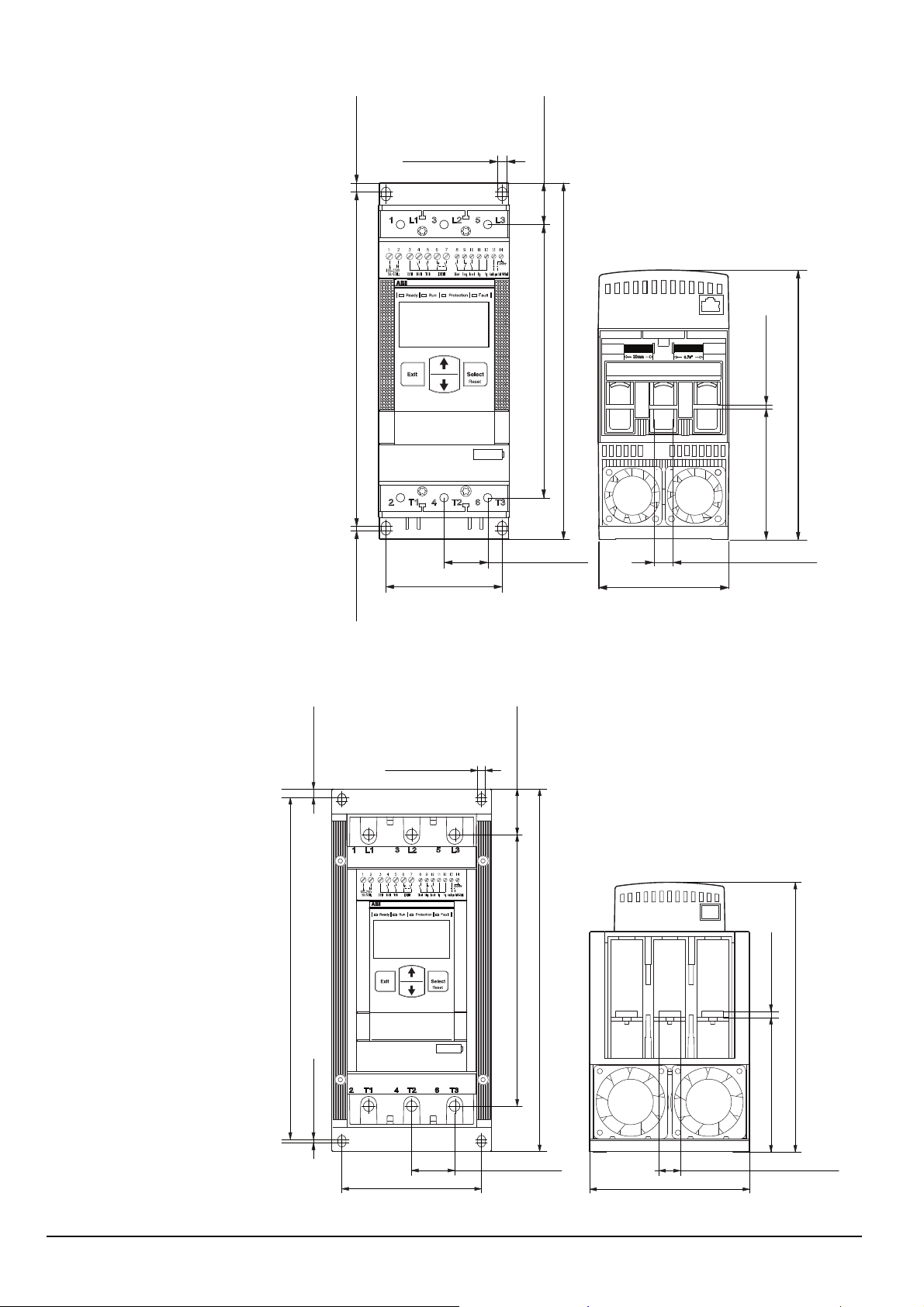

3.7.7 Drilling plan

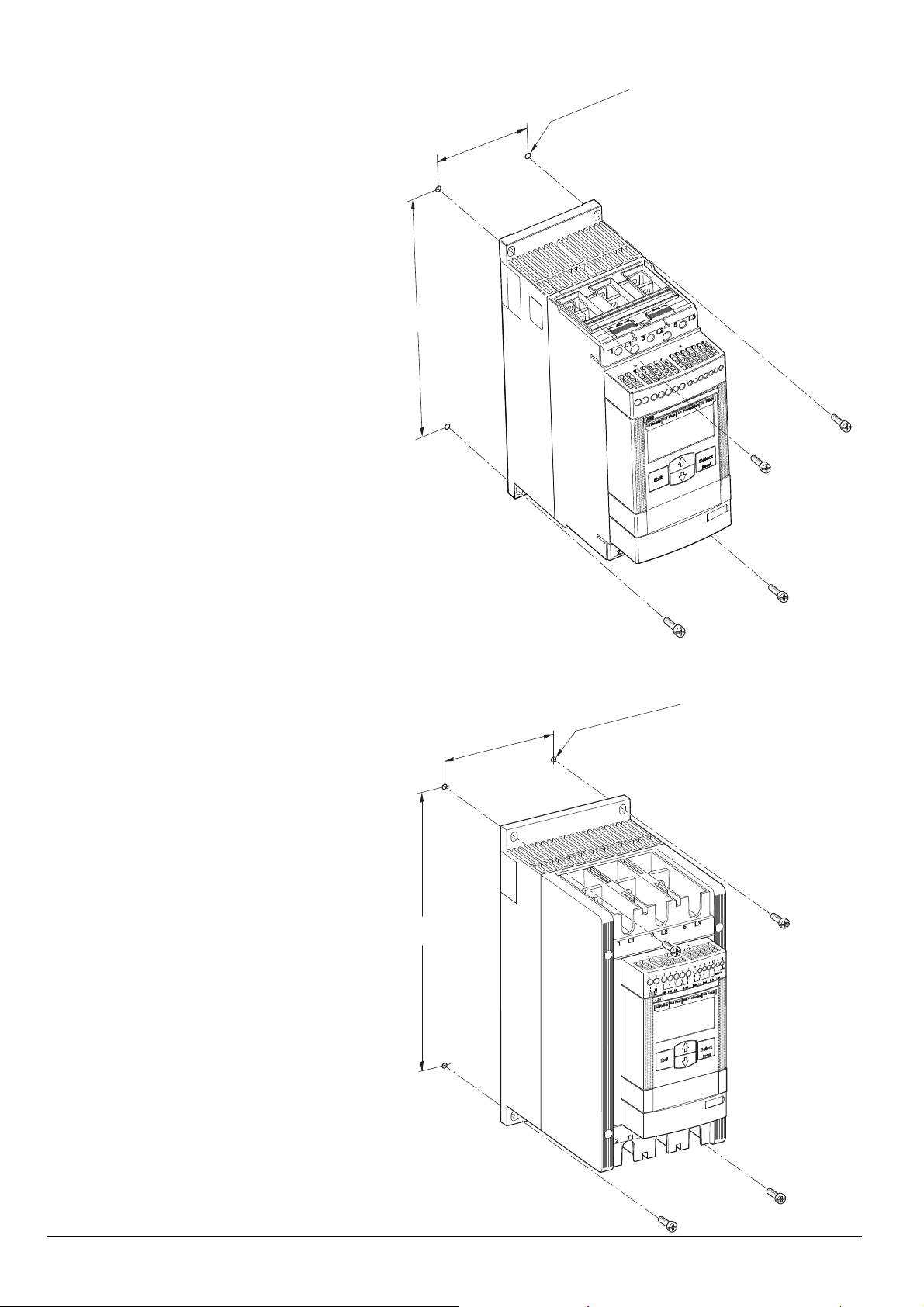

Drilling plan PSE18...PSE105

80 mm

(3.14 in)

230 mm (9.06 in)

M6 (1/4 in)

1SFC132271F0001

Drilling plan PSE142...PSE170

113,5 mm

(4.47 in)

278 mm (10.94 in)

M6 (1/4 in)

70

0-

60

2-

14

SE

P

1SFC132272F0001

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020124 Chapter 3

Page 25

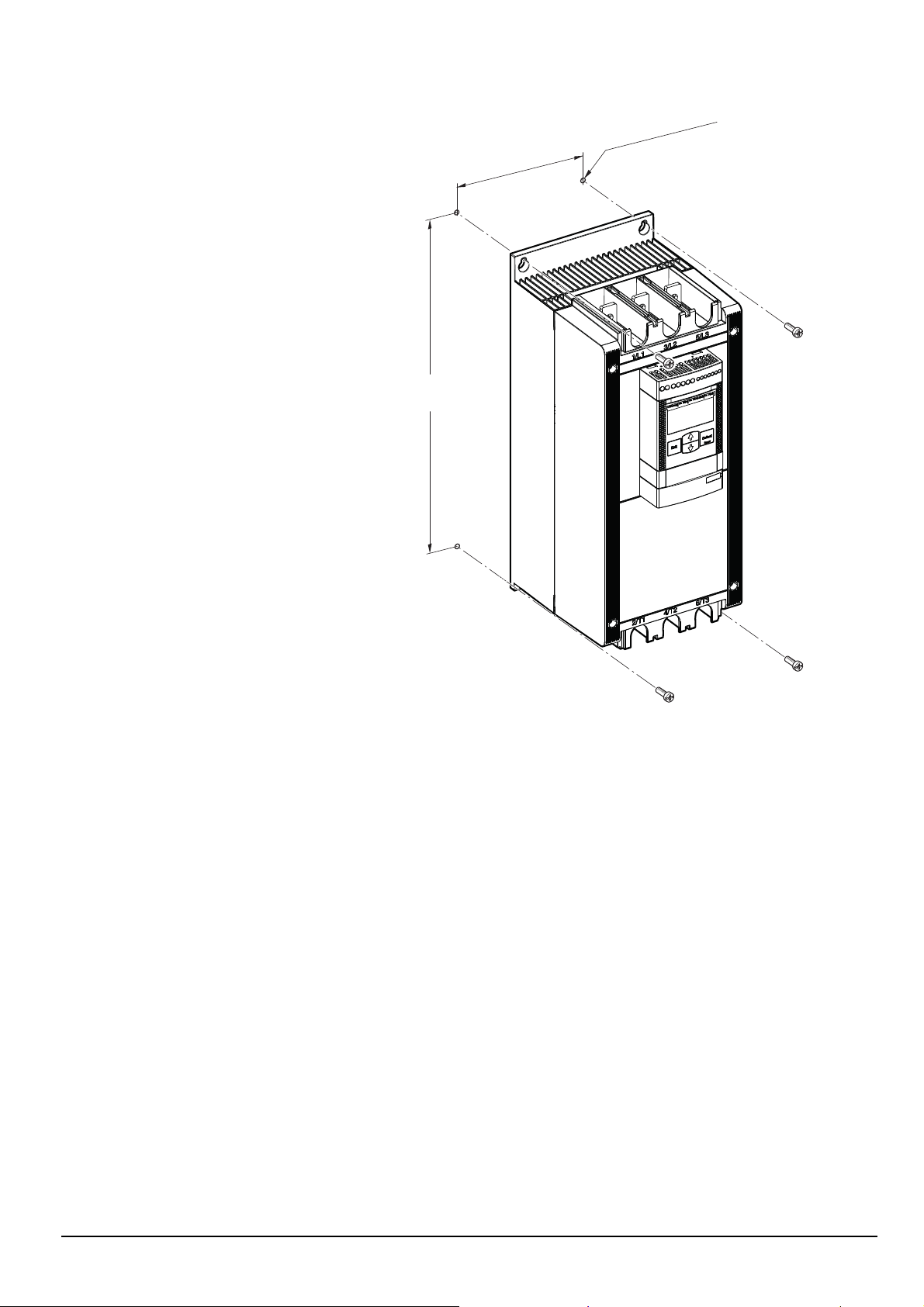

Drilling plan PSE210...PSE370

418 mm (16.46 in)

163,5 mm

M6 (1/4 in)

(6.44 in)

1SFC132273F0001

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 25 Chapter 3

Page 26

This page is intentionally left blank.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020126 Chapter 3

Page 27

Chapter 4 Mounting

Receiving, unpacking and checking ............................................................ 28

Intermediate storage .............................................................................. 28

Mounting .................................................................................................... 28

Handling when mounting ....................................................................... 28

Requirements ......................................................................................... 29

Minimum enclosure size ......................................................................... 29

Minimum distance to wall and front ........................................................ 30

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 27 Chapter 4

Page 28

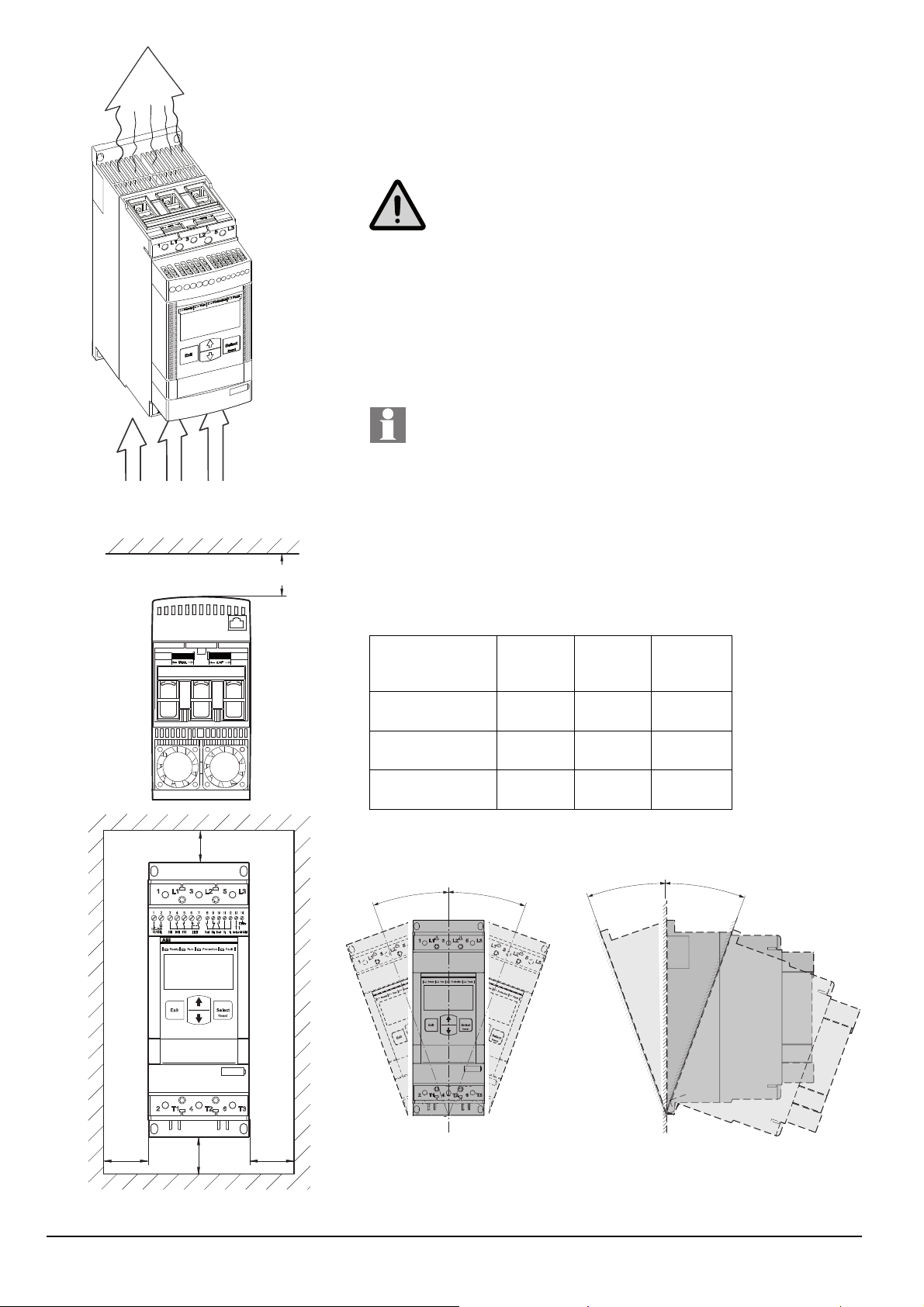

Figure 4.1: Unpacking PSE18...PSE170

Chapter 4 Mounting

This chapter describes instructions on how to receive the softstarter and how to

mount it in a proper way.

4.1 Receiving, unpacking and checking

• Check that the package is turned with the correct side up, fi gures 4.1 and

• Check for transport damages.

• Remove the transport casing.

• Visually inspect the softstarter.

• Check that the order code corresponds with the delivery documents.

1SFC132239F0001

• Check that all items are included, according to the delivery note.

• Check the softstarter as well as the package. If you fi nd any damages, please

4.1.1 Intermediate storage

Until the softstarter is mounted it should be stored in its package.

4.2.

contact the transport company or the supplier immediately.

Figure 4.2: Unpacking PSE210...PSE370

4.2 Mounting

4.2.1 Handling when mounting

The softstarter is available in three physical sizes. All models of PSE can be taken

out of the packages and be mounted without lifting equipment. See chapter 3.7.2

for weights.

Warning!

Never lift the softstarter by the connection bars, since it may cause damage

to the product.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020128 Chapter 4

Page 29

H

4.2.2 Requirements

See Chapter 3 Description for environmental requirements.

The PSE Softstarters exist in three different physical sizes which are designed to

be mounted with M6 (1/4 in.) bolts as well as bolts of equivalent dimension and

strength. Measures and drilling plans will be found in chapters 3.7.6 Dimensions

and 3.7.7 Drilling plan.

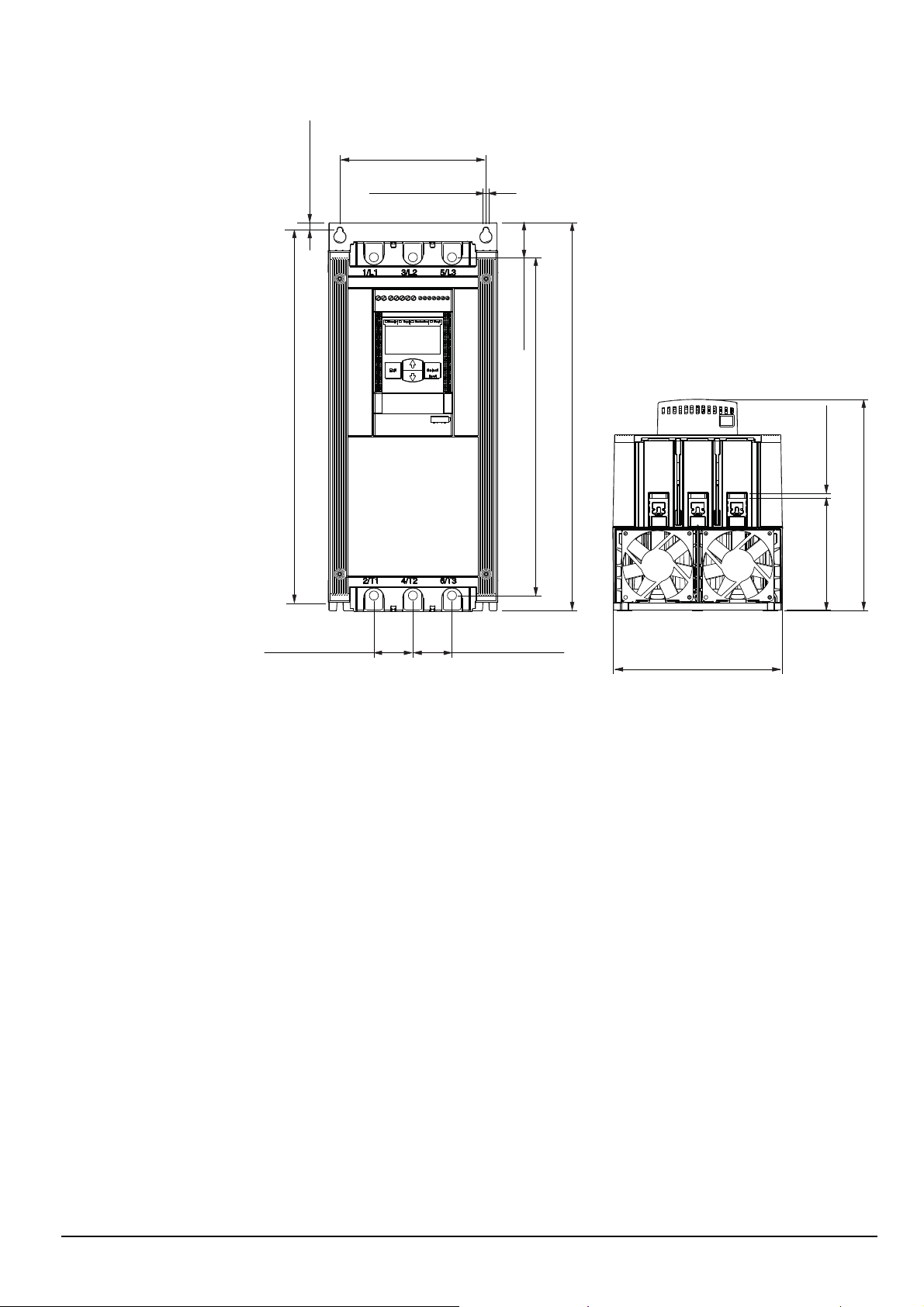

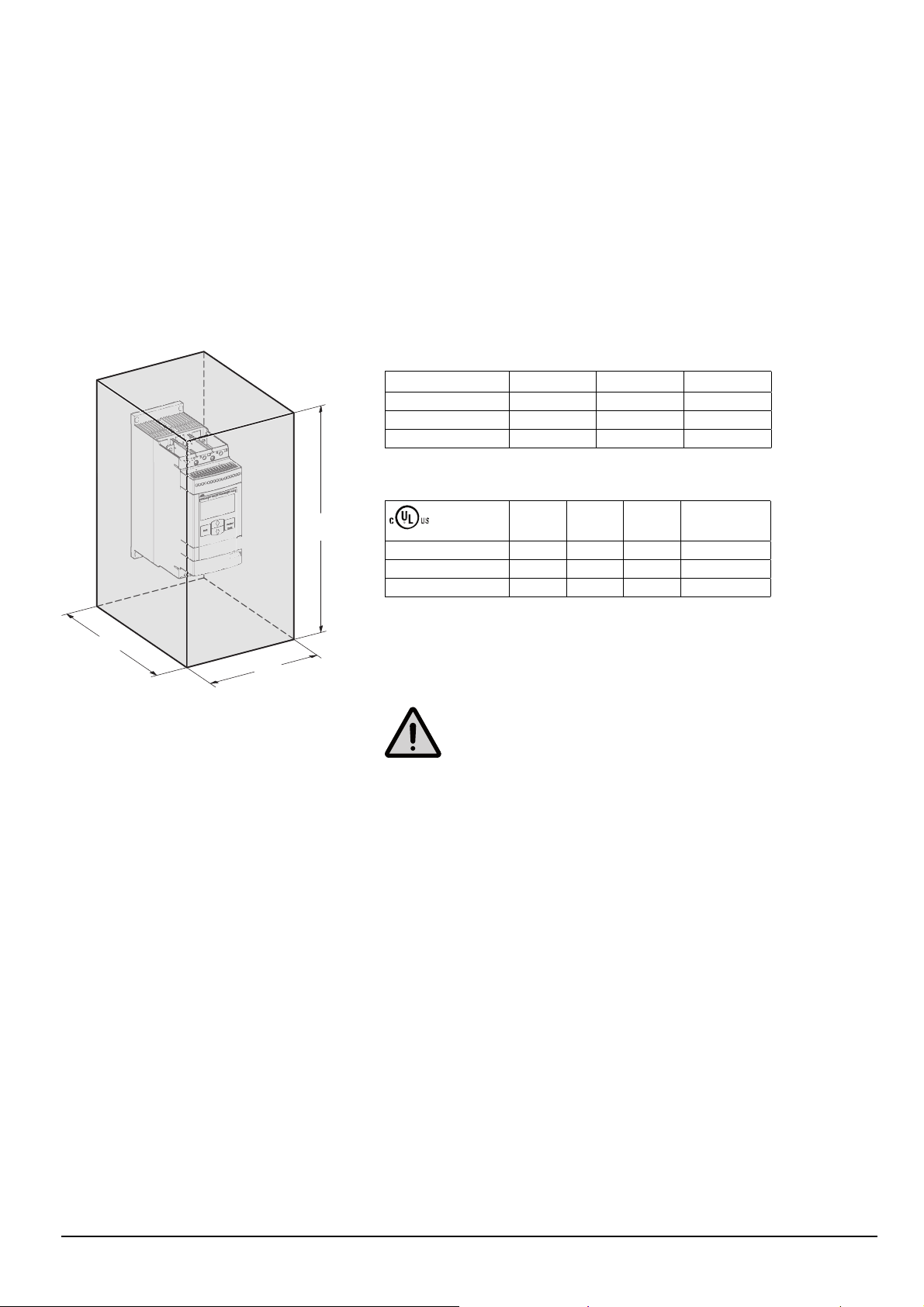

4.2.3 Minimum enclosure size

In applications where the softstarter is installed in an enclosure, the following

minimum enclosure sizes are recommended. Dimensions according to the sketch

in fi gure 4.3.

Table 4.1

IEC

PSE18...PSE105 508 610 305

PSE142...PSE170 762 914 305

PSE210...PSE370 610 762 305

Table 4.2

PSE18...PSE105 20 24 12 1

PSE142...PSE170 30 36 12 2

PSE210...PSE370 30 30 12 2

W (mm) H (mm) D (mm)

W (in) H (in) D (in) min number

of latches

D

W

Figure 4.3: Dimensions minimum enclosure size

Dimensions and drilling plan see Chapter 3 Description.

1SFC132269F0001

Warning!

Using a too small enclosure and/or failure to follow the instructions in other

ways may result in overheating of the PSE Softstarter and operational disturbances.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 29 Chapter 4

Page 30

Figure 4.4: Airways

4.2.4 Minimum distance to wall and front

Check that a suffi cient fl ow of air for cooling purposes can circulate from the bot-

tom to the top of the softstarter, and has a free passage away. Figure 4.3.

Warning!

Risk of damage to property. Ensure that no liquids, dust or conductive parts

enter the softstarter.

1SFC132240F0001

Make sure that the distances to the surrounding walls are suffi cient, and that the

mounting angle is within specifi cations shown in fi gure 4.5.

Follow the minimum distance to front and wall, as described in fi gure 4.4 and the

table below.

A

PSE 18-600-70

C

1SFC132243F000

Table 4.3

The values in table 4.3 are minimum distances.

A

(mm

[inch])

PSE18...PSE105 100

[3.937]

PSE142...PSE170 100

[3.937]

PSE210...PSE370 100

[3.937]

30

O

PSE 18-600-70

PSE 18-600-70

30

O

PSE 18-60

0-70

B

(mm

[inch])

10

[0.394]

10

[0.394]

10

[0.394]

30

O

C

(mm

[inch])

20

[0.787]

20

[0.787]

20

[0.787]

30

O

A

BB

Figure 4.5: Minimum distances to wall and front

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020130 Chapter 4

1SFC132280F0001

1SFC132242F0001

Figure 4.6: Maximum mounting angle

Page 31

Chapter 5 Connection

General ....................................................................................................... 32

Electrical connection ................................................................................... 32

Considerations when controlling two of three phases ............................. 32

Before connecting softstarters PSE18...PSE170 .................................... 33

Connection of the operational power circuit ........................................... 34

Control supply and control circuit ........................................................... 35

Control supply voltage, terminals 1 and 2 .......................................... 35

Functional earth, terminal 14 .............................................................. 36

Start and Stop, terminals 8 and 9 in circuit with terminals 11 or 12. .. 37

Reset event, terminal 10 .................................................................... 38

Analog output, terminals 13 and 14 ................................................... 39

Status output relays, terminals 3, 4, 5, 6, and 7 ................................. 40

Connection of communication devices (optional) ........................................ 41

External keypad ..................................................................................... 41

Technical data for External Keypad .................................................... 41

Transfer of parameters ....................................................................... 42

Transfer of parameters from softstarter to external keypad ............ 42

Transfer of parameters from external keypad to softstarter ............ 42

Cyber Security Deployment Guideline ......................................................... 43

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 31 Chapter 5

Page 32

Chapter 5 Connection

This chapter describes the electrical connections as well as connections for communication devices that have to be made before you can use the softstarter.

5.1 General

Warning!

Mounting and electrical connection of the softstarter shall be made in accordance with existing laws and regulations and be performed by authorized personnel.

Warning!

Hazardous voltage. Will cause death or serious injury. Turn off and lock out

all power supplying this device before starting work on this equipment.

L1

L2

L3

N

LN

Start Stop

KM1

1L1 3L2 5L3

2T1 4T2 6T3

U

V

12 1489

W

89

Start

Stop

Run

TOR Fault

NC NO

67

543

11

11

1210 13

M

3

Figure 5.1: Connection of PSE Softstarter and connection in series with a line contactor.

For basic connection, see Chapter 2 Quickstart.

For circuit diagrams for connection of the softstarter, see Chapter 11 Wiring

diagrams.

5.2 Electrical connection

5.2.1 Considerations when controlling two of three phases

Even when stopped, there will be a voltage on the motor on phase 2. This will

not start the motor and the motor will not be heated up (compare with inside

delta connection). For more information about two phase control see Chapter 3

Description.

Semiconductors do not replace air isolation and the recommended solution is to

use a line contactor to break the current. See fi gure 5.1.

Warning!

1SFC132237F0001

Depending on the two phase control a connected motor terminal always

carries live voltage. Touching terminals and other live parts can result in

death or serious injury.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020132 Chapter 5

Page 33

Since Softstarters PSE18…PSE370 has control in two phases, the connection

must be done In Line only, in accordance with the circuit diagrams in fi gure 5.2

and in Chapter 11.

PSE

1SFC132265F0001

Figure 5.2: ABB PSE Softstarter must be connected In Line only.

PSE

Warning!

1SFC132263F0001

Softstarters PSE18...PSE370 must not be connected Inside Delta since this

will cause damage to the equipment and there is a risk of death or serious

injury. Figure 5.2.

5.2.2 Before connecting softstarters PSE18...PSE170

Warning!

Before connecting the PSE18...PSE170 to operational voltage(Ue) for the

fi rst time, the supply voltage(Us) must be connected and turned on to

ensure the bypass relay is switched to open position. This is necessary to

avoid unintentional starting of the equipment during the connection.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 33 Chapter 5

Page 34

5.2.3 Connection of the operational power circuit

The softstarter is recommended to be connected with a line contactor as described in fi gure 5.1. Additional circuit diagrams will be found in Chapter 11 Wiring

diagrams.

Softstarters PSE18...PSE105 are provided with built-in cable clamps. The cables

must be stripped before connection, and the length of the exposed wire should

be 20 mm or 0.8 in. Connect according to fi gures 5.3 and 5.5.

For Softstarters PSE142...PSE370 the cables must have lugs and be connected

to the terminal bars, according to fi gure 5.4 and 5.5.

Connect the line side to terminals 1 L1, 3 L2, 5 L3.

Connect the motor to terminals 2T1, 4T2, 6T3.

The terminals marking are printed on the front of the softstarter.

5L3

3L2

1L1

2T1 4T2 6T3

Figure 5.3: PSE18...PSE105 connection of the connection

module line side and motor side terminals

PSE18...PSE105

1L1

3L2 5L3

2T1 4T2 6T3

PSE142...PSE170

1L1

3L2 5L3

2T1 4T2 6T3

PSE210...PSE370

1L1

3L2 5L3

2T1 4T2 6T3

M8

11/6-16 UNF-2S

275 lb.in

3/4-16 UNF-2A

375 lb.in

Using connection module

AWG12 .. 6

2,5 .. 10 mm

2x2,5 .. 2x10 mm

AWG6 .. 2/0

10 .. 70 mm

2x10 .. 2x70 mm

Cu 75°C only

Using connection module

ATK185: AWG4 to 300kcmil

Cu 75°C only

Using connection module

ATK300: AWG4 to 400kcmil

ATK300/2: AWG4 to 500kcmil or

2xAWG4 to 2x500kcmil

Cu 75°C only

Figure 5.5: Tightening torques and dimensions for terminal bars and lugs

5L3

3L2

1L1

Figure 5.4: PSE142...PSE370 connection of the line side and

motor side terminals

Using connection bars

2

6 Nm - 53 lb.in

}

2

2

8 Nm - 71 lb.in

2

}

M6

9 Nm - 80 lb.in

M8

18 Nm - 160 lb.in

M10

28 Nm - 240 lb.in

(If connection module is removed)

max

22 mm

(0.866 in)

Using connection bars

max

24 mm

(0.945 in)

Using connection bars

max

30 mm

(1.181 in)

2T1 4T2 6T3

max

20 mm

(0.787 in)

max

5 mm

(0.197 in)

max

22 mm

(0.866 in)

max

8 mm

(0.315 in)

max

30 mm

(1.181 in)

max

10 mm

(0.394 in)

1SFC13275F0001

Warning!

Capacitors for power factor compensation are not allowed between the

softstarter and the motor, since this can cause current peaks which can

burn the thyristors in the softstarter. If such capacitors are to be used, they

should be connected on the line side of the softstarter.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020134 Chapter 5

Page 35

5.2.4 Control supply and control circuit

Wires in industrial control applications are divided into three groups: main power

supply, control supply and control.

5.2.4.1 Control supply voltage, terminals 1 and 2

Connect neutral and live to terminal 1 and 2, as shown in fi gures 5.6 and 5.7.

Check that you have the correct control supply voltage Us.

L

N

Figure 5.6: Terminals for control supply voltage

12 34567

891011

12 13 14

M3

0,5 Nm - 4,3 lb.in

Figure 5.7: Tightening torques and wire area

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 35 Chapter 5

4 x 0,8 mm

(0.157 x 0.031 in)

2

0,2 .. 4 mm

2x0,2 .. 1,5 mm

2

0,2 .. 4 mm

2x0,2 .. 1,5 mm

, AWG 24 ... 10

2

, 2 x AWG 24 ... 16

, AWG 24 ... 10

2

, 2 x AWG 24 ... 16

Page 36

5.2.4.2 Functional earth, terminal 14

Connect the cable to an earthing point close to the softstarter. The cable should

be as short as possible. A suitable earthing point would be next to the softstarter

on the mounting plate, as shown in fi gures 5.8 and 5.9. The mounting plate

should also be earthed.

This is not a protective earth, it is a functional earth. The earthing cable should be

as short as possible. Maximum length 0.5 m.

Do not use functional ground in IT-networks, commonly found in for instance

marine applications.

1

2

3

4

5

6

7

8

9

10

11

Figure 5.8: Terminal for functional earth

12 34567

12

13

14

891011

12 13 14

M3

0,5 Nm - 4,3 lb.in

3,5 x 0,6 mm

(0.138 x 0.24 in)

AWG 24 ... 12

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

2

2

2

2

Figure 5.9: Tightening torques and wire area

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020136 Chapter 5

Page 37

5.2.4.3 Start and Stop, terminals 8 and 9 in circuit with terminals 11

or 12.

The PSE Softstarter has a built-in holding circuit and does not require sustained

signals on start input. Use internal control supply voltage from terminals 11 or 12.

Connection of start and stop terminals using conventional circuit with push buttons, see fi gures 5.10 and 5.12.

A conventional circuit with auxiliary relay is also possible, see fi gure 5.11 and 5.12.

Warning!

Do not connect an external voltage to any of the control terminals 8, 9, 10,

11, 12 and 13. Failure to observe the above may damage the softstarter and

the warranty may no longer be valid.

Start

Stop

812 3 4567 91011121314

PSE 18-600-70

L

Stop

Start

N

812 34567 91011121314

PSE 18-600-70

Figure 5.10: Terminals for start and stop, conventional

circuit with push button

12 34567

891011

12 13

14

0,5 Nm - 4,3 lb.in

Figure 5.12: Tightening torques and wire area

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 37 Chapter 5

M3

Figure 5.11: Terminals for start and stop, conventional

circuit with auxiliary relay

3,5 x 0,6 mm

(0.138 x 0.024 in)

AWG 24 ... 12

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

2

2

2

2

Page 38

5.2.4.4 Reset event, terminal 10

The reset control terminal 10 is in circuit with terminals 11 or 12 used for remote

reset of trip events. See fi gures 5.13 and 5.14.

Warning!

Do not connect an external voltage to any of the control terminals 8, 9, 10,

11, 12 and 13. Failure to observe the above may damage the softstarter and

the warranty may no longer be valid.

Figure 5.13: Terminal for reset event

12 34567

891011

12 13

Reset

812 34567 91011121314

PSE 18-600-70

14

M3

0,5 Nm - 4,3 lb.in

3,5 x 0,6 mm

(0.138 x 0.024 in)

AWG 24 ... 12

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

2

2

2

2

Figure 5.14: Tightening torques and wire area

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020138 Chapter 5

Page 39

5.2.4.5 Analog output, terminals 13 and 14

Analog output can be used for the connection of analog instruments.

If the analog output is used, the cables shall be connected to terminals 13 (+) and

14 (-). See fi gures 5.15 and 5.16.

Analog out signal can vary in the range 4 - 20 mA, corresponding to 0 - 120 percent of set value for parameter Ie. 100 percent corresponds to 17.3 mA.

Warning!

Do not connect an external voltage to any of the control terminals 8, 9, 10,

11, 12 and 13. Failure to observe the above may damage the softstarter and

the warranty may no longer be valid.

812 34567 91011121314

PSE 18-600-70

Figure 5.15: Terminals for analog output

12 34567

891011

12 13

14

M3

0,5 Nm - 4,3 lb.in

Figure 5.16: Tightening torques and wire area

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 39 Chapter 5

3,5 x 0,6 mm

(0.138 x 0.024 in)

AWG 24 ... 12

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

0,2 .. 2,5 mm

2x0,2 .. 1,5 mm

2

2

2

2

Page 40

5.2.4.6 Status output relays, terminals 3, 4, 5, 6, and 7

By connection to terminals 3, 4, 5, 6, and 7, RUN, TOR and EVENT are available

for a contactor, a PLC or a status indicator, which can use these signals as an

input.

The COM connection on terminal 3 is a shared neutral connection for terminals 4,

5, 6, and 7.

Run signal is given from terminal 4 during start ramp, running, and stop ramp if

used. It can be used to control the line contactor.

Top of Ramp ( TOR) signal is given from terminal 5 when full voltage to the motor is

applied.

The event relay is available as normal closed outlet on terminal 6 and normal open

outlet on terminal 7. It is indicating a present fault or protection. The event signal

can be used as input for a status indicating lamp or a LED.

For connection see fi gures 5.17 and 5.18.

Warning!

The same external voltage (24 V DC or 110-250 V AC) must be connected to

the output relay terminals 3, 4, 5, 6 and 7. Failure to observe the above may

damage the softstarter and the warranty may no longer be valid.

12 34567

AC

812 3 4567 91011121314

PSE 18-600-70

Figure 5.17: Terminals for status output signals

4 x 0,8 mm

M3

891011

12 13 14

0,5 Nm - 4,3 lb.in

(0.157 x 0.031 in)

AWG 24 ... 12

0,2 .. 4 mm

2x0,2 .. 1,5 mm

0,2 .. 4 mm

2x0,2 .. 1,5 mm

2

2

2

2

Figure 5.18: Tightening torques and wire area

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020140 Chapter 5

Page 41

Figure 5.19: External keypad

5.3 Connection of communication devices (optional)

5.3.1 External keypad

An external keypad for door mounting can be connected to the softstarter. A

3-meter cable including both the communication and the power supply to the

keypad makes the connection. The cable shall be connected to the external keypad connection at the bottom of the softstarter. See Figures 5.19 and 5.20.

The external keypad can also be used for transferring parameters from one softstarter to another. The parameters transferring through the external keypad should

not be performed between two different versions of fi rmware.

Note that IP66 cannot be achieved when the keypad is not mounted.

When the external keypad is used, both keypads will work in parallel, but the

softstarter built-in keypad always has the highest priority if the keys on both units

are pressed simultaneously.

5.3.1.1 Technical data for External Keypad

General data

Display LCD type

Status indicating LEDs Ready: Green

Run: Green

Proction: Yellow

Fault: Red

o

Ambient temperature Storage: -40

o

CF).

Operation: -25

+140 oF).

Standards IEC/EN 60947-4-2

UL508

CSA C22.2 No 14

Environmental ratings IP66

UL Type 1, 4X Indoor, 12

C to +70 oC (-40 oF to 158

o

C to +60 oC (-13 oF to

Figure 5.20: Connection of external keypad

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 41 Chapter 5

Page 42

5.3.1.2 Transfer of parameters

To transfer (copy) parameters from one PSE Softstarter to another, connect the

External keypad to the chosen softstarter and follow the sequence below. For

more information about navigating, see Chapter 6 in this manual. The Transfer

Parameter menu is hidden and only possible to reach when the external keypad is

connected to the softstarter. Start in Settings Level with cursor on Ie icon. Press

Arrow Up to enter Transfer Parameter menu, and the text tP will be displayed on

the LCD.

PSE 18-600-70

Figure 5.21: Transfer of parameters from softstarter

to external keypad

PSE 18-600-70

Figure 5.22: Transfer of parameters from external

keypad to softstarter

5.3.1.2.1 Transfer of parameters from softstarter to external keypad

Transfer of parameters from softstarter to external keypad is possible in all states,

1SFC132292F0001

except during ramping. During ramping it is not possible to enter the TP menu.

When you are in the Transfer Parameter menu confi rm and continue by pressing

Select. A text toSS will now be present on the LCD display. Scroll to FrSS and

confi rm selection by pressing Select key, and the text FrSS will now be fl ashing.

Continue and transfer by pressing Select. If the transfer was successful, the text

donE will be displayed on the LCD, otherwise a fault code will be displayed. Press

Exit or select to return to Transfer Parameter menu. Press then exit for returning to

a higher menu level.

5.3.1.2.2 Transfer of parameters from external keypad to softstarter

Transfer of parameters from external keypad to softstarter is possible only in

standby state. During ramping, it is not possible to enter the TP menu. If transfer

of parameters is done during TOR, a fault code will be displayed.

When you are in the Transfer Parameter menu confi rm and continue by pressing

Select. A text toSS will now be present on the LCD display. Confi rm selection of

toSS by pressing Select key and the text toSS will now be fl ashing. Continue by

pressing select. If valid parameters will be accepted, a value for parameter Rated

Motor Current Ie will be displayed, otherwise a fault code will be displayed. Scroll

and select a setting for Ie, see chapter 7.5.1. Confi rm selection and save by

pressing Select. If transfer is performed, the text donE will be displayed, otherwise

1SFC132293F0001

a fault code will be displayed. Press Exit or Select to return to Transfer Parameter

menu. Press Exit for returning to a higher menu level.

A list showing all parameters which will be transferred is available in chapter 7.3

List of available parameters.

The parameters Rated Current of the motor and PSE will not be transferred.

Display Description

Transfer Parameter

Transfer of parameters from external keypad to

softstarter

Transfer of parameters from softstarter to external

keypad

Confi rmation of successful transfer

How to operate the External keypad, see Chapter 6 Human-Machine Interface

(HMI).

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020142 Chapter 5

Page 43

5.4 Cyber Security Deployment Guideline

Cybersecurity has become of key importance for ABB customers and ABB alike.

There are several reason for that, one of them is the modern control systems that

can be distributed and interconnected, which means an increased attack surface

compared to legacy and isolated systems. The PSE softstarter can be connected

to different industial control networks either using the built-in Modbus RTU or by

using additional fi eldbus plugs.

Important: The intention with the product is not to connect it to Internet.

To protect the reliability, integrity and availability of the softstarter against

unauthorized access or attack the following countermeasures should be taken:

Restrict physical access to softstarter and industrial control network to authorized

people only. The recommendation is to install the softstarter in a locked cabinet.

PSE softstarters should only be connected to private networks. It’s the customers

responsibility to establish additional security measures if softstarter is to be

connected to unknown or public networks. Example of such security measures

are fi rewall, smart switches and VPN.

Backup/Restore - To minimize the downtime in case of malfunctioning softstarter

for some reason, the recommendation is to backup the softstarter parameters

using SoftstarterCare - Service Engineer Tool. The parameters can then be

restored using SoftstarterCare. Instruction on how to backup and restore

parameters are part of SoftstarterCare product documentation.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 43 Chapter 5

Page 44

This page is intentionally left blank.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020144 Chapter 5

Page 45

Chapter 6 Human-Machine Interface

(HMI)

Overview .................................................................................................... 46

Application ............................................................................................. 46

Design ................................................................................................... 46

LED status indicators ......................................................................... 47

LCD display and keypad .................................................................... 48

Locking/unlocking the keypad ................................................................ 49

Reset of all settings ................................................................................ 49

Reset of tripping events ......................................................................... 49

Menu structure ....................................................................................... 50

Information Level ............................................................................... 50

Settings Level and settings menu ...................................................... 50

Navigating the menu ................................................................................... 52

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 45 Chapter 6

Page 46

Chapter 6 Human-Machine Interface

This chapter describes how the Human-Machine Interface ( keypad, LED status

indicators and LCD display) works.

Ready Run

Exit

A

Protection

B

Select

Reset

C DE

Figure 6.1:

A

LED status indicators.

B

LCD display with backlight.

C

Exit key for cancelling parameter edits and

exiting one menu level.

D

Select/Reset key for changing and storing

parameter values, entering one menu level,

and to reset tripping events.

E

Navigation keys for navigating the menu and

changing parameter values. Flashing numbers

or text shown in the display indicates that the

menu/value can be changed or scrolled.

Fault

6.1 Overview

6.1.1 Application

The Human-Machine Interface is used for several purposes such as setting up the

PSE Softstarter parameters, including protection functions and fi eldbus communi-

cation. The HMI is also providing status information by LED status indicators and

the LCD display.

The PSE Softstarter monitors and displays different values. When switching on the

supply voltage the LCD will fi rst display the Information Level, which is showing

motor current, input voltage on the line side, power factor, and voltage to the motor.

The Information Level also displays information on whether the keypad is locked

or unlocked.

1SFC132235F0001

6.1.2 Design

The appearance of the HMI is showed in fi gure 6.1.

The HMI consists of:

• LED status indicators

• LCD display with backlight

• Selection and navigation keys

On start-up all LCD segments and LEDs will be briefl y illuminated.

The LCD backlight will automatically turn off after some time of inactivity. Turn it on

by pressing any key.

When switching on the supply voltage the LCD will fi rst illuminate all available seg-

ments, LEDs and the backlight. Thereafter the Information Level is displayed. See

fi gure 7.1.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020146 Chapter 6

Page 47

6.1.2.1 LED status indicators

The LED status indicators work as in table 6.1:

Table 6.1

LED Color Description

Ready Green • Off: when control supply voltage Us is off or uncon-

nected.

• Flashing light when control supply voltage Us is On

and operational voltage Ue is Off.

• Steady light when control supply voltage Us is On,

and operational voltage Ue is On.

Run Green • Off when the motor not is running.

• Flashing light when softstarter is controlling opera-

tional voltage Ue during start or stop ramp.

• Steady light when full operational voltage Ue is on

at Top of Ramp.

Protection Yellow • Off: when the softstarter has not tripped on any

protection

• Steady light on protection when reset is not possible.

• Flashing light on protection when reset is possible.

Fault Red • Off: when the softstarter has not tripped on any

fault

• Steady light on fault when reset is not possible.

• Flashing light on fault when reset is possible.

When fault or protection LED is activated, the LCD display will show the actual

fault or protection as an event code. See table 10.1.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 47 Chapter 6

Page 48

A

6.1.2.2 LCD display and keypad

The keypad is based on the same user concept as common on mobile phones.

Ready Run

Protection

Fault

See fi gure 6.1.

The LCD display contains three rows. The top row has 8 parameter icons. The

middle row has a lock symbol, 4 digits and units. The bottom row has 4 parameter icons.

On the middle row various information is presented.

A cursor A indicates which parameter value is possible to change at each position, as shown in fi gure 6.2.

Exit

Select

Reset

Figure 6.2: Cursor indicating parameter accessible

for confi guration

The Exit key for cancelling parameter edits and for exiting one menu level.

The Select/Reset key normally has more than one function, such as selecting,

changing, storing, and manual reset of tripping events, depending on present

view.

The navigation keys are used for navigating in the menu and changing parameter

values. Flashing numbers or text shown in the display indicates that the parameter

value can be changed or scrolled.

If key is held down, scrolling will be faster. When selecting from a list, the scrolling

is done in a closed loop.

You will fi nd a description of all settings in Chapter 7 Functions and confi guration

and confi guration.

The menu structure of the keypad is illustrated in fi gure 6.7.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020148 Chapter 6

Page 49

Ready Run

Protection

Fault

6.1.3 Locking/ unlocking the keypad

1. Press the Exit key to exit to the Information Level.

2. The keypad is unlocked if the middle row is not indicating the lock icon

to the right.

3. Press both Navigation keys 4 seconds to lock the keypad, and protect all

parameter settings from unintentional change from the keypad. See fi gure 6.3.

4. The keypad is locked if the a padlock is present on the middle row.

5. Press both Navigation keys 2 seconds to unlock the keypad, and allow

changes of the parameter settings.

Exit

Select

Reset

Figure 6.3: Locking/unlocking the keypad

Ready Run

Protection

Fault

6.1.4 Reset of all settings

How to reset all the changed parameters back to user default settings is described in chapter 7.7.1.

6.1.5 Reset of tripping events

The Select/Reset key can be used to reset tripping events via the keypad, see

fi gure 6.4. For details about resetting of tripping events, see chapter 7.6.

Exit

Select

Reset

Figure 6.4: Reset of tripping events

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 49 Chapter 6

Page 50

6.1.6 Menu structure

The structure of the menu is described in fi gure 6.8. All different parameters and

levels of the menu, and how they can be reached by scrolling, are also described.

Figure 6.5: Information Level

Exit

Select

Reset

Figure 6.6: Enter Settings Level pressing the

Select key.

6.1.6.1 Information Level

By pressing a key the backlight will be switched on, and the Information Level

will be displayed. The Information Level contains general operational information

described in chapter 7.1.

Use navigation keys to present all selections. The selections are presented one by

one on the middle row. See fi gure 6.5 and menu structure in fi gure 6.8.

6.1.6.2 Settings Level and settings menu

The Settings Level is reached from the Information Level by pressing the Select

key. See fi gure 6.6. and menu structure in fi gure 6.8.

The settings menu is used to set up the PSE Softstarter with parameters for the

current application.

Available settings are presented one by one on the top and bottom of the display.

Use navigation keys to move the cursor to present all selections. In fi gure 6.7 the

cursor is currently marking the parameter Rated Current Ie, which by pressing

Select key a second time will be accessible for tuning.

Figure 6.7: Settings Level

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020150 Chapter 6

Page 51

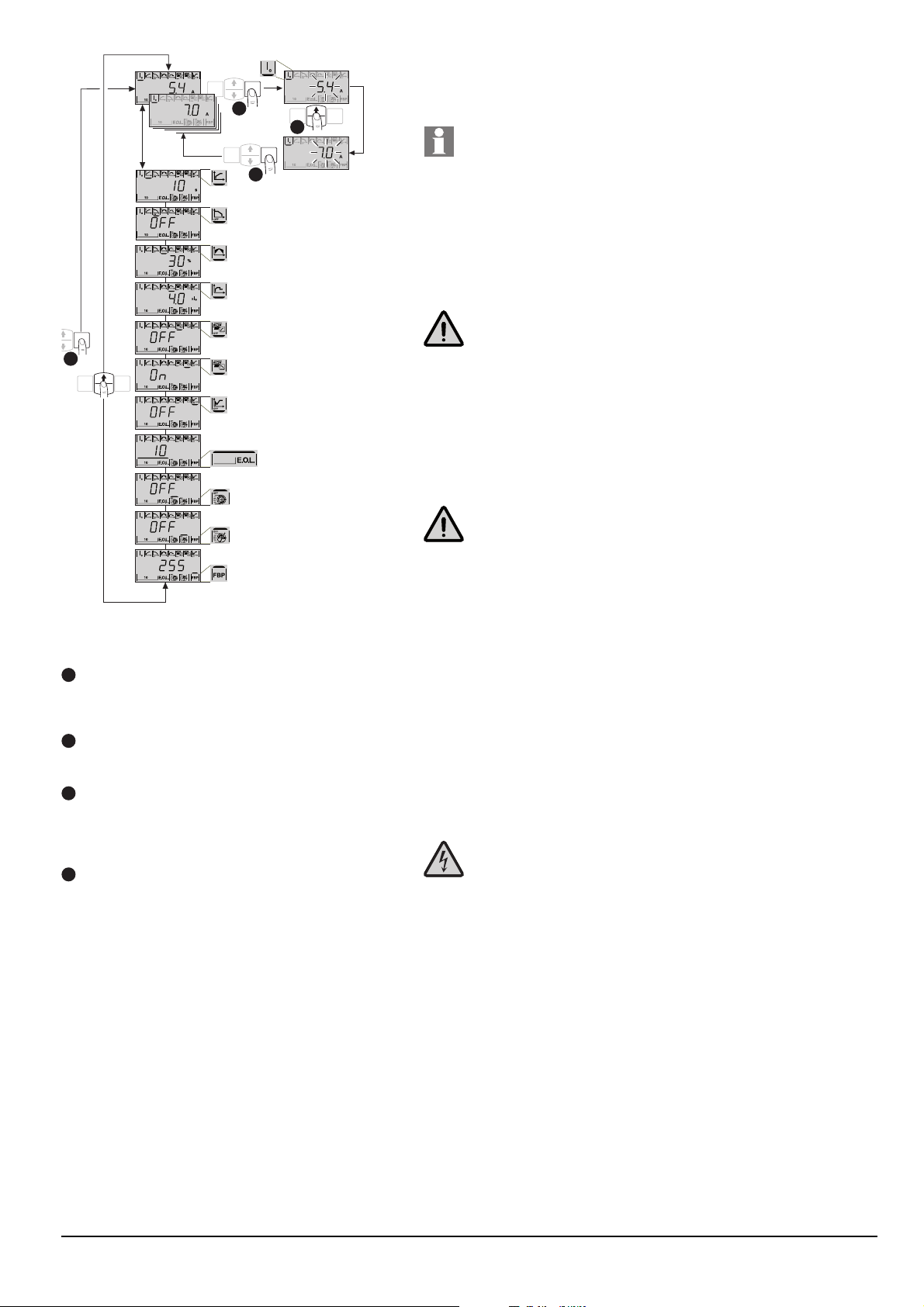

Exit

Select

AInformation Level

%

Cos

V

Lock/Unlock Settings Level

Reset all parameter settings to user default values

PSE

Settings level

Ie (Rated current of motor)

Start Ramp time

Stop Ramp time

Initial/End Voltage

Current Limit

Torque Control during start ramp

Individual

1...30 s

OFF, 1...30 s

30...70 %

1.5...7 x I

OFF

On

e

Setting of time must be performed in Start Ramp time

OFF

Torque Control during stop ramp

On

U

e

t

Kick Start

Set Initial Voltage

U

e

t

Electronic Motor Overload Protection

Set Initial Voltage

OFF

30...100

OFF

Setting of time must be performed in Stop Ramp time

HAnd

10A/10/20/30

Auto

OFF

Underload Protection

0.2...1 x I

e

HAnd

Auto

OFF

Locked Rotor Protection

0.5...7 x I

e

HAnd

Auto

dPoF

Fbp

OFF 0...255

Int 0.5–60

dPon

9.6, 19.2, 38.4,

57.6, 76.8

8E1, 8o1,

8n1, 8n2

dPoF

dPon

FieldBus

Control

Figure 6.8: Menu structure PSE Softstarter

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 51 Chapter 6

ON 0...255

dPoF

Fbp

dPon

Int 0.5–60

HAnd

trlP

Auto

LocC

9.6, 19.2, 38.4,

57.6, 76.8

8E1, 8o1,

8n1, 8n2

dPoF

dPon

HAnd

trlP

Auto

LocC

Page 52

Exit

Select

Reset

6.2 Navigating the menu

The menu is navigated by the keypad. The Navigation keys are used to scroll up

or down. The Select key is used to select a setting and save. The Exit key is used

to cancel without selecting or saving a setting, and to go to a higher level of the

menu, as illustrated in fi gure 6.9.

1. Turn on the backlight by pressing any key.

1SFC132291F0001

Figure 6.9: Press Exit key to cancel and to go to

a higher level of the menu.

2. On the Information level use the Navigation keys for scrolling the different

operational information.

3. Press the Select key to Enter the Settings level. See

A

in fi gure 6.10. A cur-

sor is marking the accessible parameter, in this case Rated Current Ie.

4. Press Select key again to enable editing of the parameter Rated Current. See

B

in fi gure 6.10. A fl ashing value on the middle row indicates that the param-

eter is available for scrolling and for selection.

5. Increase or decrease the value by pressing Navigation key repeatedly. Hold-

C

ing the key down will speed up the scrolling. See

in fi gure 6.10.

6. When the rated current of the motor is reached, press the Select key again to

D

save. See

in fi gure 6.10.

7. It is possible to select and adjust the other parameters by following the same

procedure.

8. At any point, press Exit to cancel a setting, and return to the information level.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020152 Chapter 6

Page 53

Exit

Select

Reset

B

Exit

Select

Reset

C

Exit

Select

Reset

D

Exit

Select

Reset

Exit

Select

Reset

A

Exit

Select

Reset

1SFC132268F0001

Figure 6.10: Navigating the menu

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 53 Chapter 6

Page 54

This page is intentionally left blank.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020154 Chapter 6

Page 55

Chapter 7 Functions and confi guration

Softstarter operational data ........................................................................ 56

Parameter settings ..................................................................................... 56

List of available parameters ........................................................................ 57

Basic settings principal ............................................................................... 59

Functions ................................................................................................... 60

Rated Current Ie of motor ...................................................................... 60

Start Ramp Time .................................................................................... 60

Stop Ramp Time .................................................................................... 61

Initial/End Voltage ................................................................................... 62

Current Limit .......................................................................................... 63

Torque Control during start ramp ............................................................ 64

Torque Control during stop ramp ............................................................ 65

Kick Start ............................................................................................... 66

Electronic Motor Overload Protection E.O.L. .......................................... 67

Underload Protection ............................................................................. 68

Locked Rotor Protection ........................................................................ 69

FieldBus Control (optional hardware required)......................................... 70

Fieldbus Address ............................................................................... 71

Download Parameter ......................................................................... 71

Fieldbus interface type ....................................................................... 72

Internal Modbus RTU timeout time .................................................... 72

Internal Modbus RTU baud rate ......................................................... 73

Internal Modbus RTU frame format .................................................... 73

Bypass open fault trip time ................................................................ 74

Delay before starting motor ............................................................... 74

Torque tune resistive losses ............................................................... 75

Torque controller gain ........................................................................ 75

Analog out scaling value .................................................................... 75

Fieldbus Operation When Fault .......................................................... 76

Type of Operation for Reset of Fieldbus Fault ..................................... 77

Reset of tripping events .............................................................................. 77

Special functions ........................................................................................ 78

Reset all parameter settings to user default values ................................. 78

PSE parameter ...................................................................................... 79

Representation of signals in time domain .................................................... 80

Application settings .................................................................................... 81

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 55 Chapter 7

Page 56

Chapter 7 Functions and confi guration

How to navigate the menu, see Chapter 6 Human-Machine Interface (HMI), especially chapter 6.2 Navigating the menu.

7.1 Softstarter operational data

The information level is the top level of the user menu. Information about output

current, line voltage, power factor, and voltage to the motor is displayed.

1

2

Exit

Select

Reset

4

1SFC132295F0001

Figure 7.1: Information Level, displayed information

On the information level the softstarter displays current values for:

1

Motor current (A)

2

Power factor / Cos

3

Voltage to the motor (%)

4

Input voltage on the line side (V)

The motor current is calculated as the maximum RMS value of the three phases.

Using the motor current displayed on Information level as input for setting of Current Limit, may result in too low Current Limit. This may cause a longer starting

time and unnecessary heating of the motor.

7.2 Parameter settings

Settings can be done in four different ways:

• Keypad

• Fieldbus communication (option)

• External keypad (option)

• SoftstarterCare

With the keypad or external keypad, settings can be done as individual parameter

setting of all essential parameters.

When the fi eldbus communication (option) is enabled, most parameters can also

be modifi ed from this interface.

User default parameter set is stored in the unit for a possible reset to default values. See chapter 7.7.1 about resetting parameters to user default values.

Warning!

The motor may start unexpectedly if there is a start signal present, when doing any of the actions listed below.

•

Switching from one type of control to another ( fi eldbus control / hard-

wire control).

•

Resetting events.

•

Using automatic event reset.

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020156 Chapter 7

Page 57

7.3 List of available parameters

1

A list of the available parameters for PSE18...PSE370 is visible in table 7.1.

Table 7.1

Description Display

symbol

Rated Current of motor I

Start Ramp time

Stop Ramp time

Initial/End Voltage

Current limit

e

Setting range Default

value

Individual

See tables in

chapter 3.7.3

PSE Softstarter

types. Setting

range is 30-100

percent of I

OFF, 1...30 s OFF W W T

1.5...7 x

e

1...30 s 10 s W W T

30...70 % 40 % W W T

Individual W W

I

e

7.0 x I

Access

from

HMI

Fieldbus

WW T

e

Parameter

transfer with

External Keypad

Actual setting

Torque Control during start ramp OFF/On OFF W W T

Torque Control during stop ramp

Kick Start

Electronic Motor Overload Protection

( EOL)

Tripping Class (EOL)

Type of operation (EOL)

OFF/On On W W T

OFF, 30...100 % OFF W W T

OFF, 10 A, 10,

20, 30

HAnd/Auto

10 W W T

HAnd X X T

T

R = Readable

W = Writeable

T = Will be transferred ( uploaded/ downloaded)

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M0201 57 Chapter 7

Page 58

6

1

1

2

3

4

5

6

7

Description Display

7

symbol

Setting range Default

value

Access

from

HMI

Parameter

Fieldbus

Underload Protection T

Actual setting

transfer with

External Keypad

Level

Type of operation

OFF, 0.2...1 x I

HAnd, Auto

Locked Rotor

Protection

Level OFF, 0.5...7 x I

Type of operation

Fieldbus Control

Fieldbus address

Fieldbus interface

Download Parameter

Fieldbus Operation When Fault

Type of Operation

HAnd, Auto

OFF, On

1SFC13235F0001

0...255

FbP, Int FbP W R T

dPon/dPoF

trIP/LocC

HAnd/Auto

Int only

OFF W W T

e

HAnd W W T

OFF W W T

e

HAnd W W T

OFF W R T

255

WR T

dPon W R T

LocC W R T

HAnd W R T

T

Timeout

Baudrate

Modbus frame format

R = Readable

W = Writeable

T = Will be transferred ( uploaded/downloaded)

1

HAnd = Manual reset of the protection or fault.

Auto = Automatic reset of the protection or fault.

2

OFF = Fieldbus is not allowed to control the motor.

On = Fieldbus is allowed to control the motor.

3

255 = Address of the FieldBusPlug will be used.

dPon = Download of parameters from PLC enabled.

4

dPoF = Download of parameters from PLC blocked.

0.5...60 s 0.5 W R T

9.6, 19.2, 38.4,

19.2 W R T

57.6, 76.8 kBaud

8o1, 8E1, 8n2,

8E1 W R T

8n1

5

Accessible only if On is previously selected.

trIP = Trip on fault.

LocC = Local control on fault - hardwire control is possible

Accessible only if trIP is previously selected.

HAnd = Manual reset of the protection or fault.

Auto = Automatic reset of the protection or fault.

Databits(8), Parity (Even, odd, no), Stopbits (1, 2).

Softstarters Type PSE18...PSE370 Installation and commissioning manual 1SFC132057M020158 Chapter 7

Page 59

g

e

r

p