ABB PST Softstarters Technical Catalog

Softstarters

6

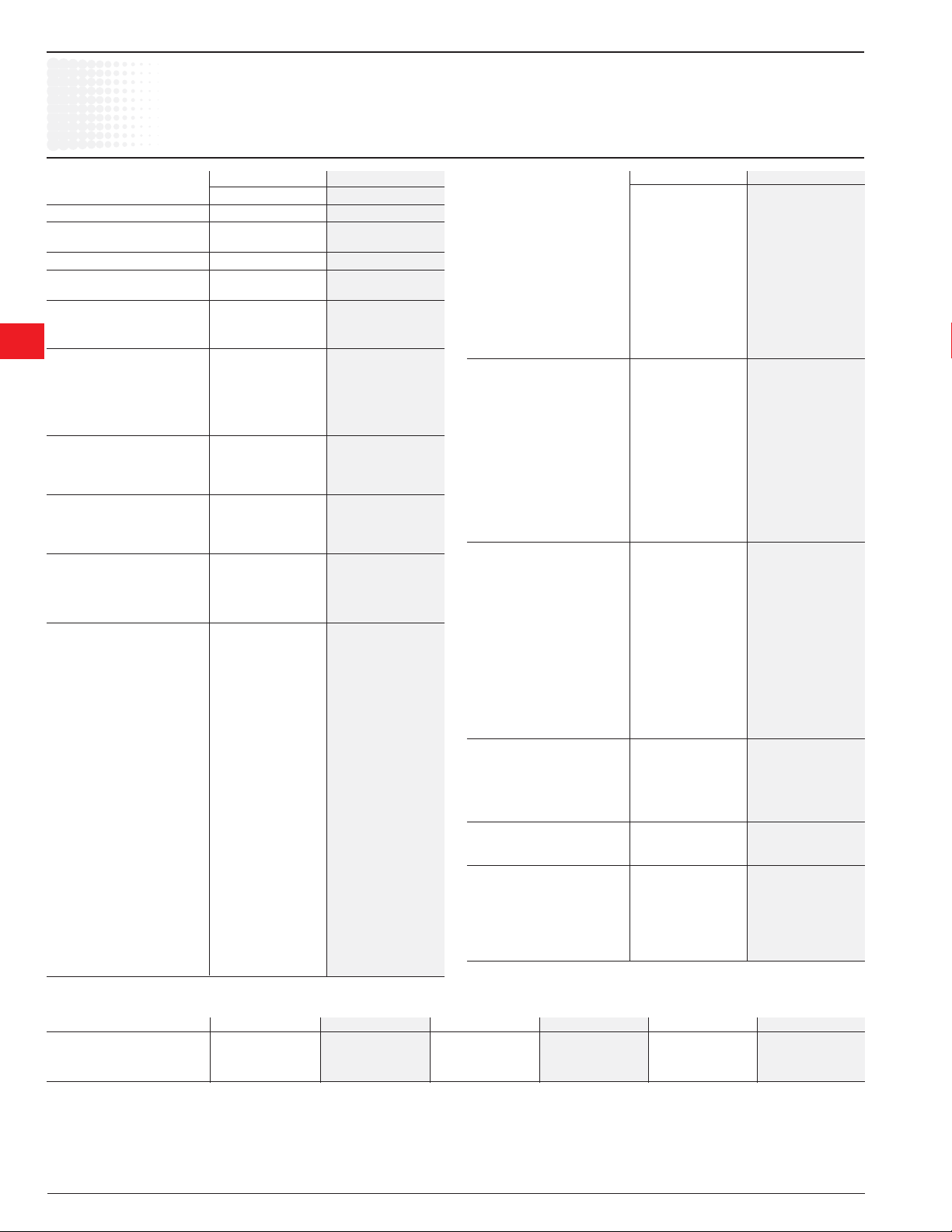

Type PST

Technical data

PST30 – 300

PSTB370 – 1050

PST30 – 300 PSTB370 – 1050

Rated insulation voltage Ui 690 V 690 V

Rated operational voltage Ue 208 – 690 V 208 – 690 V

Starting capacity

at max rated current I

Number of starts per hour 30 1 10 1

Overload capability

Overload Class 10 – 30 10 – 30

Service factor 115 % 115 %

(PSTB370 – PSTB840)

100 % (PSTB1050)

6

Ambient temperature

During operation ±0… +50 °C 2 ±0… +50 °C 2

During storage -25… +70 °C -25… +70 °C

Altitudes

Maximum altitude 4000 m 3 4000 m 3

Degree of protection

Main circuit IP10 (PST30 ... 72) IP00 (all)

IP00 ( PST85 ... 300)

Supply and Control circuit IP20 IP20

Main circuit

Built in By-pass contactor No Yes

Cooling system - Fan cooled

(thermostat controlled) Yes Yes

Supply circuit

Control voltage – one range 100 ... 250 V 100 ... 250 V

+10% / -15% +10% / -15%

50/60 Hz 50/60 Hz

± 5% ± 5%

HMI for settings

(Human Machine Interface)

20 segment display Yes Yes

Keypad with two selection

keys and two navigating keys Yes Yes

Plain text in 12 languages

(English, German, Italian,

Chinese, Finnish, Swedish,

French, Spanish, Dutch,

Russian, Turkish & Portuguese) Yes Yes

Remote HMI for settings (PSTEK)

(Human Machine Interface)

20 segment display Yes Yes

Keypad with two selection

keys and two navigating keys Yes Yes

Plain text in 12 languages

(English, German, Italian,

Chinese, Finnish, Swedish,

French, Spanish, Dutch,

Russian, Turkish & Portuguese) Yes Yes

Approvals:

Upload Parameters Yes Yes

Download Parameters Yes Yes

UL, Type 1, 12, 4/4X

r

500% for 30 sec 500% for 30 sec

PST30 – 300 PSTB370 – 1050

Signal relays

Number of programmable

signal relays (Each relay can

be programmed to be Run,

By-pass or Event signal) 3 3

K4 – Default as Run signal Yes Yes

K5 – Default as By-pass signal Yes Yes

K6 – Default as Event signal Yes Yes

Rated operational voltage Ue 250 V 250 V

Rated thermal current Ith 5 A 5 A

Rated operational current Ie

at AC-15 (Ue = 250 V) 1.5 A 1.5 A

Control circuit /Hardware inputs

Internal 24 V DC (10 mA closed) Yes Yes

Start / Stop inputs Yes Yes

Two extra programmable

inputs (Each input can be

programmed to be None, Reset,

Enable, Jog, DOL or

Start motor 2 (or 3)). Yes Yes

Signal indication LED’s

Run power on – Green Yes Yes

Fault - Red Yes Yes

Protection - Yellow Yes Yes

Protections

Electronic overload Yes Yes

Adjustable tripping classes -

Class 10 A, 10, 20 and 30 Yes Yes

Dual ramp (separate overload

function for start and run) Yes Yes

PTC connection Yes Yes

Locked rotor protection Yes Yes

Underload protection Yes Yes

Phase imbalance Yes Yes

High current (8 x I

Phase reversal protection Yes Yes

Warnings (pre-warning)

High current Yes Yes

Low current (underload) Yes Yes

Overload trip Yes Yes

Overtemp. thyristors (SCR) Yes Yes

Start of several motors

Possible to set up and start

three different motors Yes Yes

Field bus connection

Connection for

ABB FielBusPlug Yes Yes

AS-I (option cable) Yes Yes

DeviceNet (option cable) Yes Yes

Profi bus DP (option cable) Yes Yes

) Yes Yes

e

PSTB Integrated bypass ratings

PSTB370 PSTB470 PSTB570 PSTB720 PSTB840 PSTB1050

Contactor type AF260 AF300 AF400 AF580 AF750 AF750

AC3 Rating @ 480V HP 200 250 350 500 600 600

AC3 Rating A 248 302 414 590 720 720

1 Valid for 50 % on time and 50 % off time, with 3.5 x Ie for 7 seconds. If other data is required, please contact your sales offi ce

2 Above 40 ºC up to max. 50 ºC reduce the rated current by 0.8 % per ºC.

3 When used at high altitudes above 1000 meters, consult factory.

6.34 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

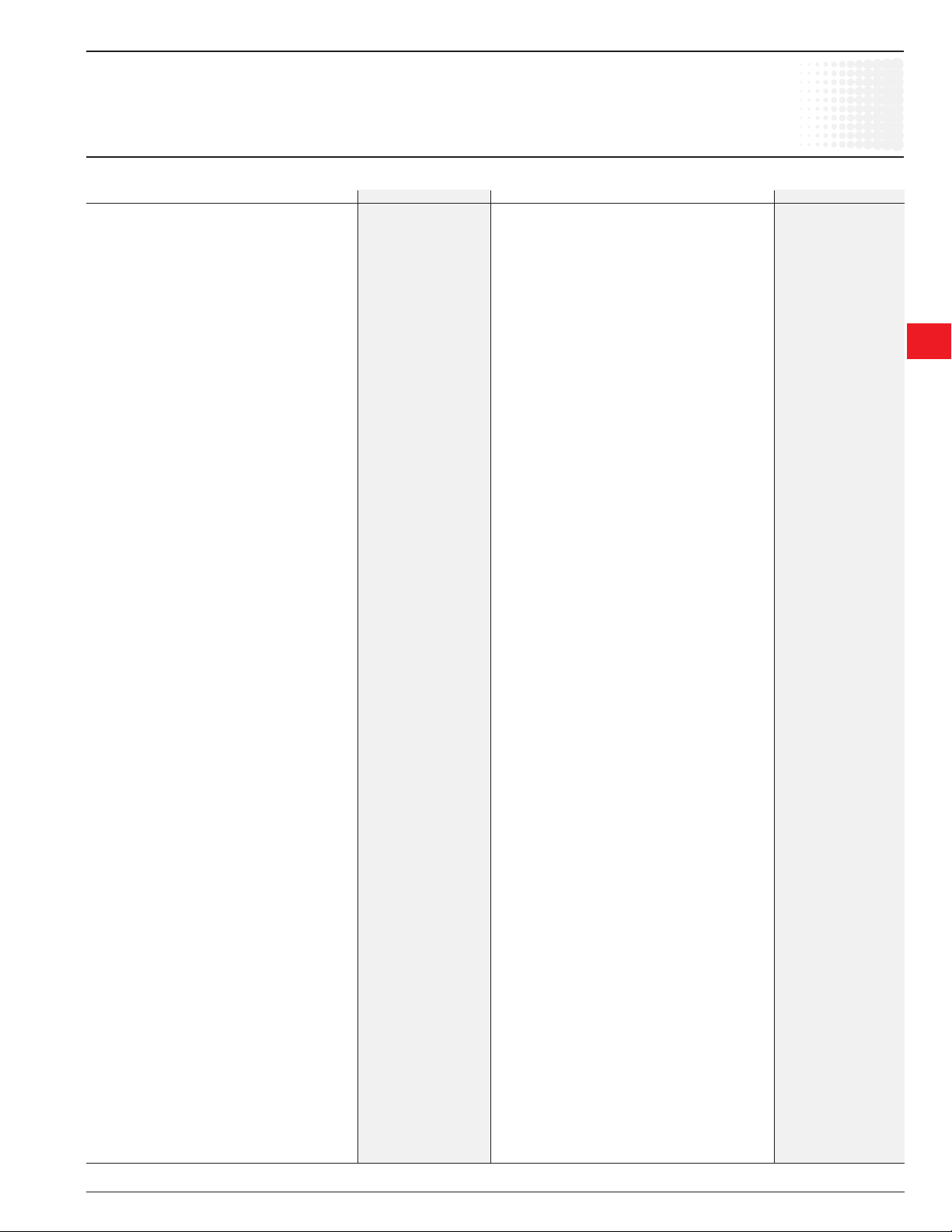

Technical data

Softstarters

Type PST

Display settings

6

Major possible settings and the displayed text and the set default values

Description Text on display (Eng) Values on display Default value

Motor FLA Setting Ie 9.0 ...1380 A divided into 19 overlapping ranges. See table, page 6.38

Time for start ramp Start Ramp 1 ... 30 s, 1 ... 120 s (Range depends on Start Range) 10 s

Time for stop ramp Stop Ramp 0 ... 30 s, 0 ... 120 s (Range depends on Stop Range) 0 s

Initial voltage for start ramp Init Volt 30 ... 70 % 30 %

End voltage for stop ramp End Volt 30 ... 70 % 30 %

Step down voltage Step Down 30 ...100 % 100 %

Level of the current limit. Current Lim 2.0 ... 5.0 x Ie 4.0 x I

Selection of Kick start Kick Start Yes, No No

Level of Kick start if selected Kick Level 50 ... 100 % 50 %

Time for Kick start if selected Kick Time 0.1 ... 1.5 s 0.2

Selectable range for start ramp Start Range 1 ... 30 s, 1...120 s 1 ... 30 s

Selectable range for stop ramp Stop Range 0 ... 30 s, 0 ... 120 s 0 ... 30 s

Overload protection Overload No, Normal, Dual Normal

Overload Class OL Class 10A, 10, 20, 30 10

Overload Class, Dual type, Start Class OL Class S 10A, 10, 20, 30 10

Overload Class, Dual type, Run Class OL Class R 10A, 10, 20, 30 10

Type of operation for overload protection OL Op Stop-M, Stop-A, Ind Stop-M

Locked rotor protection Locked Rotor Yes, No No

Trip level for locked rotor protection Lock R Lev 3.0 ... 8.0 x I

Trip time for locked rotor protection Lock R Time 0.2 ... 10 s 1.0 s

Type of operation for locked rotor protection Lock R Op Stop-M, Stop-A, Ind Stop-M

Underload protection Underload Yes, No No

Trip level for Underload protection Underl Lev 0.4 ... 0.8 x I

Trip time for Underload protection Underl Time 1...30 s 10 s

Type of operation for Underload protection Underl Op Stop-M, Stop-A, Ind Stop-M

Phase imbalance protection Phase Imb Yes, No No

Trip level for phase imbalance protection Ph Imb Lev 10...80 % 80 %

Type of operation for phase imbalance protection Ph Imb Op Stop-M, Stop-A, Ind Stop-M

High current protection High I Yes, No No

Type of operation for high current protection High I Op Stop-M, Stop-A, Ind Stop-M

Phase reversal protection Phase Rev Yes, No No

Type of operation for phase reversal protection Ph Rev Op Stop-M, Stop-A, Ind Stop-M

PTC protection PTC Yes, No No

Type of operation for PTC protection PTC Op Stop-M, Stop-A Stop-M

An external Bypass contactor is used Ext ByPass Yes, No No

High current warning Warn I=High Yes, No No

Trip level for high current warning Wa I=H Lev 0.5 ... 5.0 x Ie 1.2 x I

Low current warning Warn I=Low Yes, No No

Trip level for low current warning Wa I=L Lev 0.4 ...1.0 x Ie 0.5 x I

Overload warning Warn OL Yes, No No

Trip level for overload warning Wa OL Lev 40...99 % 90 %

Thyristor overload warning Warn SCR OL Yes, No Yes

Type of operation for phase loss fault Ph Loss Op Stop-M, Stop-A Stop-M

Type of operation for by-pass fault BP Fault Op Stop-M, Stop-A, Ind Stop-M

Type of operation for fi eldbus fault FB Fault Op Stop-M, Stop-A Stop-M

Type of operation for frequency fault Freq F Op Stop-M, Stop-A Stop-M

Type of operation for heat sink over temperature fault HS Temp Op Stop-M, Stop-A Stop-M

Type of operation for thyristor short circuit fault SCR SC Op Stop-M, Stop-A Stop-M

Function of programmable input In_0 In0 None, Reset, Enable, Jog, DOL, Start 2 Reset

Function of programmable input In_1 In1 None, Reset, Enable, Jog, DOL, Start 3 Reset

Function of programmable relay output K4 Relay K4 Run, TOR, Event Run

Function of programmable relay output K5 Relay K5 Run, TOR, Event TOR

Function of programmable relay output K6 Relay K6 Run, TOR, Event Event

Control of the softstarter with fi eldbus Fieldb Ctrl Yes, No No

Number of sequences for sequence start. No of Seq No, 2, 3 No

st

sequence, time for start ramp Start Ramp1 1...30 s, 1...120 s (Range depends on Start Range) 10 s

1

st

1

sequence, initial voltage for start ramp Init Volt1 30...70 % 30 %

st

sequence, current limit Curr Lim1 2.0 ... 5.0 x Ie 4.0 x I

1

1st sequence, setting current 1st Set Ie 9.0 ... 1380 A divided into 19 overlapping ranges See table, page 6.38

2nd sequence, time for start ramp Start Ramp2 1...30 s, 1...120 s (Range depends on Start Range) 10 s

nd

sequence, initial voltage for start ramp Init Volt2 30...70 % 30 %

2

nd

2

sequence, current limit Curr Lim2 2.0 ... 5.0 x Ie 4.0 x I

2nd sequence, setting current 2nd Set Ie 9.0 ... 1380 A divided into 19 overlapping ranges See table, page 6.38

4.0 x I

e

0.8 x I

e

e

e

e

e

e

e

e

6

Low Voltage Products & Systems 6.35

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Loading...

Loading...