Page 1

Data sheet

Power Supply CP-C.1 24/20.0

High-performance primary switch mode power supply

The CP-C.1 power supplies are ABB’s highperformance and most advanced range. With

excellent efficiency, high reliability and innovative

functionality it is prepared for the most demanding

industrial applications. These power supplies have

a 50 % integrated power reserve and operate at

an efficiency of up to 94 %. They are equipped

with overheat protection and active power factor

correction. Combinded with a broad AC and DC

input range and extensive worldwide approvals

the CP-C.1 power supplies are the preferred

choice for professional DC applications.

Giving the power to control.

2CDC 271 004 V0015

Characteristics

– Rated output voltage 24 V DC

– Power reserve design delivers up to 150 % at Ta ≤ 40 °C

– Output voltage adjustable via front-face rotary

potentiometer “OUTPUT Adjust”, 22.5-28.5 V

– Input voltage range 100-240 V AC, 90-300 V DC

– High efficiency

– Low power dissipation and low heating

– Free convection cooling (no forced cooling)

– Ambient temperature range during operation -25...+70 °C

– Open-circuit, overload and short-circuit stable

– Integrated input fuse

– DC OK - signaling output "13-14" (Relay),

Power reserve signaling output "I > IR (Transistor)

– Redundancy unit CP-A RU offering true redundancy,

available as accessory

Ordering details - CP-C.1

Input voltage range Rated output voltage / current Typ e Order code Weight (1 pce)

100-240 V AC, 90-300 V DC 24 V DC / 20 A CP-C.1 24/20.0 1SVR360763R1001 2.83 (6.23)

Approval

SEMI F47

Marks

CE

a

kg (lb)

Related products

Description Redundancy unit Typ e Order code Weight (1 pce)

kg (lb)

2 inputs each up to 20 A and 1 output up to 40 A

40 V and M 5 A

CP-A RU 1SVR427071R0000 0.89 (1.96)

Page 2

Table of contents

Characteristics ...................................................................1

Ordering details - CP-C.1 ...................................................1

Marks ..................................................................................1

Abbreviations ......................................................................2

Functions ............................................................................3

Application..........................................................................3

Power reserve .....................................................................3

Signaling output .................................................................3

Adjustable output voltage ...................................................3

LED and relay state table....................................................4

LEDs and signaling outputs ................................................4

Operating mode ..................................................................5

Parallel operation ...............................................................5

Parallel connection of power supplies for increased power ...5

Parallel connection of power supplies for redundancy ..........6

Mounting .............................................................................7

Mounting positions .............................................................7

Mounting CP-C.1 in position 7 ............................................7

Derating of output current for position 1 ..............................8

Electrical connection .........................................................8

24 and 48 V DC connection ................................................9

Connection to TN, TT networks ..........................................9

Safety instructions and warnings .......................................10

Attention! Danger to life! .....................................................10

Technical data.....................................................................11

Input circuit - Supply circuit ................................................11

User interface ....................................................................11

Output circuit - Power output .............................................11

Signaling outputs ...............................................................12

General data ......................................................................12

Electrical connection ..........................................................12

Environmental data .............................................................13

Isolation data .....................................................................13

Standards ..........................................................................13

Electromagnetic compatibility .............................................14

Technical diagrams .............................................................15

Efficiency diagrams ............................................................15

Characteristic curve of output .............................................16

Characteristic curve of temperature.....................................16

Dimensions .........................................................................17

Further documentation .......................................................17

Abbreviations

MCB - Miniature circuit breaker

AC - Alternating current

DC - Direct current

LED - Light emitting diode

L - Line

N - Neutral

PE - Protective earth

PLC - Programmable logic controller

DIN - Deutsche Industrie Norm

PELV - Protective extra low voltage

TN - Terre neutre (neutral grounded)

TT - Terre terre (grounded network)

IT - Isolé terre (isolated network)

VDE - Verein Deutscher Elektrotechniker

IP20 - international protection code

AWG - American wire gauge

IEC - International electrotechnical comission

UL - Underwriters laboratories

EN - Europäische Norm

SELV - Safety extra low voltage

EMC - Electromagnetic compatibility

SEMI - Semiconductor equipment materials international

FCC - Federal communication comission

CISPR - Comité international spécial des perturbations radioélectriques

CSA - Canadian standards association

2 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 3

Functions

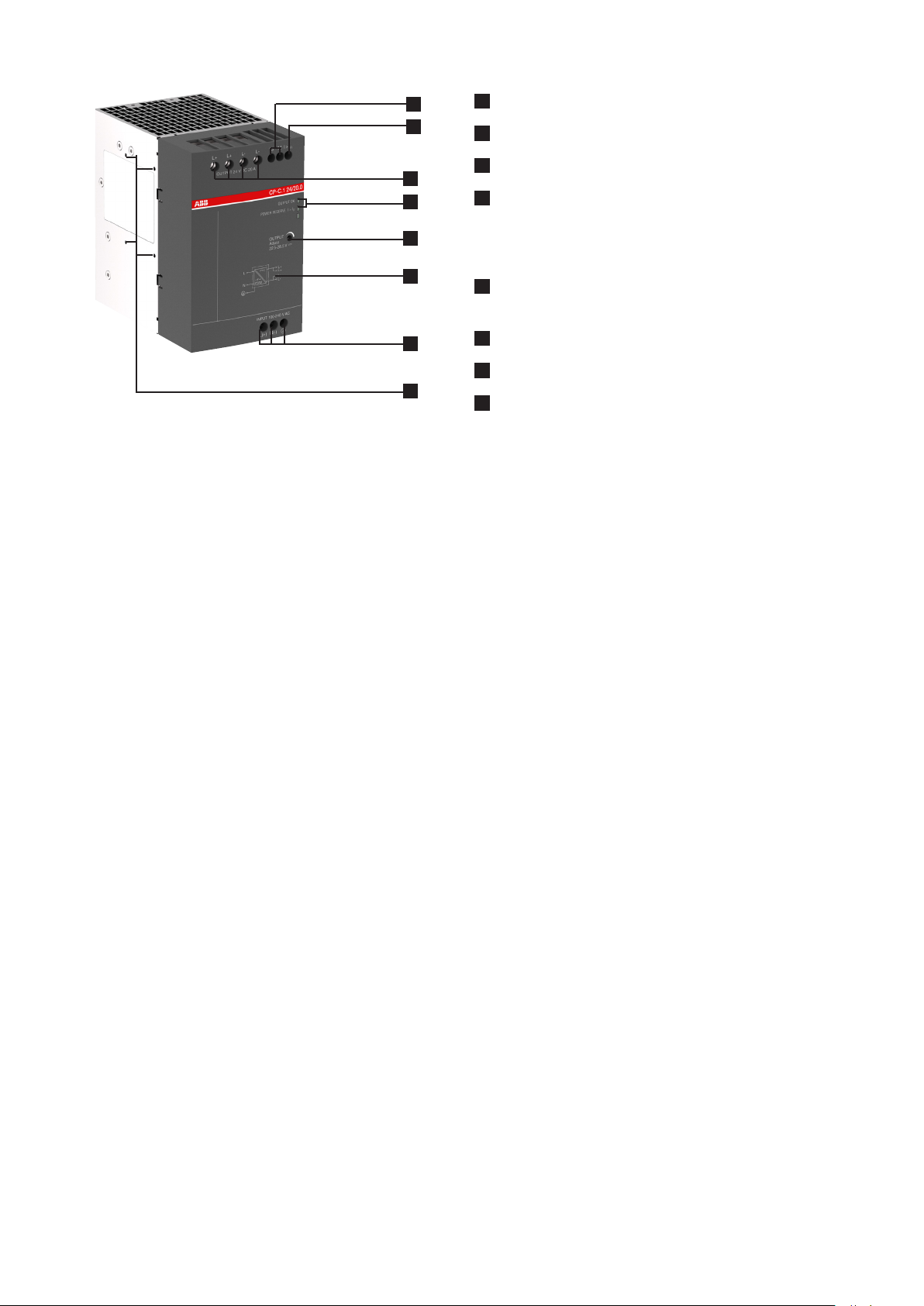

1

2

3

4

5

6

2CDC 271 004 V0015

7

8

1

13-14: Relay output to signal output OK

2

I > IR: Power reserve transistor output

3

OUTPUT L+, L-: Output terminals

4

Indication of operational states

OUTPUT OK: Green LED

POWER RESERVE I > IR: Yellow LED

5

OUTPUT Adjust: Rotary potentiometer -

Adjustment of output voltage 22.5 - 28.5 V DC

6

Circuit diagram

7

INPUT L(+), N(-), o /PE: Input terminals

8

Side mounting screw holes for DIN rail adapter / lateral mounting

Application

The primary switch mode power supply CP-C.1 has a wide AC or DC input voltage range. Furthermore the CP-C.1 is

equipped with capacitors that ensure a hold-up time of at least 40 ms. This enables worldwide usage and permits safe

operation in fluctuating networks and battery-powered applications.

The CP-C.1 has a robust metallic housing and a reliable construction which enables usage in harsh industrial environments.

The power reserve of up to 50 % enables trouble-free starting of heavy loads eliminating the need of usage of an oversized

power supply.

Power reserve

The primary switch mode power supply CP-C.1 is equipped with a power reserve functionality to handle the start-up of

particulary heavy loads (e.g. of a capacitive load or a motor). To ensure that heavy loads are started up, the CP-C.1 delivers

additionally up to 50 % of the rated output current to secure the operation of the application. This status is displayed by the

yellow LED labelled POWER RESERVE I > IR.

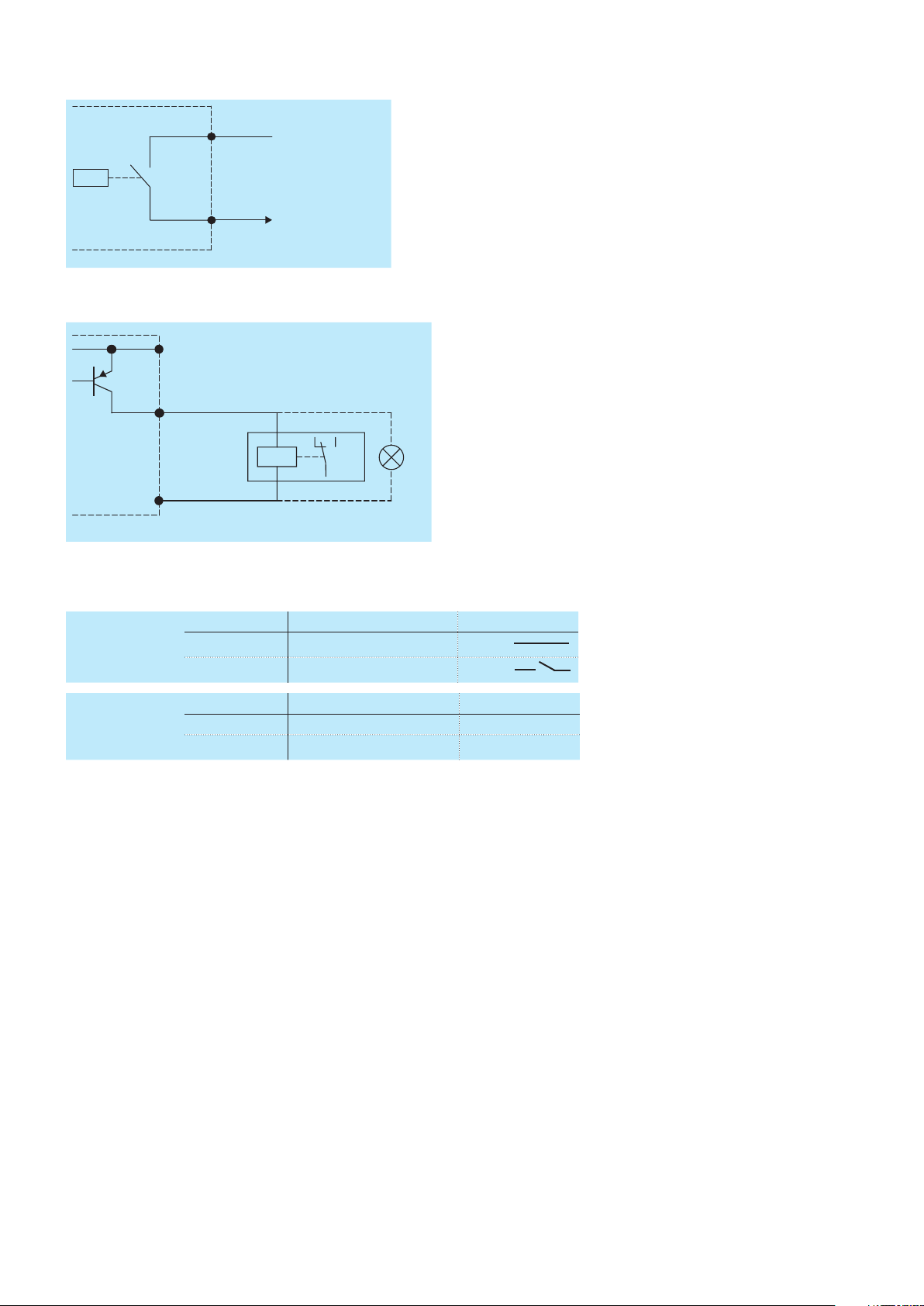

Signaling output

For the communication of the status of the power supply the CP-C.1 is equipped with a relay output to signal output OK as

well as a transistor output to indicate when the power reserve is active. These signals can be used for communication to a

higher level control system e.g. a PLC.

Adjustable output voltage

The CP-C range power supplies feature a continuously adjustable output voltage of 22.5 to 28.5 V DC. Thus they can be

optimally adapted to the application, e.g. compensating the voltage drop caused by a long line length.

Data sheet | Power Supply CP-C.1 24/20.0 - 3

Page 4

LED and relay state table

A

CP-C.

L+

CP-C.

13

max. 30 V AC, 0.5

max. 24 V DC, 1 A

(resistive load)

1

Output OK - relay output

14

Load 20 mA

I > I

R

1

Power reserve - transistor output

L-

L+

Load

2CDC 272 013 F0015

2CDC 272 014 F0015

LEDs and signaling outputs

Output voltage Output OK: LED green Relay 13-14

M 92 % of U

< 90 % of U

Output current Power reserve: LED yellow Transistor I>I

out

V

out

Z

OFF ON (closed)

II

R

I>I

R

V

Closed

Open

R

OFF (open)

It is possible to use the messaging and signaling functionality with power supplies connected in parallel.

The parallel operation has no influence on the function.

4 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 5

Operating mode

Parallel operation

There are two main reasons for a parallel connection of power supplies:

– Increase of power

– Redundancy

Up to 5 devices of the same type can be connected in parallel. For safe and reliable operation it is important to follow the

recommendations given in the following section.

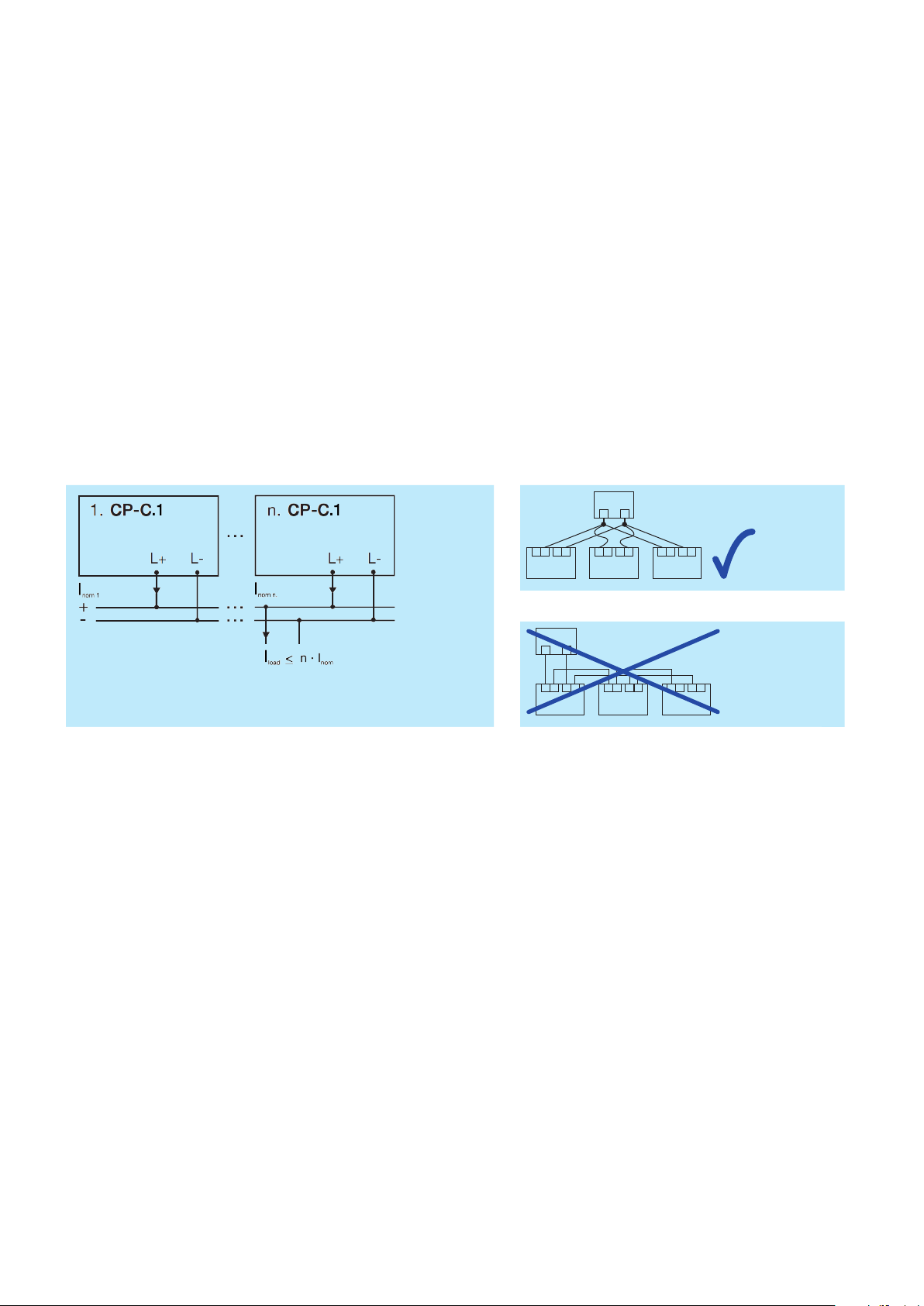

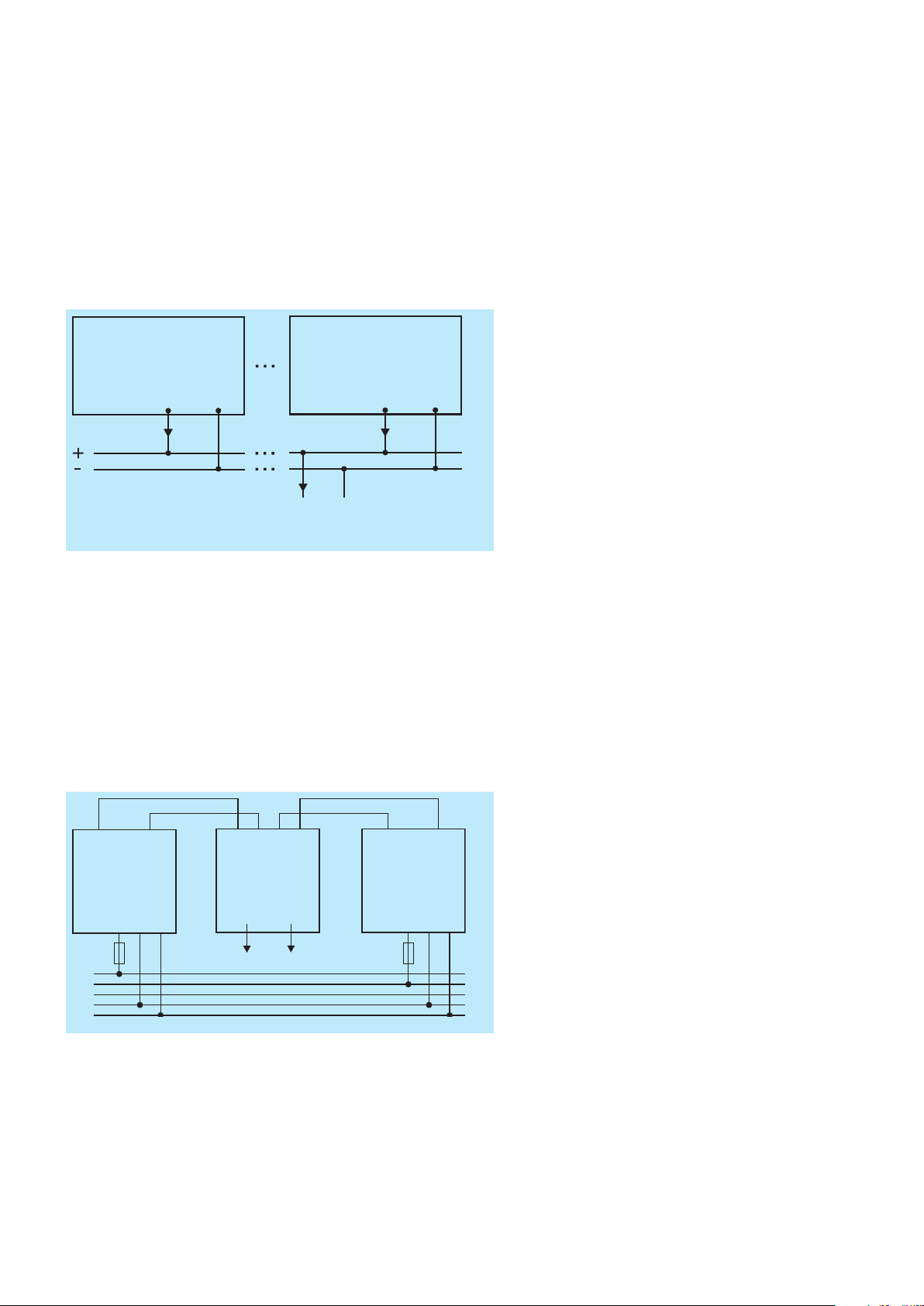

Parallel connection of power supplies for increased power

If the current required by the load is higher than a single power supply can deliver, for example after the expansion of

an existing installation, an increase of the output power can be obtained by connecting power supplies in parallel. The

following prerequisites have to be fulfilled when connecting power supplies in parallel for the purpose of increased power:

– The paralleled devices must be of the identical type.

– Repeated voltage drops on the supply lines or at the terminals would lead to unbalanced load at the common connection

point. To prevent this, you have to observe the following when connecting the power supply units:

– Identical lengths of the load supply lines.

– Identical conductor cross sections of the load supply lines.

– Terminal screws have to be fastened with the same torque to guarantee equal contact resistances.

– The output voltages of the power supplies must not differ by more than 50 mV. Otherwise, safe operation is not

possible.

load

+ -

-+ -+ -+ -+ -+ -+

1. CP-C.1 2. CP-C.1 3. CP-C.1

2CDC 272 002 F0015

Correct wiring for increased power

load

-+

-+ -+ -+ -+ -+ -+

2CDC 272 001 F0015

3. CP-C.12. CP-C.11. CP-C.1

2CDC 272 003 F0015

Installation for increased power Incorrect wiring for increased power

Important:

The devices must not be connected directly to each other! This could lead to an overload of the terminals since the

terminals are dimensioned for the maximum output current of a single power supply only. Always use a common connection

point!

Data sheet | Power Supply CP-C.1 24/20.0 - 5

Page 6

Parallel connection of power supplies for redundancy

PE

Several power supplies are connected in parallel in order to guarantee continuous operation of the system if one power

supply fails. CP-C.1 can be used in two different redundancy modes depending on what type of redundancy is required:

– Simple redundancy, n+1

– True redundancy

Simple redundancy, n+1 redundancy

For simple or n+1 redundancy, the power supplies are connected in parallel like for the increase of capacity. To achieve

redundancy the current required by the load must not exceed the maximum output power of one single power supply (in

case of “1+1 redundancy”) or n power supplies (where n is max. 4).

We recommend connecting the primary sides of the power supplies to different phases of the mains in order to obtain

continuous operation of the system if one phase fails.

CP-C.11. n. CP-C.1

L+ L+L- L-

I

r1

Simple redundancy or n+1 setup

I

(n-1) * I

Load

I

rn

r

2CDC 272 005 F0215

True redundancy

True redundancy gives higher system availability compared to simple or n+1 redundancy.

In a true redundancy setup the power supplies are decoupled from each other with decoupling diodes. This protects the

individual power supplies from affecting each other in case of failure of one unit or short cirucit on the secondary side or in

the wiring.

For two inputs of up to 20 A and one output up to 40 A the ABB redundancy unit CP-A RU (available as an accessory) can

be used.

The inputs of these units are connected to the terminals L+ and L- of the power supplies. The loads are supplied directly

from the outputs of the redundancy unit.

L+ L+L- L-

CP-C.1 CP-C.1

LNPE LNPE

++--

INPUT 1INPUT 2

CP-A RU

OUTPUT

+-+-

L1

L2

L3

N

True redundancy using a CP-A RU redundancy unit

6 - Power Supply CP-C.1 24/20.0 | Data sheet

Load

2CDC 272 006 F0215

Page 7

Mounting

Position 5

Position 7

Position 2

Position 4

Position 3

Position 1

To mount the power supply place the upper edge of the DIN rail adapter on the upper edge of the DIN rail holding the unit

slightly tilted upwards as shown in the illustration. Then tilt the unit down until the latch snaps onto the DIN rail.

2CDC 273 002 F0015

Mounting positions

2CDC 272 001 F0016

In order to ensure a sufficient convection in mounting position 1, the minimum distance to other modules must not be less

than 25 mm in vertical direction and 25 mm in horizontal direction. Details for other mounting positions on request.

Mounting CP-C.1 in position 7

To mount the power supply in position 7

remove the DIN rail adapter that is fastened

with 4 screws and attach it on the side of the

power supply.

Screwdriver: Torx T10

Tightening torque: 0.7 w0.1 Nm

2CDC 273 005 F0015

2CDC 273 008 F0015

Data sheet | Power Supply CP-C.1 24/20.0 - 7

Page 8

Derating of output current for position 1

Ambient temperature [°C]

Output current [A]

L+ L+ L-

LN

o

L-

L-

L+

L

N

PE

PWM

2CDC 272 014 F0b04

32

28

24

20

I

R

Power reserve

16

12

8

4

0

-25 -10 0

10 20 30 40 50 60 70

2CDC 272 022 F0015

Deratings for other mounting positions on request.

Demounting

To release the power supply pull the latching lever downwards with a screwdriver and press the upper side of the the

latching lever down. The device can be unhinged from the DIN rail and removed.

Electrical connection

Connect the input terminals "L“ to line and "N" to neutral conductor or to + and - with DC supply "+" to "L" and "-" to

"N". The protective earth conductor PE must be connected before putting the device into operation. The installation must

be executed acc. to EN 60950. Provide a suitable disconnecting device (e. g. line protection switch, MCB or fuse) in the

supply line. The input side of the power supply is protected by an internal input fuse.

The wiring, cable choice and their protection shall comply to the local electrical standard. We recommend choosing the

conductor cross-section as large as possible in order to minimize voltage drops. Check the polarity. The device is overload,

short-circuit and open-circuit proof. The secondary side of the power supply is electrically isolated from the input and

internally not earthed (SELV) and can be earthed for PELV.

Connection diagram

L+, L- Output voltage

L, N Input voltage

o

2CDC 272 014 F0004

2CDC 273 003 F0015

Protective earth (PE)

8 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 9

24 and 48 V DC connection

-24 V

+24 V

48 V

+

CP-C.1

CP-C.1

+

N

N

The connection diagram below shows how to setup two power supplies for +/-24 or 48 V DC output voltage.

2CDC 272 012 F0015

Connection diagram for +/-24 or 48 V DC output voltage

Connection to TN, TT networks

The user must refer to and the installation comply with local electrical codes.

The power supply can be connected to electrical supply systems with various earthing systems according to the diagrams

below.

Earth

CP-C.1

LNPE

L

N

PE

2CDC 272 xxx xxxx

CP-C.1

LNPE

TN-S 1-phase DC source, e.g. battery

CP-C.1

LNPE

L

PE

Earth

2CDC 272 xxx xxxx

TN-C 1-phase TT 1-phase

L

2CDC 272 xxx xxxx

CP-C.1

LNPE

L

N

EarthEarth

2CDC 272 xxx xxxx

In AC networks the input voltage range is defined by -15...+10 % of the rated input voltage. However, in DC networks the

rated input voltage is equal to the input voltage range.

Data sheet | Power Supply CP-C.1 24/20.0 - 9

Page 10

Safety instructions and warnings

In operation pay attention to:

– Do not modify the installation (primary and secondary side)! High current! Risk of electric

arcs and electric shock (danger to life)!

– Risk of burns: Depending on the operation conditions the housing can become hot.

– The device contains no user serviceable parts. In any case of device malfunction please

send the unit back to manufacturer.

The device must be installed by qualified persons only and in accordance with the specific

national regulations (e. g. VDE, etc.).

The CP-C.1 is a chassis-mounted unit. It is maintenance-free and does not contain any

integral setting elements and should therefore not be opened.

Before any installation, maintenance or modification work:

– Read the operating and installation instructions carefully and completely!

– Disconnect the system from the supply network and protect against switching on!

Before start of operation the following must be ensured:

– Connection to mains or DC supply according to the specific national regulations for class

of protection I.

– Power supply cables and unit must be sufficiently fused. A disconnecting device has to

be provided for the end product to disengage unit and supply cables from supply mains

if required.

– The protective earth conductor must be connected to the terminal PE.

– Rate the output lines for the output current of the power supply and connect them with

the correct polarity.

– In order to ensure sufficient convection the distance to the other devices has to be

considered.

Attention! Improper installation/operation may impair safety of personnel and cause

operational difficulties or destruction of the unit.

Attention! Danger to life!

Disconnect the system from the supply network before executing any works at the device

and protect against switching on! The power supply contains components with high stored

energy and circuits with high voltage! Do not introduce any objects into the unit and do not

open the unit.

With some units of this range the output is capable of providing hazardous energy. Ensure

that the service personnel is protected against inadvertent contact with parts carrying

energy.

If the internal fuse is blown most probably the device is defect. In this case an examination

of the device by the manufacturer is necessary.

10 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 11

Technical data

Data at Ta = 25 °C, Uin = 230 V AC and rated values, typical values unless otherwise indicated

Input circuit - Supply circuit

L (+), N (-)

Rated input voltage U

in

Input voltage range AC 85-264 V AC

Typical input current at 115 V AC

at 230 V AC

Typical power consumption at 230 V AC

Rated frequency AC

Frequency range

Inrush current limiting, cold state

Let-trough energy I2t , cold state at 230 V AC

Discharge current towards PE

Hold-up time at 115 V AC

at 230 V AC

Internal input fuse

Recommended backup fuse for wire protection at

2

1.5 mm

characteristic

max. rating

Power factor correction (PFC)

Transient overvoltage protection

100-240 V AC, 90-300 V DC

DC 90-300 V DC

4.6 A

2.3 A

508 W

DC, 50/60Hz

45-65 Hz

< 30 A

< 3.5 mA

min. 40 ms

min. 40 ms

T12A, not exchangeable

1 pole miniature circuit breaker ABB type S 200

B or C

16 A

yes, active

yes, varistor

User interface

Indication of operational states

Output voltage LED ‘OUTPUT OK ‘ (green) ON 92 % adjusted U

Flashing 90 % adjusted U

Power reserve LED ‘I > IR’ yellow OFF I ≤ I

ON I > I

R

R

out

out

Output circuit - Power output

L+, L-

Rated output voltage 24 V DC

Tolerance of the output voltage ± 1 %

Adjustment range of the output voltage 22.5-28.5 V DC

Rated output power 480 W

Rated output current I

Reserve output current

R

- 25 °C Ta 60 °C

- 25 °C Ta 40 °C

Short-circuit current limiting 27.7 A

Derating of the output current

60 °C < Ta 70 °C

Deviation width of output voltage load change statical

10- 90 %

dynamical 0-100 % < 5%, class B acc. to IEC/EN 61204

change of input voltage

within the rated input

voltage

Control time at rated load < 0.1 %, class A acc. to IEC/EN 61204

Starting time after applying the supply voltage at rated load < 500 ms, class C acc. to IEC/EN 61204

with 3500 µF

Rise time at rated load < 10 ms

with 3500 µF

Fall time < 20 ms

Residual ripple and switching peaks BW = 20 MHz < 120 mVpp, class A acc. to IEC/EN 61204

Parallel connection yes, up to 5 devices, to enable redundancy and to

Series connection yes, max. 2 devices to increase voltage

20 A

26.0 A continuously

3.5 %/°C

< 1 %, class C acc. to IEC/EN 61204

< 5 ms, class B acc. to IEC/EN 61204

increase power, current not symmetrical

Data sheet | Power Supply CP-C.1 24/20.0 - 11

Page 12

No-load, overload and short-circuit behavior

Characteristic curve of output U/I characteristic curve with power reserve

Short-circuit protection continuous short-circuit stability

Short-circuit behavior current limiting

Resistance to reverse feed ≤ 35 V DC

Overload protection constant current limitation

Overtemperature protection protection by switch off in case of overtemperature

(thermal protection), automatic restart

No-load protection continuous no-load stability

Starting of capacitive loads yes

Signaling outputs

OUTPUT OK signaling output

Type of output 13 -14 relay, n/o contact

ON (contact closed) 92 % adjusted U

OFF (contact open) 90 % adjusted U

Contact ratings max. switching voltage / current 30 V AC - 0.5 A / 24 V DC - 1 A (resistive load)

min. switching voltage / current 5 V DC / 1 mA

POWER RESERVE signaling output

Type of output I > IRtransistor, short-circuit proof

Active / ON (closed) I > I

Inactive / OFF (open) I ≤ I

R

R

Ratings voltage/current 24 V DC / ≤ 20 mA

out

out

General data

Efficiency at rated output power up to 94 %

Power loss at rated output power 28 W

at 50% of rated output power 17 W

at no load < 3.6 W

Duty time 100%

MTBF acc. to MIL 217 HDBK on request

Dimensions see ‘Dimensions’ on page 17

Net weight see ‘Ordering details - CP-C.1’ on page 1

Material of housing cover zinc-coated sheet-steel

housing shell aluminium

front plastic, PA6, V-0

Mounting DIN rail (EN 60715), snap-on mounting without any tool

Mounting position 1,7

Minimum distance to other units horizontal 25 mm (0.98 in)

ver tica l 25 mm (0.98 in)

Degree of protection (IEC/EN 60529) housing / terminals IP20 / IP20

Protection class (EN 61140) I

Electrical connection

Input circuits (L(+), N(-), o/PE)

Connection capacity rigid 0.5-4.0 mm² (20-10 AWG)

fine-strand with(out) wire end ferrule 0.5-2.5 mm² (20-12 AWG)

Stripping length 8 mm (0.315 in)

Tightening torque 0.5 Nm (4.4 lb.in)

Recommended screw driver PH2 / Ø 4.0 x 0.8 mm

12 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 13

Output circuits (L+, L+, L-, L-)

Connection capacity rigid 2.5-16.0 mm² (12-6 AWG)

fine-strand with(out) wire end ferrule 2.5-10 mm² (12-8 AWG)

Stripping length 10 mm ( 0.394 in)

Tightening torque 1.2 Nm (10.5 lb-in)

Recommended screw driver PH2 / Ø 4.0 x 0.8 mm

Signaling output (13-14, I > IR)

Connection capacity rigid 0.5-4.0 mm² (20-10 AWG)

fine-strand with(out) wire end ferrule 0.5-2.5 mm² (20-12 AWG)

Stripping length 8 mm (0.315 in)

Tightening torque 0.5 Nm (4.4 lb.in)

Recommended screw driver PH2 / Ø 4.0 x 0.8 mm

Environmental data

Ambient temperature range operation -25…+70 °C (-13 ... +158 °F)

rated output power -25...+60 °C (-13 ... +140 °F)

storage -40…+85 °C (-40 ...+185 °F)

transportation -40…+85 °C (-40 ...+185 °F)

Climatic class (IEC/EN 60721-3-1) storage

Climatic class (IEC/EN 60721-3-2) transportation

Climatic class (IEC/EN 60721-3-3) operation 3K3 (-25…+70 °C / -13 ... +158 °F)

Damp heat, cyclic (IEC/EN 60068-2-30) Test Db: 55°C, 2 cycles

Vibration, half-sine (IEC/EN 60068-2-6)

Shock, half-sine (IEC/EN 60068-2-27)

Altitude without restriction 2000 m

Isolation data

Rated impulse withstand voltage U

Rated insulation voltage Ui (EN 50178) input circuit / output circuit 300 V

Overvoltage category (EN 50178) < 2000m III

Overvoltage category (IEC/EN 60950-1) < 2000m II

Pollution degree (IEC/EN 60950-1; EN 50178) 2

Test voltage, type test (IEC/EN 60950-1) input circuit / output circuit 4.24 kV DC

Test voltage, routine test input circuit / output circuit 1.5 kV AC

Protective separation (IEC/EN 60950-1) input circuit / output circuit Yes

(EN 50178) input circuit / output circuit 4 kV (1.2/50 µs)

imp

input circuit / PE 4 kV (1.2/50 µs)

input circuit / relay contact 4 kV (1.2/50 µs)

output circuit / relay contact 0.5 kV (1.2/50 µs)

relay contact / PE 0.5 kV (1.2/50 µs)

output circuit / PE 0.5 kV (1.2/50 µs)

input circuit / PE 300 V

input circuit / relay contact 300 V

output circuit / relay contact 50 V

relay contact / PE 50 V

output circuit / PE 50 V

2000…5000m II

2000…5000m I

input circuit / PE 2.12 kV DC

relay contact / output circuit 0.707 kV DC

output circuit / PE 0.707 kV DC

input circuit / PE 1.5 kV AC

relay contact / output circuit 1.5 kV AC

output circuit / PE 0.5 kV DC

input circuit / relay contact Ye s

Data sheet | Power Supply CP-C.1 24/20.0 - 13

Page 14

Standards

Product standard IEC/EN 61204

Low Voltage Directive 2006/95/EC (valid until 19 April 2016) /

EMC directive 2004/108/EC (valid until 19 April 2016) /

RoHS directive 2011/65/EC

Electrical safety IEC/EN 60950-1

Industrial control equipment UL 508 / CSA 22.2 No 107.1

Electronic equipment for use in power installations EN 50178

Protective extra low voltage PELV (EN 50178)

Safety extra low voltage SELV (IEC/EN 60950-1)

Limitation of harmonic line currents IEC/EN 61000-3-2

2014/35/EU (valid from 20 April 2016)

2014/30/EU (valid from 20 April 2016)

Electromagnetic compatibility

Low-voltage power supplies, d.c. output – Part 3:

Electromagnetic compatibility (EMC)

Interference immunity to IEC/EN 61000-6-1 and IEC/EN 61000-6-2

electrostatic discharge (ESD) IEC/EN 61000-4-2 Level 4, 8 kV / 15 kV

radiated, radio-frequency, electromagnetic field IEC/EN 61000-4-3 Level 3, 10 V/m

electrical fast transient / burst IEC/EN 61000-4-4 Level 4, 4 kV

surge IEC/EN 61000-4-5 Level 3: L-N 2 kV , Level 4: L/N-PE 4 kV

conducted disturbances, induced by radio-frequency

fields

power frequency magnetic fields IEC/EN 61000-4-8 30 A/m (A)

damped oscillatory magnetic fields IEC/EN 61000-4-10 Level 4, 30 A/m (to be confirmed)

voltage dips, short interruptions and voltage variations IEC/EN 61000-4-11 Class 3

ring waves IEC/EN 61000-4-12

harmonics and interharmonics IEC/EN 61000-4-13 Class 3 (to be confirmed)

conducted, common mode disturbances in the frequency

range 0 Hz to 150 kHz

damped oscillatory waves IEC/EN 61000-4-18

Interference emission IEC/EN 61000-6-4

limits for harmonic current emissions IEC/EN 61000-3-2 Class A

limitation of voltage changes ect. IEC/EN 61000-3-3

Information technology equipment radio disturbance

characteristics limits and methods of measurement

Industrial scientific and medical (ISM) radio-frequency

equipment electromagnetic disturbance characteristics

limits and methods of measurement

Voltage sags SEMI F47 passed

Federal Communications Commission FCC15 compliant

IEC/EN 61000-4-6 Level 3, 10 V

IEC/EN 61000-4-16 Level 3, 10 V (to be confirmed)

IEC/CISPR 22,

EN 55022

IEC/CISPR 11,

EN 55011

IEC/EN 61204-3

Class A

Class A

14 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 15

Technical diagrams

Efficiency [%]

out

[A]

Power loss [W

]

I

out

[A]

Efficiency [%]

]

Power loss [W

]

]

Efficiency [%]

T

a

[°C]

Data at Ta = 25 °C, Uin = 230 V AC and rated values, typical values unless otherwise indicated

Efficiency diagrams

The efficiency and thus the power loss depends on the output current, input voltage, output voltage and ambient

temperature as illustrated in the diagrams below.

40

95.0

90.0

85.0

80.0

5

Typical efficiency over output current

94.5

94.0

93.5

93.0

92.5

92.0

91.5

85

110 130 150 170 190

Typical efficiency over AC input voltage

25201510

230 250210

I

Uin [VAC

30

20

10

0

0

2CDC 272 003 F0216

4812 16

Typical power loss over output current

40

35

30

25

85

110 130 150 170 190

2CDC 272 006 F0216

Typical power loss over AC input voltage

20 24

230

250210

Uin [VAC

2CDC 272 005 F0216

2CDC 272 007 F0216

at 100% load

94.5

at 150% load

94.0

93.5

93.0

92.5

92.0

-25 -15 -5 5

25 35 45 55 65

15

Typical efficiency over ambient temperature

2CDC 272 008 F0216

Data sheet | Power Supply CP-C.1 24/20.0 - 15

Page 16

Characteristic curve of output

at 24 V at 22.5 V at 28.5 V

23

Output voltage [V]

Ambient temperature [°C]

Output current [A]

30

25

20

15

10

5

0

04812162024283

Output current [A]

Characteristic curve of output at Ta = 25 °C

Characteristic curve of temperature

32

28

24

20

I

R

16

12

8

4

0

-25 -10 0

Characteristic curve of temperature at U

Power reserve

10 20 30 40 50 60 70

= 24 V

out

4

2CDC 272 019 F0015

2CDC 272 022 F0015

The switch mode power supply CP-C.1 is able to supply at 24 V DC output voltage and at an ambient temperature of

– ≤ 40 °C a continuous output current of typ. ≤ 26 A

– ≤ 60 °C the rated current of 20 A

At ambient temperatures of > +60 °C the output power has to be reduced by 3.5 % per Celcius degree temperature

increase.

At thermal overload the device will switch-off as soon as the internal temperature exceeds the acceptable level. The exact

ambient temperature threshold depends on the mounting position and load of the power supply.

If the switch mode power supply is loaded with an output current > 26 A, the operating point is passing through the U/I

characteristic curve shown.

The device is equipped with an overtemperature protection function. It will switch-off as soon as the internal

overtemperature protection function is activated.

16 - Power Supply CP-C.1 24/20.0 | Data sheet

Page 17

Dimensions

144,8 [5.70”]

]8

in mm and inch

137,3 [5.41”]

129,8 [5.11”]

126,8 [4.99”]

40,0 [1.57”]

60,0 [2.36”

2,00 [3.23”]

136,0 [5.35”]

129,4 [5.09”]

CP-C.1 24/5.0 CP-C.1 24/10.0 CP-C.1 24/20.0

129,4 [5.09”]

129,4 [5.09”]

2DCDC 272 028 F0015

Further documentation

Document title Document type Document number

Electronic products and relays Technical catalogue 2CDC 110 004 C02xx

CP-C.1 Instruction manual 1SVC 360 560 M0000

CAD system files

You can find the CAD files for CAD systems at

http://abb-control-products.partcommunity.com/portal/portal/abb-control-products

-> Low Voltage Products & Systems -> Control Products -> Power Supplies.

Data sheet | Power Supply CP-C.1 24/20.0 - 17

Loading...

Loading...