Page 1

Bushing Potential Device,Type PBA2

PTAE-APD903

IZUA 7711-210

Instructions for Installation and Maintenance

Page 2

All possible contingencies which may arise during installation, operation, or maintenance, and all details and

variations of this equipment do not purport to be covered by these instructions. If further information is desired

by purchaser regarding his particular installation, operation or maintenance of his equipment, the local ABB Inc

representative should be contacted.

2

ABB

Page 3

Description

Application

The condenser bushing potential device is a means for

securing small amounts of 60 hertz power at 115 volts

and 66.4 volts from high voltage lines through the medium

of the condenser bushing. For 115kV and higher voltages

this device is the most economical means of securing

such small amounts of power.

These devices provide a 115 and 66.4 volt output which

is substantially proportional to the system line-to-ground

voltage and in phase with it. This output is commonly

used to energize synchroscopes, voltmeters, and voltage

responsive relays. The device accuracy is not adequate

for use with metering instruments where revenue is involved.

Construction

The potential device is built in an outdoor, weatherproof,

steel housing arranged for mounting on the side of an oil

circuit breaker or transformer in the vicinity of one of the

condenser bushings. A special cable assembly of

weatherproof construction, and with a grounded external

shield, connects the potential device to one of the metallic

layers of the condenser bushing.

The device network (see Fig. 6) consists of a main transformer

having adjustable reactance, an auxiliary transformer of

adjustable ratio, a tapped capacitor to correct burden power

factor, a protective spark gap, and a dead-front adjusting

panel.

A grounding switch permits de-energizing the device, and a

heater (to be energized from an external voltage source)

prevents internal sweating of the housing.

Standardized mounting dimensions permit the interchangeability

with most standard ABB or Westinghouse units sold since

the middle of 1934. The standard device is electrically usable

for most bushings having capacitance taps per IEEE

C57.19.01-2000 Type A: Normally Grounded having the tap

on the second metallic layer above ground potential

includes substan

tured since the middle of 1935 and having a voltage rating of

115kV or higher. Cable lengths (see Fig. 2) are also standard

for circuit breakers, but special lengths are general for transformers. End fittings of cables are common for all.

tially all Westinghouse bushings manufac-

. This

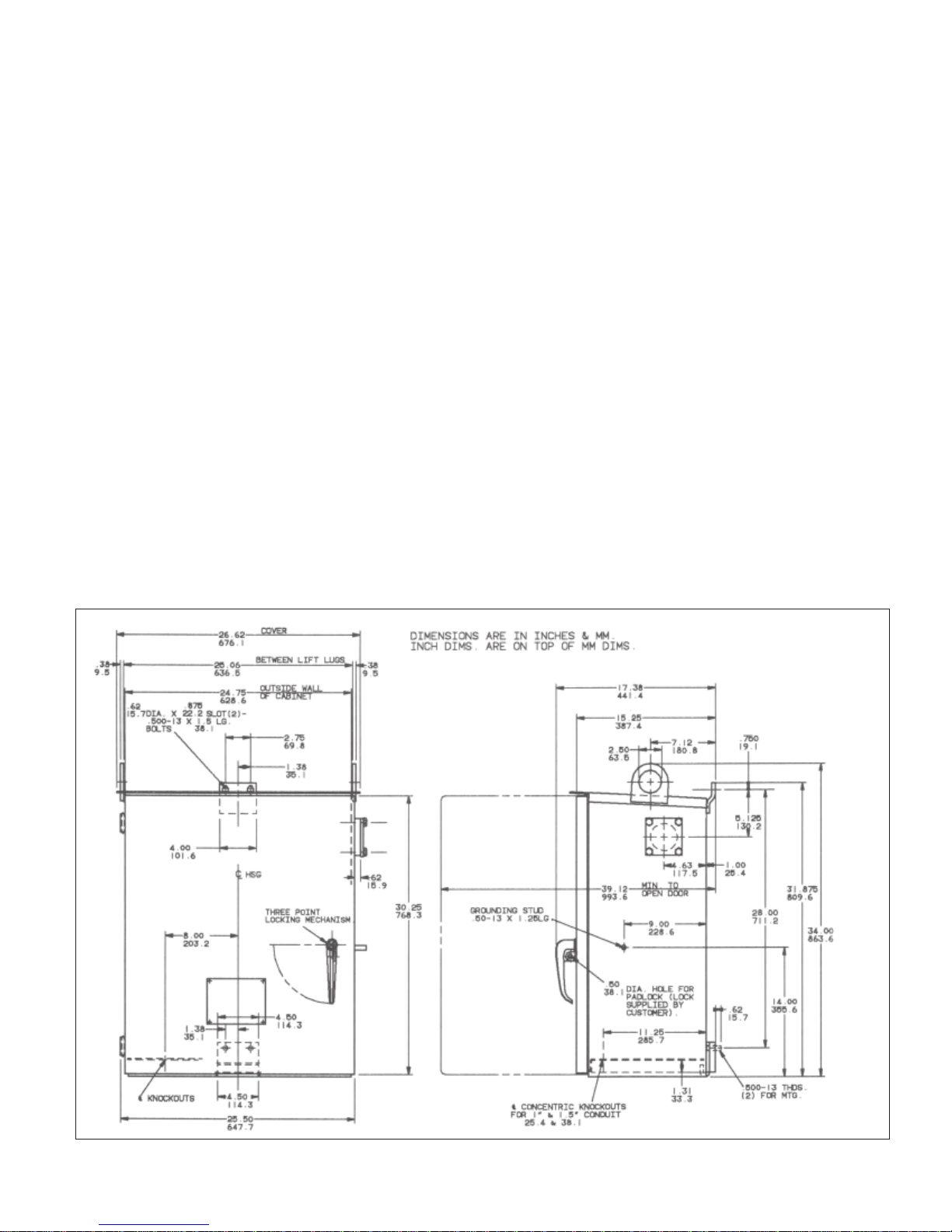

Figure 1: Outline and Mounting

ABB

3

Page 4

PBA CABLE DRAW NUT

"

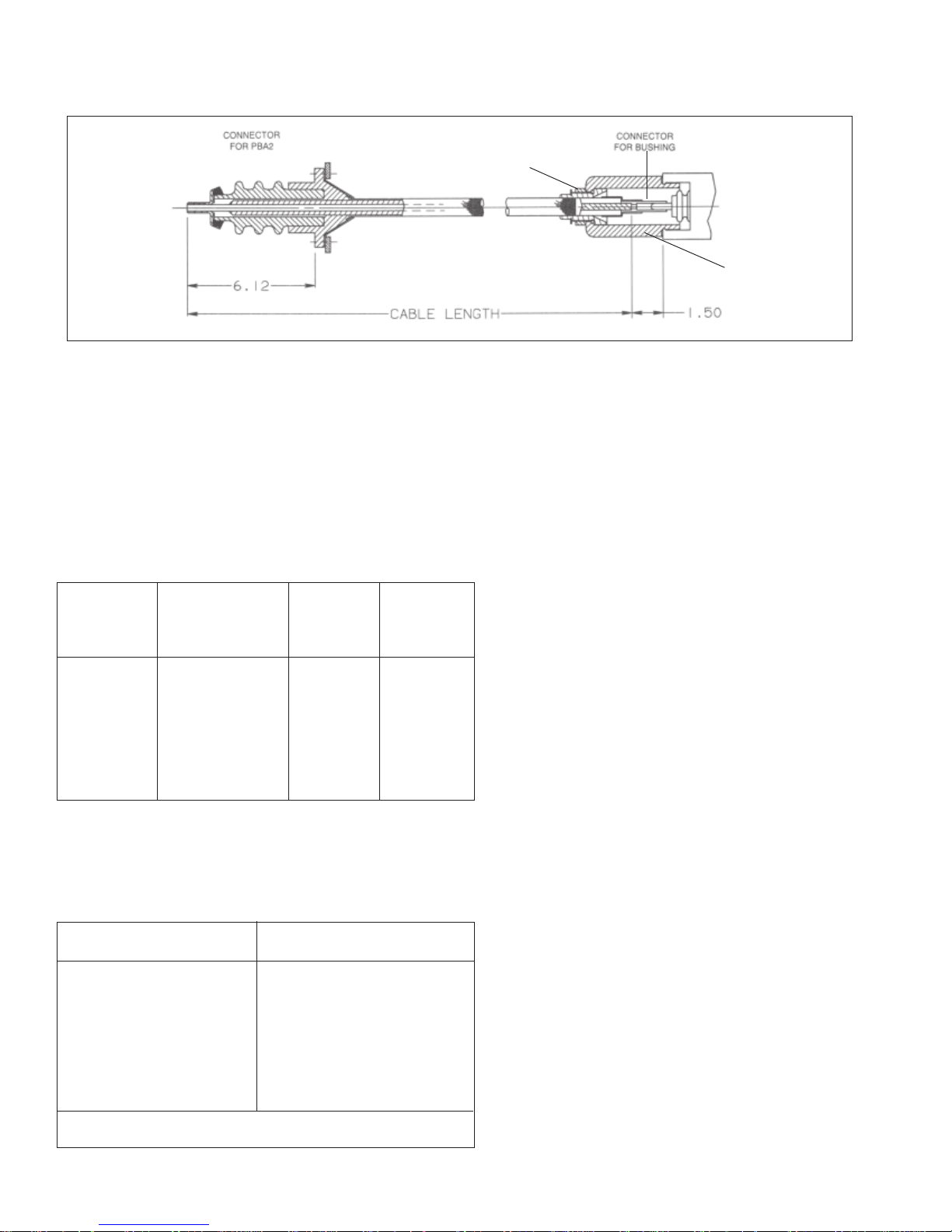

Figure 2: Cable Lead-in Assembly

Rating

Each device has output voltages of 115 and 66.4 for the

main burden (terminals S1, S2, S3) and an auxiliary winding

provides the same voltages (terminals Z1, Z2, Z3) for use

when broken-delta connections are required.

The burden ratings of the standard devices, when used with

standard bushings in each case, are shown in Table 1.

Table 1

System System Max. Watts* Device

Voltage Voltage Total Style**

Line-To-Line Line-To-Ground Burden ***

115 kV 66.4 kV 25 3D69822G01

138 kV 79.7 kV 35 3D69822G01

161 kV 93.0 kV 45 3D69822G02

230 kV 133 kV 80 .....................

287 kV 166 kV 100 .....................

330-345 kV 191-199 kV 150 .....................

* In no case shall the burden on the auxiliary winding (Z1, Z2, Z3) exceed 75 watts.

** Styles do not include lead-in cable, see Table 2.

*** These designs are for ABB or Westinghouse bushings. Bushings by

other vendors require special PBA configuration.

PBA CONNECTION

HOUSING

"

Since the device rating is a function both of the system

voltage and of the particular bushing capacitance values, it

is obvious that special bushings, or standard bushings

used at non-standard voltages may have burden ratings

which are at variance with the foregoing tabulation. In this

connection it is to be noted that the auxiliary capacitance

built into each device varies according to the device

ap

plication. See page 10 “Calculation of Approximate

Adjustment.”

Performance

The Type PBA2 Potential Device is a Class”“A” device as

defined by AIEE Standard # 31 and NEMA Standards

SG4-1968. The regulation characteristics with respect to

varying line voltage and varying burden meet the limits

established by these standards.

Since this type of device is basically a series-tuned

device it is sensitive to the system frequency. For small

frequency deviations there is practically no ratio effect,

but there is a slight phase shift. For example, a deviation

of one hertz in 60 will produce a phase shift up to 2

degrees, depending on the particular bushing device and

system voltage. The greatest phase shift is experienced

when the potential device is loaded to its rating, and when

the normal system voltage is low relative to the bushing

rating.

Table 2. Cables with Type A Connectors

Cable Length* Style#

96" 3D69768G01

120" 3D69768G02

144" 3D69768G03

168" 3D69768G04

192" 3D69768G05

216" 3D69768G06

240" 3D69768G07

*Cable lengths other than those listed can be ordered if necessary

4

When high-speed directional relays are energized from

this device, it is recommended that the basic burden be

power factor corrected to 100%, or slightly leading, and

that the device be loaded to its rating in watts (as shown

on the nameplate), by adding parallel resistance if

necessary. The purpose of this is to reduce to a minimum

the possibility of incorrect relay operation, which might

result from device output transients following a system

short circuit extremely close to a device.

ABB

Page 5

Erection

The potential device may be lifted from its crate or pallet

and handled by means of the two lifting lugs on the side of

its roof to mount it on the circuit breaker or the transformer.

Depending on the particular breaker or transformer bracket

provided for the lower edge of the potential device, proceed

as follows (see Fig. 1):*

a. If the lower device support on the transformer or breaker

carries two tapped holes then bolt the J bracket, which

is shipped loose with the potential device, to this pad

using the two countersunk head bolts provided. There

is a notch in the center of the rear lower flange of the

device, which will fit into the hook provided by this J

bracket. Rest the weight of the potential device into

this bracket and place the two bolts into the two slots

of the upper device support, and secure these in place.

b. If the transformer or breaker carries a lower device

support consisting of a bent steel bar, and with two

notches cut into its edge instead of two tapped holes,

then the J bracket may be scrapped and the potential

device rested directly on the notched bar. The upper

end is bolted into place with the two bolts.

c. In either case, the paint shall be scraped away from the

upper pad where it is bolted against the corresponding

pad on the breaker or transformer in order to assure a

good ground connection at this point.

d. The primary connection is made by installing the high

voltage cable assembly of Fig. 2. This is done with the

bushing grounded. The cable is installed by

t

he mounting flange cover from the side of the po

device housing and removing the cover from the tap

receptacle on the bushing flange. The tap receptacle

on the bushings of recent manufacture may be found

filled with approximately one pint of transformer oil, which

will drain out when the cover is removed. Discharge the

bushing tap layer by touching the socket

contact with a grounded wire.

removing

tential

1. If the bushing is ABB O plus C or other type that

permits addition of transformer oil to the test tap with

the tap cover in place, you may choose to fill the PBA

connector housing with transformer oil. In this case,

do not add the petrolatum to the PBA connector housing.

2. Otherwise, pack the inside of the PBA connector hous

ing

with the petrolatum provided, taking care to leave no

air pockets.

e. Push the bushing connector into the tap, then thread the

PBA connector housing into the threaded portion of the

bushings tap. Tighten by hand, approximately 1/4 turn

after the gasket is in contact with both the tap and the

connector housing. Lubricate the gasket with a thin

application of transformer oil or petrolatum whichever is

being used.

f. Turn the PBA cable draw nut clockwise, until tight.

g. If you have chosen to fill the PBA connector housing with

transformer oil, do so now. Please see the bushing's

application literature for filling instructions and oil expansions

space requirements.

h. Place the porcelain end of the cable assembly into the

hole in the side of the potential device housing.

Bolt the two flanges in place using the hardware

provided. The composition flange at the cable end

is also the gasket. Draw up the bolts progressively

around the cable so that there is not excessive pressure

at any point. Tighten up the bolts only sufficient to create

a slight bulge all around the edge of the composition.

i. Connect the internal jumper connection in line with

diagram of Fig. 6 by opening the

partially dropping the front panel assem

It is suggested that when a device is installed and con

PBA'S door and

bly.

nected

that its voltage adjustment be set to a minimum (and the

ground switch opened) until such time as the normal burden is connected and the device adjusted.

* If the device is to be mounted on equipment that is not

manufactured by ABB, the mounting arrangement may

be slightly different than described here.

ABB

5

Page 6

Adjusting

General

The Type PBA2 is a ‘resonant’ or ‘in-phase’ device having

Class’“A” performance, and hence it must be adjusted or

tuned to match a specific bushing and a specific burden. A

reference voltage of known value and phase angle position

is required to make this initial adjustment. This reference

voltage is usually supplied from the secondary voltage of a

potential transformer of the desired ratio, which is connected

line-to-ground to the same phase of the transmission line

as the bushing to which the potential device is mounted.

However, the reference voltage may be taken from another

potential device which has been previously adjusted, or it

may be taken from the low voltage secondary of the power

transformer provided it is known that voltage is in phase

with the line-to-ground voltage of the transmission line. The

object is to have a reference voltage for comparison, this

reference voltage to be approximately 115 volts (or this value

divided by 1.73) as may be decided upon for the device

output, and this voltage to be in phase with the transmission

line-to-ground voltage.

There are three adjustments provided on the device adjusting

panel; these are power factor correction of the burden, phase

angle adjustment of the transformer to series tune the

bushing reactance, and voltage adjustment to control the

burden voltage. The phase angle adjustment shows its

effect by shifting the phase angle of the secondary or output

voltage. The controls on the adjusting panel are marked

power-factor correction, volt-amperes, phase-angle, and

inductive reactance, and voltage adjustment.

The numbers on the respective adjustments are in terms of

volt-amperes of power factor correction; active turns of

reactance winding and volts-primary of the ratio transformer.

The values are useful in making the device adjustment.

It is desirable to adjust the device with the final burden in

place. If this is not possible then a synthetic burden shall be

used having the identical volt-ampere and power factor

characteristics of the actual burden.

The adjustment procedure requires a voltmeter of fairly high

impedance to check the magnitude of the output voltage,

whether 115 volts or 66.4 volts (note that the ratio of these

two voltages in the output is fixed so that only one of them

need be adjusted and checked). To check the phase angle

of the output voltage requires either a phase angle meter

having two voltage coils, a low voltage voltmeter, or an

oscilloscope. The oscilloscope is probably the most

satisfactory

for phase angle adjustment.

If the reference voltage being used is the exact magnitude

desired then the entire adjustment can be made by using

two voltmeters (one reading about 150 volts, and the other

about 5 volts) by connecting the ground of the reference

and the ground of the device output together and then

checking voltage between the line terminals, first with the

150 scale voltmeter and finally with the 5 scale voltmeter.

The device will be correctly adjusted when the voltage

between line terminals is a minimum (less than 1 volt).

Procedure

Power Factor Correction

Correct the power factor of the burden to unity, or to a slightly

leading angle. This is the first step and may be done by

switching in an amount of capacitive volt-amperes, to match

the reactive volt-amperes of the burden. In the case of

delta-connected burdens operating from a bank of three

potential devices, it may be simplest to excite the total burden

from a separate voltage source and to adjust the capacitors

to secure unit power-factor in each phase. This can be done

by grounding terminal S3 (Fig. 3) of each device and applying

the three-phase test voltage to the three S1 terminals, or

the three S2 terminals, depending on the voltage. The primary

shall be de-energized for this test and the ground switch

open.

If in this test the protective gap flashes over this may be

stopped by making a radical change in the phase angle

setting, such as by reversing the BUCK-BOOST switch, or

by changing large sections of turns in the tapping arrangement.

As an alternative, the reactive volt-amperes can be calculated

and the corresponding capacitive volt-amperes set on each

device.

Phase Angle and

Voltage Adjustment

There is some interdependence between the phase angle

and voltage adjustment and so these will be considered

together. These are the final adjustments and are best made

with the final burden (power factor corrected) connected in

its final form to the potential device. The device adjustment

is basically a single-phase procedure, even when connected

into a 3 phase group.

6

ABB

Page 7

Figure 3: Connection Diagram

For this adjustment the device must be connected to its

final condenser bushing, with normal line-to-ground voltage

on the bushing stud, and with a reference voltage available

for comparison. See also ADJUSTING-GENERAL above.

The ratio or output voltage adjustment is a matter of voltage

magnitude only, and this is checked by voltmeter reading.

The phase angle of the output voltage may be checked by

low reading voltmeter, by phase angle meter or by oscillo

as previously mentioned.

Fig. 4 is the circuit diagram for checking the phase angle

and ratio using the oscilloscope with vertical and horizontal

sweeps each energized at 115 volts 60 hertz. The oscillo

ABB

scope,

scope

shall be adjusted so that the total deflection in each the

vertical and the horizontal directions is roughly the same.

The reference and the output voltages are in phase when

the trace on the oscilloscope is the nearest possible to a

single straight line. Some variation in the wave form of the

two voltages may prevent the trace from ever becoming a

perfect straight line. When the voltages are out of phase,

the trace tends to be an ellipse; it would be a circle with the

two voltages 90 degrees out of phase. The oscilloscope as

used here will not distinguish in-phase from 180o out-of-phase.

7

Page 8

Make up the circuit of Fig. 4 with the ground switch of the

device in the closed position, which de-energizes the device.

Place all of the rotary switches and the toggle switch of the

phase angle adjustment in the zero position and set the

voltage adjustment dials to maximum (which is primary

voltage and hence will give the minimum output voltage).

Next open the device ground switch and shift the voltage

adjustment dials to obtain approximately 115 volts S1 to S3.

Note the oscilloscope trace; it is very probably an approximate

ellipse. To determine which direction to proceed from here,

switch in 24 or 48 turns of the phase angle adjustment and

then note the position of the buck-boost switch which gives

the nearest to a straight line trace on the oscilloscope. This

simple check should establish the correct position of the

buck-boost switch and then the finer adjustments of the

phase angle switches is a straight forward procedure to secure a

straight line trace on the oscilloscope. Start by first trying the

larger steps (192 turns is the largest step) and if any step is in

excess of that required then drop back to the next lower turns

in the same switch. For example, with the three rotary switches

in the zero position, and if 192 is then found to be excessive

then return the toggle switch to zero and try 144 turns on the

top rotary switch. If this is still excessive then turn the top

rotary switch back down to 96 turns, and so on, until some

points is reached which is short of the required amount. Then

proceed to the middle and lower rotary switches in order until

the closest setting is reached. The total number of turns

tapped in is the sum of the settings on the three rotary

switches and the 0 to 192 toggle switch. Reference to figure

5 will give an idea of the effect of the various number of turns

of the reactance winding, both buck and boost.

Figure 4: Test Circuit Using Oscilloscope

8

ABB

Page 9

Figure 5: Curve of Ohms versus Turns of Reactance

ABB

9

Page 10

Excessive transformer reactance (refer to Fig. 5) will result in

a lagging voltage at the burden, and vice versa.

When a straight line is being approached on the oscilloscope,

the output voltage shall be checked and readjusted to the

desired value. The final setting is with the correct output

voltage and with the oscilloscope trace the closest possible

to a straight line, bearing in mind that differences in wave

form of the two voltages will prevent a perfect straight line.

To check for polarity correctness, connect terminal S3 to the

ground of the reference voltage and then check the voltage

between S1 terminal and the polarity terminal of the reference

voltage. With correct polarity this voltage will be zero and

with reversed polarity the voltage will be approximately 230.

If an oscilloscope is not available then use two voltmeters,

one high scale and one low scale, and with these measure

the difference or error voltage and the output voltage. This

plan, which uses the difference voltage, pre-supposes that

the reference voltage is of the exact magnitude, which is

desired for the adjusted device.

In the case of delta-connected three-phase burdens, it is

necessary to make preliminary or approximate adjustments

of each device first and to then re-check and trim each device

one or more times until the three phase voltages to ground

are equal and each in phase with its reference voltage.

When final adjustment is accomplished, with the burden

connected, check voltage H2-H3. This voltage shall not

exceed 172V. Voltage in excess of 172V indicates excess

burden connected to the device and excess voltage on

the primary of the transformer.

Calculation of Approximate Adjustment

If the capacitance values C1, C2 and C3 of Fig. 6 are known,

then it is possible to calculate the approximate adjustment

of a device when used with a particular bushing at a specific

line voltage. It is assumed that the burden is corrected to

substantially unit power factor. For this purpose the nominal

values of C3 (in the potential device) are,

Device C3

S#3D69822G01 2000pF

S#3D69822G02 3000pF

All others Check the device for value

The values of C1 and C2 shall also be used in picofarads.

If C4 is obtained by measuring a bushing mounted in a

grounded structure, it will contain appreciable stray

capacitance to ground. Since this stray capacitance is not

effective in the circuit of the potential device it is more

accurate to use 0.85C4.

Figure 6: Schematic Diagram

10

ABB

Page 11

Capacitance C2 similarly measured will contain an

insignificant percentage of stray capacitance.

Capacitance C1 is then:

C2 x 0.85C4

C1=

C2 – 0.85C4 (1)

Approximate adjustments may be calculated using the

nomograph (Fig. 7) and the instructions on the following

pages or the equations below.

First calculate the bushing tap voltages as if no potential

device burden were present. This is determined from the

relation:

e = E

C1

C1 + C2 + C3 (2)

Where e is the open circuit tap voltage in volts and E is the

actual system line-to-ground voltage at the condenser bushing.

The dial setting of the voltage adjustment should then total,

dial volts = 173 — e

44.1 (3)

For the phase angle adjustment it is necessary to know the

capacitive reactance XC which must be series tuned. This

value in ohms is, for 60 hertz:

XC = 10

12

377* (C1+C2+C3) (4)

*377 = 2 πf, with f = 60 hertz

Using this value of XC refer to curve Fig. 5 and using the

same value of reactance determine whether the device

reactance switch is to be in the BUCK or BOOST position

and further determine the number of turns required in the

phase angle adjustment. Now set the rotary switches and

toggle switch of the phase angle adjustment so that the

total turns are the same as that determined from the curve.

Figure 7: Nomograph for PBA2 Potential Device

ABB

11

Page 12

Use of nomograph for PBA 2 potential device

1. Calculate the sum of C1 + C2 + C3 using capacitance

values of Fig. 3. Mark that value on the first scale on the

monograph.

2. Mark C1 on the second scale

3. Draw a straight line through the points on the C1 + C2 +

C3 scale and the C1 scale extending to the reference line.

4. Locate the system voltage, which the PBA2 device is

measuring on the line volts scale.

5. With a straight line connect the points on the reference

line (where the first connecting line intersects the reference

line) and the line volts scale, extending to the dial volts scale.

6. Read the correct value for the dial setting of the voltage

adjustment on the dial volts scale.

7. Read the number of turns buck or boost to switch in on

the furthest left scale opposite the C1 + C2 + C3 point.

Example

C1=300, C2=3000, C3=3000,

Line Volts=138 kV

C1+C2+C3=300+3000+3000=6300 Picofarads

Reading the Scale – Dial Volts=87

Turns Boost=42

Unusual Combinations

Unusual combinations of voltage, bushing, potential device

and burden can be checked for workability by calculation.

Unit power factor burdens are assumed.

Equation (3) above means that the open circuit tap voltage

e will be workable if it lies between 3000 volts and 7600

volts. Of course with e as large as 7600 it would not be

possible to carry any burden on the device, since the

operating tap voltage rises with added burden, and 7600 is

the limiting voltage on the transformer primary.

If the exploration of the paragraph above shows the

combination to be workable then its burden carrying ability

can be roughly checked by the following:

The reactance XC of equation (4) must be in the range of

125,000 to 800,000 ohms for 60 hertz, or 104,000 to

670,000 ohms for 50 hertz.

Let ex = maximum permissible reactance

voltage.

then ex = (7600)2 - e

Max. watts = ex

XC K (6)

Constant K from empirical equation K = .95 + .078XC/

100,000 but not less than 11.

2

e

x

(5)

Application Notes

Heater

Each device contains two vitreous enameled resistors of

1200 ohms each. These are to be energized from an

external source for the purpose of preventing the internal

sweating of the device. Sweating is objectionable from the

point of view of corrosion and also it may temporarily affect

some of the high voltage insulation resulting in adjustment

unbalance. The resistors may be connected series,

parallel or singly and may in any arrangement be energized

by either 115 or 230 volts giving a range of 5.5 to 88 watts.

The suggested arrangement of the two in parallel at 115

volts gives 22 watts of heating.

Protective Gap

The protective gap across the primary of each device is

sealed to prevent modification of its setting by reason of

atmospheric changes. It is set to breakdown at 15 to 16

kV 60 hertz, which is sufficiently high to permit operation of

the device indefinitely at line-to-line system voltage. The

gap will flashover if a short, or overload, is placed on the

output of the device, since the primary voltage of the

device rises in proportion to the output watts. Continued

arcing of the gap will not cause damage for the reason that

the current which can flow is limited to a very low value by

the impedance of the condenser bushing.

Over voltage Operation

These potential devices may be operated at over voltages

up to line-to-line potential for several hours without damage.

Over voltages will result if one or two lines of ungrounded

system become grounded.

Fusing of Burdens

Inasmuch as the possible output is limited by the protective

gap there is no object in attempting to protect burdens by

use of fuses.

12

ABB

Page 13

Figure 8: Transformer Tap and Ratio Chart

Operating Tap Voltage

The primary of the device transformer is designed for

continuous operation at voltages not in excess of 7600

volts. Therefore, it is necessary to check the voltage

H2-H3 after any alteration to be certain this voltage

does not exceed 172V.

Adjustment-Need For

The adjustment of a potential device is in effect a

“tuning” procedure to affect a “match” between con

ABB

denser

bushing, a potential device and a burden. Therefore,

since any one of these is not a perfect duplicate of any

other of its own kind, it is necessary to completely

re-adjust when any one of the combination is changed.

Auxiliary Winding

The output winding with terminals Z1, Z2 and Z3 is

designed for a maximum of 75 watts, and no more

than this amount of burden shall be connected to the

Z terminals, even though the total rating of the device

may be in excess of 75 watts in some cases.

13

Page 14

Grounding

Any one terminal of either the “S” winding or the “Z”

winding of a device may be grounded (it is not necessary)

if desirable for the purposes of the connected burden.

The primary of the device transformer is grounded to

the device housing and it in turn is grounded to the

transformer or breaker tank by the device mounting

and by the sheath of the lead-in cable. The current,

which flows to ground, is a small fraction of an ampere.

Type of Burden

Burdens having ferro-magnetic cores shall be

sub

stantially linear in impedance to 1.73 times normal

voltage.

Broken Delta Burdens

The burden connected to the Z terminals, under

condition of maximum zero sequence voltage, shall

not exceed 50% of the device rating.

Record of Adjustment

A record of the adjustment setting of a given device in

a given location will consist of a record of the following:

Volt-amperes of power factor correction, “Buck” or

“Boost” of reactance switch, total turns of reactance

tapped in, and total volts on primary of voltage

adjustment transformer.

Trouble Shooting

Inability to make voltage of phase angle adjustment

calls for the following:

1. Recheck the reference voltage for phase angle po

2. Recheck the circuit being used for adjustment.

3. Check accuracy of voltmeter being used, and also

of phase angle meter if one is being used. Note that

phase angle meters may not register correctly if coils

are not operated at their rated voltage or current.

sition.

4. Recheck degree of power factor correction.

5. Calculate the approximate adjustment in line with

,

sections on “Calculation of Approximate Adjustment”

and”“Unusual Combinations” to be sure device is

ap

plicable to the combination at hand.

6. Check for loose, grounded or open connections within

device.

7. Frequency other than 60 hertz on system, such as

25 hertz or 50 hertz.

Variability in performance of device may be due to some

loose connections, to electrical leakage to ground at

the primary voltage of the transformer, or to shorted

turns of transformer primary. The electrical leakage might

be in the bushing tap, in the lead-in cable or in the

potential device.

Flashing of gap means an overburden on the device, or

a ground or short either inside or outside the device, or

a defective gap. The gap shall flash over in the region

15 to 20 kV 60 hertz.

A shifting of adjustment with passage of time can be

indicative of deterioration of the condenser bushing.

Poor ratio regulation will result from increased losses in

the device, and this may result from poor connections

or shorted turns in transformers.

Maintenance

The bushing potential device is a piece of static

equipment and requires no maintenance other than to

see that the heater is energized when it is required, to

see that the paint finish is kept in good condition, and

to be sure no extraneous objects rest on the lead-in

cable. If there is suspicion of change in voltage output

then see Trouble Shooting above.

14

ABB

Page 15

Notes

ABB

15

Page 16

DISCLAIMER OF WARRANTIES

AND LIMITATION OF LIABILITY

THERE ARE NO UNDERSTANDINGS, AGREEMENTS,

REPRESENTATIONS OR WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OTHER THAN THOSE SPECIFICALLY SET

OUT BY AN EXISTING CONTRACT BETWEEN THE

PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE

OBLIGATION OF SELLER. THE CONTENTS OF THIS

DOCUMENT SHALL NOT BECOME PART OF OR

MODIFY ANY PRIOR OR EXISTING AGREEMENT,

COMMITMENT OR RELATIONSHIP.

THE INFORMATION, RECOMMENDATIONS, DESCRIPTION

AND SAFETY NOTATIONS IN THIS DOCUMENT ARE

BASED ON OUR EXPERIENCE AND JUDGEMENT WITH

RESPECT TO BUSHINGS. THIS INFORMATION SHOULD

NOT BE CONSIDERED TO BE ALL INCLUSIVE OR

COVERING ALL CONTINGENCIES. IF FURTHER

INFORMATION IS REQUIRED, ABB INC. SHOULD BE

CONSULTED.

NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE OR MERCHANTABILITY, OR WARRANTIES

ARISING FROM COURSE OF DEALING OR USAGE OF

TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS, DESCRIPTIONS, AND SAFETY

NOTATIONS CONTAINED HEREIN. IN NO EVENT WILL

ABB INC. BE RESPONSIBLE TO THE USER IN CONTRACT,

IN TORT (INCLUDING NEGLIGENCE), STRICT LIABILITY

OR OTHERWISE FOR ANY SPECIAL, INDIRECT, INCIDEN

TAL,

OR CONSEQUENTIAL DAMAGE OR LOSS WHATSOEVER

INCLUDING BUT NOT LIMITED TO DAMAGE TO OR LOSS

OR USE OF EQUIPMENT, PLANT OR POWER SYSTEM,

COST OF CAPITAL, LOSS OF PROFITS OR REVENUES,

COST OF REPLACEMENT POWER, ADDITIONAL

EX

PENSES IN THE USE OF EXISTING POWER FACILITIES,

OR CLAIMS AGAINST THE USER BY ITS CUSTOMERS

RESULTING FROM THE USE OF THE INFORMATION,

RECOMMENDATIONS, DESCRIPTION, AND SAFETY

NOTATIONS CONTAINED HEREIN.

Printed in USA by Tennessee Industrial Printing Services, Inc.

ABB Inc.

1128 S. Cavalier Drive

Alamo, TN 38001, USA

Telephone: 731-696-5561

Fax: 731-696-5269

www.abb.com/electricalcomponents

IZUA 7711-210 en, September 2003 Replaces IB 33-357-1F, September 1993

Loading...

Loading...