Page 1

Intermittent duty

(ops/h)

140

120

100

80

60

40

Switching frequency

20

0

0 20 40 60 80 100(%)

ta = 0.5s

ta = 1s

ta = 1.5s

ta = 3s

ta = 3.5s

Closing time

Switching frequency

in relation to load factor.

ta: motor starting time

Technical data

for Overload relays

Technical

TA25DU – TA110DU

Switching frequency

To avoid nuisance tripping, TA and T thermal O/L relays have been designed to withstand roughly 15

switching operations per hour with an approximately equal distribution between working and rest cycles.

In these conditions, the motor starting time must not exceed 1 second and the starting current must

be lower than or equal to 6 times the motor In.

For intermittent operations, the diagram opposite specifies relay operating limits.

Example: Motor starting time: .................1 sec.

Tripping limits at ambient temperatures varying by + 20°C

Load factor: .............................40 %

Switching frequency: ............... 60 ops./h according to diagram

1.5

1.4

1.3

1.2

1.1

1.0

0.9

ultiple of the setting current

M

-20 -10 0 10 20 30 40 50

Ambient temperature

compensation limits

according to IEC 947-4-1

No tripping

Ambient temperature

Tripping

Ambient temperature compensation

Thermal O/L relays are compensated against ambient

temperature variations by a compensation bimetal which

is sensitive to the ambient temperature.

Thermal O/L relays are designed to operate between –5

°C and +40 °C in compliance with standard IEC947-4-1.

For a wider range of –25° C to +55 °C consult the graph

opposite.

Example: tripping at –25 °C. Tripping takes place before

1.5 times the setting current.

Resetting: TA25DU – TA110DU thermal O/L relays have

convertible manual/automatic resetting.

Delivery: in manual resetting mode.

data

OVERLOAD RELAYS: General info: 3.1 – 3.2 Selection: 3.3 – 3.4 Accessories: 3.5 – 3.6 Technical data: 3.7 – 3.10 Dimensions: 3.11 – 3.12

AC 1030 – 6/98

ABB Control Inc. 3.7

Overload relays

Page 2

Technical data

Technical

data

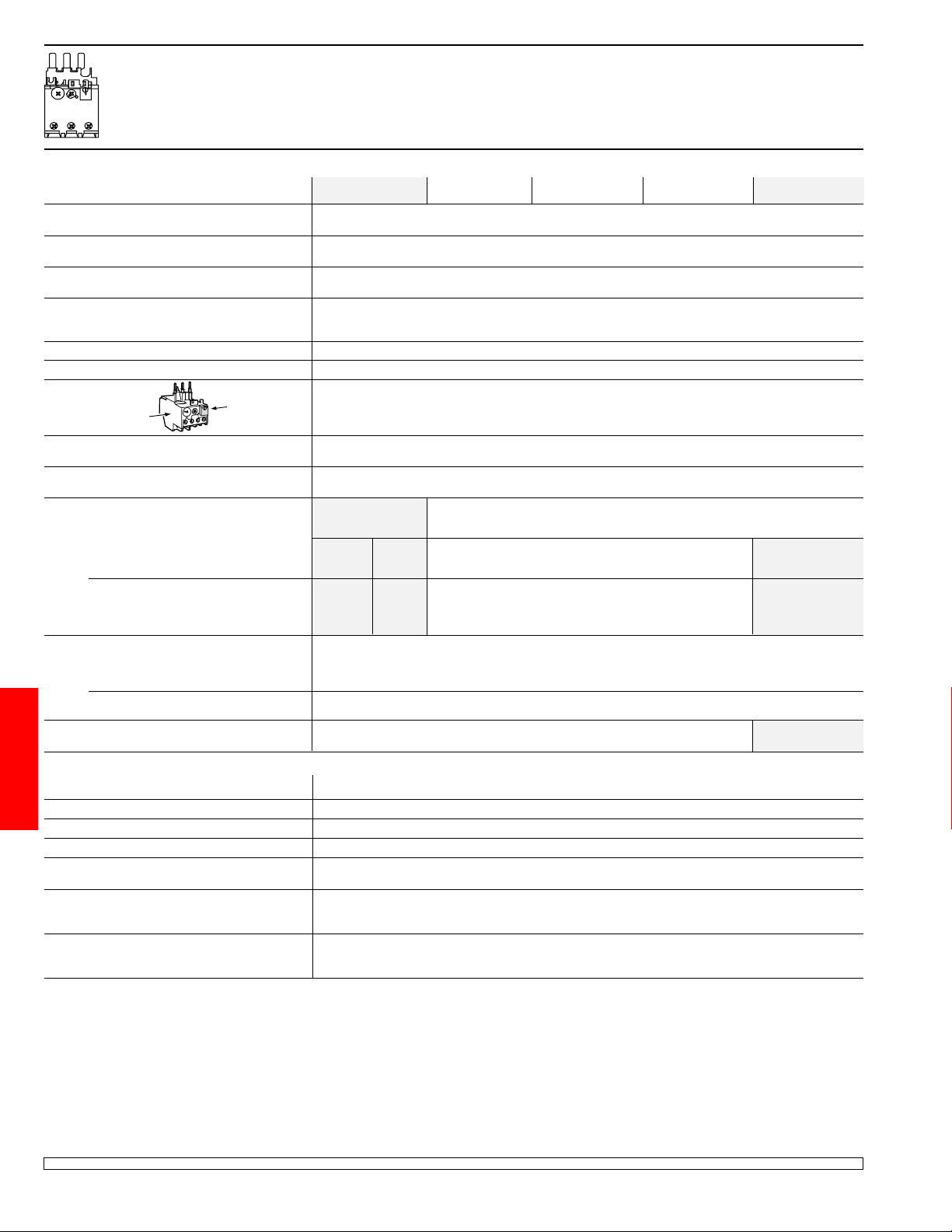

General technical data

Types TA25DU TA42DU TA75DU TA80DU TA110DU

Standards: (main standards:

international, European and national)

Rated insulation voltage U

according to IEC947–4–1

Rated impulse withstand voltage U

according to IEC947–4–1

Permissible ambient temperature

Climatic withstand DIN 50017 Humidity in alternate climate KFW, 30 cycles

Mounting positions 1

Shock withstand shock duration ms 15

at nominal I

Critical direction

of shocks A1, A2 multiples of g 12

Resistance to vibrations

(±1 mm, 50 Hz) multiples of g 8

Mounting — on contactor Latching below the contactor, screw fixing on main terminals

Terminals and cross-sectional areas

for main conductors (motor side)

Terminals and cross-sectional area

for auxiliary conductors

Overload relays

Degree of protection according to IEC144, IEC529

DIN 40 050, NFC20-010 and VDE110/Part. 106

— for storage

— with compensation °C

e

— separate with DB - kit Using screws: 2 x M4 or 35 mm EN50022

• screw terminal to 18-25 A

— with cable clamp M4 —

— via tunnel connector — M5 M6 M6 M6 HC, M8

— flat type for lug or busbar — — — — — —

• conductor cross-sectional area AWG 16 – 8 16 – 8 8 – 1 8 – 1 8 – 1 6 – 1

— rigid solid or rigid stranded mm22 x 1.5 – 6 1 x 10 1 x 2.5 – 35 or 2 x 2.5 x 16 16 – 35

— flexible with cable end mm

— recommended busbars mm — — — — — 12 x 3

• screw terminal (screw size)

— with cable clamp M 3.5

• conductor cross sectional area

— rigid solid or rigid stranded AWG 2 x 18 – 24

i

A1

for Overload relays

TA25DU – TA110DU

V

imp

A2

kV

°C

TA25DU setting ranges: TA25DU setting ranges:

from 0.1-0.16A

2

2 x 1.5 – 4

UL, CSA, IEC947–4–1, VDE0660, NFC63 650, BS4941, EN60947-4-1

600V (UL); 690V (IEC)

6

–25 to +55 (maximum values: see page 3.7)

2 x 0.75 – 6

–40 to +70

24-32 A

1 x 2.5 – 25 or 2 x 2.5 x 10 16 – 35

2 3

Pole characteristics

Number of poles 3

Setting ranges see page 3.4

Tripping class according to IEC947–4 10A

Operating frequency Hz 0 – 400

Tripping frequency Up to 15 ops./h or 60 ops./h with 40 % load factor when neither

without untimely tripping the starting current of 6 x In nor the starting time 1s are exceeded.

Resistance per phase in mΩ

and heat dissipation in W see page 3.9

at the maximum current setting

Protection fuses

co-ordination with short circuit protection To be sized per NEC Article 430-152

devices

1 On a support at an angle of ±30° in relation to the vertical plane (standard position). Other positions possible except mounting on a horizontal plane (in this case the tripping mechanism

would be located above the bimetals).

2 All the terminals are protected against direct contact according to VDE0106/Part. 100. (without additional terminal shrouds).

3 All the terminals are protected against direct contact according to VDE0106/Part. 100. (with additional terminal shrouds).

OVERLOAD RELAYS: General info: 3.1 – 3.2 Selection: 3.3 – 3.4 Accessories: 3.5 – 3.6 Technical data: 3.7 – 3.10 Dimensions: 3.11 – 3.12

3.8 ABB Control Inc.

AC 1030 – 6/98

Page 3

Technical data

for Overload relays

TA25DU – TA110DU

Auxiliary contacts Normally Closed N.C. Normally Open N.O.

Terminal marking 95 – 96 97 – 97

Rated insulation voltage U

Conventional thermal current (in free air) I

Rated operation current Ie' AC-15

Rated operational current I

Protection against short circuits

gG (gl) fuses (according to IEC269 A 10 6

S271/S 281 circuit breaker A k3 k1

Maximum potential difference VAC 500 500

between N.C. and N.O. auxiliary contacts VDC 440 440

up to 240V A 3.0 1.5

up to 440V A 1.9 0.95

up to 500V A 1.0 0.75

up to 250V A 0.12 0.04

i

DC-13

e

Resistance and Joule Loss per phase

TA25DU Thermal O/L relay

Setting range Resistance Joule loss

from – to current

A A mΩ W

0.1 – 0.16 85850.0 2.2

0.16 – 0.25 85150.0 2.2

0.25 – 0.4 13750.0 2.2

0.4 – 0.63 5370.0 2.2

0.63 – 1.0 2190.0 2.2

1.0 – 1.4 1120.0 2.2

1.3 – 1.8 670.0 2.2

1.7 – 2.4 383.0 2.2

2.2 – 3.1 229.0 2.2

2.8 – 4.0 137.0 2.2

3.5 – 5.0 87.5 2.2

4.5 – 6.5 61.0 2.2

6.0 – 8.5 30.4 2.2

7.5 – 11 18.2 2.2

10 – 14 11.2 2.2

13 – 19 6.3 2.3

18 – 25 4.7 2.9

24 – 32 3.2 3.3

per phase per phase at

VAC 500 500

A 10 6

th

TA42DU Thermal O/L relay

max. setting

Setting range Resistance Joule loss

A–A mΩ W

18 – 25 5.5 3.43

22 – 32 2.89 2.91

29 – 42 1.84 3.24

per phase per phase

TA75DU Thermal O/L relay

18 – 25 5.5 3.43

22 – 32 2.89 2.91

29 – 42 1.84 3.24

36 – 52 1.3 3.51

45 – 63 0.936 3.72

60 – 80 0.615 3.94

TA80DU Thermal O/L relay

29 – 42 1.84 3.24

36 – 52 1.3 3.51

45 – 63 0.936 3.72

60 – 80 0.615 3.94

TA110DU Thermal O/L relay

80 – 100 0.378 3.78

Technical

data

Overload relays

OVERLOAD RELAYS: General info: 3.1 – 3.2 Selection: 3.3 – 3.4 Accessories: 3.5 – 3.6 Technical data: 3.7 – 3.10 Dimensions: 3.11 – 3.12

AC 1030 – 6/98

ABB Control Inc. 3.9

Page 4

T ripping curves

Technical

data

for Overload relays

TA25DU – TA110DU

TA25DU TA42DU TA75DU TA80DU TA110DU

TA-DU and T-DU thermal O/L relays are 3 pole with manual or automatic resetting mode selection. The reset button can also be used for

stopping.

Built in auxiliary contacts are physically separate and, consequently, can be used in different circuits (control circuit/indication circuit).

Each relay is temperature compensated and ensures phase failure protection.

Protective relays up to size TA75DU are protected against direct contact from the front face.

The connecting terminals are delivered in open position with (+,-) posidrive screws and screwdriver guidance. It is advisable to tighten unused

terminal screws.

Thermal O/L relay tripping curves

TA25DU, T25DU TA42DU, TA75DU and TA80DU TA110DU

(tripping class 10A) (tripping class 10A) (tripping class 10A)

120

100

80

60

40

20

10

8

Minutes

Tripping time

Seconds

4

2

1

40

20

10

2 Phases

868

6

4

3 Phases

2

from warm state

1

0.8 1 2 3 4 5 6 7 8 9 101.2 1.5

Tripping current

in multiples of the setting current

Overload relays

from cold state

2 Phases

3 Phases

Minutes

Tripping time

Seconds

120

100

80

60

40

20

10

8

4

2

1

40

20

2 Phases

10

3 Phases

868

6

4

2

1

from warm state

0.8 1 2 3 4 5 6 7 8 9 101.2 1.5

Tripping current

in multiples of the setting current

from cold state

2 Phases

3 Phases

Minutes

Tripping time

Seconds

120

100

80

60

40

20

10

8

4

2

1

40

20

3 Phases

10

868

6

4

2 Phases

2

from warm state

1

0.8 1 2 3 4 5 6 7 8 9 101.2 1.5

Tripping current

in multiples of the setting current

from cold state

2 Phases

3 Phases

OVERLOAD RELAYS: General info: 3.1 – 3.2 Selection: 3.3 – 3.4 Accessories: 3.5 – 3.6 Technical data: 3.7 – 3.10 Dimensions: 3.11 – 3.12

3.10 ABB Control Inc.

AC 1030 – 6/98

Loading...

Loading...