Page 1

Retort Control in the Food Industry

using the C360

Product Application Guide

AG/RCP–007_2

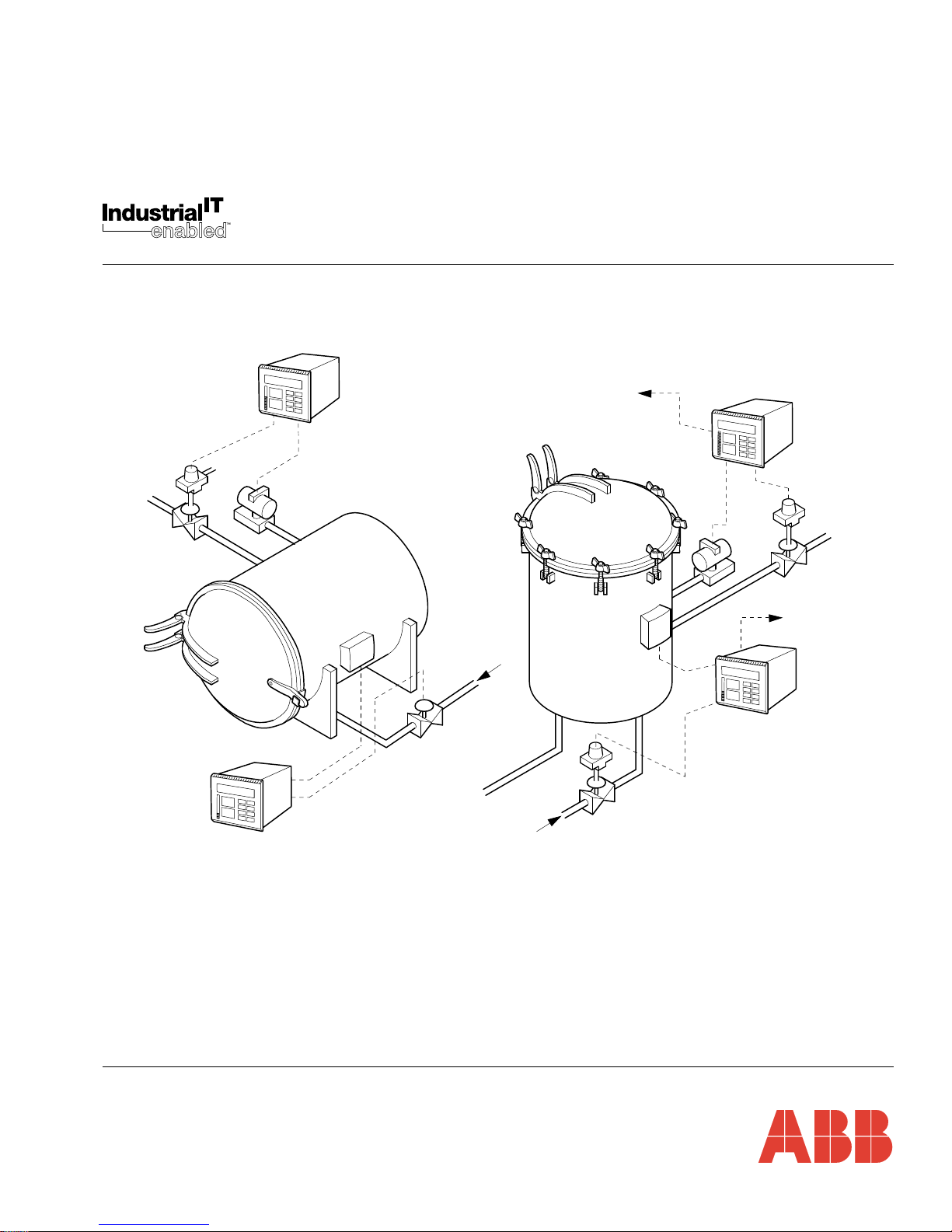

Fig. 1 Horizontal and Vertical Retorts

1.623

108

.6

11

.35

C360

Multi-Recipe

Profile Controller

11

.82

Steam

Steam

C360

Multi-Recipe

Profile Controller

C360

Multi-Recipe

Profile Controller

C360

Multi-Recipe

Profile Controller

Current to

Pressure

Converter

Current to

Pressure

Converter

Current to

Pressure

Converter

Retransmission

Output to

Recorder

Retransmission

Output to

Recorder

Page 2

Retort Control in the Food Industry using the C360

AG/RCP-007_2

2

Why Use the C360?

The C360 ensures high quality retorting and increases productivity. Features making it

ideal for retorts include:

▲

Automatic temperature control for increased production and operational efficiency.

▲

Up to twenty set point profiles, including guaranteed ramp and soak with individual

hysteresis for precise temperature profiles and improved product quality.

▲

Dedicated front panel for Ramp/Soak profile applications.

▲

Retransmission facility for recording purposes as standard.

▲

Fully programmable using PC Configuration software.

▲

Status indicators, a deviation bargraph and three displays showing process

variable, set point and output/segment/program all improve operator efficiency.

▲

Fast startup with self-seeking set point.

▲

Direct-connected RTD and/or thermocouple inputs reduce installation costs.

▲

Easy-clean NEMA4X/IP66 front face.

▲

Front panel profile control keys can be locked out for additional process

security.

Features and Benefits

Comprehensive Ramp/Soak Display

▲

The large, easy-to-read front panel displays of the C360 allow the operator to see

displayed information from a distance. This information includes process variable

in the upper display (red LEDs) and control set point (green LED’s) in the center

display. The lower, multifunctional display provides the following information:

program number and segment running, time remaining in the current segment

and output in %.

▲

The controller also includes status indicators; secret-til-lit LEDs showing the

type of segment being run (ramp-up, hold, ramp-down). Also featured is a

multi-color deviation bar graph which provides the operator with an immediate

representation of the deviation between process value and set point.

PC Configurable

▲

The PC Configuration Editor software (C100/0700) allows very quick and easy

setup of the

C360. Complete configurations can be stored on floppy disk allowing

an unlimited number of different cook cycles to be stored and downloaded when

needed.

▲

Reports can be printed of the controller's configuration for historical records.

Direct Connecting I/O Reduces Installation Costs

▲

With the C360, RTD or thermocouple inputs are connected directly to the

instrument. Linearization and ranging are automatic. This not only simplifies

installation, it also reduces installation costs by eliminating the need for special

termination panels or conversion equipment.

Page 3

Retort Control in the Food Industry using the C360

AG/RCP-007_2

3

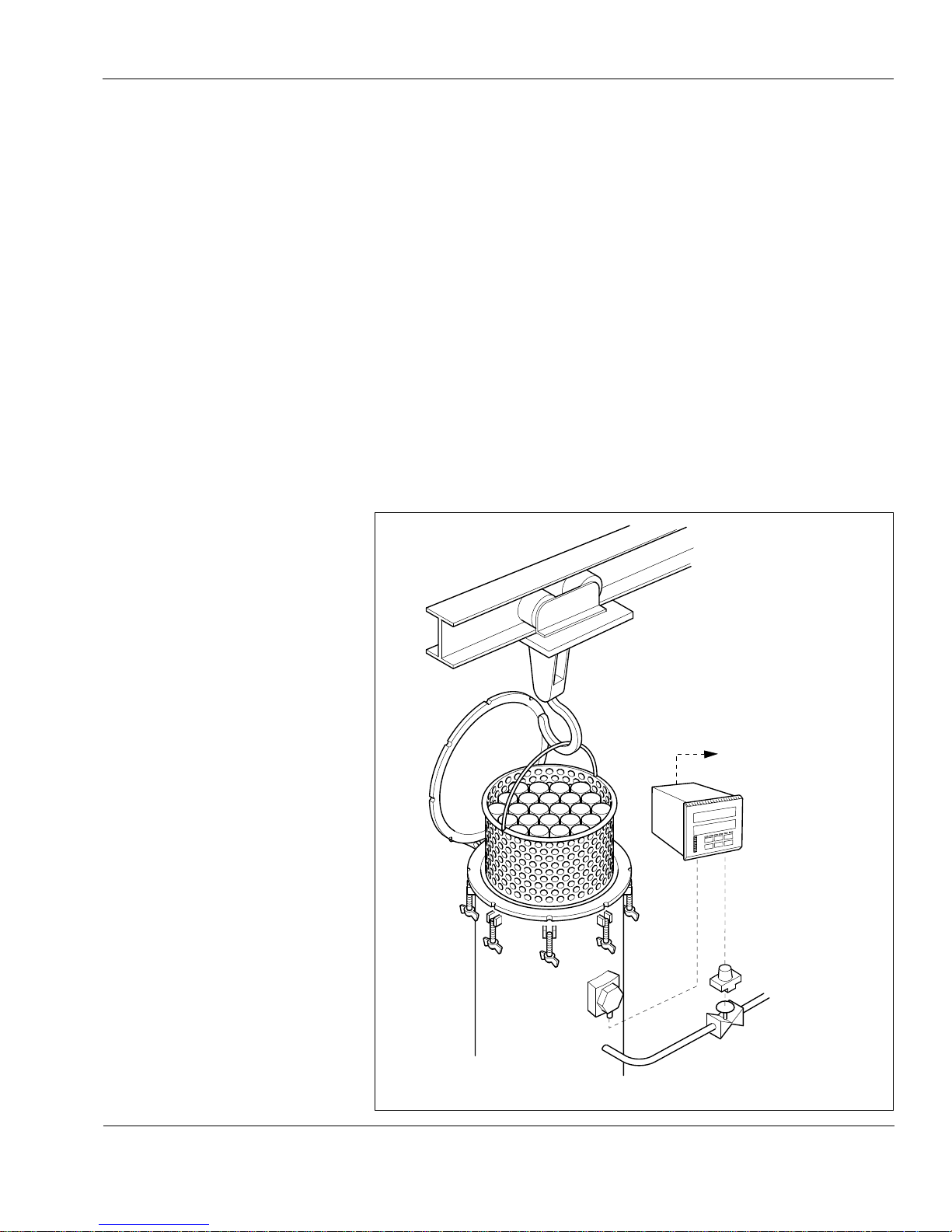

Fig. 2 Loading a Vertical Retort

The Application

Much of the food consumed each year is preserved by packaging it in hermeticallysealed containers in a process known as canning.

One of the most important steps in the canning of foods is 'thermal processing', more

commonly referred to as the retorting operation. In this operation, strict specifications,

concerning both time and temperature, must be adhered to and repeated, batch after

batch, to obtain sterile product and uniform quality.

Processing is done in batches using a cylindrical, pressurized vessel called a retort.

Retorts are classified as either vertical or horizontal, depending on the position of

its long axis. A vertical retort is loaded from the top whereas a horizontal retort is

loaded from one end.

In either retort type, the canned product is cooked by one of two processes:

▲

Steam cooking for product stored in metal containers

▲

Water cooking for product stored in glass jars

Steam cooking is done in a steam atmosphere devoid of air and water cooking is

done in steam heated water.

A

1

A

2

L

R

S

T

M

108

.6

108

.6

C360

Multi-Recipe

Profile Controller

Current to

Pressure

Converter

Retransmission

Output to

Recorder

Page 4

Retort Control in the Food Industry using the C360

AG/RCP-007_2

4

C100

Pressure Controller

Steam

Pressure Relief

Control Valv e

C360

Temperature Controller

The Retorting

Process –

Steam Cooking

The cooking sequence is similar in both vertical and horizontal retorts:

• Load retort with canned product

• Lock cover or door

• Vent the retort

• Raise to cooking temperature

• Cook product for a predetermined period of time

• Either cool with water under pressure (normally used for large cans)

or pressure relieve (normally used for small cans)

• Water cool at atmospheric pressure

• Unload retort

Loading, locking the cover or door and unloading are strictly manual functions.

▲

Venting Period

Venting the retort is the first step in the cooking cycle and takes place after the door, or

cover, is screwed down tightly on the loaded retort. Its purpose is to eliminate the air in

the retort. Steam is used to purge the air from the retort in order to obtain a steam-only

atmosphere. It is important to get the air out of the retort before the cooking period

starts because air, due to poor heat conductivity, acts as an insulator preventing the

canned product from being adequately cooked. Proper venting is achieved by purging

for a preset time period and to a desired temperature – there are no shortcuts.

▲

Raise-to-Cook Temperature Period

This period occurs after the completed vent period and is the interim period from the

vent temperature to cook temperature.

Fig. 3 Loading a Horizontal Retort

Page 5

Retort Control in the Food Industry using the C360

AG/RCP-007_2

5

▲

The Cook Period

This period is essential in order to cook the product thoroughly, thereby destroying any

organisms that could later spoil it. These organisms, called spores, are able to withstand

several hours of atmospheric boiling water temperature, but are destroyed in a short

time at a temperature of 116 to 121°C (240 to 250°F).

The correct temperature and the duration of the cook period are equally important in

achieving the desired objectives. Overcooking not only increases costs, it also causes

loss of taste or appearance of the finished product.

Fig. 4 Sparge Tubes

▲

Pressure Relief Period

The retort pressure, attained as a result of cooking at high temperature in a closed

vessel, must be relieved before the product can be removed safely. If the retort has

been filled with small cans, the pressure can be reduced to atmospheric immediately

in a process known as blowdown.

However, if the retort contains large cans, it is necessary to lower their internal

pressure before blowdown takes place to prevent them from exploding or distorting.

The reduction of internal can pressure is obtained by circulating cooling water through

the retort whilst maintaining retort pressure at the value attained during cooking by

introducing pressurizing air. When can internal pressure has dropped to a safe

value, indicated by the temperature of the cooling water leaving the retort dropping

to a desired value, blowdown can take place without the threat of can damage.

▲

Water Cooling Period

In order to increase retort production, small cans are removed from the retort immediately

after blowdown and immersed in a cooling canal prior to labeling. Larger cans, after

cooling in the retort, may require further cooling in the same manner. The determining

factor is the temperature of the product at the time it is packed in cases. This temperature

is critical because cans that are too cool may rust externally, while those that are too

warm prior to being cased and closely stacked in storage will cool too slowly and be

damaged by 'stack burn', or spoiled by creating conditions that encourage the growth

of thermophile bacteria.

The cooling canal is a rectangular-shaped, cold-water filled channel near the retort

through which the can-filled baskets are pulled after they are unloaded from the

retort. The length of the canal, the temperature of the water and the speed of the

conveyor determines the final can temperature. When a cooling canal is used instead

of the retort for final cooling, the reduced retort-time cycle increases production.

Page 6

Retort Control in the Food Industry using the C360

AG/RCP-007_2

6

The Retort Process –

Water Cooking

Product in glass jars is processed in a water-filled retort that is heated with steam. The

topmost jars must be covered by 100 to 150mm (4 to 6in.) of water throughout the

cycle and the water must be agitated to provide uniform cooking. Good agitation of the

heated water is attained by introducing air into the steam supply line to create a bubbling

action.

To ensure that the jar lids remain tightly sealed, the retort pressure is maintained slightly

higher than internal jar pressure. Pressurizing the retort also means that cooking

temperatures in excess of 100°C (212°F) can be achieved.

Cooling Water

Manual By-pass

Hand Valv e

108

.6

C360

Multi-Recipe

Profile Controller

Fig. 5 Ancilliary Control Capability

Page 7

Retort Control in the Food Industry using the C360

AG/RCP-007_2

7

Preheat Period

During the first cycle, the vertical retort is filled with water prior to loading the jars. On

subsequent cycles, the water used to cool down the last batch remains in the retort.

The temperature of this water is too low for the next batch of hot-product filled jars –

glass cannot withstand a thermal shock of more than 28°C (50°F).

The water must therefore be heated with steam to a predetermined temperature before

the jars are immersed. This operation is called preheat. The preheat water temperature

must not be more than 8°C (15°F) above product temperature to avoid raising the

internal jar pressure which would cause the jar lids to open.

Preheating in a horizontal retort is not possible because the jars must be loaded and

the door closed before water can be added. The water used to fill the retort must be

preheated externally.

Raise to Cook Temperature Period

The period in which the water is heated from initial temperature to cook temperature is

referred to as the 'raise to cook' period and should be kept to a minimum to prevent

overcooking.

The Cook Period

Both temperature and time are critical for the same reasons as outlined in steam cook.

The Pressure Cool Period

The internal jar pressure must be lowered sufficiently to prevent it from forcing the jar

lids open after cooking. To do this, retort pressure is maintained above jar internal

pressure as cooling water is circulated through the retort to cool the product and

reduce the pressure in the jar. Temperature reduction is done quickly to stop the

cooking of the product.

Pressure Relief Period

After the jars have been cooled sufficiently, the retort pressure may be reduced to

atmospheric (blown down) without danger to the containers.

Atmospheric Cooling Period

After blowdown, and with the retort cover or door open, cooling water can be circulated

through the retort in order to continue the product cooling process. Alternatively, the

jars can be removed and submerged in a cooling canal before labeling.

Page 8

AG/RCP–007 Issue 2

ABB Limited

Howard Road, St Neots

Cambridgeshire

PE19 8EU

UK

Tel: +44 (0)1480 475321

Fax: +44 (0)1480 217948

ABB Inc.

125 E. County Line Road

Warminster

PA 18974

USA

Tel: +1 215 674 6000

Fax: +1 215 674 7183

ABB has Sales & Customer Support

expertise in over 100 countries worldwide

www.abb.com

The Company’s policy is one of continuous product

improvement and the right is reserved to modify the

information contained herein without notice.

Printed in UK (12.03)

© ABB 2003

Loading...

Loading...