Page 1

Installation Guide

Circular Chart Recorder

IM/C1900–INS_13

and Recorder/Controller

C1900 Series

Page 2

ABB

The Company

EN ISO 9001:2000

We are an established world force in the design and manufacture of instrumentation for industrial

process control, flow measurement, gas and liquid analysis and environmental applications.

As a part of ABB, a world leader in process automation technology, we offer customers

Cert. No. Q 05907

application expertise, service and support worldwide.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivalled

EN 29001 (ISO 9001)

service and support.

The quality, accuracy and performance of the Company’s products result from over 100 years

experience, combined with a continuous program of innovative design and development to

Lenno, Italy – Cert. No. 9/90A

incorporate the latest technology.

The UKAS Calibration Laboratory No. 0255 is just one of the ten flow calibration plants operated

Stonehouse, U.K.

by the Company and is indicative of our dedication to quality and accuracy.

0255

Electrical Safety

This equipment complies with the requirements of CEI/IEC 61010-1:2001-2 'Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use'. If the equipment is used in a manner NOT specified by the Company, the protection

provided by the equipment may be impaired.

Symbols

One or more of the following symbols may appear on the equipment labelling:

Warning – Refer to the manual for instructions

Caution – Risk of electric shock

Protective earth (ground) terminal

Earth (ground) terminal

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of the

Technical Publications Department.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in conditions of high pressure and/

or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures

must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets (where applicable) may be

obtained from the Company address on the back cover, together with servicing and spares information.

Direct current supply only

Alternating current supply only

Both direct and alternating current supply

The equipment is protected

through double insulation

Page 3

CONTENTS

1 INTRODUCTION

Section Page

1 INTRODUCTION ........................................................... 1

2 PREPARATION ............................................................. 2

2.1 Accessories ........................................................2

2.2 Checking the Code Number ............................... 2

2.2.1 Non-upgradeable Version...................... 2

3 MECHANICAL INSTALLATION .................................... 3

3.1 Siting .................................................................. 3

3.2 Mounting ............................................................ 3

3.2.1 Wall-/Pipe-Mounting.............................. 4

3.2.2 Panel Mounting .....................................5

4 ELECTRICAL INSTALLATION ...................................... 6

4.1 Identifying the Input/Output Modules .................. 7

4.2 Channel Connections ......................................... 7

4.2.1 Selecting the Analog Input Type(s) ......... 8

4.2.2 Voltage and Current .............................. 9

4.2.3 2-wire Transmitter Input......................... 9

4.2.4 Thermocouple ....................................... 9

4.2.5 Resistance Thermometer (RTD) ............. 9

4.2.6 Logic Inputs .......................................... 9

4.2.7 Analog Output ....................................... 9

4.2.8 Relay Output ........................................9

4.2.9 Motorized Valve................................... 10

4.3 Module Connections ......................................... 11

4.3.1 Standard I/O or Analog + Relay

(Module Types 1, 2 and 7) ...................11

4.3.2 Four Relay Module (Module Type 3)..... 11

4.3.3 Eight Digital Inputs or Outputs

(Module Types 4 and 5 respectively) .... 11

4.4 Power Supply Connections ............................... 13

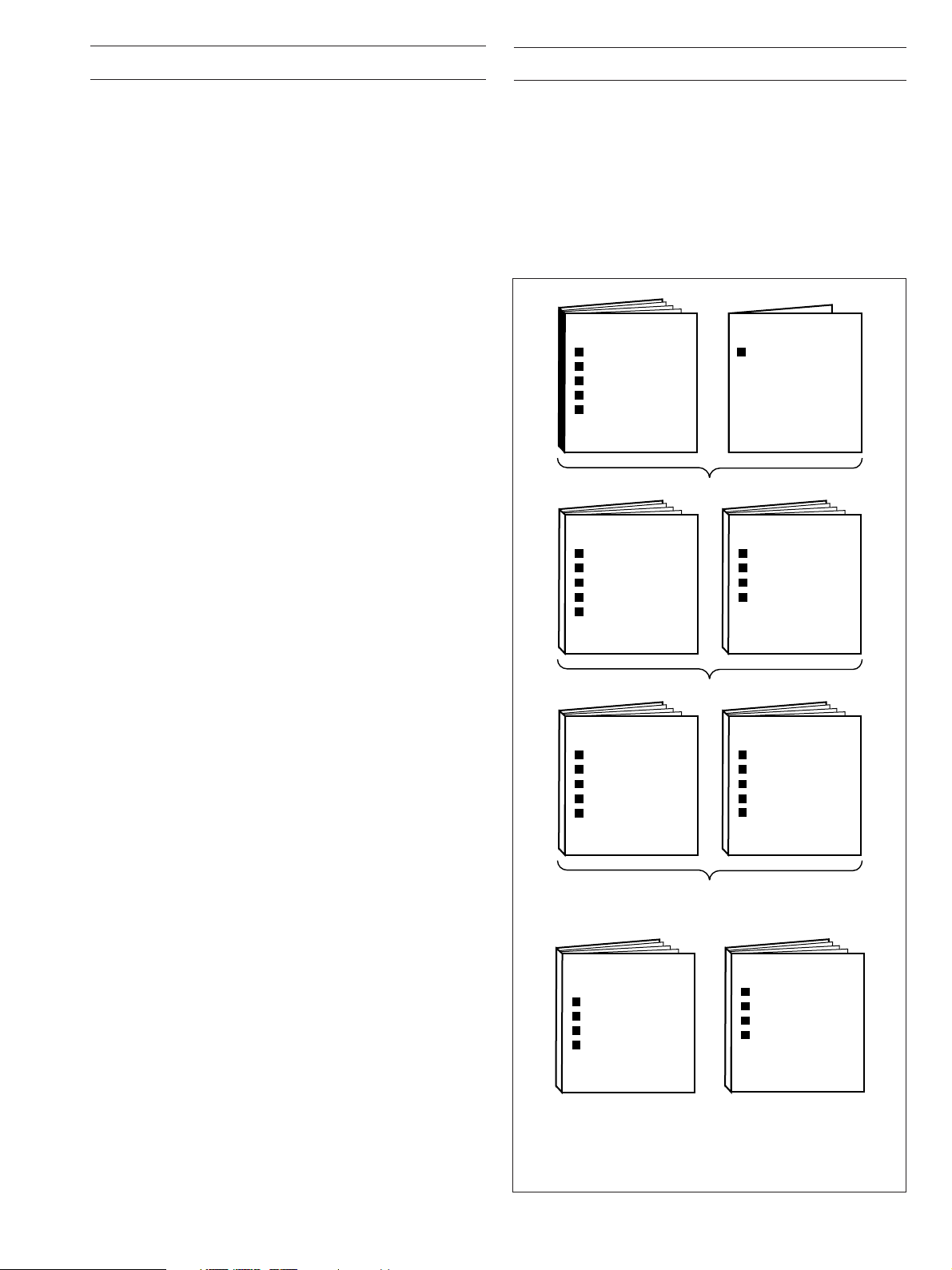

The documentation for the C1900 series of circular chart

recorders is shown in Fig. 1.1. The

Standard Manuals, including

the data sheet, are supplied with all instruments. The

Supplementary Manuals supplied depend on the specification of

the instrument.

This manual includes an Installation Record which should be

completed as a log of the electrical installation. The record is

useful when carrying out initial instrument programming and can

be retained for future reference.

INSTALLATION

Product Identification

Siting

Mounting

Electrical Connections

Installation Record

Part No.

IM/C1900–INS

Recorders and Controllers

OPERATION

Setting Up

Error Messages

Displays & Controls

Operating Level

Simple Fault Finding

Par t No.

IM/C1900–OGR

Recorders Only

DATA SHEET

Full Specification

Par t No.

SS C1900

PROGRAMMING

General Programming

Basic Config. Level

Advanced Config. Level

Connections & Links

Par t No.

IM/C1900–PGR

5 INSTALLATION RECORD ...........................................13

OPERATION

Setting Up

Error Messages

Displays & Controls

Operating Level

Simple Fault Finding

Par t No.

IM/C1900–OGC

Controllers Only

A – Standard Manuals

ADVANCED SOFTWARE

OPTIONS

Flow Totalization

Ramp/Soak Profile

Math Functions

Timer Functions

Par t No.

IM/C1900–ADV

B – Supplementary Manuals

Fig. 1.1 C1900 Documentation

PROGRAMMING

General Programming

Basic Config. Level

Control Config. Level

Advanced Config. Level

Connections & Links

Par t No.

IM/C1900–PGC

MODBUS (RTU)

Serial Adaptors

Serial Connections

Programming Pages

ASCII Tables

Par t No.

IM/C1900–MOD

1

Page 4

2 PREPARATION

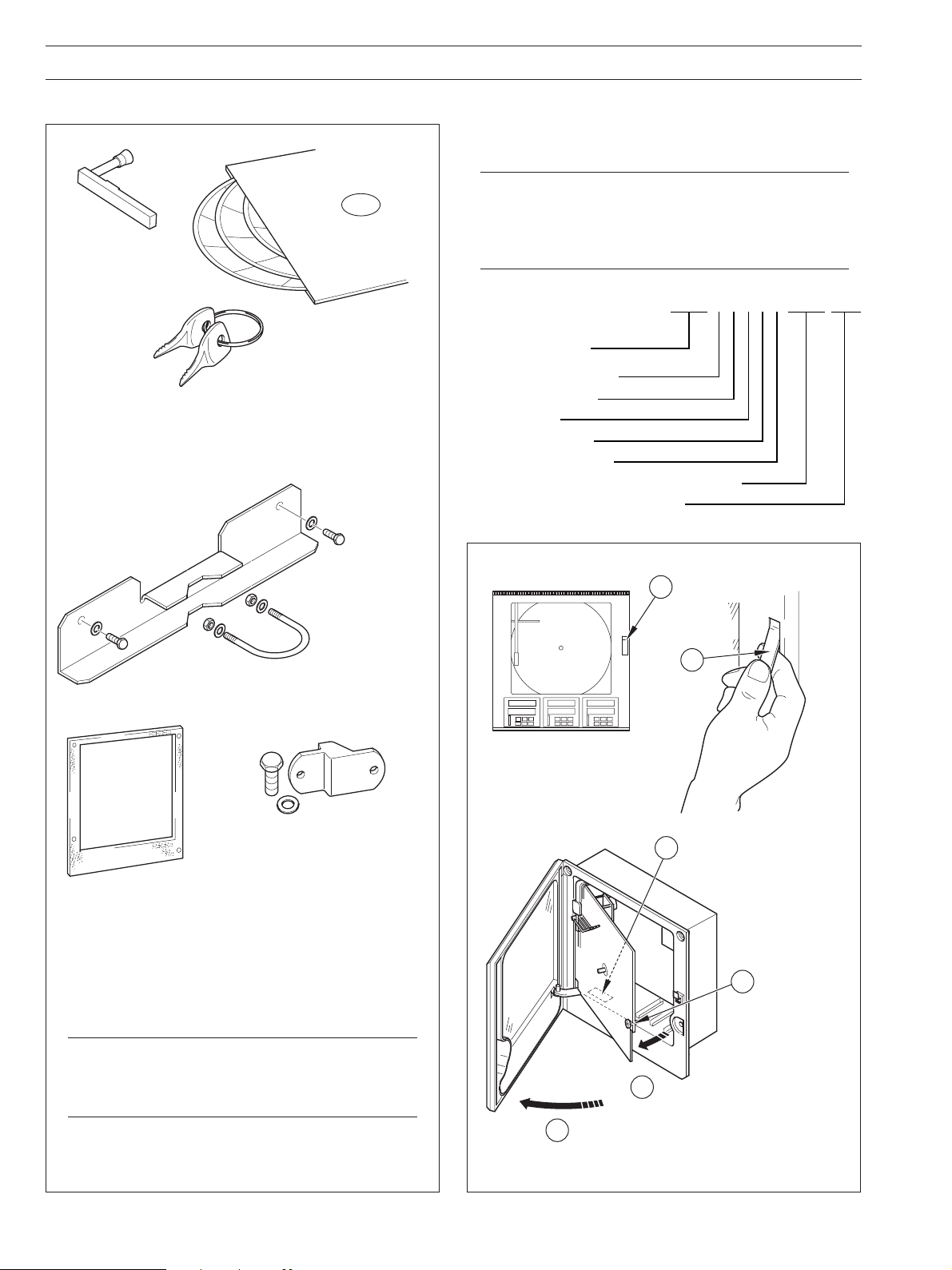

2.1 Accessories – Fig. 2.1 2.2 Checking the Code Number – Fig. 2.2

2.2.1 Non-upgradeable Version

Note. The 1901J is a basic, non-upgradeable single

pen recorder. This version is not fitted with an analog

output, relay, transmitter power supply unit or digital

Pen Capsule

1 to 4

(depending on

no. of channels)

Charts

(Pack of 3)

Keys

(door lock versions only)

A – Standard Accessories

(kit contains 2 sets

of items shown)

inputs and no additional modules can be fitted. The full

identification code is shown below.

1901J A 0 0 1 1 00000 STD

C1900

single pen recorder

Electrical code – standard

Option module – none

Options – none

Door lock – not fitted

Power supply – 115V AC

Modules fitted in module positions 2 to 6 – none

Special Settings – company standard

Case-to-Panel Gasket

C1900/0149

(see

Note below)

B – Optional Accessories

Pipe-mounting Kit

C1900/1713

Wall-mounting Kit

C1900/1712

(kit contains 4 sets

of items shown)

1

release handle

Pull handle

to release

door...

6

Push to

2

Check code number against

the Data Sheet –

SS/C1900R or SS/C1900RC

4

Loosen

captive screw

Note. If panel-mounting to NEMA 4X standard is

required, a continuous bead of suitable silicon

sealant must be applied between the case flange

and the panel. Do not use the optional gasket.

Fig. 2.1 Accessories

2

Swing chart plate forward

5

...and open door

3

Fig. 2.2 Checking the Code Number

Page 5

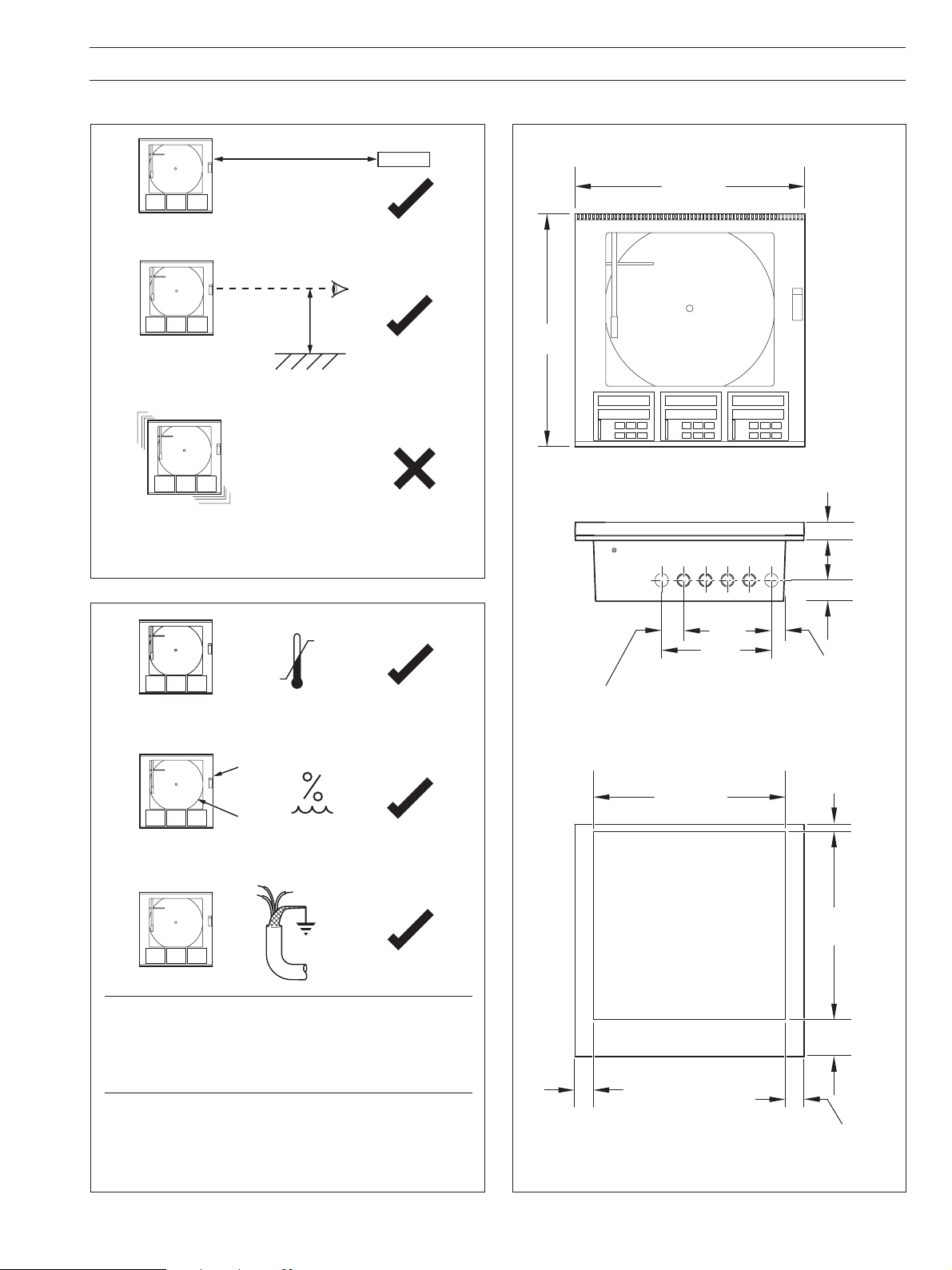

12.63 (320.8)

12.63

( 320.8)

0.32 (8.3)

2.23

(56.8)

1.18 (30.1)

1.18 (30.1)

Dimensions in inches (mm)

2.60 (66)

1.38 (35.1)

0.94 (22.4)

7.22

(183.4)

1.44 (36.6) – Typical Space Between

Adjacent Knockout Centers

1.30 (33)

15.23

(386.8)

15.04 (382)

3 MECHANICAL INSTALLATION

3.1 Siting – Figs 3.1 and 3.2 3.2 Mounting – Figs. 3.3 to 3.5

Minimum

A – Close to Sensor

B – At Eye-level Location

C – Avoid Vibration

Fig. 3.1 General Requirements

Sensor

A – Within Temperature Limits

B – Within Humidity Limits

Caution. Select a location away from strong electrical

and magnetic fields. If this is not possible, particularly in

applications where mobile communications equipment

is expected to be used, screened cables within earthed

(grounded) metal conduit must be used.

0°C

(32°F)

Min.

0 to 95% RH

0 to 80% RH

+

55°C

(131°F)

Max.

C – Use Screened Cables

Fig. 3.2 Environmental Requirements Fig. 3.3 Overall Dimensions

3

Page 6

…3 MECHANICAL INSTALLATION

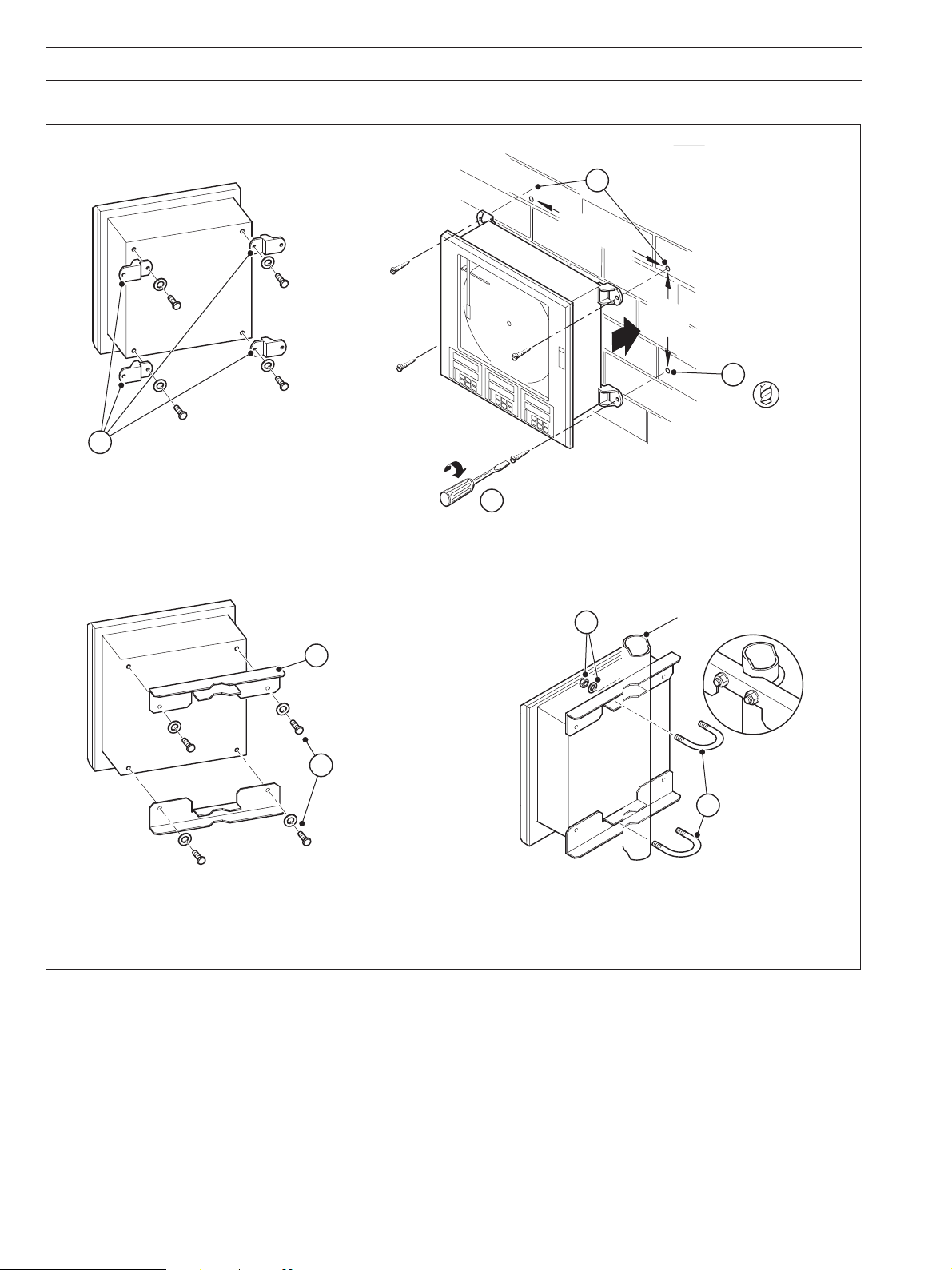

3.2.1 Wall-/Pipe-Mounting – Fig. 3.4

1

Secure mounting

brackets (4) to case

14.81 (376.3)

Secure instrument to

4

wall using suitable fixings

2

Mark fixing centers on wall (4)

11.06

(281.0)

Drill suitable

holes (4)

3

A – Wall-mounting (Optional)

Position mounting

1

brackets to suit horizontal

pipe-mounting or vertical

pipe-mounting as required

Secure mounting

2

brackets to case using

bolts and washers

B – Pipe-Mounting (Optional)

Fig. 3.4 Wall-/Pipe Mounting

Secure using

two nuts and

washers

3

/8 in. (60mm) OD

2

4

horizontal or vertical pipe

Fit 'U' bolts

3

into brackets

4

Page 7

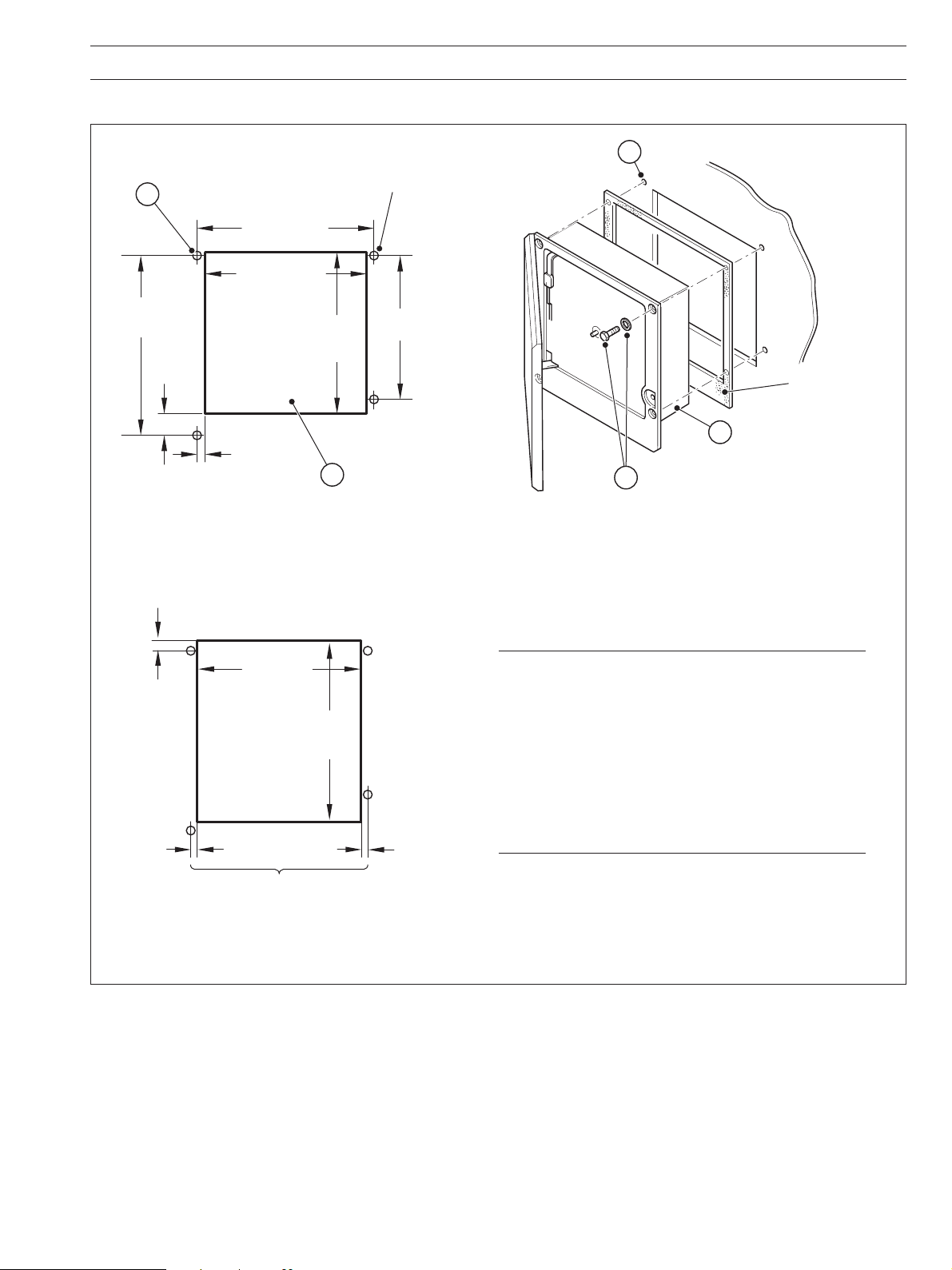

3.2.2 Panel Mounting – Fig. 3.5

3 MECHANICAL INSTALLATION

Dimensions in inches (mm)

Mark four mounting holes

2

14.00 (355.6)

12.72 (323.08)

minimum

14.19

(360.4)

1.70

(43.2)

0.64 (16.25)

Minimum Cut-out Dimensions

0.20

(5.0)

4 holes 0.281 dia.

or tap for

12.72

(323.1)

minimum

1

Cut hole in panel

Note 1

(see

1

/4 in. thread

11.25

(285.8)

below)

Drill four suitable holes

3

Locate instrument

4

in cut-out

Secure in panel using

5

four bolts, washers and nuts

Optional gasket

(see

Note 2

below)

0.15 (3.8)

minimum

13.7 (348.0)

maximum

14.6

(371.0)

maximum

Ensure cut-out positioned centrally

between mounting holes

Maximum Cut-out Dimensions

Notes.

1. The instrument can be inserted into a panel cut-out

2. If panel-mounting to NEMA 4X hosedown standard

0.15 (3.8)

minimum

Fig. 3.5 Panel Mounting

of any size between the minimum and maximum

dimensions illustrated, provided the cut-out is

positioned centrally relative to the fixing holes. If the

panel cut-out is larger than the maximum, a locally

manufactured adaptor plate will be required.

is required, a continuous bead of suitable silicon

sealant must be applied beween the case flange

and the panel. Do not use the optional gasket.

5

Page 8

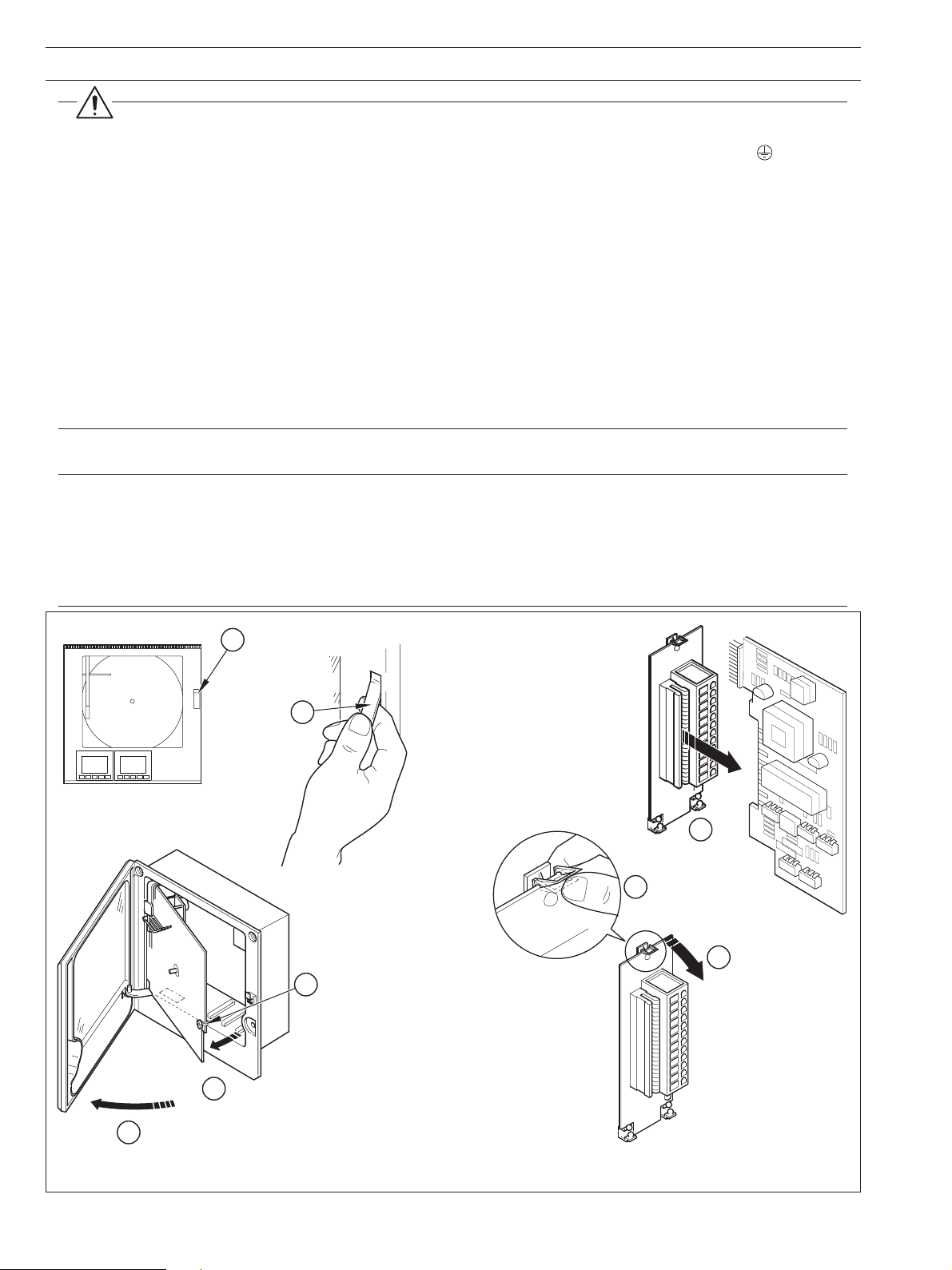

4 ELECTRICAL INSTALLATION

Warnings.

•To comply with Underwriter Laboratories (UL) and Canadian Standards Association (CSA) certification, route signal leads

and power cables in earthed (grounded), flexible metal conduit. Use the Position 1 protective ground stud

terminal module ground stud) to ground the flexible metal conduit.

• Instruments not fitted with the optional internal on/off switch and fuse must have a disconnecting device such as a switch

or circuit breaker conforming to local safety standards fitted to the final installation. It must be fitted in close proximity to

the instrument within easy reach of the operator and must be marked clearly as the disconnection device for the

instrument.

• Remove all power from supply, relay and any powered control circuits and high common mode voltages before accessing

or making any connections.

• Use cable appropriate for the load currents. The terminals accept cables up to 14AWG (2.5mm

• The instrument and all inputs and outputs conform to Mains Power Input Insulation Category II.

• All connections to secondary circuits must have basic insulation.

• After installation, there must be no access to live parts e.g. terminals.

•Terminals for external circuits are for use only with equipment with no accessible live parts.

• If the instrument is used in a manner not specified by the Company, the protection provided by the equipment may be

impaired.

• All equipment connected to the instrument’s terminals must comply with local safety standards (IEC 60950, EN601010-1).

Notes.

• Always route signal leads and power cables separately.

• Use screened cable for signal inputs and relay connections. Connect the screen to the earth (ground) stud – see Fig. 4.10.

• The terminal blocks can be removed from the main PCB when making connections – see Fig. 4.1. Before removing a

module, note its position.

• If wall- or pipe-mounting to NEMA 4X hosedown standard is required, suitable cable glands must be used to prevent

water ingress.

2

).

(NOT the

Push to

1

release handle

Pull handle

to release

2

door...

4

Loosen

captive screw

Swing chart plate forward

5

7

6

Unplug

Module

Release

Clip

8

Remove Terminal

Block Assembly

...and open door

3

Fig. 4.1 Removing Terminal Block Assembly

6

Page 9

2 3 4 5 6

Additional

Functions

Additional

Functions

Channel 2

(Green Pen)

Channel 3

(Blue Pen)

Module

Positions

2 3 4 5 6

Channel 4

(Black Pen, Violet Event

Pen or Additional Functions)

See

Note

Below

Channel 1

(Red Pen)

Not available on

non-upgradeable

version

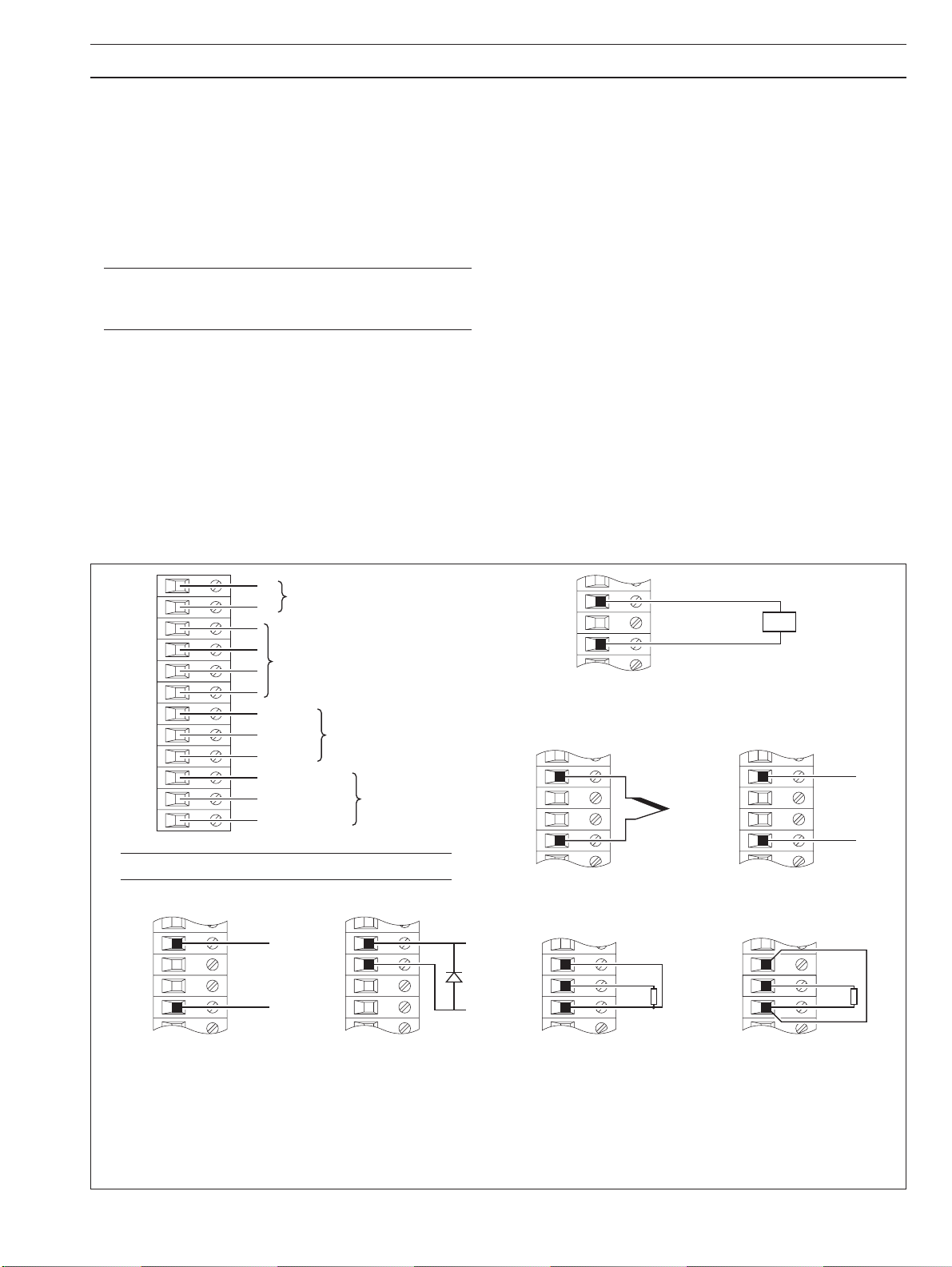

4.1 Identifying the Input/Output Modules – Fig. 4.2

To gain access to the modules, open the door and chassis – see

Fig. 2.2. There are six module positions as shown in

Fig. 4.2.

4.2 Channel Connections

Channel 1 connections are made directly to the terminal block

mounted on the motherboard.

Other Channel connections are made to standard I/O modules,

fitted in positions 2, 3 or 4 – see Fig. 4.2.

Warning. The maximum channel to channel

voltage (between any 2 channels) must not exceed

500V DC.

4 ELECTRICAL INSTALLATION…

Notes.

• Module positions can also be used for

additional I/O modules (module types 1 and

2) for use with math functions.

• The module type is marked on the

component side of the PCB.

Fig. 4.2 Module Positions and Functions

7

Page 10

…4 ELECTRICAL INSTALLATION

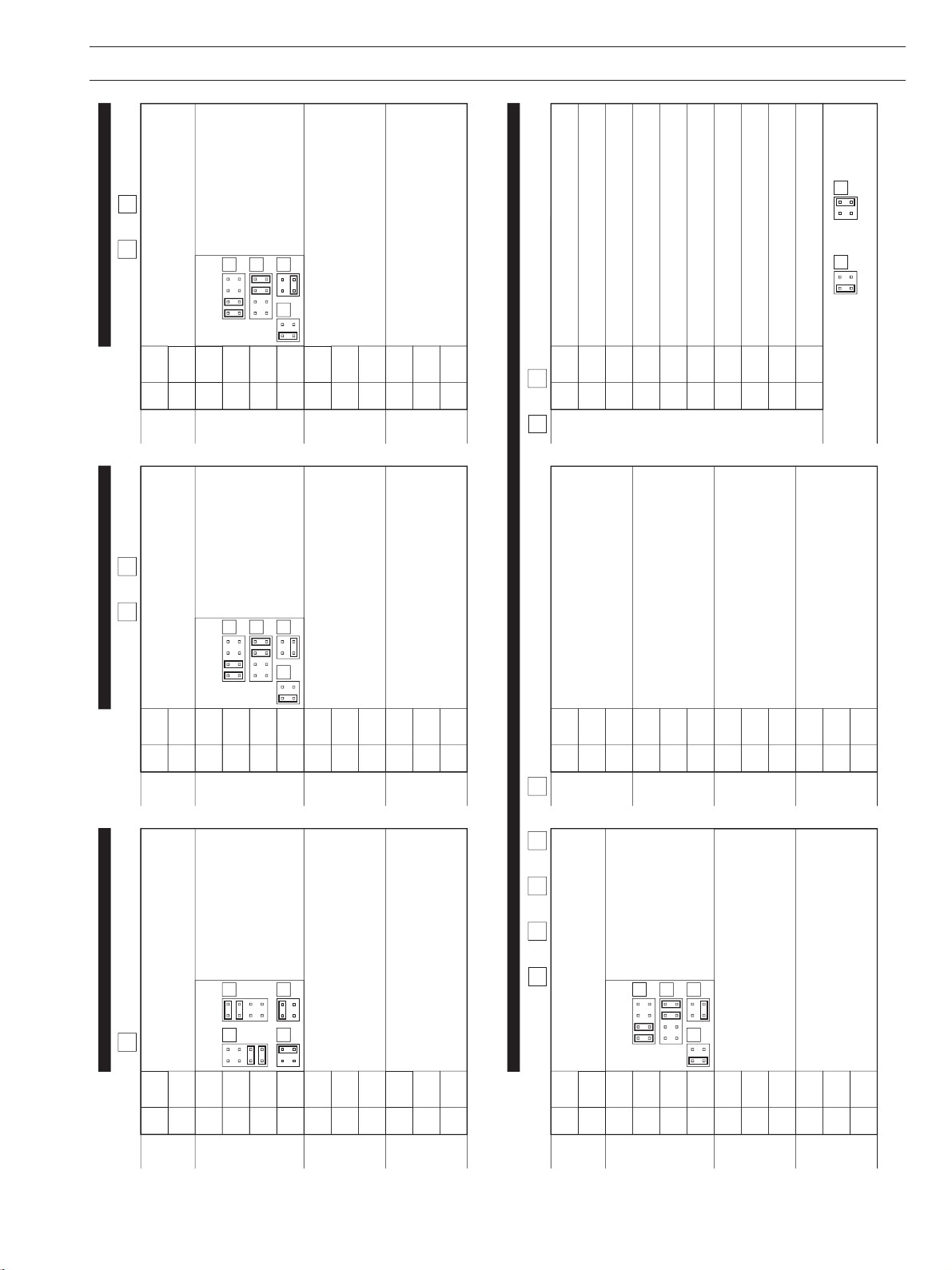

4.2.1 Selecting the Analog Input Type(s) – Figs. 4.3 and 4.4

Plug-in links are used to select the input type:

Channel 1 PL1 & PL8 on the main p.c.b. (Fig. 4.3)

Channels 2 to 4 PL1 & PL3 on the module (Fig. 4.4)

5

PL1

8

mV THC

4

1

5

PL1

8

mA V RTD & Resistance

PL8PL8

1

2

4

3

1

2

2-wire Transmitter All Other Input Types

Fig. 4.3 Selecting the Input Type (Main Board)

PL3 PL3

3

4

2-wire Transmitter

41

2

1

3

4

2

1

All Other Input Types

41

R50

R44

C110

PL1

54

8

1

C18

41

23

PL8

C122

+

R53

C12

+

C13

C25

L14

L11

TRA9

TR9

L17

2 3 4 5 6

C83

C117

+

STAR

DJ4 IC19

C104

IC6

TR6

+

C119

L22

R64

JC50

C126

D15

IC5

4

1

4

3

R56

C33

C17

C16

R21

C34

R26

R30

R24

C27

C23

C15

R44

C22

C35

C13

C10

PL3

4

C24

C26

C29

C19

C20

C21

C30

IC20

R36

R27

C14

PL1

R22

C25

R25

C38

L5

INPUT/OUTPUT MODULE

58

PL1 PL1

58

mA V RTD & ResistancemV THC

Fig. 4.4 Selecting the Input Type (I/O Modules)

elbaCgnitasnepmoC

3481SB1.69CMISNA41734NID03.oNtraP7394SB

elpuocomrehTfoepyT+–esaC+– esaC+–esaC+– esaC

)K(lA-iN/rC-iNnworBeulBdeRwolleYdeRwolleYdeRneerGneerGneerGetihW*neerG

)E(iN-uC/rC-iN———teloiVetihW*teloiV

)N(lisiN/lisirciNegnarOeulBegnarOegnarOdeRegnarO—kniPetihWkniP

)SdnaR(hR-tP/tPetihWeulBneerGkcalBdeRneerGdeRetihWetihWegnarOetihW*egnarO

)B(hR-tP/hR-tP———yerGetihW*yerG

)T(iN-uC/uCetihWeulBeulBeulBdeReulBdeRnworBnworBnworBetihW*nworB

)J(noC/eFwolleYeulBkcalBetihWdeRkcalBdeReulBeulBkcalBetihW*kcalB

)01734NID(noC/eF——

deR/eulBeulBeulB

01734NID

Table 4.1 Thermocouple Compensating Cable

stiucricefasyllacisnirtnirofeulBesaC*

—

8

Page 11

4 ELECTRICAL INSTALLATION…

4.2.2 Voltage and Current – Fig. 4.5

Input impedances:

Low voltage (mV) >10M

Voltage >10M

Current (mA) 100

4.2.3 2-wire Transmitter Input – Fig. 4.5

Power for the transmitter is supplied by terminal 6.

Note. The voltage across terminals 4 and 6 is 20V

(nominal). This is due to internal voltage drops across a

shunt resistor and measurement circuitry.

4.2.4 Thermocouple – Fig. 4.5

Use correct compensating cable between the thermocouple

and the terminals – see Table 4.1 (previous page).

Automatic cold junction (ACJC) is incorporated but an

independent cold (reference) junction may be used.

4.2.5 Resistance Thermometer (RTD) – Fig. 4.5

If long leads are necessary it is preferable to use a 3-lead

resistance thermometer.

If 2-lead resistance thermometers are used each input must be

calibrated to take account of the lead resistance.

4.2.6 Logic Inputs – Fig. 4.5

The two logic inputs accept either volt-free (switch) or TTL (5V)

input types and can be used for remote switching of many

recorder functions, e.g. chart stop/go, alarm acknowledgment,

totalizer reset etc. Refer to the

Programming Guide,

IM/C1900–PGR or IM/C1900–PGC.

4.2.7 Analog Output – Fig. 4.5

4.2.8 Relay Output – Fig. 4.5

Relay specification:

Type single pole changeover

Voltage 250V AC 250V DC

Current 5A AC 5A DC

Loading (non inductive) 1250VA 50W

Isolation, contacts to earth 2kV RMS

1

2

3

4

5

6

7

8

9

10

1

12

+

Analog Output (See

Analog Input see B to H

Common

Logic 1

Logic 2

Normally Open

Common

Normally Closed

Logic Inputs (See

Relay Output

Note. Not applicable on Type 2 Modules.

A Summary of Connections

3

6

+

3

4

Note

below)

Note

below)

+

4

6

+

D 2-wire Transmitter

(not available on non-upgradeable version)

3

+

6

E Thermocouple

4

5

6

Red

White

Red

See

Tx

Note

+

3

6

F Low Voltage (mV)

Link

4

5

6

White

Red

below

+

B Voltage

* Recommended diode:

Diode forward voltage > 0.8 V @ 20 mA or use 2 x 1N4001 general purpose diodes in series

C Current

(non 2-wire transmitters)

Fig. 4.5 Channel Connections

G 3-wire RTD

H 2-wire RTD & Resistance

*

9

Page 12

…4 ELECTRICAL INSTALLATION

4.2.9 Motorized Valve – Fig. 4.6

A motorized valve with or without feedback requires 2 relays (common and normally open terminals) to drive the valve in either

direction. Any two relays can be allocated for this function. Fig. 4.6 A shows two possible combinations.

Note. For valves with position feedback using low voltage (mV),

voltage (V) or current (C), refer to Fig. 4.5 B, C and F for connections.

(L)

10

1st

11

Module

10

2nd

11

Module

Type 1 and/or Type 2

Modules (see

Type 1 or Type 2

Module

Four Relay Module

2

3

4

5

6

Note 1

below)

Valve

Positioner

Power

Supply

100%

0%

Motorized

Valve Drive

L

N

(N)

Motorized

Valve Drive

Type 1 or Type 2

Module

4

5

Module

6

1st or 2nd

(see

Note 2

Link

below)

0%

100%

4

5

Module

6

1st or 2nd

(see

Note 2

Link

below)

0%

100%

A – Standard Feedback Slidewire Configuration B – Alternative Feedback Slidewire Configuration

Notes.

1 Type 1 and type 2 modules have one relay output, therefore two modules are required.

2 Link must be connected at valve drive end, not at the controller terminals.

Fig 4.6 Motorized Valve Connections (using feedback slidewire)

10

Page 13

1

2

7

8

9

10

11

12

3

4

5

6

Common

Input 1

Common

Input 7

Input 8

Input

Connections

Input 5

Input 6

Input 3

Input 4

Input 2

Common

Output 1

Common

Output 7

Output 8

Output

Connections

Output 5

Output 6

Output 3

Output 4

Output 2

or

4 ELECTRICAL INSTALLATION…

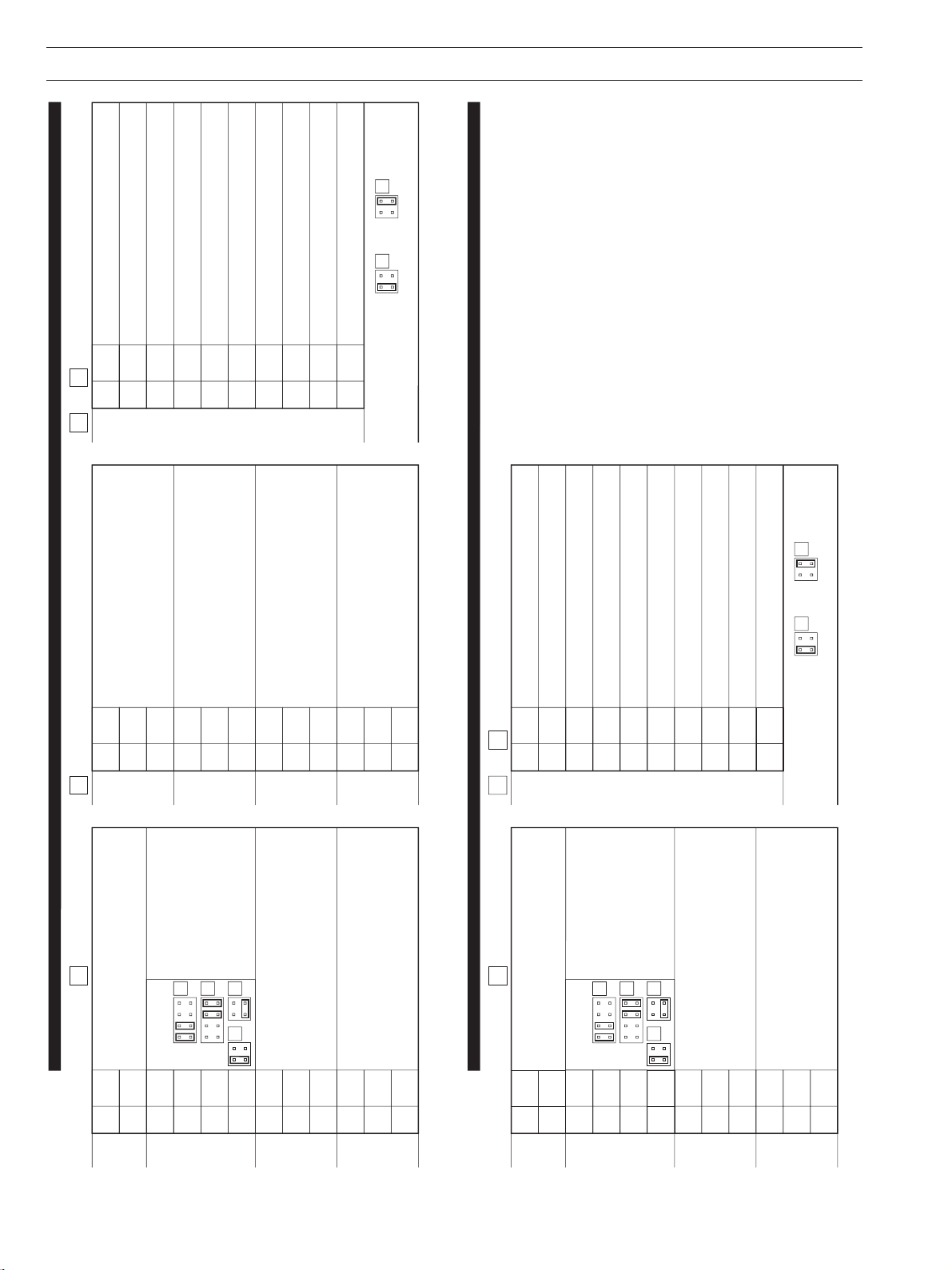

4.3 Module Connections

4.3.1 Standard I/O or Analog + Relay

(Module Types 1, 2 and 7) – Fig. 4.5

The connections are the same as Channel connections to the

main board. Refer to Section 4.2.

4.3.2 Four Relay Module (Module Type 3) – Fig. 4.7

1

2

3

4

5

6

7

8

9

10

11

12

Normally Closed

Normally Open

Common

Normally Closed

Normally Open

Common

Normally Closed

Normally Open

Common

Normally Closed

Normally Open

Common

Relay 1

Relay 2

Relay 3

Relay 4

4.3.3 Eight Digital Inputs or Outputs

(Module Types 4 and 5 respectively) –

Figs. 4.8 and 4.9

A plug-in link is used to select the board's function; digital inputs

or digital outputs – see Fig. 4.8. The maximum current drain from

each TTL output must not exceed 5mA.

PL2

14

PL2 PL2

3

4

Digital Inputs

2

1

Digital Outputs

3

4

2

1

Fig. 4.7 Four Relay Module Connections

(Module Type 3)

Fig. 4.8 Selecting the Digital Module Function

(Module Types 4 and 5)

Fig. 4.9 Eight Digital Inputs or Outputs Connections

(Module Types 4 and 5)

11

Page 14

…4 ELECTRICAL INSTALLATION

4.4 Power Supply Connections – Fig. 4.10

2 3 4 5 6

Power Switch (Optional)

Fuse (Optional)

– see Note 1 below

Note. Recorders manufactured before June 2005 are

fitted with a Mainboard that is not equipped with a

universal power supply. Ensure the supply voltage

selector switch is set correctly and the appropriate fuse

is fitted – see Fig 4.11.

1 or 4

X

Code Label

1 9 x x x x x x x x x x x x x x

Digit 10

3 or 6

Selector not Fitted

(24V AC Version)

2 or 5

115

230

Line

Neutral

Remove Plug, Connect

Earth (Ground) Stud –

see Note 2 below

Power Supply Leads to

Plug and Refit Plug

Warning. If the optional internal power

switch and fuse are not fitted, an external

disconnection device and fuse must be

fitted – see also Warnings on page 6.

Line

Neutral

Before making any electrical connections,

see Warnings on page 6

Notes.

1. Fuse rating:

500mA (20 X 5mm) Type T

2. Ensure that the Earth (Ground) lead is longer than

the Line and Neutral leads.

Position 1

Position2Position3Position4Position5Position

6

Fuse (Optional)

– see Note below

Note. Fuse ratings:

115V Supply 1A (20 x 5mm) Type T

1

230V Supply

/2A (20 x 5mm) Type T

24V Supply 4A (20 x 5mm) Type T

Fig. 4.11 Power Supply Selection

(Recorders Manufactured Before June 2005 Only)

115

12

Fig. 4.10 Power Supply Connections

Page 15

**

*

Link Positions

Module Type (Tick Box)Module Type

NC

1

Analog

Output

Analog

Input

Logic

Inputs

Relay

Output

+

2

–

3

4

5

6

7

C

8

L1

9

L2

10

NO

1

C

12

1

NC

1

Analog

Output

Analog

Input

Logic

Inputs

Relay

Output

+

2

–

3

4

5

6

7

C

8

L1

9

L2

10

NO

1

C

12

NC

1

Analog

Output

Analog

Input

Logic

Inputs

Relay

Output

+

2

–

3

4

5

6

7

C

8

L1

9

L2

10

NO

1

C

12

*

*

*

*

**

Not applicable on Module Type 2 Not applicable on Module Type 2

C

1

Relay

Output 1

Relay

Output 2

Relay

Output 3

Relay

Output 4

2

3

4

5

6

7

8

9

10

NC

1

NO

12

1

Logic I/Ps (Type 4) or Logic O/Ps (Type 5)

C

2

1

3

4

5

6

7

6

8

7

9

8

10

C

Position 1

1

2

Module Type (Tick Box)

1

2

6

7

Position 2 Position 3

1

Position 4

NC

1

Analog

Output

Analog

Input

Logic

Inputs

Relay

Output

+

2

–

3

4

5

6

7

C

8

L1

9

L2

10

NO

1

C

12

*

*

*

Not available on Module Type 2

3

4

5

C

NC

NO

C

NC

NO

C

NC

NO

2

3

4

5

Link Positions

(Tick Boxes)

Module Type (Tick Box)

(Tick Box)

Type 4 Type 5

Link Positions

(Tick Boxes)

2

Link Positions

(Tick Boxes)

Link Positions

(Tick Boxes)

5 INSTALLATION RECORD

13

Page 16

*

*

Link Positions

1

Logic I/Ps (Type 4) or Logic O/Ps (Type 5)

C

2

1

3

4

5

6

7

6

8

7

9

8

10

C

Module Type (Tick Box)

2

Position 6

NC

1

Analog

Output

Analog

Input

Logic

Inputs

Relay

Output

+

2

–

3

4

5

6

7

C

8

L1

9

L2

10

NO

1

C

12

*

*

*

Not available on Module Type 2

4

5

2

3

4

5

(Tick Box)

Type 4 Type 5

Link Positions

(Tick Boxes)

Link Positions

C

1

Relay

Output 1

Relay

Output 2

Relay

Output 3

Relay

Output 4

2

3

4

5

6

7

8

9

10

NC

1

NO

12

1

Logic I/Ps (Type 4) or Logic O?ps (Type 5)

C

2

1

3

4

5

6

7

6

8

7

9

8

10

C

Module Type (Tick Box)

2

Position 5

NC

1

Analog

Output

Analog

Input

Logic

Inputs

Relay

Output

+

2

–

3

4

5

6

7

C

8

L1

9

L2

10

NO

1

C

12

*

*

*

Not available on Module Type 2

3

4

5

C

NC

NO

C

NC

NO

C

NC

NO

2

3

4

5

(Tick Box)

Type 4 Type 5

Link Positions

(Tick Boxes)

…5 INSTALLATION RECORD

14

Page 17

NOTES

15

Page 18

…NOTES

16

Page 19

PRODUCTS & CUSTOMER SUPPORT

Products

Automation Systems

• for the following industries:

– Chemical & Pharmaceutical

– Food & Beverage

– Manufacturing

– Metals and Minerals

– Oil, Gas & Petrochemical

– Pulp and Paper

Drives and Motors

• AC and DC Drives, AC and DC Machines, AC Motors to 1kV

• Drive Systems

• Force Measurement

• Servo Drives

Controllers & Recorders

• Single and Multi-loop Controllers

• Circular Chart and Strip Chart Recorders

• Paperless Recorders

• Process Indicators

Flexible Automation

• Industrial Robots and Robot Systems

Customer Support

We provide a comprehensive after sales service via a Worldwide

Service Organization. Contact one of the following offices for

details on your nearest Service and Repair Centre.

United Kingdom

ABB Limited

Tel: +44 (0)1480 475321

Fax: +44 (0)1480 217948

United States of America

ABB Inc.

Tel: +1 215 674 6000

Fax: +1 215 674 7183

Flow Measurement

• Electromagnetic Flowmeters

• Mass Flow Meters

• Turbine Flowmeters

• Flow Elements

Marine Systems & Turbochargers

• Electrical Systems

• Marine Equipment

• Offshore Retrofit and Refurbishment

Process Analytics

• Process Gas Analysis

• Systems Integration

Transmitters

• Pressure

• Temperature

• Level

• Interface Modules

Valves, Actuators and Positioners

• Control Valves

• Actuators

• Positioners

Water, Gas & Industrial Analytics Instrumentation

• pH, Conductivity, and Dissolved Oxygen Transmitters and

Sensors

• Ammonia, Nitrate, Phosphate, Silica, Sodium, Chloride,

Fluoride, Dissolved Oxygen and Hydrazine Analyzers.

• Zirconia Oxygen Analyzers, Katharometers, Hydrogen Purity

and Purge-gas Monitors, Thermal Conductivity.

Client Warranty

Prior to installation, the equipment referred to in this manual must

be stored in a clean, dry environment, in accordance with the

Company's published specification.

Periodic checks must be made on the equipment's condition. In

the event of a failure under warranty, the following documentation

must be provided as substantiation:

1. A listing evidencing process operation and alarm logs at time of

failure.

2. Copies of all storage, installation, operating and maintenance

records relating to the alleged faulty unit.

Page 20

ABB has Sales & Customer Support

expertise in over 100 countries worldwide

www.abb.com

The Company’s policy is one of continuous product

improvement and the right is reserved to modify the

information contained herein without notice.

Printed in UK (10.08)

© ABB 2008

IM/C1900–INS Issue 13

ABB Limited

Howard Road, St Neots

Cambridgeshire

PE19 8EU

UK

Tel: +44 (0)1480 475321

Fax: +44 (0)1480 217948

ABB Inc.

125 E. County Line Road

Warminster

PA 18974

USA

Tel: +1 215 674 6000

Fax: +1 215 674 7183

Loading...

Loading...