Page 1

—

ABB MEASUREMENT & ANALYTICS | OPERATING GUIDE | IM/C1900-OGR REV. L

C1900

Circular chart recorder

Measurement made easy

—

C190 0

circular chart recorder

For more information

Further publications are available for free download

from:

www.abb.com/recorders

or by scanning this code:

Data Sheet

C1900

Circular chart recorder

Quick Reference Guide

C1900

Circular chart recorder

Installation Guide

C1900

Circular chart recorder and

recorder / controller

Programming Guide

C1900

Circular chart recorder

Operating Instructions

C1900

Circular chart recorder and

recorder/controller

User Guide

C1900

Circular chart recorder and

recorder/controller

Search for or click on

DS/C1900R-EN

IM/C1900 -QR

IM/C1900-INS

IM/C1900 -P GR

IM/C1900-MOD

IM/C190 0- ADV

Page 2

Use of instructions

Health and safety

Warning – an instruction that draws attention to the risk of

injury or death.

Caution – an instruction that draws attention to the risk of

damage to the product, process or surroundings.

Note – clarification of an instruction or additional information.

Information.

Information – further reference for more detailed information

or technical details.

It must be understood that operation of damaged equipment

could, under certain operational conditions, result in degraded

process system performance leading to personal injury or

death. Therefore, comply fully with all Warning and Caution

notices.

Information in this manual is intended only to assist our

customers in the efficient operation of our equipment. Use of

this manual for any other purpose is specifically prohibited and

its contents are not to be reproduced in full or part without

prior approval of the Technical Publications Department.

To ensure that our products are safe and without risk to health,

the following points must be noted:

• The relevant sections of these instructions must be read

carefully before proceeding.

• Warning labels on containers and packages must be

observed.

• Installation, operation, maintenance and servicing must

only be carried out by suitably trained personnel and in

accordance with the information given.

• Normal safety precautions must be taken to avoid the

possibility of an accident occurring when operating in

conditions of high pressure and/or temperature.

• Chemicals must be stored away from heat, protected from

temperature extremes and powders kept dry. Normal safe

handling procedures must be used.

• When disposing of chemicals ensure that no two chemicals

are mixed.

Safety advice concerning the use of the equipment described in

this manual or any relevant hazard data sheets (where

applicable) may be obtained from the Company address on the

back cover, together with servicing and spares information.

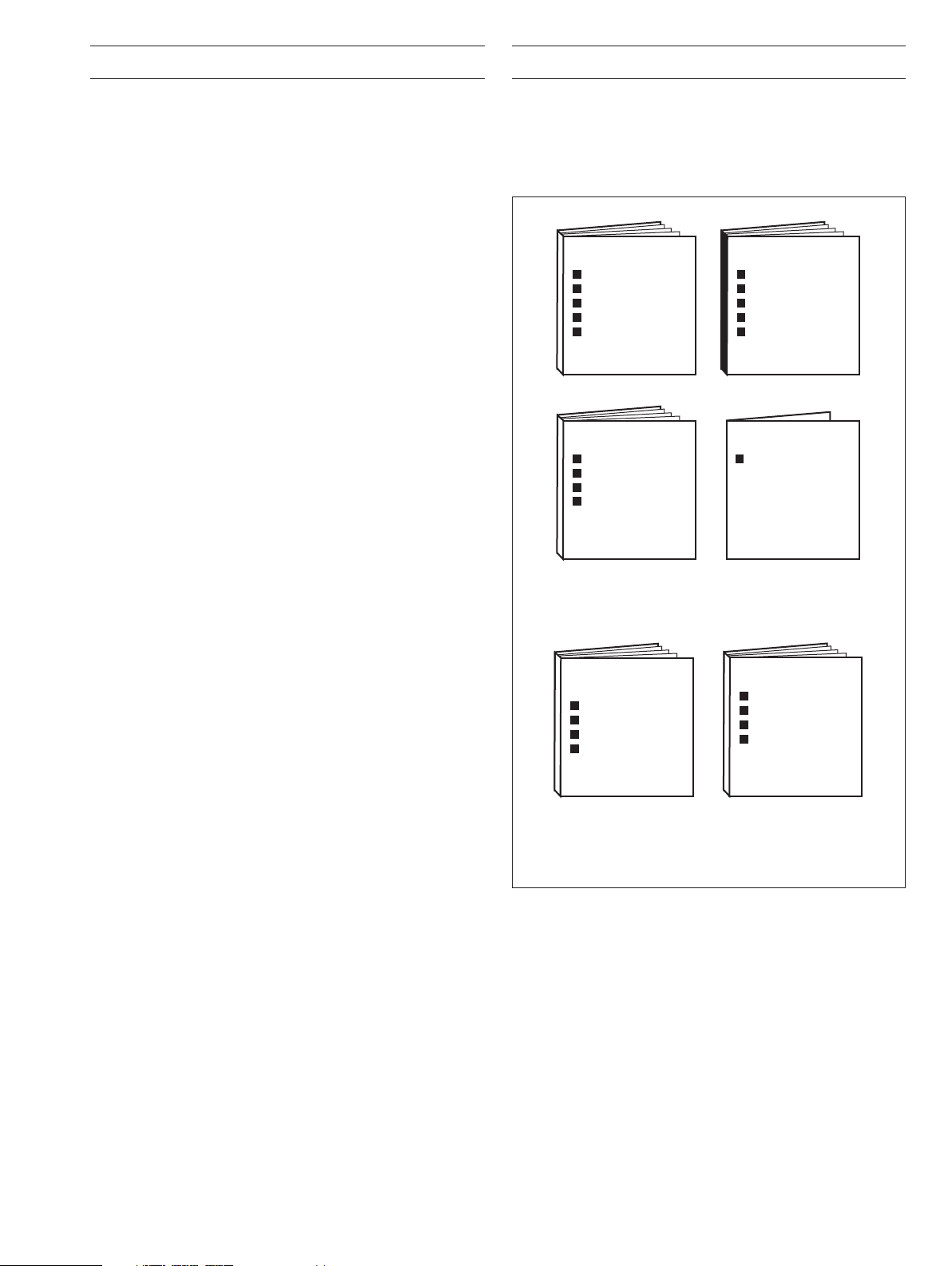

Page 3

Part No.

IM/C1900–INS

INSTALLATION

Product Identification

Siting

Mounting

Electrical Connections

Installation Record

OPERATION

Setting Up

Error Messages

Operating Level

Simple Fault Finding

PROGRAMMING DATA SHEET

Full Specification

Part No.

IM/C1900–OGR

Displays & Controls

Part No.

IM/C1900–PGR

Part No.

SS C1900

Flow Totalization

Ramp/Soak Profile

Math Functions

Timer Functions

MODBUS (RTU)

Serial Adaptors

Serial Connections

Programming Pages

ASCII Tables

Part No.

IM/C1900–ADV

Part No.

IM/C1900–MOD

ADVANCED SOFTWARE

OPTIONS

A – Standard Manuals

B – Supplementary Manuals

General Programming

Basic Config. Level

Advanced Config. Level

Connections and Links

CONTENTS 1 INTRODUCTION

Section Page

1 INTRODUCTION ........................................................... 1

2 SETTING UP ................................................................. 2

2.1 Instrument Power-up .......................................... 2

2.1.1 Power-up Error Codes .......................... 3

2.2 Fitting the Chart ..................................................4

2.3 Fitting the Pen Capsule(s) ................................... 4

3 DISPLAYS & CONTROLS............................................. 5

3.1 Displays and LED Indicators ............................... 5

3.2 Use of Controls ................................................... 6

4 OPERATION.................................................................. 7

4.1 Input Error Messages .......................................... 8

4.2 Operating Page Displays ..................................... 9

4.3 Alarm Acknowledge Page ................................. 10

4.3.1 Alarm Indications ................................. 10

4.3.2 Acknowledging Alarms ........................ 10

4.3.3 Using the Alarm

Acknowledge Page ............................. 10

4.4 Totals Page Displays ......................................... 11

4.5 Access to Configuration Levels .........................12

5 SIMPLE FAULT FINDING ........................................... 13

The documentation for the C1900 series of circular chart

recorders is shown in Fig. 1.1. The

Standard Manuals, including

the data sheet, are supplied with all instruments. The

Supplementary Manuals supplied depend on the specification of

the instrument.

6 SPARES LIST ............................................................. 14

Fig. 1.1 C1900 Documentation

1

Page 4

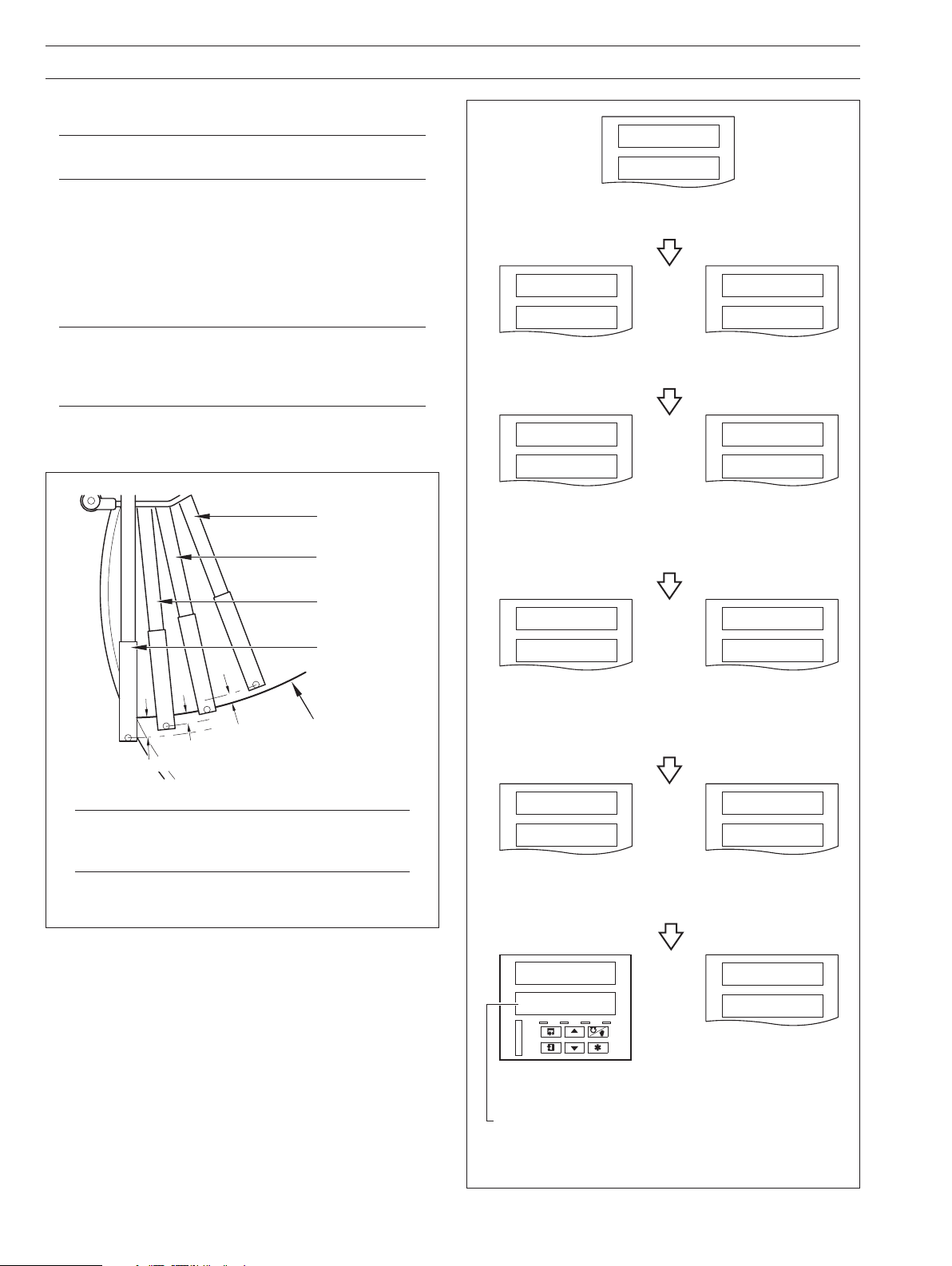

2 SETTING UP

2.1 Instrument Power-up – Fig. 2.1 and 2.2

Caution. Ensure that all connections, especially to the

earth stud, are made correctly.

a) Check that the input sensors are installed correctly.

b) Check that the pen(s) are installed correctly – see Fig. 2.1.

c) Switch on the supply to the instrument, any power-operated

control circuits and the input signals. Wait for the pens to

settle.

Note. On power-up, the pens are moved to an off-

chart position for automatic referencing. Pen chatter

may occur on those pens nearest the reference

position. This is a normal function of the instrument.

d) The start-up sequence shown in Fig. 2.2 is displayed on

faceplate 1 when the supply is first switched on.

Blue Pen

(Channel 3)

Red Pen

(Channel 1)

Green Pen

(Channel 2)

Black Pen

(Channel 4)

Note

– see

Chart Time Line

0.35 (8.8)

0.175 (4.4)

0.175 (4.4)

Dimensions in inches (mm)

1914 J

tESt

Instrument Test identifies the instrument type, e.g.

1914J – see Table 2.1 in the

CPU

PASS

CPU Test carries out check of processor circuitry – see

Error Codes

below.

CONFIG

PASS

Configuration Test carries out check of non-volatile

memories containing the instrument configuration, then

indicates pass or fail – see

CAL

PASS

Calibration Test carries out check of non-volatile

memories containing the calibration data for each analog

input and output, then indicates pass or fail – see

below.

Codes

Installation Manual.

CPU

or

FAIL

CONFIG

or

FAIL

Error Codes

CAL

or

FAIL

below.

Error

Note. If the true time line event option is fitted, the

violet event pen records on the same time line as

the red pen, but on the outer edge of the chart.

Fig. 2.1 Checking the Pen(s) Installation

2

bb rAM

PASS

Battery Back RAM Test carries out check of batterybacked RAM, then indicates pass or fail – see

below.

Codes

or

!00.3

200.3

AL

AT

RMT

MAN

Normal Display

Not applicable on single

channel instruments

Fig. 2.2 Instrument Displays at Start-up

or

bb rAM

FAIL

Error

A––––F

–2–4––

Error Codes are

displayed in the event

of a fault – see Section

2.1.1.

Page 5

2 SETTING UP…

2.1.1 Power-up Error Codes

If any of the power-up tests fail (see Fig. 2.2), error codes are displayed to identify the fault. Refer to Fig. 2.3 for error code

interpretations.

A––––F

–2–4––

Code Error Action

– No error

1 Main board

2 Module in position 2

3 Module in position 3

4 Module in position 4

5 Module in position 5

6 Module in position 6

Code Error Action

– No error None

A

Configuration and battery-backed RAM errors

Calibration errors

Analog input and/or analog

output calibration is corrupt

Main program data stored in non-volatile

memory on main board is corrupt

None

Power down and then up again.

If fault remains, contact the local Service

Organisation.

Check and correct program data

C

d

F

Acknowledging Error Codes

Note. Acknowledging the Error Code clears the error state but does not rectify the fault.

After acknowledging the error, carry out the relevant action detailed in the above tables.

Timer set up stored in battery backed RAM is corrupt

Maths set up stored in battery back RAM is corrupt

Totalizer set up in battery backed RAM has been corrupt

ACKNLG

or

ErrOrS

Fig. 2.3 Power-up Error Codes

Check and correct data in

Check and correct data in

Check and correct data in

* Refer to the

Advanced Software Manual

100.3

200.5

Set Up Timer Page*

Set Up Maths Page*

Set Up Totals Page*

3

Page 6

…2 SETTING UP

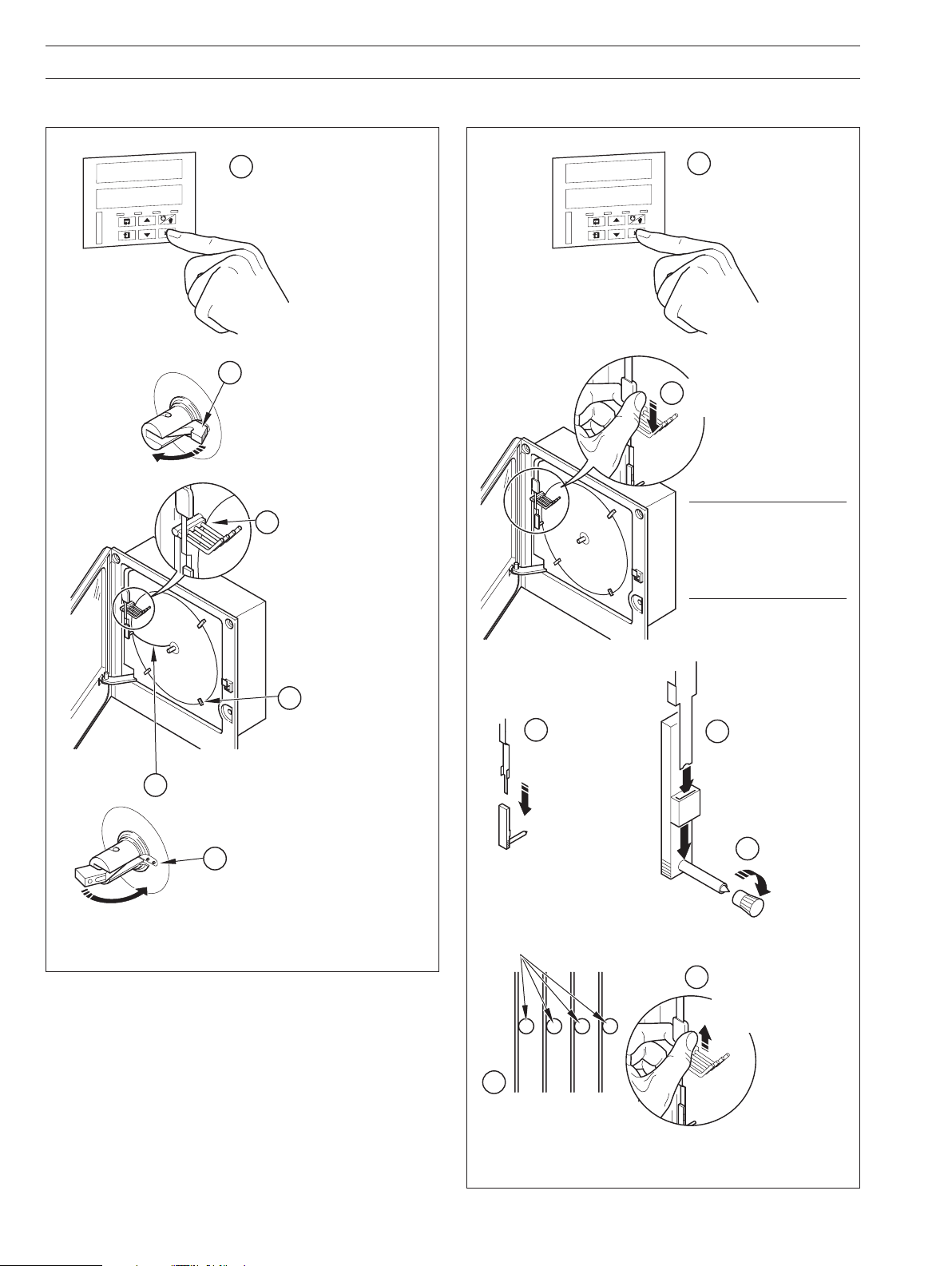

2.2 Fitting the Chart – Fig. 2.4 2.3 Fitting the Pen Capsule(s) – Fig. 2.5

Raise pens

75.0

dEG F

T

A

T

M

R

L

A

Raise pens

1

N

A

M

Lift the chart clamp

2

and remove the chart

75.0

dEG F

T

A

T

M

R

L

A

N

A

M

1

Gently pull the arm off

2

the bracket – see

Note

Fit new chart ensuring

3

that it is beneath the

pen lifter bars

4

Rotate chart to align the

5

time line with the red pen

(see also Fig. 2.1)

Lower the chart clamp

6

Fig. 2.4 Fitting the Chart

Locate chart

under guides

Lifter bars

3

Remove spent

capsule

Note. Take care not

to bend the arms

during removal and

refitting, as pen

clashing may result.

Fit new pen capsule

4

ensuring that the arm

locates in the pen

capsule slot

Remove cap

5

Slide pen assembly onto

7

the appropriate bracket

until it clips into place –

Note

see

6

Ensure that the arm is

positioned above its lifter

bar

Fig. 2.5 Fitting the Pen Capsules

4

Page 7

3 DISPLAYS & CONTROLS

The displays, LED indicators and operation/programming

controls are located on the faceplate on the front panel of the

instrument – see Fig 3.1.

3.1 Displays and LED Indicators – Fig. 3.1

The displays comprise 2 rows of 6 characters.

At the top of each programming page (the page header) both

displays are used to describe the particular page selected.

When parameters within the selected page are viewed the upper

display shows the parameter and the lower display shows the

value or setting for that parameter.

Alarm and Channel states are indicated by separate LEDs on the

faceplate of the front panel of the instrument – see Sections 4.1,

4.2 and 4.3.

Displays

LED Indicators –

see Section 4

Information.

AL1 – Channel 1

AL2 – Channel 2

AL3 – Channel 3

AL4 – Channel 4

CH1 – Channel 1

CH2 – Channel 2

CH3 – Channel 3

CH4 – Channel 4

8.8.8.8.8.8.

8.8.8.8.8.8.

Controls – Refer to Fig.

3.2(a) to (f) for functions

Status of process variable alarms

Current channel displayed

Fig. 3.1 Location of Displays,

Controls and LED Indicators

A

B

C

D

E

F

G

H

I

J

K

A

b

or

c

C

d

E

F

G

or

h

H

I

J

K

Table 3.1 Character Set

L

M

N

O

P

Q

R

S

T

U

V

Y

L

M

N

O

P

Q

r

S

t

U

V

Y

or

or

n

o

5

Page 8

…3 DISPLAYS & CONTROLS

3.2 Use of Controls – Fig. 3.2(a) to (f)

Return from

any frame

Page 1

Frame 1

Frame 2

Frame 3

Frame 4

Page 2

Frame 1

Frame 2

Frame 3

Fig. 3.2(a) Advancing to Next Page

Page X

Frame 1

Advance to

next Frame

Frame 2

Frame 3

Frame 4

Fig. 3.2(b) Moving Between Parameters

Parameter Value

Adjust

Note. Continued pressure on the and keys

causes the rate of change of the displayed value to

increase. To make small adjustments operate the keys

momentarily.

Fig. 3.2(c) Adjusting a Parameter Value

Lift/Lower pen on alternate operations

Notes.

• The

Chart Page

key can be enabled or disabled in the Set Up

, BASIC CONFIGURATION LEVEL.

• If 'Auto Pen Lift Drop' has been selected in the Set Up

Chart Page

, the pens return automatically to their

operating positions after a five minute delay.

Fig. 3.2(e) Lifting/Lowering the Pens

Information. The key is programmed in the Set Up

Function Keys Page, ADVANCED CONFIGURATION

LEVEL.

Acknowledge all alarms

or

Operating Page

Page X

Parameter 1

Parameter 2

Op. Page

Parameter 1

Parameter 2

Return operator to top of

Page X

Parameter 1

Parameter 2

Note. The key returns the instrument display to the

start of the operating page only when the display is at

the top of any page.

.

Parameter X

Y

Select

Z

Note. Continued pressure on the and keys

causes the rate of change of the displayed value to

increase. To make small adjustments operate the keys

momentarily.

Fig. 3.2(d) Selecting a Parameter Choice

6

Fig. 3.2(f) Selecting Programmable Functions

Page 9

If Totalizer option

is not fitted or Totalizers

3 & 4 are off

PV1 & PV2

ACKNLG

ALArMS

Acknowledge Alarms

Alarm Identity/Type

SECOdE

____

Security Code

Alarm Acknowledge Page

Section 4.3 Page 10

Total Page

Section 4.4 Page 11

Security Code Page

Section 4.5 Page 12

Totalized Value

Reset Total

Stop/Go

____

____

PV1 & Units

PV2 & Units

tOtALS

PAGE

rESEt

t1___

COUNt

____

Total 1

Reset Total

Stop/Go

rESEt

t2___

COUNt

____

Total 2

____

____

____

____

____

____

____

____

____

____

Time

tIME

____

Date

dAtE

____

See

Note

If Totalizer option

is not fitted or

Totalizers 1 & 2 are off

Faceplate 1 Pages

PV3 & PV4

ACKNLG

ALArMS

Acknowledge Alarms

Alarm Identity/Type

Operating Page

Section 4.2 Page 9

Alarm Acknowledge Page

Section 4.3 Page 10

Total Page

Section 4.4 Page 11

Totalized Value

____

____

PV3 & Units

PV4 & Units

tOtALS

PAGE

Reset Total

Stop/Go

rESEt

t3___

COUNt

____

Total 3

Reset Total

Stop/Go

rESEt

t4___

COUNt

____

Total 4

____

____

____

____

____

____

____

____

____

____

Time

tIME

____

Date

dAtE

____

See

Note

Faceplate 2 Pages

OPrtOr

LEVEL

bASIC

CONFIG

AdVNCd

CONFIG

Basic Config

Advanced Config

Operator Level

Only applicable

with Timer option

Only applicable

with Timer option

Operating Page

Section 4.2 Page 9

______

ISS _

EPROM Identity

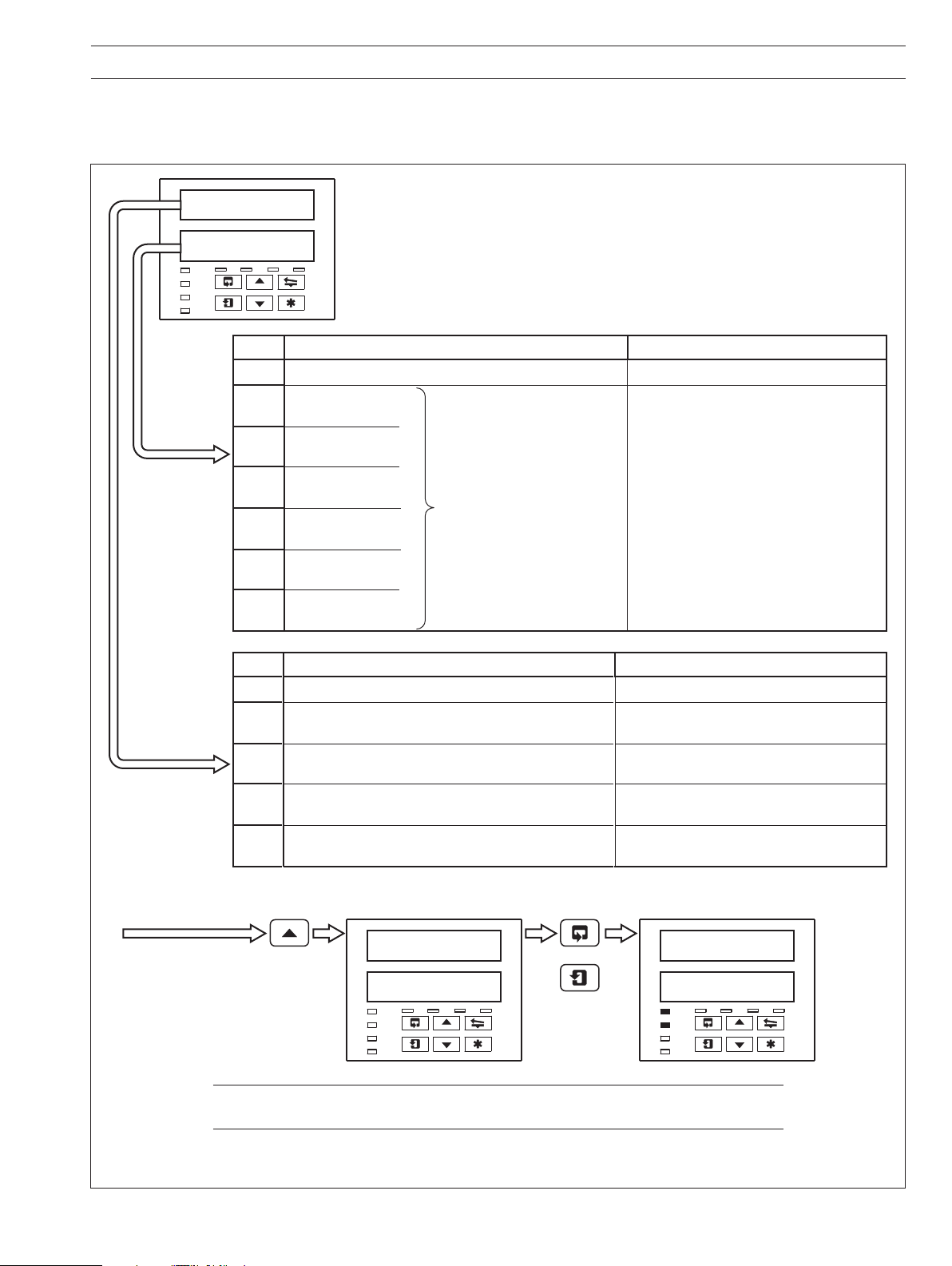

4 OPERATION

Fig. 4.1 Summary of Operating Level

pages are displayed only if an alarm is active.

Alarm Acknowledge

Note. The

7

Page 10

…4 OPERATION

The instrument has dedicated Operating Pages in the OPERATOR LEVEL – see Sections. 4.1 to 4.4. These pages are used for general

monitoring of the process measurements and are not affected by the security system which inhibits access to the PROGRAMMING

LEVELS

only – see Section 4.5 on page 12.

4.1 Input Error Messages – Fig. 4.2

Message Reason Action

Ad.FAIL

F–INPt

Examples

Internal analog to digital converter system hardware has failed • Check that the input/output board is located correctly

Input is above or below fault detection level.

or

Input exceeds the limits for the linearizer selected

in its socket.

• Power down and up

If the 'Ad.FAIL' message is still present, contact the

local service organization

• Check input source for possible broken sensor

• Check input connections

• Check input link position

• Check input configuration in

Set Up Input Page

Ad.FAIL

200.5

Note. Error messages are cleared automatically when the fault condition no longer exists.

Hardware failure on

Process Variable 1

Fig. 4.2 Input Error Messages Displayed in the Operating Page

200.5

F–INPt

Input out of range on

Process Variable 4

8

Page 11

4.2 Operating Page Displays

Faceplate 1 for channels 1 and 2 Faceplate 2 for channels 3 and 4

4 OPERATION…

100.3

200.5

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

100.3

dEG F

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

200.5

dEG F

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Process Variable 1 (PV1)

Process Variable 2 (PV2)*

*Not displayed on single pen

recorder.

Process Variable 1 (PV1)

Temperature Units for PV1

as set in the

CONFIGURATION LEVEL.

BASIC

Display is blank if 'NONE' is

selected.

Process Variable 2 (PV2)

Temperature Units for PV2

as set in the

CONFIGURATION LEVEL.

Display is blank if '

BASIC

NONE' is

selected.

300.3

400.5

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

300,3

dEG F

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

400.5

dEG F

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Process Variable 3 (PV3)

Process Variable 4 (PV4)*

* Not displayed on three pen

recorders.

Process Variable 3 (PV3)

Temperature Units for PV3

as set in the

CONFIGURATION LEVEL.

BASIC

Display is blank if 'NONE' is

selected.

Process Variable 4 (PV4)

Temperature Units for PV4

as set in the

CONFIGURATION LEVEL.

Display is blank if '

BASIC

NONE' is

selected.

tIME

12. 00

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

dAtE

24 JAN

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Current Time*

Time* (displayed using 24hr

clock)

*Displayed only when timer

option is fitted.

Current Date*

Day and Month*

*Displayed only when timer

option is fitted.

tIME

12. 00

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

dAtE

24 JAN

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Current Time*

Time* (displayed using 24hr

clock)

*Displayed only when timer

option is fitted.

Current Date*

Day and Month*

*Displayed only when timer

option is fitted.

9

Page 12

…4 OPERATION

4.3 Alarm Acknowledge Page

4.3.1 Alarm Indications – Fig. 4.3

The definitions for alarm states (on, off or flashing) are detailed in

Fig. 4.3.

4.3.2 Acknowledging Alarms

Note. Channel 1 and 2 alarms can be acknowledged

only from faceplate 1. Channel 3 and 4 alarms (if

applicable) can be acknowledged only from faceplate 2.

Unacknowledged alarms can be acknowledged from the

faceplate controls on the front panel in two ways:

OPERATING LEVEL – by pressing the key at any

In the

frame (providing the key is programmed for this function –

see Section 4.1 in the Programming Manual).

Alarm Acknowledge Page – by pressing the key –

In the

see Section 4.3.3 following.

No LED illuminated indicates no

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Fig. 4.3 Alarm LED Indications

alarms active.

The

Alarm Acknowledge Page

displayed in the

OPERATOR LEVEL

is not

A flashing LED indicates an

unacknowledged alarm on that

channel. For example, a flashing

AL1

LED indicates an

unacknowledged alarm on

channel 1.

The

Alarm Acknowledge Page

now displayed in the

LEVEL

.

is

OPERATOR

A constant LED indicates that all

active alarms have been

acknowledged on that channel.

The

Alarm Acknowledge Page

remains in the

OPERATOR LEVEL

until all alarm conditions are

cleared on that channel.

.

4.3.3 Using the Alarm Acknowledge Page

No Alarm Active

302

795

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Alarm Activated

302

802

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

ACKNLG

ALArM5

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

A2HPrC

800

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

A2HPrC

ACKNGd

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

No LED indicators illuminated.

Alarm Active

AL2 LED indicator flashing,

indicating active alarm on

channel 2.

Use

Alarm Acknowledge Page.

key to go to top of

Alarm Acknowledge Page

Use

key to advance to next

frame

Alarm Identity

Upper display: shows the alarm

identity and type.

Lower Display: shows the trip

level of the alarm identified in

the upper display.

Acknowledge Alarm

Use key to acknowledge

the alarm (see). When the alarm

is acknowledged, '

displayed and a constant LED

indicates the acknowledged

alarm.

ACKNGd' is

10

If there are more active alarms on channel 2 the LED continues to

flash until all alarms for that channel have been acknowledged.

Note. The key or a digital input can also be used to

acknowledge alarm, if programmed.

Page 13

4 OPERATION…

4.4 Totals Page Displays

This page is omitted from both faceplates if the Totalizer Option is not fitted. The page is also omitted from faceplate 1 if both Totals

1 and 2 are set to

Software Options Manual.

OFF and from faceplate 2 if both Totals 3 and 4 are set to OFF – refer to the Set Up Totals Page in the Advanced

tOtALS

PAGE

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

1234

5678

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

rESEt

tI NO

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

If

YES

selected

t1 YES

t1 YES

t1 NO

tOtALS

PAGE

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

8765

4321

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

rESEt

tI NO

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Front Panel (Batch) Flow Total 1 (3)

The batch flow total is calculated from process variable

1 (3). The flow total can be reset if

Totals Page is set to 'ENbL–Y'.

Reset Enable in Set Up

The flashing channel LED indicates the flow total

displayed.

For example, a flashing channel 1 LED indicates

Total 1 parameters displayed.

Flow

Counter Reset

The Front (Batch) Flow Total can be reset to the

Value in Set Up Totals Page if required.

Preset

Select 't1 YES' to reset the counter ( 't1' indicates

Flow Total 1 ).

Note. If the Counter Reset is disabled in Set Up Totals

Page, the counter reset frame is omitted.

COUNt

StOP

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Repeat for Total 2 (if applicable)

1234

5678

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

GO

GO

StOP

COUNt

StOP

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Repeat for Total 4 (if applicable)

8765

4321

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Counter Stop/Go

GO' to start the counter or 'StOP' to stop it.

Select '

Note. If the Counter Stop/Go is disabled in

Set Up

Totals Page, the frame can be viewed but not altered. If

a digital signal is assigned to the Totalizer Stop/Go, an

active digital signal sets the counter to

GO and the

Counter cannot be stopped from the front panel.

Front Panel (Batch) Flow Total 2 (4)

Repeat the above procedure for

Flow Total 2 (4).

Note. The number of totalizers is dependent on the

number of pens fitted to the instrument e.g. a 3 pen

instrument has 3 totalizers.

11

Page 14

…4 OPERATION

4.5 Access to Configuration Levels

A security system is used to prevent tampering with the programmed parameters by utilizing a password giving access to all

programming pages – refer to the

SECOdE 100.0

CH1

AL1 AL2 AL3 AL4 CH1

CH2

CH3

CH4

Correct

Password

PEN 1

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

PEN 4

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

2001

Programming Manual.

Security Code

the pen adjustment

password

75.5 100

Incorrect

Password

Pen Position Adjustment (Pens 1 to 4)

The position of any trend pen can be adjusted against a reference standard (without

changing the displayed value). Each pen can be adjusted in steps upwards (towards

the edge of the chart) or downwards (towards the center of the chart).

When this feature is enabled, a password must be entered before adjustments can

be made.

Note if pen adjustment is disabled or if the password is incorrect, the four Pen

Adjustment frames are not displayed.

For each trend pen, the lower part of the frame shows the pen position adjustment.

Pen position adjusted downwards by > 25 steps

Pen position adjusted downwards by between 1 and 25 steps

Pen position not adjusted

Pen position adjusted upwards by between 1 and 25 steps

Pen position adjusted upwards by > 25 steps

adjusts the pen position upwards (towards outer edge of chart)

adjusts the pen position downwards (towards center of chart)

The pen adjustment frame for any given pen only appears if the pen is a Trend pen

EPROM

Version

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Security Code Page

Set the security code to the correct

password using the

keyes and use the key

to advance to other programming

levels (OPERATOR, BASIC

CONFIGURATION and ADVANCED

CONFIGURATION).

The password is programmed in

the Access Page in the

BASIC CONFIGURATION LEVEL.

and

OPrtOr

LEVEL

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

BASIC

CONFIG

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

ISS _

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

EPROM Identification

Use the

Identification Frame. The upper display

shows the EPROM version, e.g. 2001

and the lower display shows the EPROM

issue number.

OPt ION

tYPE 0

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

12

EPROM

Issue

Number

key to advance to the EPROM

Option

Shows the software key option type.

For details of the options, refer to the

Data Sheet, SS/C1900R

AdUNCd

CONFIG

CH1

AL1 AL2 AL3 AL4

CH2

CH3

CH4

Page 15

5 SIMPLE FAULT FINDING

Symptom Possible Cause Action

Does not power up a) Internal fuse (if fitted) is blown a) Check wiring, rectify fault and replace fuse

b) Internal power switch (if fitted) is OFF b) Turn power switch ON

c) Power supply connections are incorrect c) Check connections

Chart does not appear to move a) Very slow chart speed selected a) Select required chart speed in

Chart Page

Set Up

b) Chart stop function enabled b) De-activate source being used to stop

chart – see

Set Up Chart Page

Pens in recording position but do not drop Chart stop function enabled De-activate source used to stop chart – see

onto paper

Set Up Chart Page

Red pen does not move beyond 94% When real time event pen is fitted the red pen Use chart range which prevents the need to go

position on chart cannot go beyond 94% to prevent pens beyond 94% of maximum on chart

clashing

Pen lift switch on front panel does not Pen lift switch is disabled Enable pen-lift switch in

Set Up Chart Page

work

Pens do not remain lifted when pen lift key Auto pen drop feature is enabled Disable auto pen drop in

Set Up Chart Page

if

is used this is not required

Analog inputs are slow to respond A large filter time has is set Set digital filter value to give required response

in

Set Up Inputs

Time or date incorrect Not set for correct local time Set correct time and date in

Page

– refer to

Advanced Software Manual

Totalizers cannot be set to STOP or GO Operator STOP/GO selection is not enabled Enable counter STOP/GO in the

in the

OPERATOR LEVEL Totals Page

Set Up Clock

Set Up

Totalizer cannot be set to STOP Digital signal assigned to the total STOP/GO De-activate digital signal assigned to total

function is active STOP/GO function

External relays connected to relays in Arc suppression capacitors are provided Remove the arc suppression components –

instrument fail to de-energize across the relay contacts and capacitor IC4 and IC5 on mainboard

leakage current may be sufficient to prevent IC6 and IC7 on standard I/O and analog relay

an external relay from de-energizing IC3 to IC10 on 4 relay module

13

Page 16

6 SPARES LIST

Item Part No.

Pen Capsules (pack of 3)

Black ............................................................................................................................................................................. C1900/0119

Blue ............................................................................................................................................................................... C1900/0120

Red ................................................................................................................................................................................ C1900/0121

Green ............................................................................................................................................................................. C1900/0122

Violet* ............................................................................................................................................................................ C1900/0123

Pen Arm Assemblies

ER/C Type Chart (J or R in Code Number) – Standard Pen ........................................................................................... C1900/0076

ER/C Type Chart (J or R in Code Number) – Event Pen ................................................................................................ C1900/0078

PX105 and PXR105 Type Chart (K or S in Code Number) – Standard Pen ................................................................... C1900/0075

PX105 and PXR105 Type Chart (K or S in Code Number) – Event Pen ......................................................................... C1900/0077

Fuses

24V ................................................................................................................................................................................ B11071 (4A)

115V .............................................................................................................................................................................. B11070 (1A)

230V ....................................................................................................................................................................... B11069 (500mA)

*True time line event option only.

14

Page 17

NOTES

15

Page 18

NOTES

16

Page 19

Sales SoftwareService

Page 20

—

ABB Limited

Measurement & Analytics

Howard Road, St. Neots

Cambridgeshire, PE19 8EU

UK

Tel: +44 (0)870 600 6122

Fax: +44 (0)1480 217 948

Email: enquiries.mp.uk@gb.abb.com

ABB Inc.

Measurement & Analytics

125 E County Line Road

Warminster, PA 18974

USA

Tel: +1 215 674 6000

Fax: +1 215 674 7183

abb.com/measurement

—

We reser ve the right to m ake techni cal changes or modify the co ntents of th is docume nt

with out prior notice . With reg ard to purch ase orders, the agreed par ticula rs shall prevail.

ABB do es not accept any respon sibilit y whatsoever for potent ial error s or possible lack of

information in this document.

We reser ve all right s in this document and in the su bject matter and illustration s containe d

therein. Any rep roduction, disclos ure to third pa rties or utilization of its contents – in

whole o r in parts – is for bidden w ithout prior writ ten consent of AB B.

© ABB 20 18

IM/C19 00-OG R Rev. L 09.2018

Loading...

Loading...