Page 1

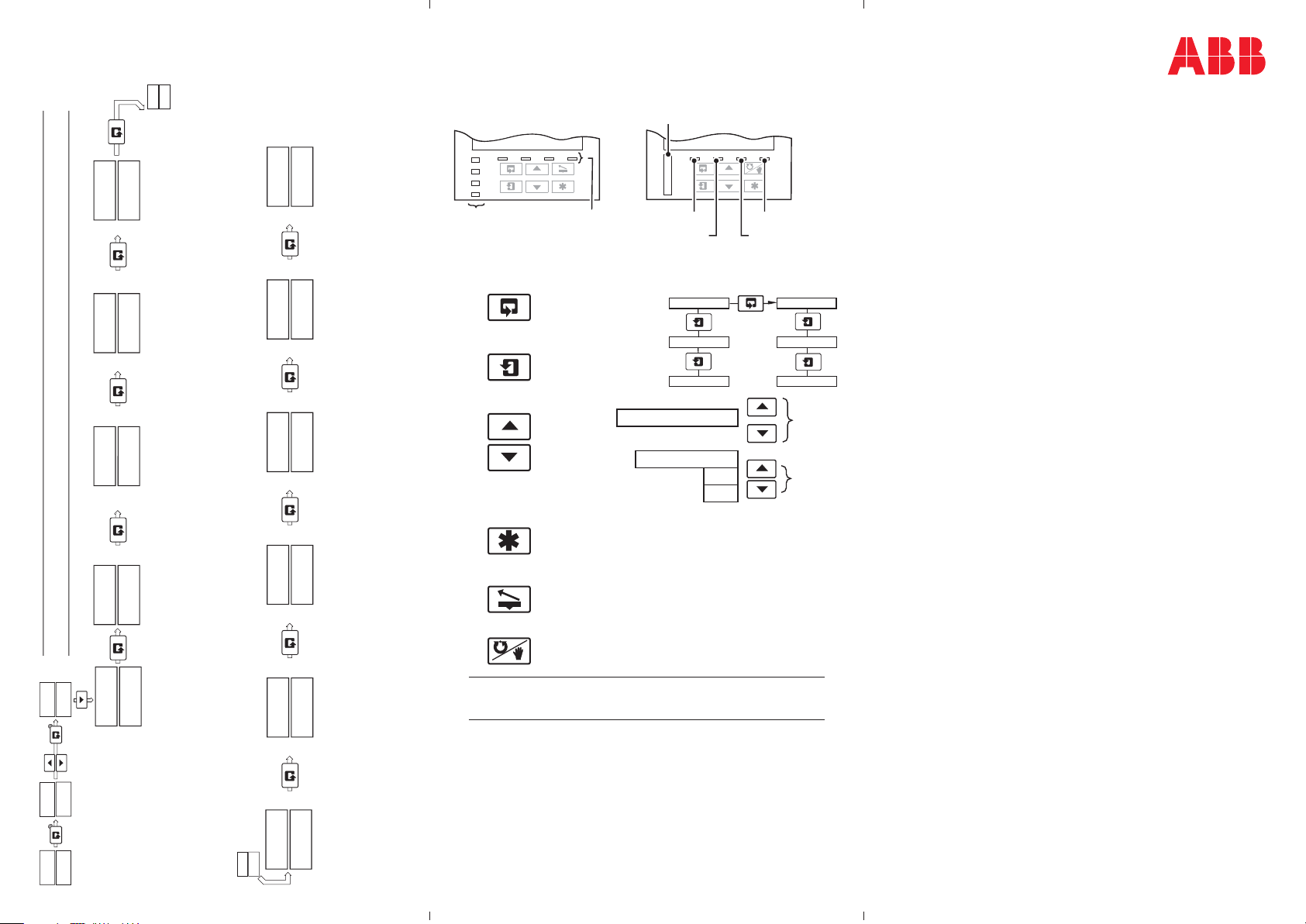

Basic configuration overview Displays and controls

A

A

Controller Faceplate

Bar Graph (Indicates deviation of

ABB ME ASUREMENT & ANALYTICS | IM/C1900-QC

SEtUP

Recorder Faceplate

rELAYS

measured value from set point)

8.001

AL3

SEtUP

ALArMS

Setup Alarms – p13

Set alarms to trip on

process value, control

output , setpoint

deviation, rate of change.

SCALE

ADJUSt

Scale Adjustment – p24

Allows spot calibration to

eliminate system loop

errors.

AL1 AL2

CH1

CH2

CH3

CH4

Currently

Displayed

Channel

AL4

Process

Variable

Alarm

Status

Alarm Status

Remote Set

Point in Use

Sideways Scroll

ACCESS

PAGE

Access Page – p22

Disable access to

configuration and tuning

SEtUP

CHArt

Setup Chart Speed – p9

chart revolution and pen

lift/drop parameters.

Set the duration of one

facilities.

dIGtAL

INPUtS

Setup

Digital Input – p21

Set polarity of external

SEtUP

PENrNG

'magnification' of the

trace. Default is 0 to

100% of engineering

Setup Pen Range – p8

Used to adjust the

range.

Set in engineering units.

digital signals.

Down Scroll

Raise and Lower

Parameter Value

or

Parameter X

8.001

AL

AT

RMT

MAN

Manual Control

Auto-tune

in Progress

Advance to next page

Page 1

Frame 1

Advance to

next frame

Frame 2

Y

Page 2

Frame 1

Frame 2

Adjust

Select

Z

Function Key

Alarm acknowledge; Auto-tune; Pen lift/ lower;

Profile Control; Local/Remote or 'Home' – See

Programming Guide, 'Advanced Configuration'

Pen Lift

SEtup

INPUt

Setup Inputs – p4

Set the type, linearizer,

ranges and fault levels for

Note. Refer to the relevant page of the Programming Guide for further information.

SEtUP

each input – see overleaf.

ANALOG

Setup

Analog Output – p20

Set an output as control

or re-transmission.

Auto/Manual

(Recorder Only)

(Controller Only) Switches between automatic

and manual control modes.

Raises and lowers the chart pen.

Note. All programming is carried out using the

OPrtOr

LEVEL

bASIC

CONFIG

dIGtAL

OUtPtS

Setup

Digital Outputs – p18

open/closed state.

Set source used to

activate each output and

define normally

faceplate keys and displays.

ABB Limited

Measurement & Analytics

Howard Road, St. Neots, Cambridgeshire, PE19 8EU, UK

Tel: +44 (0)870 600 6122 | Fax: +44 (0)1480 217948

MMMMMM

SECOdE

99.99

00.001

SEtUP

ALArMS

SEtUP

rELAYS

Setup Relays – p15

Set source used to

activate each relay and

define normally

open/closed state.

Email: enquiries.mp.uk@gb.abb.com

www.abb.com/measurement

© ABB 20 18 | Spec ificat ions subject to change w ithout notice.

IM/C19 00-QR Rev. E 08. 2018

C1900 recorder and

recorder/controller

Quick reference guide

Operating Guide

Alarms

Acknowledge

LED status

uto-tune

Enable/disable

Setup

Status

uto/manual select

Chart ......................................... 4

Control

Cascade

Heat/cool ......................

On/off

Output adjust ....................... 13

Standard

Displays & controls ... 5, 6, 34, 35

Fault-finding ..............

Auto-tune diagnostics .......... 24

Input error messages

Power up error codes ............2

Manual tuning

Pen – fitting ............................... 4

Process variable ...................... 13

Profile control .......................... 12

Program select .................... 19

Reset

Skip segment ....................... 19

Status

Security Access

Configuration level ............... 18

Password

Tune level – access

Self-test .....................................2

Set point

Bias

..................................... 14

Ratio .................................... 14

Type selection

Time/date

Totalizer ............................ 17, 37

................ 16, 36

...................

16, 36

................................ 21

..................... 23

................................... 21

.................................. 23

.................. 12

.............................. 12

11, 12

...........................

.......................

26, 30

10, 26

2, 9, 24, 38

............. 9

.......................... 28

................................... 19

.................................. 15

............................. 18

............. 18

...................... 14

................................ 15

Programming Guide

Alarms

..................................... 10

Analog outputs ........................ 21

Auto/manual select enable ......45

Bargraph increment .................45

Chart set up .............................. 9

Configuration

...................................... 3

Basic

Control

................................. 29

Advanced

Control

............................ 48

..................................... 37

Action on input fail ............... 43

Action on power fail

Digital outputs .........................19

Function keys

.......................... 49

Inputs (PV, RSP, P-FB) ..............4

Assign .................................. 53

Logic equations .......................50

Logic inputs

Passwords

................

............................... 24

Pen ....................................... 8, 9

Functions .............................52

Scale adjust

.................. 26, 27

Position feedback – see Inputs

Process variable – see Inputs

Relays

...............................

Remote set point – see input .......

Retransmission outputs –

Analog Outputs

Scale Adjust (span/offset) ........26

Set point

Spot calibration –

......................

see Scale Adjust

Installation Guide

Accessories

Electrical Installation

Siting ......................................... 3

Mounting/Dimensions ............... 4

Power Supplies ....................... 12

Inputs/Outputs .......................... 7

............................... 2

............. 39

23, 46, 47

16, 17

see

30–33, 45

.................. 6

Page 2

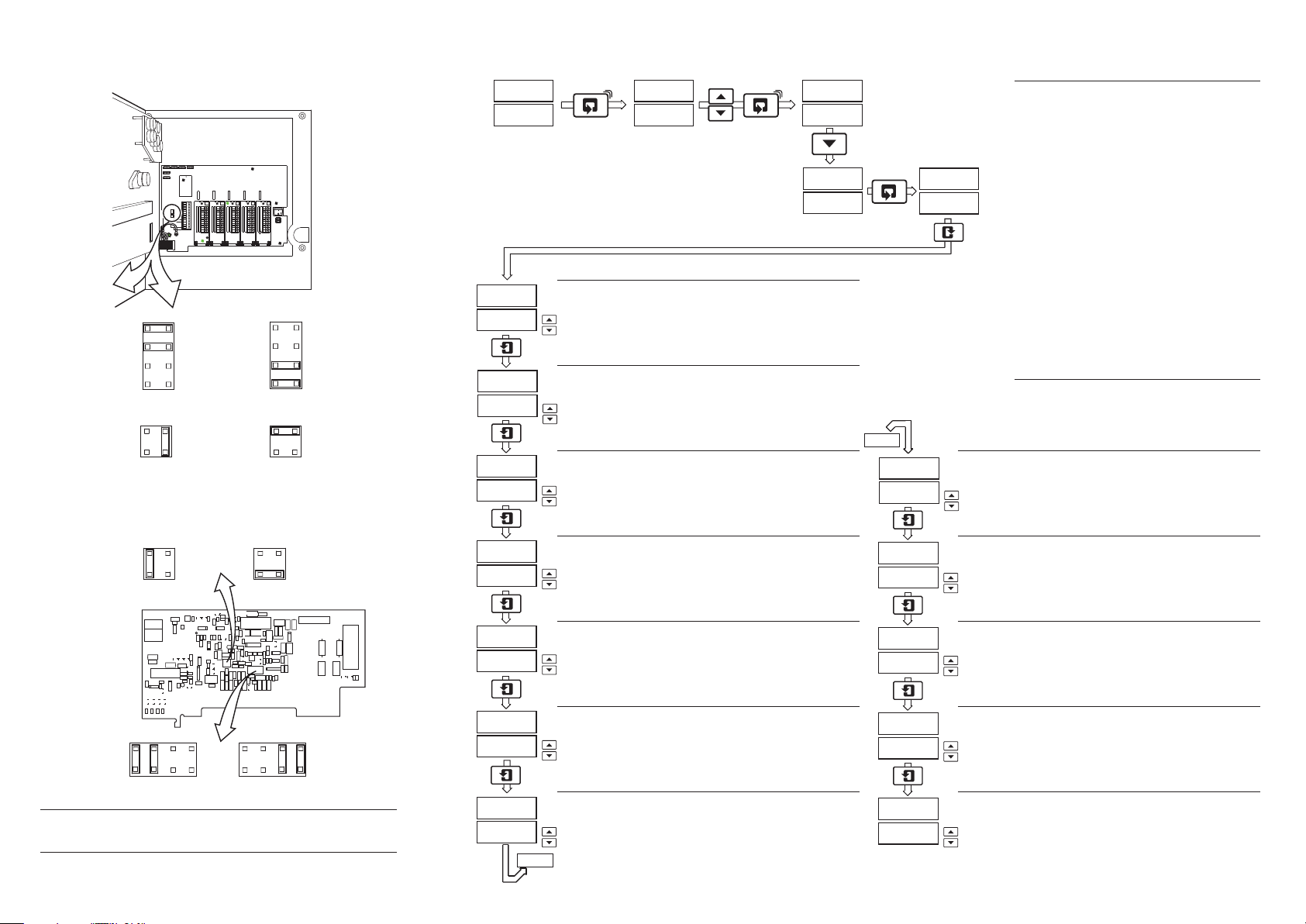

Setting analog input links Configuring analog inputs

mV THC

2-wire

Transmitter

2-wire

Transmitter

2 3 4 5 6

5

PL1

8

1

2

PL8

4

or

1

4

or

3

5

PL1

8

PL8

1

2

Fig. 1 Input Links – Channel 1

PL3 PL3

2

3

4

1

2

3

1

4

INPUT/OUTPUT MODULE

4

mA V RTD &

Resistance

1

4

All Other

Input Types

3

All Other

Input Types

100.0

99.9

SELECt

____

INtYP

____

LNtYP

___

rNG-HI

___

rNG-LO

___

SECOdE

MMMMMM

OPrtOr

LEVEL

bASIC

CONFIG

Select Channel –

be configured

Input type

tCPL (Thermocouple), rtd (RTD) and LO OH

(< 750 Ohms) HI OH (> 750 Ohms).

Linearizer:

B, N, E, T, S, A. Other options are 5/2,, 3/2,

SQrt, rtd or NONE.

Range High:

this to 20.00, or for 0 to 5V, set to 5.0. The frame

does not appear if tCPL or rtd are used.

Range Low:

input range, e.g. 4.00, for 4 to 20mA, or 0.0 for

0 to 5V.

Choose the input channel to

– _A_P (mA), VOLt (V), _U.Lt (mV),

If using a thermocouple set to J, K,

For a 4 to 20mA current input, set

Set the low end of the electrical

ENG-HI

dEC-Pt

____

ENG-LO

___

bSPd

___

SEtup

INPUt

Information. The alphabet used to

display page and parameter titles is

as follows:

A –

A

B –

b

C –

C

D –

d

E –

E

F –

F

G –

G

H –

H

I –

I

J –

J

K –

K

L –

L

Decimal Point:

or

c

h

or

Select the decimal point position

M –

N –

O –

P –

Q –

R –

S –

T –

U –

V –

Y –

M

N

O

P

Q

r

S

t

U

V

Y

or

n

or

o

for the process variable, e.g. 300.0.

Engineering Range Low:

Select the lowest

engineering value that will be displayed when the

input is at its minimum value – e.g. for an

engineering range of 0 to 300.0 °F set to 0.0.

Broken Sensor Drive:

Determine pen action

when the input signal fails: NONE – pen follows

failed input; UP – pen driven to full scale;

dN – pen driven to zero scale.

mV THC

41

PL1

8

5

41

mA V RTD &

Resistance

PL1

8

5

Warning. Ensure that the unit is isolated from all power

supplies before removing I/O boards.

Fig. 2 Input Links – Channels 2 to 4 (If fitted)

UNItS

___

ENG-HI

____

dEC-Pt

Units:

Select NONE if the input is not temperature,

otherwise select dEG F or dEG C.

Engineering Range High:

Select the highest

engineering value that will be displayed when the

input is at its maximum value – e.g. for an

engineering range of 0 to 300.0 °F set to 3000.

FdLP

___

PrGFLt

___

Fault Detection Drive:

Determine maximum

input travel outside engineering range before an

error is detected. E.g. for a 0 to 300°F range, a

10% fault level will trigger at 330°F.

Input Filter:

Adjust the instrument response time

from 0 to 60 seconds in one second increments

to reduce pen jump & dampen out noisy signals.

Loading...

Loading...