Page 1

—

ABB MEASUREMENT & ANALYTICS | USER GUIDE

C1300

Advanced circular chart recorder

Measurement made easy

—

C130 0 advanced c ircular

chart recorder

For more information

Further publications are available for free download

from:

www.abb.com/measurement

or by scanning this code:

Advanced circular chart recorder

Datasheet

Advanced circular chart recorder

User Guide supplement

Advanced sofware options

Advanced circular chart recorder

User Guide supplement

Modbus communications option

Search for or click on

Page 2

Electrical Safety

Health and Safety

This equipment complies with the requirements of CEI/IEC

for Measurement, Control and Laboratory Use’. If the

the protection provided by the equipment may be impaired.

Symbols

equipment labelling:

Warning – refer to the manual for instructions

Caution – risk of electr ic shock

Protective earth (ground) terminal

Earth (ground) terminal

Direc t current supply only

Alternating current supply only

To ensure that our products are safe and without risk to health,

the following points must be noted:

• The relevant sections of these instructions must be read

carefully before proceeding.

• Warning labels on containers and packages must be

observed.

• Installation, operation, maintenance and servicing must

only be carried out by suitably trained personnel and in

accordance with the information given.

• Normal safety precautions must be taken to avoid the

possibility of an accident occurring when operating in

conditions of high pressure and/or temperature.

• Chemicals must be stored away from heat, protected from

temperature extremes and powders kept dry. Normal safe

handling procedures must be used.

• When disposing of chemicals ensure that no two chemicals

are mixed.

Safety advice concerning the use of the equipment described in

this manual or any relevant hazard data sheets (where

applicable) may be obtained from the Company address on the

back cover, together with servicing and spares information.

Both direct and alternating current supply

The equipment is protected through double insulation

Information in this manual is intended only to assist our

customers in the efficient operation of our equipment. Use of

this manual for any other purpose is specifically prohibited and

its contents are not to be reproduced in full or part without

prior approval of the Technical Publications Department.

Page 3

C1300

Advanced circular chart recorder Contents

Contents

1 Preparation ......................................................................2

1.1 Preparing the Recorder for First Use ........................2

1.2 Powering up the Recorder .......................................4

1.2.1 Recorder Status and Error Page ...................5

2 Operation .........................................................................6

2.1 Display Screens and Operator Keys .........................6

2.2 Input Error Messages and Alarm Icons .....................7

2.3 Operating Pages ......................................................8

2.3.1 Accessing the Operating Pages ....................8

2.3.2 Autoscroll .....................................................9

2.3.3 Input (Pen) Channel Display – Separate ......10

2.3.4 Input (Pen) Channel Display – Dual ..............11

2.3.5 Input (Pen) Channel Display – Separate

and Dual .....................................................12

2.3.6 Totalizer Display – Separate ........................13

2.3.7 Totalizer Display – Rate with Total ............... 13

2.3.8 Totalizer Display – Total with Rate ...............14

2.3.9 Totalizer Display – Dual Total ......................14

2.3.10 Totalizer Display – Dual + Flow Rate ...........15

2.3.11 Data Logging .............................................15

2.4 Totalizer Log ..........................................................16

2.5 Totalizer Control .....................................................17

2.6 Alarm Set Point Adjustment ...................................18

3 Configuration .................................................................19

3.1 Introduction ............................................................19

3.2 Preparation for Configuration .................................19

3.3 Configuration Level Security ...................................19

3.4 Common Configuration ..........................................20

3.5 Channels Configuration ..........................................24

3.6 Alarms Configuration ..............................................31

3.7 Totalizer Configuration ...........................................35

3.8 Relay Configuration ................................................42

3.9 Digital Input and Output Configuration ....................43

3.10 Analog Output Configuration ..................................45

3.11 Logic Equation Configuration .................................47

3.12 Data Logging Configuration ....................................50

3.13 System Clock Configuration ...................................54

3.14 Pen Function ..........................................................55

3.15 Calibration ..............................................................56

3.16 Backing Up and Restoring Configurations ..............58

3.16.1 Backing Up a Configuration ........................58

3.16.2 Restoring a Configuration ...........................59

5 Electrical Installation .................................................... 64

5.1 Identifying the Input/Output Modules ..................... 66

5.2 Channel Connections ............................................ 66

5.2.1 Selecting the Analog Input Type(s) .............. 67

5.2.2 Voltage and Current ................................... 69

5.2.3 2-wire Transmitter Input) ............................ 69

5.2.4 Thermocouple ............................................ 69

5.2.5 Resistance Thermometer (RTD) .................. 69

5.2.6 Logic Inputs ............................................... 69

5.2.7 Analog Output ............................................ 69

5.2.8 Relay Output .............................................. 69

5.3 Module Connections .............................................. 70

5.3.1 Standard I/O or Analog + Relay

(Module Types 1, 2 and 7) .......................... 70

5.3.2 Four Relay Module (Module Type 3) ........... 70

5.3.3 Eight Digital Inputs or Outputs

(Module Types 4 and 5 respectively) ........... 70

5.4 Power Supply Selection

and AC Connections ............................................. 71

6 Fault Diagnosis ............................................................. 72

7 Spares and Accessories .............................................. 73

8 Specification ................................................................. 74

Appendix A – Signal Sources ........................................... 77

Appendix B – Units ........................................................... 78

Appendix C – Installation Record .................................... 80

Index .................................................................................. 82

Acknowledgments ........................................................... 84

4 Mechanical Installation .................................................60

4.1 Siting .....................................................................60

4.2 Mounting ................................................................61

4.2.1 Wall-/Pipe-Mounting ...................................62

4.2.2 Panel Mounting ...........................................63

IM/C1300 Rev. J 1

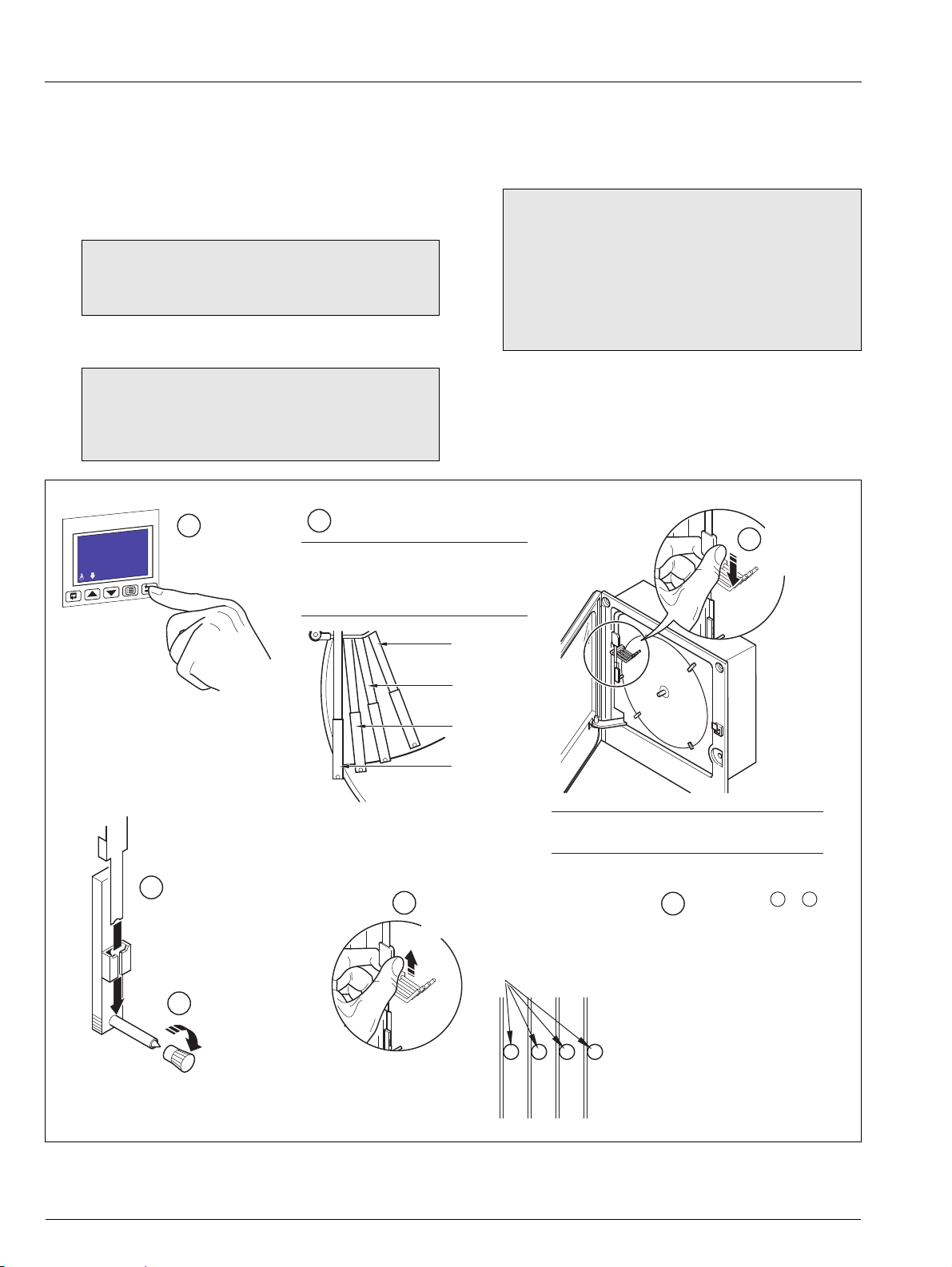

Page 4

C1300

Gently pull

the pen arm

off its bracket

3

Note. Do not bend the pen arm during removal

and re-fitting as pen clashing may result.

Raise pens

1

Input 1

-999.99

deg C

5

Remove cap

Fit the correct colored pen

capsule ensuring that the arm

locates in the pen

capsule slot

4

Red Pen

(Channel 1)

Green Pen

(Channel 2)

Blue Pen

(Channel 3)

Black Pen

(Channel 4)

2

Identify pens

Note. The number of pens fitted (and

the colors of the pen capsules

supplied) depends on the recorder

model.

Slide pen arm and capsule

assembly onto the appropriate

bracket until it clips into place

6

ensuring that the arm is

positioned above its lifter bar

7

Repeat steps to for

remaining pens as required

3 6

Advanced circular chart recorder 1 Preparation

1 Preparation

1.1 Preparing the Recorder for First Use

Prepare the recorder for first use as follows:

1. Install the recorder – see Section 4, page 60.

2. Connect the recorder – see Section 5, page 64.

Warning. Ensure all connections are made correctly,

especially to the earth (ground) stud – see Section

5.4, page 71.

3. Switch on the power supply to the recorder.

4. Fit the pen capsule(s) – see Fig. 1.1.

Note.

Ensure the correct colored capsule is fitted to

the appropriate pen arm. Each pen arm is

identified by a colored band – see Fig. 1.1.

If the violet, true-time line event option is fitted,

the pen records on the same time line as the red

pen, but on the outer edge of the chart.

Note. On power-up, the pen arm(s) is (are) moved to

an off-chart position for automatic referencing. Pen

chatter may occur on the pen(s) nearest the reference

position. This is a normal function of the recorder.

5. Fit a chart – see Fig. 1.2 on page 3.

Fig. 1.1 Fitting the Pen Capsule(s)

2 IM/C1300 Rev. J

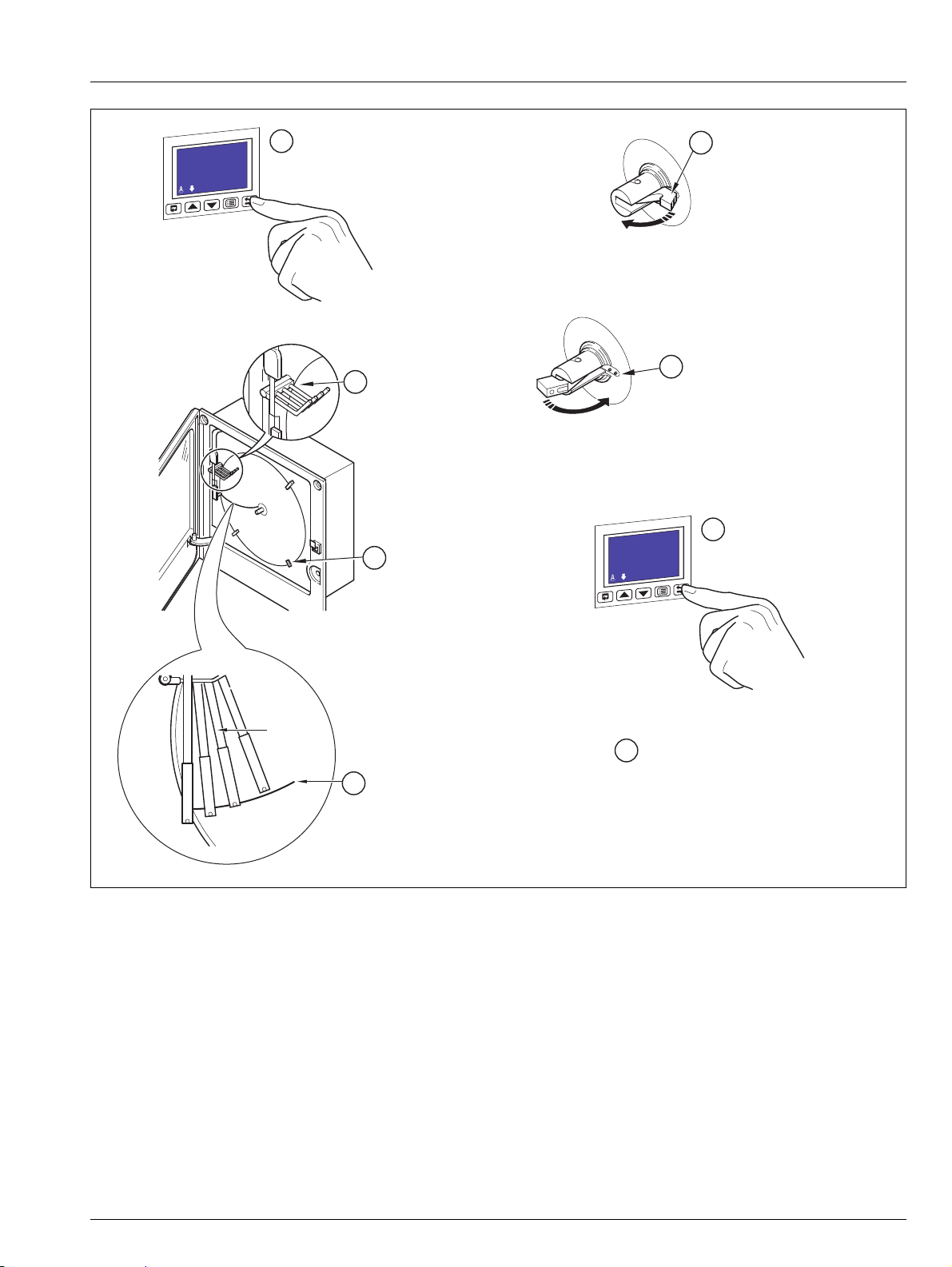

Page 5

C1300

Lift the chart clamp

2

Lower the chart clamp and press down

firmly to ensure that the 2 locating pins

pierce the paper

6

Ensure pen(s) in

raised position

1

Input 1

-999.99

deg C

Fit a chart ensuring

that it is beneath the

pen lifter bars

Locate chart

under guides

Rotate chart to align the

time line with the red pen

3

4

Red Pen

5

Lower pen(s)

7

Input 1

-999.99

deg C

Switch off the power supply to the recorder

8

Advanced circular chart recorder 1 Preparation

Fig. 1.2 Fitting a Chart

IM/C1300 Rev. J 3

Page 6

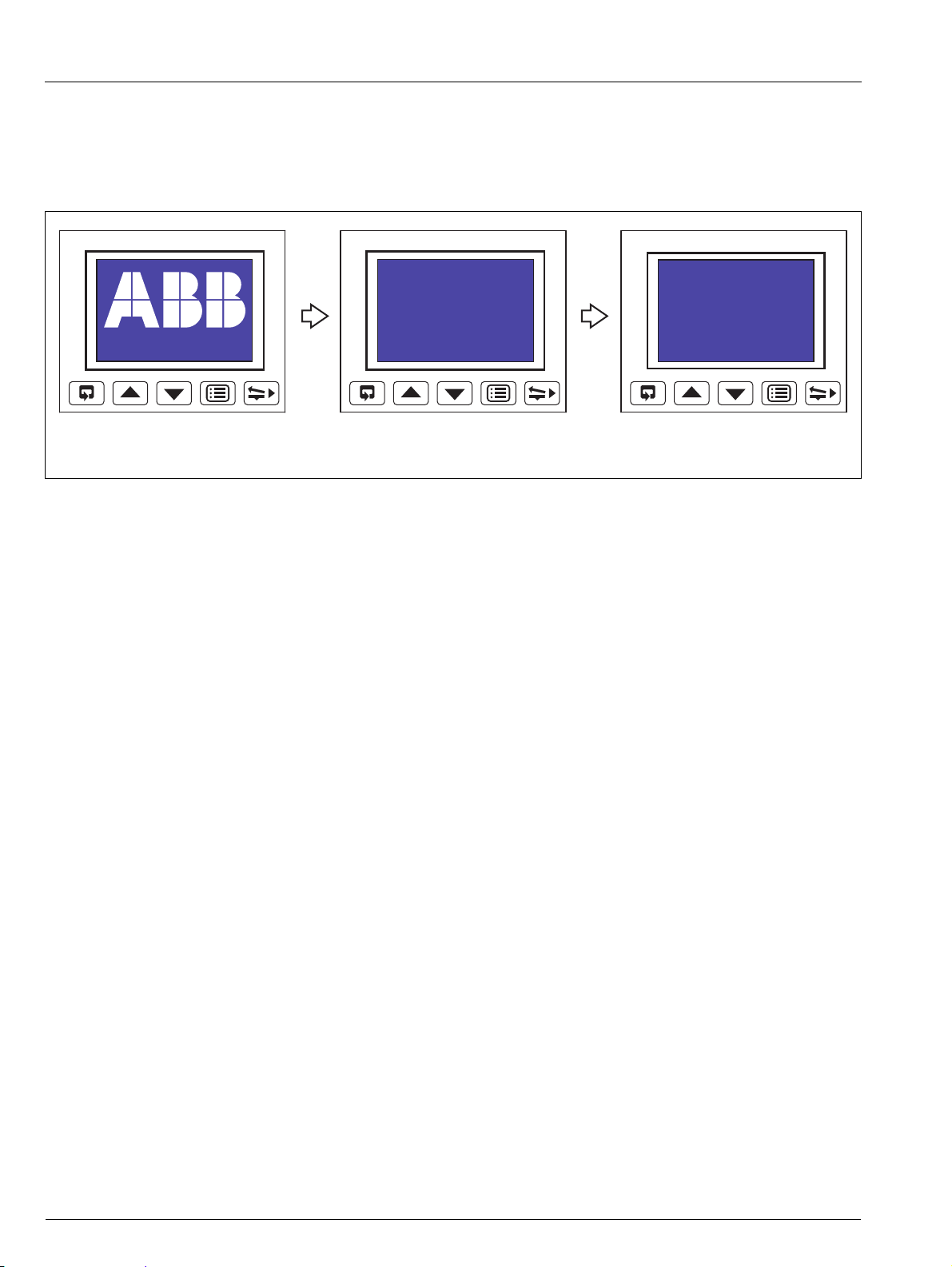

C1300

WWW.abb.com

Self Tests, Software Key and

Module Identification

Instrument Type and Software Version

C1314J

Software Issue

1

Main: CFG Test :Pass

SKey:Type B :Pass

Mod2:Not Fitted

Mod3:Not Fitted

Mod4:Not Fitted

Mod5:Not Fitted

Mod6:Not Fitted

Advanced circular chart recorder 1 Preparation

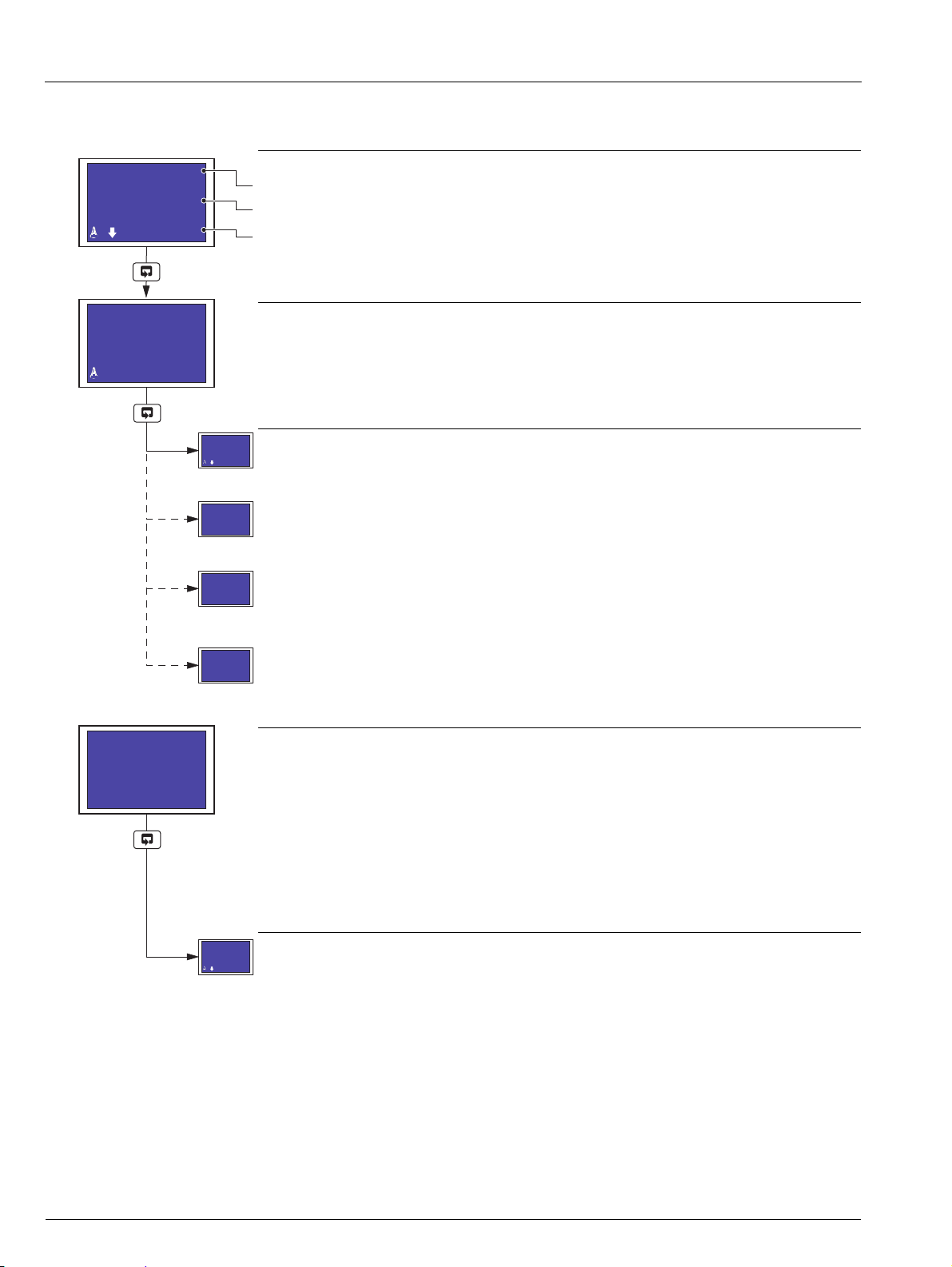

1.2 Powering up the Recorder

To power up the recorder:

1. Switch on the supply to the recorder, any power-operated control circuits and the input signals. Wait for the pens to settle.

2. The start-up self-test sequence shown in Fig. 1.3 is shown on display screen 1 when the power supply is first switched on.

Fig. 1.3 Recorder Start-up Self-test Sequence

4 IM/C1300 Rev. J

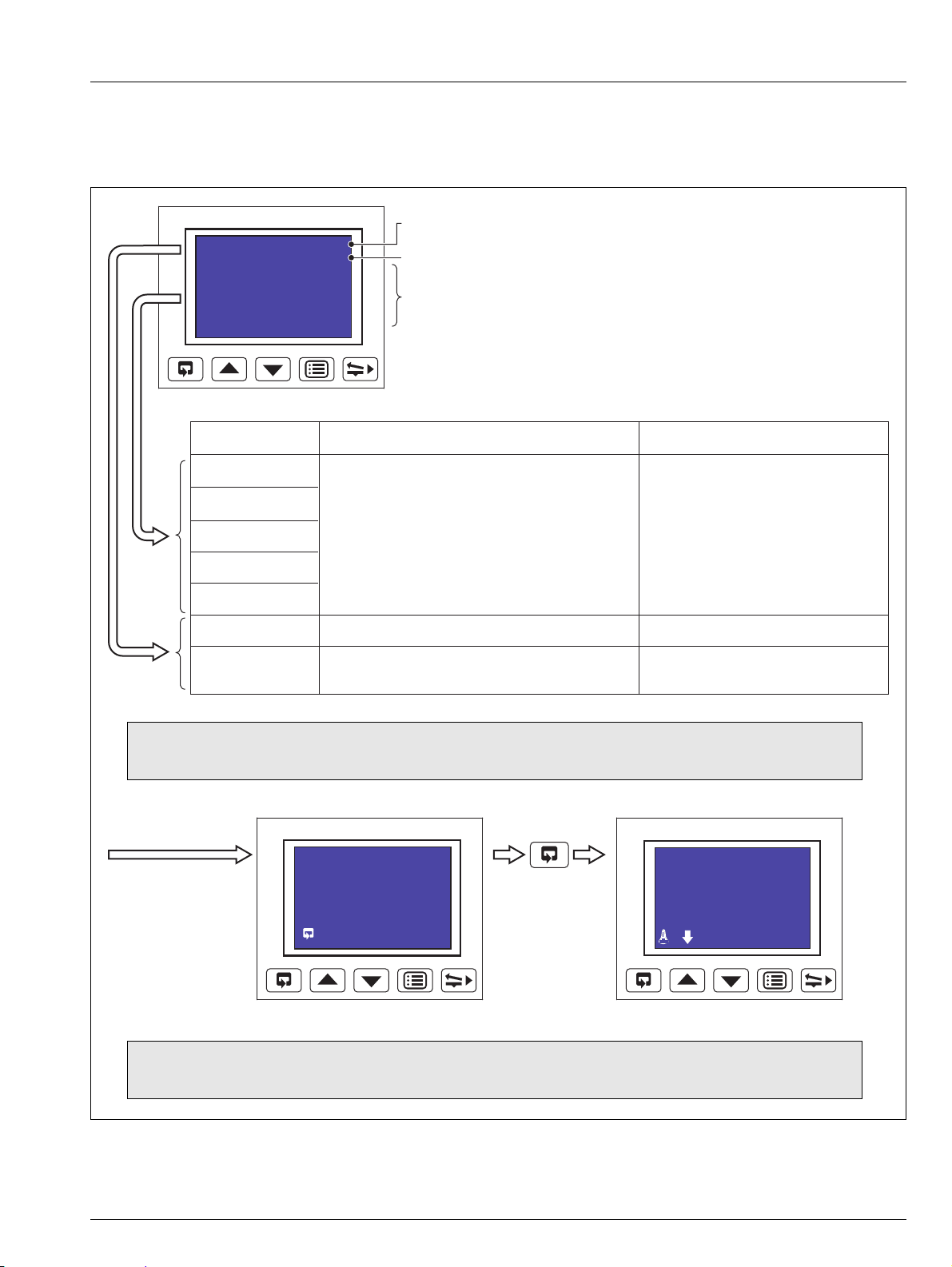

Page 7

C1300

Main: CFG Test :Pass

SKey:Type B :Pass

Mod2:Not Fitted

Mod3:Not Fitted

Mod4:Not Fitted

Mod5:Dig Out :Pass

Mod6:RS485 :Pass

Main Board CPU and Configuration Test Results

Software Key (see

Note below) Identification and Test Result

Module Identification and Test Results

Acknowledging Errors

Mod2:Not Fitted

Mod3:Not Fitted

Mod4:Not Fitted

Mod5:Dig Out :Fail

Mod6:RS485 :Pass

Acknowledge

Input 1

-999.99

deg C

Component Possible Cause Action

Module in position 2

Module in position 3

Module in position 4

Module in position 5

Module in position 6

Main Board

Software Key

Analog input and/or analog output calibration is corrupt.

Power down and then up again.

If the fault persists, contact the Company.

Configuration stored in non-volatilememory is corrupt.

Check and correct program data.

If the fault persists, contact the Company.

Note. The software key is optional hardware that is fitted to enable optional software features – Totalizers, Math

Blocks, System Clock and Timers.

Note. Acknowledging an Error Message clears the error state but does not rectify the fault. After acknowledging an

error, carry out the appropriate action detailed in the above table.

Advanced circular chart recorder 1 Preparation

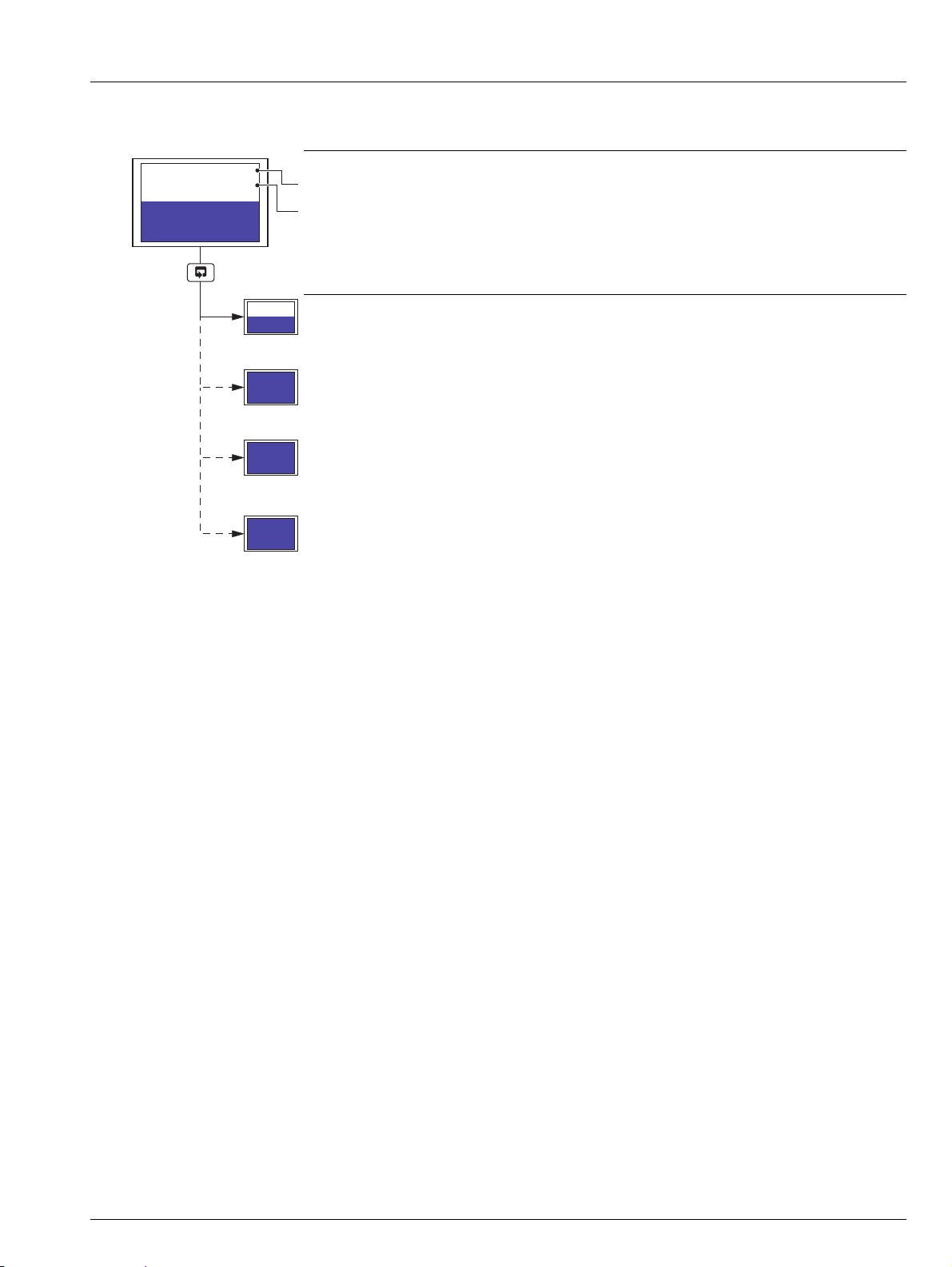

1.2.1 Recorder Status and Error Page

If any of the start-up self-tests (see Fig. 1.3) fail, the error message 'Fail' is displayed. Refer to Fig. 1.4 for possible cause and remedial

action information.

Fig. 1.4 Start-up Error Messages

IM/C1300 Rev. J 5

Page 8

C1300

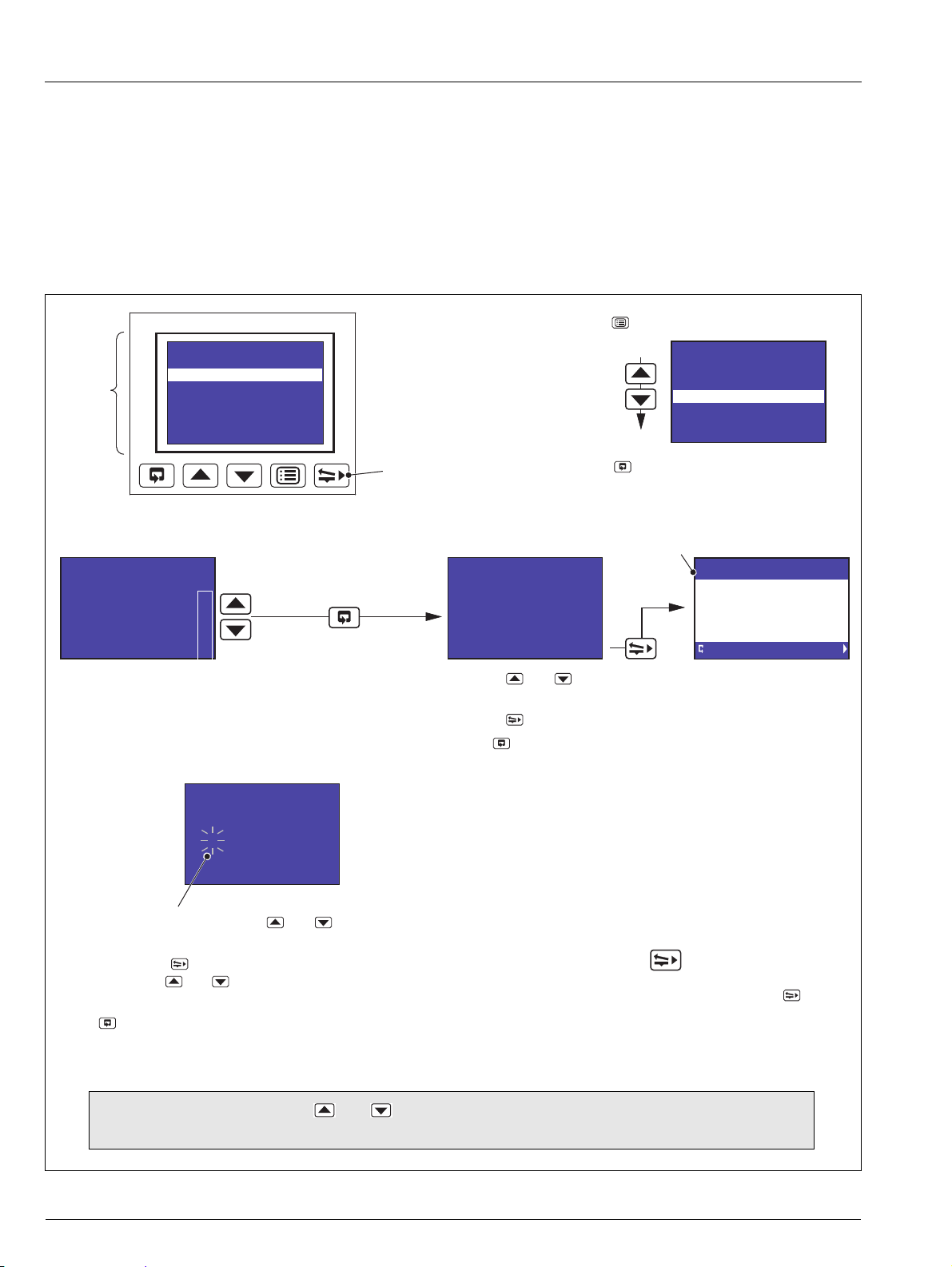

Making a Selection

Enter/Edit User-defined Information

Adjusting and Storing a Parameter Value

Select

Save selection and

advance to next screen

Raise/Lower Pens

If Auto Pen Drop is set to Yes (Section 3.4), the

key

raises/lowers the pen(s) on alternate operations when

Operating Level is selected from the Main Menu.

Press to advance to the next screen

Main Menu Screen

Press

to open the main menu screen

Select Channel

Pen

4

3

2

1

Pen 1 Tag

Boiler 1

Edit>

_ Pen 1 Tag

_!#$%&()*+,./01234

56789:;<=>?@ABCDEFGHI

JKLMNOPQRSTUVWXYZ[\]^

_abcdefghijklmnopqrs

tuvwxyz{|}WºdbSp ?

Exit Cursor

Use the and keys to select the character to be displayed

at the cursor position see

Note below.

Use the

key to move the cursor.

Press to save the new value and advance to the next screen.

Pen 1 Eng. Hi

100.00 deg C

The first number flashes. Use the and keys to

change the value as required see

Note below.

Each press of the

key selects the next number to

the right. Use the

and keys to change the value

as required see

Note below.

Press to save the new value and advance to the

next screen.

Display

Screen

Operator Keys

Operating Level

Alarm Setpoints

Security Code

Common

Channels

Alarms

Relays

Digital I/O

Highlight a

menu item

Operating Level

Alarm Setpoints

Security Code

Common

Channels

Alarms

Relays

Digital I/O

Display Screen and Operator Keys

Cursor

Note. Continued pressure on the and keys causes the rate of change of the displayed value to increase.

Press the keys momentarily to make small adjustments.

Advanced circular chart recorder 2 Operation

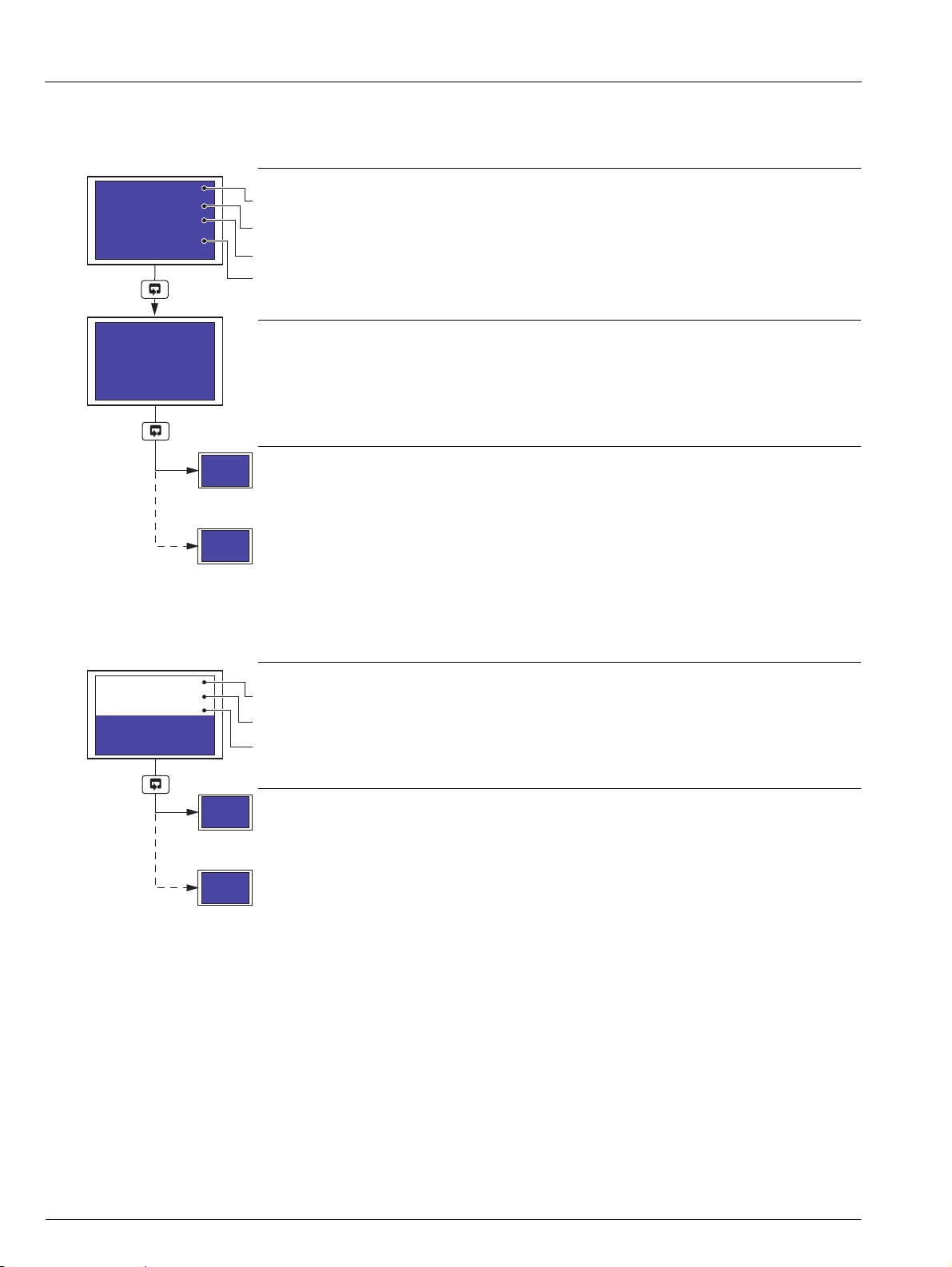

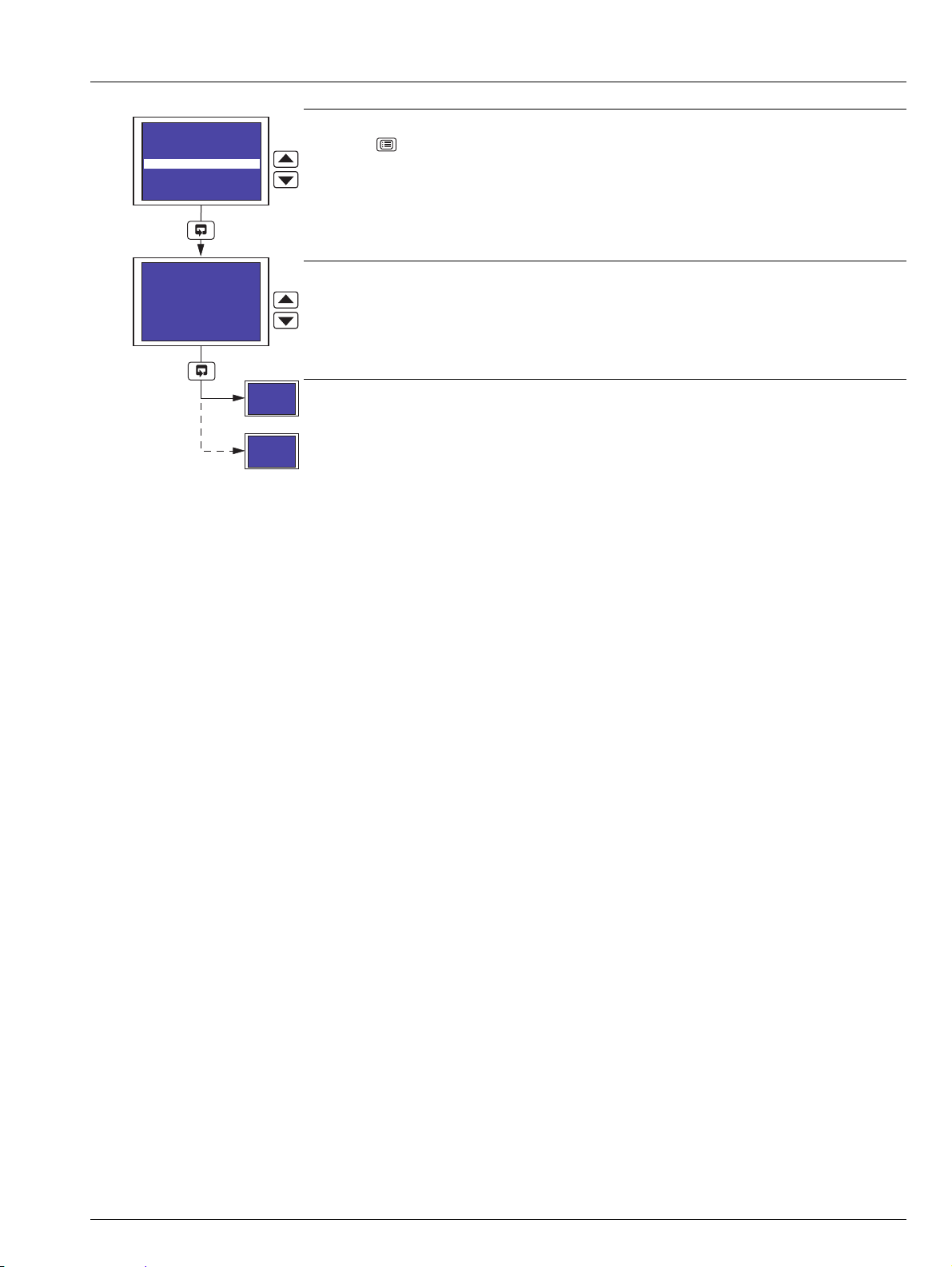

2Operation

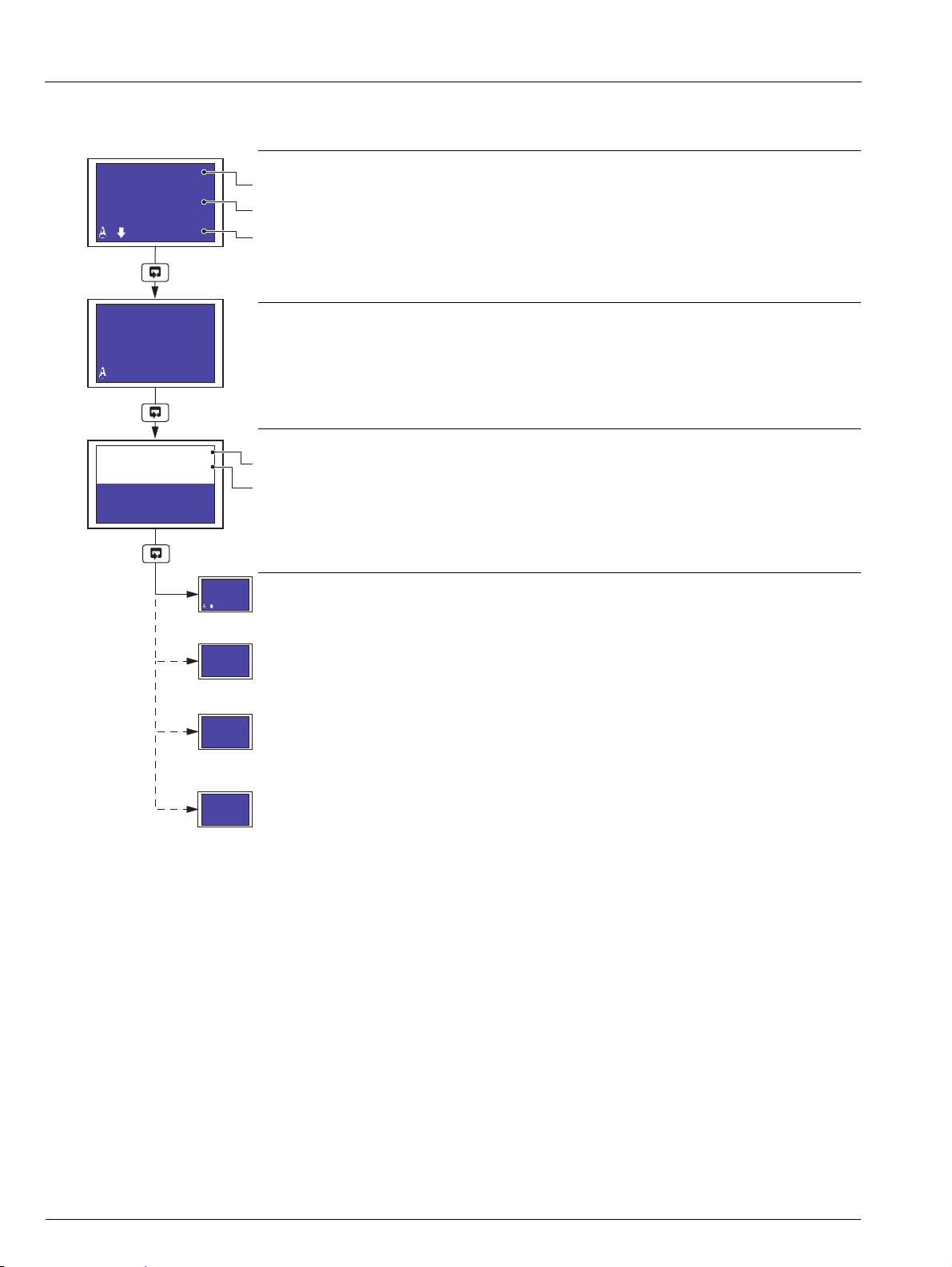

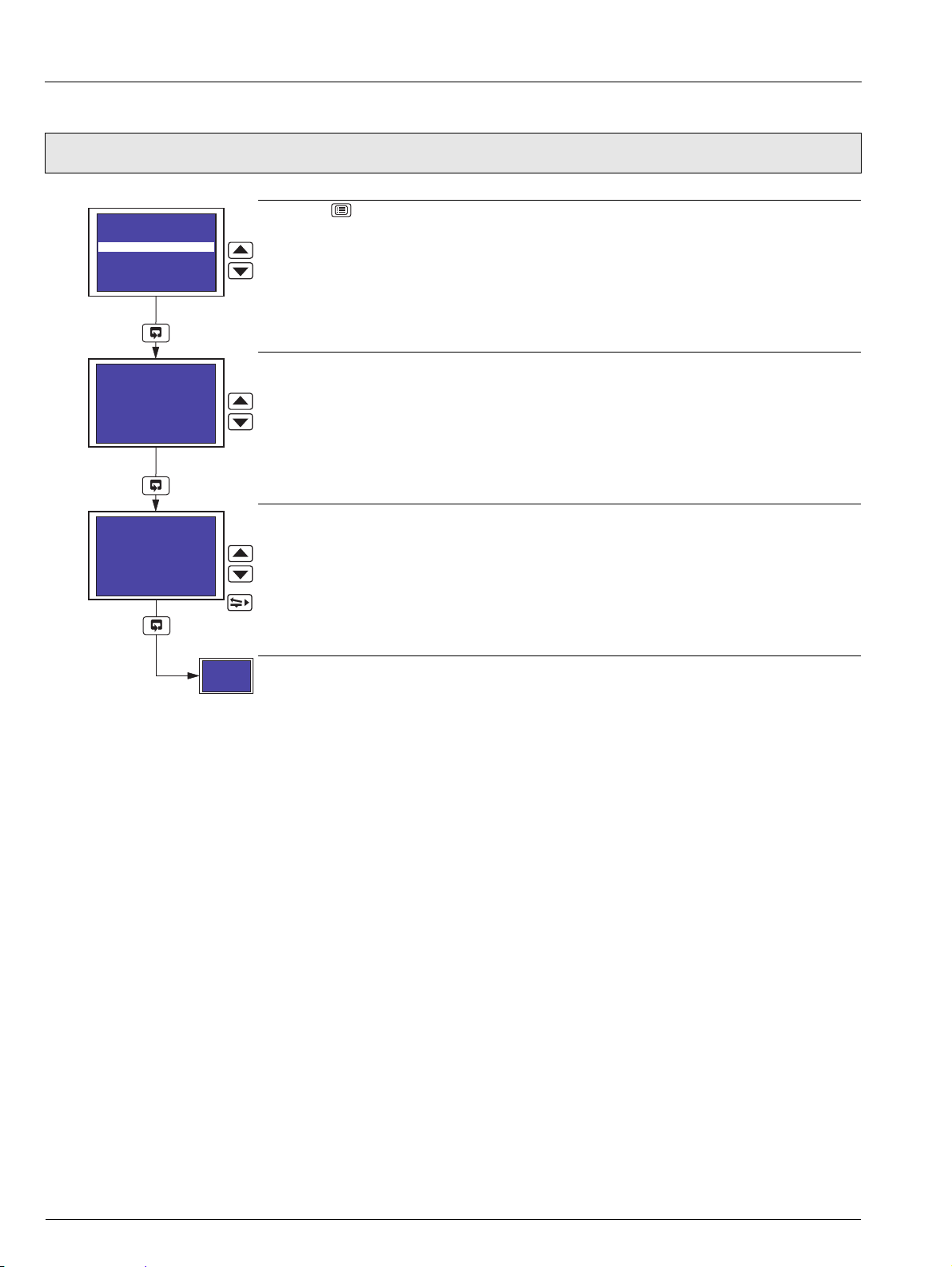

2.1 Display Screens and Operator Keys

Up to two faceplates are fitted to the front of the recorder, each comprising a display screen and associated operator keys – see

Fig. 2.1.

Each high resolution, dot matrix display screen shows the operating and programming information for up to two input channels in a

variety of formats.

Alarm states are indicated by icons in the lower left corner of the display screen(s) – see Fig. 2.3 on page 7.

Fig. 2.1 Display Screen and Operator Keys

6 IM/C1300 Rev. J

Page 9

C1300

Hardware failure on

Process Variable 1

Examples

Input out of range on

Process Variable 1

Boiler 1

Error3

gal/d

Boiler 1

F-inpt

gal/d

Message Reason Action

Error1

Error2

Error3

Finpt

Unspecified error from the Analog to Digital Converter

Corrupt data from the Analog to Digital Converter

No reply from the Analog to Digital Converter

Input is above or below fault detection level

or

Input exceeds the limits for the linearizer selected

Check that the input/output board is located correctly in its socket

see Section 5.1

Power down and up

If the error message is still present, contact the Company

Check input source for possible broken sensor

Check input connections

Check input link position

Check input configuration see Section 3.5

Note. Error messages are cleared automatically when the fault condition no longer exists.

Global Alarm Indicator displayed if any alarm in any channel is active

High Process

Low Process

relevant only to the channel currently displayed

Fast Rate

Slow Rate

Advanced circular chart recorder 2 Operation

The recorder has dedicated Operating Pages in the Operating Level – see Sections 2.3 to 2.6. These pages display the process

measurements and are not affected by the security system which inhibits access to the Configuration Pages – see Section 3.3,

page 19.

2.2 Input Error Messages and Alarm Icons

Fig. 2.2 Input Error Messages Displayed in the Operating Page

Fig. 2.3 Alarm Icons

IM/C1300 Rev. J 7

Page 10

C1300

Operating Level

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Input 1

-999.99

deg C

Advanced circular chart recorder 2 Operation

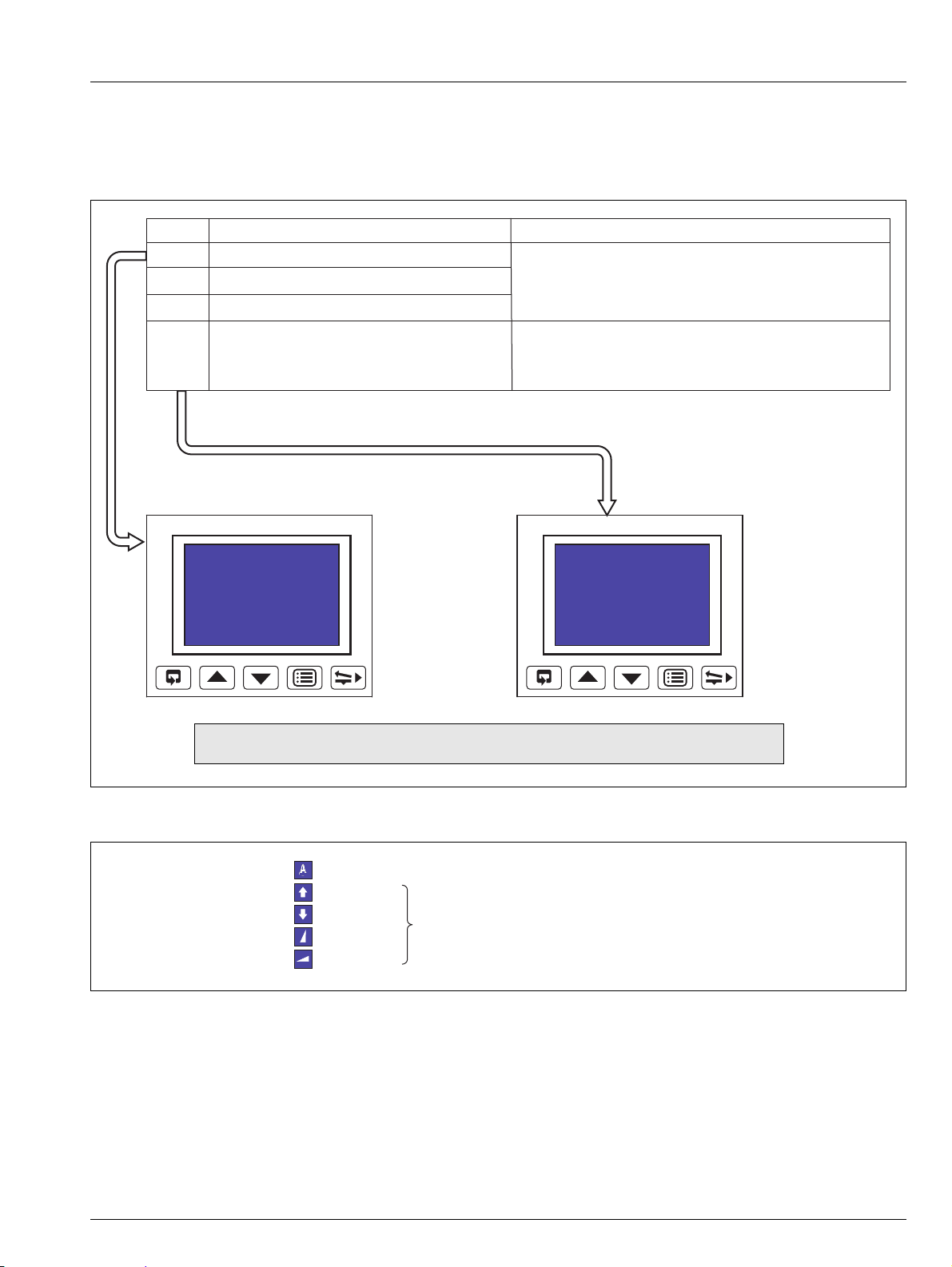

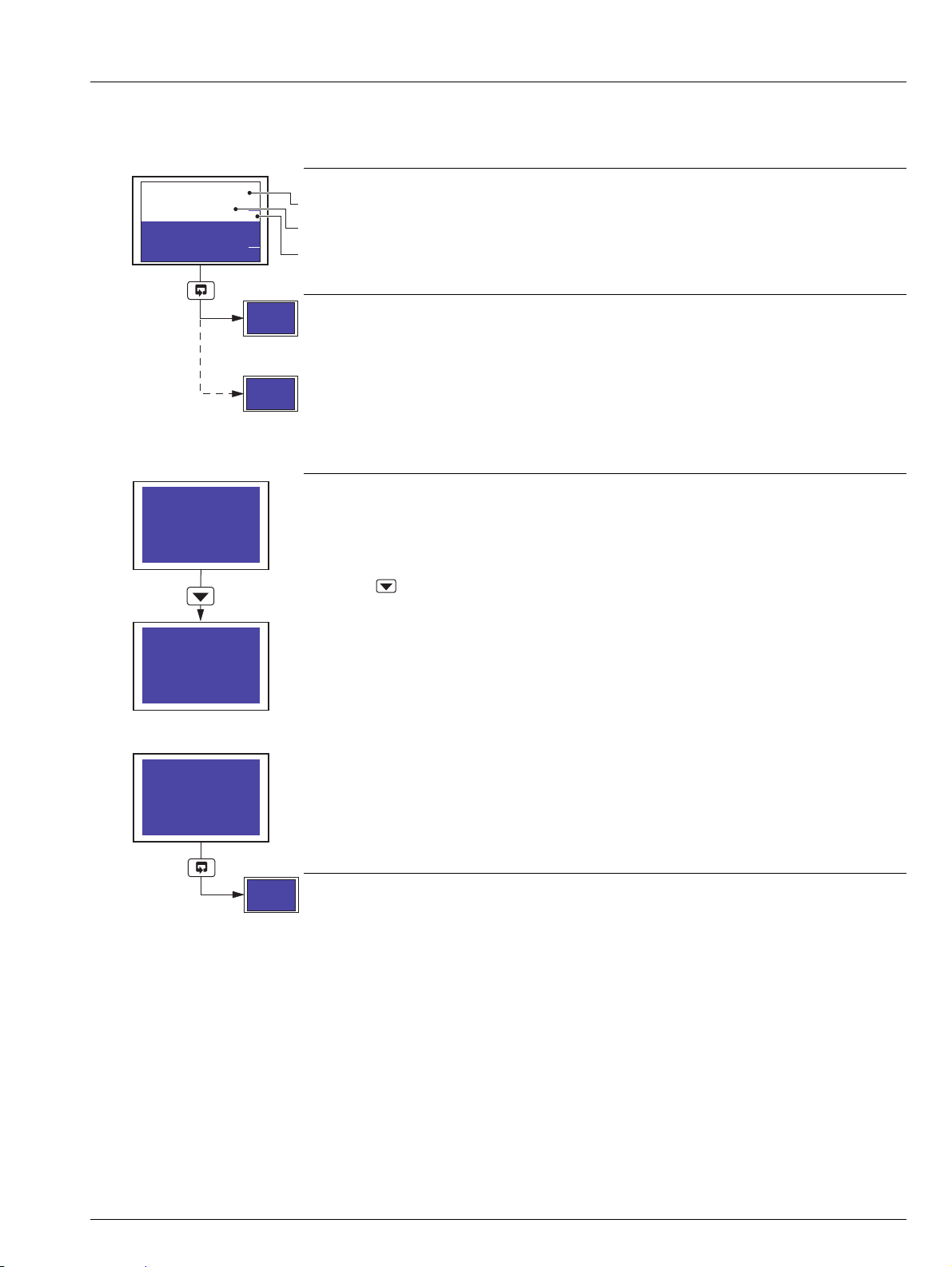

2.3 Operating Pages

Overview.

The following information is displayed in the Operating Pages:

– Input (pen) channel readings

– Data logging status (if data logging option is enabled by installation of the appropriate hardware)

– System time/date (if any one of the Totalizer, Math or Timers software options are enabled by installation of the

appropriate software key)

– Totalizer readings (if the totalizer software option is enabled by installation of the appropriate software key)

– Totalizer log (if the totalizer software option is enabled by installation of the appropriate software key)

– Totalizer control (if the totalizer software option is enabled and Totalizer Reset is set to YES – see Section 3.4, page 20.)

– Alarm set points (if Alarm Adjust is set to Yes – see Section 3.4, page 20.)

The Input (pen) channel and totalizer displays are configured separately (see Pen Ch Display and Totals Display in Section

3.4) and each can be displayed in one of several ways. Input channel information can be displayed without totalizer information

and vice-versa.

Input channel 1 and 2 information and system time/date is shown on display screen 1.

If the recorder is fitted with the optional second faceplate:

– Input channel 3 and 4 information, together with system time/date is shown on display screen 2

– Totalizer logs, totalizer control and alarm set point adjustment for pens 3 and 4 and associated totalizers are accessed

from the menu shown on display screen 2 when the key is pressed on faceplate 2.

Totalizer information is shown on the same display screen as the pen to which the totalizer is assigned.

All channel and totalizer configuration is done using faceplate 1.

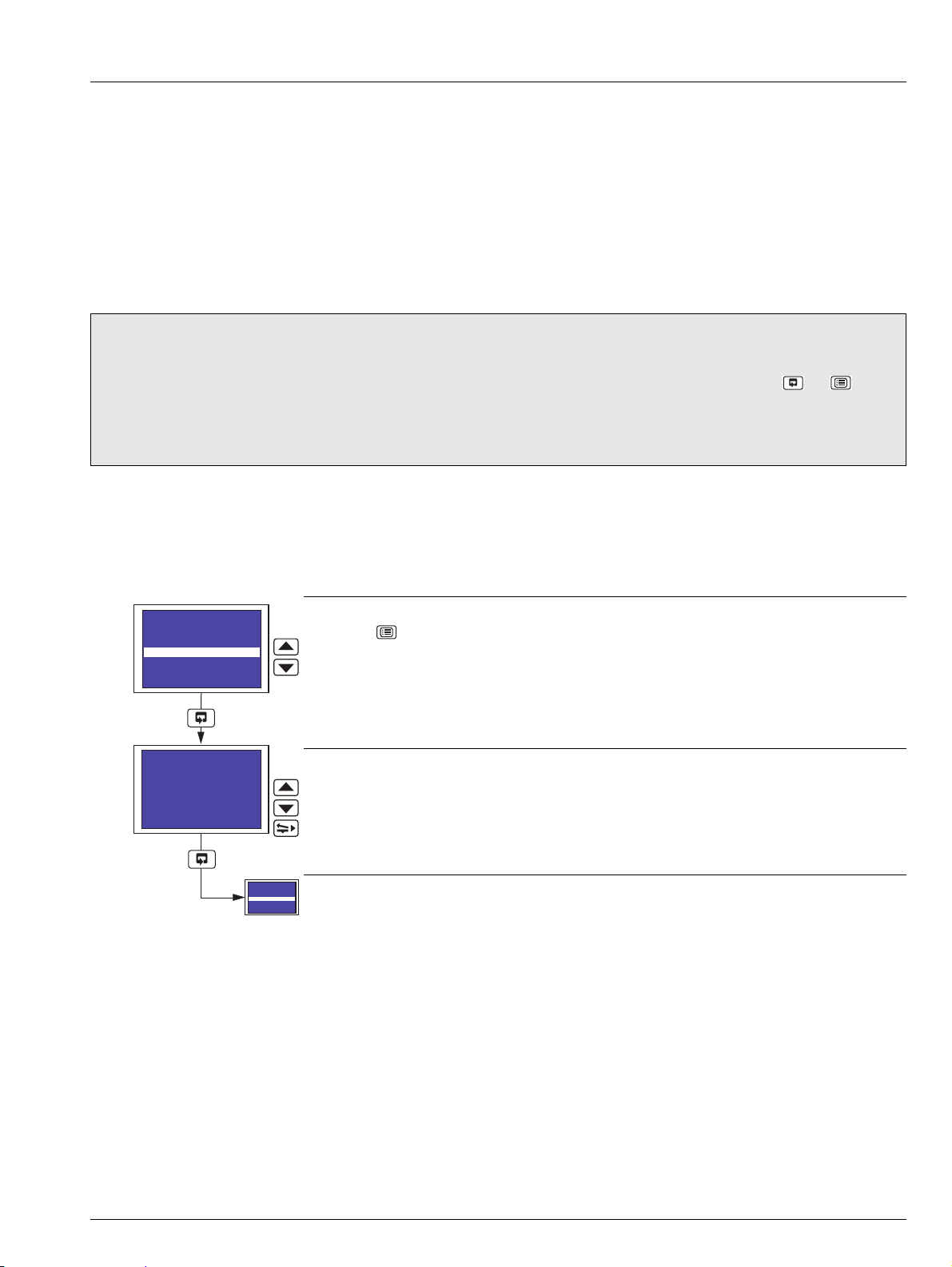

2.3.1 Accessing the Operating Pages

Press the key to open the Main Menu.

Highlight Operating Level.

see Section 2.3.3, page 10.

8 IM/C1300 Rev. J

Page 11

C1300

Input 1

-999.99

deg C

Autoscroll On

Slow Rate

Autoscroll On

Fast Rate

Autoscroll Off

Autoscroll On

Slow Rate

Advanced circular chart recorder 2 Operation

2.3.2 Autoscroll

Autoscroll

When Autoscroll is set to On, each Operating Page screen is displayed in turn for a period of

time determined by the rate selected:

Slow Rate – each screen is displayed in turn for 10 seconds

Fast Rate – each screen is displayed in turn for 5 seconds

Press the key from any Operating Page screen to initiate Autoscroll in Slow Rate mode.

Press the key again to switch to Fast Rate mode.

When in Fast Rate mode, press the key to switch to Slow Rate mode.

When in Slow Rate mode, press the key to switch Autoscroll off.

Press the key at any time to switch Autoscroll off.

IM/C1300 Rev. J 9

Page 12

C1300

Input 1

-999.99

deg C

System Time

Tuesday

25th May 2004

14:33:48

Input 2

O.OOO

m3/s

Totalizer 1

000000000

Input 1

-999.99

deg C

Input 1

-999.99

deg C

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Advanced circular chart recorder 2 Operation

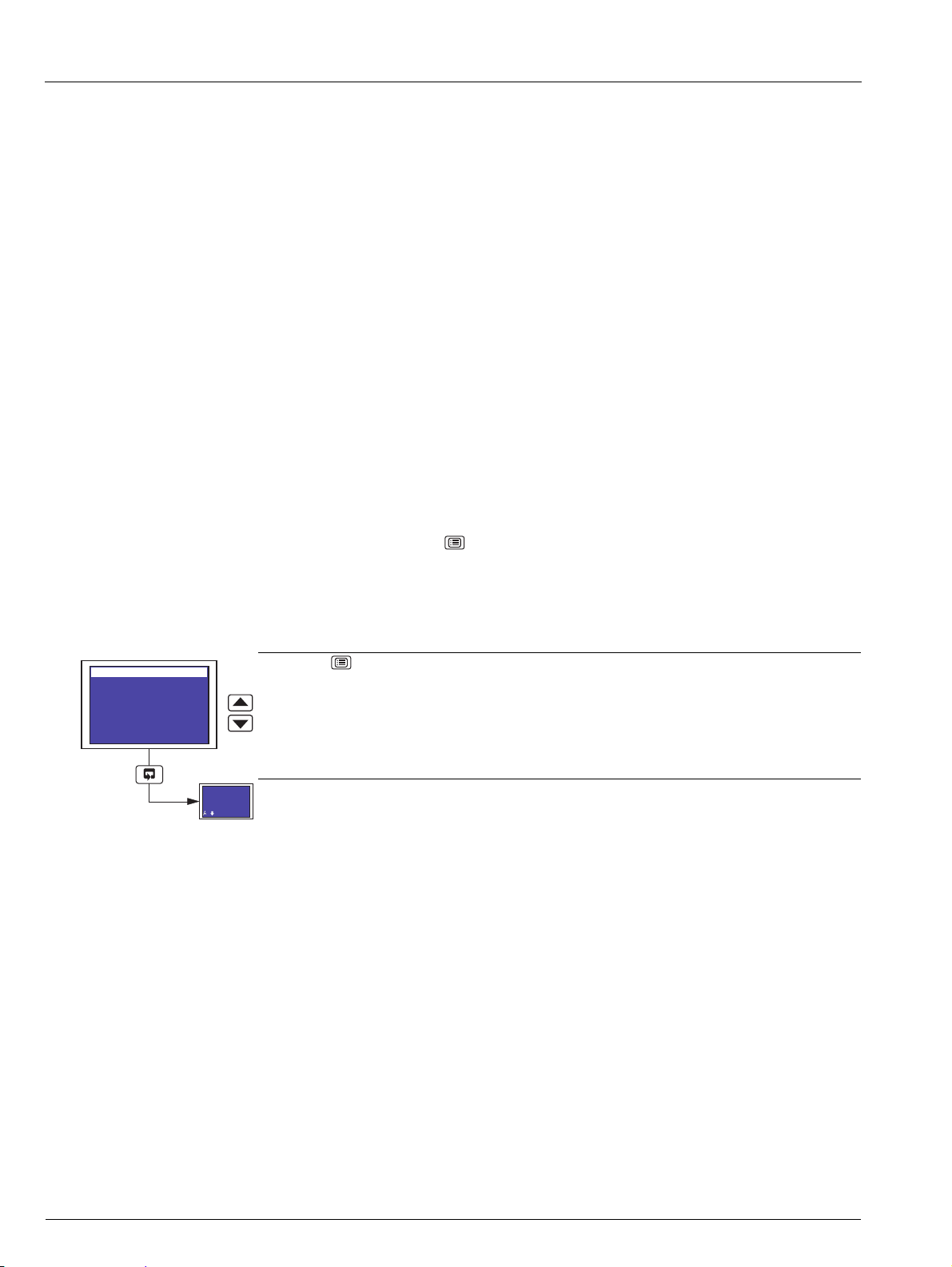

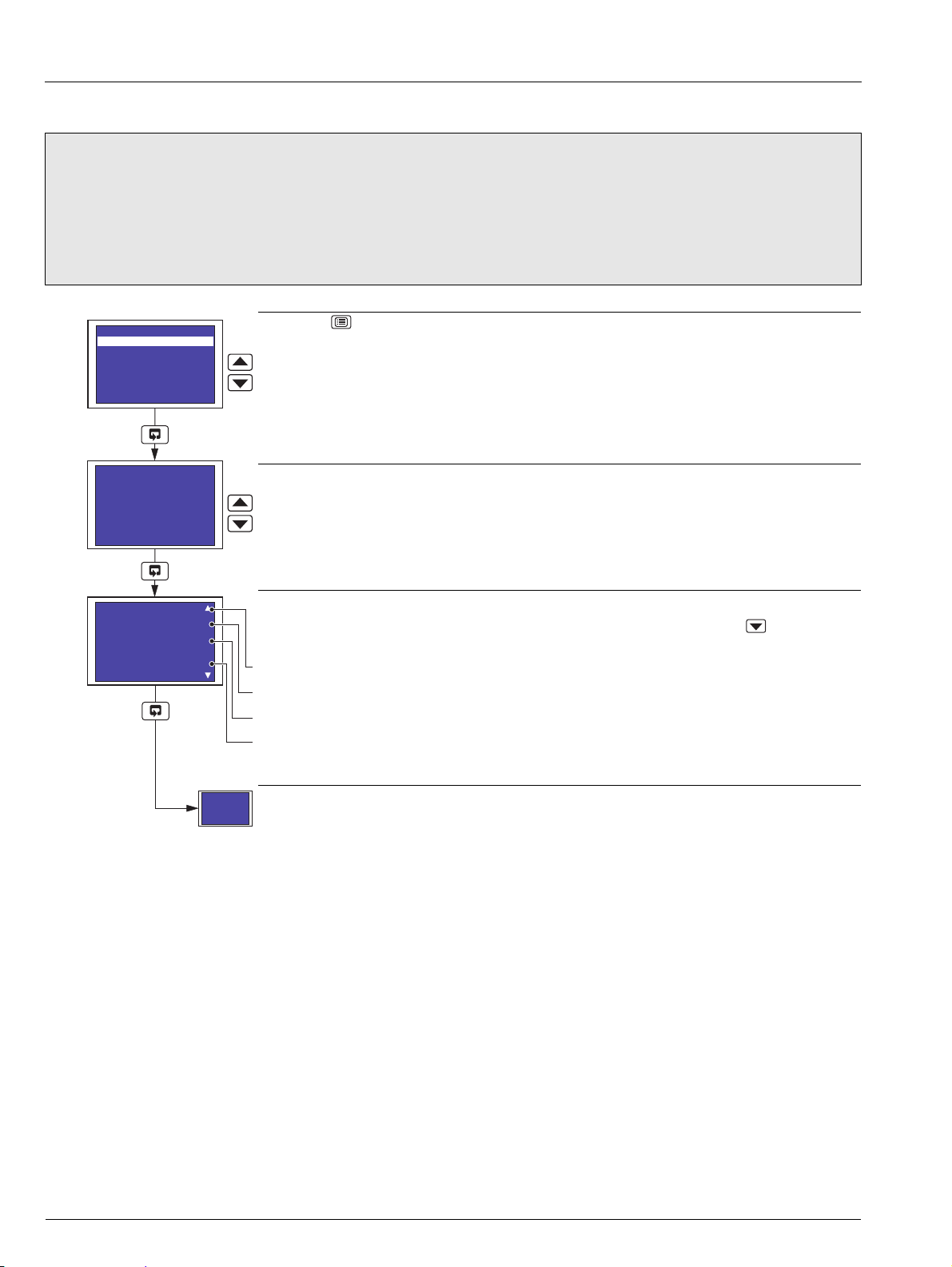

2.3.3 Input (Pen) Channel Display – Separate

The following screens are displayed only if Pen Ch Display is set to Separate – see Section 3.4, page 20.

Input Channel 1 (Pen 1)

Channel tag.

Measured value.

Alarm icons and measured value units.

Note. If Pen 1 Source is set to None (Section 3.14), only a measured value of 0 is displayed.

Input Channel 2 (Pen 2)

Note. If Pen 2 Source is set to None (Section 3.14), only a measured value of 0 is displayed.

Totalizer, Math or Timers software options not enabled by installation of the appropriate software

key and optional Data Logging hardware not installed – return to top of page.

Totalizer software option enabled by installation of the appropriate software key and To ta l s

Display not set to Off (Section 3.4) – see Sections 2.3.6 to 2.3.10.

Optional Data Logging hardware installed – see Section 2.3.11, page 15.

Optional Data Logging hardware not installed and Totalizer software option enabled by

installation of the appropriate software key and Totals Display set to Off (Section 3.4) –

continued below.

System Time/Date Display

Notes.

Available only if any one of the Totalizer, Math or Timers software options are enabled by

installation of the appropriate software key, or the optional Data Logging hardware is

installed.

If Pen Ch Display and Totals Display are set to Off (Section 3.4) and any of the above

software options are enabled and the optional Data Logging hardware is not installed, the

System Time Display is the only Operating Page screen available.

Return to top of page.

10 IM/C1300 Rev. J

Page 13

C1300

Input 1

O.O l/s

Input 2

O.OOO m3/s

Totalizer 1

000000000

Input 1

O.O l/s

Input 2

O.OOO m3/s

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Advanced circular chart recorder 2 Operation

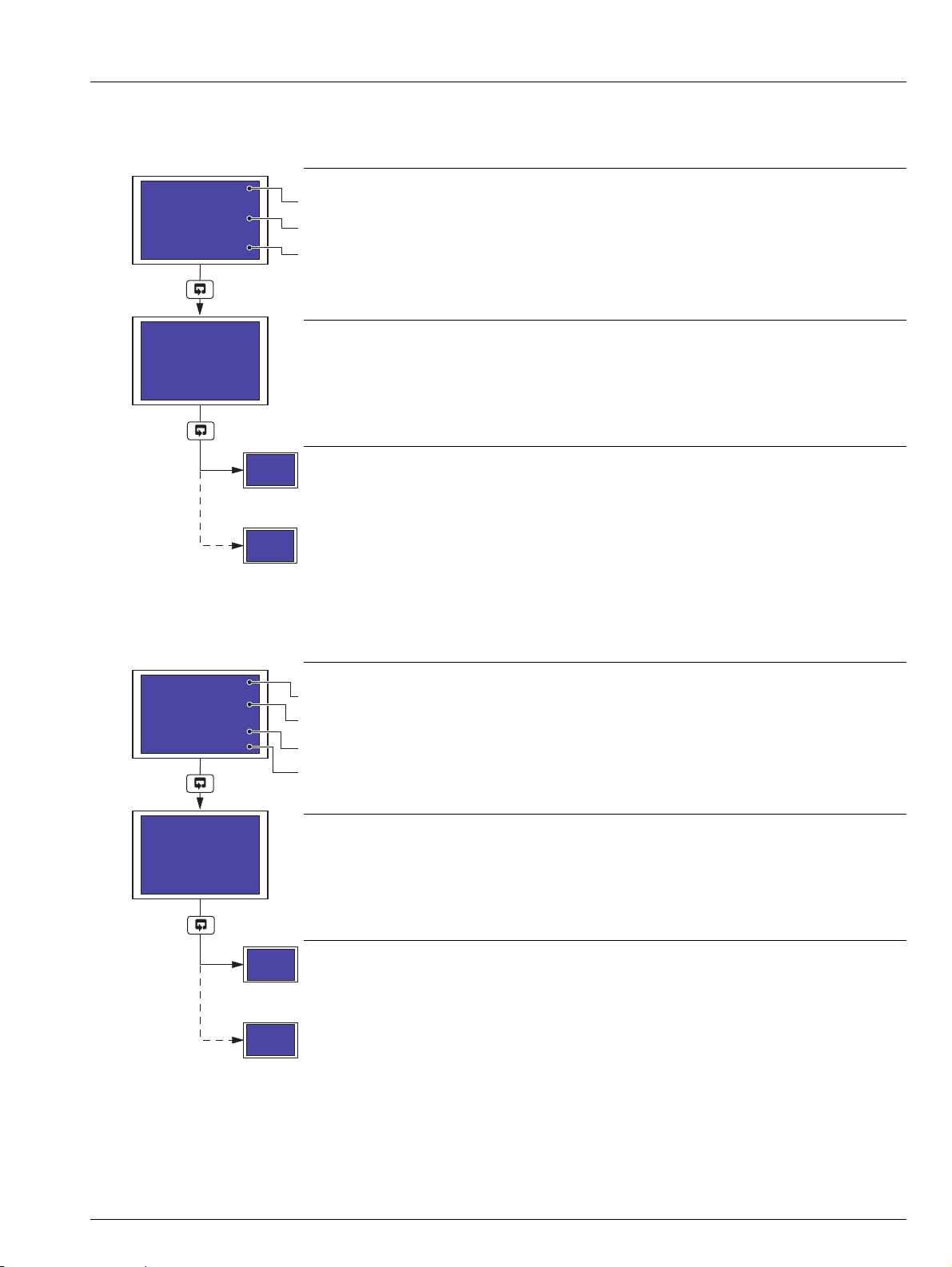

2.3.4 Input (Pen) Channel Display – Dual

The following screens are displayed only if Pen Ch Display is set to Dual – see Section 3.4, page 20.

Input Channels 1 and 2 (Pens 1 and 2)

Channel tag.

Measured value and units.

Note. If Pen X Source (where X is the pen number) is set to None (Section 3.14), only a

measured value of 0 is displayed for that channel.

Totalizer, Math or Timers software options not enabled by installation of the appropriate software

key and optional Data Logging hardware not installed – return to top of page.

Totalizer software option enabled by installation of the appropriate software key and Totals

Display not set to Off (Section 3.4) – see Sections 2.3.6 to 2.3.10.

Optional Data Logging hardware installed – see Section 2.3.11, page 15.

Optional Data Logging hardware not installed and Totalizer software option enabled by

installation of the appropriate software key and Totals Display set to Off (Section 3.4) – see

Section 2.3.3, page 10.

IM/C1300 Rev. J 11

Page 14

C1300

Input 2

O.OOO

m3/s

Input 1

-999.99

deg C

Input 1

O.O l/s

Input 2

O.OOO m3/s

Totalizer 1

000000000

Input 1

-999.99

deg C

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Advanced circular chart recorder 2 Operation

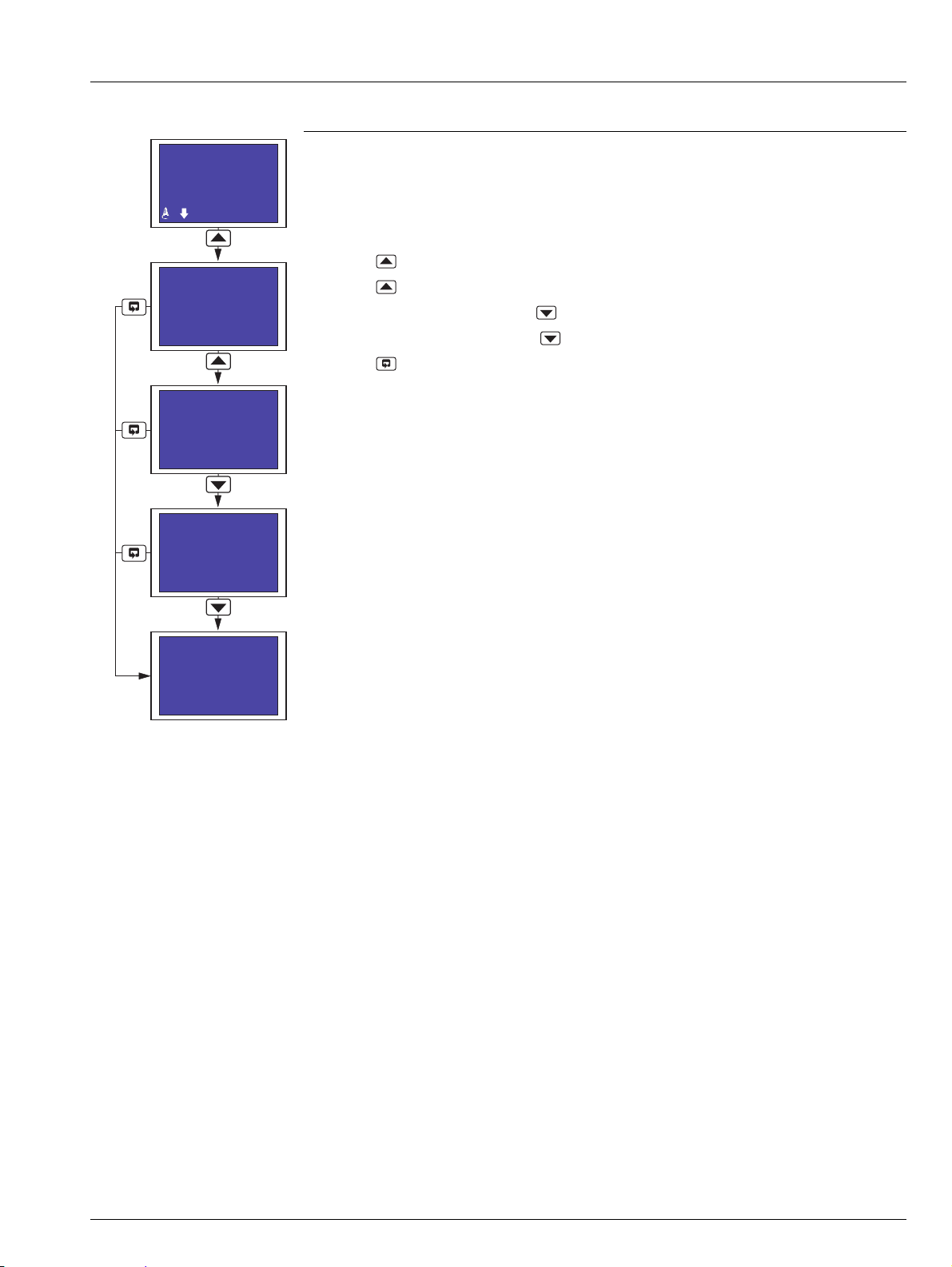

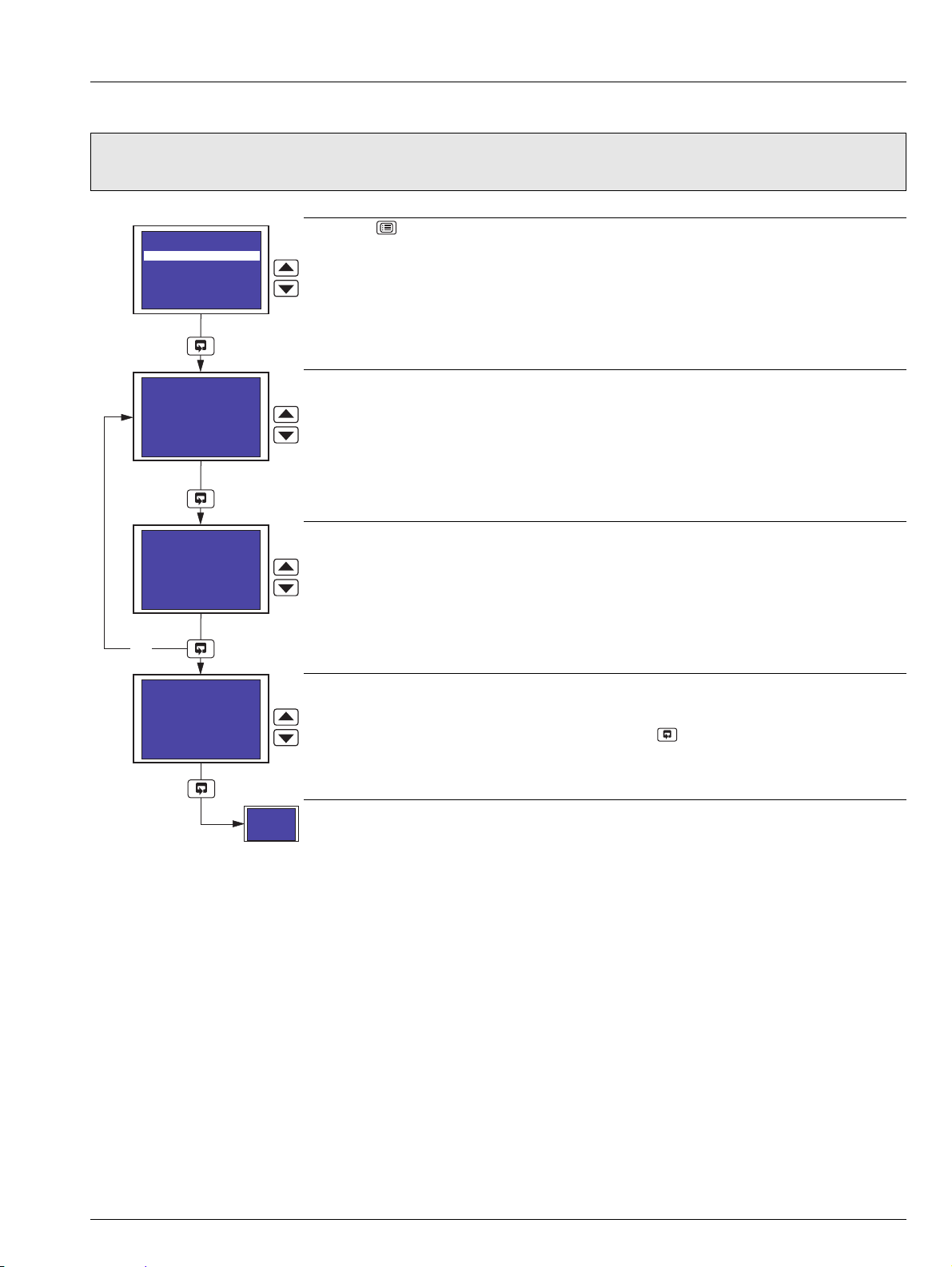

2.3.5 Input (Pen) Channel Display – Separate and Dual

The following screens are displayed only if Pen Ch Display is set to Separate & Dual – see Section 3.4, page 20.

Input Channel 1 (Pen 1)

Channel tag.

Measured value.

Alarm icons and measured value units.

Note. If Pen 1 Source is set to None (Section 3.14), only a measured value of 0 is displayed.

Input Channel 2 (Pen 2)

Note. If Pen 2 Source is set to None (Section 3.14), only a measured value of 0 is displayed.

Input Channels 1 and 2 (Pens 1 and 2)

Channel tag.

Measured value and units.

Note. If Pen X Source (where X is the pen number) is set to None (Section 3.14), only a

measured value of 0 is displayed for that channel.

Totalizer, Math or Timers software options not enabled by installation of the appropriate software

key and optional Data Logging hardware not installed – return to top of page.

Totalizer software option enabled by installation of the appropriate software key and To ta l s

Display not set to Off (Section 3.4) – see Sections 2.3.6 to 2.3.10.

Optional Data Logging hardware installed – see Section 2.3.11, page 15.

Optional Data Logging hardware not installed and Totalizer software option enabled by

installation of the appropriate software key and Tot a l s D i s p la y set to Off (Section 3.4) – see

Section 2.3.3, page 10.

12 IM/C1300 Rev. J

Page 15

C1300

Totalizer 1

000000000

Ml

Totalizer 2

000000000

gal

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Input 1

87.6 gal

000005320

gal

Input 2

856.35 Ml

000027839

Ml

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Advanced circular chart recorder 2 Operation

2.3.6 Totalizer Display – Separate

The following screens are displayed only if Totals Display is set to Separate (Section 3.4) and Tot X Source (where X is the totalizer

number) is set to anything other than None – see Section 3.7, page 35.

Totalizer 1

Totalizer tag.

Totalizer value.

Totalizer value units.

Totalizer 2

Optional data logging hardware installed – see Section 2.3.11, page 15.

2.3.7 Totalizer Display – Rate with Total

The following screens are displayed only if Totals Display is set to Rate with Total (Section 3.4) and To t X S o u r c e (where X is the

totalizer number) is set to anything other than None – see Section 3.7, page 35.

Optional data logging hardware not installed – see Section 2.3.3, page 10.

Totalizer 1

Channel tag.

Measured value and measured value units.

Totalizer value.

Totalizer value units.

Totalizer 2

Optional data logging hardware installed – see Section 2.3.11, page 15.

IM/C1300 Rev. J 13

Optional data logging hardware not installed – see Section 2.3.3, page 10.

Page 16

C1300

Totalizer 1

000005320

gal

87.6 gal

Totalizer 2

000027839

Ml

856.35 Ml

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Totalizer 1

000005320

gal

Totalizer 2

000027839

Ml

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Advanced circular chart recorder 2 Operation

2.3.8 Totalizer Display – Total with Rate

The following screens are displayed only if Totals Display is set to Total with Rate (Section 3.4) and Tot X Source (where X is the

totalizer number) is set to anything other than None – see Section 3.7, page 35.

Totalizer 1

Totalizer tag.

Totalizer value.

Totalizer units.

Measured value and measured value units.

Totalizer 2

Optional data logging hardware installed – see Section 2.3.11, page 15.

Optional data logging hardware not installed – see Section 2.3.3, page 10.

2.3.9 Totalizer Display – Dual Total

The following screen is displayed only if Totals Display is set to Dual Total (Section 3.4) and Tot X Source (where X is the totalizer

number) is set to anything other than None – see Section 3.7, page 35.

Totalizers 1 and 2

Totalizer tag.

Totalizer value.

Totalizer units.

Optional data logging hardware installed – see Section 2.3.11, page 15.

Optional data logging hardware not installed – see Section 2.3.3, page 10.

14 IM/C1300 Rev. J

Page 17

C1300

87.6

gal/h

000279513

|1

472.6

gal/h

008831908

|2

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

System Time

Tuesday

25th May 2004

14:33:48

Data Logging

Status: Online

Memory Used: 25%

Remove Card

Data Logging

Status: Offline

It is now safe to

remove the

Compact Flash

(59s)

Data Logging

Status: Not Present

Advanced circular chart recorder 2 Operation

2.3.10 Totalizer Display – Dual + Flow Rate

The following screen is displayed only if Totals Display is set to Dual + Flow Rate (Section 3.4) and Tot X Source (where X is the

totalizer number) is set to anything other than None – see Section 3.7, page 35.

Totalizers 1 and 2

Measured value and measured value units.

Totalizer value.

Totalizer units and channel number.

Optional data logging hardware installed – see Section 2.3.11, below.

Optional data logging hardware not installed – see Section 2.3.3, page 10.

2.3.11 Data Logging

Data Logging Status

Provides information on current data logging status.

Press the key to place data logging off-line.

When data logging is off-line, the Compact Flash card can be removed safely.

If the card is not removed within 1 minute, data logging is placed on-line automatically. A timer

indicates the number of seconds remaining before data logging resumes.

This screen is displayed when a Compact Flash card is not inserted.

Data logging starts automatically when a Compact Flash card is inserted.

see Section 2.3.3, page 10.

IM/C1300 Rev. J 15

Page 18

C1300

Select Totalizer

Totalizer 1

Select Totalizer

Totalizer 1

19th Apr 04 15:30

Totalizer 1

000047824

gal

Max : 78

Min : 22

Avg : 56

Operating Level

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Advanced circular chart recorder 2 Operation

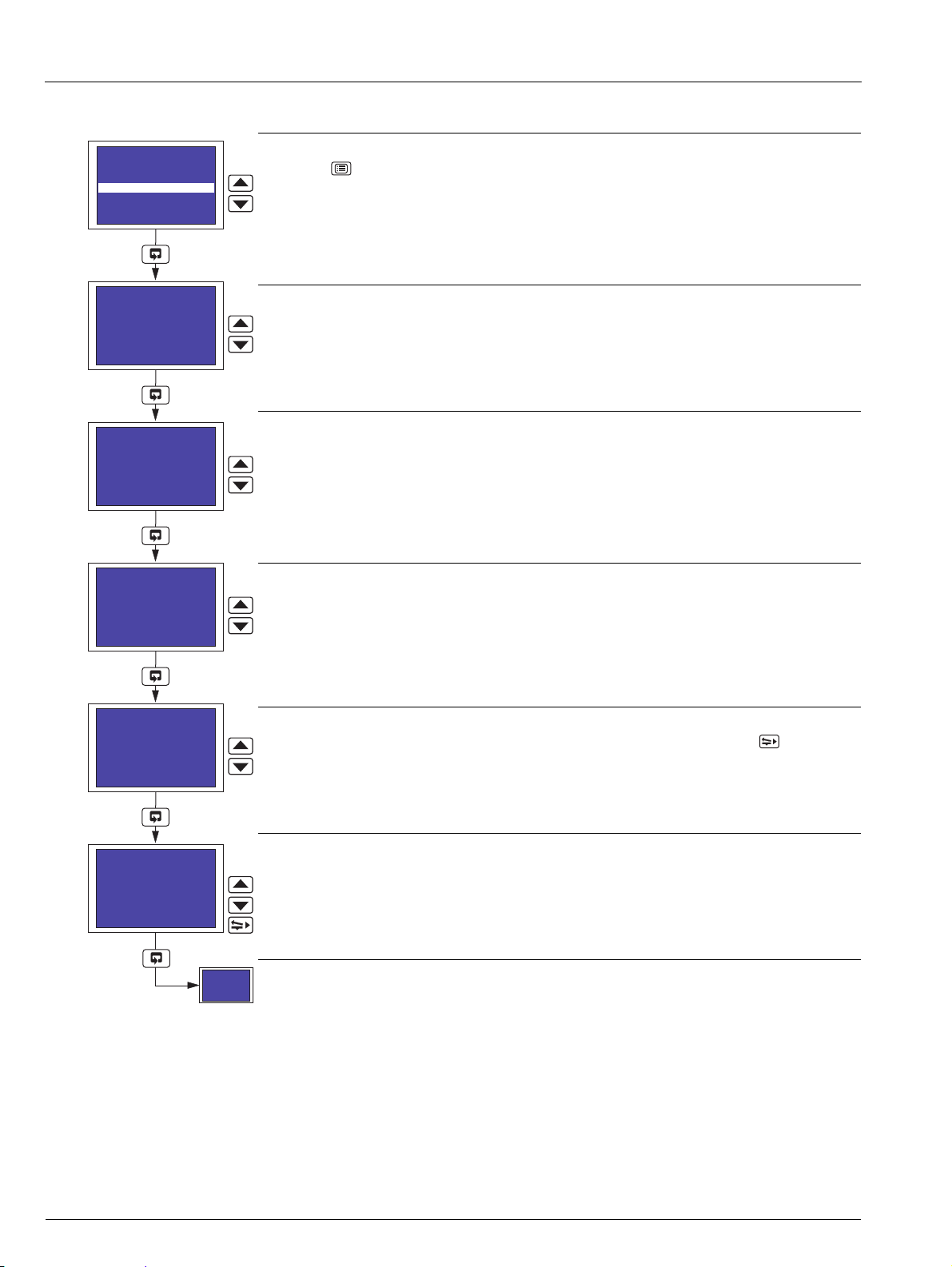

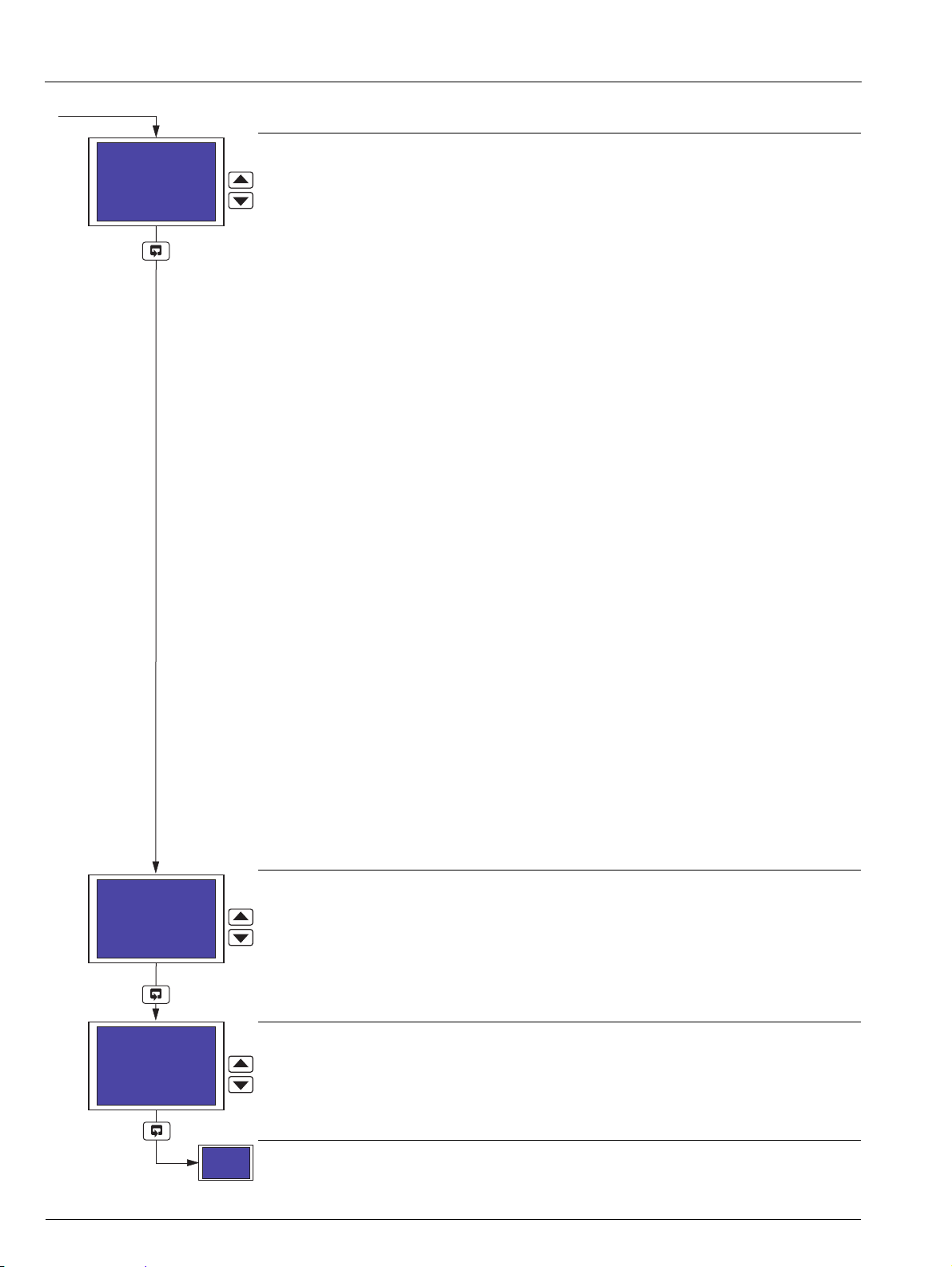

2.4 Totalizer Log

Note.

The totalizer log is available only if the totalizer software option is enabled by installation of the appropriate software key.

The recorder can store up to 21 log entries for each enabled totalizer. When the maximum number of entries has been

reached, the oldest data is overwritten by the newest.

A new log entry is created for each totalizer at the interval selected in the Tot X Log Enable parameter (where X is the

totalizer number) – see Section 3.7, page 35.

Press the key to open the Main Menu.

Highlight Totalizer Log.

Select Totalizer

Select the totalizer log to display.

Totalizer Log

The first log displayed for the selected totalizer is the most recent. Use the key to display

each log in descending date order.

Date and time.

Totalizer tag.

Current value and units.

Maximum, minimum and average values.

Note. If no log entries exist, Log is empty is shown on the display screen.

Return to top of page.

16 IM/C1300 Rev. J

Page 19

C1300

Select Totalizer

Totalizer 1

Totalizer 1

Reset - NO

000000913

Operating Level

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Totalizer 1

Confirm - NO

000000913

NO

Totalizer 1

Reset - NO

000000913

Advanced circular chart recorder 2 Operation

2.5 Totalizer Control

Note. Totalizer control is available only if the totalizer software option is enabled by installation of the appropriate software key

and Totalizer Reset is set to YES – see Section 3.4, page 20.

Press the key to open the Main Menu.

Highlight Totalizer Control.

Select Totalizer

Select the totalizer to reset.

Reset Totalizer

Select YES to reset the totalizer.

Confirm Reset Totalizer

Select YES to reset the totalizer.

Note. If YES is selected, the totalizer is reset when the key is pressed.

Return to previous frame.

IM/C1300 Rev. J 17

Page 20

C1300

Select Alarm

A1

A1 Trip

10.000 deg C

Operating Level

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Select Alarm

A1

Advanced circular chart recorder 2 Operation

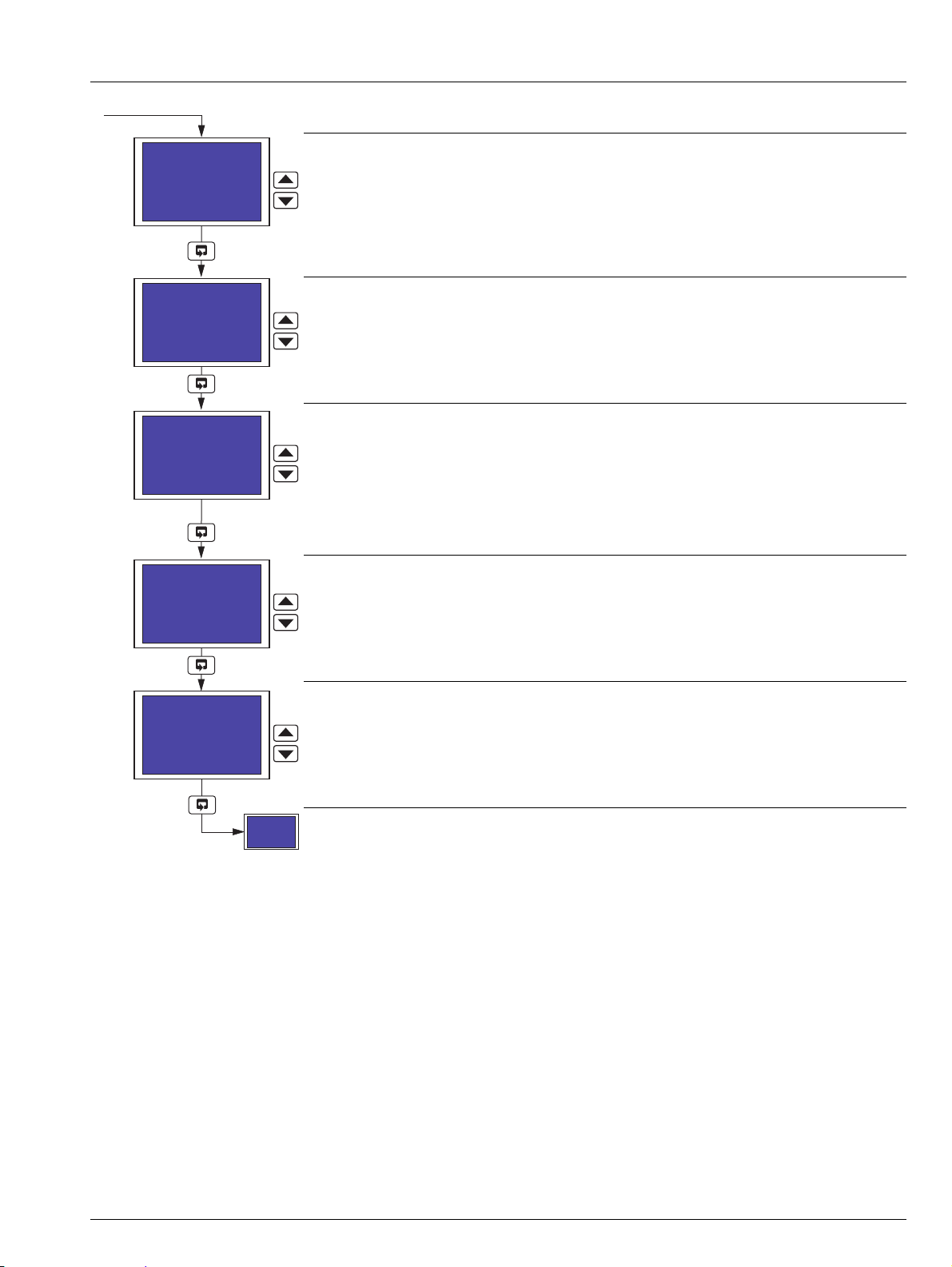

2.6 Alarm Set Point Adjustment

Note. Alarm set point adjustment is available only if Alarm Adjust is set to YES – see Section 3.4, page 20.

Press the key to open the Main Menu.

Highlight Alarm Adjust.

Select Alarm

Select the alarm to adjust.

Alarm Set Point

Adjust the alarm set point.

Return to top of page.

18 IM/C1300 Rev. J

Page 21

C1300

Enter Code

0000

Operating Level

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Operating Level

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Advanced circular chart recorder 3 Configuration

3 Configuration

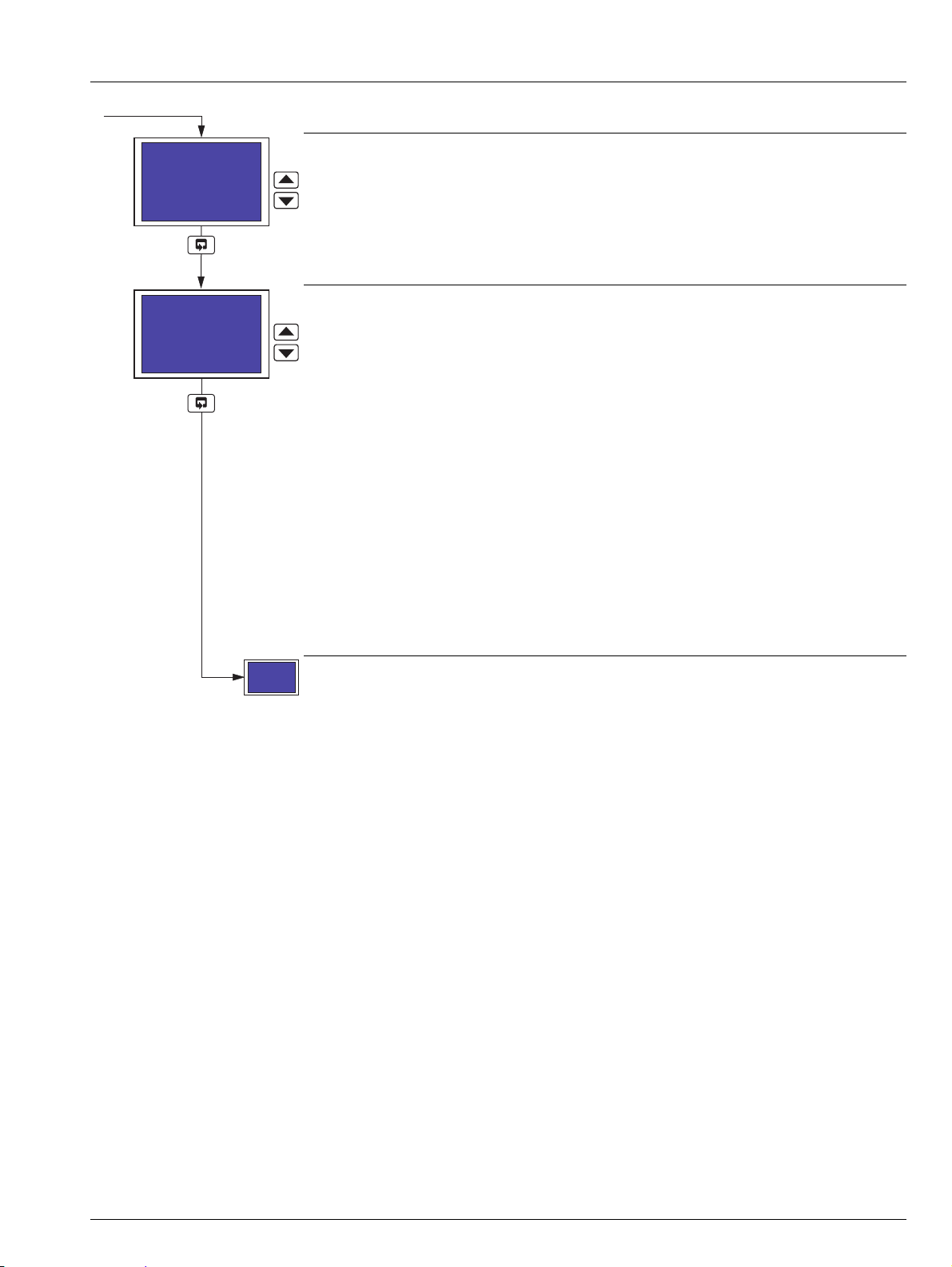

3.1 Introduction

The configuration procedures are used to make changes to the operating parameter values and for scale adjustment. Configuration

of all channels is performed from faceplate 1.

The configuration settings can be backed up to a PC and restored to the recorder as required – see Section 3.16, page 58.

An overview of the Configuration Pages is on the rear cover fold-out.

When changing the input type, it may be necessary to reposition the input selector links accordingly – see Section 5.2.1, page 67.

3.2 Preparation for Configuration

Note.

Isolate any external alarm/control circuits if inadvertent operation during configuration is undesirable.

The recorder responds instantly to parameter changes. These are saved automatically when either the or key is

pressed.

The display screen of faceplate 2 (if fitted) shows Configuration Mode when the configuration pages are accessed by

scrolling past Security Code in the Main Menu on the display screen of faceplate 1.

3.3 Configuration Level Security

Unauthorized access to the configuration pages is prevented by the use of a security code.

The security code, set to '0' when the recorder is despatched, can be set to any value from 0 to 9999 – see Configure Password in

Section 3.4 on pgae 20. When set to anything other than '0', access to all configuration menus (i.e. all menus below Security Code)

is prevented. Enter the correct code to enable access to the configuration menus.

Security Code

Press the key to open the Main Menu.

Highlight Security Code.

Enter Security Code

Enter the correct security code.

Return to Main Menu.

IM/C1300 Rev. J 19

Page 22

C1300

Chart Duration

24 hours

Totalizer Log

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Totalizers

Stop Chart Srce

None

Auto Pen Drop

YES

Pen Lift Enable

YES

Config Password

0000

Line Rejection

50 Hz

Advanced circular chart recorder 3 Configuration

3.4 Common Configuration

Common Configuration

Press the key to open the Main Menu.

Highlight Common.

Chart Duration

Select the chart duration required per revolution of the chart:

between 1 and 167 hours in 1 hour increments

between 7 and 32 days in 1 day increments

Stop Chart Source

Select the source required for stopping the chart.

Refer to Appendix A on page 77 for a description of sources.

Auto Pen Drop

Select YES to enable the pen(s) to drop automatically onto the chart 5 minutes after they are

lifted.

If NO is selected, the pen(s) remain lifted until they are dropped manually by the operator.

Pen Lift Enable

Select YES to enable the pen(s) to be raised and lowered using the pen lift key ( ).

Configure Password

Select a code between 1 and 9999.

20 IM/C1300 Rev. J

Continued on next page.

Page 23

C1300

Totals Display

Separate

Line Rejection

50 Hz

Pen Ch Display

Separate

Advanced circular chart recorder 3 Configuration

Line Rejection

Select the frequency of the mains supply to ensure maximum noise rejection on analog inputs.

Pen Channel Display

Select the style of input (pen) channel display required in the Operating Page – see Sections 2.3.3

to 2.3.5.

Off – input channel information is not displayed in the Operating Page

Separate – input channel information for channels 1 and 2 is shown separately

on display screen 1. Input channel information for channels 3 and 4

(3 and 4 pen recorders only) is shown separately on display screen 2

– see Section 2.3.3, page 10

Dual – input channel information for channels 1 and 2 is shown

simultaneously on display screen 1. Input channel information for

channels 3 and 4 (3 and 4 pen recorders only) is shown

simultaneously on display screen 2 – see Section 2.3.4, page 11

Separate & Dual – input channel information for channels 1 and 2 is first shown

separately, then simultaneously on display screen 1. Input channel

information for channels 3 and 4 (3 and 4 pen recorders only) is first

shown separately, then simultaneously on display screen 2 – see

Section 2.3.5, page 12

Continued on next page.

IM/C1300 Rev. J 21

Page 24

C1300

Totals Display

Separate

Other Ch Display

NO

Alarm Adjust

NO

Totalizer Reset

NO

Advanced circular chart recorder 3 Configuration

Totalizers Display

Note. Displayed only if the totalizer software option is enabled by installation of the appropriate

software key.

Select the style of totalizer display required in the Operating Page – see Sections 2.3.6 to 2.3.10.

Off – totalizer values are not displayed in the Operating Page

Separate – totalizer values for totalizers assigned to channels 1 and 2 are

shown separately on display screen 1. Totalizer values for totalizers

assigned to channels 3 and 4 (3 and 4 pen recorders only) are

shown separately on display screen 2 – see Section 2.3.6, page 13

Rate with Total – totalizer values for totalizers assigned to channels 1 and 2, together

with the current measured values for channels 1 and 2, are shown

separately on display screen 1. Totalizer values for totalizers

assigned to channels 3 and 4 (3 and 4 pen recorders only),

together with the current measured values for channels 3 and 4,

are shown separately on display screen 2 – see Section 2.3.7, page

13

Total with Rate – the current measured values for channels 1 and 2, together with

totalizer values for totalizers assigned to channels 1 and 2, are

shown separately on display screen 1. The current measured

values for channels 3 and 4 (3 and 4 pen recorders only), together

with totalizer values for totalizers assigned to channels 3 and 4, are

shown separately on display screen 2 – see Section 2.3.8, page 14

Dual Total – totalizer values for totalizers assigned to channels 1 and 2 are

shown simultaneously on display screen 1. Totalizer values for

totalizers assigned to channels 3 and 4 (3 and 4 pen recorders only)

are shown simultaneously on display screen 2 – see Section 2.3.9,

page 14

Dual + Flow Rate – totalizer values for totalizers assigned to channels 1 and 2, together

with the current measured values for channels 1 and 2, are shown

simultaneously on display screen 1. Totalizer values for totalizers

assigned to channels 3 and 4 (3 and 4 pen recorders only),

together with the current measured values for channels 3 and 4,

are shown simultaneously on display screen 2 – see Section

2.3.10, page 15

Note. Do not select Dual + Flow Rate if a totalizer is not assigned to each of the channels to

be displayed – see Section 3.7, page 35.

Other Channels Display

Select YES to display information for input channels not assigned to pens.

Alarm Adjust

Select YES to enable alarm set point adjustment in the Operating Page – see Section 2.6, page

18.

Continued on next page.

22 IM/C1300 Rev. J

Page 25

C1300

Contrast 1

100%

Contrast 2

100%

Brightness 1

100%

Brightness 2

100%

Chart Duration

24 hours

Totalizer Reset

NO

Advanced circular chart recorder 3 Configuration

Totalizer Reset

Note. Displayed only if the totalizer software option is enabled by installation of the appropriate

software key.

Select YES to enable the totalizers to be reset in the Operating Page – see Section 2.5, page 17.

Contrast 1

Select the required contrast setting for display screen 1, between 0 and 100%.

Contrast 2

Note. Shown only if faceplate 2 is fitted.

Select the required contrast setting for display screen 2, between 0 and 100%.

Brightness 1

Select the required brightness setting for display screen 1, between 0 and 100%.

Brightness 2

Note. Shown only if faceplate 2 is fitted.

Select the required brightness setting for display screen 2, between 0 and 100%.

Return to top of page.

IM/C1300 Rev. J 23

Page 26

C1300

Input Type Linearizer

Type

5/2

3/2

Ö

RTD

THC N

THC B

THC E

THC L

THC J

THC T

THC S

THC R

THC K

None

Temp. Units Engineering Range

(Display Range)

Programme

Filter

°F

°C

None

RTD

THC

Current

Voltage

Millivolts

Low resistance

High resistance

Broken Sensor

Protection Drive

Upscale

Downscale

Electrical

Range

Value set to 0

Value set low

Value set high

Fault Detection

Level

10 %

Fault Detection

Level

10 %

4.0 (Input Range Low)

20.0 (Input Range High)

200

0

220

20

Input Type Linearizer

Type

5/2

3/2

Ö

RTD

THC N

THC B

THC E

THC L

THC J

THC T

THC S

THC R

THC K

None

Temp. Units

°F

°C

None

RTD

THC

Current

Voltage

Millivolts

Low resistance

High resistance

Engineering Range

(Display Range)

Programme

Filter

Broken Sensor

Protection Drive

Upscale

Downscale

Value set to 0

Value set low

Value set high

Fault Detection

Level

10 %

Fault Detection

Level

10 %

2000

0

2200

200

Advanced circular chart recorder 3 Configuration

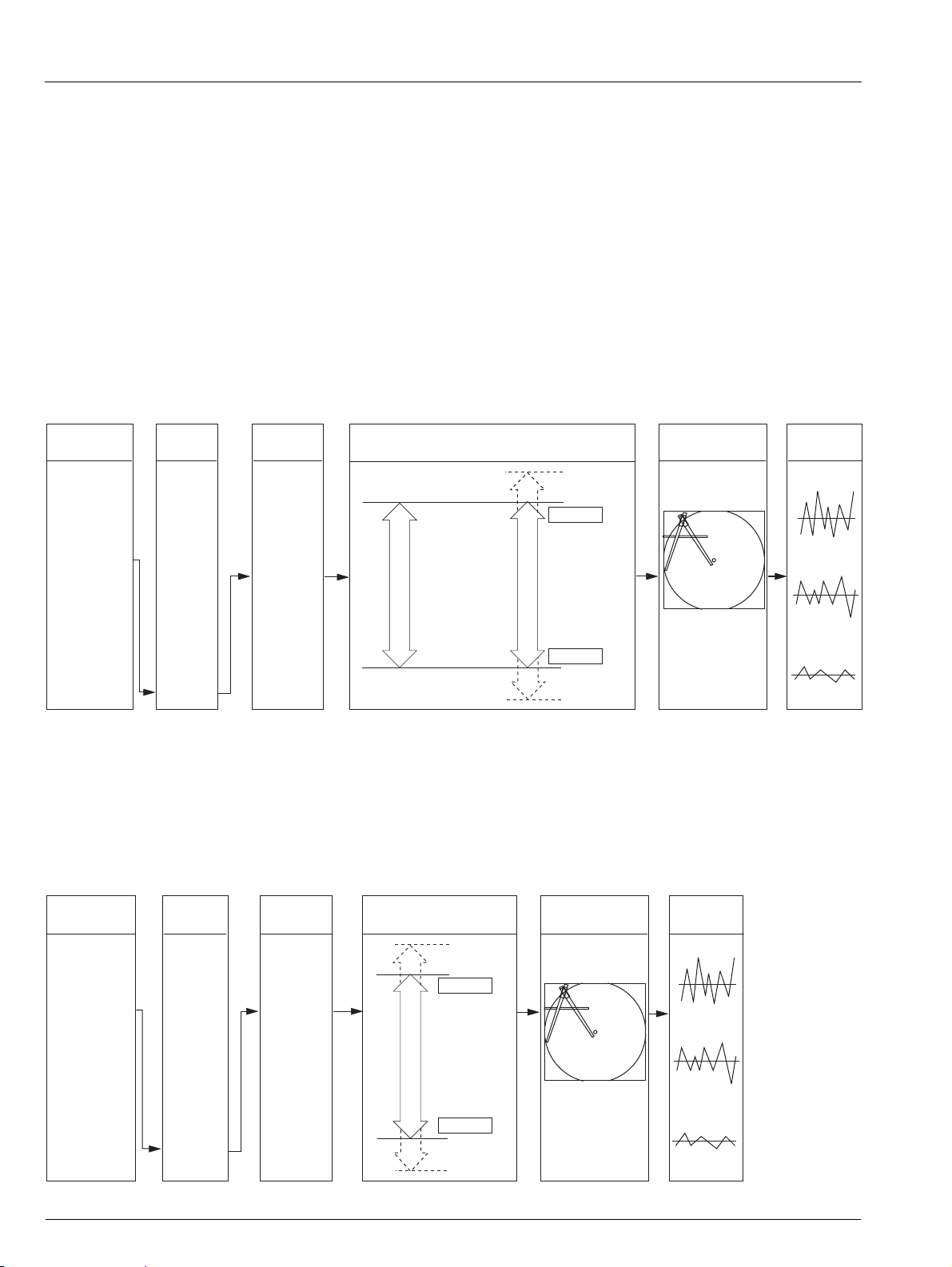

3.5 Channels Configuration

Overview.

Universal inputs – mV, mA, V, THC, RTD and resistance.

Internal cold junction compensation.

Linearization – enables use of non-linearizing temperature transmitters or any electrical input.

Programmable fault levels and actions.

Digital filter – reduces the effect of noise on inputs.

Example A – setting up:

a current input of 4 to 20mA

displaying a range of 0 to 200psi

a fault detection level 10% above 200psi (engineering/display range) and 10% below 0psi (engineering/display range)

in the event of a fault being detected and/or the fault detection level being exceeded, the process variable is driven downscale.

Example B – setting up:

a Type K thermocouple

displaying temperature in °F

displaying a range of 0 to 2000°F

a fault detection level 10% above 2000°F (engineering/display range) and 10% below 0°F (engineering/display range)

in the event of a fault being detected and/or the fault detection level being exceeded, the process variable is driven upscale.

24 IM/C1300 Rev. J

Page 27

C1300

Select Channel

Pen 1

Totalizer Control

Alarm Setpoints

Security Code

Common

Channels

Alarms

Totalizers

Relays

Pen 1 Tag

Input 1

Edit>

Pen 1 Off Tag

Pen 1 Event Off

Edit>

Advanced circular chart recorder 3 Configuration

Channels Configuration

Press the key to open the Main Menu.

Highlight Channels.

Select Channel

Select the channel to configure.

Note. If Pen X Function or Pen X Source (where X is the pen number) is set to Off or None

respectively (Section 3.14), that pen cannot be selected.

Pen X Function set to Tre nd (Section 3.14) – continued on next page.

Pen X Function set to Event (Section 3.14) – continued on page 30.

IM/C1300 Rev. J 25

Page 28

C1300

Select Channel

Pen 1

Pen 1 Tag

Input 1

Edit>

Pen 1 Input Type

High Ohm

Pen 1 Lin. Type

Type K

Pen 1 Units

101 mV

Pen X Function

set to Trend

(Section 3.13)

Millivolt

Milliamp

High Ohm

Low Ohm

Volts

Thermocouple

Rtd

None

Advanced circular chart recorder 3 Configuration

Channel Tag

Press the key to open the Edit screen.

Use the , and keys to enter the channel tag required – see Fig. 2.1 on page 6.

Note. Any characters not permitted in this tag are skipped when scrolling through the selection.

Press the key to close the edit screen and save the tag.

Channel Input Type

Select the required channel input type:

None –None

Millivolt – Millivolt (150mV)

Milliamp – Current

High Ohm – High resistance (>750)

Low Ohm – Low resistance (750)

Volts – Voltage

Thermocouple – Thermocouple

Rtd – Resistance thermometer

Return to top of page.

Linearizer Type

Select the required linearizer type.

None – No linearizer

Type K – Type K thermocouple

Type R – Type R thermocouple

Type S – Type S thermocouple

Type T – Type T thermocouple

Type J – Type J thermocouple

Type E – Type E thermocouple

Type N – Type N thermocouple

Type B – Type B thermocouple

Rtd – Resistance thermometer

Square Root – Square root

3/2 –X

5/2 –X

3/2

(Open channel flow applications)

5/2

(Open channel flow applications)

Continued on next page.

26 IM/C1300 Rev. J

Page 29

C1300

Pen 1 Units

101 mV

Pen 1 Elect. Hi

150.0 mV

Pen 1 Elect. Lo

40.0 mV

Pen 1 Dec. Point

XXX.XX

Pen 1 Eng. Hi

010.00 mV

Input Type

set to

Thermocouple

or RTD

Advanced circular chart recorder 3 Configuration

Channel Units

Select any of the units pre-programmed into the recorder or select 113 Custom and the ,

and keys to enter the units required – see Fig. 2.1 on page 6.

Notes.

Any characters not permitted in user-defined units are skipped when scrolling through the

selection.

Refer to Appendix B on page 78 for a description of the units pre-programmed into the

recorder.

Electrical Input Range High

Set the maximum electrical input value required, within the limits shown in Table 3.1.

Electrical Input Range Low

Set the minimum electrical input value required, within the limits shown in Table 3.1.

Decimal Point

Select the decimal point position for the engineering and chart ranges.

Continued on next page.

Input Type Electrical Range Low Electrical Range High Minimum Span (Low to High)

Millivolts 0 150 5.0

Milliamps 0 50 1.0

Resistance (High) 0 9999 400

Resistance (Low) 0 750 20

Volts 0 5 0.1

Table 3.1 Limits of Electrical Ranges

IM/C1300 Rev. J 27

Page 30

C1300

Pen 1 Eng. Hi

010.00 mV

Pen 1 Eng. Lo

000.00 mV

Pen 1 Chart Hi

010.00 mV

Pen 1 Brk Sensor

Downscale

Pen 1 Chart Lo

000.00 mV

Advanced circular chart recorder 3 Configuration

Engineering Range High

Set the maximum engineering value required, within the limits shown in Table 3.2.

Engineering Range Low

Set the minimum engineering value required, within the limits shown in Table 3.2.

Chart Range High

Set the maximum value, in engineering units, required on the chart.

Note. If the Engineering Range High setting is changed, the Chart Range High setting is reset

automatically to the same value.

Chart Range Low

Set the minimum value, in engineering units, required on the chart.

Note. If the Engineering Range Low setting is changed, the Chart Range Low setting is reset

automatically to the same value.

Continued on next page.

Linearizer Type Minimum Maximum Minimum Span Minimum Maximum Minimum Span

Type K –100 1300 65 –148 2372 117

Types R & S –18 1700 320 0 3092 576

Type T –250 300 60 –418 572 108

Type J –100 900 50 –148 1652 90

Type E –100 900 45 –148 1652 81

Type N –200 1300 90 –328 2372 162

Type B –18 1800 710 0 3272 1278

Rtd –200 600 25 –328 1112 45

Performance accuracy is not guaranteed below 400°C (725°F) for types B, R and S thermocouples.

Minimum span below zero for Type T thermocouples is 70°C (126°F).

Minimum span below zero for Type N thermocouples is 105°C (189°F).

THC standard DIN 4730 IEC 584.

RTD standard DIN 43760 IEC 751.

Linearizer Type Minimum Maximum

Square Root

3/2

5/2

None

Table 3.2 Limits of Engineering Ranges

Degrees Celsius Degrees Fahrenheit

Engineering Range High and Low

–999 9999

28 IM/C1300 Rev. J

Page 31

C1300

Pen 1 Brk Sensor

Downscale

Pen 1 Fault Lev.

10 %

Pen 1 Filter

Off

Select Channel

Pen 1

Advanced circular chart recorder 3 Configuration

Broken Sensor Protection Drive

In the event of an input failure, the process variable is driven in the direction selected:

Downscale – Process variable driven below zero

None – Process variable driven in direction of failure

Upscale – Process variable driven beyond full scale

Fault Detection Level Percentage

Set a tolerance level, between 0 and 100% of the engineering range, to allow for deviation of the

input signal above or below the input span before an input failure is detected.

Example – setting the fault detection level to 10% on input range of 50 (Engineering Range

Low) to 250 (Engineering Range High) bar causes an analog input failure fault to be detected

below 30 bar and above 270 bar.

Notes.

On some ranges the input circuitry may saturate before the fault level setting is reached. In

this case, an error is detected below the level set.

If an input exceeds the minimum or maximum value for the selected linearizer, an error is

detected regardless of the fault level setting.

Pen Filter

Filters the process variable input, i.e. if the input is stepped it smooths the transition between

steps and may also be used for some degree of cleaning of noisy inputs. The filter time

represents the time a step in the input takes to change the displayed process variable from 10 to

90% of the step.

Set the value required, between Off and 60 seconds in 1 second increments.

Return to top of page.

IM/C1300 Rev. J 29

Page 32

C1300

Pen 1 Off Tag

Pen 1 Event Off

Edit>

Pen 1 In Tag

Pen 1 Event In

Edit>

Pen 1 Out Source

None

Select Channel

Pen 1

Pen X Function

set to Event

(Section 3.13)

Pen 1 Out Tag

Pen 1 Event Out

Edit>

Pen 1 In Source

None

Advanced circular chart recorder 3 Configuration

Pen Off Tag

Press the key to open the Edit screen.

Use the , and keys to enter the pen off tag required – see Fig. 2.1 on page 6.

Note. Any characters not permitted in this tag are skipped when scrolling through the selection.

Press the key to close the edit screen and save the tag.

Pen In Tag

Press the key to open the Edit screen.

Use the , and keys to enter the pen in tag required – see Fig. 2.1 on page 6.

Note. Any characters not permitted in this tag are skipped when scrolling through the selection.

Press the key to close the edit screen and save the tag.

Pen Out Tag

Press the key to open the Edit screen.

Use the , and keys to enter the pen out tag required – see Fig. 2.1 on page 6.

Note. Any characters not permitted in this tag are skipped when scrolling through the selection.

Press the key to close the edit screen and save the tag.

Pen In Source

Select a digital source to move the pen inwards on the chart.

Refer to Appendix A on page 77 for a description of sources.

Pen Out Source

Select a digital source to move the pen outwards on the chart.

Refer to Appendix A on page 77 for a description of sources.

Return to top of page.

30 IM/C1300 Rev. J

Page 33

C1300

High Process

Low Process

Process

Variable

Hysteresis

Hysteresis

Trip Point

Alarm On

Alarm Off

Alarm On

Alarm Off

Output

Alarm Trip Point

Alarm On

Alarm Off

Time in seconds

Counter

Started

Counter

Reset

Counter

Started

Hysteresis Time

Elapsed

Counter

Reset

40 00

70 130

Time Hysteresis Status

Example shows time hysteresis set to 70 seconds used with a high process alarm

Advanced circular chart recorder 3 Configuration

3.6 Alarms Configuration

Overview.

Four alarms per channel – identified A1 to D1 (for channel 1) up to A4 to D4 (for channel 4).

High/Low process alarms.

Fast/Slow rate alarms.

Adjustable hysteresis value – prevents oscillation of alarm state.

Time hysteresis – enables delayed triggering of alarms.

Fig. 3.1 High and Low Process Alarm with Hysteresis

Fig. 3.2 Time Hysteresis Alarm

IM/C1300 Rev. J 31

Page 34

C1300

Alarm On

Alarm Off

Falling Fast Rate

Alarm On

Alarm Off

Rising Fast Rate

10.1

1 hour

1 hour

9.5

1 hour

9.5

T T

1 hour

10.1

T T

The maximum time it takes to detect an alarm condition is

present (T), in seconds, is calculated as follows:

T = 10.81 + x 2

The time it takes for the alarm state to be cleared once the

alarm condition has been removed is also equal to T.

Examples shown are for a trip value of 10%/hour on a PV engineering range of 0.0 to 100.0

1800

Trip Value

T = 10.81 + x 2

1800

10

T=382 seconds

The maximum time it takes to detect an alarm condition is

present (T), in seconds, is calculated as follows:

T = 10.81 + x 2

The time it takes for the alarm state to be cleared once the

alarm condition has been removed is also equal to T.

10.1

Examples shown are for a trip value of 10%/hour on a PV engineering range of 0.0 to 100.0

Alarm On

Alarm Off

Falling Slow Rate Rising Slow Rate

1 hour

9.5

T

Alarm On

Alarm Off

1800

Trip Value

1 hour

10.1

1 hour

9.5

1 hour

T T T

T = 10.81 + x 2

1800

10

T=382 seconds

Advanced circular chart recorder 3 Configuration

Fig. 3.3 Fast Rate Alarms with Hysteresis

Fig. 3.4 Slow Rate Alarms with Hysteresis

32 IM/C1300 Rev. J

Page 35

C1300

Select Alarm

A1

Alarm Setpoints

Security Code

Common

Channels

Alarms

Totalizers

Relays

Digital I/O

A1 Type

Off

A1 Trip

000.00 mV

Off

Advanced circular chart recorder 3 Configuration

Alarms Configuration

Press the key to open the Main Menu.

Highlight Alarms.

Select Alarm

Select the alarm to be configured.

Alarm Type

Select the alarm type required:

Off – No alarm

High Process – See Fig. 3.1 on page 31

Low Process – See Fig. 3.1 on page 31

Fast Rate – See Fig. 3.3 on page 32

Slow Rate – See Fig. 3.4 on page 32

Continued on next page.

IM/C1300 Rev. J 33

Page 36

C1300

A1 Trip

000.00 mV

A1 Hysteresis

000.00 mV

A1 Time Hyst

0000 Secs

Select Alarm

A1

Advanced circular chart recorder 3 Configuration

Trip L e v e l

Set the value at which the alarm is to activate.

For High and Low Process alarms, the value is set in engineering units.

For Fast and Slow Rate alarms, the trip level is set as a percentage of the engineering span

(engineering range high – engineering range low) per hour, between 500 and 500% in 0.1%

increments.

Hysteresis

Set the hysteresis value, either in engineering units (High and Low Process alarms) or as a

percentage of the engineering span (Fast and Slow Rate alarms).

Hysteresis is operational only when the alarm is active. The alarm is activated at the trip level but

is de-activated only after the alarm variable has moved into the safe region by an amount equal to

the hysteresis value. For rate alarms this setting is a percentage of the trip level.

Time Hysteresis

Set the time hysteresis value required, between 0 and 9999 seconds.

If a Time Hysteresis value is set, the alarm becomes active only when the alarm condition is

present continuously for the time set.

If a Hysteresis value is also set (see above) and an alarm is activated, the alarm remains active

until the process variable moves outside the hysteresis band. When the alarm condition no longer

exists the alarm becomes inactive immediately, i.e. time hysteresis does not affect turning off of

alarm states.

Return to top of page.

34 IM/C1300 Rev. J

Page 37

C1300

Advanced circular chart recorder 3 Configuration

3.7 Totalizer Configuration

Overview.

Up to four, 9-digit totalizers – assignable to any pen, analog input or math block (if math software option enabled by

installation of the appropriate software key).

Count up or count down.

Automatic count rate calculation – wherever possible, the recorder calculates the count rate automatically according to

source units, totalizer units and engineering range, from 0.0001 to 99.9999 counts/second.

External counter pulse – can be used to energize relays or digital outputs (a maximum of 4 pulses per second are generated).

Wrap function – with external wrap pulse used to energize relays or digital outputs.

Programmable preset and predetermined count values – for (batch) flow total.

Adjustable cut-off values.

Operator level reset and stop/go.

Digital signal reset and stop/go.

When enabled by installation of the appropriate software key, the totalizer software provides indication and recording of flow rates

from input signals with linear, square law or power law characteristics. Totalization is available for each channel and can be switched

on or off as required.

The flow total for any channel can be viewed on the same display screen as the input (pen) channel to which it is assigned. The flow

total can also be reset using the control keys on the associated faceplate. An additional internal 'Secure' total is also provided that

can be reset only in the Totalizer Configuration level.

External counters with their own power supplies can be driven using 4 relay and digital output module options.

Count Rate

Totalizers are normally used in flow applications and their purpose is to summate the volume of process fluid passing the point of

measurement. Totalizers have no relationship to time and continue to count up or down (dependant on setting) until instructed to

reset. A trip meter on a typical family car is an example of a basic totalizer – the meter counts and displays the distance travelled by

the vehicle until reset by the driver. In this example, the speedometer and trip meter read in the same unit of distance.

Flow totalization is more complex than that of a trip meter. In flow totalization, the flow recorder typically measures the instantaneous

value in one flow unit whilst the totalizer counts in a larger flow unit. When configuring a totalizer, a count rate must be calculated and

entered to compensate for the difference between the totalized measurement unit and the instantaneous measurement unit.

Where possible, the recorder calculates automatically the count rate for the most popular measurement units, e.g. gallons, cubic feet,

liters and cubic meters. When configuring a totalizer, first ensure that the unit of measurement (Channel Units) selected for the

channel to which the totalizer is assigned is a volumetric unit (i.e. quantity per unit of time, for example gallons per hour) – see Section

3.5, page 24. Finally, enter the required Totalizer unit of measurement. If the recorder holds the relationship data between th

e selected

measurement and totalizer units, 'Automatic' is displayed under the count rate to indicate that it has been set automatically. If the

relationship data is not in the recorder's look-up table, 'Manual' is displayed and the count rate must be set manually – see next

page.

IM/C1300 Rev. J 35

Page 38

C1300

Volume relationship

Full scale flow

--------------------------------------------------

number of seconds in time-base Seconds to pass one totalizer unit=

6.229 (imperial gallons in 1ft3

300 (imperial gallons max. flow rate)

------------------------------------------------------------- -------------------------------

60 (seconds in 1 minute) 1.2458 seconds to pass 1ft

3

=

1

Seconds to pass 1 totalizer unit

------------------------------------------------------------- --------------------- - Totalizer count rate=

1

1.2458

------------------ 0.803=

Advanced circular chart recorder 3 Configuration

Calculating The Count Rate Manually

The count rate determines how many units the totalizer increments per second when the flow input signal is at 100%. To calculate

this parameter manually, follow the procedure below:

1. Calculate the volume relationship

Typically the unit of measure used by the totalizer is larger than that used for displaying the instantaneous flow-rate. Use

standard conversion tables to calculate how many times the flow units used for the input will fit into the desired totalizer unit.

Example: Measurement channel units is set to gallons/minute. Instantaneous process flow-rate (engineering range) is 0-300

imperial gallons/minute, totalizer is required to increment in cubic feet. From standard conversion tables, 1 cubic foot = 6.229

imperial gallons.

2. Calculate the unit time

Ensuring that the time-base of the instantaneous flow-rate is used, the following equation determines how many seconds it will

take at full scale flow for a single totalizer unit to pass the measurement point:

Example:

3. Calculate the count rate

The totalizer count rate is the reciprocal of the result of the calculation above:

Example:

36 IM/C1300 Rev. J

Page 39

C1300

Select Totalizer

T1 Configuration

Security Code

Common

Channels

Alarms

Totalizers

Relays

Digital I/O

Retransmission

Tot 1 Source

Pen 1

Tot 1 Tag

Totalizer 1

Edit>

Secure Total 1

000000000

gal

None

T(1 to 4)

Configuration

T(1 to 4)

Secure Total

Advanced circular chart recorder 3 Configuration

Note. Totalizer configuration is available only if the totalizer software option is enabled by installation of the appropriate software

key.

Totalizers Configuration

Press the key to open the Main Menu.

Highlight Totalizers.

Select Totalizer

Select the totalizer to be configured.

Continued on page 41.

Totalizer Source

Select the source for the totalizer.

Note. Any of Pens 1 to 4, Analog Inputs 1 to 6 or Math Blocks 1 to 4 (if Math software option is

enabled by installation of the appropriate software key) are assignable to a totalizer.

Continued on next page.

IM/C1300 Rev. J 37

Page 40

C1300

Tot 1 Tag

Totalizer 1

Edit>

Tot 1 Count Dir

Up

Tot 1 Count Rate

00.0000

Manual

Tot 1 Units

18 gal/h

(Imp)

Advanced circular chart recorder 3 Configuration

Totalizer Tag

Press the key to open the Edit screen.

Use the , and keys to enter the totalizer tag required – see Fig. 2.1 on page 6.

Note. Any characters not permitted in this tag are skipped when scrolling through the selection.

Press the key to close the edit screen and save the tag.

Count Direction

Select the count direction:

Up – Incremental counter (Preset Value < Predetermined Value)

Down – Decremental counter (Preset Value > Predetermined Value)

Totalizer Units

Select any of the units pre-programmed into the recorder or select 113 Custom and use the

, and keys to enter the units required – see Fig. 2.1 on page 6.

Notes.

Any characters not permitted in user-defined units are skipped when scrolling through the

selection.

Refer to Appendix B on page 78 for a description of the units pre-programmed into the

recorder.

Continued on next page.

38 IM/C1300 Rev. J

Page 41

C1300

Tot 1 Count Rate

00.0000

Manual

Tot 1 Cut Off

0000.0 gal/h

Tot 1 Preset

000005000

gal/h

Tot 1 Wrap

YES

Tot 1 Predet

000004500

gal/h

Advanced circular chart recorder 3 Configuration

Totalizer Count Rate

Automatic – the recorder has calculated the count rate automatically. No further

adjustment is possible.

Manual – the count rate must be calculated manually (see page 36). Use the ,

and keys to enter the calculated count rate in pulses per second, from

00.0000 to 99.9999 in 0.0001 increments.

Note. To configure the totalizer for Automatic count rate calculation:

1. Ensure that the unit of measurement (Channel Units) selected for the channel to which the

totalizer is assigned is a volumetric unit (i.e. quantity per unit of time, for example gallons

per hour) – see Section 3.5, page 24.

2. Enter the required Totalizer unit of measurement (Totalizer Units) – see previous page.

If the recorder holds the relationship data between the selected measurement and totalizer units,

Automatic is displayed under the count rate to indicate that it has been set automatically.

Totalizer Cut Off

Set the value, in engineering units, at which the totalizer is to stop counting.

Totalizer Preset Value

Set the value, in engineering units, from which the totalizer is to start counting and the value that

is applied when the totalizer is reset.

Totalizer Predetermined Value

Set the value, in engineering units, at which the totalizer stops or wraps.

Continued on next page.

IM/C1300 Rev. J 39

Page 42

C1300

Tot 1 Wrap

YES

Tot 1 Reset Srce

None

Tot 1 Reset Days

Monday

Tot 1 Reset Hour

00:00

Tot 1 Run Source

None

Tot 1 Run Source

None

Timed

Advanced circular chart recorder 3 Configuration

Totalizer Wrap

Select the required totalizer wrap action:

YES – the total is reset automatically to the preset value when the predetermined value is

reached.

NO – the count stops when the predetermined value is reached

Totalizer Reset Source

If required, select a digital signal to reset the totalizer or select Timed to configure the totalizer to

reset at a predetermined time.

Refer to Appendix 1 for description of sources.

Anything other than Timed selected – continued on next page.

Totalizer Reset Day

Select the day or days on which the totalizer is to reset:

Monday to Sunday – the totalizer resets on the day selected

Mon-Fri – the totalizer resets every Monday to Friday inclusive

All – the totalizer resets every day

1st of Month – the totalizer resets on the 1st day of every month

Totalizer Reset Time

Select the time of day at which the totalizer is to reset, from 00:00 (midnight) to 23:00 (11 pm) in

1 hour increments.

Continued on next page.

40 IM/C1300 Rev. J

Page 43

C1300

T1 Secure Reset

NO

Select Totalizer

T1 Secure Total

Select Totalizer

set to

T1 Secure Total

Tot 1 Run Source

None

Tot 1 Log Enable

None

Select Totalizer

T1 Configuration

Secure Total 1

000000000

gal

Tot 1 Log Start

00:00

None

Prior to reset

12 hours

24 hours

Select Totalizer

T1 Configuration

Advanced circular chart recorder 3 Configuration

Totalizer Run Source

If required, select a digital signal to start the totalizer.

Refer to Appendix A on page 77 for a description of sources.

Totalizer Log Enable Source

If required, select the frequency at which the addition of the current totalizer values to the totalizer

log is triggered:

None – current totalizer values are not added to the totalizer log

Prior to reset – current totalizer values are added as the totalizer resets

12 hours – current totalizer values are added every 12 hours

24 hours – current totalizer values are added every 24 hours

Return to top of page.

Totalizer Log Start Time

Enter the time at which logging is to start.

Return to top of page.

Totalizer Secure Total

Secure Total Reset

Select YES to reset the secure total.

The secure total is reset to either 000000000 (Count Direction set to Up) or 999999999 (Count

Direction set to Down).

IM/C1300 Rev. J 41

Return to top of page.

Page 44

C1300

Relay SourceSelect Relay Output

Logic Equation 1

Logic Equation 8

Digital Input 1

Digital Input 2

Alarm A1

Alarm D4

None

Polarity Selection

Relay 5.1

Relay 5.2

Relay 5.3

Relay 5.4

Module Position

Relay No.

Alarm A1

Active

Energized

Positive

Alarm A1

Active

De-energized

Negative

Alarm A1

Inactive

Positive

Alarm A1

Inactive

Energized

Negative

De-energized

Relay Contacts

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

NO

Source State Polarity Relay State

Select Relay

Relay 1.1

Common

Channels

Alarms

Totalizers

Relays

Digital I/O

Analog Output

Modbus

Relay 1.1 Source

Alarm A1

Rly 1.1 Polarity

Negative

Select Relay

Relay 1.1

None

Advanced circular chart recorder 3 Configuration

3.8 Relay Configuration

Overview.

Relays – can be energized by alarms, logic equation results (math software option enabled by installation of the appropriate

software key), digital inputs, real time events (timer software option enabled by installation of the appropriate software key) and

totalizer wrap signal (totalizer software option enabled by installation of the appropriate software key)

External totalizer count function – external counter can be driven only by Module Type 3 (4-relay module) fitted in module

positions 4, 5 or 6 (see Section 5.2, page 66).

Polarity – allows fail-safe settings

Relay Configuration

Press the key to open the Main Menu.

Highlight Relays.

Select Relay

Select the relay to be configured.

Relay Source

Select the source required to activate the selected relay.

Refer to Appendix A on page 77 for a description of sources.

42 IM/C1300 Rev. J

Relay Polarity

Select the polarity required for the selected relay:

Positive – relay is energized when the relay source is active (On)

Negative – relay is energized when the relay source is inactive (Off)

Return to top of page.

Page 45

C1300

Digital Input 1

Active

Positive

Energized

Negative De-energized

Positive

Energized

Negative

De-energized

Digital Input 1

Active

Digital Input 1

Inactive

Digital Input 1

Inactive

Polarity Selection

Source State Polarity Output StateDigital Source

Logic Equation 1

Logic Equation 4

Digital input 1

Digital input 2

Alarm A1

Alarm D4

None

Select Digital Output

Output 5.1

Output 5.2

Output 5.3

Output 5.4

Output 5.5

Output 5.6

Output 5.7

Output 5.8

Module Position

Output No.

Select Dig I/O

Output 6.1

Channels

Alarms

Totalizers

Relays

Digital I/O

Analog Output

Modbus

Math Blocks

Dout 6.1 Source

Alarm A1

Din 1.x Polarity

Positive

Advanced circular chart recorder 3 Configuration

3.9 Digital Input and Output Configuration

Overview.

The Digital I/O menu selection is displayed only if a digital input/output module is fitted – see Section 5.3.3, page 70.

Up to 24 digital outputs available – depending on the module types fitted.

Digital outputs – can be energized by alarms, logic equation results (math software option enabled by installation of the

appropriate software key), digital inputs, real time events (timer software option enabled by installation of the appropriate

software key) and totalizer wrap signal (totalizer software option enabled by installation of the appropriate software key).

External Totalizer count function – external counter can be driven only by Module Type 5 (8-digital output module) fitted in

module positions 4, 5 or 6 (see Section 5.2, page 66).

Polarity – inverts the effect of the selected source on the output state.

Digital I/O Configuration

Press the key to open the Main Menu.

Highlight Digital I/O.

Select Digital Input/Output

Select the digital input or output to be configured.

Output X.X selected – continued on next page.

Input X.X selected – continued on next page.

IM/C1300 Rev. J 43

Page 46

C1300

Dout 6.1 Source

Alarm A1

Dout6.1 Polarity

Positive

Select Dig I/O

Input 1.x

Din 1.x Polarity

Positive

Select Dig I/O

Input 1.x

Select Dig I/O

set to

Output X.X

Select Dig I/O

set to

Input X.X

Advanced circular chart recorder 3 Configuration