Page 1

ABB industrial drives

Hardware manual

BSFC-02C charging controller

Page 2

List of related manuals

General manuals Code (English)

Safety instructions for ACS880 multidrive cabinets and modules 3AUA0000102301

Electrical planning instructions for ACS880 multidrive cabinets

and modules

Cabinet design and construction instructions for ACS880

multidrive modules

BCU-02/12/22 control units hardware manual 3AUA0000113605

Supply module manuals

ACS880-204 IGBT supply units as modules hardware manual 3AUA0000131525

ACS880 IGBT supply control program firmware manual 3AUA0000131562

ACS880-304 +A003 diode supply modules hardware manual 3AUA0000102452

ACS880-304 +A018 diode supply modules hardware manual 3AXD50000011408

ACS880 diode supply control program firmware manual 3AUA0000103295

ACS880-904 regenerative rectifier modules hardware manual 3AXD50000020457

ACS880 regenerative rectifier control program firmware manual 3AXD50000020827

Inverter module manuals and guides

ACS880-104 inverter modules hardware manual 3AUA0000104271

ACS880 primary control program firmware manual 3AUA0000085967

ACS880 primary control program quick start-up guide 3AUA0000098062

3AUA0000102324

3AUA0000107668

Brake module and DC/DC converter module manuals

ACS880-604 1-phase brake chopper modules hardware

manual

ACS880-604 3-phase brake chopper modules hardware

manual

ACS880-604 (3-phase) brake control program firmware manual 3AXD50000020967

ACS880-1604 DC/DC converter modules hardware manual 3AXD50000023642

ACS880 DC/DC converter control program firmware manual 3AXD50000024671

Option manuals and guides

ACS-AP-x Assistant control panels user’s manual 3AUA0000085685

Drive composer start-up and maintenance PC tool user’s

manual

Drive (IEC 61131-3) application programming manual 3AUA0000127808

Installation frames for ACS880 multidrive modules hardware

manual

FDPI-02 diagnostics and panel interface user’s manual 3AUA0000113618

FSO-12 safety functions module user’s manual 3AXD50000015612

Manuals and quick guides for I/O extension modules, fieldbus

adapters, etc.

You can find manuals and other product documents in PDF format on the Internet. See section Document

library on the Internet on the inside of the back cover. For manuals not available in the Document library,

contact your local ABB representative.

3AUA0000106244

3AXD50000022033

3AUA0000094606

3AXD50000010531

Page 3

Hardware manual

BSFC-02C charging controller

Table of contents

3. Installation

2017 ABB Oy. All Rights Reserved.

3AXD50000027498 Rev A

EN

EFFECTIVE: 2017-04-10

Page 4

Page 5

5

Table of contents

1. Introduction to the manual

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Static electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. Hardware description

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BSFC unit overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BSFC layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

BSFC connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

BSFC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connections of the DC supply circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inverter power switch-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Details of the locking solenoid control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inverter power switch-off sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Planning the installation of the BSFC unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Placing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wire selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Protecting against contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

List of components needed in power supply circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting and removing the BSFC unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring the BSFC unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Technical data

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Optical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Circuit diagrams

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Charging circuit 1xR8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Charging circuit 2xR8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6. Dimension drawings

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page 6

6

BSFC-02C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 7

Introduction to the manual 7

1

Introduction to the manual

Contents of this chapter

This chapter gives the basic information on the manual.

Compatibility

The manual is compatible with the BSFC-02C charging controller.

Safety instructions

Follow all safety instructions delivered with the drive equipment.

• Read the complete safety instructions before you install, commission, or use the drive.

The complete safety instructions are given in ACS880 multidrive cabinets and

modules safety instructions [3AUA0000102301(English)].

Note: The installation must always be designed and made according to applicable local

laws and regulations. ABB does not assume any liability whatsoever for any installation

that breaches the local laws and/or other regulations. Furthermore, if the

recommendations given by ABB are not followed, the drive system may experience

problems that the warranty does not cover.

WARNING! Perform the electrical safety precautions before starting any work on

the installation. Ignoring the precautions can cause physical injury or death, or

damage to the equipment. Only a qualified electrician is allowed to work on the

installation.

Page 8

8 Introduction to the manual

1. Clearly identify the work location.

2. Disconnect the circuit to be worked on completely. After disconnection, always wait for

5 minutes to let the capacitors discharge.

3. Secure against re-connection. Lock the disconnectors and attach warning notices.

4. Provide protection against adjacent live parts.

5. Verify by measuring that there is no voltage present.

6. Carry out grounding and short-circuiting when necessary. Refer to local regulations

and EN 50110-1:2004.

Ask for a work permit. Only the nominated person in control of the electrical installation

work is allowed to issue a work permit.

Static electricity

WARNING! Circuit boards contain components sensitive to electrostatic

discharge (ESD). Wear a grounding wrist band when handling the boards. Do not

touch the boards unnecessarily.

Intended audience

The manual is intended for cabinet designers, and installation, commissioning and

maintenance personnel of ACS800 and ACS880LC multidrive modules.

The reader is expected to know the standard electrical wiring practices, electronic

components, and electrical schematic symbols.

Contents of the manual

This manual consists of the following chapters:

Hardware description describes BSFC-02C unit.

Installation guides in planning the installation of the BSFC-02C unit.

Technical data contains technical specifications.

Circuit diagrams contains connection diagrams.

Dimension drawings contains the dimensional drawings of the BSFC-02C unit.

Inquiries

Address any inquiries about the product to the local ABB representative, quoting the type

code and the serial number of the unit. If the local ABB representative cannot be

contacted, address inquiries to the manufacturing facility.

Page 9

2

Hardware description

Hardware description 9

Contents of this chapter

This chapter shows an overview of the BSFC unit and describes the connectors, settings

and LEDs. In addition, it contains circuit diagram examples of the DC supply circuit of

ACS880 frame R8i modules, and describes switch-on and switch-off sequences of the

units.

BSFC unit overview

ACS880 frame size R8i inverter modules can be connected to the drive DC bus through a

switch/disconnector (or switch fuse). This configuration requires a charging circuit to

charge the DC capacitors of the modules in a controlled way. The DC voltage can be

directly connected to the modules only after the capacitors are charged to a sufficient

level. The BSFC is a unit that monitors the charging, and controls switch-on and switch-off

of the DC voltage.

In addition to inverter units, the BSFC can be used with other units consisting of R8i

modules, such as brake or DC/DC converter units. One BFSC unit controls the charging of

1...3 frame R8i modules.

The BSFC unit can be snapped onto a standard mounting rail.

Page 10

10 Hardware description

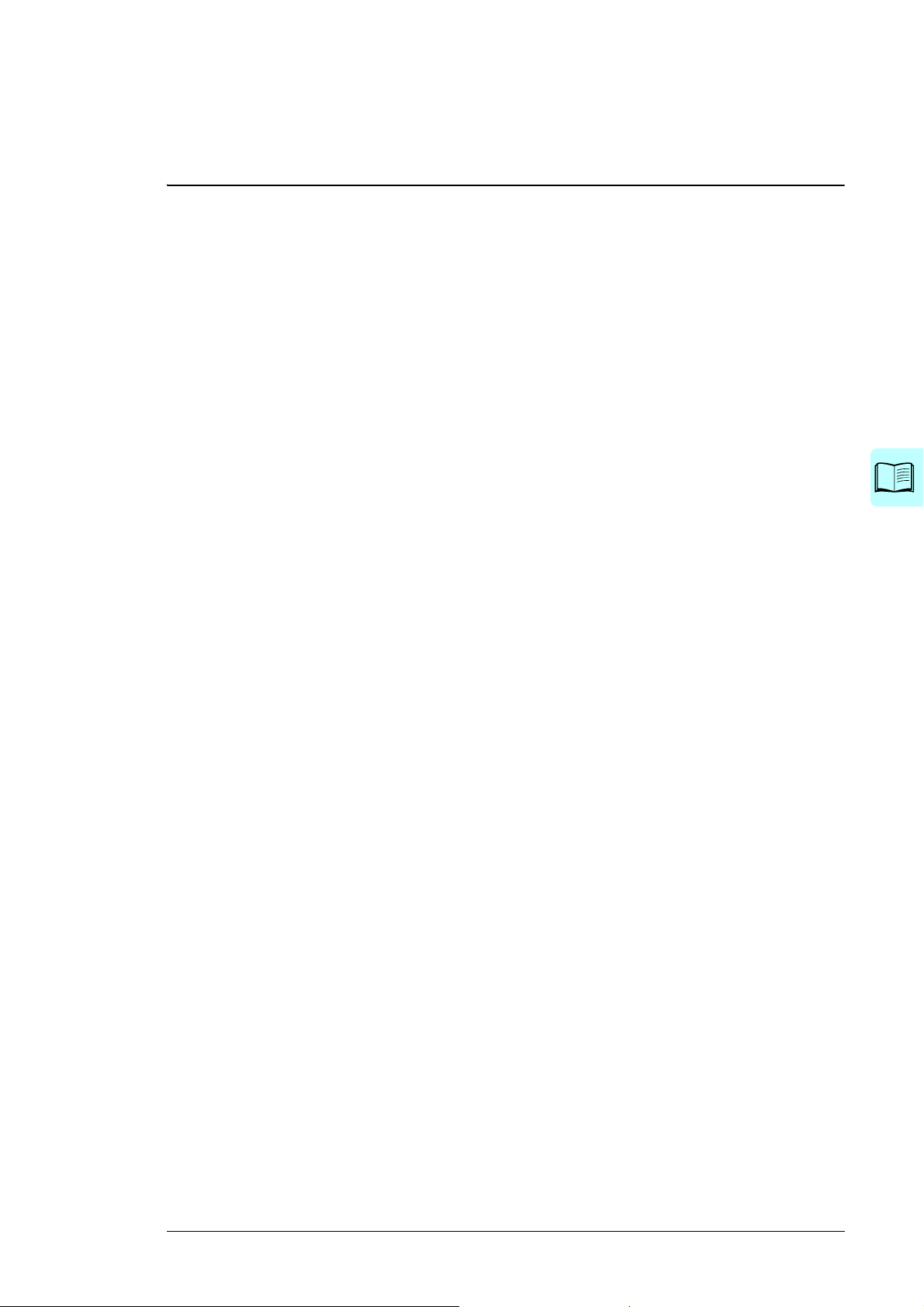

Symbol Description Layout

X4 Switch status monitoring (Q10 and Q11).

X5 Power supply input for BSFC and operating

voltage output for switch/disconnector locking

solenoid.

V1…V6 Fiber optic links to Inverter 1, 2 and 3.

S1…S3 Enable switches for charging circuit monitoring

(Inverter 1, 2 and 3).

Note: The BSFC do not allow the closing of the

DC switch/disconnector unless monitoring is

enabled for at least one inverter module.

STAT 1…3 Inverter charging status LEDs (3 pcs).

U

DC

1…3 Inverter “ready for start” LEDs (3 pcs).

PWR BSFC power on LED.

PWR

RATINGS

SUPPLY VOLTAGE (X5)

230 V, 50/60Hz, 20 mA

115 V, 50/60 Hz, 40 mA

SOLENOID CONTROL

OUTPUT (X5) 115/230 V

AC, MAX 2A

EXCITATION VOLTAGE

OUTPUT (X4)

15 V DC, MAX 10mA

OPER. TEMPERATURE

MAX +85 °C

BSFC-02C

SWITCH FUSE

CONTROLLER

IND. CONT. EQ.

1PD8

UDC

UDC

TO BE USED WITH

ABB DRIVES ONLY.

MAXIMUM RATED

SYSTEM VOLTAGE

UL: 600 V AC

IEC: 690 V AC

UDC

X5

1 L

2 N

3 PE

4

5 LSOL

6 NSOL

X4

1 15V

2 AUX2

3 GND

4 GND

STAT

S3

V3

V4

S2

V1

V2

S1

DIS

EN

DIS

EN

DIS

EN

INV1

INV2

INV3

STAT

STAT

V5

V6

STAT

BSFC layout

Page 11

Hardware description 11

BSFC connectors

Connector Signal Description

X4 Switch status monitoring (inverter switch/disconnector (Q11), and inverter charging

switch (Q10)).

1 +15 V Supply voltage for switch status monitoring circuit (Q10 and Q11). Max. 10 mA

2 AUX2 Digital input monitoring the switch status (Q10 and Q11).

3 GND Ground for control electronics

4 GND Ground for control electronics

X5 Power supply input & switch/disconnector locking solenoid control output

1 L External 230/115 V AC input

2 N Neutral

3 PE Protective Earth

4 NC Not connected

5 LSOL 230/115 V AC control voltage for switch Q11 locking solenoid

6 NSOL Neutral for switch Q11 locking solenoid

V1 INV1 EN Optical transmitter (start enable to Inverter 1)

V2 U

V3 INV2 EN Optical transmitter (start enable to Inverter 2)

V4 U

V5 INV3 EN Optical transmitter (start enable to Inverter 3)

V6 U

1 Optical receiver (UDC > 80% acknowledgement from Inverter 1)

DC

2 Optical receiver (UDC > 80% acknowledgement from Inverter 2)

DC

3 Optical receiver (UDC > 80% acknowledgement from Inverter 3)

DC

BSFC LEDs

Name Colour Indication Illuminates when

INV1 STAT Yellow Charging of Inverter 1 is in

progress, or Inverter 1 is

not in use

INV2 STAT Yellow Charging of Inverter 2 is in

progress, or Inverter 2 is

not in use

INV3 STAT Yellow Charging of Inverter 3 is in

progress, or Inverter 3 is

not in use

INV1 U

INV2 U

INV3 U

PWR Green BSFC power on Voltage for internal logic (5 V) is present.

Green Inverter 1 ready to start Signal UDC1 indicates that DC voltage of

DC

Green Inverter 2 ready to start See UDC1.

DC

Green Inverter 3 ready to start See UDC1.

DC

Switch Q11 main contacts are open (auxiliary

contact connected to connector X4 is open).

See INV1 STAT.

See INV1 STAT.

Inverter 1 capacitor bank is above 80% of the

nominal.

Page 12

12 Hardware description

-K11.1

A2 A1

1314

-Q11.1

2122

12

-P11.1

X1X2

GREEN

Chg OK

=-DOOR

-UDC

2

-UDC

1

;I1V60

;I1V50

DIS

EN

DIS

EN

DIS

EN

PE

LSOL

NSOL

INV 2

INV 1

INV 3

S3

N

L

AUX2

GND

GND

15V

IR3+

S2

S1

IR+

IR2+

UDCUDC

STATSTAT

STATSTAT

UDCUDC

UDCUDC

STATSTAT

IR-

IR2-

IR3-

-A11.1

X1:1

X1:2

X1:3

X2:1

X2:2

X2:3

X3:1

X3:2

X3:3

X4:1

X4:2

X4:3

BSFC-XX

SWITCH FUSE CONTROLLER

X4:4

X5:1

X5:2

X5:3

V3

V1

V2

X5:4

X5:5

X5:6

V5

V6

V4

L

N

230V AC; 115V AC

R8i module 1

DC supply

to R8i module

DC bus

-Q10.1

Connections of the DC supply circuit

No. Description

1 Drive DC bus

2 Main DC switch disconnecter

3 Charging switch fuse

4 Charging resistors

5 Solenoid that locks the manual operation mechanism

6 Indicator lamp on the cabinet door

7 BSFC unit

8 R8i module DC input connection

Page 13

Hardware description 13

Inverter power switch-on sequence

The terms and designations used in the table below refer to the diagram in section

Connections of the DC supply circuit.

Operation What happens

1. User turns charging

circuit switch Q10 to 1

(ON) position.

2. Inverter capacitor bank

charges.

3. BSFC unit detects that

the charging is

completed: U

signal(s) are received

from inverters

(U

>80%

DC

acknowledgement from

Inverter(s)).

4. User turns

switch/disconnector

Q11 to 1 (on) position.

5. User turns switch Q10

to 0 (off) position.

DC

Charging of inverter capacitors starts through the charging resistors [R10].

Auxiliary contact 1-2 of Q10 opens. BSFC prevents starting of inverter and

closing of switch/disconnector Q11.

“INV1 STAT” and “PWR” LEDs are on.

BSFC monitors inverter U

“INV STAT” and “PWR” LEDs are on.

BSFC connects operating voltage to solenoid of switch/disconnector Q11.

Solenoid releases the locking mechanism enabling operation of the

handle.

“INV UDC” and “PWR” LEDs are on. The “charging OK” light on the

cabinet door illuminates indicating that capacitor charging is complete and

operation of the switch/disconnector Q11 is allowed.

Main contacts 1-2…7-8 of switch Q11 connect inverter(s) to DC power

supply.

Auxiliary contact 13-14 of switch Q11 closes.

Auxiliary contact 21-22 of switch Q11 opens, de-energizing the solenoid

and the “charging OK” LED on the cabinet door.

“INV UDC” and “PWR” LEDs are on.

BSFC receives “main switch ON, charging switch OFF” indication through

terminal AUX2.

BSFC sends an enable signal to inverter through the fiber optic link.

“INV UDC” and “PWR” LEDs on.

signal through fiber optic link(s) INV1…INV3.

DC

Miscellaneous

Details of the locking solenoid control

The closing of the DC switch/disconnector is enabled by locking solenoid when:

• DC voltage of all inverter modules monitored by the BSFC unit exceed 80% of the

nominal value. (BSFC receives

• Switch/disconnector handle is in 0 (off) position.

U

signals from inverters).

DC

Page 14

14 Hardware description

Inverter power switch-off sequence

The terms and designations used in the table below refer to section Connections of the DC

supply circuit.

Operation What happens

1. User stops the inverters.

(Do not open the

switch/disconnector while

the inverters are loaded).

2. User turns switch Q11

handle to 0 (off) position.

3. Inverter capacitor bank

discharges.

Switch Q11 disconnects inverter(s) from the DC power supply.

Contact 13-14 of Q11 switches off the AUX2 signal on the BSFC unit.

BSFC switches INV1 EN signal off disabling inverter start.

Auxiliary contact 21-22 closes energizing the solenoid of switch Q11.

Solenoid releases the locking mechanism of switch Q11. Normal

operation (on/off) of the handle is possible as long as inverter DC

voltage remains high.

“INV UDC” and “PWR” LEDs. LED “Charging OK” light on the cabinet

door illuminates.

Inverter DC voltage decreases to zero gradually. When below 80% of

nominal:

• Inverters switch off U

• BSFC switches off the operating voltage to solenoid of switch Q11.

Locking mechanism activates preventing operation of switch into on

position.

“INV UDC” and “PWR” LEDs are on.

signals from BSFC unit.

DC

Page 15

3

Installation

Installation 15

Contents of this chapter

This chapter instructs how to install the BSFC unit into a user-defined cabinet.

Planning the installation of the BSFC unit

Placing

Install the BSFC unit in a heated indoor environment. Ensure the temperature meets the

requirement given in chapter Technical data. Also ensure that the ambient conditions meet

the requirements of the hardware manual of the inverter modules.

Do not install the BSFC unit far from the inverters. The fiber optic cable(s) between the unit

and inverter(s) must not exceed four meters in length.

WARNING! No condensation is allowed. There are connectors that are connected

to drive main circuit potential.

Wire selection

See chapter Circuit diagrams on page 19.

Page 16

16 Installation

Mounting Removing

2

3

2

1b

1a

Protecting against contact

WARNING! Protect the BSFC unit against accidental contact. There are

connectors that are connected to drive main circuit potential.

List of components needed in power supply circuit

Component Acquire…

Switch/disconnector kit (DC

switch/disconnector, BSFC

unit, charging switch,

charging resistors)

DC fuses for inverter …from ABB or according to the ABB specification.

Charging circuit fuses …from ABB or according to the ABB specification.

Pair of fibre optic cables for

BSFC – inverter connection

Main DC supply

cables/busbars

Charging circuit cables,

BSFC power supply

cables, switch/disconnector

control cables

…from ABB.

…from ABB or according to the ABB specification.

… according to the ABB specification.

… from any source according to the ABB specification.

Charging circuit wire specification, see chapter Circuit diagrams on page 19.

Always use the cables recommended by ABB or equivalent. The cables are

connected to drive main circuit.

Mounting and removing the BSFC unit

1. Mount the unit by snapping the feet onto a 35 mm EN50022 mounting rail (1a).

2. Remove the unit by bending the feet outwards lightly (2) and lifting the unit

simultaneously (3).

Wiring the BSFC unit

Connect the wiring according to the diagrams in chapter Circuit diagrams on page 19.

Page 17

4

Technical data

Technical data 17

Contents of this chapter

This chapter contains the technical specifications of the BSFC unit.

Power supply input

(X5)

Solenoid control

output (X5)

Switch feedback input

(X4)

Optical links (V1…V6) Avago Versatile Link series 5 MBd optical transmitters & receivers

Operating voltage 115…230 V AC +10/%, 50/60 Hz

Current consumption 40/80 mA typical (230/115 V AC)

Protection by Microfuse 2 A, slow

6-position detachable screw terminal block (FCI OQ0601500000G), wire size max.

2

2.5 mm

Control voltage 115 or 230 V AC, +10/-15%

Control current max. 2 A for 3.5 s or max. 4 A for 20 ms

Protection by Microfuse 2 A, slow (common with power supply input)

6-position detachable screw terminal block, wire size max. 2.5 mm

Voltage output 15 V DC max. 10 mA

4-position detachable screw terminal block (FCI OQ0471500000G), wire size max.

2.5 mm

Max. optical cable (POF) length 5 m

.

2

2

Page 18

18 Technical data

Standards applied Safety requirements: EN 50178 Electronic equipment for use in power installations

IEC 61800-5-1 Semiconductor power converters for adjustable frequency drive

systems

UL 508 C Industrial Control Equipment

EMC emission: EN/IEC 6100-6-4:2007 Emission standard for industrial

environments

EMC immunity: EN/IEC 61000-6-2:2005 Immunity for industrial environments

Operating temperature Free air circulation: +0...+50 °C (+32 ... +122 °F)

Forced convection cooling: Max. +70 °C, min. air flow 2 m/s

Dimensions

(L × W × D)

Mounting On 35 mm mounting rail EN 50022, vertical or horizontal

Other features UL approved (UL Listed according to UL 508 C)

247 × 79 × 66.5 mm (9.72” x 3.11” x 2.62”)

Conformal coating as standard

Optical components

Handle fiber optic cables with care. When unplugging optic cables, always grab the

connector, not the cable itself. Do not touch the ends of the fibers with bare hands as the

fiber is extremely sensitive to dirt. The specifications of the optic cable are as follows:

• Storage temperature: -55...+85 °C (-67…+185 °F)

• Installation temperature: -20...+70 °C (-4…+158 °F)

• Maximum short-term tensile force: 50 N (11.2 lbf)

• Minimum short-term bend radius: 25 mm (1.0”)

• Minimum long-term bend radius: 35 mm (1.4”)

• Maximum long-term tensile load: 1 N (3.6 ozf)

• Flexing: Max. 1000 cycles

ABB drive products in general utilize 5 and 10 MBd (megabaud) optical components from

Avago Technologies’ Versatile Link range. Please note that the optical component type is

not directly related to the actual communication speed.

Note: The optical components (transmitter and receiver) on a fiber optic link must be of the

same type.

Plastic optical fiber (POF) cables can be used with both 5 MBd and 10 MBd optical

®

components. 10 MBd components also enable the use of Hard Clad Silica (HCS

which allow longer connection distances thanks to their lower attenuation. HCS

) cables,

®

cables

cannot be used with 5 MBd optical components.

Page 19

5

Circuit diagrams

Circuit diagrams 19

Contents of this chapter

This chapter shows the connections between the switch/disconnector, the charging

controller and one or two inverters. The BSFC unit is supplied from 115...230 V AC power

source.

Page 20

3AXD10000572471

-

ACS880

BSFC connection e xample

Charging circuit 1xR8i

Circuit Diagram2017.01.05 V anin Oleg

2017.01.05 A sikainen Mika

1314

=-Q11.1

21

43

2122

3334

4142

U2 V2 W2

=-X11.1

U2 V2 W2

1.1PE

module R8i

-

=-T11.1

+

1xR8i Module

V60

V50

;X13:3

2K

;X13:4

;X13:5

2K

;X13:6

;I1V603E;I1V50

DC BUS

+

-

=-UDC-

2

=-UDC+

2

=-UDC-

1

=-UDC+

1

MAIN CIRCUITCHARGING CIRCUIT

+

-

DC circuit c omponents and

connections depend on R8i

module application. *

-K11.1

A2 A1

=-Q10.1

1

3

5

78

6

4

2

12

=-P11.1

X1X2

GREEN

Chg OK

=-DOOR

=-GND

GND1

=-1.1PE

1PE

14J

;X13:3

14E

;X13:4

;X13:5

15E

;X13:6

LN

;Q10.1:2

3D

;Q10.1:1

2H

7D

;Q10 .1:1

7D

=-R10.1

DISENDISENDIS

EN

PE

LSOL

NSOL

INV 2

INV 1

INV 3

S3

N

L

AUX2

GND

GND

15V

IR3+

S2

S1

IR+

IR2+

UDCUDC

STATSTAT

STATSTAT

UDCUDC

UDCUDC

STATSTAT

IR-

IR2-

IR3-

=-A11.1

X1:1

X1:2

X1:3

X2:1

X2:2

X2:3

X3:1

X3:2

X3:3

X4:1

X4:2

X4:3

BSFC-XX

SWITCH FUSE CONTROLLER

X4:4

X5:1

X5:2

X5:3

V3V1V2

X5:4

X5:5

X5:6

V5V6V4

=-R1.1

12

3

=-R2.1

12

3

=-R3.1

12

3

=-R4.1

12

3

-X13

1

-X13

5

2 3 4 6

-X13

7

8 9 10 11 12 13 14 15

20 Circuit diagrams

Charging circuit 1xR8i

Page 21

Circuit diagrams 21

3AXD10000572476

ACS880

BSFC connecti on example

Charging circuit 2xR8i

Circuit Diagram2017.01.05 V anin Oleg

2017.01.05 A sikainen Mika

1314

=-Q11.1

21

43

2122

65

87

3334

4142

U2 V2 W2

=-X11.1

U2 V2 W2

1.1PE

module R8i

-

=-T11.1

+

2xR8i Modules

U2 V2 W2

=-X11.2

U2 V2 W2

module R8i

-

=-T11.2

+

V60

V50

V60

V50

;X13:3

2K

;X13:4

;X13:5

2K

;X13:6

;I1V603E;I1V50

;I2V603E;I2V50

DC BUS

+

-

1.2PE

MAIN CIRCUITCHARGING CIRCUIT

+

-

=-UDC-

1

=-UDC+

1

=-UDC-

2

=-UDC+

2

DC circuit c omponents and

connections depend on R8i

module application. *

=-K11.1

A2 A1

=-Q10.1

1

3

5

78

6

4

2

12

=-P11.1

X1X2

GREEN

Chg OK

=-DOOR

=-GND

GND1

;I1V60

14J

;I1V50

;I2V60

15J

;I2V50

;X13:3

15E

;X13:4

;X13:5

15E

;X13:6

=-R1.1

12

3

=-R2.1

12

3

=-R5.1

12

3

=-R6.1

12

3

=-R3.1

12

3

=-R4.1

12

3

;Q10.1:2

3D

;Q10.1:1

2H

;Q10 .1:2

7D

;Q10 .1:1

7D

=-R10.1

=-1.1PE

1PE

LN

DISENDISENDIS

EN

PE

LSOL

NSOL

INV 2

INV 1

INV 3

S3

N

L

AUX2

GND

GND

15V

IR3+

S2

S1

IR+

IR2+

UDCUDC

STATSTAT

STATSTAT

UDCUDC

UDCUDC

STATSTAT

IR-

IR2-

IR3-

=-A11.1

X1:1

X1:2

X1:3

X2:1

X2:2

X2:3

X3:1

X3:2

X3:3

X4:1

X4:2

X4:3

BSFC-XX

SWITCH FUSE CONTROLLER

X4:4

X5:1

X5:2

X5:3

V3V1V2

X5:4

X5:5

X5:6

V5V6V4

-X13

1

-X13

52 3 4 6

-X13

7

8 9 10 11 12 13 14 15

Charging circuit 2xR8i

Page 22

22 Circuit diagrams

Page 23

6

Dimension drawings

Dimension drawings 23

Contents of this chapter

This chapter contains dimension drawings of BSFC-02C charging controller.

Page 24

24 Dimension drawings

PWR

RATINGS

SUPPLY VOLTAGE (X5)

230 V, 50/60Hz, 20 mA

115 V, 50/60 Hz, 40 mA

SOLENOID CONTROL

OUTPUT (X5) 115/230 V

AC, MAX 2A

EXCITATION VOLTAGE

OUTPUT (X4)

15 V DC, MAX 10mA

OPER. TEMPERATURE

MAX +85 °C

BSFC-02C

SWITCH FUSE

CONTROLLER

IND. CONT. EQ.

1PD8

UDC

UDC

TO BE USED WITH

ABB DRIVES ONLY.

MAXIMUM RATED

SYSTEM VOLTAGE

UL: 600 V AC

IEC: 690 V AC

UDC

X5

1 L

2 N

3 PE

4

5 LSOL

6 NSOL

X4

1 15V

2 AUX2

3 GND

4 GND

STAT

S3

V3

V4

S2

V1

V2

S1

DIS

EN

DIS

EN

DIS

EN

INV1

INV2

INV3

STAT

STAT

V5

V6

STAT

BSFC-02C

Page 25

Further information

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting the type

designation and serial number of the unit in question. A listing of ABB sales, support and

service contacts can be found by navigating to www.abb.com/searchchannels.

Product training

For information on ABB product training, navigate to new.abb.com/service/training.

Providing feedback on ABB Drives manuals

Your comments on our manuals are welcome. Navigate to

new.abb.com/drives/manuals-feedback-form.

Document library on the Internet

You can find manuals and other product documents in PDF format on the Internet at

www.abb.com/drives/documents.

Page 26

Contact us

www.abb.com/drives

www.abb.com/drivespartners

3AXD50000027498 Rev A (EN) 2017-04-10

Loading...

Loading...