Page 1

Doc. No. 1SDH000760R0002 - L5785

Automatic transfer switch ATS022

Installation and operating instructions

Page 2

Page 3

Contents

Installation and operating instructions, ATS022

Contents

1. Safety notes ....................................................................................................................... 4

2. Explanation of abbreviations and terms ......................................................................... 5

2.1. General information ....................................................................................................................... 5

2.2. Times ............................................................................................................................................. 5

3. Introduction ........................................................................................................................ 6

3.1 Product overview ...........................................................................................................................6

3.2 Application scenarios .................................................................................................................... 6

4. Applications of device ATS022 ......................................................................................... 8

4.1 Switching Main Line – Emergency Line (2CBs) .............................................................................8

4.2 Switching Main Line – Emergency generator (2CBs) ....................................................................9

4.3 Non priority loads control (NPL) ..................................................................................................10

4.4 Control of two independent power supply lines separated by Tie (3CBs Bus Tie) .....................14

4.5 Automatic switching without inverse procedure .........................................................................15

4.6 Line Priority Selection .................................................................................................................. 16

5. Using the automatic transfer switch ............................................................................. 17

5.1 Interface.......................................................................................................................................17

5.2 LED indicators ............................................................................................................................. 18

5.3 Keypad keys ................................................................................................................................ 19

5.4 Setting the operating modes ....................................................................................................... 20

5.4.1 Manual mode ............................................................................................................................... 20

5.4.2 Automatic mode .......................................................................................................................... 20

5.5 Graphic Display ........................................................................................................................... 21

5.5.1 LN1 and LN2 lines status indication ............................................................................................ 22

5.5.2 Browsing through the Menu ........................................................................................................22

5.6 Using pushbuttons in manual mode ...........................................................................................26

5.7 Test Modes .................................................................................................................................. 26

6. Input and output signals ................................................................................................. 28

6.1 Output signals (DO1…DO12) ......................................................................................................28

6.2 Input signals ................................................................................................................................ 29

7. Technical data .................................................................................................................. 36

8. Installation of device ATS022 ......................................................................................... 37

8.1. Door-mounted Automatic Transfer Switch ATS022 ....................................................................37

8.2. DIN rail-mounted Automatic Transfer Switch ATS022.................................................................38

9. Regulatory standards ...................................................................................................... 39

10. Troubleshooting ............................................................................................................... 40

1SDH000760R0002

3

Page 4

Installation and operating instructions, ATS022

1. Safety notes

1. Safety notes

Before using the ATS022 unit, read the following “Safety notes”:

using the unit without following the indications can lead to malfunctioning and, in

some cases, hazardous conditions.

If there are doubts about safe use, the unit must be put out of service.

The automatic transfer switch ATS022 must be prevented from operating the circuit breakers before:

• accessing the circuit breakers

• performing maintenance on circuit breakers or any electrical circuits powered by them

• performing any operation where opening/closing the circuit breaker could be dangerous

During maintenance:

• set the "Manual" mode.

• lock the circuit breaker mechanically in the open position.

Safe use is not guaranteed if:

• the device has been damaged during transport

• the device shows visible signs of damage

• the device does not work

• the device has been stored for a long period

Even if the device seems to be in stand-by status switch it off from the control circuit, as there is risk of it

operating the circuits without warning.

1SDH000760R0002

4

Page 5

2. Explanation of abbreviations and terms

Installation and operating instructions, ATS022

2. Explanation of abbreviations and terms

2.1. General information

ATS:

ATS022:

CB:

CB1:

CB2:

CB3:

LN1:

LN2:

Bus Tie:

NPL:

NPL BUS TIE:

Modbus RTU:

Automatic Transfer Switch; automatic switching device

ATS of the ATS02x series, version with display and Modbus communication.

Circuit Breaker; low voltage automatic Circuit Breaker.

CB on line LN1.

CB on line LN2.

CB for Bus Tie, NPL and NPL BUS TIE operating modes.

Power supply line No.1.

Power supply line No.2.

Operating mode with busbar tie circuit breaker.

Operating mode with non priority control circuit breaker

Operating mode with non priority control circuit breaker for non priority loads control

Communication protocol.

2.2. Times

NOTE: All the details of the times and switching logics are described in the Chapters concerned.

TS:

TCE:

TBS:

TCN:

TGOFF:

TC:

- Opening delay of main line CB, after detection of fault in mains (generator is not in

use)

- Generator start delay, after detection of fault in mains (generator in use).

Closing delay of CB2 of line LN2

Opening delay of emergency line CB, after detection of stabilised voltage on main line.

Closing delay of CB1 of line LN1

Generator switching off delay, after closure of main line CB.

Delay in opening and closing of CB3 in Bus Tie application.

1SDH000760R0002

5

Page 6

Installation and operating instructions, ATS022

3. Introduction

3. Introduction

3.1 Product overview

The automatic transfer switch ATS022 is used in all installations where switching is required between two

lines to ensure the supply of loads in case of a fault on one line.

ATS022 selects the power supply line by acting directly on the CBs provided on the lines: ATS022 can be

used with automatic CBs and ABB SACE switch-disconnectors.

The device monitors the voltage of the main line and emergency line and records the following faults:

• Maximum and minimum voltage

• Maximum and minimum Frequency

• Phase balance

• Voltage imbalance

• Frequency imbalance

ATS022 does not require an auxiliary safety power supply since it is powered directly by the line

voltages.

If both lines are absent, ATS022 enters Powersave mode (maximum duration 1 minute) in which the

device is active and in stand-by for one of the power supply lines to be restored. When the Powersave

period ends, the LED switches off and the device awaits a line voltage. The moment the main or the

emergency line is restored, the unit analyses the conditions of the lines monitored and the status of the

circuit breakers and proceeds with the switching operation in accordance with the situation concerned.

The safety auxiliary supply is obligatory in the following cases:

• utilisation of Modbus RS485 communication

• utilisation in systems with rated frequency 16 2/3Hz

• utilisation in single-phase systems with Un 57,5…109VAC

A 24VDC ….110VDC auxiliary safety power supply can be used (-10%, +15%).

ATS022 can be used in systems with rated frequency 50Hz, 60Hz, 400Hz, 16 2/3 Hz that can be set from

the menu.

The device can be used in systems with single-phase, three-phase with Neutral and three-phase

without neutral, setting can be done from the menu. ATS022 makes it possible to select from the display

a different distribution system between Line LN1 and Line LN2. ATS022 can be used in manual or

automatic mode. In the first case the circuit breakers must be controlled by means of the pushbuttons

present on the front panel of the device, while in automatic mode, the switching logic is controlled

directly by the device

The device is equipped with a front graphic display by means of which the user can check the settings

and display the status of the unit and the circuit breakers connected to it.

It is also possible to integrate the ATS022 device inside a communication network which uses the

Modbus RS485 protocol.

3.2 Application scenarios

The ATS022 device can be used in the following applications:

• Main line – Emergency line switching

• Main line – Emergency generator switching

ATS022 makes it possible to operate a thrid circuit breaker CB3 and can therefore also be used in the

following applications which can be set on the menu:

• non priority loads control with CB3 on starting line (3CBs NPL)

• non priority loads control with CB3 Bus Tie (3CBs NPL Bus Tie)

• control of two independent power supply lines separated by Bus Tie (3CBs Bus Tie)

1SDH000760R0002

6

Page 7

3. Introduction

The ATS022 also makes it possible to select which of the lines is the main one and which one is

secondary, also with the system running.

The following selections are possible, set from the menu:

• Main line: Line LN1

• Main line: Line LN2

• No priority line

In automatic mode, it is possible to select whether or not the switching procedure must include inverse

switching.

The following selections are possible:

• with inverse procedure

• without inverse procedure

Installation and operating instructions, ATS022

1SDH000760R0002

7

Page 8

Installation and operating instructions, ATS022

4. Applications of device ATS022

4. Applications of device ATS022

The ATS022 device controls all the switching sequences by applying the time delays that can be set:

Time delays Description Value

Opening delay of main line CB after detection of a fault in the

TS Delay

TBS Delay Opening delay of emergency line CB. 0…59s, 1,2,3…30min

TCE Delay Closing delay of line LN2 CB2 0…60s

TCN Delay Closing delay of CB1 of line LN1. 0…60s

TC Delay

TGOFF Delay Generator switching off delay after closure of line LN1 CB1. 0…59s, 1,2,3…30min

Table 4.1: Description of time delays

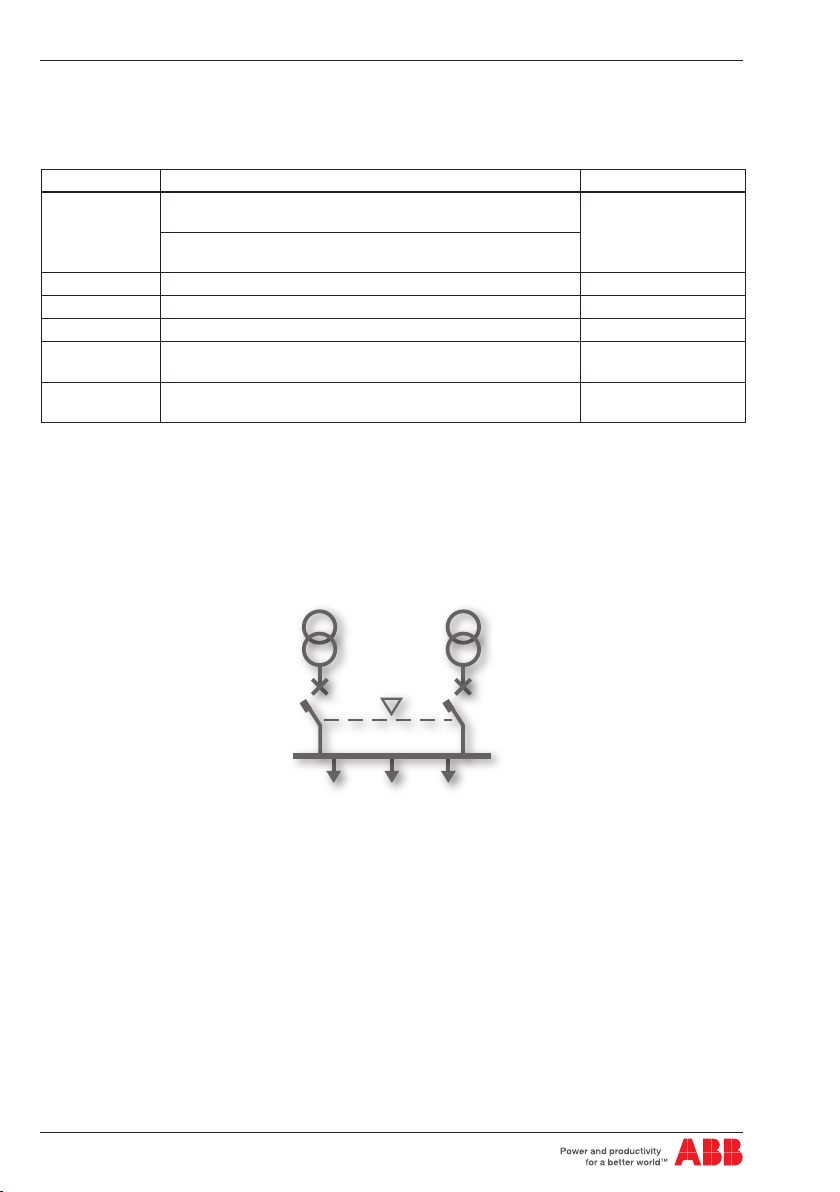

4.1 Switching Main Line – Emergency Line (2CBs)

Description

Both lines are normally present; in cause of anomaly on the main line,

ATS022 switches to the emergency line used as the reserve line.

mains (Generator is not in use)

Generator start delay after detection of a fault in the mains

(Generator in use).

Opening and closing delay of CB3 if used in Bus Tie

application.

0…30s

0…60s

KA00428

Figure 4.1: 2CBs application layout – generator not in use

1SDH000760R0002

8

Page 9

4. Applications of device ATS022

Installation and operating instructions, ATS022

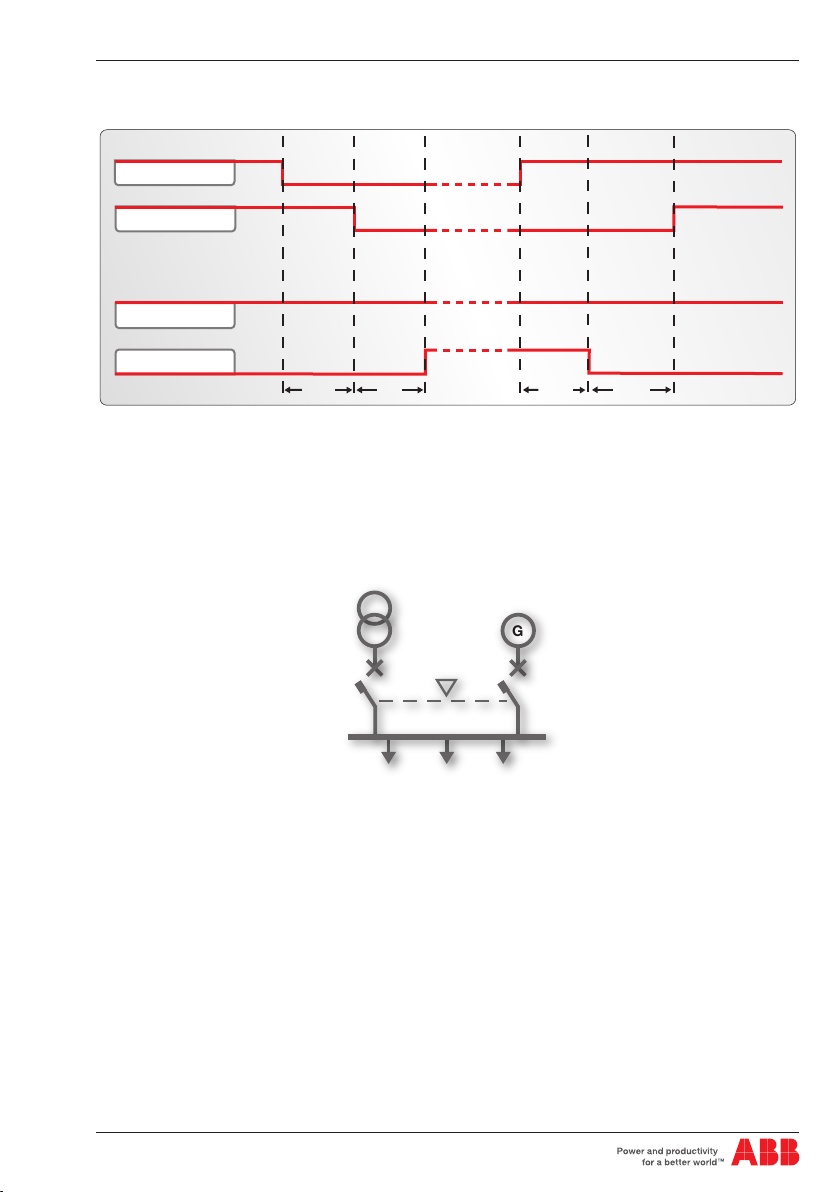

Time diagrams

Line 1 ok

CB1 CLOSED

Line 2 ok

CB2 CLOSED

TS

TCE

TBS

TCN

Figure 4.2: 2CBs application time diagram - main line LN1

4.2 Switching Main Line – Emergency generator (2CBs)

Description

In case of main line failure ATS022 automatically starts up an emergency generator and, as soon as

power on the generator side is available, ATS022 starts the automatic switching procedure.

KA00427

Figure 4.3: 2CBs application layout – generator in use

1SDH000760R0002

9

G

Page 10

Installation and operating instructions, ATS022

4. Applications of device ATS022

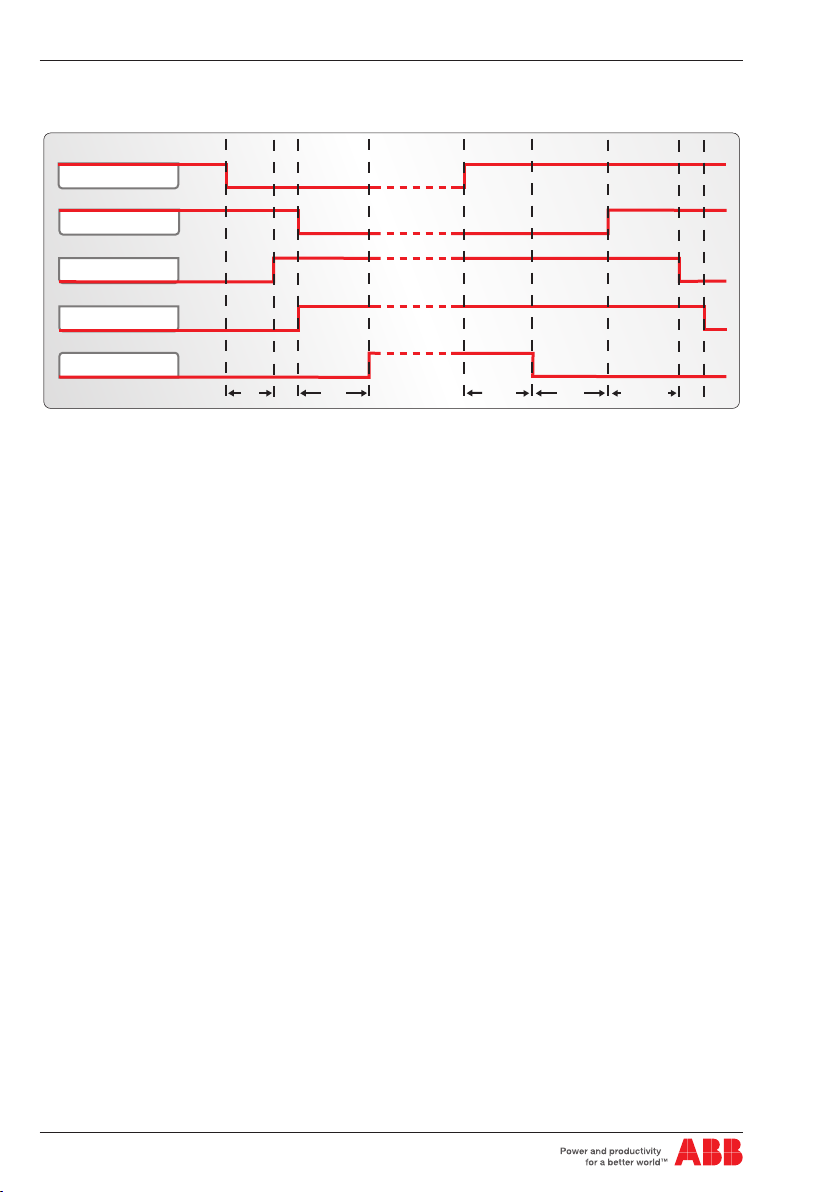

Time diagrams

Line 1 ok

CB1 CLOSED

Gen start

Line 2 ok

CB2 CLOSED

TS TCE TCNTBS TGOFF

Figure 4.4: 2CBs application time diagram - generator in use

4.3 Non priority loads control (NPL)

Description

In case of main line failure the ATS022 starts the switching procedure and controls the non priority loads

by opening closing circuit breaker CB3.

ATS022 acquires the CB3 open/close status from the dedicated input DI11 and commands the opening

and closing by activating output DO11.

The application of non priority loads requires the use of two CT-AWE typed timed relays for operating the

opening and closing of CB3.

Two configurations are possible for utilisation depending on the position of circuit breaker CB3:

• CB3 in Bus Tie position (3CBs NPL – BUS TIE)

• CB3 on starting line (3CBs NPL).

It is possible to select from two options from the menu on the display:

• only disconnection of non priority loads by opening CB3 (manual re-closure). In this case timed relays

CT-AWE are not necessary

• disconnection and re-connection of non priority loads by opening and closing of CB3

For more details refer to the wiring diagrams of the product.

1SDH000760R0002

10

Page 11

4. Applications of device ATS022

Installation and operating instructions, ATS022

CB1

CB3

NPL

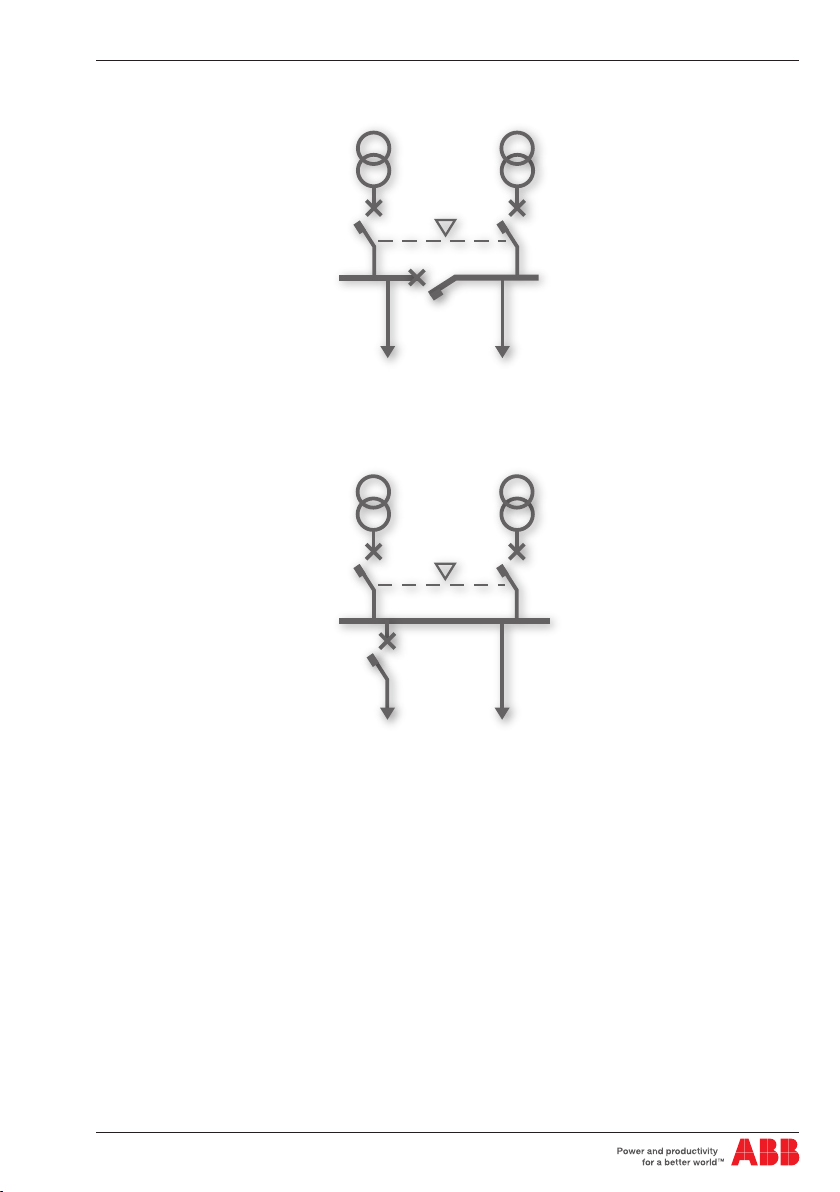

Figure 4.5: Application layout 3CBs NPL BUSTIE

CB1

CB3

NPL

Figure 4.6: Application layout 3CBs NPL

CB2

CB2

1SDH000760R0002

11

Page 12

Installation and operating instructions, ATS022

4. Applications of device ATS022

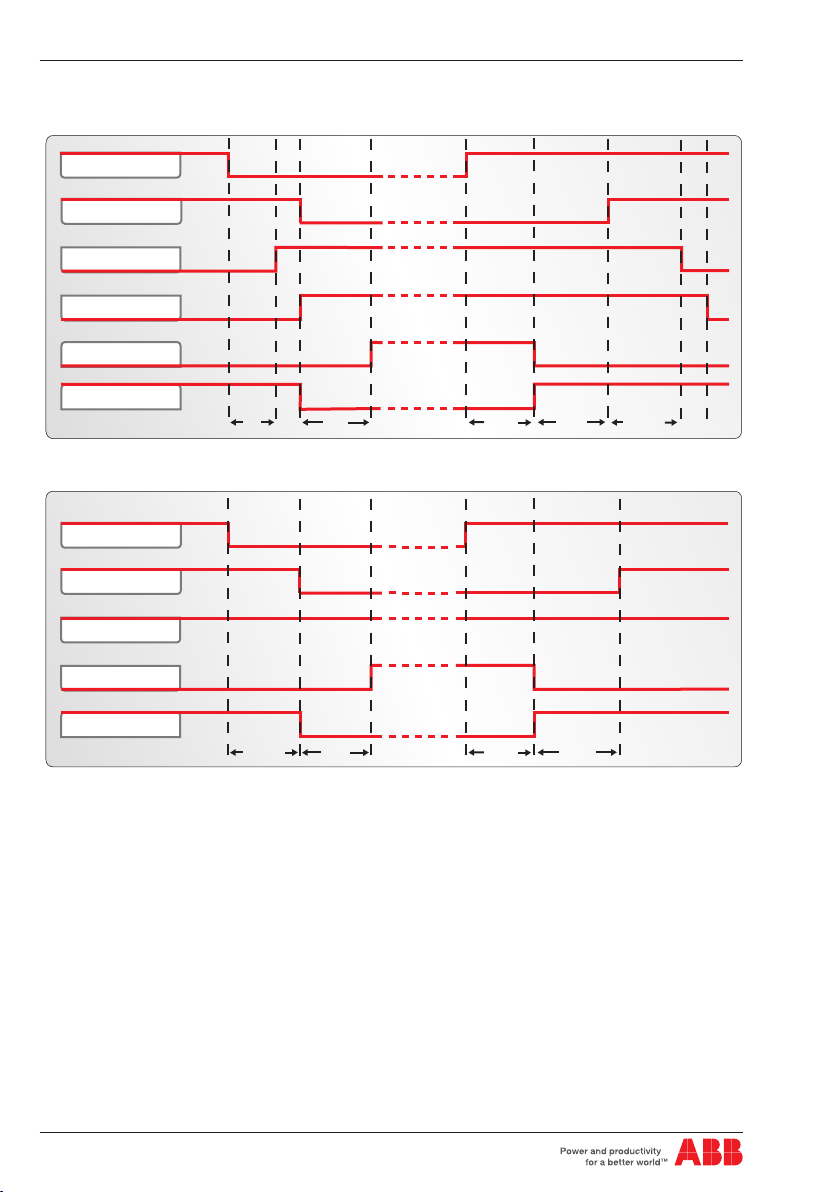

Time diagrams

Line 1 ok

CB1 CLOSED

Gen start

Line 2 ok

CB2 CLOSED

CB3 CLOSED

TS

TCE

TBS

Figure 4.7: Application time diagram 3CBs NPL BUS TIE - generator in use

Line 1 ok

CB1 CLOSED

TCN

TGOFF

Line 2 ok

CB2 CLOSED

CB3 CLOSED

TS TCE TCNTBS

Figure 4.8: Application time diagram 3CBs NPL BUS TIE - generator not in use - main line LN1

1SDH000760R0002

12

Page 13

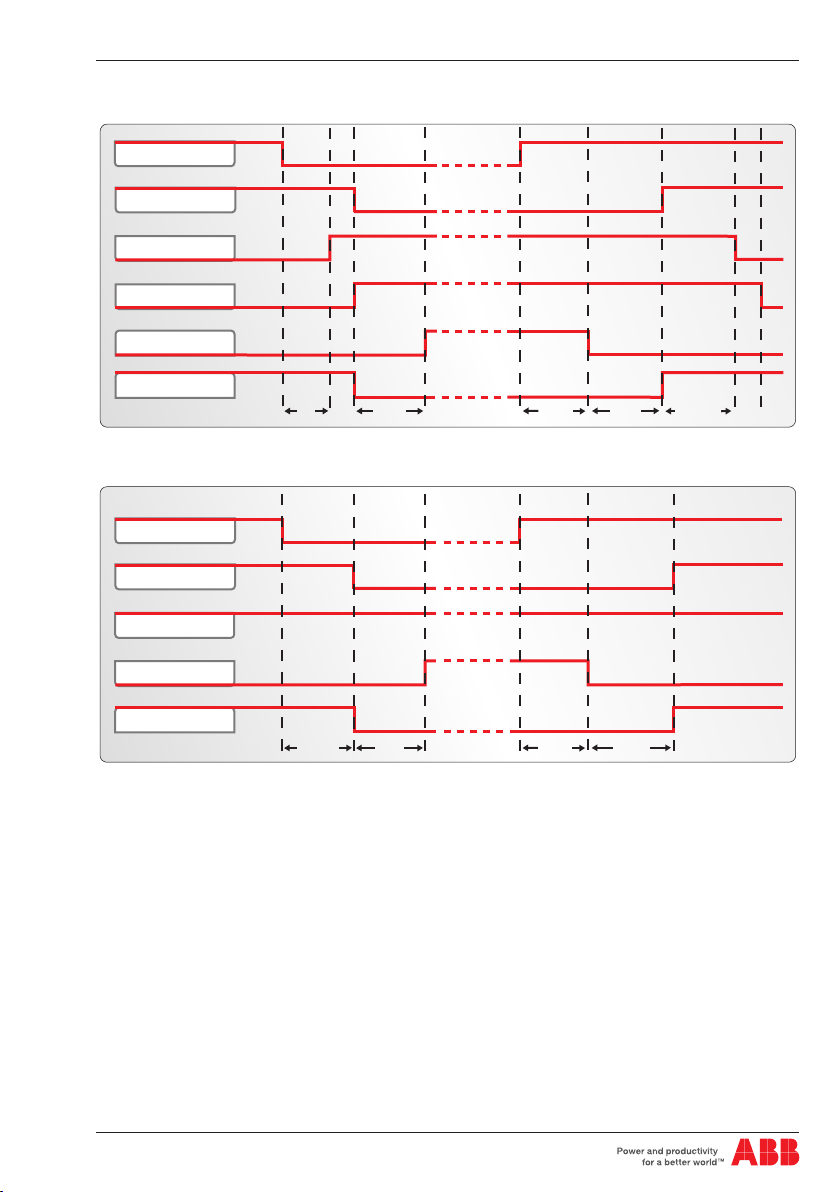

4. Applications of device ATS022

Line 1 ok

CB1 CLOSED

Gen start

Line 2 ok

CB2 CLOSED

CB3 CLOSED

TS TCE TCNTBS

Installation and operating instructions, ATS022

Figure 4.9: Application time diagram 3CBs NPL- generator in use

Line 1 ok

CB1 CLOSED

TGOFF

Line 2 ok

CB2 CLOSED

CB3 CLOSED

TS TCNTBS

TCE

Figure 4.10: Application time diagram 3CBs NPL - generator not in use - main line LN1

1SDH000760R0002

13

Page 14

Installation and operating instructions, ATS022

4. Applications of device ATS022

4.4 Control of two independent power supply lines

separated by Tie (3CBs Bus Tie)

Description

Lines LN1 and LN2 supply two different sections of the plant separated by a bus tie circuit breaker CB3,

normally open.

In case of failure of one of the two supply lines, ATS022 closes CB3; the available line thus powers both

the sections downline. When the line is restored ATS022 restores the normal plant conditions by opening

CB3.

ATS022 acquires the open/close status of the device by means of dedicated input DI11 and commands

the opening and closing by activating output DO11.

The Bus Tie application requires the use of two CT-AWE type timed relays for operating the opening and

closing of CB3.

The three circuit breakers CB1 – CB2 – CB3 must be interlocked mechanically for reasons of safety

(Emax circuit breakers – C type interlock).

CB1

CB3

Figure 4.11: Application layout 3CBs BUS TIE

Time diagrams

Line 1 ok

CB1 CLOSED

Line 2 ok

CB2 CLOSED

CB3 CLOSED

TS TC TCNTBS

Figure 4.12: Application time diagram 3CBs BUS TIE – line LN1 failure

CB2

1SDH000760R0002

14

Page 15

4. Applications of device ATS022

Line 1 ok

CB1 CLOSED

Line 2 ok

CB2 CLOSED

CB3 CLOSED

TS TC TCNTBS

Installation and operating instructions, ATS022

Figure 4.13: Application time diagram 3CBs BUS TIE – line LN2 failure

4.5 Automatic switching without inverse procedure

Description

Following an anomaly of the main line, ATS022 switches on an emergency line (1). If the mains supply

is restored, the inverse switching procedure is not started up (2). If there is a fault in the reserve line,

ATS022 must open the emergency switch (3) and wait for restoration of the emergency line to reclose (4),

without in any case providing for switching on the main line. This operating mode is also applicable if the

generator is present: in this case, after time Ts the generator is started up and as soon as the emergency

line is available CB1 is opened.

ATTENTION If ATS022 is not powered by the auxiliary supply and by any of the two lines the device

waits for at least one of the two lines (5) to return before proceeding with the switching procedure (6).

The option is not available in case of 3CBs Bus Tie application and in case of selection of the no priority

line option.

Time diagrams

(1) (2) (3) (4) (5) (6)

Line 1 ok

CB1 CLOSED

Line 2 ok

CB2 CLOSED

TS

TCE

TBS TCE

TBS

Figure 4.14: 2CBs application time diagram - generator not in use – without inverse switching

procedure

1SDH000760R0002

15

Page 16

Installation and operating instructions, ATS022

4. Applications of device ATS022

4.6 Line Priority Selection

Description

ATS022 allows selection of the main line by means of the menu on the display. The following selections

are possible:

- main line: Line LN1

- main line: Line LN2 (selection possible only if generator is not in use)

- no line priority: ATS022 ensures power supply to the load from any of the two lines without

considering either of these as priority, therefore, for example, following switching on line LN2 due

to failure of line LN1, ATS022 remains on line LN2 even if LN1 is restored.

Time diagrams

Line 1 ok

CB1 CLOSED

Line 2 ok

CB2 CLOSED

TS TCE TBS TCN

Figure 4.16: Time Diagram no line priority – generator non in use

Line 1 ok

CB1 CLOSED

Gen start

Line 2 ok

CB2 CLOSED

TS TCE

Figure 4.17: Time diagram no line priority – generator in use

1SDH000760R0002

16

Page 17

4. Applications of device ATS022

Installation and operating instructions, ATS022

5. Using the automatic transfer switch

5.1 Interface

ATS022

M3010004A

Status of the line

Code

1

No voltage

2

Undervoltage

3

Overvoltage

4

Phase missing

5

Voltage unbalance

6

Incorrect phase sequence

7

Invalid frequency

2

5

1

16

15

14

10

11

RESET

12

13

97 34 86

Figure 5.1: Description of ATS022 front panel interface

Ref. Description

1 CB1: pushbutton for opening/closing circuit breaker CB1

2 CB2: pushbutton for opening/closing circuit breaker CB2

3 CB3: CB3 opening/closure procedure graphic indication (combination of UP-DOWN keys for at

least 2sec)

4 RESET: pushbutton for automatic/manual mode selection and alarms reset

5 TEST: test modes selection pushbutton

6 ENTER: pushbutton for confirming an action

7 ESC: pushbutton for returning to the previous step

8 UP: pushbutton for moving up on the menu

9 DOWN: pushbutton for moving down on the menu

10 LED POWER: indicates presence of power supply

11 LED AUTO: indicates automatic or manual mode

1SDH000760R0002

17

Page 18

Installation and operating instructions, ATS022

Ref. Description

12 LED ALARM: indicates active alarm

13 Tx/Rx LED: indicates bus communication status

14 GRAPHIC DISPLAY

15 PLATE SHOWING LINES STATUS CODES

16 Serial No.

Table 5.1: Description of ATS022 interface

5. Using the automatic transfer switch

5.2 LED indicators

Alarm

The steady red Alarm LED may indicate the switching logic disabled condition or one of the following

events:

• circuit breakers command failed

• protection releases tripped

• removal of circuit breakers

• generator alarm

• logic disabling from input DI3

• both CBs closed

The alarm LED switches Off indicating that the switching logic is enabled and no alarms are present

Auto

The Auto LED indicates the operating mode:

• manual: LED Off

• automatic: steady green LED

• test: flashing green LED

Power

LED Power LED indicates the presence of power supply:

• power supply present: steady green LED indicates power supply from line voltage or from auxiliary

source present

• no power supply: LED Off indicates that both lines are not present and that the Powersave condition

has ended. The switching logic is in stand-by for return of one of the line voltages

• Powersave: green flashing LED indicates, if both lines are absent and if no auxiliary power supply is

present, that the device is active and is in stand-by for return of one of the line voltages (maximum

duration 1 minute). When the Powersave period ends, the LED switches off and the device awaits

a line voltage. The moment the normal or the emergency line is restored, with ATS022 in automatic,

the unit analyses the conditions of the lines monitored and the status of the circuit breakers and

proceeds with the switching operation in accordance with the situation concerned.

TX/RX

The TX/RX LED indicates the bus communication status.

• Communication via bus under way: green LED flashing at variable frequency

• Communication via bus not active: LED Off

1SDH000760R0002

18

Page 19

5. Using the automatic transfer switch

Installation and operating instructions, ATS022

5.3 Keypad keys

CB1 key

In manual mode, press the CB1 key for Opening/Closure of circuit breaker CB1.

CB2 key

In manual mode, press the CB2 key for Opening/Closure of circuit breaker CB2.

RESET

Press RESET to select the Manual or Automatic operating mode.

In case of alarm, press RESET to reset the alarm and the device returns to manual mode. Press RESET

again to bring the device to automatic mode.

TEST key

Press the TEST key to set the test modes of the

direct and inverse switching sequences.

ATS022 must be in the manual position. To exit TEST mode press

RESET.

Enter key

Used for confirming the action or entry to the menu.

ESC key

Used for cancelling an action and returning to previous menu.

UP key

Used for moving up on the menu.

DOWN key

Used for moving down on the menu.

1SDH000760R0002

19

Page 20

Installation and operating instructions, ATS022

5. Using the automatic transfer switch

5.4 Setting the operating modes

5.4.1 Manual mode

To select the Manual operating mode of unit ATS022:

a. Make sure the Power LED is On, see Figure 5.2/1

b. If the Auto LED is OFF, see Figure 5.2/2, the automatic transfer switch is in Manual mode.

c. If the AUTO LED is ON, press RESET, see Figure 5.2/3 . The Auto LED switches to OFF and the

device is in Manual Mode, see Figure 5.2/4 .

1 2

Manual mode

!

OR

2 3 4

CB2

TEST

CB1

KA00345IT

Figure 5.2: Description of manual mode selection procedure for ATS022

5.4.2 Automatic mode

To select the Automatic operating mode of unit ATS022:

a. Make sure the Power LED is On, see Figure 5.3/1

b. Press RESET once, see Figure 5.3/2. If the Auto LED is ON, the automatic transfer switch ATS022 is

in Automatic mode, see Figure 5.3/3

c. If the Auto LED is OFF, press RESET again, see Figure 5.3/3; the Auto LED switches to ON and the

device is in Automatic mode/ Figure 5.3/4

1 2 3

CB2

TEST

CB1

Automatic Mode

!

Manual mode

!

OR

3

KA00347IT

4

CB2

TEST

CB1

Figure 5.3: Description of automatic mode selection procedure for ATS022

1SDH000760R0002

20

5

!

Automatic Mode

Page 21

5. Using the automatic transfer switch

5.5 Graphic Display

1

14

Installation and operating instructions, ATS022

7 2 15 19 10

6 20

LN1

LN2

TBS..

LN1:

0,0

0,0

3

LN2:

0,0

5

Figure 5.4: Description of ATS022 display

Ref. Description

1 LN1: line 1

2 LN2: line 2

3 CB1 status graphic indicator

4 CB2 status graphic indicator

5 CB3 status graphic indicator

6 LN1 power presence icon

7 LN2 power presence icon

8 application type indicator

9 manual mode indicator

10 test mode indicator

11 generator presence indicator

12 generator start (UP arrow)/stop (DOWN arrow) indicator

13 open/close command execution indicator

14 timing indicator

15 LN1 power measurement

16 LN2 power measurement

17 LN1 frequency measurement

18 LN2 frequency measurement

19 LN1 line status code

20 LN2 line status code

21 local/remote mode indicator

Table 5.2: Description of ATS022 display

NPL

8

0,0

4

1613

18

V

Hz

V

Hz

1

GT

G

1

M

L

17

11

12

9

21

1SDH000760R0002

21

Page 22

Installation and operating instructions, ATS022

5. Using the automatic transfer switch

5.5.1 LN1 and LN2 lines status indication

The presence/absence of lines LN1 and LN2 is shown graphically on the display by means of filled/

empty icons, see Figure 5.4/6 – 5.4/7, and a specific status code

If there is an anomaly on the line voltage, the icon concerned is empty and the error code is displayed as

defined by the following Table:

Line status Code

No power 1

Minimum voltage 2

Maximum voltage 3

Phase missing 4

Phase imbalance 5

Inverted sequence 6

Frequency out of range 7

Table 5.3: Description of line status codes ATS022

5.5.2 Browsing through the Menu

Press Enter to access the main Menu. Three different levels of configuration of the unit can be accessed

from the main menu:

Figure 5.5: Description of main menu ATS022

Access to the configuration pages requires a 4-digit password which must be entered using the UP,

DOWN and ENTER keys.

The password is valid for one minute after the last pressing of a key.

For the first access to the system the password is 0001; subsequently change the password as desired.

If the password is lost or forgotten, contact the service centre.

1SDH000760R0002

22

Page 23

5. Using the automatic transfer switch

Installation and operating instructions, ATS022

Configuration of the System

The system configuration section makes it possible to set:

- The parameters of the two lines

Parameters of lines LN1 - LN2 Value Factory settings

100V/57V– 115V/66V - 120V/70V - 208V/120V

- 220V/127V - 230V/132V -

Rated voltage

Rated frequency 50Hz - 60 Hz, 16 2/3 Hz, 400 Hz 50Hz

Number of phases LN1 1 phase / 3 phases with N / 3 phases without N 3 phases with N

Number of phases LN2 1 phase / 3 phases with N / 3 phases without N 3 phases with N

Presence of external voltage

transformer

Primary voltage TV

Secondary voltage TV

240V/138V - 277V/160V - 347V/200V 380V/220V - 400V/230V - 415V/240V 440V/254V - 480V/277V

absent/present

(for voltages greater than 480VAC)

100V/57V– 115V/66V - 120V/70V - 208V/120V

- 220V/127V - 230V/132V 240V/138V - 277V/160V - 347V/200V 380V/220V - 400V/230V - 415V/240V 440V/254V - 480V/277V - 500V/288V 550V/317V - 600V/347V - 660V/380V 690V/400V - 910V/525V - 950V/550V 1000V/577V - 1150V/660V

100V/57V– 115V/66V - 120V/70V - 208V/120V

- 220V/127V - 230V/132V 240V/138V - 277V/160V - 347V/200V 380V/220V - 400V/230V - 415V/240V 440V/254V - 480V/277V

400V/230V

absent

690V/400 V

400V/230 V

Table 5.4: Description of parameters of lines ATS022

- Type of application

Type of application Value Factory settings

Protection devices

2CBs / 3CBs NPL opening only / 3CBs NPL

opening&closing / 3CBs NPL BusTie / 3CBs Bus Tie

2CBs

Utilisation of generator Generator not in use / Generator in use Generator not in use

Priority Line Line LN1 / Line LN2 / No priority Line Line LN1

Switching With inverse procedure/Without inverse procedure With inverse procedure

Table 5.5: Description of types of application ATS022

Device configuration

The device configuration section makes it possible to set:

- Limit thresholds

Limit thresholds Value Factory settings

Min/max voltage

threshold

Min/max frequency

threshold

-30% …-5%, +5% … +30%, step ± 1%

(Imbalance of voltage set at same threshold)

-15%; +15%

-10% …-1%, +1% … +10%, step ± 1% -1%; +1%

Table 5.6: Description of limit thresholds ATS022

1SDH000760R0002

23

Page 24

Installation and operating instructions, ATS022

5. Using the automatic transfer switch

- Time delays

Time delays Value Factory settings

TS Delay 0…30s, step 1s 0s

TBS Delay 0…59s, , step 1s, 1,2,3…30min, step 1min 0s

TCE Delay 0…60s, step 1s 3s

TCN Delay 0…60s, step 1s 3s

TC Delay 0…60s, step 1s 3s

TGOFF Delay 0…59s, , step 1s, 1,2,3…30min, step 1min 5s

Table 5.7: Description of time delays ATS022

- Digital inputs

Digital Input Value Factory settings

Digital Input DI10 - function

Digital Input DI10 - type NO/NC NO

Digital Input DI8 - type NO/NC NO

Table 5.8: Description of inputs ATS022

disabled/generator start/logic enabling/remote

reset/EMERGENCY BLOCK

Generator Start

- Modbus parameters

Modbus Value Factory settings

Modbus Address 1…247 1

Modbus Baud Rate 9600/19200/38400 bps 9600

Modbus Stop Bits 0,1 1

Modbus Parity even, odd, absent absent

mode local, remote local

Table 5.9: Description of Modbus parameters ATS022

- Language and backlit display

Function Value Factory settings

Backlighting duration Always On, 0…59s, step 1s, 1,2,3…30min, step 1min Always On

Language

Table 5.10: Description of language and backlighting ATS022

English/Italian/German/French/Spanish/Finnish/

Russian/Chinese

English

1SDH000760R0002

24

Page 25

5. Using the automatic transfer switch

Diagnostics

The diagnostics section makes it possible to access the following pages:

Values Measured: the voltage and frequency values measured on lines LN1 and LN2 can be consulted

on the display.

Alarms Log: the latest alarms/events are displayed, up to a maximum of 20. The number of alarms is

shown at the top of the page and the latest alarm is always at the top of the list. The log is cleared by

selecting Clear Log and pressing Enter.

Installation and operating instructions, ATS022

Diagnostics

2/2

Measured Values

Alarm Log

SW: 1A

KA00477

Figure 5.5: Description of diagnostics menu ATS022

Figure 5.6: diagnostics – values measured page ATS022

Figure 5.7: diagnostics – Alarms Log page ATS022

SN: 12345678

1SDH000760R0002

25

Page 26

Installation and operating instructions, ATS022

5. Using the automatic transfer switch

5.6 Using pushbuttons in manual mode

Opening/Closing circuit breakers CB1, CB2

In manual mode the circuit breakers can be controlled by means of pushbuttons CB1 and CB2. In case

of a fault, the alarms are activated by the same methods as those for the automatic switching sequence.

Pressing the CB1 key:

• If CB1 is closed, the opening command is sent to CB1

• If CB1 and CB2 are both open, the closing command is sent to CB1

• If CB1 is open and CB2 is closed, no operation is carried out

Pressing CB2 key:

• If CB2 is closed, the opening command is sent to CB2

• If CB2 and CB1 are both open, the closing command is sent to CB2

• If CB2 is open and CB1 is closed, no operation is carried out

Opening/Closing circuit breaker CB3

In manual mode, combination of the UP and DOWN keys allows Opening/Closing of circuit breaker CB3.

• CB3 opening: press the UP and DOWN keys simultaneously for at least 2 seconds.

• CB3 closing: press the UP and DOWN keys simultaneously for at least 2 seconds.

Manual Start/Stop of generator

In manual mode, the combination of the RESET, CB1 and CB2 keys allows Start/Stop of the generator.

• Generator Start: keeping RESET pressed, press CB1

• Generator Stop: keeping RESET pressed, press CB2

5.7 Test Modes

ATS022 makes it possible to select two different test modes:

• testing the entire switching procedure (complete Test)

• generator start/stop test (gen set test)

WARNING: when the test procedure ends, the user must make sure the device is not left accidentally in

TEST mode

Complete Test

With ATS022 in manual mode, press TEST: all the LEDs, except Tx/Rx, flash twice simultaneously and

then the Auto LED Auto flashes every 0.5 sec.; the graphic display shows the icon T.

The test procedure varies according to the application selected:

1SDH000760R0002

26

Page 27

5. Using the automatic transfer switch

2 CBs 3CBs NPL

1. Press TEST; start generator

(not performed if generator is NOT in use)

2. Press TEST; CB1 Opening

4. Press TEST; CB2 Closure

5. Press TEST; CB2 Opening

6. Press TEST; CB1 Closure

8. Press TEST; stop generator

(not performed if generator is NOT in use)

3CBs NPL Bus Tie 3CBs Bus Tie

1. Press TEST; start generator

(not performed if generator is NOT in use)

2. Press TEST; CB1 Opening

3. Press TEST; CB3 Opening

4. Press TEST; CB2 Closure

5. Press TEST; CB2 Opening

6. Press TEST; CB3 Closure

7. Press TEST; CB1 Closure

8. Press TEST; stop generator

(not performed if generator is NOT in use)

Table 5.11: Description of complete TEST mode ATS022

At the end of the procedure, press TEST again to resume the sequence.

Alarms, if any, on the protection devices control are activated in the same manner as the automatic and

manual operating modes.

The user can stop the TEST sequence by pressing the RESET.

1. Press TEST; start generator

(not performed if generator is NOT in use)

2. Press TEST; CB1 Opening

3. Press TEST; CB3 Opening

4. Press TEST; CB2 Closure

5. Press TEST; CB2 Opening

6. Press TEST; CB1 Closure

7. Press TEST; CB3 Closure

(not performed if ATS022 has activated the

DISCONNECTION ONLY function)

8. Press TEST; stop generator

(not performed if generator is NOT in use)

1. Press TEST; CB1 Opening

2. Press TEST; CB3 Closure

3. Press TEST; CB3 Opening

4. Press TEST; CB1 Closure

5. Press TEST; CB2 Opening

6. Press TEST; CB3 Closure

7. Press TEST; CB3 Opening

8. Press TEST; CB2 Closure

Installation and operating instructions, ATS022

Gen Set Test

This test mode makes it possible to test only the generator start and stop with the plant running without

opreating the circuit breakers on the line in any manner whatsoever, only if the ATS022 is set with the

generator in use, otherwise the Gen Set Test is not performed.

1SDH000760R0002

27

Page 28

Installation and operating instructions, ATS022

With ATS022 in manual mode, keep the TEST key pressed for at least 3 seconds, on releasing the TEST

key, all the LEDs, except Tx/Rx, flash simultaneously four times and then the Auto LED flashes at 0.5Hz;

the graphic display shows the GT icon.

The test procedure is as follows:

1. Press TEST; start generator

2. Press TEST; stop generator

Table 5.12: Description of test method GEN SET ATS022

5. Using the automatic transfer switch

1SDH000760R0002

28

Page 29

6. Input and output signals

Installation and operating instructions, ATS022

6. Input and output signals

6.1 Output signals (DO1…DO12)

DO1, DO2, DO3, DO4: Circuit breakers open/close command

Output signals DO1, DO2, D03, DO4 control the opening and closure of circuit breakers CB1 and CB2

connected to ATS022.

The control logic integrated in the device punctually checks the correct operation of the circuit breakers

following the command.

If the change in status of the circuit breaker is not received within 5 seconds of sending the command,

the device considers the command as failed and operates as below:

• alarm LED lights up.

• DO6 alarm output activation

• DO9 alarm output activation

The alarm relative to the failed operation is recorded in the section concerned of the "Alarms Log".

To reset the alarm press RESET:

the alarm is reset and ATS022 goes into manual mode.

Press RESET again to bring ATS022 to automatic mode.

DO5 Emergency generator start/stop command

Start and stop of the Emergency generator are controlled by means of a bistable relay, making it possible

to maintain the generator start command even when the powersave mode runs out.

• contact DO5 (X23:1 ; X23:2 - NO):

- stop unit = contact open

- start unit = contact closed

• contact DO5 (X23:2 ; X23:3 - NC):

- stop unit = contact closed

- start unit = contact open

DO6 Alarm signal

When an alarm is generated, contact DO6 switches, the switching logic is disabled and the alarm LED

lights up.

To reset the alarm press RESET:

the alarm is reset, the Alarm LED turns Off and the ATS022 enters manual mode.

Press RESET again to bring ATS022 to automatic mode.

DO7-DO8 Not available

DO9 Circuit breaker operation failed alarm indication

When the opening or closing command of a circuit breaker fails, contact DO9 closes; the switching logic

is disabled and the Alarm LED lights up.

To reset the alarm press RESET:

the alarm is reset, the Alarm LED turns Off and the ATS022 enters manual mode.

Press RESET again to bring ATS022 to automatic mode.

DO10 Automatic/Manual mode indication

Contact DO10 indicates the operating mode of the device:

• DO10 open: ATS022 operates in automatic mode

• DO10 closed: ATS022 operates in manual mode

DO11 CB3 circuit breaker control

Depending on the operating mode set, contact DO11 allows control of only opening or opening/closing

of circuit breaker CB3:

Protection Devices selection DO11 NOTES

2 CBs not used

1SDH000760R0002

29

Page 30

Installation and operating instructions, ATS022

6. Input and output signals

3CBs NPL used

3CBs NPL Bus Tie used CT-AWE* type timed relays required

3CBs Bus Tie used CT-AWE* type timed relays required

*The CT-AWE must be adjusted with a time between 200ms and 300ms.

Table 6.1: Description of DO11 functions - ATS022

CT-AWE type timed relays required if

selected opening&closing option

DO12 Logic enabled/disabled indication

Contact DO12 indicates whether switching logic is enabled or disabled:

• DO12 open: logic enabled

• DO12 closed: logic disabled

6.2 Input signals

DI1, DI2 Status signals of circuit breakers CB1, CB2

Inputs DI1, DI2 must be connected to auxiliary contacts of the status of the circuit breakers of the normal

and emergency lines

• DI1, DI2 open: CB open

• DI1, DI2 closed: CB closed

DI3 Switching Logic Activation/Deactivation

Input DI3 is used for enabling/disabling the switching logic. The function may be used for integrating

generic alarms coming from the plant the presence of which leads to disabling of ATS022 automatic

switching logic.

• DI3 open: logic disabled

• DI3 closed: logic enabled

DI4, DI5 Circuit breakers activation indication

The auxiliary opening contacts of the normal and emergency lines must be connected to contacts DI4,

DI5 for activation of the trip.

• DI4, DI5 open: CB tripped

• DI4, DI5 closed: CB not tripped

In case of trip of a circuit breaker (CB1 or CB2):

• the trip indication contact opens

• the switching logic is disabled

• Alartm contact DO6 is closed

• contact DO12 is closed

• the Alarm LED lights up

• the Auto LED switches Off

To reset the TRIP indication press RESET.

• The TRIP indication is reset

• Alarm LED switches Off

• ATS022 operates in manual mode

• contact DO10 is closed

Press RESET again to bring ATS022 to Automatic mode

• contact DO10 is opened

• the Auto LED lights up

DI6, DI7 Circuit breakers CB1, CB2 removed/inserted position indication

The auxiliary position contacts of the circuit breakers of the normal and emergency lines must be

1SDH000760R0002

30

Page 31

6. Input and output signals

connected to inputs DI6 and DI7 in removable execution.

• DI6, DI7 open: CB removed

• DI6, DI7 closed: CB inserted

If the circuit breaker is removed:

• the position indication contact opens

• the switching logic is disabled

• Alartm contact DO6 is closed

• contact DO12 is closed

• the Alarm LED lights up

• the Auto LED switches Off

When the circuit breaker is inserted:

• the position indication contact closes

• the switching logic is re-enabled

• Alarm LED switches Off

• ATS022 operates in manual mode

• contact DO10 is closed

• Alarm contact DO6 is opened

• contact DO12 is opened

• the Auto LED switches Off

To set the device in automatic mode press RESET

• contact DO10 is Opened

• the Auto LED lights up

Installation and operating instructions, ATS022

DI8 Generator Alarm

Input DI8 is used for connecting various alarms coming from the emergency generator: drop in oil

pressure, Over Temperature, etc.

Input DI8 may be set as normally open (NO) or normally closed (NC) by means of the menu on the

graphic display.

In case of an active generator alarm

• the switching logic is disabled

• Alartm contact DO6 is closed

• contact DO12 is closed

• the Alarm LED lights up

• the Auto LED switches Off

• contact DO10 is closed

• the display shows "generator alarm"

When the DI8 signal is deactivated:

• Alarm LED switches Off

• Alarm contact DO6 is opened

• contact DO12 is opened

• ATS022 operates in manual mode

• the "generator alarm" message disappears from the display

To set the device in automatic mode press RESET

• contact DO10 is Opened

• the Auto LED lights up

DI9 Forced switching on emergency power supply line

In certain industrial processes, supply of power from the emergency generator may be required instead

of from the normal power supply line, for brief moments, in order to avoid possible operating anomalies

of the supply and ensure high levels of reliability.

1SDH000760R0002

31

Page 32

Installation and operating instructions, ATS022

In automatic mode, by activating input DI9 the forced switching procedure is started up on the

emergency line:

• Generator Start

• opening of circuit breaker on normal line

• closure of circuit breaker on emergency line

The power supply from the emergency line persists as long as the command remains active. When the

command is deactivated, the unit proceeds with the switching procedure on the normal line.

6. Input and output signals

2 CBs:

If DI9 is closed:

• Generator Start

• Opening of circuit breaker CB1

• closure of circuit breaker CB2

If DI9 is open:

• opening of circuit breaker CB2

• closure of circuit breaker CB1

• generator stop

3CBs NPL:

If DI9 is closed:

• Generator Start

• Opening of circuit breakers CB1 and CB3

• closure of circuit breaker CB2

If DI9 is open:

• opening of circuit breaker CB2

• closure of circuit breakers CB1 and CB3

• generator stop

3CBs NPL BUS TIE:

If DI9 is closed:

• Generator Start

• Opening of circuit breakers CB1 and CB3

• closure of circuit breaker CB2

1SDH000760R0002

32

Page 33

6. Input and output signals

Installation and operating instructions, ATS022

If DI9 is open:

• opening of circuit breaker CB2

• closure of circuit breakers CB3 and CB1

• generator stop

DI10 Programmable input

The function associated with input DI10 can be selected from the menu on the display, from among the

following options:

• forced generator start: this function makes it possible to test the correct switching ON/OFF of the

generator with the plant running

Contact type set Description of function

NC Open =gen start; Closed = gen stop

NO Closed =gen start; Open = gen stop

• Enabling automatic switching logic: this function makes it possible to inhibit the automatic

switching logic of the device following an alarm present in the field.

The logic can, however, be disabled if one of the conditions involving the disabling exist

Contact type set Description of function

NC

NO

Closed = switching enabled;

Open switching disabled

Open = switching enabled;

Closed switching disabled

• Reset from Remote: this function allows reset of the device logic in remote by means of remote

actuator.

Contact type set Description of function

NC

NO

Closed = remote reset not active;

Open = remote reset active

Closed = remote reset active;

Open = remote reset not active

• Emergency Block: this function allows prior opening of both circuit breakers of the power supply

and emergency lines and permanent disabling of the switching logic. This function can be used, for

example, in case of an alarm coming from a fire-fighting system which requires immediate opening of

the circuit breakers and disabling of the switching logic.

Contact type set Description of function

NC

NO

Closed = emergency block not active;

Open = emergency block active

Closed = emergency block active;

Open = emergency block not active

Input DI10 may be set as normally open (NO) or normally closed (NC) by means of the menu on the

graphic display.

DI11 CB3 circuit breaker status signal

Input DI11 is connected to the CB3 circuit breaker status auxiliary contacts.

• DI11 open: CB open

• DI11 closed: CB closed

Uscita per controllo CB1

Output to control CB1

Salida para control CB1

Sortie pour controle CB1

Ausgang zur steuerung CB1

Uscita per controllo CB2

Output to control CB2

Salida para control CB2

Sortie pour controle CB2

Ausgang zur steuerung CB2

1SDH000760R0002

Linea 1

Line 1

Linea 1

Ligne 1

Leitung 1

ATS022

33

Linea 2

Line 2

Linea 2

Ligne 2

Leitung 2

Uscita per controllo Gen Start/Stop

Output to control Gen Start/Stop

Salida para control Gen Start/Stop

Sortie pour controle Gen Start/Stop

Ausgang zur steuerung Gen Start/Stop

Uscita per controllo CB3

Output to control CB3

Salida para control CB3

Sortie pour controle CB3

Ausgang zur steuerung CB3

Page 34

Installation and operating instructions, ATS022

Figure 6.1: Control circuit diagram ATS022

Connectors Description DI/DO Type

X11:1 Normal Line LN1: L1 - -

X11:2 Normal Line LN1: L2 - -

X11:3 Normal Line LN1: L3 - -

X11:4 Normal Line LN1: N - -

X12:1 Emergency Line LN2: L1 - -

X12:2 Emergency Line LN2: L2 - -

X12:3 Emergency Line LN2: L3 - -

X12:4 Emergency Line LN2: N - -

X41:1 + Auxiliary power supply - -

X41:2 - Auxiliary power supply - -

X21:1 Com - -

X21:2 CB1 opening command DO1 NO

X21:3 CB1 closure command DO2 NO

X22:1 Com - -

X22:2 CB2 opening command DO3 NO

X22:3 CB2 closure command DO4 NO

X23:1 generator start/stop command D05 Open =gen stop; Closed = gen start

X23:2 Com - -

X23:3 generator start/stop command D05 Closed =gen stop; Open = gen start

X24:1 CB3 opening command D011 NO

X24:2 Com - -

X24:3 CB3 closure command D011 NC

X29:1 ATS022 unit alarm indication DO6

X29.2 not used DO7 -

X29:3 not used DO8 -

X29:4

X29.5 automatic/manual mode indication DO10

X29:6 logic enabled/disabled indication DO12

X29:7 Com - -

X31:1 logic enabling input DI3

X31:2 CB1 status input DI1 0=CB open; I=CB closed

X31:3 CB2 status input DI2 0=CB open; I=CB closed

X31:4 Com - -

X32:1 CB3 status input DI11 0=CB open; I=CB closed

X32.2 programmable input DI10 NO/NC

circuit breakers command alarm

indication

6. Input and output signals

Open = no alarm;

Closed = alarm

DO9

Open = no alarm;

Closed = alarm

Open = Automatic;

Closed = Manual

Open = logic enabled;

Closed = logic disabled

Open = logic disabled;

Closed = logic enabled

1SDH000760R0002

34

Page 35

6. Input and output signals

Connectors Description DI/DO Type

X32:3 switching forcing input DI9 NO

X32:4 generator alarm input DI8 NO/NC

X32.5 CB1 position input DI7 0=CB removed; I=CB inserted

X32:6 CB2 position input DI6 0=CB removed; I=CB inserted

X32:7 CB1 trip input DI5 0=no CB trip; I=CB trip

X32:8 CB2 trip input DI4 0=no CB trip; I=CB trip

X32.9 Com - -

X51:1 Modbus DATA B - -

X51:2 Modbus DATA A - -

X52:3 Modbus GND - -

X61 Earth connection - -

Table 6.2: Description of function and type connector ATS022

Installation and operating instructions, ATS022

1SDH000760R0002

35

Page 36

Installation and operating instructions, ATS022

7. Technical data

7. Technical data

ATS022 Value

Three-phase voltage used

Connected voltage 100Vac - 480Vac (+/-20%)

Phase voltage 57,7Vac - 277Vac (+/-20%)

Safety auxiliary voltage 24Vdc - 110 Vdc (-10% / +15%)

Frequency 50-60-400-16 2/3 Hz

Single-phase voltage used

Phase voltage

57,7Vac - 277Vac (+/-20%)

Safety auxiliary voltage 24Vdc - 110 Vdc (-10% / +15%)

Frequency 50-60-400-16 2/3 Hz

Measurement precision

Voltage 1%

Frequency 1%

Relay utilization category 8 A, AC1, 250 V

Relay/connectors utilization category 6 A, AC1, 250 V

Over voltage category III, Uimp 6 kV

Power consumption Max 12W

IP rating IP20

Device weight 1314g

Operating temperature -20 / +60 °C

(4

Storage temperature -25 / +80°C

Humidity r.h=95% T=25…60°C

Altitude Max. 2000m

NOTES

(1 In single-phase system it is not possible to select Un 100 V, 115 V, 120 V.

(2 In single-phase system, if Un is between 57.7 - 109 V an auxiliary safety power supply is necessary

(3 In case of rated frequency 16 2/3 Hz, an auxiliary safety power supply must be used. If the rated

voltage is greater than 100 VAC external transformers must be used.

(4 If the ATS022 is used in environments with extremely low temperatures (less than - 10°C) it is

advisable to use a safety auxiliary power supply to avoid display problems of the graphic display.

Table 7.1: Technical data ATS022

(1

(2

(3

1SDH000760R0002

36

Page 37

8. Installation of device ATS022

Installation and operating instructions, ATS022

8. Installation of device ATS022

The automatic transfer switch ATS022 can be mounted on the front of the panel door or on DIN rail.

8.1. Door-mounted Automatic Transfer Switch ATS022

The Automatic Transfer Switch ATS022 can be door-mounted as shown in Figure 8.1.

2

1

160

139

91

KA00379

Figure 8.1: Door-mounted ATS022

1SDH000760R0002

2a

2b

37

Page 38

Installation and operating instructions, ATS022

8. Installation of device ATS022

8.2. DIN rail-mounted Automatic Transfer Switch ATS022

The automatic transfer switch ATS022 can be mounted on a 35mm DIN rail as shown in Figure 8.2.

1

KA00500

KA00377

Togliere

3

35mm

EN 50022

2

145

97

3

KA00484IT

1 2

Figure 8.2: DIN rail-mounted ATS022

1SDH000760R0002

38

Page 39

9. Regulatory standards

Installation and operating instructions, ATS022

9. Regulatory standards

ATS022 conforms to the following regulatory standards:

• European Directive 73/23 “LVD – Low Voltage Directive”

• EN 50178 electronic equipment for use in power Installations

• EN-IEC 62103 electronic equipment for use in power Installations

• EN-IEC 60947-5-1 low voltage switchgear and control gear: control circuit devices and switching

elements

• Electromagnetic compatibility EN 50081-2, EN 50082-2

• Environmental conditions IEC 68-2-1, IEC 68-2-2, and IEC 68-2-3

• EN-IEC 61000-4-2: Electromagnetic compatibility (EMC) - Part 4: Testing and measurement

techniques Section 2: Electrostatic discharge immunity test Basic EMC Publication (IEC 61000-4-2

[8KV air, 4KV cont])

• EN-IEC 61000-4-3, Electromagnetic compatibility (EMC) - Part 4: Testing and measurement

techniques Section 3: Radiated, radio-frequency, electromagnetic field immunity test (IEC 61000-4-3

[level 3])

• EN-IEC 61000-4-4, Electromagnetic compatibility (EMC) - Part 4: Testing and measurement

techniques Section 4: Electrical fast transient/burst immunity test Basic EMC Publication (IEC 610004-4 [level 2/3])

• EN-IEC 61000-4-5, Electromagnetic compatibility (EMC) - Part 4: Testing and measurement

techniques Section 5: Surge immunity test (IEC 61000-4-5 [level 1/2])

• EN-IEC 61000-4-6: Electromagnetic compatibility (EMC) - Part 4: Testing and measurement

techniques (IEC 61000-4-6 [level 3])

• EN-IEC 61000-4-8: Electromagnetic compatibility (EMC) - Part 4: Testing and measurement

techniques (IEC 61000-4-8 [level 5])

• EN 50093, Electromagnetic compatibility (EMC) - Part 4: Testing and measurement techniques

Section 11: Voltage dips, short interruptions and voltage variations immunity test (IEC 61000-4-11,

[100ms/5s] B, C criterion)

• CISPR11 (30MHz...1GHz): Emission (Generic Standard, Industrial) – Radiated

• CISPR11 (0.15MHz…30MHz): Emission (Generic Standard, Industrial) – Conducted

• CISPR/CEI 1000-6-3: Part 6: Generic standards – Section 3: Emission standard for residential,

commercial and light-industrial environments

• IEC 60068-2-2: Environmental testing. Part 2: Tests. Test B: Dry heat

• IEC 60068-2-6: Environmental testing. Part 2: Tests. Test Fc: vibration (sinusoidal)

• IEC 60068-2-27: Environmental testing. Part 2: Tests. Test Ea and guidance: shock

• IEC 60068-2-30: Environmental testing. Part 2: Tests. Test Db and guidance: Damp heat, cyclic

• IEC 60068-2-1: Environmental testing. Part 2: Tests. Test A: cold (-20 °C ± 3 °C, 16 hours)

1SDH000760R0002

39

Page 40

Installation and operating instructions, ATS022

10. Troubleshooting

The alarms are shown by means of a message on the ATS022 display. The

Alarm messages are shown in the Table below:

Table 10.1: Alarms ATS022

Alarm Fault Action

CB1 opening failed

CB2 opening failed

CB3 Opening failed

CB1 closure failed

CB2 closing failed

CB1 removed circuit breaker CB2 is removed

CB2 removed circuit breaker CB2 is removed

Logic block

External fault

Trip CB1 Circuit breaker CB1 has tripped

Trip CB2 Circuit breaker CB2 has tripped

Generator alarm Generator alarm input DI8 active

Table 10.1: Alarms ATS022

circuit breaker CB1 on normal line

does not open within 5s

circuit breaker CB2 on emergency

line does not open within 5s

circuit breaker CB3 bus-tie does not

open within 5s

circuit breaker CB1 on normal line

does not close within 5s

circuit breaker CB2 on emergency

line does not close within 5s

Enabled/disabled logic input DI3

inactive

Both circuit breakers are closed (DI1

and DI2 active)

the alarm can be reset by means of the

RESET button.

the alarm can be reset by means of the

RESET button.

the alarm can be reset by means of the

RESET button.

the alarm can be reset by means of the

RESET button.

the alarm can be reset by means of the

RESET button.

The logic is blocked and ATS enters manual

mode.

Reset by inserting CB1.

The logic is blocked and ATS enters manual

mode.

Reset by inserting CB2.

The logic is blocked. Reset by activating DI3

Check wiring

The logic is blocked as long as input DI4 is

deactivated

The logic is blocked as long as input DI5 is

deactivated

The logic is blocked as long as input DI8 is

activated

10. Troubleshooting

1SDH000760R0002

40

Page 41

Installation and operating instructions, ATS022

1SDH000760R0002

41

Page 42

Due to possible development of Standards as

well as of materials, the characteristics and

dimensions specified in this Installation and

operating instructions may be considered as

binding only after confirmation by ABB SACE

Division.

© Copyright 2011 ABB. All rights reserved.

For more information please contact:

ABB S.p.A.

ABB SACE Division

Via Baioni, 35

24123 Bergamo - Italy

Phone: +39 035 395 111

Fax: +39 035 395 306 - 433

www.abb.com

Loading...

Loading...