Page 1

SYSTEM VERSION 6.1

ABB Ability™ System 800xA / Advant® OCS

Control Builder A 1.4

Installation

Page 2

Page 3

SYSTEM VERSION 6.1

ABB Ability™ System 800xA / Advant® OCS

Control Builder A 1.4

Installation

Document Number: 3BSE066174R301

Document Revision: A

Release: April 2019

Trace back information Main Publication:

Tool version: 5.2.025

Build date: 2019-04-10 at 09:54:08

Domain: ABBPA

Workspace, version, checked in: Control Builder A, a52, 2019-04-10

Master: ix-388808-Control Builder A 1.4 Installation.xml

Recipe: ix-389038-Control Builder A 1.4 Installation.rcp

PDF stylesheet: ix-315381-PDF-Stylesheet.xml

Customer stylesheet: ix-315380-CustomerStylesheet.xml

Page 4

Notice

This document contains information about one or more ABB products and may include a description of or a reference

to one or more standards that may be generally relevant to the ABB products. The presence of any such description of

a standard or reference to a standard is not a representation that all of the ABB products referenced in this document

support allof the features of the described or referenced standard. In order to determine the specific features supported

by a particular ABB product, the reader should consult the product specifications for the particular ABB product.

ABB may have one or more patents or pending patent applications protecting the intellectual property in the ABB

products described in this document.

The information in this document is subject to change without notice and should not be construed as a commitment

by ABB. ABB assumes no responsibility for any errors that may appear in this document.

Products described or referenced in this document are designed to be connected, and to communicate information and

data via a secure network. It is the sole responsibility of the system/product owner to provide and continuously ensure

a secure connection between the product and the system network and/or any other networks that may be connected.

The system/product owners must establish and maintain appropriate measures, including, but not limited to, the

installation of firewalls, application of authentication measures, encryption of data, installation of antivirus programs,

and so on, to protect the system, its products and networks, against security breaches, unauthorized access, interference,

intrusion, leakage, and/or theft of data or information.

ABB Ltd and its affiliates are not liable for damages and/or losses related to such security breaches, any unauthorized

access, interference, intrusion, leakage and/or theft of data or information.

ABB verifies the function of released products and updates. However system/product owners are ultimately responsible

to ensure that any system update (including but not limited to code changes, configuration file changes, third-party

software updates or patches, hardware change out, and so on) is compatible with the security measures implemented.

The system/product owners must verify that the system and associated products function as expected in the environment

they are deployed.

In no event shall ABB be liable for direct, indirect, special, incidental or consequential damages of any nature or kind

arising from the use of this document, nor shall ABB be liable for incidental or consequential damages arising from use

of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written permission from ABB, and the

contents thereof must not be imparted to a third party nor used for any unauthorized purpose.

The software or hardware described in this document is furnished under a license and may be used, copied, or disclosed

only in accordance with the terms of such license. This product meets the requirements specified in EMC Directive

2014/30/EU and in Low Voltage Directive 2014/35/EU.

Trademarks

All rights to copyrights, registered trademarks, and trademarks reside with their respective owners.

Copyright © 2019 by ABB.

All rights reserved.

Page 5

Table of Contents

Table of Contents

About This User Manual

1 Installation of Control Builder A

7General .............................................................................................................

7User Manual Conventions .................................................................................

7Warning, Caution, Information, and Tip Icons ......................................

8Terminology .......................................................................................................

9Released User Manuals and Release Notes ....................................................

111.1 Installation Procedures ......................................................................................

111.1.1 Recommended PC Performance and Capacity ...................................

111.1.2 Software Requirements ......................................................................

131.1.3 CBA Suite Installation ..........................................................................

141.1.4 800xA Common 3rd Party Install .........................................................

141.1.5 Central Licensing System ....................................................................

161.1.6 Control Builder A Products ..................................................................

191.1.7 Manual Installation ...............................................................................

211.1.8 Additional Displays During On-line Builder Installation ........................

231.1.9 Engineering Board setup .....................................................................

241.2 Server and Client Configuration ........................................................................

251.2.1 Server Configuration - DCOM ..............................................................

311.2.2 Client configuration – Engineering Board Setup ..................................

331.3 PU410 External Engineering Board ..................................................................

331.3.1 Introduction ..........................................................................................

341.3.2 PU410 Specification .............................................................................

371.3.3 Mechanical Installation ........................................................................

45Revision History .....................................................................................................

3BSE066174R301 A 5

Page 6

3BSE066174R301 A 6

Page 7

About This User Manual

General

About This User Manual

General

Any security measures described in this User Manual, for example, for user access,

password security, network security, firewalls, virus protection, etc., represent possible

steps that a user of an 800xA/Advant OCS® System may want to consider based on

a risk assessment for a particular application and installation. This risk assessment,

as well as the proper implementation, configuration, installation, operation,

administration, and maintenance of all relevant security related equipment, software,

and procedures, are the responsibility of the user of the 800xA/Advant OCS® System.

This user manual describes the installation of Control Builder A.

Control Builder A is a configuration tool for AC 100 and AC 400 Series Controllers. Control

Builder A can be installed in a 800xA system or separate from 800xA.

User Manual Conventions

Microsoft Windows conventions are normally used for the standard presentation of

material when entering text, key sequences, prompts, messages, menu items, screen

elements, etc.

Warning, Caution, Information, and Tip Icons

This User Manual includes Warning, Caution, and Information where appropriate to point

out safety related or other important information. It also includes Tip to point out useful

hints to the reader. The corresponding symbols should be interpreted as follows:

Electrical warning icon indicates the presence of a hazard that could result in electrical

shock.

Warning icon indicates the presence of a hazard that could result in personal injury.

Caution icon indicates important information or warning related to the concept

discussed in the text. It might indicate the presence of a hazard that could result in

corruption of software or damage to equipment/property.

3BSE066174R301 A 7

Page 8

About This User Manual

Terminology

Information icon alerts the reader to pertinent facts and conditions.

Tip icon indicates advice on, for example, how to design your project or how to use

a certain function

Although Warning hazards are related to personal injury, and Caution hazards are

associated with equipment or property damage, it should be understood that operation

of damaged equipment could, under certain operational conditions, result in degraded

process performance leading to personal injury or death. Therefore, fully comply with all

Warning and Caution notices.

Terminology

A complete and comprehensive list of terms is included in System 800xA Terminology

and Acronyms (3BSE089190*). The listing includes terms and definitions that apply to

the 800xA System where the usage is different from commonly accepted industry standard

definitions.

DescriptionTerm

AC 100

AC 400

Control Builder A

800xA

3BSE066174R301 A 8

Advant Controller 100 - Advant (Master) family of Controllers: AC 55,

AC 70, AC 80, AC 110 and AC 160.

Advant Controller 100 integration into Process Portal A800xA for AC 100

Advant Controller 400 - Advant (Master) family of Controllers: AC 410

and AC 450.

Advant Controller 400 integration into Process Portal A800xA for Advant Master

Control Builder A is a configuration tool used to configure and program

the Advant Controller 100 and Advant Controller 400.

Product containing functionality for efficient control and

supervision of an automated process. Key functions are

presentation of process graphics, process dialogs and

presentation of alarms and trends.

Control Builder A with all its software productsCBA Suite Installation

Page 9

About This User Manual

Released User Manuals and Release Notes

Released User Manuals and Release Notes

Table: Related Documentation

DescriptionTitle

System 800xA 6.0 Licensing Information

(2PAA111691-600)

Application Builder User’s Guide (3BDS100560*)

Function Chart Builder User’s Guide

(3BDS100595*)

On-line Builder User’s Guide (3BDS100596*)

On-line Builder Reference Manual (3BSE001974*)

Bus Configuration Builder User’s Guide

(3BDS100312*)

PROFIBUS Library Editor User’s Guide

(3BDS100603R201)

AMPL Configuration Advant Controller 100 Series

Reference Manual (3BSE009626R501)

AMPL Configuration Advant Controller 400 Series

Reference Manual (3BSE002417R601)

Source Code Handling User's Guide

(3BSE003838R101)

Control Builder A 1.4 Release Notes

(3BSE080911*)

Provides information about Central Licensing

System (CLS).

This book describes the Application Builder (APB).

This book describes the Function Chart Builder

(FCB).

This book describes the On-line Builder (ONB).

This book describes the functions of On-line

Builder (ONB).

This book describes the Bus Configuration Builder

tool of the Control Builder A product.

This book describes the utility PROFIBUS Library

Editor of Control Builder A

This manual describes the AC 100 engineering

workflow.

This manual describes the AC 400 engineering

workflow.

This manual describes how to use source code

for Function Chart Builder.

This release notes describes new and changed

functions of Control Builder A 1.4

A complete list of all User Manuals and Release Notes applicable to System 800xA is

provided in System 800xA Released User Documents (3BUA000263*).

3BSE066174R301 A 9

Page 10

3BSE066174R301 A 10

Page 11

1 Installation of Control Builder A

1.1 Installation Procedures

1 Installation of Control Builder A

1.1 Installation Procedures

1.1.1 Recommended PC Performance and Capacity

Recommended performance and capacity of the PCs for different node types can be

found through http://www.abb.com/product/us/9AAC171278.aspx.

If PU410 is used, a separate Network interface is required in the personal computer.

1.1.2 Software Requirements

McAfee VirusScan® Enterprise and Symantec Endpoint Protection (SEP) have been

tested and are qualified virus scanners for use with Control Builder A.

The user should make sure that the installation procedure completes without exposing

the computers to malware or malicious network traffic of any sort.

This can only be done by limiting the communication to the system and by performing

separate virus scanning of any portable media or disks before connecting them to the

system nodes during the installation. After completing the system installation and

configuration (post installation) it is recommended to perform a full virus scan of all

computers in the system.

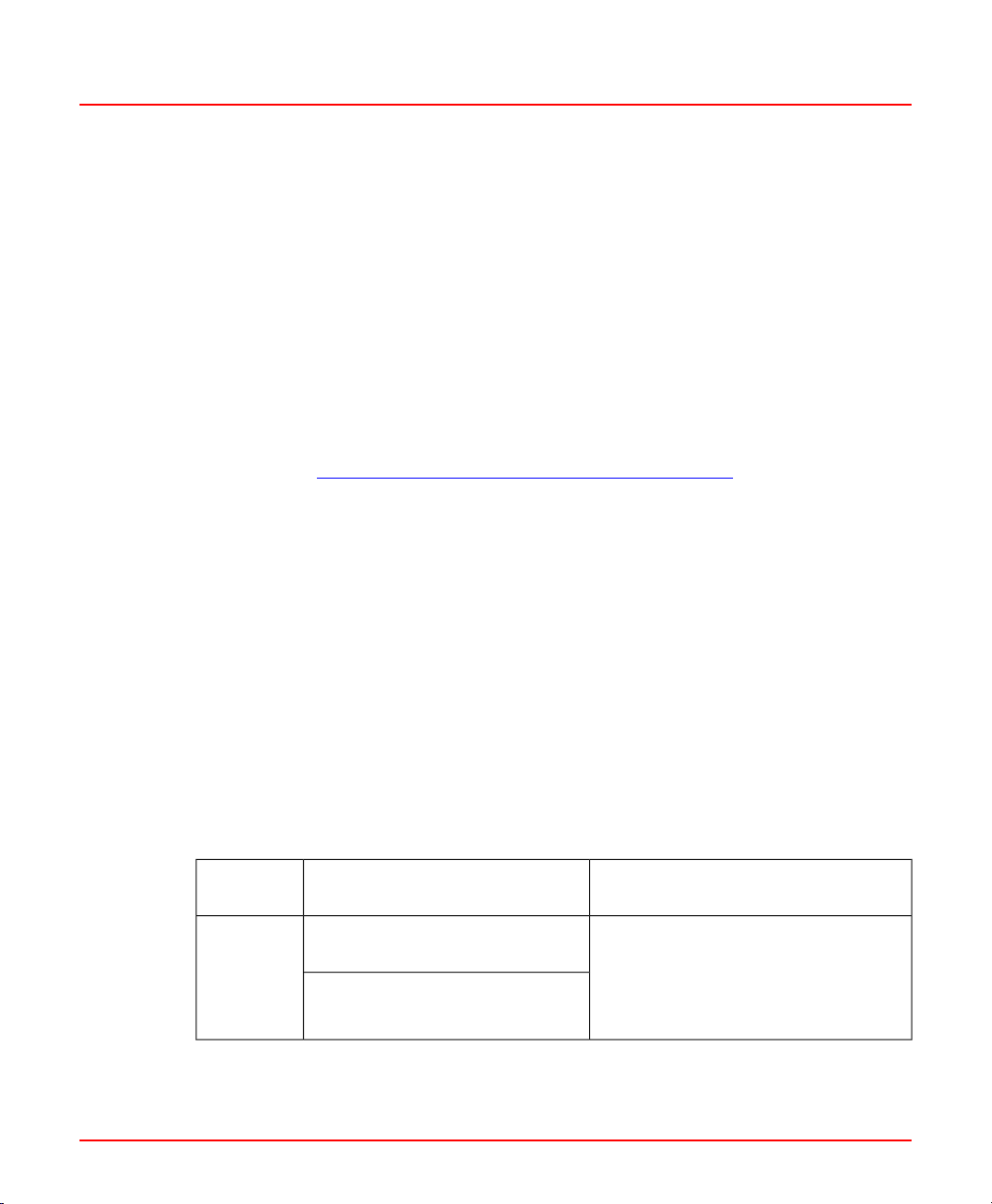

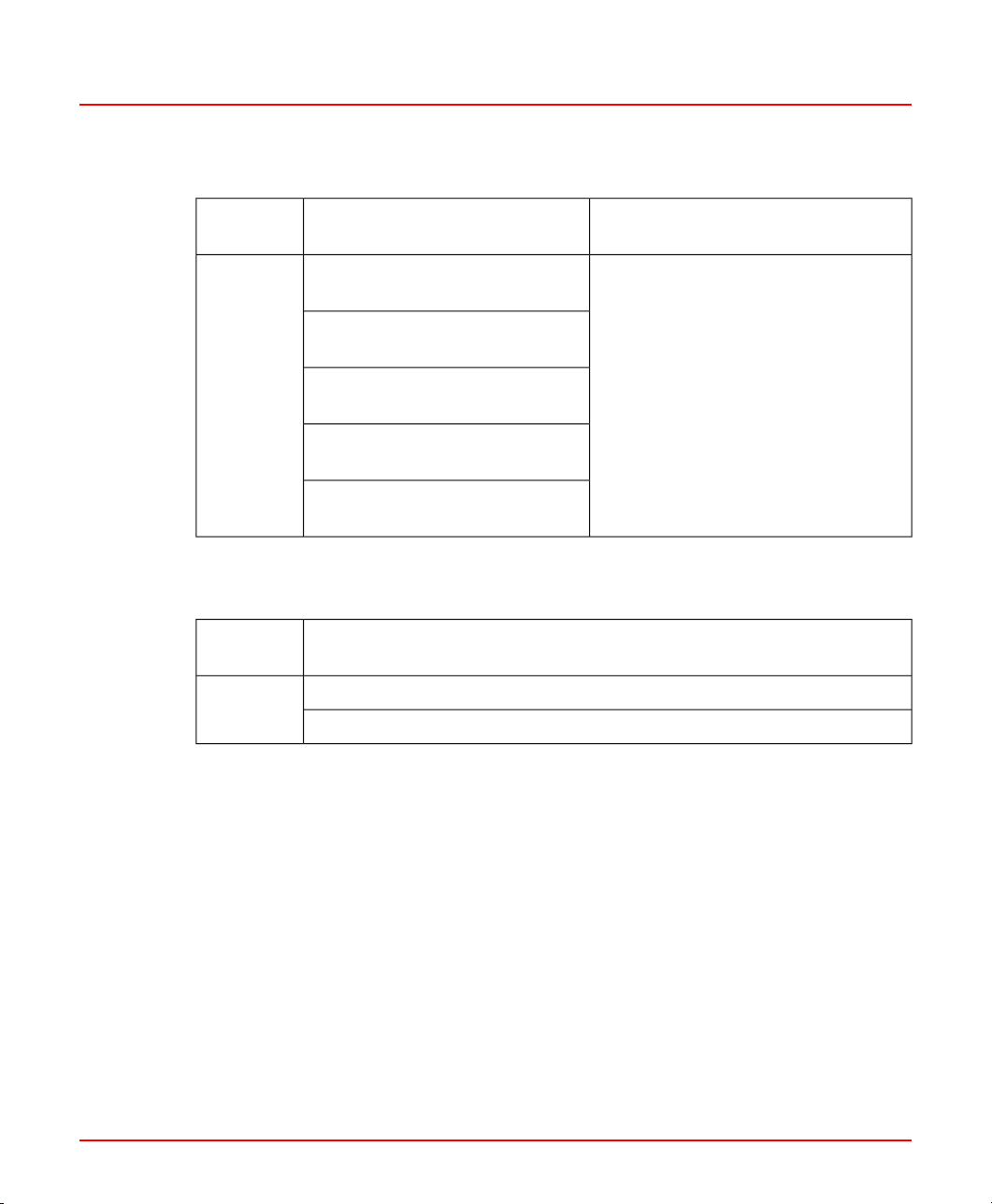

Table 1.1: Server Operating Systems

System

Version

6.1

3BSE066174R301 A 11

Operating System version

Windows Server 2016 LTSB

Standard/Datacenter

Windows Server 2012 R2

Standard/Datacenter Update

1. 64-bit Versions to be used

1

Required Hotfixes and additional

Comments

Server with Desktop Experience. Install

the latest qualified update as per Third

Party Security Updates Validation

Status for System 800xA,

3BSE041902.

Page 12

1 Installation of Control Builder A

1.1 Installation Procedures

Table 1.2: Client Operating Systems

System

Version

Operating System version

Windows 10 Enterprise 2016

LTSB

Windows 10 IoT Enterprise 2016

LTSB

6.1

Windows 10 Enterprise 2015

LTSB

Windows 10 IoT Enterprise 2015

LTSB

Windows 8.1 Update

Professional/Enterprise

1. 64-bit Versions to be used

Table 1.3: Prerequisite Software

System

Version

Required Software (Included on the CBA Media)

ABB 800xA Common 3rd Party Install

6.1

ABB Central Licensing System (CLS) has to be installed

1

Required Hotfixes and additional

Comments

Install the latest qualified update as

per Third Party Security Updates

Validation Status for System 800xA,

3BSE041902.

3BSE066174R301 A 12

Page 13

1 Installation of Control Builder A

1.1 Installation Procedures

1.1.3 CBA Suite Installation

1. Log on the computer as a user with administrator privileges.

2. Insert the Control Builder A installation media and the Autorun display is seen as

shown in Figure 1.1.

Figure 1.1: Control Builder A autorun display

3BSE066174R301 A 13

Page 14

1 Installation of Control Builder A

1.1 Installation Procedures

3. If the Autorun display does not appear, double click on the autorun.exe located in

the root of the Control Builder A installation media.

4. Click on Release Notes in the upper right of the Autorun display to get information

about Control Builder A.

Click on CBA Suite Installation and the menu as shown in Figure 1.2 appears:

Figure 1.2: Autorun display with CBA Suite Installation selected.

1.1.4 800xA Common 3rd Party Install

800xA Common 3rd Party Install should be installed before any other installation. Click

on Install 800xA Common install to proceed.

1.1.5 Central Licensing System

Click on Install Central Licensing System to install 800xA Central licensing system.

For a single Engineering Station it is recommended to select a standalone installation,

which will not require enabling of Internet Information Services (IIS) components.

More information on Central Licensing System (CLS) is available in System 800xA 6.0

Licensing Information (2PAA111691-600) .

3BSE066174R301 A 14

Page 15

1 Installation of Control Builder A

1.1 Installation Procedures

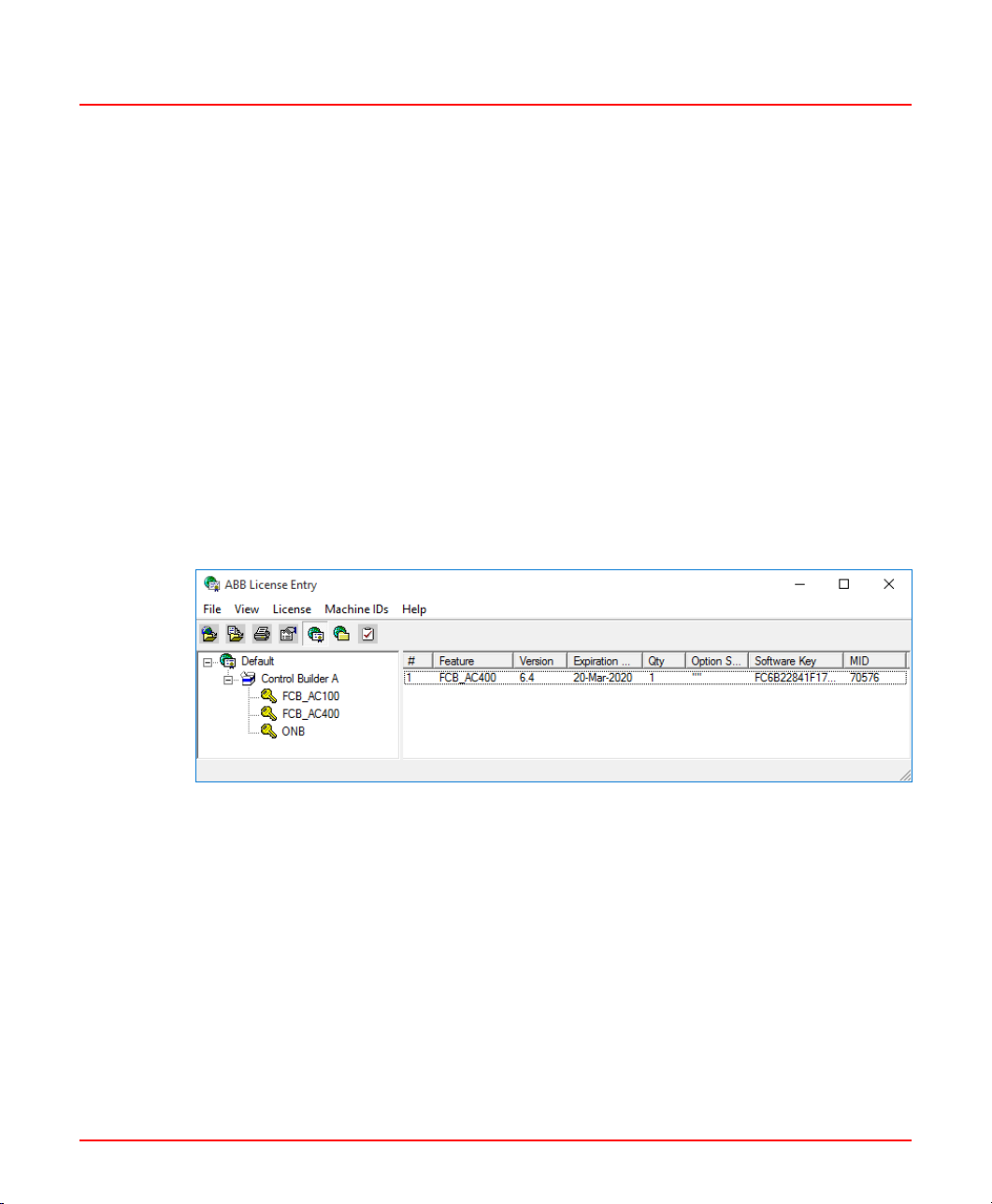

Three different licenses for Control Builder A:

• FCB_AC100

One licence is required for each PC running Function Chart Builder with node type

AC 100, e.g. AC 55, AC 70, AC 110 or AC 160.

• FCB_AC400

One licence is required for each PC running Function Chart Builder with node type

AC 400.

• ONB

One licence is required for each PC running On-line Builder.

Load Control Builder A licenses (.SLA file) into the licensing system with the ABB

License Entry tool:

In the ABB start menu choose ABB System 800xA > System > Licensing > License

Entry and then File > Load / Replaces Licenses.

Figure 1.3 shows an example of CBA licenses as presented in ABB Licence Entry tool:

Figure 1.3: CBA licenses in the ABB License Entry tool

3BSE066174R301 A 15

Page 16

1 Installation of Control Builder A

1.1 Installation Procedures

1.1.6 Control Builder A Products

1. Click on Install Control Builder A Suite, see Figure 1.2 to start installation of Control

Builder A products. The display shown in Figure 1.4 appears.

Figure 1.4: ABB Control Builder A Installation Wizard

2. Click Next to continue.

3BSE066174R301 A 16

Page 17

1 Installation of Control Builder A

1.1 Installation Procedures

3. Select Control Builder A products by modifying the check boxes .

Figure 1.5: Selecting the Control Builder A products

AMPL PC & DB Element Library for all supported targets will be installed as part of

Function Chart Builder.

Use the Browse button to change the Configuration Path and the Installation

Path and the Project Path. But it is recommended to keep the default values.

Figure 1.6 displays the Control Builder A products already installed.

3BSE066174R301 A 17

Page 18

1 Installation of Control Builder A

1.1 Installation Procedures

Figure 1.6: Control Builder A products installed

4. Click Next to continue.

There are no more installation selections for Application Builder, Function Chart

Builder and Bus Configuration Builder. Additional displays for On-line Builder are

described in Additional Displays During On-line Builder Installation on page 21.

5. Click Finish to exit.

Verify the Control Builder A installation

To verify the Control Builder A installation go to Control Panel > Program and Features.

Figure 1.7 shows an example of entries after a complete Control Builder A installation.

Each product can be uninstalled separately.

3BSE066174R301 A 18

Page 19

1 Installation of Control Builder A

1.1 Installation Procedures

Figure 1.7: Example for complete Control Builder A installation

Always uninstall AMPL PC and DB Element Libraries before Function Chart Builder.

Windows Firewall

Click on Configure Windows Firewall, see Figure 1.2, to configure the Windows Firewall

for the Control Builder A products. Only required if the computer will act as a server.

Restart the computer after Control Builder A is installed before configuring the firewall.

1.1.7 Manual Installation

A manual installation can be made as an alternative to the CBA Suite Installation

described in the previous section.

Click on Manual Installation in the Autorun display.

Click on 3rd Party Software & Tools and click on 800xA Common Install to install the

software manually. See figure 1.8.

3BSE066174R301 A 19

Page 20

1 Installation of Control Builder A

1.1 Installation Procedures

Figure 1.8: Autorun Window - 3rd Party Software and Tools

Central licensing and RNRP can be installed by clicking on Base Functionalities, see

figure 1.9.

Figure 1.9: Autorun Window - Base Functionalities

By clicking on Control Builder A, each of the Control Builder A products can be installed

individually by clicking on the corresponding product, see figure 1.10.

3BSE066174R301 A 20

Page 21

1 Installation of Control Builder A

1.1 Installation Procedures

Figure 1.10: Autorun Window - Control Builder A

AMPL PC & DB Element Library must be installed after Function Chart Builder is

installed.

1.1.8 Additional Displays During On-line Builder Installation

Some additional selections must be made during On-line Builder installation:

3BSE066174R301 A 21

Page 22

1 Installation of Control Builder A

1.1 Installation Procedures

Figure 1.11: Selecting the location for the Engineering Board

More info about PU410, including configuration of Network Interface Card, can be found

in section PU410.

Driver Installation

Figure 1.12 displays for about two minutes during the PU410 driver installation. 13 driver

instances and 13 WudfHost processes (visible in the Windows Task Manager) will be

created by the driver installation.

3BSE066174R301 A 22

Page 23

1 Installation of Control Builder A

1.1 Installation Procedures

Figure 1.12: Updating drivers during PU410 driver installation

1.1.9 Engineering Board setup

The Engineering Board setup (EBSetup) window is displayed if LOCAL was selected as

Engineering Board location during installation.

To configure the Engineering board:

1. Insert the MB300 Network number of the Engineering Board in the Network 1/2 field.

2. Insert the MB300 node number in the Node field.

3BSE066174R301 A 23

Page 24

1 Installation of Control Builder A

1.2 Server and Client Configuration

3. Select the MasterBus protocols: MB300, MB300F or MB300E in the Protocol field.

Figure 1.13: Configuring the EBSetup

4. Click OK to continue.

1.2 Server and Client Configuration

Function Chart Builder (FCB) and On-line Builder (ONB) can run in a client/server

configuration. The user interface is running in the client and the controller connected to

the servers, see figure 1.14.

3BSE066174R301 A 24

Page 25

1 Installation of Control Builder A

1.2 Server and Client Configuration

Figure 1.14: Configuration Diagram

The communication between client and server is based on DCOM which require some

configurations described in the rest of this section.

1.2.1 Server Configuration - DCOM

The following DCOM settings are required on servers to enable access in CBA from

clients:

1. Press Flag + R, select Run and type dcomcnfg.

2. Click on Component Services > Computers > My Computer, right click and select

Properties.

3BSE066174R301 A 25

Page 26

1 Installation of Control Builder A

1.2 Server and Client Configuration

3. Select the Default Properties tab, check Enable Distributed COM on this

computer as shown in Figure 1.15

Figure 1.15: Enabling Distributed COM on this computer

3BSE066174R301 A 26

Page 27

1 Installation of Control Builder A

1.2 Server and Client Configuration

4. If server for ONB, browse to AdvaBuild Engineering Board Server in the main

DCOM config window. If server for FCB, browse to AdvaBuild Communicator as

shown in Figure 1.16.

Figure 1.16: Selecting component services

3BSE066174R301 A 27

Page 28

1 Installation of Control Builder A

1.2 Server and Client Configuration

5. Right click, select Properties and click on Security tab.

Figure 1.17: Security settings

6. Select Customize and click Edit... in the Launch and Activation Permissions

area.

3BSE066174R301 A 28

Page 29

1 Installation of Control Builder A

1.2 Server and Client Configuration

7. Add the user group IndustrialITUser and check Allow option for all listed permissions

and click OK as shown in Figure 1.18.

Figure 1.18: Setting the Launch and Activation Permission

You can replace IndustrialITUserS with the user group or the user(s) you want to

allow access to CBA from Clients. This is applicable for the rest of the configuration.

3BSE066174R301 A 29

Page 30

1 Installation of Control Builder A

1.2 Server and Client Configuration

8. Select the Identity tab, check The launching user and click OK.

Figure 1.19: Selecting the user account to run this application

3BSE066174R301 A 30

Page 31

1 Installation of Control Builder A

1.2 Server and Client Configuration

1.2.2 Client configuration – Engineering Board Setup

Configure the following on clients with CBA installed. Enter the servers with the CBA

option ONB installed that are planned to be used for connection to the controllers in the

Engineering Board Setup dialog as follows:

1. In ABB Start menu select ABB Advant Master > Control Builder A > Utilities >

Engineering Board Setup.

2. Select the Use Engineering Board of the following servers as shown in Figure

1.20 to add the concerned servers. Click OK.

Figure 1.20: Adding servers using the EBSetup dialog box

3BSE066174R301 A 31

Page 32

1 Installation of Control Builder A

1.2 Server and Client Configuration

3. The On-line Builder tries to use an engineering board on a server starting with the

first computer in the list. The first running and not locked PC is used as server.

• Click the Add button to add another computer to the server list.

• Click Disable to disable a PC for use as Engineering Board server.

• Click Delete to remove a PC from the Engineering Board server list.

• Use the Move Up and Move Down buttons to rearrange the listed servers.

• Use the Test Server button to test the selected Engineering Board Server as

shown in Figure 1.21.

Figure 1.21: Testing the Engineering Board Server

Result from Connect Call shows text containing the result of the connect call.

The most common messages are:

• The operation completed successfully

The server PC is correctly configured and is able to work as server for On-line

Builder.

• The RPC server is unavailable

3BSE066174R301 A 32

Page 33

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

This message occurs when the server PC could not be reached. Possible

reasons for this are that the server might be switched off or the network

connection fails

• Access is denied

User is not allowed to access this server PC.

• Class not registered

On-line Builder is not installed on the server PC or the registration is deleted.

View Server Events and View Client Events

You can inspect any event on the server side by pressing View Server Events. The

same can be done for events on the client.

Locked by

If a server is locked, the locking user is displayed in the Locked by control.

Unlock

Use this button to unlock the server. Unlock is not allowed if the server is a Connectivity

Server.

The session established by this user is interrupted!

1.3 PU410 External Engineering Board

1.3.1 Introduction

The external RTA unit PU410 replaces the engineering board PU516. PU410 is a

standalone hardware unit which supports both single and dual point to point connection

via Ethernet. Single or redundant connection with MasterBus 300 is enabled via RJ-45

connectors. It also has one port for direct connection to a AC 400 controller.

3BSE066174R301 A 33

Page 34

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

1.3.2 PU410 Specification

• Connectors

– Two shielded RJ-45 connectors for 100Mbit/s full duplex communication with

the PC.(PC 1 and 2 ports)

– Two shielded RJ-45 connectors for 10Mbit/s half duplex communication with

MasterBus 300/300E or eDCN control network. (MB300/eDCN 1 and 2 ports)

– Two 15-pos DSUB socket connector for RS232 and RS422 communication

with Control Builder A, CBA. (CBA port)

– One 9-pos DSUB socket connector for RS232 communication for debug and

upgrading of firmware. (SERVICE port)

• Power

100-230V AC, 50-60 Hz.

• Power consumption

Typical 12W without I/O connected. Maximum 25W.

• Size

HxWxD (mm): 45 x 433 x 243.

• Net weight: 3.2 kg.

3BSE066174R301 A 34

Page 35

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

The information label shown in figure 1.22 is attached underneath the unit.

Figure 1.22: PU410 Information label

In case of rack assembly, place the PU410 unit so that the connectors and the reset

button are within reach.

Before returning the PU410 unit for maintenance or repair, always remove accessories

such as brackets and cables.

3BSE066174R301 A 35

Page 36

F P

R IP

Rear View

F P

RIP

Front View

PU410

ABB

SERVICE

PC

1

2

MB300/eDCN

1

2

CBA DCN2 DCN1

9-pos Dsub

socket

RJ-45

connectors

15-pos Dsub

socket

connector

connector

IEC 320

power

connector

Reset switch

LED indicators meaning, front and rear:

LED

indicators

P= Power (green)

F = Fault (red)

IP = IP address reset (yellow)

R = Run (green ashing)

Two spare

LEDs

Ventilation

holes

Ventilation

holes

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

Figure 1.23 shows the rear and front view of PU410.

Figure 1.23: Front and rear view of PU410

Since the PU410 unit includes a supervised fan it is recommended to check the fan and

vacuum clean the unit from time to time.

If a fan problem is detected the red fault LED will be illuminated and the unit will shut

down. The red fault LED will still be illuminated until the unit is reset, even if the fan

problem disappears.

The red fault LED can illuminate for other problems as well.

3BSE066174R301 A 36

Page 37

Two brackets included for 19”

rack mounting

Two feets included

for stand alone

mounting

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

The red fault LED will also illuminate for a few seconds at PU410 start-up.

1.3.3 Mechanical Installation

The PU410K01 kit includes brackets for 19” rack mount and for floor or desktop mounting.

Figure 1.24: Brackets for PU410 Installation in 19" rack or stand alone

Connection to AC 400

Connect PU410 to AC 400 controller directly by using CBA port or use the MB300 ports

to connect via MB300.

Connection to Engineering Station

The PU410 unit has two ports called PC 1 and 2 for connection to the Engineering Station.

Only one port is necessary for the communication but if redundancy is wanted both ports

can be used if RNRP is configured.

3BSE066174R301 A 37

Page 38

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

Figure 1.25: Connecting PU410 to Engineering station

• Always use shielded Cat 5e (or better) twisted pair cross-over cables to reduce

electric noise disturbances. The maximum cable length is 30m but keep cable length

as short as possible.

• The default IP addresses of PU410 are for the PC 1 port 172.16.168.50 and for the

PC 2 port 172.17.168.50.

3BSE066174R301 A 38

Page 39

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

• The recommended IP address for the Network Interface Card, NIC, in the Engineering

Station is 172.16.168.1 with subnet mask 255.255.252.0 when using single cable.

Figure 1.26: Internet Protocol (TCP/IP) Properties

• The default IP address of PU410 and identical IP address of NIC can be used in

multiple Engineering Stations, as 172.16.168.x and 172.17.168.x are ‘local’ IP

addresses.

• When using dual cables, the IP address of the additional NIC in the Engineering

Station is recommended to be 172.17.168.1 with subnet mask 255.255.252.0. The

status of the dual connection can be viewed in the RNRP network event monitor,

provided that RNRP is installed in Engineering Station.

3BSE066174R301 A 39

Page 40

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

• When the connection between Engineering Station and PU410 is lost, e.g. due to

communication problem or power loss in PU410, it will be detected in the Engineering

Station after four seconds if RNRP is configured.

• The PU410 unit communicates with 100Mbit/s on the PC 1 and 2 ports. It is

recommended to configure the network interface card in the Engineering Station to

100Mbit/s full duplex.

Figure 1.27: Example of NIC Configuration

• RNRP can be used to supervise the communication between the Engineering Station

and PU410. The detection time for lost communication will increase from 4s to at

least 30s if RNRP is not configured correctly. No additional RNRP configuration is

required when the default implicit configuration of RNRP is used.

3BSE066174R301 A 40

Page 41

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

• If the default implicit configuration of RNRP is modified, an explicit configuration of

RNRP must be added for the PU410 connection. Configure "Network area" to 10

and "Network area local" to 1 if the default IP addresses for PU410 are used.

• The IP address and subnet mask of PU410 can be modified by a tool, but this is

required only if Network area 10 (NetId 172.16.40.0) is already used in the

Engineering Station (refer to Modify IP address of PU410 on page 41). RNRP

requires the IP address of the first port of PU410 to always start with 172.16 (in

PU410 FW version 1.0.1.0 and earlier). The default IP addresses of PU410 are

restored by pressing and holding down the reset switch of PU410 for about 20

seconds until the yellow IP LED is lit.

Modify IP address of PU410

The IP address of PU410 shall be modified only if NetId 172.16.40.0 is already used

in Engineering Station.

Execute the following steps to modify the IP address of PU410.

1. Start the ManagementTool.exe located in

C:\AdvaBNT\ONB\32r1\Driver PU410.

2. Select the IP Config view and click Get.

3. Modify the IP settings and click Set.

The modified IP address will be effective when the PU410 is reset, in the Reset view or

by pressing the reset switch of PU410 unit.

3BSE066174R301 A 41

Page 42

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

Figure 1.28: IP Config view of Management Tool

After modifying the IP address of PU410, the Target IP address of Management Tool

must be modified in the Settings menu to get contact again. The Target IP address

is shown at the bottom left in the Management Tool.

A registry setting must be modified in the Engineering Station to match the modified IP

address of PU410 (see Figure 8). Right click the IP address, select Modify from the

context menu, and enter the Primary IP address of PU410. This modification is effective

when the Engineering Station is restarted.

3BSE066174R301 A 42

Page 43

1 Installation of Control Builder A

1.3 PU410 External Engineering Board

Figure 1.29: IP address setting in Registry

3BSE066174R301 A 43

Page 44

3BSE066174R301 A 44

Page 45

Revision History

Revision History

Revision History

This section provides information on the revision history of this User Manual.

Revision History

The following table lists the revision history of this User Manual.

The revision index of this User Manual is not related to the Control Builder A revision.

Revision

Index

DateDescription

August 2014Published for Control Builder A 1.4/0-

April 2019Published for Control Builder A 1.4/2A

3BSE066174R301 A 45

Page 46

3BSE066174R301 A 46

Page 47

Page 48

www.abb.com/800xA

www.abb.com/controlsystems

800xA is a registered or pending trademark

of ABB. All rights to other trademarks reside

with their respective owners.

We reserve the right to make technical

changes to the products or modify the

contents of this document without prior

notice. With regard to purchase orders,

the agreed particulars shall prevail.

ABB does not assume any responsibility

for any errors or incomplete information in

this document.

We reserve all rights to this document

and the items and images it contains.

The reproduction, disclosure to third parties

or the use of the content of this document

– including parts thereof – are prohibited

without ABB’s prior written permission.

Copyright © 2019 ABB.

All rights reserved.

3BSE066174R301 A

Loading...

Loading...