Page 1

—

OPTIONS FOR ABB DRIVES

ACx-AP-x Assistant control panels

User’s manual

Page 2

—

List of related manuals

Tool and maintenance manuals Code (English)

Drive composer PC tool user's manual 3AUA0000094606

Option manuals and guides

ACx-AP-x Assistant control panels User’s manual 3AUA0000085685

CDPI-01 communication adapter module User’s manual 3AXD50000009929

DPMP-01 mounting platform for ACP-AP control panel 3AUA0000100140

DPMP-02/03 mounting platform for ACP-AP control

panel

You can find manuals and other product documents in PDF format on the Internet. See

section Document library on the Internet on the inside of the back cover. For manuals

not available in the Document library, contact your local ABB representative.

3AUA0000136205

Page 3

User’s manual

ACx-AP-x Assistant control panels

Table of contents

2018 ABB Oy. All Rights Reserved.

3AUA0000085685 Rev E

EN

EFFECTIVE: 2018-07-11

Page 4

Page 5

Table of contents 5

Table of contents

1. Introduction to the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Installation and start-up

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety

3. Control panel overview

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Display, keys and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

USB connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

RJ-45 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type code label on the panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type code label on the panel package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Battery cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wireless interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Basic operation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

User interface overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control panel navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Navigation memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Home view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Navigating in the Home view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Common user tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Basic operation of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System information and help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Faults and warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Basic settings and assistants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Backups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 6

6 Table of contents

5. Functions in the main Menu

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Navigating in the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Complete list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

By function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Favorites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Modified. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adding parameters to the Home view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Editing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Editing numeric parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Editing selection list parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Editing bit-field parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Editing texts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Resetting counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Assistants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Launching an assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Generating a QR code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Energy efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

History graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Load profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Backups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Creating a parameter backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Restoring a parameter backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

System info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Primary settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6. Functions in the Options menu

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Options menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting the reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Editing the contents of the Home view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7. Control of multiple drives

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Connecting multiple drives to a control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Selecting drive menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Selecting a drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Panel features with multiple drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Panel views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

The Help page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Graph data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Page 7

Table of contents 7

Backups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Customized content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Assistants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Faults and warnings with multiple drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Faults and warnings in the currently selected drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Faults and warnings in other drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8. Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Identifying error and warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9. Service and maintenance

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Removing the control panel cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Cleaning the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Cleaning the connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Replacing the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Control panel software updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Recycling instructions and environmental information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10. Panel-to-PC USB connection

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

USB connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting control panel to PC USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Connecting a PC tool to a drive through the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Connecting in local control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Connecting in remote control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Transferring files between the control panel and a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11. Technical data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

IEC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

LCD specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Bluetooth interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Bluetooth encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

FCC and Industry Canada certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

FCC ID: 2AFNGAPWSERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

IC: 20555-APWSERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 8

8 Table of contents

Generic disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Cybersecurity disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Further information

Page 9

Introduction to the manual 9

1

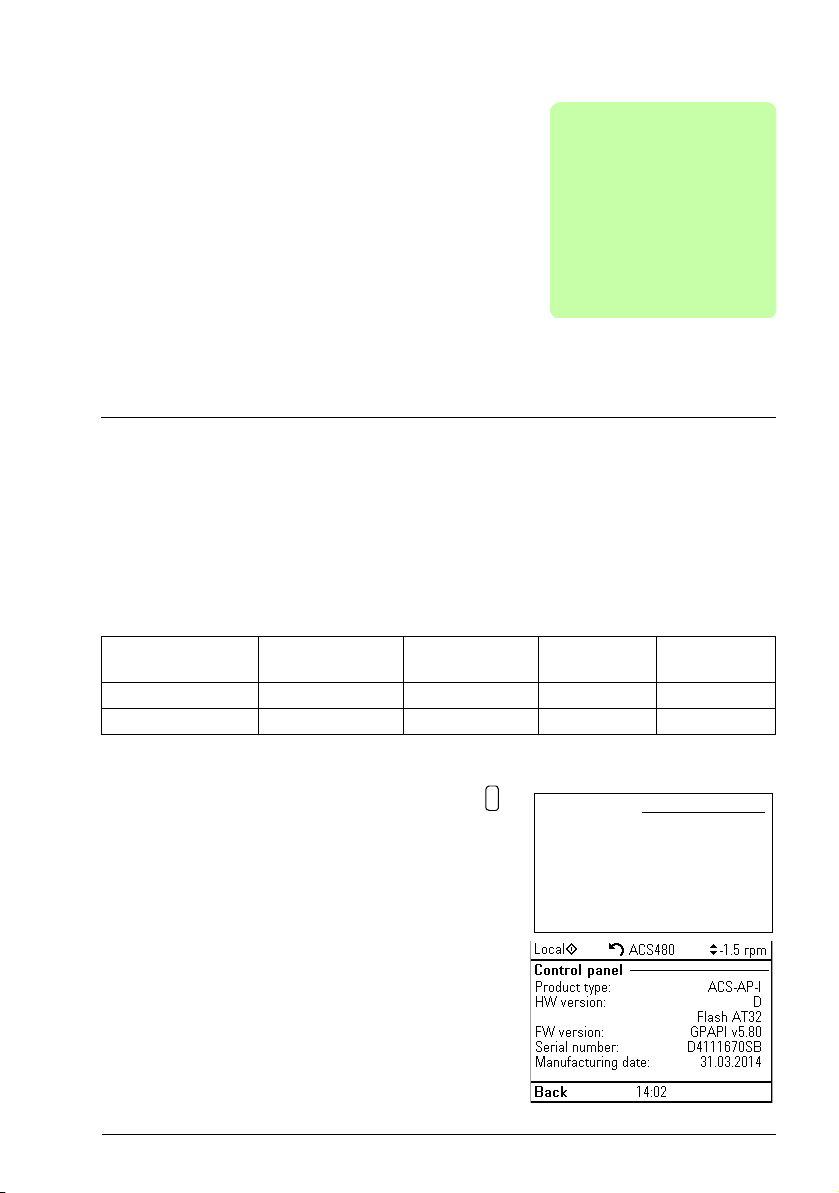

Control panel

Product type: ACS-AP-I

HW version: D

FW version: GPAPI v5.80

?

Introduction to the manual

What this chapter contains

The chapter describes the applicability, compatibility, intended audience and the

contents of this manual.

Applicability

This manual applies to the following panel types and their versions:

Control panel type ACS-AP-I and

ACS-AP-S

Hardware version C or later A or later C or later A or later

Software version 4.61 or later 5.01 or later 5.00 or later 5.40 or later

ACS-AP-W ACH-AP-H ACH-AP-W

You can also view panel details in the panel itself using either of the two methods:

• With panel still not powered, press and hold

(help) button, then power up the panel through

USB or drive.

or

• With panel powered up, go to Menu

info

→ Control panel.

→ System

Page 10

10 Introduction to the manual

Note: The images and instructions in this manual are examples, each based on a

specific control panel and drive type combination. The details may vary with different

control panels or drive types.

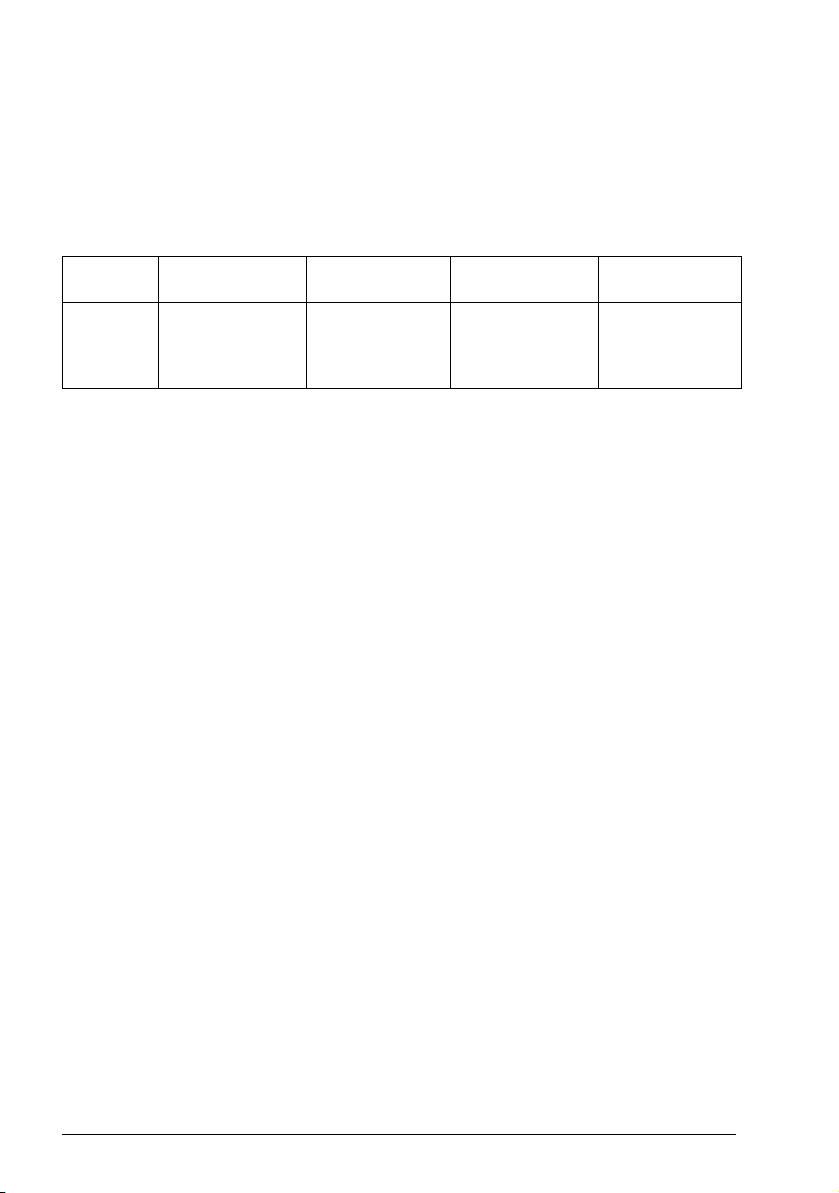

Compatibility

The following drive(s) are compatible with these panel types.

Control

panel type

Drive ACS380, ACS480,

ACS-AP-I ACS-AP-S ACS-AP-W ACH-AP-H,

ACH-AP-W

ACS530, ACS560,

ACS580, ACQ580,

ACS860, ACS880

ACS380, ACS4 80,

ACS530, ACS5 60,

ACS580

ACS380, ACS480,

ACS530, ACS560,

ACS580, ACQ580 ,

ACS860, ACS880

ACH480,

ACH580 , ACQ580

Note: This table may not be comprehensive. See the appropriate drive manual for

more details.

Safety

Follow all safety instructions delivered with the drive.

Intended audience

This manual is intended for persons who use an ACx-AP-x Assistant control panel.

Contents of the manual

The information in the manual is organized in the following chapters:

• Installation and start-up describes the installation and start-up of the control panel.

• Control panel overview describes the main parts of the control panel and their

functions.

• Basic operation describes the menu structure, views and basic functions of the

control panel.

• Functions in the main Menu describes the functions in the main Menu.

• Functions in the Options menu describes the functions in the Options menu.

• Control of multiple drives describes how to control several drives with one control

panel.

• Fault tracing describes how to identify different fault and warning messages and

how to solve problem situations.

• Service and maintenance describes service-related functions and routine

maintenance tasks.

• Panel-to-PC USB connection describes interaction between a PC and the control

panel.

Page 11

Introduction to the manual 11

• Technical data describes the parts, dimensions and materials of the control panel,

and other technical data about the control panel.

Page 12

12 Introduction to the manual

Page 13

Installation and start-up 13

2

A

B

Installation and start-up

What this chapter contains

The chapter describes how to install and start-up the Assistant control panel for the

first time.

Installation

Attach the control panel directly to the drive

or use a separate mounting kit (for

example, for cabinet door mounting).

To attach the control panel,

1. Place its bottom end into the bottom of

the slot in the drive (A).

2. Pivot the control panel and push the

upper part (B) until you hear a click.

To detach the control panel,

1. Release the control panel by pressing

the clip (B).

2. Pull the upper end of the control panel

out of the slot in the drive.

Page 14

14 Installation and start-up

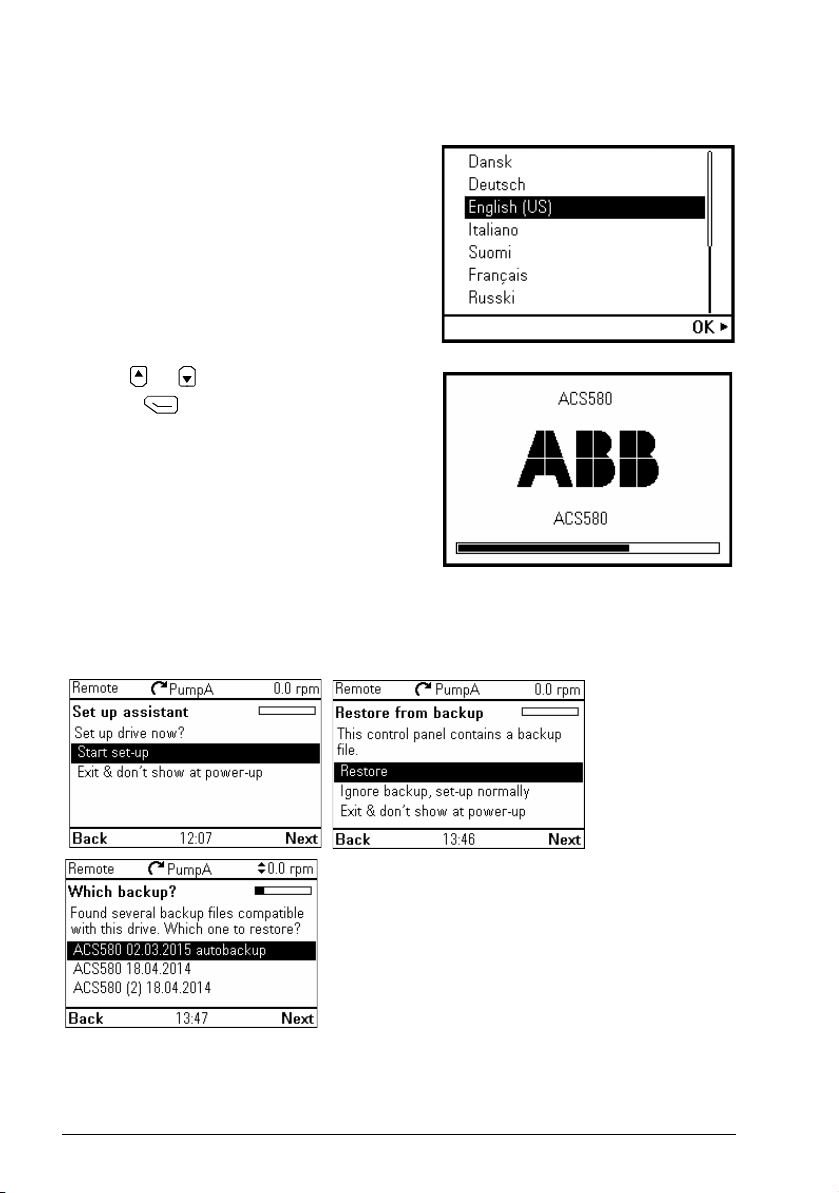

First start-up

To start-up the control panel for the first time,

follow the instructions:

1. Obey all drive-specific safety precautions.

2. Install the control panel. See instructions

in Installation (page 13).

3. Power up the drive.

The control panel start-up begins

automatically.

shows the language selection view.

4. Use or to select a language.

5. Press to confirm your selection

Wait until the control panel completes

uploading the language file. Its progress is

indicated by a progress bar.

If there is a Basic set-up assistant in the drive, or if the control panel already contains

a compatible backup (or backups) that could be copied to the drive, the control panel

prompts a question.

Wait until the control panel

.

Page 15

Installation and start-up 15

Once you are in the Home view, the control panel is ready for use.

Page 16

16 Installation and start-up

Page 17

Control panel overview 17

3

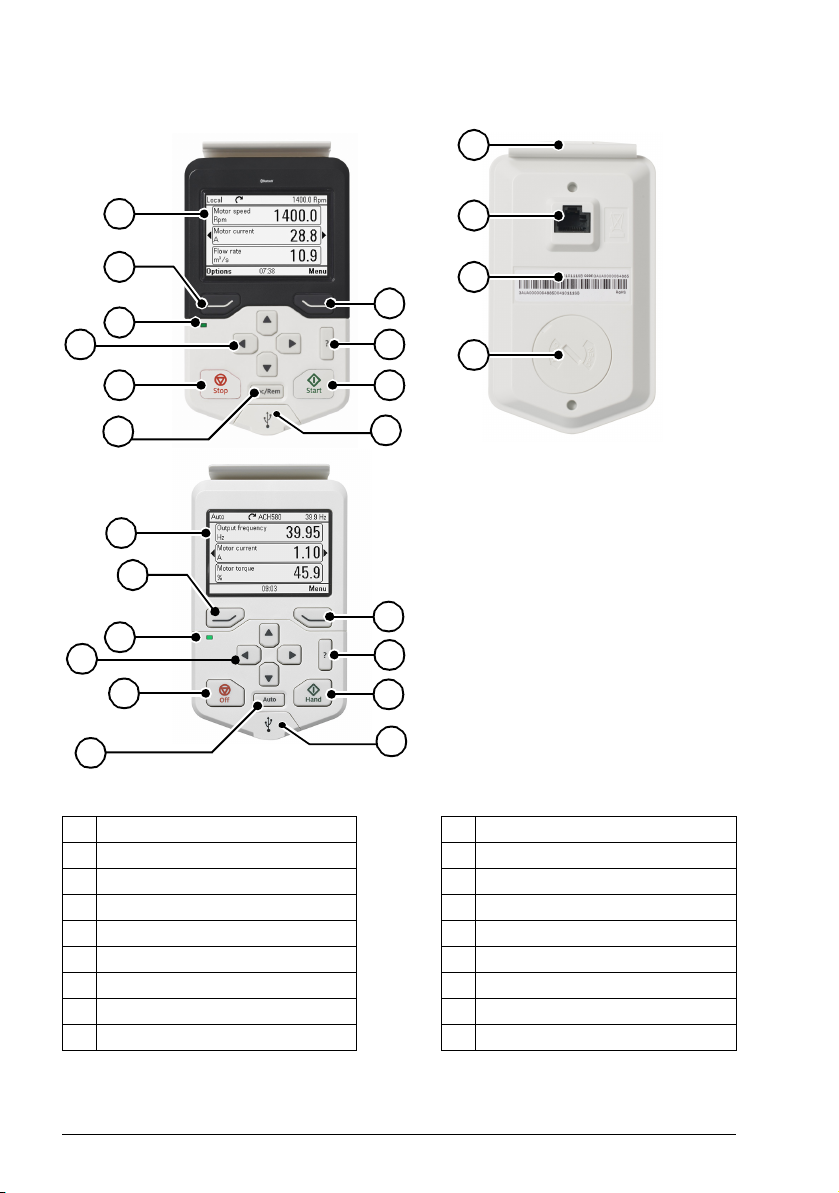

Control panel overview

What this chapter contains

The chapter describes the display, keys and main parts of the Assistant control panel.

Page 18

18 Control panel overview

12

11

13

14

1

4

3

6

7 8

5

10

2

9

1

2

3

4

5

6

15

16

17

10

Display, keys and parts

1 Display 10 USB connector

2 Left softkey 11 C lip

3 Right softkey 12 RJ-45 connector

4 Status LE D 13 Type code label on the panel

5 Help 14 Battery cover

6 Arrow keys 15 Off

7Stop (see Start and Stop)16Hand

8 Start (see Start and Stop)17Auto

9 Local/Remote (see Loc/Rem)

Page 19

Control panel overview 19

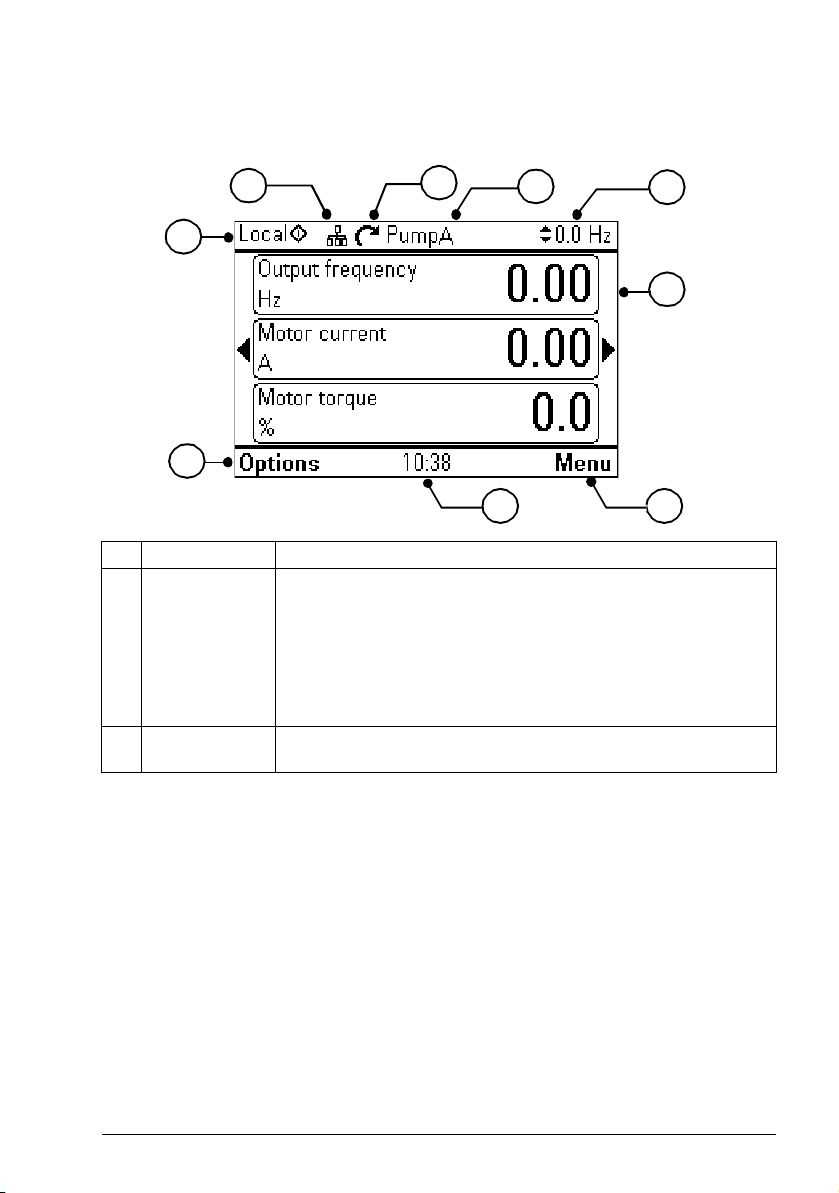

1

2

3

4

6

7

7

5

8

Display

In most views, the following control panel elements are shown on the display:

No. Panel element Function

1 Control location

and related icons

2 Panel bus Indicates that there are more than one drive connected to this

Indicates how the drive is controlled:

No text: The drive is in local control, but controlled from another

device. The icons in the top pane indicate which actions are allowed.

Local: The drive is in local control, that is, controlled from the control

panel.

Remote: The drive is in remote control, that is, controlled through I/O

or fieldbus.

panel.To switch to another drive, go to Options

→ Select drive.

Page 20

20 Control panel overview

Status icon Animation Drive status

- Stopped

- Stopped, start inhibited

Blinking Stopped, start command given but start inhibited

Blinking Faulted

Blinking Running, at reference, but the reference value is 0

Rotating Running, not at reference

Rotating Running, at reference

No. Panel element Function

3 Status icon Indicates the status of the drive and the motor. The direction of the

arrow indicates forward (clockwise) or reverse (counter-clockwise)

active reference direction.

Note: For non-rotating driven equipment, the numbers 1 and 0 are

used to indicate that the drive is running or stopped, respectively.

4 Drive name If a name is given, it is displayed at the top pane. By default, it is

blank. You can change the name in the Primary settings (page 45) or

Settings menu (page 44).

5 Reference value Speed, frequency and so on, are shown with its unit. For information

6 Content area Displays the actual content of the view in this area. The content

7Softkey

selections

8 Clock Displays the current time. The time can be changed through the

on changing the reference value, see Setting the reference (page 50).

varies from view to view. The example view above is the main view of

the control panel which is called the Home view.

Displays the functions of the softkeys (

context.

Primary settings (page 45) or Settings menu (page 44).

and ) in a given

You can adjust the display contrast and backlight functionality in the Primary settings

(page 45) or Settings menu (page 44).

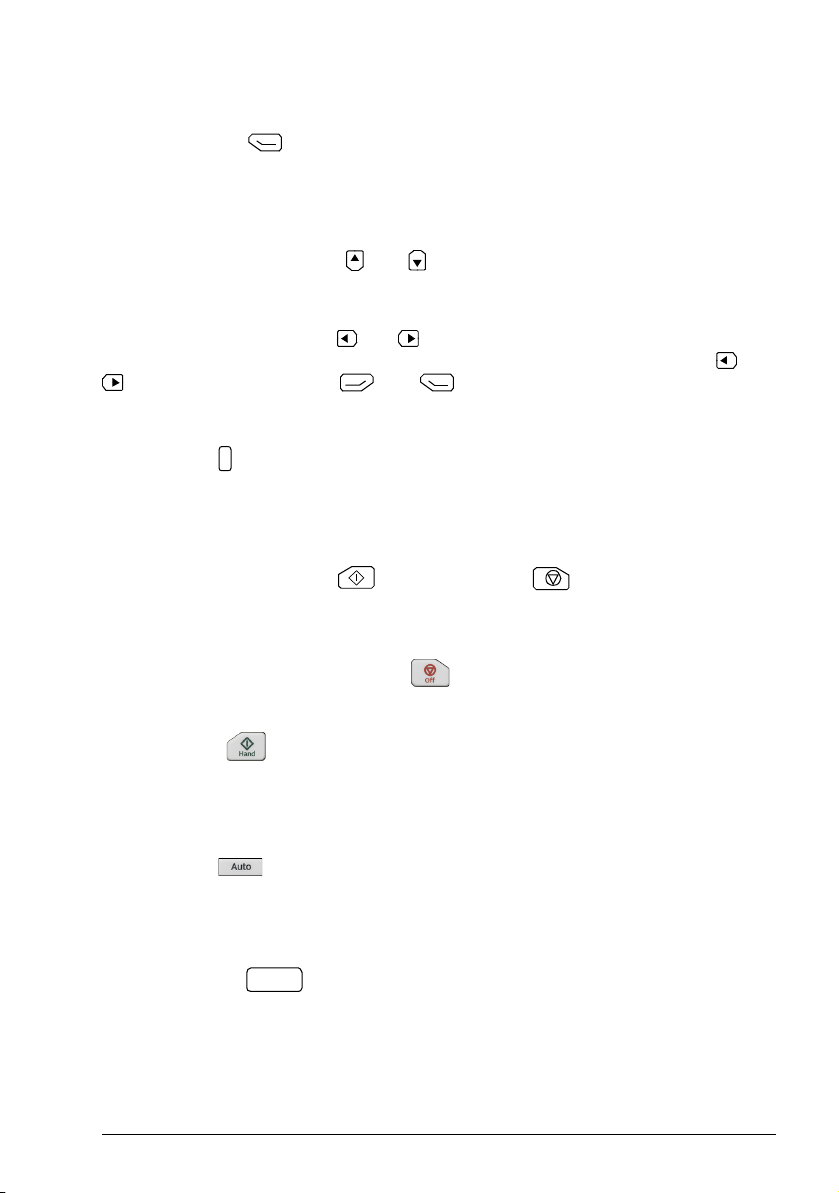

Keys

The keys of the control panel are described

below.

Left softkey

The left softkey ( ) is usually used for

exiting and canceling. Its function in a given

situation is shown by the softkey selection in

the bottom left corner of the display.

Holding down exits each view in turn until you are back in the Home view. This

function does not work in special screens.

Page 21

Control panel overview 21

?

Loc/Rem

Right softkey

The right softkey ( ) is usually used for selecting, accepting and confirming. The

function of the right softkey in a given situation is shown by the softkey selection in

the bottom right corner of the display.

Arrow keys

The up and down arrow keys ( and ) are used to highlight selections in menus

and selection lists, to scroll up and down on text pages, and to adjust values when,

for example, setting the time, entering a passcode or changing a parameter value.

The left and right arrow keys ( and ) are used to move the cursor left and right in

parameter editing and to move forward and backward in assistants. In menus, and

function the same way as

and , respectively.

Help

The help key (

) opens a help page. The help page is context-sensitive, in other

words, the content of the page is relevant to the menu or view in question. See Help

(page 28) for more information on the help page.

Start and Stop

In local control, the start key ( ) and the stop key ( ) start and stop the drive,

respectively.

Off

In Hand and Auto control, the Off key ( ) is used to stop the drive.

Hand

The Hand key ( ) is used to start the drive in local mode. When the drive is

running, if you switch to Auto mode, the drive changes the control location to Remote

mode and the drive may stop.

Auto

The Auto key ( ) is used to run the drive automatically. The control is selected

from primary or secondary or any DI. You can give the reference inputs in Menu ->

Primary settings -> Drive or by setting the values in parameter groups 19 and 20.

Loc/Rem

The location key ( ) is used to switch the control between the control panel

(Local) and remote connections (Remote). When switching from Remote to Local

while the drive is running, the drive keeps running at the same speed. When

switching from Local to Remote, the status of the remote location is adopted. See the

drive-specific firmware manual for more details.

Page 22

22 Control panel overview

Key shortcuts

The table below lists key shortcuts and combinations. Simultaneous key presses are

indicated by the plus sign (+).

Shortcut Available in... Effect

+ + any view Save a screenshot. Up to fifteen images can be stored

in the control panel memory. For instructions on how to

transfer the images into a PC, see section Transferring

files between the control panel and a PC (page 66).

+ ,

any view Adjust backlight brightness.

+

+ ,

any view Adjust display contrast.

+

or Home view Adjust reference.

+ parameter edit

views

Revert an editable parameter to its default value.

+ any view Show/hide parameter index and parameter group

numbers.

(keep down)

any view Return to Home view by pressing down the key until

Home view is shown.

Status LED

The control panel has a status LED that indicates if there are any faults or warnings

present. The table below shows the meaning of the LED indications.

Green, continuous The drive is functioning normally.

Green, flickering Data is transferred between the PC tool and drive through the USB

connection of the control panel.

Green, blinking There is an active warning in the drive.

Red, continuous There is an active fault in the drive.

Blue, blinking Bluetooth interface is enabled.It is in discoverable mode and ready

Blue, flickering Data is transfered through the Bluetooth interface of the control

for pairing.

panel.

For further information on fault and warning indications, see Identifying error and

warning messages (page 57).

USB connector

The USB connector is used for connecting the control panel to a PC. When

connected, the control panel acts as an USB adapter for data transfer between the

PC tool and the drive. It is also possible to transfer data between the PC and the

control panel through the USB connection.

Page 23

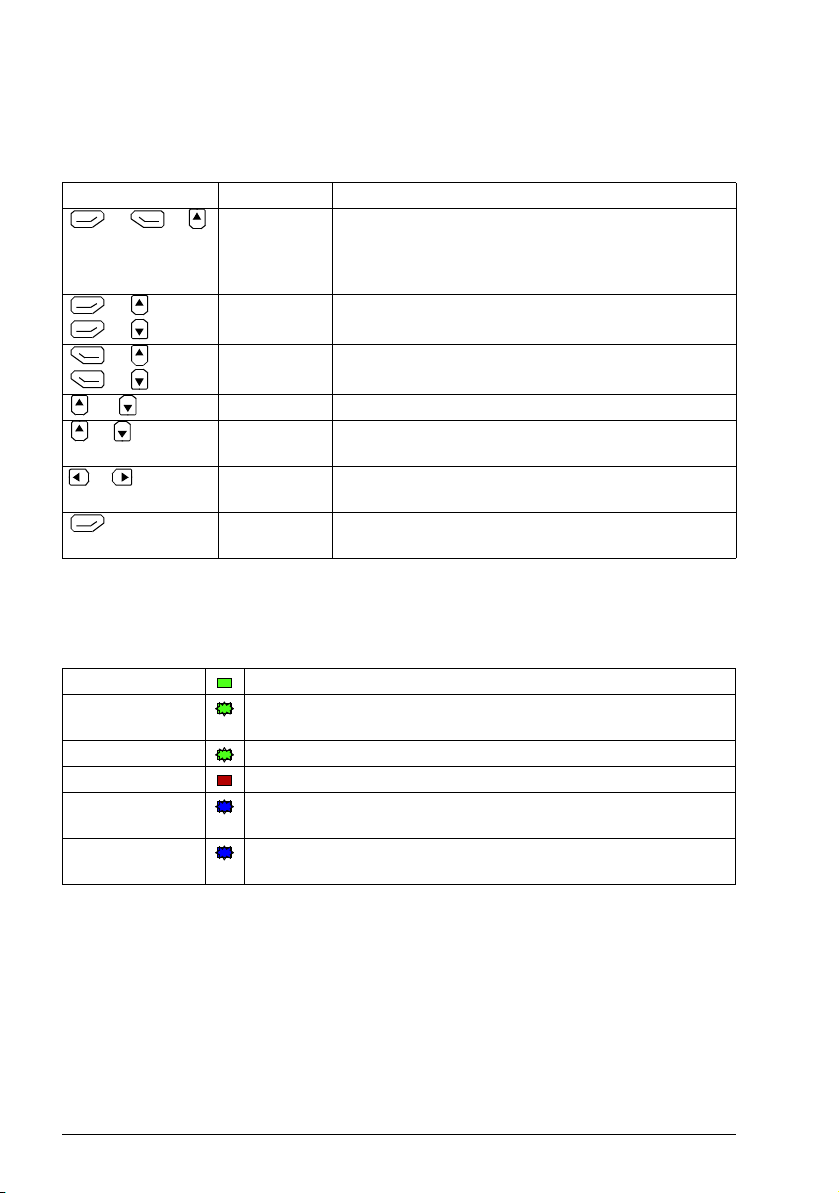

Control panel overview 23

ABB Oy M/N ACS-AP-W S/N:B5320064WU CODE:3AXD50000025964

3AXD5000002 5964B5320064WU RoHS SW: v5.02

FCC ID: 2AFNGAPWSERIES IC:20555-APWSERIES

Type code

ABB Oy

Bar

code

Bar code in readable text

FCC ID

and IC CANADA

numbers

SW version

RoHS marking

MRP code

Serial number

DMS document: 3AXD00000602026

ACS-A-I ABB Oy

6438177306757 SW: v5.80

Type code

ABB Oy

SW version

RoHS marking

MRP code

of the kit

Serial number

of panel inside

the kit

3AUA000008831 RoHS

S/N: A0210001LL

EAN code

Bar code

EAN bar code

EAN number

code

DMS document: 3 AXD00000602026

See Panel-to-PC USB connection (page 63).

RJ-45 connector

The RJ-45 connector is used to electrically connect the control panel to the drive.

Mechanical connection is achieved with the clip on the top.

Type code label on the panel

The type code label on the panel contains revision information. See an example label

below.

Note: FCC ID and IC CANADA numbers are applicable only for ACS-AP-W and ACHAP-W wireless control panels.

Type code label on the panel package

The type code label on the panel package contains revision information. See an

example below.

Page 24

24 Control panel overview

Battery cover

Underneath the battery cover there is a compartment for the battery that powers the

real-time clock of the control panel.

Wireless interface

The ACS-AP-W and ACH-AP-W Assistant control panels with Bluetooth interface

enable wireless interface for ABB drives. The wireless panels are also embedded

with powerful processor and memory that enables faster communication.

The functions of

• ACS-AP-W panel are same with ACS-AP-I and ACS-AP-S panels, and

• ACH-AP-W panel are same with ACH-AP-H panel.

Page 25

Basic operation 25

4

Basic operation

What this chapter contains

The chapter describes the basic operations and components of the user interface. It

also lists the common user tasks and provides instructions to complete the task.

User interface overview

The user interface has the following main components:

Component Description

Home view Used to monitor signals. See Home view (page 22).

Menu Access to most functions of the control panel. See the detailed

description in chapter Functions in the main Menu (page 31).

Options Used to set a reference, change the motor direction, select the drive,

edit Home view pages, and see the fault and warning status. See the

detailed description in chapter Functions in the Options menu

(page 27).

Help Provides information on the current view or menu or on possible

problems associated with it. See Help (page 22).

Faults and warnings View faults and warnings when the drive or control panel experiences

an error. See Fault tracing (page 57).

Page 26

26 Basic operation

Parameters

Assistants

Energy efficiency

Event log

History graphs

Backups

System info

Settings

Home view

Reference

Direction change

Select drive

Edit Home view

Menu

Options

Active faults

Active warnings

Control panel navigation

Use the arrow keys and softkeys for navigation. Follow the choices on the screen.

Note: The menu shown is an example only. The Menu varies based on the drive/

device to which the panel is connected.

Navigation memory

The Assistant control panel has a navigation memory that allows you to backtrack

your steps through the user interface with the arrow keys and . The path you

have last accessed remains in the memory for 10 minutes.

• The left arrow key ( ) moves you backwards in the menu structure.

If you press repeatedly, you return back to the Home view.

• The right arrow key ( ) moves you forward in the menu structure.

If you press repeatedly, you move forward along the path in the menu structure

you had previously accessed.

Page 27

Basic operation 27

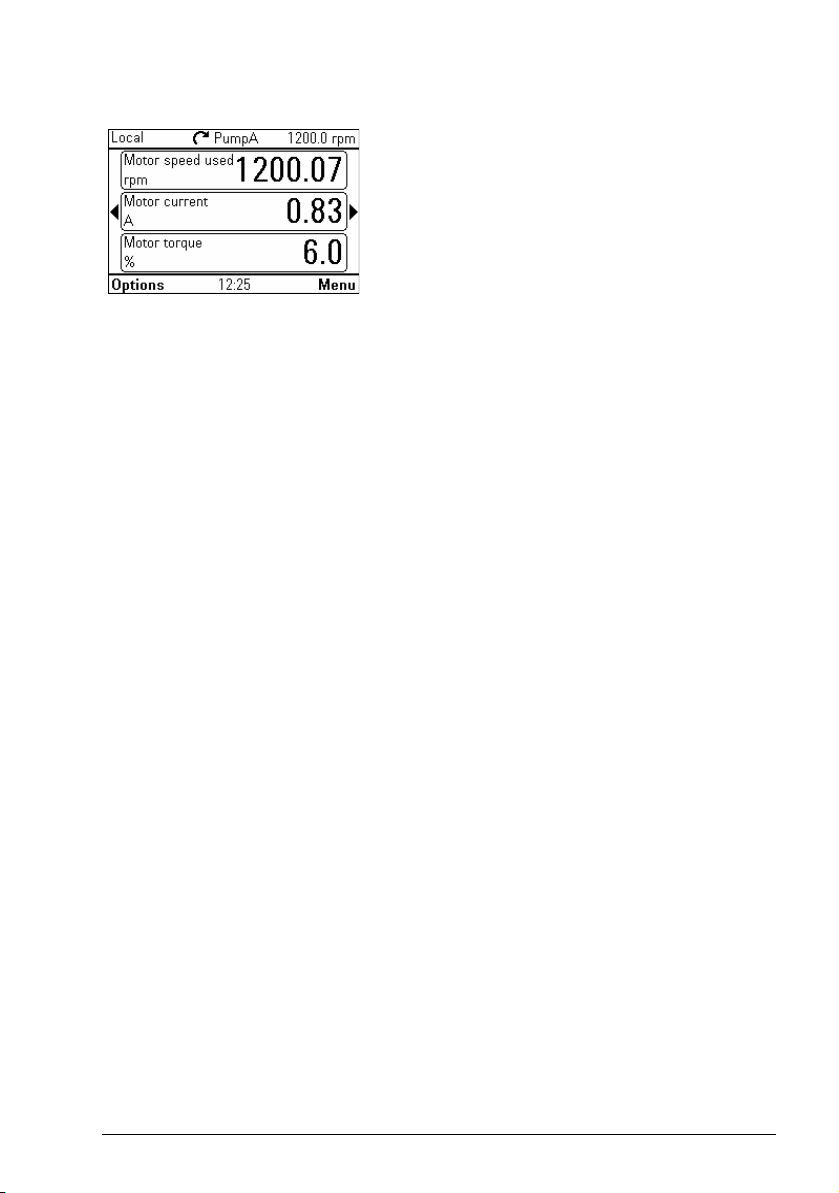

Home view

The main view of the control panel is called the Home view. In the Home view, you

can monitor the status of the drive, such as its speed, torque or power. The Home

view has one or more pages, each of which can display up to three signals.

The number of pages and the signals shown on each page are customizable, and the

Home view configuration is saved to the drive whenever you change it. The maximum

total number of signals displayed varies from 9 to 21, depending on the drive. In the

example below, three Home view pages are used, showing different display formats.

Each application macro and user set has a default Home view configuration. When

you select an application macro or restore a user set, the Home view configuration

changes accordingly. There is a default Home view configuration in each drive, which

can be restored in the Primary settings (page 45) or Settings (page 44) menu.

Note: The Menu varies based on the drive/device to which the panel is connected.

The Home view opens automatically when you power up the drive. The Home view is

also displayed from the Options menu or the main Menu if no key is pressed for

10 minutes.

Tip: You can return to the Home view from any view except special screens by

holding down the left softkey

.

Navigating in the Home view

• Use and to move between the different pages of the Home view. The

page numbers are shown while you scroll between pages.

• Use or to adjust the reference (visible in the top right corner). See also

Setting the reference (page 27).

•Press (Menu) to open the main Menu (see Functions in the main Menu

on page 31).

•Press

Options menu on page 27).

(Options) to open the Options menu (see Functions in the

Page 28

28 Basic operation

???

Help

You can open a context-sensitive help page in all menus and views by pressing .

The help page provides information on the use of the current view or menu, or on

possible problems associated with it.

On the help page, you can press again or press (Exit) to exit.

Using

itself. See instructions in section Applicability (page 9).

, you can also view details of control panel type and version in the panel

Page 29

Basic operation 29

Loc/Rem

Common user tasks

The following tables list common user tasks and describes how to complete the task.

See chapters Functions in the main Menu (page 33) and Functions in the Options

menu (page 49) for detailed descriptions of functions in the menus.

Note: The Menu options varies based on the drive/device to which the control panel

is connected.

Basic operation of the drive

Task Actions

Start and stop the drive. In local control, press to start the drive and

to stop the drive.

Set the reference (for example, speed) in

the Home view.

Switch between local and remote control. Press .

Change the direction of motor rotation. In local control, go to Home view, press

Parameters

In local control, go to Options > Reference. Set

the reference with the arrow keys. For detailed

instructions, see Setting the reference (page 50).

(Options) to open the Options menu and select

Direction change.

Task Actions

Choose parameters displayed on the

Favorites list.

View/edit parameters. Go to Menu

Add parameters to the Home view. See Editing the contents of the Home view

Show/hide parameter index and group

numbers.

Restore parameter default value. In the editing mode, press + .

View parameters that differ from

Application Macro defaults.

Go to Menu → Parameters → Favorites →

Edit. See also Editing the list of favorites

(page 35).

→ Parameters → Complete list to

view parameters.

See Editing parameters (page 35) for instructions

on editing parameters.

(page 50).

Press + .

To save the default value, press (Save).

Go to Menu

→ Parameters → Modified.

Page 30

30 Basic operation

???

System information and help

Task Actions

How to get help. Press to open the context-sensitive help.

To view drive information. Go to Menu

To view control panel version. Go to Menu

To view application program

license.

To view Product application

information.

Go to Menu

Go to Menu

→ System info → Drive.

→ System info → Control panel.

→ System info → Licenses.

→ System info → Product application.

Faults and warnings

See Fault tracing (page 57) for detailed information on faults and warnings.

Task Actions

Hide/view an active fault. Faults are automatically displayed. If you hide a fault by

Open help page on a fault. Press to view the help page.

Reset an active fault. Press (Reset) to reset an active fault.

View tripping faults. Go to Menu

Hide/view an active warning. Warnings are automatically displayed. If you hide a warning

Open help page on a warning. Press (How to fix) or to view the help page.

Reset an active warning. Warnings disappear automatically once the condition that

View past warnings and faults. Go to Menu

pressing (Hide), it automatically reappears after 60

seconds of no key presses. You can also view the fault

through Options > Active faults.

→ Event log → Faults.

by pressing (Hide), it automatically reappears if the

warning is still active after 60 seconds of no key presses.

has triggered it goes away.

→ Event log → Other events.

Basic settings and assistants

Task Actions

Adjust backlight brightness. Press and hold , and press or .

Adjust display contrast. Press and hold , and press or .

Change language. Go to Menu

Change time and date, and

related settings.

Launch an assistant. Go to Menu

Go to Menu

launch.

→ Settings → Language.

→ Settings → Date & time.

→ Assistants and select an assistant to

Page 31

Basic operation 31

Backups

Task Actions

Create a backup. See Creating a parameter backup (page 42).

Restore a backup. See Restoring a parameter backup (page 42).

Page 32

32 Basic operation

Page 33

Functions in the main Menu 33

5

Functions in the main Menu

What this chapter contains

The chapter describes the functions in the main Menu.

Menu

All functions of the control panel are accessed

through the Menu which is the main menu of the

user interface. The sub-menus of the Menu are

listed below and they are described in more

detail in the subsequent sections. The submenus depend on the product that is controlled

with the control panel.

The following sub-menus varies based on the drive/device to which the panel is

connected:

Sub-menu Function See page...

Parameters View and edit parameters. 34

Assistants Launch an assistant. 34

Energy eff iciency

Event log View information on faults and warnings. 40

History graphs View the load profile. 41

Backups Save settings in the control panel memory and restore them

System info View information on the drive and options. 43

Settings View and change time and date settings, language, display

Use energy-saving features. 40

41

to the drive.

43

and other settings, and edit texts.

Page 34

34 Functions in the main Menu

Sub-menu Function See page...

Primary settings View and change settings related to motor, PID, fieldbus,

advanced functions, clock, region, and display.

I/O Provides terminal name, number, electrical status and

logical meaning of the drive.

Diagnostics Provides faults and warnings information and helps to

resolve potential problems.

45

46

46

Navigating in the Menu

• Use or to select a menu item.

•Use or (Exit) to go back to the Home view.

•Use

or (Select) to enter the selected sub-menu.

Parameters

In the Parameters menu, you can view and edit

parameters. There are four sub-menus through

which you can access the parameters. In each

sub-menu, the grouping principle of the

parameters is different.

In each sub-menu, you can edit a parameter by

highlighting it and pressing (Edit). Counter

parameters and certain number, text and bit field

parameters are read-only and can be viewed by pressing (View).

Complete list

In the Complete list sub-menu, all parameter

groups are listed in numerical order. If you select a

parameter group, all parameters in that group are

listed and you can view and edit the parameters.

Parameter numbers are always displayed in this

sub-menu.

By function

This functionality is available in a future release.

Page 35

Favorites

In the Favorites sub-menu, only user-selected

parameters are listed. The order is determined by

the parameter number.

Editing the list of favorites

1. Select Edit.

2. Check parameters you want to show on the list

by pressing (Select).

3. Press (Done) to exit and save changes.

Modified

In the Modified sub-menu, only the parameters

whose values differ from the Application Macro

defaults are listed. The order is determined by the

parameter number.

Adding parameters to the Home view

Functions in the main Menu 35

When you view a read-only parameter in the

Parameters menu, you can add the parameter to the Home view.

•Press (Add to view) to open the

Home view in the editing mode then you

can add the parameter to an empty display

slot or replace an existing parameter with it.

•Press (Back) to go back to the

parameter view.

Editing the Home view functions are described in

more detail in Editing the contents of the Home

view (page 50).

Editing parameters

You can edit parameter values with the arrow keys.

1. Press

2. Press (Edit).

3. Use and to change the value.

4. Press (Save) to save the value, or press (Cancel) to exit the

parameter view and discard any changes.

(Select) to select the desired parameter from the list.

Page 36

36 Functions in the main Menu

5. Press + to restore the default value of the parameter (this does not save it).

See the sections below for more information on editing specific parameter types.

Editing numeric parameters

Numeric parameters include parameters with linear numeric values, passcodes, time

and date parameters, durations and exception dates. For numeric parameters with

linear values, the minimum and maximum values are displayed in the bottom left and

right corners of the content area, respectively.

• Use and to highlight digits.

• Use and to change the value.

• Press (Save) to save the value and exit the view.

• To cancel and exit, press (Cancel).

Editing selection list parameters

A selection list consists of mutually exclusive

options, such as the language selection list.

• Use and to move the cursor.

• Press (Save) to select and save the

highlighted option.

• To cancel and exit, press (Cancel).

Some selection list parameters allow you to choose another parameter as its value. In

addition to a preset list of options, you can select a parameter freely, represented by

the selection Other in the list.

Page 37

To select a parameter, follow the instructions:

2

3

4

1

1. Select Other to move to a list of parameter

groups.

2. Select a parameter group to move to a list of

parameters.

3. Depending on the parameter you are editing,

you must select a parameter or an individual bit,

or you may choose either of the two.

• If the right softkey label is Select, you must

select an individual bit as the value of the

parameter you are editing. Press

(Select) to move to a bit selection list.

• If the right softkey label is Save, you can

• If the right softkey label is Save and there is

4. Select a bit if applicable (see the previous step).

Press to invert the selected bit and press

select that parameter as the value of the

parameter you are editing. Press

(Save) to save the selection.

also an arrow on the right hand side of the

selection, you can choose an individual bit or

all the bits in that parameter. Press to

move to a bit selection list. If you want select

all the bits in the parameter, press

(Save) instead.

(Save) to save the selection.

Functions in the main Menu 37

The parameter or bit is now selected as the

parameter value.

Page 38

38 Functions in the main Menu

Editing bit-field parameters

A bit-field parameter is a bit word whose individual

bits can be edited. The labels describe the function

of each bit, and the current state of the bit is shown

as 1 or 0.

• Use and to select a bit.

• To change a bit value, press or .

• To save the bit values and exit, press

(Save).

• To cancel and exit, press (Cancel).

Editing texts

Texts that you can edit with the control panel

include parameter display names in the Home view

and their units, drive names, fault and warning

names, and other customizable notes or names.

• To select the character mode ((lower case /

upper case / numbers / special characters),

press

and then

Now you can start adding characters. The

mode remains selected until you select

another one.

• To add a character, highlight it with

• To remove a letter, press

• Press (Save) to accept the new

setting, or press

to the previous view without making

changes.

unit symbol is highlighted

select the mode with and .

and then press .

.

(Cancel) to go back

Note: The current software version supports only

the English character set (a...z).

Resetting counters

Counters are parameters that measure incremental quantities associated with the

use of the drive such as runtime or energy consumption. Counters are updated

automatically and cannot be edited, but it is possible to reset a counter to zero by

pressing down (Reset) for three seconds.

Note: If a trigger value is defined for the counter, the counter’s progress from zero to

the trigger value is shown as a bar graph.

Page 39

Functions in the main Menu 39

Assistants

In the Assistants menu, you can launch an assistant, which is a sequence of steps

that help you to complete a task, such as setting up the control panel to use with the

drive and the motor, or fixing a fault. You can also generate a QR code, which is an

optical code containing information of the drive. The code can be read with ABB

application and mobile device.

Launching an assistant

1. Use and to highlight the desired

assistant.

2. Press (Select).

3. Follow the instructions on the screen to

complete the task defined by the assistant:

• Use and to select settings.

• To edit a setting, press (Edit or

Select).

• Use and to move between the pages of the assistant. The progress bar

on the upper right corner of the screen indicates the progress.

• To exit the assistant, press (Exit).

Most settings accessed in assistant steps can also be accessed through the main

Menu or the Parameters menu, but the steps the assistants are more user-friendly.

Note: If you used the Assistants menu, complete all steps to save the changes,

otherwise the changes are canceled.

Generating a QR code

1. In the Assistants menu, select QR code using and and press

(Select).

2. Press (Continue).

Page 40

40 Functions in the main Menu

The control panel collects data and generates the code.

Press << or >> to navigate to the next screen.

You can also generate QR code from Menu

System info (page 43).

→ System info → QR code. See

Energy efficiency

In the Energy efficiency menu, you can view and

configure parameters related to energy savings,

such as kWh counters.

Event log

In the Event log menu, you can view information

collected on faults and warnings. Events are

automatically logged. See Fault tracing (page 57)

for more information on faults and warnings.

• Faults sub-menu displays the faults that

are tripped the drive.

• Other events sub-menu displays all other

faults, and warnings and their details.

• Active faults and Active warnings sub-menu displays the faults and

warnings which are active.

Page 41

History graphs

The History graphs menu contains Trends and

Load profile sub-menu.

Trends

This functionality is available in a future release.

Load profile

In the Load profile submenu, you can view and

configure load profiles. The menu contains the

following sub-menus:

• Amplitude logger 1: Opens a Histogram view,

which displays the motor current as a

distribution histogram. This logger cannot be

reset.

• Amplitude logger 2: Opens a Histogram view,

which displays the contents of an amplitude

logger as a distribution histogram. You can

select the signal to be monitored.

• Load profile configuration: Select the signal

to be monitored in Amplitude logger 2.

• Peak value logger: Select a signal to be

monitored by a peak value logger.

Functions in the main Menu 41

For more information on load profiles, see the appropriate firmware manual.

Backups

In the Backups menu, you can save parameter

settings in the control panel memory and restore

parameter settings from a backup to the drive. You

can store up to two backup files on the control

panel.

The assistant panel has a dedicated space for one

automatic backup. An automatic backup is created

two hours after the last parameter change. After completing the backup, the panel

waits for 24 hours before checking if there are additional parameter changes. If there

are, it creates a new backup overwriting the previous one.

You can copy backup files to and from a PC with any file manager application

(example, Windows Explorer).

Page 42

42 Functions in the main Menu

Some of the Backup icons are listed below:

Creating a parameter backup

1. In the Backups menu, select Create backup.

If there is a free backup slot in the control panel,

the following step is skipped.

2. Use and to select one of the existing

backup files, and press Replace.

3. Wait until the backup is completed. An animation

is shown on the control panel during the backup

process. The control panel automatically returns

to the Backups menu.

Note: If the backup process is canceled or

interrupted, the previously saved backup file is not

deleted or damaged. Thus, if you accidentally start a

backup process, you can safely cancel it before its

completion.

Restoring a parameter backup

1. In the Backups menu, select the backup file you want to restore.

2. Select View backup contents and check that it is the correct backup file and that

it is suitable for restoring.

Note: This functionality is available in a future release.

3. Select one of the restore options:

• To restore all settings, select Restore all

parameters.

• To restore a set of parameters, select

Select par restore group and select the

desired parameters from the list, and then

select Restore.

• To select application parameters, select

Select application items and select the desired parameters from the list and

then select Restore.

• To select user parameters sets, select Select user sets and select the desired

user set from the list and then select restore.

Page 43

Functions in the main Menu 43

• To select production data items, select

Select prod. data items and select the

desired production data and then select

restore.

4. Wait until the restore is completed. An

animation is shown on the control panel

during the restoring process.The control panel

automatically returns to the Backups menu.

System info

In the System info menu, you can view information about the drive, control panel,

fieldbus and any installed option modules. You can also generate a QR code that

contains the drive information.

Sub-menu Function

Drive Shows information on the selected

component, such as firmware version, serial

number, type code, device ID number or

date of manufacture.

Note: The content of the view varies

between different drive types.

Control panel Shows information on the hardware and

software version of the control panel.

Page 44

44 Functions in the main Menu

Sub-menu Function

QR code Shows an optical code containing

information of the dr ive. The code can be

read with ABB application and mobile

device.

To generate the QR code, press

(Continue).

The control panel collects data and creates

the code.

Settings

The Settings menu has the following sub-menus:

Sub-menu Function

Language Select different language in the control panel.

Date & time Set date and time, and select their display settings and whether the control

Edit texts Customize editable user interface texts, such as the drive name.

Display settings Set backlight power save on/off and adjust display contrast and brightness.

Reset to defaults Reset settings to their default

panel automatically adjusts the time for daylight savings changes. The time

and date display setting determines how time stamps are formatted.

values.

Erase fault log: This functionality

is available in a future release.

Reset Home view layout: Default

Home view settings are restored.

Reset all parameters: This

functionality is available in a future

release.

Page 45

Functions in the main Menu 45

Sub-menu Function

Show in lists Show or hide the numeric IDs of:

• parameters and groups

• option list items

•bits

• devices in Options

Pass code Enter pass codes into this parameter to activate further access levels (for

example additional parameters).

→ Select drive.

Primary settings

The Primary settings menu has the following sub-menus.

Note: The contents displayed may vary based on the drive/device to which the panel

is connected. The menu shown is only an example.

Sub-menu Function

Macro Set up drive control and reference source by selecting from a set of

predefined wiring configurations.

Drive Adjust drive related settings, such as control location, run permissions,

Motor Adjust motor-related settings, such as control mode, nominal values, ID

Loop controller Set up loop controller settings and actual values. Loop controller is only

Pump and fan

control

Communication Use the drive with a fieldbus.

Start, stop,

reference

Ramps Set up acceleration and deceleration settings.

Limits Set the allowed operating range. This function is intended to protect the

ramps, limits, constants speeds, flying starts references.

run or thermal protection. Note that the settings that are visible depend

on other selections, for example vector or scalar control mode, used

motor type or selected start mode.

used in remote control.

Controls one motor connected to the drive and up to 3 auxiliary motors.

Set up start/stop commands, reference, and related features, such as

constant speeds or run permissions.

motor, connected hardware and mechanics. The drive stays within

these limits, no matter what r eference value it gets.

Page 46

46 Functions in the main Menu

Sub-menu Function

PID Set up the settings and actual values for the process PID controller. PID

is only used in remote control.

Fieldbus To make the protocol configurations easier.

Advanced options/

functions

Clock, region,

display

Reset to defaults Enables you to reset the Home view to its original factory state.

Contains settings for advanced functions, such as triggering or resetting

faults through I/O, or switching between entire set of settings.

Contains settings for language, date and t ime, display (such as

brightness) and settings for changing how information is displayed on

screen.

I/O

In the I/O menu, each row provides terminal name,

number, electrical status and logical meaning of

the drive. Each row also provides a sub-menu that

provides further information on the menu item and

allow you to make changes to the I/O connections.

Diagnostics

The Diagnostics menu provides diagnostic

information, such as faults and warnings and helps

you to resolve potential problems. Use the menu

to make sure that the drive setup is functioning

correctly.

Note: The contents displayed may vary based on

the drive/device to which the panel is connected,

and the menu shown is only an example.

Sub-menu Function

Start, stop,

reference, summary

Limit status Describes any limits currently affecting operation. If the drive is running

Active faults Shows the currently active faults and provides instructions on how to fix

Active warnings Shows the currently active warnings and provides instructions on how to

Active inhibits Shows the currently active inhibits. The drive cannot start. Drive is not

Fault & event log Lists the faults, warnings and other events that have occurred in the

Shows where the drive is currently taking its start, stop commands and

reference. The view is updated in real time. If the drive is not starting or

stopping as expected, or runs at undesired speed, use this view to find

out where the control comes from.

at undesired speed, use this view to find out if any limitations are active.

and reset.

fix and reset.

parameterized correctly.

drive.

Page 47

Functions in the main Menu 47

Sub-menu Function

Fieldbus Provides status information and sent and received data from fieldbus for

troubleshooting.

Load profile Provides status information of load distribution (that is, drive running

time spent on each load level) and peak load levels.

Page 48

48 Functions in the main Menu

Page 49

Functions in the Options menu 49

6

Functions in the Options menu

What this chapter contains

The chapter describes functions in the Options menu.

Options menu

In the Options menu, you can control the settings

related to the Home view.

Note: The contents displayed may vary based on

the drive/device to which the panel is connected.

The menu shown is only an example.

The Options menu has the following sub-menus:

Sub-menu Function

Reference Set the reference value by using

when you save them with a key press

(page 50).

Direction change Change the direction of the motor rotation in local control mode.

Select drive Enable or disable the panel bus. If enabled, view the status of drives in

the panel bus and select which drive to control with the control panel.

See chapter Control of multiple drives (page 53).

Edit Home view Edit the contents of the Home view. See Editing the contents of the

Home view (page 50).

Active faults View an active faults. See chapter Fault tracing (page 57).

Active warnings View an active warnings. See chapter Fault tracing (page 57).

and . The changes take place

. See Setting the reference

Page 50

50 Functions in the Options menu

Loc/Rem

60.0

1200.0 rpm

Two-signal page in editing mode Empty page in editing mode

Softkey labels

and a blinking

cursor indicate

that the

control panel is

Setting the reference

You can change the reference when the drive is in the local control mode. You can

also change the reference in remote control mode if the drive configuration permits it.

Changes take effect when saved with a key press.

1. Press

to switch to the local control mode, if the text in the top left

corner of the display reads Remote.

2. In the Options menu, select Reference.

3. Change the reference by using the following keys:

• Use or to select a digit to edit.

• Use and to change the value of the selected digit.

4. Press

changes. The control panel returns to the Home view.

Tip: To adjust the reference from the Home view, press

or and the reference changes immediately. The

reference value is highlighted when you are changing it. If

you hold down the arrow key, the rate at which the value

changes accelerates.

(Save) to save the reference value, or (Cancel) to discard the

Editing the contents of the Home view

1. In the Options menu, select Edit Home view. This opens the Home view in the

editing mode.

2. In the editing mode, you can add, edit and delete the displayed parameters.

After editing the contents, press (Done) to confirm the changes and to exit

the editing mode and return to the Home view.

3. In the editing mode, use and

Home view.

• To add a new page, navigate to the page that reads Press Add to make a new

screen.

• To edit, add or delete parameters on an existing page, navigate to that page.

to move between the different pages of the

Page 51

Functions in the Options menu 51

2

31

4. Use and to move the cursor highlight.

• To add a new parameter to an existing page,

highlight an area above, between or below

an existing parameter.

• To edit or remove an existing parameter,

highlight that parameter.

5. Press (Edit) to open the Display Slot

menu.

6. Choose a parameter, its display settings and

scaling.

Note: Parameters whose values have textual

representations (such as the names of bit

states) or contain characters other than

numbers (such as dates or durations) are

automatically displayed as text. For these parameters, Display style and

selections pertaining to numeric parameters are not available.

• Parameter: Select the parameter to show in the selected slot. The most

commonly used parameters are listed as presets.

For bit field parameters, you can select either a single bit or the full bit field to add

to the Home view. With individual bits, the bit state is displayed. Full bit fields are

shown in either hexadecimal or binary format.

Note: If Empty is selected, the parameter is removed from the Home view.

• Display style: Select how the signal values are displayed. It is possible to use

different display types on the same page.

• Numeric: The parameter values are displayed as numbers (see figure 1

below). If there is only one parameter on the page, a bar graph is also

displayed.

• Gauge/bar: When there is one parameter on the page, the parameter value is

shown as a dial gauge (see picture 3 below). When there are two or three

parameters on the same page, the value is displayed as a bar graph (see the

slots in figure 2 below).

• Graph 15 minutes, 30 minutes, 1 hour or 24 hours: The parameter value is

displayed as a graph within the selected time frame (see the bottom slot in

picture 2).

Page 52

52 Functions in the Options menu

Scaling with Display signal min/max as and Signal min/max

actual min actual max

actual value

Signal min Signal max

Display signal min as Display signal max as

0

-32767 32768

-3000 6000

-50.00 100.00

display value

Note: The data shown in the graph is not stored in the drive memory, that is, if

you remove or restart the control panel, the data is lost.

• Display decimals: Specifies how many decimals are shown.

• Display name: Enter a custom label to show in the Home view instead of the

parameter name.

• Min and Max: This function depends whether Scale value range is selected or

not:

• Scale value range not selected: Select the minimum and maximum signal

values that are shown on graph displays.

• Scale value range selected: Select the actual values of the parameter that

correspond to Display min as and Display max as (see below).

• Scale value range: Select if you want to specify the value range.

• Display min as and Display max as: Select the minimum and maximum

values shown in the Home view.

This feature allows application-specific scaling to be applied.

If the parameter value is below the minimum or above the maximum, the text

Off the scale is displayed. In the graph format, small arrows are shown instead

to indicate values off the scale.

• Display unit: Customize the unit shown in Home view when scaling is used.

Page 53

Control of multiple drives 53

7

A

CB D

Control of multiple drives

What this chapter contains

The chapter describes how to control several drives with one control panel.

Connecting multiple drives to a control panel

1. Connect the control panel (A) to the first drive (B) in the panel bus.

2. Connect the first drive (C) to the second (D), the second to the third, and so on, by

daisy chaining RJ-45 leads.

Note: Each drive must have a node ID set with drive parameter 49.01 Node ID

number.

The picture shows panel bus example with ACS880-01 drives. The ACX580 and

ACX480 drives have dedicated panel bus adapters with two RJ-45 slots.

Page 54

54 Control of multiple drives

Selecting drive menu

In the Options menu, select Select drive

which lists all the drives connected to the

panel bus and shows their current status. If

panel bus is not enabled, only one drive is

shown.

In the panel bus, If the connection to the

currently selected drive fails, Select drive

menu is shown with the other drive list.

In the Select drive menu, any drives to which the connection is lost are shown in

dimmed text.

Selecting a drive

If there are multiple drives connected to the same panel bus, you can select which

drive to control with the control panel.

1. In the Options menu, select Select drive to open a list of connected drives.

2. Use and to move the cursor. When a drive is highlighted, the green LED on

the drive blinks for one second.

3. Press (Select) to change control to the highlighted drive.

Panel features with multiple drives

Panel views

In a panel bus configuration, the control panel communicates with one drive at a time.

Any information shown on the control panel, such as the status bar or signals in the

Home view pertain to the currently selected drive. Similarly, the control panel stores

data to its memory only from the currently selected drive.

Changes to the Home view configuration and any parameter changes are saved in

the drive. They can be transferred to other drives using the backup feature.

You can view information on other drives in the panel bus and switch to another drive

in the Select drive menu.

The Help page

The content of the Help page is drive-specific, and it always refers to the currently

selected drive.

Page 55

Control of multiple drives 55

Graph data

The data for the graph format in the Home view is stored in the control panel only for

the selected drive. Upon changing the selected drive, any stored graph data is

discarded, and graph data collection begins for the new drive.

History graphs and all related settings (signal selection, horizontal timescale) are

saved in the drive, and the History graphs menu shows always the graphs for the

currently selected drive. Data collection takes places independently in each drive.

Backups

The control panel can store backups from different drives. Conversely, backups from

a drive can be uploaded to another drive.

Customized content

Each drive in the panel bus has its own custom content because all the

customizations are stored in the drive.

Assistants

Assistants are drive-specific, which means that different drives in the panel bus can

have different assistants. However, the assistant framework is the same for all

assistants in all drives.

Faults and warnings with multiple drives

Faults and warnings in the currently selected drive

Faults and warnings in the currently selected drive are shown as normal.

Faults and warnings in other drives

Faults in the other drives in the panel bus appear

as remote faults.

Faults that require a restart look like any other

remote faults. They are shown normally if you

switch to the drive in which the fault has

occurred.

In the Fault view, the keys have the following

functions:

•Press

reappear as with regular faults.

•Press (Switch,) to connect to the faulted drive.

Only active warnings in the selected drive are shown in the control panel. To view

warnings in another drive, you must select that drive in the Select drive menu.

(Hide), to go back to the previous view. The fault view does not

Page 56

56 Control of multiple drives

Page 57

Fault tracing 57

8

Event Icon

Fault activate

Fault reset

Warnin g activat e

Warning deactivate

Pure event activate

Pure event deactivate

Fault tracing

What this chapter contains

This chapter describes how to identify different fault and warning messages that are

shown on the control panel and how to solve problem situations.

Identifying error and warning messages

Faults and warnings are drive states that occur when the drive detects a problem in

its operation. The display message, backlight and LED indications help you to identify

the problem.

Some of the fault and warning icons and their descriptions are mentioned below.

Page 58

58 Fault tracing

Refer to the table below to identify faults and warnings.

Display LED Type

continuous red See Faults (page 59).

blinking red Faults of this type require stopping and

restarting the drive before it continues to

function normally.

See Faults (page 59).

continuous red A fault has occurred in another drive in the

blinking green See Warnings (page 59).

panel bus.

continuous green The connection between the control panel

continuous green The control panel type is not compatible

continuous green The connection between the control panel

and the drive is faulty.

Check that the connection cable is

properly attached.

with the drive you attempt to use it with.

See Compatibility (page 10).

and the drive has been lost.

Check the control panel network

connections.

Select another drive.

Page 59

Fault tracing 59

?

?

Faults

Faults are problems that require your attention before you start the drive again.

Refer the following steps to solve the fault situation:

1. Identify and eliminate the cause of the fault. In the Fault view, you can see the

fault code. Refer to the relevant firmware manual for more information on the

fault.

2. Reset the fault by pressing (Reset) in the Fault view.

In the Fault view, the keys have the following functions:

•Press

back to the previous view. If there is also an active warning, it is displayed instead.

The fault view reappears after 60 seconds if no keys have been pressed.

•Press (Reset) to reset the fault and return to the previous view.

• Press the

to the Fault Diagnostics Assistant which helps you solve the fault situation.

(Hide) or any of the arrow keys to temporarily hide the fault and go

key to open the context-sensitive help. The help page has a shortcut

Warnings

Warnings mean that a possible problem has been detected and may need attention,

and the drive can still run. A warning message disappears once the condition that

triggered it goes away.

•Press

If the warning is still active after 60 seconds of no key presses, the Warning view

reappears automatically.

• Press the

(Hide) to hide the warning message and go back to the previous view.

key to open the context-sensitive help.

Note: If multiple warnings are active, the total number of active warnings is displayed.

Use and to scroll through the warnings.

Page 60

60 Fault tracing

Page 61

Service and maintenance 61

9

1

2

3

Service and maintenance

What this chapter contains

This chapter describes the service and maintenance tasks of the Assistant control

panel.

Removing the control panel cover

It is possible to remove the control panel cover to clean any dust inside the cover or to

change the cover to customize the control panel.

The cover consists of two parts, both of

which can be removed. You do not need

tools to remove the covers.

1. Open the USB connector cover.

2. Remove the lower part of the control

panel cover.

3. Remove the upper part of the cover.

Reinstall the covers in the reverse order.

Cleaning the control panel

Use a soft damp cloth to clean the control

panel. Avoid harsh cleaners which could

scratch the display window.

Page 62

62 Service and maintenance

Cleaning the connectors

Control panel has two connectors, RJ-45 connector (panel back side) and USB