Page 1

ABB industrial drives

Firmware manual

ACS880-M04 machinery control program

Page 2

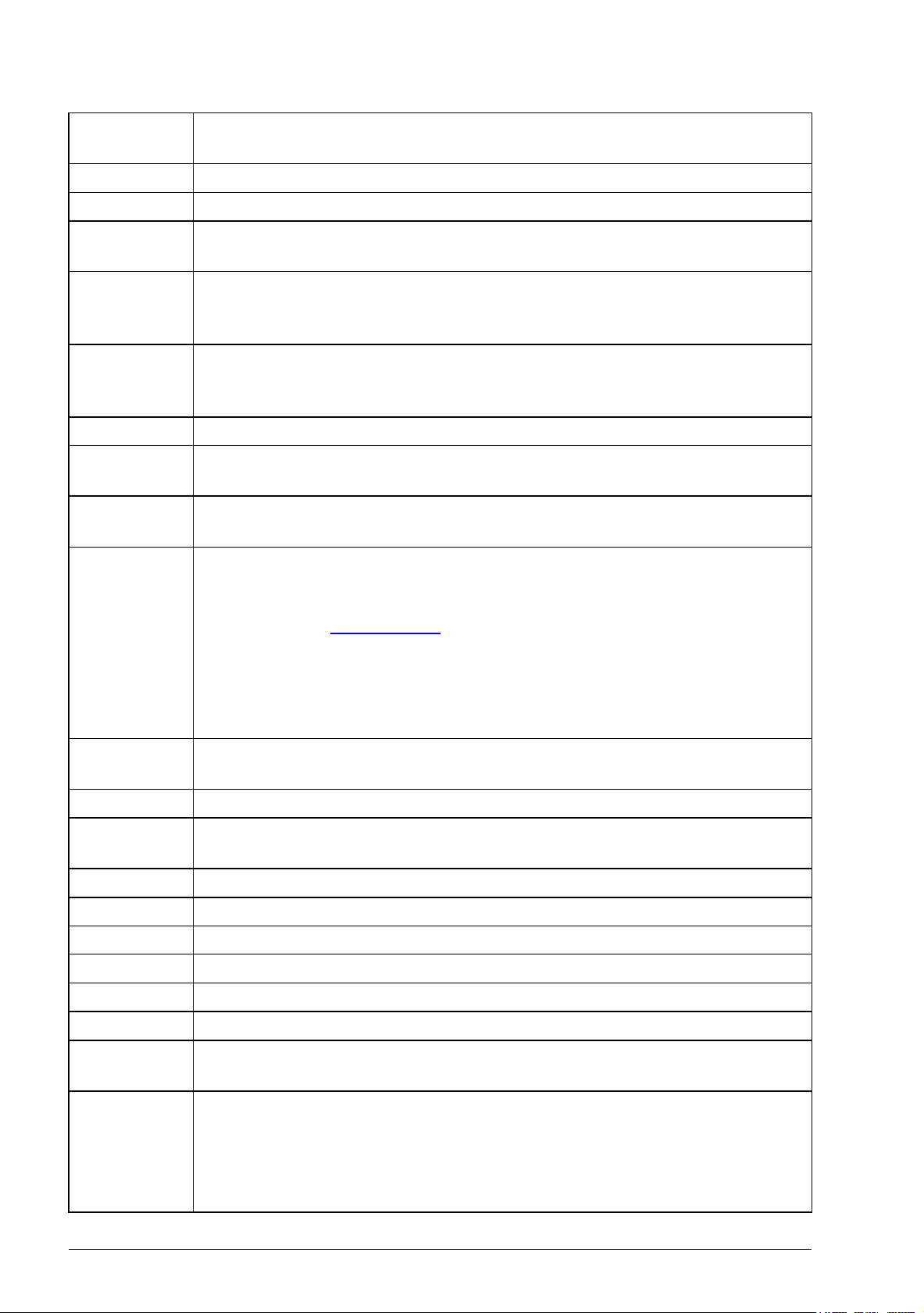

List of related manuals

Drive hardware manuals Code (English)

ACS880-M04 drives hardware manual 3AXD50000028613

*ACS880-01 drives hardware manual 3AUA0000078093

*ACS880-04 drive modules (200 to 710 kW, 300 to 700 hp)

hardware manual

Drive firmware manuals and guides

Adaptive programming application guide 3AXD50000028574

Drive (IEC 61131-3) application programming manual 3AUA0000127808

Option manuals and guides

ACS880-M04 Quick installation guide 3AXD50000032345

ACX-AP-x Assistant control panels user’s manual 3AUA0000085685

ACS-BP-S Basic control panels user’s manual 3AXD50000032527

Drive composer Start-up and maintenance PC tool User’s

manual

Manuals and quick guides for I/O extension modules,

fieldbus adapters, encoder interfaces, etc.

3AUA0000128301

3AUA0000094606

You can find manuals and other product documents in PDF format on the Internet. See section

Document library on the Internet on the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

*A list of links to all manuals applicable to this product is available in the Document library:

Page 3

Firmware manual

ACS880-M04 machinery control program

Table of contents

2016 ABB Oy. All Rights Reserved.

3AXD50000030629 Rev A

EN

EFFECTIVE: 2016-04-11

Page 4

Page 5

Table of contents 5

Table of contents

List of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Introduction to the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Using the control panel

Safety

3. Start-up

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Control locations and operating modes

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Local control vs. external control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operating modes of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Speed control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Torque control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Frequency control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Special control modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5. Program features

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Drive configuration and programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Programming via parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Adaptive programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Application programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmable analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmable analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmable digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmable relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Programmable I/O extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Page 6

6 Table of contents

Master/follower functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

External controller interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Direct torque control (DTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Reference ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Constant speeds/frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Critical speeds/frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Speed controller autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Oscillation damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rush control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Encoder support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Position counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Scalar motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Autophasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Flux braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

DC magnetization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Application control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Application macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Motor potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

DC voltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Overvoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Undervoltage control (power loss ride-through) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Voltage control and trip limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Safety and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Motor thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Thermal protection of motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Other programmable protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Automatic fault resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Fault and warning messages, data logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Signal supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Maintenance timers and counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Energy saving calculators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

User parameter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Data storage parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

du/dt filter support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6. Application macros

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Default parameter settings for the Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Default control connections for the Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Page 7

Table of contents 7

7. Parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Summary of parameter groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Parameter listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

01 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

03 Input references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

04 Warnings and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

05 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

06 Control and status words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

07 System info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

10 Standard DI, RO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11 Standard DIO, FI, FO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

12 Standard AI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

13 Standard AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

14 I/O extension module 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

15 I/O extension module 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

19 Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

20 Start/stop/direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

21 Start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

22 Speed reference selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

23 Speed reference ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

24 Speed reference conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

25 Speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

26 Torque reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

28 Frequency reference chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

30 Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

31 Fault functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

32 Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

33 Generic timer & counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

35 Motor thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

36 Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

43 Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

44 Mechanical brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

45 Energy efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

46 Monitoring/scaling settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

47 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

49 Panel port communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

50 Fieldbus adapter (FBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

51 FBA A settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

52 FBA A data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

53 FBA A data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

54 FBA B settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

55 FBA B data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

56 FBA B data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

58 Embedded fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

60 DDCS communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

61 D2D and DDCS transmit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

62 D2D and DDCS receive data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

90 Feedback selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

Page 8

8 Table of contents

91 Encoder module settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

92 Encoder 1 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

93 Encoder 2 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

95 HW configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

96 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

97 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

98 User motor parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

99 Motor data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

200 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

8. Additional parameter data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

Fieldbus addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

Parameter groups 1…9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Parameter groups 10…99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 442

9. Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Warnings and faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Pure events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Editable messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Warning/fault history and analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Event logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Other data loggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

Parameters that contain warning/fault information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

QR Code generation for mobile service application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 482

Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 503

10. Fieldbus control through the embedded fieldbus interface (EFB)

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

Connecting the fieldbus to the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 528

Setting up the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 529

Setting the drive control parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

Basics of the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

Data input/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

Register addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

About the control profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 536

The ABB Drives profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 537

Control Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 537

Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 539

Page 9

Table of contents 9

State transition diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 541

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

Modbus holding register addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543

The Transparent profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

Modbus function codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 545

Exception codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

Coils (0xxxx reference set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 547

Discrete inputs (1xxxx reference set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 548

Error code registers (holding registers 400090…400100) . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

11. Fieldbus control through a fieldbus adapter

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

Basics of the fieldbus control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 554

Control word and Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 555

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 557

Contents of the fieldbus Control word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

Contents of the fieldbus Status word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 559

The state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 560

Setting up the drive for fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 561

Parameter setting example: FPBA (PROFIBUS DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 562

12. Control chain diagrams

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 565

Speed reference source selection I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

Speed reference source selection II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 567

Speed reference ramping and shaping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 568

Motor feedback configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

Load feedback and position counter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 570

Speed error calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

Speed controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 572

Torque reference source selection and modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

Operating mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 574

Reference selection for torque controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575

Torque limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 576

Torque controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 577

Frequency reference selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 578

Frequency reference modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 579

Master/Follower communication I (Master) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

Master/Follower communication II (Follower) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 581

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

Page 10

10 Table of contents

Page 11

Introduction to the manual 11

1

Introduction to the manual

What this chapter contains

This chapter describes the contents of the manual. It also contains information on the

compatibility, safety and intended audience.

Applicability

This manual applies to ACS880-M04 machinery control program version 2.4x.

The firmware version of the control program is visible in parameter 07.05 Firmware

version, or the System info in the main menu on the drive control panel.

Safety instructions

Obey all safety instructions delivered with the drive.

• Read the complete safety instructions before you install, commission, or use

the drive. The complete safety instructions are delivered with the drive as part of

the Hardware manual as a separate document.

• Read the firmware function-specific warnings and notes before changing

parameter values. These warnings and notes are included in the parameter

descriptions presented in chapter Parameters.

Target audience

This manual is intended for people who design, commission, or operate the drive

system.

Page 12

12 Introduction to the manual

Contents of the manual

This manual contains the following chapters:

• Using the control panel provides basic instructions for the use of the control panel.

• Control locations and operating modes describes the control locations and

operating modes of the drive.

• Program features contains descriptions of the features of the ACS880-M04

primary control program.

• Application macros contains a short description of each macro together with a

connection diagram. Macros are pre-defined applications which will save the user

time when configuring the drive.

• Parameters describes the parameters used to program the drive.

• Additional parameter data contains further information on the parameters.

• Fault tracing lists the warning and fault messages with possible causes and

remedies.

• Fieldbus control through the embedded fieldbus interface (EFB) describes the

communication to and from a fieldbus network using the embedded fieldbus

interface of the drive.

• Fieldbus control through a fieldbus adapter describes the communication to and

from a fieldbus network using an optional fieldbus adapter module.

• Control chain diagrams showing the parameter structure within the drive.

Related documents

Note: A quick start-up sequence for a speed control application is provided by

ACS880-M04 Quick installation and start-up guide (3AXD50000032345), delivered

with the drive.

See the List of related manuals on the inside of front cover.

Page 13

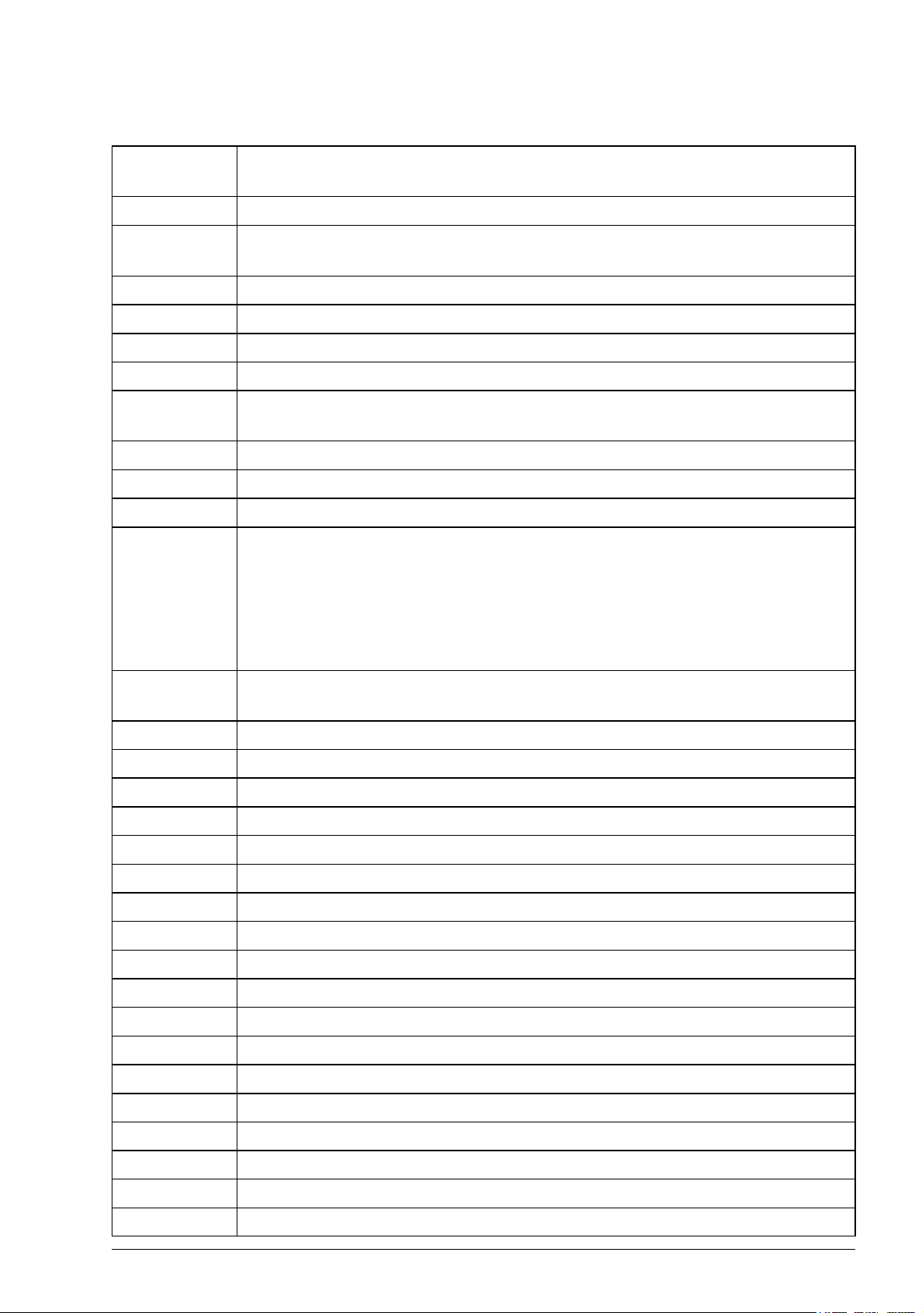

Terms and abbreviations

Introduction to the manual 13

Term /

abbreviation

ACS800 A product family of ABB drives

ACS-AP-I,

ACS-AP-W

ACS-BP-S Basic control panel

AI Analog input; interface for analog input signals

AO Analog output; interface for analog output signals

DC link DC circuit between rectifier and inverter

DDCS Distributed drives communication system; a protocol used in communication

DI Digital input; interface for digital input signals

DIO Digital input/output; interface that can be used as a digital input or output

DO Digital output; interface for digital output signals

Drive Frequency converter for controlling AC motors. The drive consists of a rectifier

Definition

Assistant control panel. Type of control panels used with ACS880-M04 drives

between ABB drive equipment

and an inverter connected together by the DC link. In drives up to

approximately 500 kW, these are integrated into a single module (drive

module). Larger drives typically consist of separate supply and inverter units.

The ACS880-M04 primary control program is used to control the inverter part

of the drive.

DriveBus A communication link used by, for example, ABB controllers. ACS880-M04

drives can be connected to the DriveBus link of the controller.

DTC Direct torque control. See page 45.

FBA Fieldbus adapter

FCAN-01 Optional CANopen adapter

FCNA-01 Optional ControlNet adapter

FDCO-0x Optional DDCS communication module

FDNA-01 Optional DeviceNet adapter

FECA-01 Optional EtherCAT® adapter

FEN-01 Optional TTL encoder interface module

FEN-11 Optional absolute encoder interface module

FEN-21 Optional resolver interface module

FEN-31 Optional HTL encoder interface module

FENA-11 Optional Ethernet/IP, Modbus/TCP and PROFINET IO adapter

FENA-21 Optional dual-port Ethernet/IP, Modbus/TCP and PROFINET IO adapter

FEPL-02 Optional POWERLINK adapter

FIO-01 Optional digital I/O extension module

FIO-11 Optional analog I/O extension module

FPBA-01 Optional PROFIBUS DP adapter

FSCA-01 Optional Modbus/RTU adapter

Page 14

14 Introduction to the manual

Term/

Definition

abbreviation

FSO-xx Optional safety functions module

HTL High-threshold logic

ID run Motor identification run. During the identification run, the drive will identify the

characteristics of the motor for optimum motor control.

IGBT Insulated gate bipolar transistor; a voltage-controlled semiconductor type

widely used in inverters and IGBT supply units due to their easy controllability

and high switching frequency

Inverter unit In large drives (> 500 kW approx.), the part of the drive that converts DC to

AC for the motor. Consists of one or more inverter modules and their auxiliary

components.

I/O Input/Output

ModuleBus A communication link used by, for example, ABB controllers. ACS880-M04

drives can be connected to the optical ModuleBus link of the controller.

Motor-side

See inverter unit.

converter

Network

control

With fieldbus protocols based on the Common Industrial Protocol (CIP

such as DeviceNet and Ethernet/IP, denotes the control of the drive using the

TM

),

Net Ctrl and Net Ref objects of the ODVA AC/DC Drive Profile. For more

information, see www.odva.org

, and the following manuals:

• FDNA-01 DeviceNet adapter module User’s manual (3AFE68573360

[English]), and

• FENA-01/-11 Ethernet adapter module User’s manual (3AUA0000093568

[English]).

Parameter User-adjustable operation instruction to the drive, or signal measured or

calculated by the drive

PLC Programmable logic controller

Power unit Contains the power electronics and power connections of the drive (or inverter

module). The drive control unit is connected to the power unit.

PTC Positive temperature coefficient

RFG Ramp function generator.

RO Relay output; interface for a digital output signal. Implemented with a relay.

SSI Synchronous serial interface

STO Safe torque off

TTL Transistor-transistor logic

UPS Uninterruptible power supply; power supply equipment with battery to

maintain output voltage during power failure

ZCU Type of control unit used in ACS880-M04 drives (primarily in drive modules, or

inverter/supply units consisting of a single power module). Consists of an I/O

board built into a plastic housing.

Depending on the type of hardware, the control unit may be integrated into or

fitted onto the drive/inverter module, or installed separately.

Page 15

Using the control panel 15

2

Using the control panel

Refer to

• ACX-AP-x assistant control panels user’s manual (3AUA0000085685 [English])

and

• ACS-BP-S assistant control panels user’s manual (3AXD50000032527 [English]).

Page 16

16 Using the control panel

Page 17

3

Start-up

Start-up 17

Contents of this chapter

This chapter describes the basic start-up sequence of an ACS880-M04 machinery

drive.

In this guide, the drive is set up using the ACS-AP-I control panel. The start-up

sequence can also be carried out using the Drive composer PC tool.

Before you start

Make sure the drive is mechanically and electrically installed as described in the

Quick installation guide and/or Hardware manual.

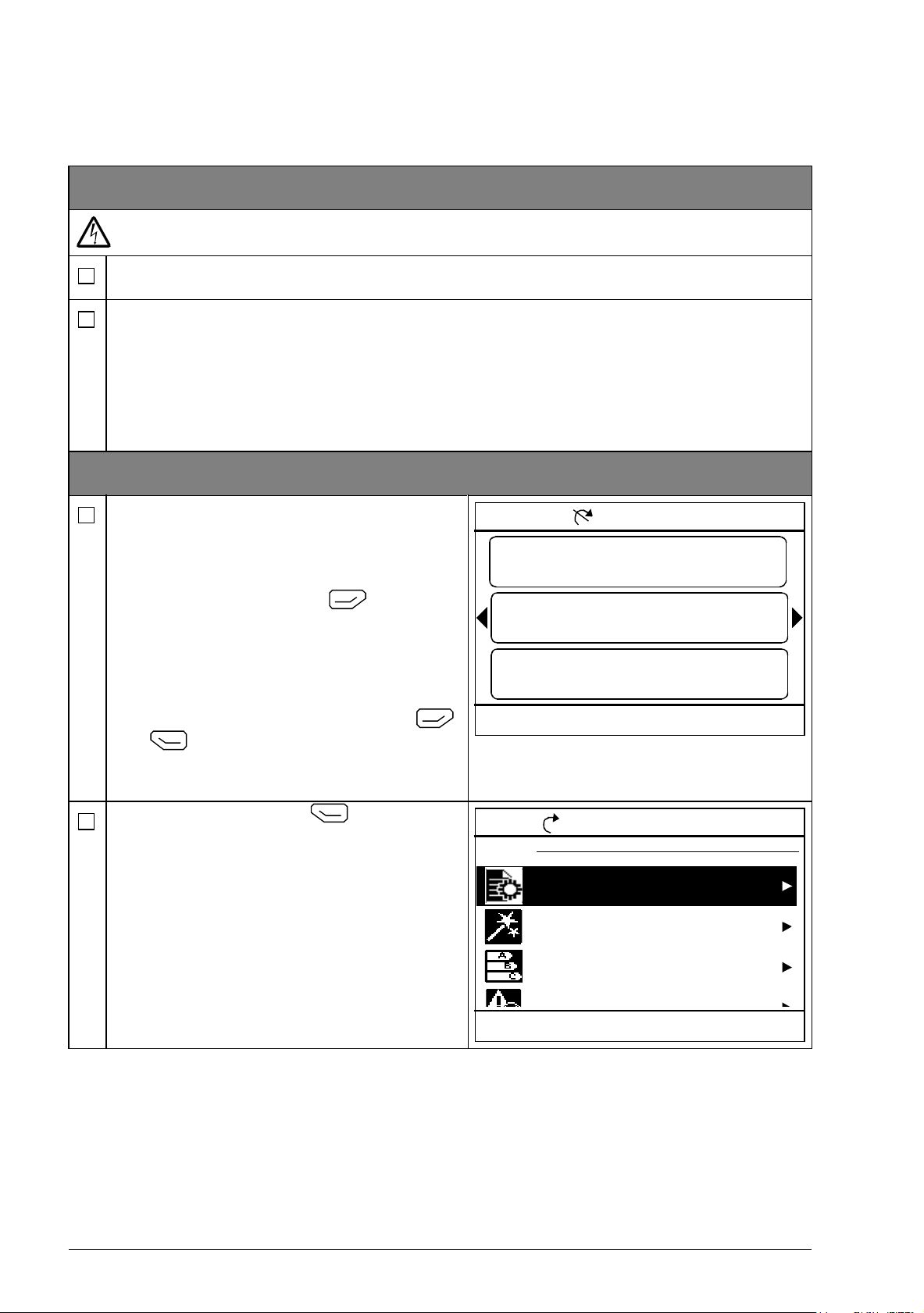

Safety

WARNING! Follow all safety instructions of the drive. Only qualified electricians are

allowed to start up the drive. Never work on the drive, the brake chopper circuit, the

motor cable or the motor when power is applied to the drive. Always make sure by

measuring that no voltage is actually present.

WARNING! Make sure that the machinery into which the drive with brake

control function is integrated fulfills the personnel safety regulations.

Note that the frequency converter (a Complete Drive Module or a Basic Drive

Module, as defined in IEC 61800-2), is not considered as a safety device mentioned

in the European Machinery Directive and related harmonized standards. Thus, the

personnel safety of the complete machinery must not be based on a specific

frequency converter feature (such as the brake control function), but it has to be

implemented as defined in the application specific regulations.

Page 18

18 Start-up

Remote 0.0 rpm

0.00

0.00

Motor torque

%

0.0

Motor current

A

Motor speed used

rpm

Options

12:34

Menu

ACS880

Remote 0.0 rpm

Menu

Parameters

Assistants

Energy efficiency

Event log

Exit

12:34

Select

Start-up

Safety

WARNING! Obey all safety instructions for the drive. Only qualified electricians are

allowed to start up the drive.

Check the installation. See the installation checklist in the Hardware manual.

Check that the starting of the motor does not cause any danger.

De-couple the driven machine if

• there is a risk of damage in case of an incorrect direction of rotation, or

•a Normal ID run is required during the drive start-up, when the load torque is higher

than 20% or the machinery is not able to withstand the nominal torque transient during

the ID run.

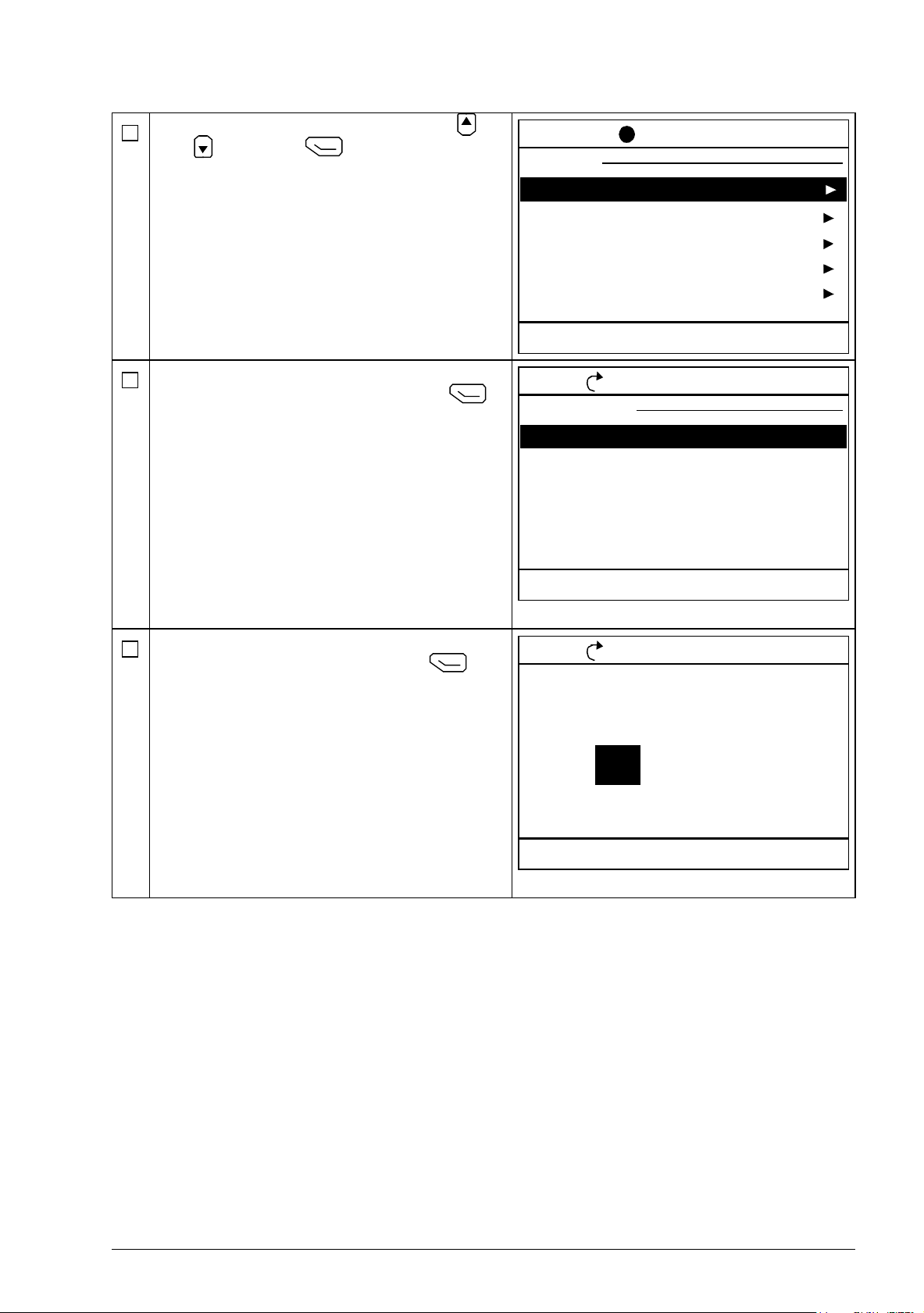

1 – Power-up, date and time settings

Power up the drive.

Note: It is normal that warning messages

appear at various points along the start-up

process. To hide a message and to resume

the start-up process, press .

Hide any warnings now to enter the Home

view (shown on the right).

The two commands at the bottom of the

display (in this case, Options and Menu),

show the functions of the two softkeys

and located below the display. The

commands assigned to the softkeys vary

depending on the context.

In the Home view, press (Menu).

The main Menu (right) appears.

Page 19

Highlight Settings on the menu using

Remote 0.0 rpm

Settings

Language

Date & time

Back

12:34

Select

Edit texts

Display settings

x

ACS880

Reset to defaults

Next daylight saving start 28.03.

Remote 0.0 rpm

Date & time

Date

Back

12:35

Edit

Time

Show date as

01.01.1980

12:34:56

day.month.year

Show time as 24-hour

Daylight saving EU

Remote 0.0 rpm

Date

Cancel

12:35

Save

Day Month Year

Tuesday

.01.198001

and and press (Select).

In the Settings menu, highlight Date & time

(if not already highlighted) and press

(Select).

Start-up 19

In the Date & time menu, highlight Date (if

not already highlighted) and press

(Select).

Page 20

20 Start-up

Remote 0.0 rpm

0.00

0.00

Motor torque

%

0.0

Motor current

A

Motor speed used

rpm

Options

12:34

Menu

ACS880

Loc/Rem

Local 0.0 rpm

0.00

0.00

Motor torque

%

0.0

Motor current

A

Motor speed used

rpm

Options

12:36

Menu

Local 0.0 rpm

Menu

Parameters

Assistants

Energy efficiency

Event log

Exit

12:36

Select

Set the correct date:

• Use and to move the cursor left

and right.

• Use and to change the value.

•Press (Save) to accept the new

setting.

Check/adjust all the remaining settings in the

Date & time menu.

The Show clock setting determines whether

the time is shown at all times in the bottom

pane of the display.

After you have made the settings, press

(Back or Exit) repeatedly until the

Home view (right) reappears.

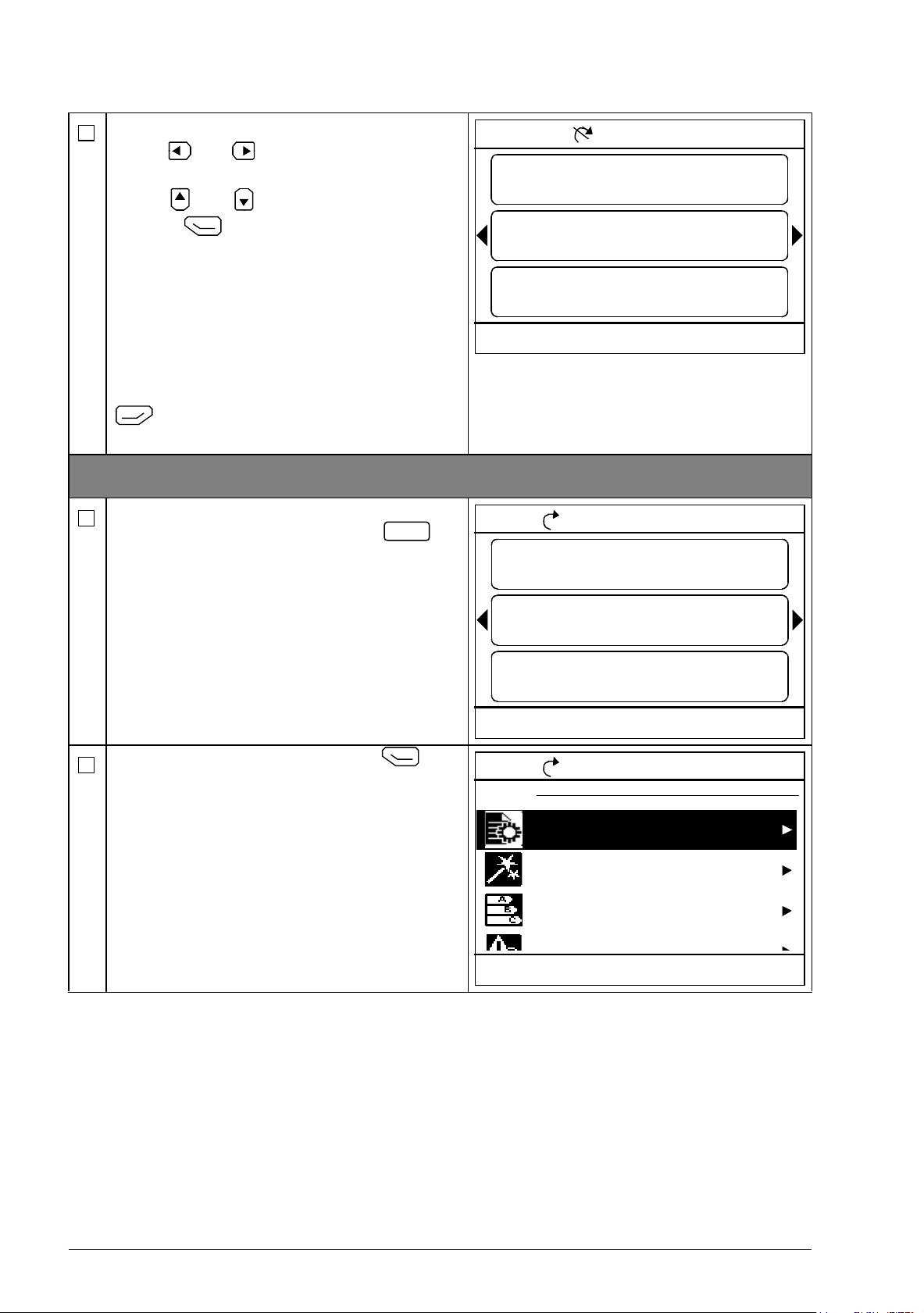

2 – Supply voltage and motor data settings

Switch to local control to ensure that external

control is disabled by pressing the

key. Local control is indicated by the text

“Local” in the top pane.

Open the main Menu by pressing

(Menu).

Page 21

Highlight Parameters and press

Local 0.0 rpm

Parameters

Complete list

By function

Back

12:36

Select

Favorites

Modified

x

ACS880

Local 0.0 rpm

Complete list

01 Actual values

03 Input references

04 Warnings and faults

05 Diagnostics

06 Control and status words

07 System info

Back

12:36

Select

Local 0.0 rpm

95 HW configuration

95.01 Supply voltage

Back

12:36

Edit

95.08 DC switch monitoring

Not given

Internal 24 V

Disable

95.15 Special HW settings 0000

95.20 HW option wor... ...0 0000 0000

ACS880

95.04 Control board supply

Local 0.0 rpm

95.01 Supply voltage

[0] Not given

[1] 208…240 V

Cancel

12:36

Save

[2] 380…415 V

[3] 440…480 V

[4] 500 V

(Select).

Highlight Complete list using and

and press (Select).

A listing of parameter groups is displayed.

Start-up 21

Highlight parameter group 95 HW

configuration and press (Select).

Note that the list wraps around in either

direction between groups 99 and 01. In this

case, it is quicker to use to locate group

95 on the list.

After selecting a group, a listing of

parameters within the group is displayed.

Highlight parameter 95.01 Supply voltage (if

not already highlighted) and press

(Edit).

The available parameter settings are listed.

Page 22

22 Start-up

Local 0.0 rpm

95 HW configuration

95.01 Supply voltage

Back

12:36

Edit

95.08 DC switch monitoring

380...415 V

Internal 24 V

Disable

95.15 Special HW settings 0000

95.20 HW option wor... ...0 0000 0000

ACS880

95.04 Control board supply

M2AA 200 MLA 4

1475

1475

1470

1470

1475

1770

32.5

56

34

59

54

59

0.83

0.83

0.83

0.83

0.83

0.83

3GAA 202 001 - ADA

180

IEC 34-1

6210/C36312/C3

Cat. no

35

30

30

30

30

30

50

50

50

50

50

60

690 Y

400 D

660 Y

380 D

415 D

440 D

V

Hz kW

r/min A

cos

IA/IN

t

E/s

Ins.cl. F

IP 55

No

IEC 200 M/L 55

3

motor

ABB Motors

3 ~ motor M2BJ 280SMB 10 B3

No 3424522

A

BB Motors

Ins.cl. F IP 55

V

400 DHz50kW55

r/min

600

A

103

cos

M

0.97

IA/IN

t

E/s

Prod. code 2GBJ285220-ADA405445477

6316/C3

6316/C3

630kg

IEC 34-1

S1 SPEC INSUL.

JK-21640-1

Highlight the correct setting on the list and

press (Save).

Press (Back) to display the list of parameter groups again. Select parameter group

99 Motor data, and set parameter 99.03 Motor type.

Set parameter 99.04 Motor control mode.

DTC = Direct torque control; Scalar

DTC is suitable for most cases. Scalar mode is recommended if

• the nominal current of the motor is less than 1/6 of the nominal current of the drive,

• the drive is used for test purposes with no motor connected, or

• the drive controls multiple motors and the number of motors connected is variable.

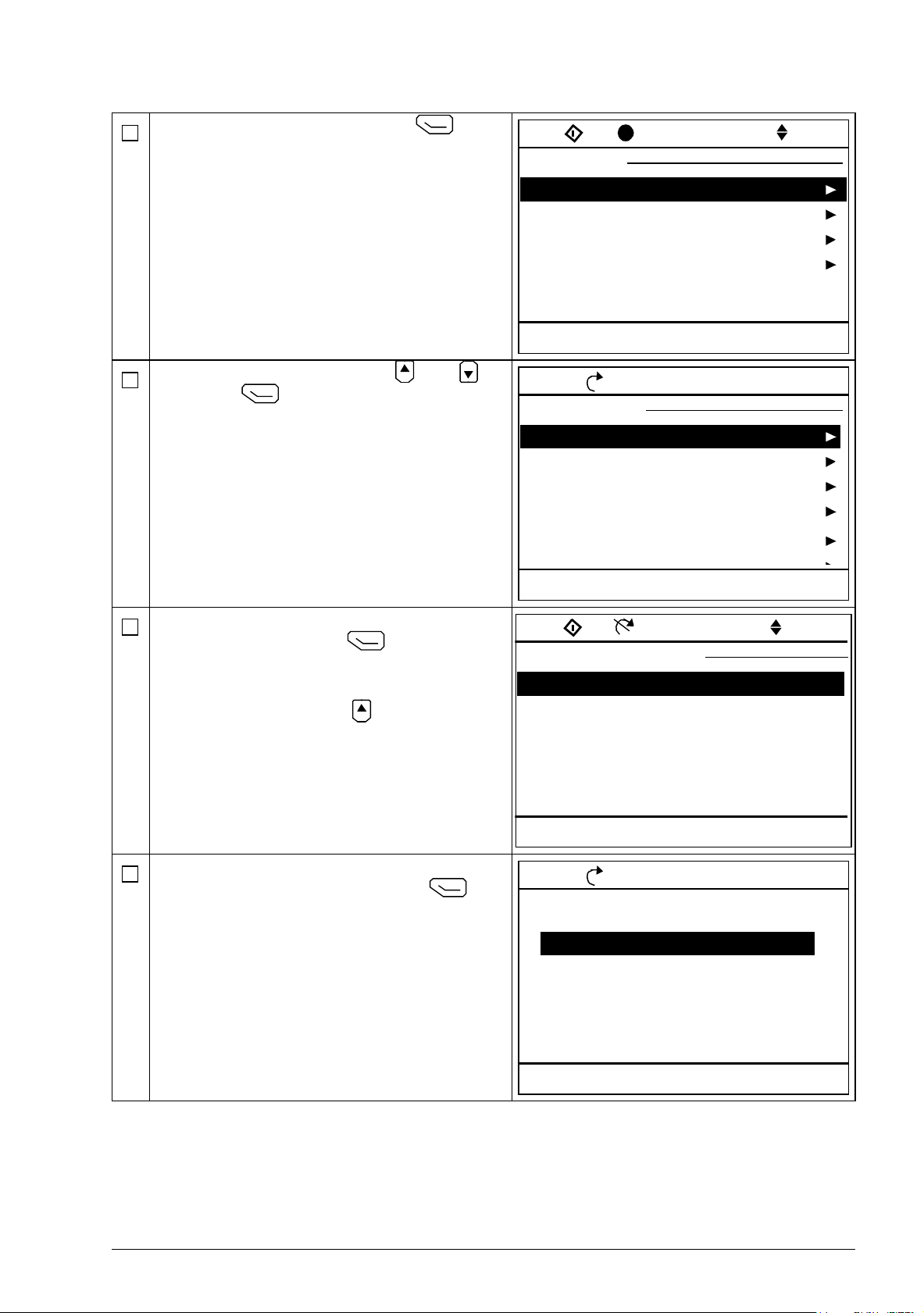

Refer to the motor nameplate for the following parameter settings. Whenever possible, enter

the values exactly

as shown on the motor nameplate.

Example of a nameplate of an induction

(asynchronous) motor:

99.06 Motor nominal current

The allowable range is

• in DTC mode: 1/6 × I

• in Scalar mode: 0 … 2 × I

Note: With numerical parameter values:

• Use and to change the value of a digit.

• Use and to move the cursor left and right.

•Press (Save) to enter the value.

Hd

… 2 × IHd of the drive

Hd

Example of a nameplate of a permanent

magnet motor:

Page 23

Make the following parameter settings in the same manner.

99.07 Motor nominal voltage

Start-up 23

The allowable range is 1/6 × U

… 2 × UN of the drive.

N

With permanent magnet motors, the nominal voltage is the BackEMF voltage at nominal

speed. If the voltage is given in volt/rpm (eg. 60 V per 1000 rpm), the voltage at a nominal

speed of 3000 rpm is 3 × 60 V = 180 V. Note that nominal voltage is not the same as

equivalent DC motor voltage (EDCM) given by some manufacturers. The nominal voltage

can be calculated by dividing the EDCM voltage by 1.7 (or square root of 3).

99.08 Motor nominal frequency

With permanent magnet motors, if the nominal frequency is not shown on the nameplate,

it can be calculated using the following formula:

f = n × p / 60

where n = nominal motor speed, p = number of pole pairs.

99.09 Motor nominal speed

99.10 Motor nominal power

99.11 Motor nominal cos Φ

99.12 Motor nominal torque

These values are not required, but can be entered to improve control accuracy. If you do

not know the correct values, leave the parameters at 0. DO NOT enter estimated values.

99.13 ID run requested

This parameter selects the mode of the identification run (DTC motor control mode only).

Note: The drive must be in local control for the identification run.

WARNING! The identification run modes marked thus * will run the motor in the

forward direction (see below for details). Make sure it is safe to run the motor

before choosing any of these modes.

*Normal mode should be selected whenever possible.. The driven machinery must be de-

coupled from the motor if

• the load torque is higher than 20%, or

• the machinery is not able to withstand the nominal torque transient during the

identification run.

*Reduced mode should be selected if the mechanical losses are higher than 20%, ie. the

load cannot be de-coupled, or full flux is required to keep the motor brake open (eg. with

conical motors).

The Standstill mode should be selected if neither the *Normal or *Reduced mode can be

used. Notes:

• This mode cannot be used with a permanent magnet motor if the load torque is higher

than 20% of nominal.

• Mechanical brake is not opened by the logic for the identification run.

Ensure that the Safe torque off and emergency stop circuits (if present) are closed.

Start the identification run by pressing the

(Start) button.

A warning will indicate that the

identification run is in progress.

Page 24

24 Start-up

Check that the motor runs in the correct direction (forward direction shown below).

The identification run has completed when the drive stops and the value of parameter

99.13 reverts to None.

If the motor ran in the wrong direction, correct the motor cabling or adjust parameter

99.16 Motor phase order.

Page 25

Control locations and operating modes 25

4

Control locations and operating modes

What this chapter contains

This chapter describes the control locations and operating modes supported by the

control program.

Page 26

26 Control locations and operating modes

Control panel or Drive

composer PC tool (optional)

Fieldbus adapter (Fxxx)

1) Extra inputs/outputs can be added by installing optional I/O extension modules (FIO-xx) in

drive slots.

2) Encoder or resolver interface module(s) (FEN-xx) installed in drive slots.

MOTOR

PLC

M

3~

I/O

1)

Embedded fieldbus

interface (EFB) or

master/follower link

External control

Local control

Encoder

ACS880-M04

Control panel

2)

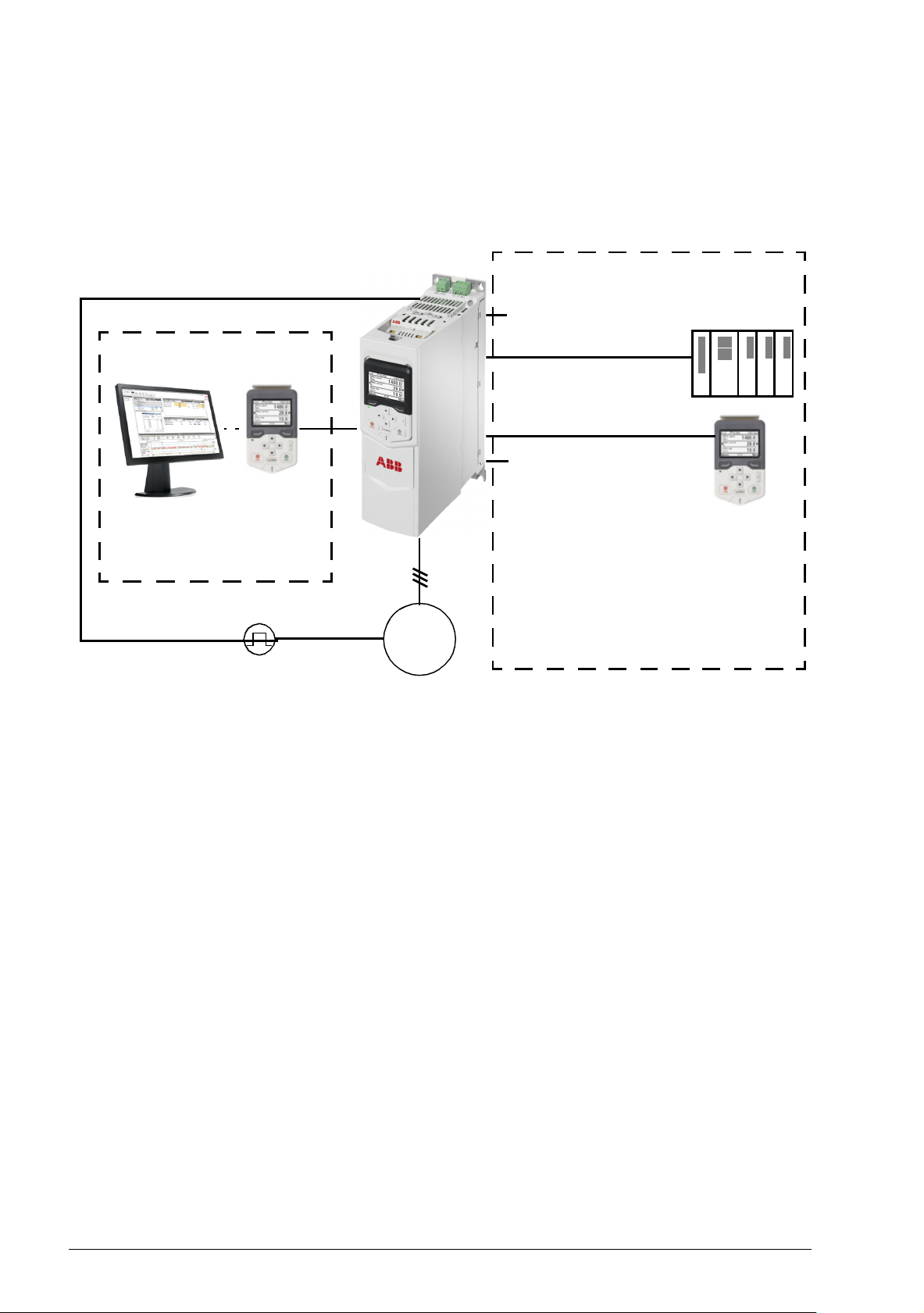

Local control vs. external control

The ACS880-M04 has two main control locations: external and local. The control

location is selected with the Loc/Rem key on the control panel or in the PC tool.

Local control

The control commands are given from the control panel keypad or from a PC

equipped with Drive composer when the drive is set to local control. Speed and

torque control modes are available for local control; frequency mode is available

when scalar motor control mode is used (see parameter 19.16 Local control mode).

Local control is mainly used during commissioning and maintenance. The control

panel always overrides the external control signal sources when used in local control.

Changing the control location to local can be prevented by parameter 19.17 Local

control disable.

The user can select by a parameter (49.05 Communication loss action) how the drive

reacts to a control panel or PC tool communication break. (The parameter has no

effect in external control.)

Page 27

Control locations and operating modes 27

External control

When the drive is in external control, control commands are given through

• the I/O terminals (digital and analog inputs), or optional I/O extension modules

• the embedded fieldbus interface or an optional fieldbus adapter module

• the master/follower link, and/or

• the control panel.

Two external control locations, EXT1 and EXT2, are available. The user can select

the sources of the start and stop commands separately for each location by

parameters 20.01…20.10. The operating mode can be selected separately for each

location (in parameter group 19 Operation mode), which enables quick switching

between different operating modes, for example speed and torque control. Selection

between EXT1 and EXT2 is done via any binary source such as a digital input or

fieldbus control word (see parameter 19.11 Ext1/Ext2 selection). The source of

reference is selectable for each operating mode separately.

Using the control panel as an external control source

The control panel can also be used as a source of start/stop commands and/or

reference in external control. Selections for the control panel are available in the

start/stop command source and reference source selection parameters.

Reference source selection parameters have two selections for the control panel. The

difference between the two selections is in the initial reference value after the

reference source switches to the control panel.

The panel reference is saved whenever another reference source is selected. If the

reference source selection parameter is set to Control panel (ref saved), the saved

value is used as the initial reference when control switches back to the panel. Note

that only one type of reference can be saved at a time: for example, attempting to use

the same saved reference with different operating modes (speed, torque, etc.)

causes the drive to trip on 7083 Panel reference conflict. The panel reference can be

separately limited by parameters in group 49 Panel port communication.

With the reference source selection parameter set to Control panel (ref copied), the

initial panel reference value depends on whether the operating mode changes with

the reference source. If the source switches to the panel and the operating mode

does not change, the last reference from the previous source is adopted. If the

operating mode changes, the drive actual value corresponding to the new mode is

adopted as the initial value.

Page 28

28 Control locations and operating modes

Motor feedback

configuration

(p 569)

Speed

reference

source selection

I

(p 566)

Speed controller

(p 572)

Speed reference

source selection

II

(p 567)

Speed reference

ramping and

shaping

(p 568)

Speed error

calculation

(p 571)

Torque

reference

source selection

and modification

(p 573)

Reference

selection for

torque controller

(p 575)

Frequency

reference

source selection

and modification

(p 578)

Operating mode

selection

(p 574)

Torque

controller

(p 577)

DTC motor

control mode

Scalar motor

control mode

Torque limitation

(p 576)

Frequency

reference

modification

(p 579)

Load feedback

and position

counter

configuration

(p 570)

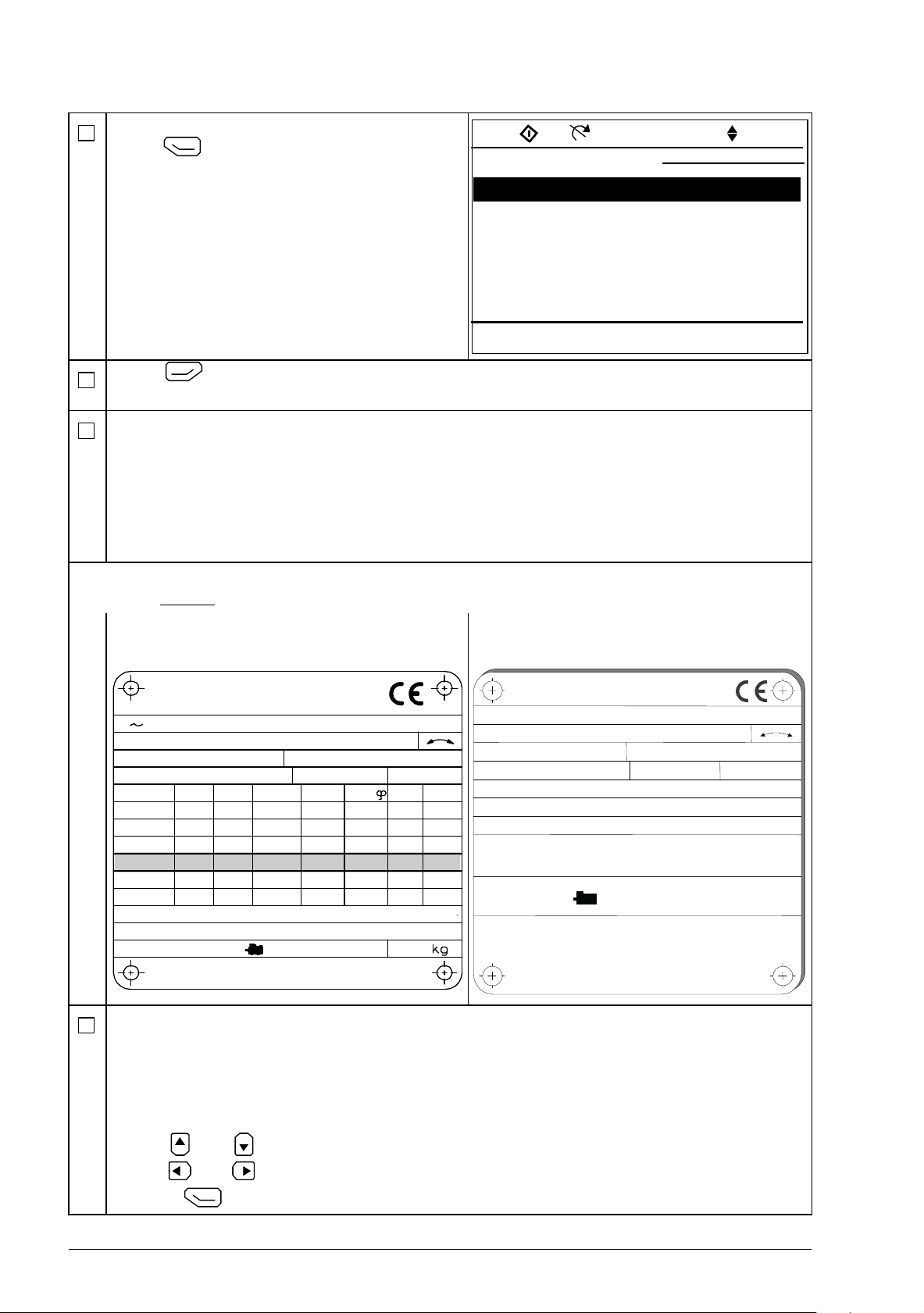

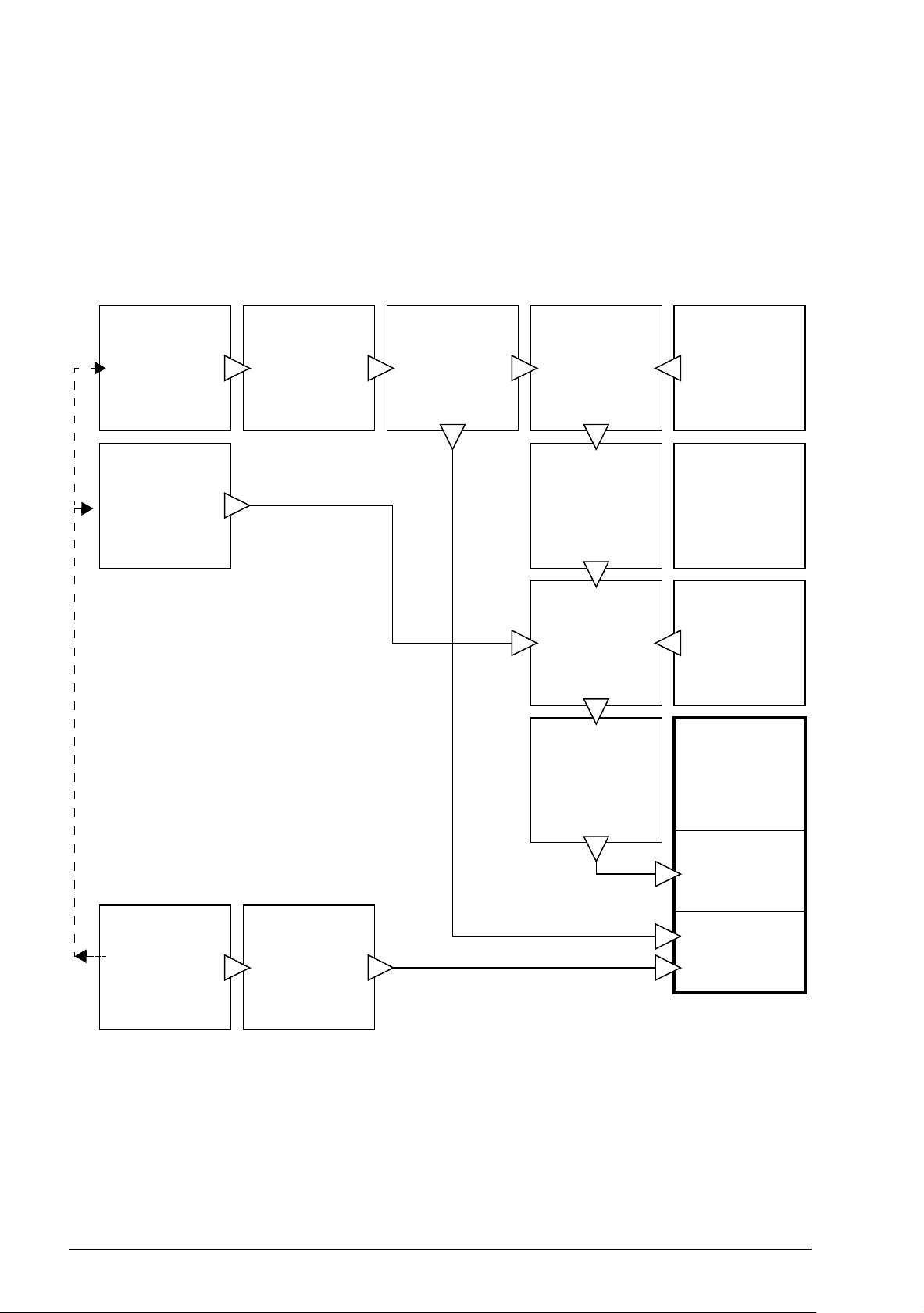

Operating modes of the drive

The drive can operate in several operating modes with different types of reference.

The mode is selectable for each control location (Local, EXT1 and EXT2) in

parameter group 19 Operation mode.

The following is a general representation of the reference types and control chains.

The page numbers refer to detailed diagrams in chapter Control chain diagrams.

Page 29

Control locations and operating modes 29

Speed control mode

The motor follows a speed reference given to the drive. This mode can be used either

with estimated speed as feedback, or with an encoder or resolver for better speed

control accuracy.

Speed control mode is available in both local and external control. It is also available

both in DTC (Direct Torque Control) and scalar motor control modes.

Torque control mode

Motor torque follows a torque reference given to the drive. Torque control is possible

without feedback, but is much more dynamic and accurate when used in conjunction

with a feedback device such as an encoder or a resolver. It is recommended that a

feedback device is used in crane, winch or lift control situations.

Torque control mode is available in DTC motor control mode for both local and

external control locations.

Frequency control mode

The motor follows a frequency reference given to the drive. Frequency control is only

available in scalar motor control mode.

Special control modes

In addition to the control modes mentioned above, the following special control

modes are available:

• Emergency stop modes Off1 and Off3: Drive stops along the defined deceleration

ramp and drive modulation stops.

• Jogging mode: Drive starts and accelerates to the defined speed when the

jogging signal is activated. For more information, see section Jogging (page 57).

Page 30

30 Control locations and operating modes

Page 31

5

Program features

Program features 31

What this chapter contains

The control program contains all of the parameters (including actual signals) within

the drive. This chapter describes some of the more important functions within the

control program, how to use them and how to program them to operate.

Page 32

32 Program features

Application program

Firmware

Speed control

Torque control

Frequency control

Drive logic

I/O interface

Fieldbus interface

Protections

Feedback

Standard

block library

Function block

program

Drive control program

Parameter

interface

M

Drive configuration and programming

The drive control program is divided into two parts:

• firmware program

• application program.

The firmware program performs the main control functions, including speed and

torque control, drive logic (start/stop), I/O, feedback, communication and protection

functions. Firmware functions are configured and programmed with parameters, and

can be extended by application programming.

Programming via parameters

Parameters configure all of the standard drive operations and can be set via

• the control panel, as described in chapter Using the control panel

• the Drive composer PC tool, as described in Drive composer user’s manual

(3AUA0000094606 [English]), or

• the fieldbus interface, as described in chapters Fieldbus control through the

embedded fieldbus interface (EFB) and Fieldbus control through a fieldbus

adapter.

All parameter settings are stored automatically to the permanent memory of the drive.

However, if an external +24 V DC power supply is used for the drive control unit, it is

highly recommended to force a save by using parameter 96.07 Parameter save

manually before powering down the control unit after any parameter changes have

been made.

If necessary, the default parameter values can be restored by parameter 96.06

Parameter restore.

Page 33

Program features 33

Adaptive programming

Conventionally, the user can control the operation of the drive by parameters.

However, the standard parameters have a fixed set of choices or a setting range. To

further customize the operation of the drive, an adaptive program can be constructed

out of a set of function blocks.

The Drive composer pro PC tool (version 1.9 or later, available separately) has an

Adaptive programming feature with a graphical user interface for building the custom

program. The function blocks include the usual arithmetic and logical functions, as

well as eg. selection, comparison and timer blocks. The program can contain

approximately 20 blocks depending on block size and the number of inputs and

outputs used.

The physical inputs, drive status information, actual values, constants and data

storage parameters can be used as the input for the program. The output of the

program can be used eg. as a start signal, external event or reference, or connected

to the drive outputs. See below for a listing of the available inputs and outputs. Note

that connecting the output of the adaptive program to a selection parameter will writeprotect the parameter.

The status of the adaptive program is shown by parameter 07.30 Adaptive program

status.

For more information, see the Adaptive programming application guide

(3AXD50000028574 [English]).

Inputs available to the adaptive program

Input Source

I/O

DI1 10.02 DI delayed status, bit 0

DI2 10.02 DI delayed status, bit 1

DI3 10.02 DI delayed status, bit 2

DI4 10.02 DI delayed status, bit 3

DI5 10.02 DI delayed status, bit 4

DI6 10.02 DI delayed status, bit 5

DIIL 10.02 DI delayed status, bit 15

AI1 12.11 AI1 actual value

AI2 12.21 AI2 actual value

DIO1 11. 0 2 DIO delayed status, bit 0

DIO2 11. 0 2 DIO delayed status, bit 1

Actual signals

Motor speed 01.01 Motor speed used

Output frequency 01.06 Output frequency

Motor current 01.07 Motor current

Motor torque 01.10 Motor torque

Motor shaft power 01.17 Motor shaft power

Status

Enabled 06.16 Drive status word 1, bit 0

Inhibited 06.16 Drive status word 1, bit 1

Ready to start 06.16 Drive status word 1, bit 3

Page 34

34 Program features

Inputs available to the adaptive program

Input Source

Tripped 06.11 Main status word, bit 3

At setpoint 06.11 Main status word, bit 8

Limiting 06.16 Drive status word 1, bit 7

Ext1 active 06.16 Drive status word 1, bit 10

Ext2 active 06.16 Drive status word 1, bit 11

Data storage

Data storage 1 real32 47.01 Data storage 1 real32

Data storage 2 real32 47.02 Data storage 2 real32

Data storage 3 real32 47.03 Data storage 3 real32

Data storage 4 real32 47.04 Data storage 4 real32

Data storage 5 real32 47.05 Data storage 5 real32

Data storage 6 real32 47.06 Data storage 6 real32

Data storage 7 real32 47.07 Data storage 7 real32

Data storage 8 real32 47.08 Data storage 8 real32

Outputs available to the adaptive program

Output Target

I/O

RO1 10.24 RO1 source

RO2 10.27 RO2 source

RO3 10.30 RO3 source

AO1 13.12 AO1 source

AO2 13.22 AO2 source

DIO1 11.06 DIO1 output source

DIO2 11.10 DIO2 output source

Start control

Ext1/Ext2 selection 19.11 Ext1/Ext2 selection

Run enable 1 20.12 Run enable 1 source

Ext1 in1 cmd 20.03 Ext1 in1 source

Ext1 in2 cmd

Ext1 in3 cmd 20.05 Ext1 in3 source

Ext2 in1 cmd 20.08 Ext2 in1 source

Ext2 in2 cmd 20.09 Ext2 in2 source

Ext2 in3 cmd 20.10 Ext2 in3 source

Fault reset 31.11 Fault reset selection

Speed control

Ext1 speed reference 22.11 Speed ref1 source

Ext2 speed reference 22.12 Speed ref2 source

Speed additive 1 22.15 Speed additive 1 source

Frequency control

Ext1 frequency reference 28.11 Frequency ref1 source

Ext2 frequency reference 28.12 Frequency ref2 source

Torque control

Ext1 torque reference 26.11 Torque ref1 source

Ext2 torque reference 26.12 Torque ref2 source

Torque additive 2 26.25 Torque additive 2 source

Limit function

Minimum torque 2 30.21 Minimum torque 2 source

Maximum torque 2 30.22 Maximum torque 2 source

20.04 Ext1 in2 source

Page 35

Program features 35

Outputs available to the adaptive program

Output Target

Events

External event 1 31.01 External event 1 source

External event 2 31.03 External event 2 source

External event 3 31.05 External event 3 source

External event 4 31.07 External event 4 source

External event 5 31.09 External event 5 source

Application programming

The functions of the firmware program can be extended with application

programming. Application programmability is optionally available for the ACS880M04 primary control program.

Application programs can be built out of function blocks based on the IEC 61131-3

standard using a PC tool available separately.

For more information, see Programming manual: Drive application programming

(IEC 61131-3) (3AUA0000127808 [English]).

Page 36

36 Program features

Control interfaces

Programmable analog inputs

The control unit has two programmable analog inputs. Each of the inputs can be

independently set as a voltage (0/2…10 V or -10…10 V) or current (0/4…20 mA)

input by a jumper or switch on the control unit. Each input can be filtered, inverted

and scaled. The number of analog inputs can be increased by installing FIO-11 I/O

extensions (see Programmable I/O extensions below).

The drive can be set to perform an action (for example, to generate a warning or fault)

if the value of an analog input moves out of a predefined range.

Settings

Parameter group 12 Standard AI (page 136).

Programmable analog outputs

The control unit has two current (0…20 mA) analog outputs. Each output can be

filtered, inverted and scaled. The number of analog outputs can be increased by

installing FIO-11 I/O extensions (see Programmable I/O extensions below).

Settings

Parameter group 13 Standard AO (page 141).

Programmable digital inputs and outputs

The control unit has six digital inputs, a digital start interlock input, and two digital

input/outputs (I/O that can be set as either an input or an output).

One digital input (DI6) doubles as a PTC thermistor input. See section Motor thermal

protection (page 73).

Digital input/output DIO1 can be used as a frequency input, DIO2 as a frequency

output.

The number of digital inputs/outputs can be increased by installing FIO-01 or FIO-11

I/O extensions (see Programmable I/O extensions below).

Settings

Parameter groups 10 Standard DI, RO (page 122) and 11 Standard DIO, FI, FO

(page 130).

Page 37

Program features 37

Programmable relay outputs

The control unit has three relay outputs. The signal to be indicated by the outputs can

be selected by parameters.

Relay outputs can be added by installing FIO-01 I/O extensions.

Settings

Parameter group 10 Standard DI, RO (page 122).

Programmable I/O extensions

Inputs and outputs can be added by using I/O extension modules. One or two

modules can be mounted on the slots of the control unit.

The table below shows the number of I/O on the control unit as well as optional I/O

extension modules.

Digital

Location

Control unit 6 + DIIL2223

FIO-01 - 4 - - 2

FIO-11 -231 -

inputs

(DI)

Digital I/Os

(DIO)

Analog

inputs

(AI)

Analog

outputs

(AO)

Relay

outputs

(RO)

Two I/O extension modules can be activated and configured using parameter groups

14…15.

Note: Each configuration parameter group contains parameters that display the

values of the inputs on that particular extension module. These parameters are the

only way of utilizing the inputs on I/O extension modules as signal sources. To

connect to an input, choose the setting Other in the source selector parameter, then

specify the appropriate value parameter (and bit, for digital signals) in group 14 and

15.

Settings

Parameter groups 14 I/O extension module 1 (page 147) and 15 I/O extension

module 2 (page 169).

Page 38

38 Program features

Fieldbus control

The drive can be connected to several different automation systems through its

fieldbus interfaces. See chapters Fieldbus control through the embedded fieldbus

interface (EFB) (page 527) and Fieldbus control through a fieldbus adapter (page

551).

Settings

Parameter groups 50 Fieldbus adapter (FBA) (page 330), 51 FBA A settings (page

341), 52 FBA A data in (page 342), and 53 FBA A data out (page 343), 54 FBA B

settings (page 344), 55 FBA B data in (page 345), 56 FBA B data out (page 346), and

58 Embedded fieldbus (page 346).

Page 39

Program features 39

(For example)

Control word

Speed reference

Torque reference

(For example)

Status word

01.01 Motor speed used

01.10 Motor torque

Master

M

~

M

~

Master/follower link

DDCS

Follower

DDCS

Fieldbus control

External control system (eg. PLC)

Process master

Process follower

Speed-controlled

master

Torque- or speedcontrolled follower

Master/follower functionality

General

The master/follower functionality can be used to link several drives together so that

the load can be evenly distributed between the drives. This is ideal in applications

where the motors are coupled to each other via gearing, chain, belt, etc.

The external control signals are typically connected to one drive only which acts as

the master. The master controls up to 10 followers by sending broadcast messages

over an electrical cable or fiber optic link. The master can read feedback signals from

up to 3 selected followers.

Page 40

40 Program features

The master drive is typically speed-controlled and the other drives follow its torque or

speed reference. In general, a follower should be

• torque-controlled when the motor shafts of the master and the follower are rigidly

coupled by gearing, chain etc. so that no speed difference between the drives is

possible

• speed-controlled when the motor shafts of the master and the follower are flexibly

coupled so that a slight speed difference is possible. When both the master and

the follower are speed-controlled, drooping is also typically used (see parameter

25.08 Drooping rate). The distribution of load between the master and follower

can alternatively be adjusted as described under Load share function with a

speed-controlled follower below.

Note: With a speed-controlled follower (without load sharing), pay attention to the

acceleration and deceleration ramp times of the follower. If the ramp times are set

longer than in the master, the follower will follow its own acceleration/deceleration

ramp times rather than those from the master. In general, it is recommended to set

identical ramp times in both the master and the follower(s). Any ramp shape settings

(see parameters 23.16…23.19) should only be applied in the master.

In some applications, both speed control and torque control of the follower are

required. In those cases, the operating mode can be switched by parameter (19.12

Ext1 control mode or 19.14 Ext2 control mode). Another method is to set one external

control location to speed control mode, the other to torque control mode. Then, a

digital input of the follower can be used to switch between the control locations. See

chapter Control locations and operating modes (page 25).

With torque control, follower parameter 26.15 Load share can be used to scale the

incoming torque reference for optimal load sharing between the master and the

follower. Some torque-controlled follower applications, eg. where the torque is very

low, or very low speed operation is required, may require encoder feedback.

If a drive needs to quickly switch between master and follower statuses, one user

parameter set (see page 82) can be saved with the master settings, another with the

follower settings. The suitable settings can then be activated using eg. digital inputs.

Load share function with a speed-controlled follower

Load sharing between the master and a speed-controlled follower can be used in

various applications. The load share function is implemented by fine-tuning the

follower speed reference with an additional term based on a torque reference. The

torque reference is selected by parameter 23.42 Follower speed corr torq source (by

default, reference 2 received from the master). Load share is adjusted by parameter

26.15 Load share and activated by the source selected by 23.40 Follower speed

correction enable. Parameter 23.41 Follower speed correction gain provides a gain

adjustment for the speed correction. The final correction term added to the speed

reference is shown by 23.39 Follower speed correction out. See the block diagram on

page 571.

Page 41

Program features 41

Notes:

• The function can be enabled only when the drive is a speed-controlled follower in

remote control mode.

• Drooping (25.08 Drooping rate) is ignored when the load share function is active.

• The master and follower should have the same speed control tuning values.

• The speed correction term is limited by the speed error window parameters 24.44

Speed error window low and 24.43 Speed error window high. An active limitation

is indicated by 06.19 Speed control status word.

Communication

A master/follower link can be built by connecting the drives together with fiber optic

cables (may require additional equipment depending on existing drive hardware), or

by wiring together the XD2D connectors of the drives. The medium is selected by

parameter 60.01 M/F communication port.

Parameter 60.03 M/F mode defines whether the drive is the master or a follower on

the communication link. Typically, the speed-controlled process master drive is also

configured as the master in the communication.

The communication on the master/follower link is based on the DDCS protocol, which

employs data sets (specifically, data set 41). One data set contains three 16-bit

words. The contents of the data set are freely configurable using parameters

61.01…61.03. The data set broadcast by the master typically contains the control

word, speed reference and torque reference, while the followers return a status word

with two actual values.

The default setting of parameter 61.01 M/F data 1 selection is Follower CW. With this

setting in the master, a word consisting of bits 0…11 of 06.01 Main control word and

four bits selected by parameters 06.45…06.48 is broadcast to the followers.

However, bit 3 of the follower control word is modified so that it remains on as long as

the master is modulating, and its switching to 0 causes the follower to coast to a stop.

This is to synchronize the stopping of both master and follower.

Note: When the master is ramping down to a stop, the follower observes the

decreasing reference but receives no stop command until the master stops

modulating and clears bit 3 of the follower control word. Because of this, the

maximum and minimum speed limits on the follower drive should not have the same

sign – otherwise the follower would be pushing against the limit until the master finally

stops.

Three words of additional data can optionally be read from each follower. The

followers from which data is read are selected by parameter 60.14 M/F follower

selection in the master. In each follower drive, the data to be sent is selected by

parameters 61.01…61.03. The data is transferred in integer format over the link, and

displayed by parameters 62.28…62.36 in the master. The data can then be

forwarded to other parameters using 62.04…62.12.

Page 42

42 Program features

Master/follower wiring with electrical cable

Master

Termination ON

1

2

3

4

1

2

3

4

1

2

3

4

XD2D

B

XD2D

XD2D

A

BGND

Shield

B

A

BGND

Shield

B

A

BGND

Shield

Follower 1

Termination OFF

Follower n

Termination ON

See the hardware manual of the drive for wiring and termination details.

To indicate faults in the followers, each follower must be configured to transmit its

status word as one of the above-mentioned data words. In the master, the

corresponding target parameter must be set to Follower SW. The action to be taken

when a follower is faulted is selected by 60.17 Follower fault action. External events

(see parameter group 31 Fault functions) can be used to indicate the status of other

bits of the status word.

Block diagrams of the master/follower communication are presented on pages 580

and 581.

Construction of the master/follower link