Page 1

—

EN

USADADE

ESFIFR

IT

NLPLPT

RU

SVTRZH

ABB INDUSTRIAL DRIVES

ACS880-11 drives

Quick installation guide

Page 2

List of related manuals in English

ACS880-11 manuals

Drive manuals and guides Code (English)

ACS880 primary control program firmware manual 3AUA0000085967

Quick start-up guide fo r ACS880 drives with primary control

program

ACS880-11 hardware manual

ACS880-11 quick installation guide

ACX-AP-x assistant control panels user’s manual

Option manuals and guides

ACS880 drive module frames R1 to R9 for cabinet installation

(options +P940 and +P944) supplement

ACS880-11, ACS880-31, ACH580-31 and ACQ580-31 UK

gland plate (+H358) installation guide

FCAN-01 CANopen adapter module user's manual

FCNA-01 ControlNet a dapter module user's manual

FDNA-01 DeviceNet™ adapter module user's manual

FECA-01 EtherCAT adapter module user's manual

FENA-01/-11/-21 Ethernet adapter module user's manual 3AUA0000093568

FEPL-02 Ethernet POWERLINK adapter module user's manual 3AUA0000123527

FPBA-01 PROFIBUS DP adapter module user's manual

FSCA-01 RS-485 adapter module user's manual 3AUA0000109533

Tool and maintenance manuals and guides

Drive composer PC to ol user's manual 3AUA0000094606

Converter module capacitor reforming instructions

NETA-21 remote monitoring tool user's manual

NETA-21 remote monitoring tool installation and start-up guide 3AUA0000096881

You can find manuals and other product documents in PDF format on the Internet.

See section

Document library on the Internet

on the inside of the back cover. For manuals not

available in the Document library, contact your local ABB representative.

3AUA0000098062

3AXD50000045932

3AXD50000048138

3AUA0000085685

3AUA0000145446

3AXD50000110711

3AFE68615500

3AUA0000141650

3AFE68573360

3AUA0000068940

3AFE68573271

3BFE64059629

3AUA0000096939

The code below opens an online listing of the manuals applicable to this product.

Page 3

EN – Quick installation guide 3

EN – Quick installation guide

This guide briefly describes how to install the drive. For complete information on

installation, see ACS880-11 drives hardware manual (3AXD50000045932 [English]).

For start-up instructions, see ACS880 drives with primary control program quick

start-up guide (3AUA0000098062 [English]).

To read a manual, go to www.abb.com/drives/documents

number.

and search for the document

Obey the safety instructions

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur:

• Only qualified electrical professionals are allowed to install and maintain the

drive.

• Never work on the drive, motor cable or motor when main power is applied. If

the drive is already connected to the input power, wait for 5 minutes after

disconnecting the input power.

• Never work on the control cables when power is applied to the drive or to the

external control circuits.

• Do not connect the drive to a voltage higher than what is marked on the type

designation label.

• Always ground the drive, the motor and adjoining equipment to the protective

earth (PE) bus of the power supply.

•Frames R6

Use a lifting device for lifting. Do not tilt the drive. Manual lifting, or overturning due

to the tilting, can cause physical injury. Make sure that the wall and the fixing

devices can carry the weight.

• Make sure that debris from drilling, cutting and grinding does not enter the drive.

• Make sure that the floor below the drive and the wall where the drive is installed

are non-flammable.

and R8: The drive module is heavy and its center of gravity is high.

Check if capacitors need to be reformed

EN

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

If the drive has not been powered (either in storage or unused) for over three years,

you must reform the capacitors.

You can determine the manufacturing date from the serial number, which you find on

the type designation label attached to the drive. The serial number is of format

MYYWWRXXXX. YY and WW tell the manufacturing year and week as follows:

Page 4

4 EN – Quick installation guide

YY: 17, 18, 19, … for 2017, 2018, 2019,

…

WW: 01, 02, 03, … for week 1, week 2, week 3, …

For information on reforming the capacitors, see Converter module capacitor

reforming instructions (3BFE64059629 [English]), available on the Internet at

www.abb.com/drives/documents

.

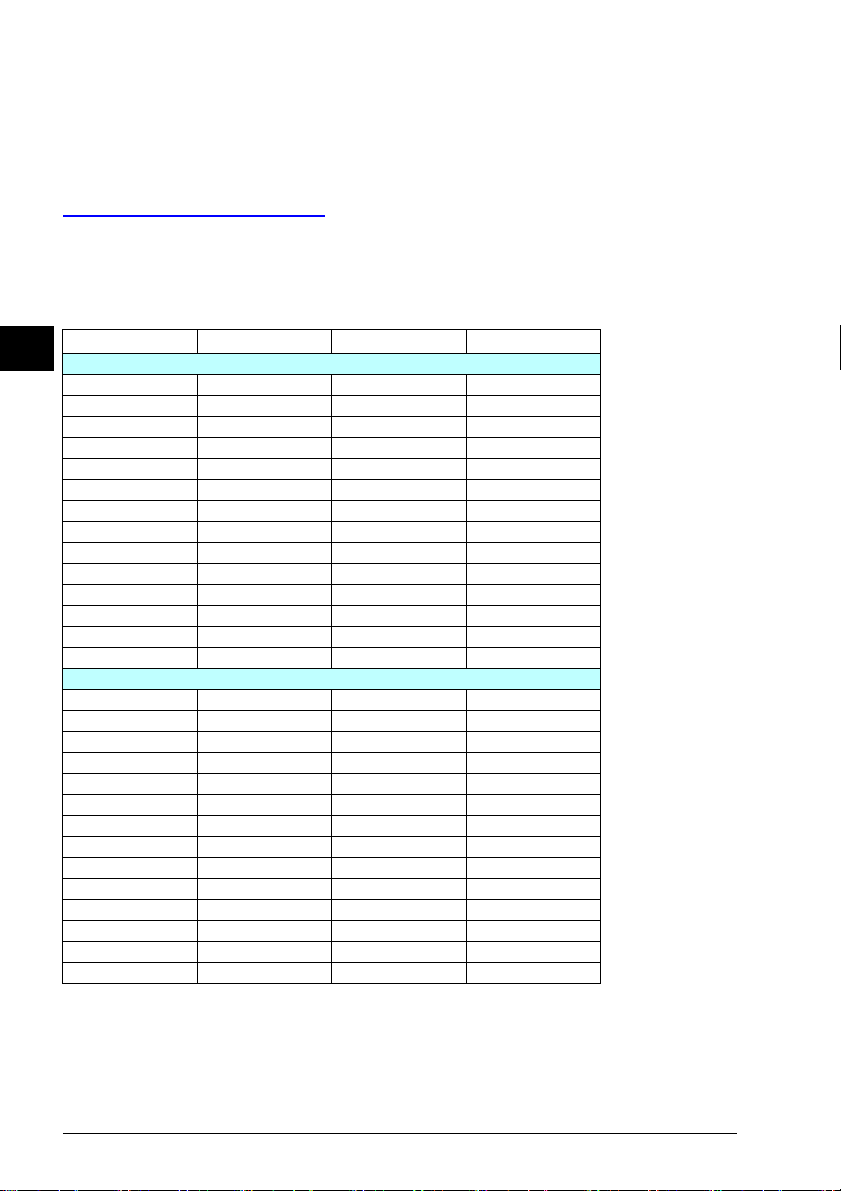

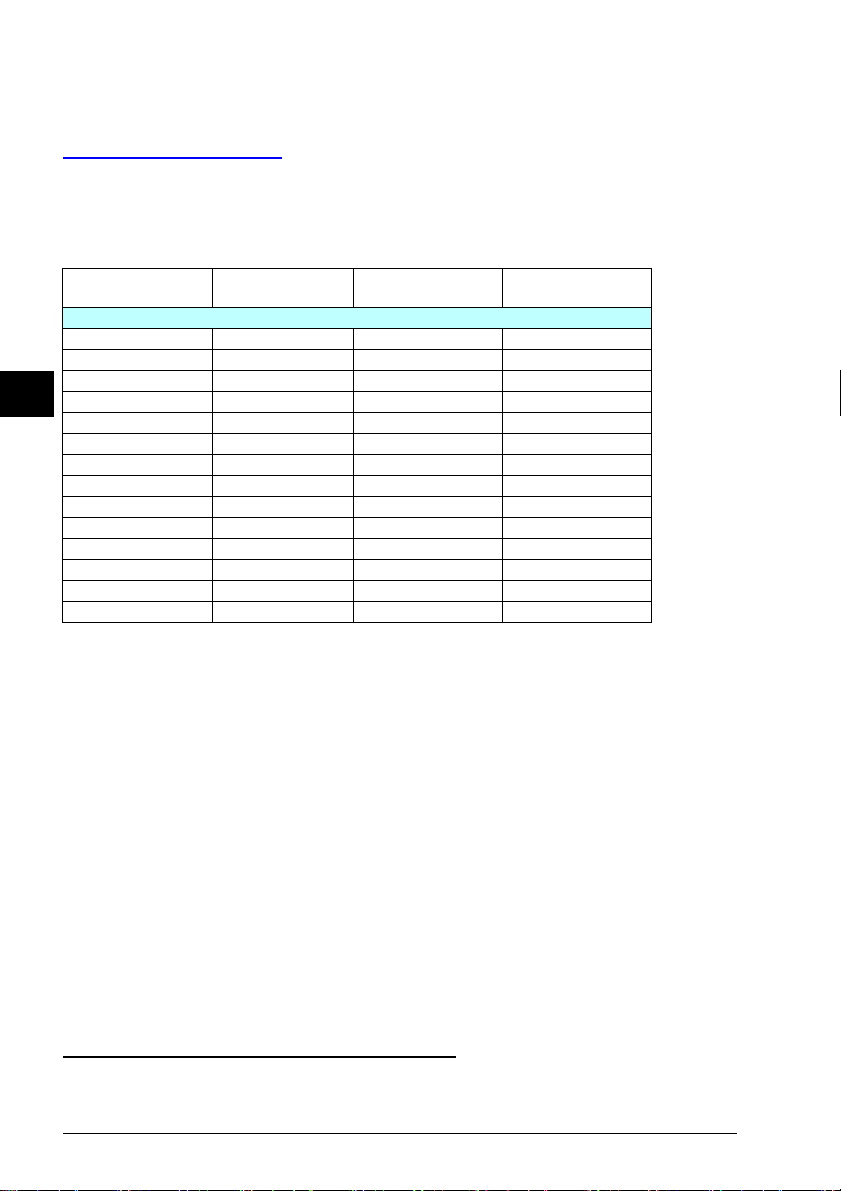

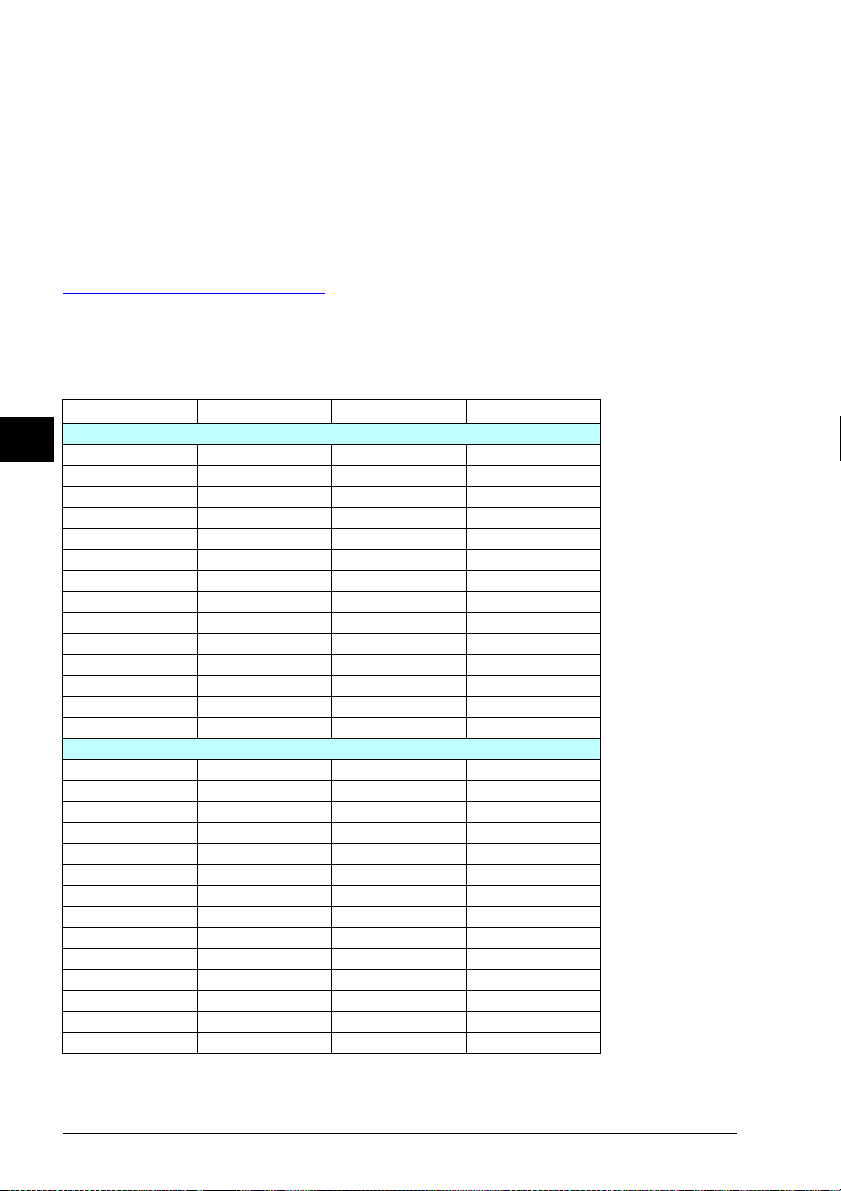

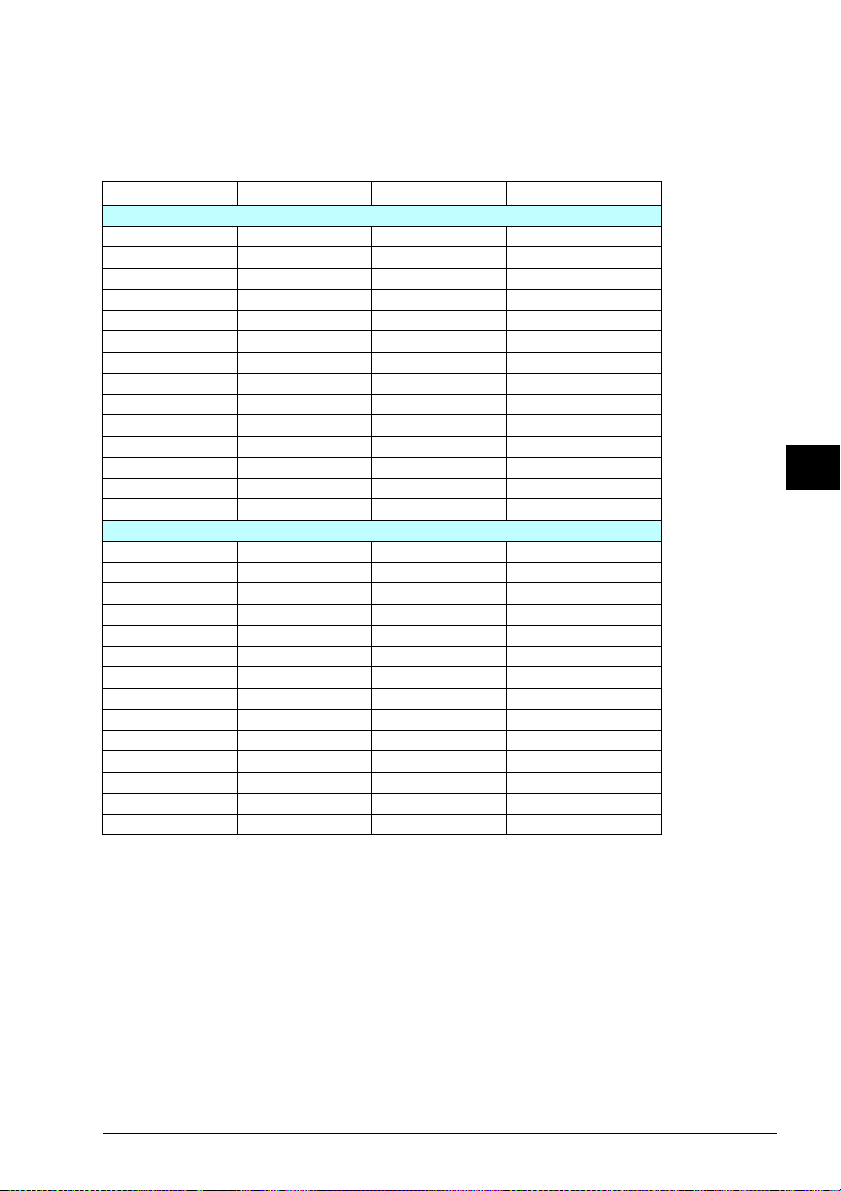

Data

IEC ratings

EN

DA

DE

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

ACS880-11-

3-phase UN = 400 V (380…415 V)

09A4-3 3×1.5 170M1561 226

12A6-3 3×1.5 170M1561 329

017A-3 3×6 170M1563 395

025A-3 3×6 170M1563 579

032A-3 3×10 170M1565 625

038A-3 3×10 170M1565 751

FI

045A-3 3×16 170M1566 912

061A-3 3×25 170M1567 1088

072A-3 3×35 170M1568 1502

087A-3 3×50 170M1569 1904

105A-3 3×50 170M3817 1877

145A-3 3×95 170M3817 2963

169A-3 3×120 170M5809 3168

206A-3 3×150 170M5810 3990

3-phase UN = 500 V (380…500 V)

07A6-5 3×1.5 170M1561 219

11A0-5 3×1.5 170M1561 278

014A-5 3×6 170M1563 321

021A-5 3×6 170M1563 473

027A-5 3×10 170M1565 625

034A-5 3×10 170M1565 711

040A-5 3×16 170M1566 807

052A-5 3×25 170M1567 960

065A-5 3×35 170M1568 1223

077A-5 3×35 170M1569 1560

101A-5 3×50 170M3816 1995

124A-5 3×95 170M3817 2800

156A-5 3×120 170M5808 3168

180A-5 3×150 170M5810 3872

Cable (mm

2

) aR fuse Losses (W)

3AXD00000588487

Select the power cables

See Data on page 4.

Page 5

EN – Quick installation guide 5

Ensure cooling

See Data on page 4. No condensation or frost is allowed. The allowed operating

temperature range of the drive without derating is -15 to +40 °C.

Protect the drive and input power cable

See Data on page 4.

A – Install the drive on the wall

See figure A on page 137.

B – Remove the cover

Remove the cover/s. See figures B (R3) and B (R6, R8)... on page 137.

C – Check the compatibility with IT (ungrounded) and corner-grounded delta systems

See figure C on page 137.

WARNING! If the drive will be connected on an IT (ungrounded or high-

resistance grounded) system or on a corner-grounded delta system,

disconnect the EMC filter (option +E202) and ground-to-phase varistor. See the drive

hardware manual.

D – Check the insulation of the power cables and the motor

Connect the motor cable at the motor end. For minimum radio frequency interference,

ground the motor cable shield 360 degrees at the cable entry of the motor terminal

box. See figure D on page 137.

Check the insulation of motor and motor cable. See figure D on page 137. Note:

Moisture inside the motor casing will reduce the insulation resistance. If moisture is

suspected, dry the motor and repeat the measurement.

Check the insulation of the input cable before connecting it to the drive. Obey the local

regulations.

EN

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

E – Attach the warning stickers in local languages

See figure E on page 138.

Page 6

6 EN – Quick installation guide

F – Connect the power cables

Use symmetrical shielded cable for motor cabling. If the cable shield is the sole PE

conductor, make sure that is has sufficient conductivity for the PE.

Note for fr

power cabling. See the hardware manual for more information.

Procedure:

ame R3: Make sure that you have an additional PE conductor in the input

1. Frame R6

(R6, R8)… on page 138. Frame R8

EN

DA

DE

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

plates.

2. Remove the rubber grommets from the bottom plate for the cables to be

connected. See figure …F… on page 138.

3. Cut an adequate hole into the rubber grommets. Slide the grommets onto the

cables.

4. Prepare the ends of the cables. See figure …F… on page 138.

The bare shield will be grounded 360 degrees. Mark the pigtail made from the

FI

shield as a PE conductor with yellow-and-green color.

Two alternative symmetrical three-conductor cable types are shown, and one

four-conductor cable type. The four-conductor cable is only allowed for the input

power cabling.

If you use aluminum cables, put grease to the peeled aluminum cable before

connecting it to the drive.

5. Put the cables through the holes of the cable entry plate and attach the grommets

to the holes.

6. Connect the cables (use the torques defined in the figure). See figures …F… on

page 138 and 139:

• Ground the shield 360 degrees by tightening the clamp of the power cable

• Connect the twisted shield of the cable to the grounding terminal.

• Use a separate grounding PE cable (6a) or a cable with a separate PE

•Frame R3:

• Connect the phase conductors of the motor cable to the T1/U, T2/V and T3/W

and R8: Remove the shroud on the power cable terminals. See figure F

: For easier installation, remove the side

grounding shelf onto the stripped part of the cable.

conductor (6b) if the conductivity of the shield does not meet the requirements

for the PE conductor. If the protective PE conductor is smaller than 10 mm

you must use a second earthing conductor. See the hardware manual for

more information.

Connect the additional PE conductor of the input power cabling.

terminals and the phase conductors of the input cable to the L1, L2 and L3

terminals.

2

,

Page 7

EN – Quick installation guide 7

7. Frame R6 types bigger than -040A-x: Cut tabs in the shroud for the installed

cables. Frame R8:

shroud for the input cables. See figure …F (R6, R8)… on page 139.

8. Frames R6

…F (R6, R8)… on page 139.

9. Secure the cables outside the drive mechanically.

Install the side plates if removed. Knock out holes in the

and R8: Install the shroud on the power cable terminals. See figure

G – Connect the control cables

Procedure:

EN

1. Remove the front cover(s) if not already removed.

2. Frame R3

3. Cut an adequate hole into the rubber grommet and slide the grommet onto the

cable. Slide the cable through a hole in the bottom plate and attach the grommet

to the hole.

4. Route the cables. Frame R3:

Frame R6:

on page 140.

5. Ground the outer shield of the cable 360 degrees under the grounding clamp.

Keep the cable unstripped as close to the terminals of the control board as

possible.

6. Secure the cables inside the drive mechanically.

7. Frame R3

drive end, and ground them at the other cable end. Cut any unconnected wires at

the drive end. Frame R6

wire under the clamp below the control unit.

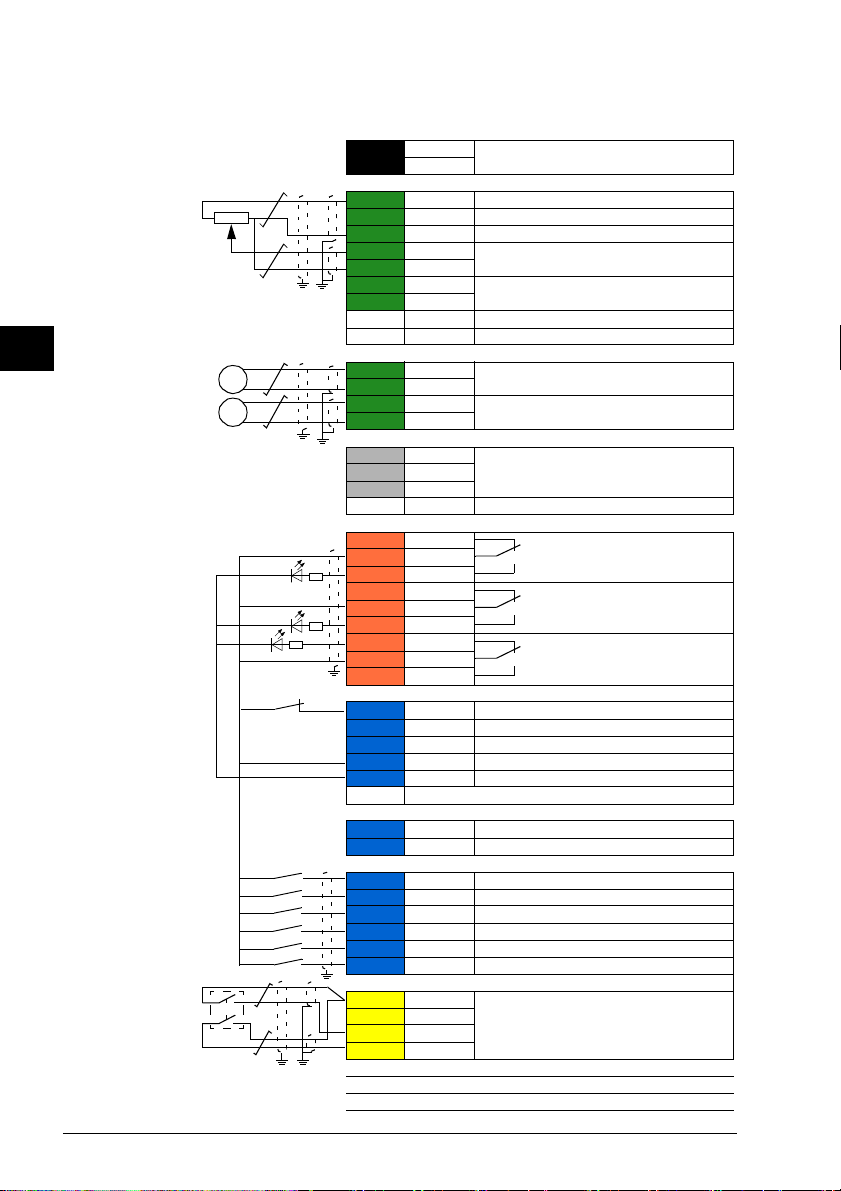

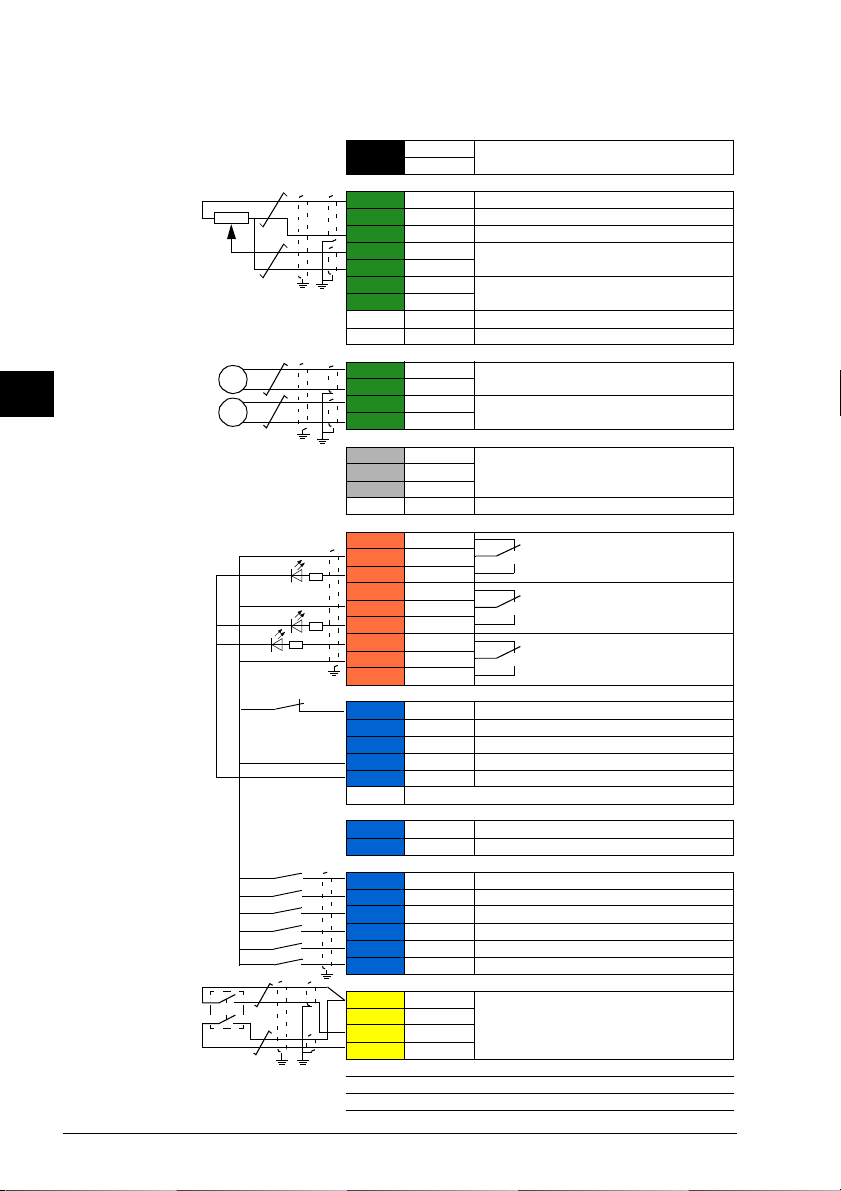

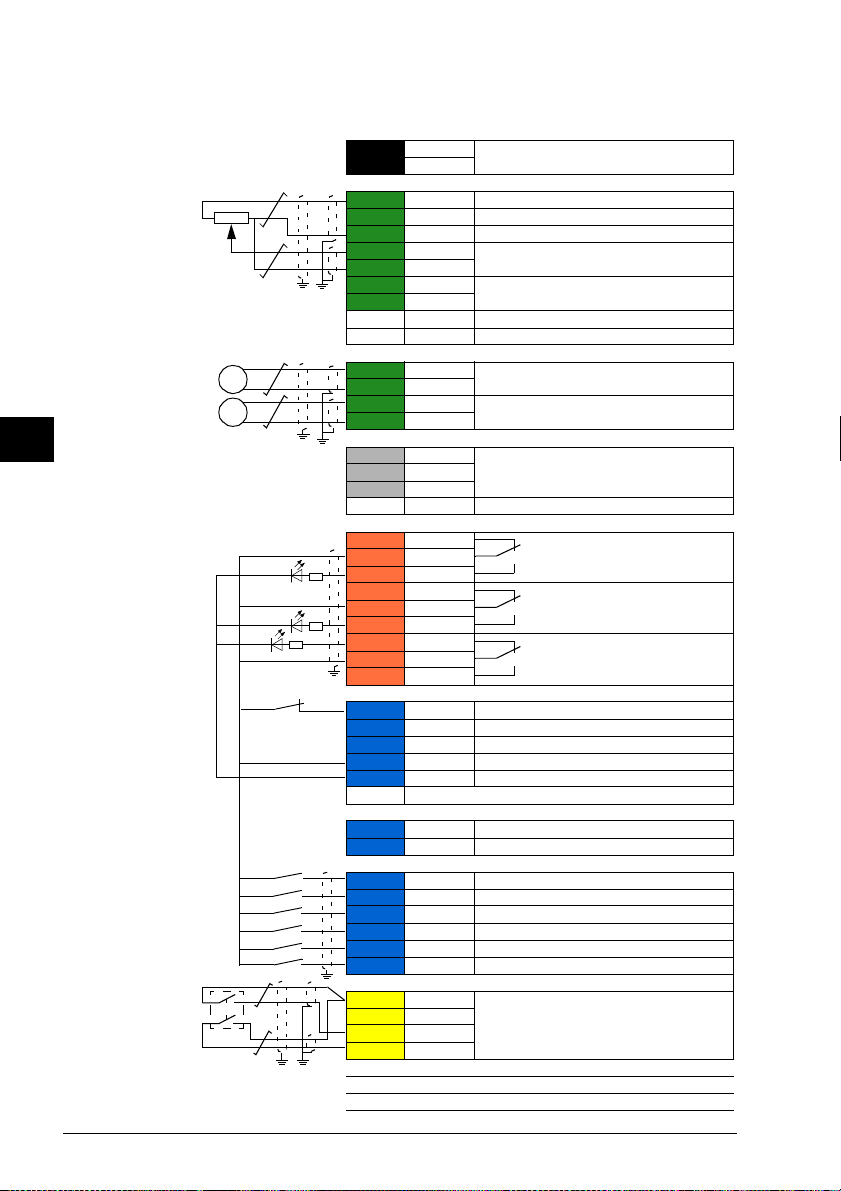

8. Connect the conductors to the appropriate terminals of the control unit. See

Default IO connection diagram on page 8.

9. Wire the optional modules if included in the delivery. See the option module user's

manual or installation guide.

10. Secure the cables outside the drive mechanically.

Note:

• Leave the other ends of the control cable shields unconnected.

• Keep any signal wire pairs twisted as close to the terminals as possible.

: Lift the control panel holder up. See figure G (R3)… on page 139.

See figure …G (R3)… on page 139.

See figure …G (R6)… on page 139. Frame R8: See figure …G (R8)…

: Leave the pair cable shields and grounding wires unconnected at the

and R8: Ground the pair-cable shields and grounding

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

H – Reinstall cover(s)

See figures H (R3, R6, R8)... on page 140.

Page 8

8 EN – Quick installation guide

Fault

XPOW External power input

1 +24VI

24 V DC, 2 A

2 GND

XAI Reference voltage and analog inputs

1 +VREF 10 V DC, RL 1…10 kohm

2 -VREF -10 V DC, RL 1…10 kohm

3 AGND Ground

4 AI1+ Speed reference 0(2)…10 V, Rin >

200 kohm

5 AI1-

6 AI2+ By default not in use. 0(4)…20 mA, Rin =

100 ohm

7 AI2-

J1 J1 AI1 current/voltage selection jumper

J2 J2 AI2 current/voltage selection jumper

XAO Analog outputs

1 AO1 Motor spee d rpm 0…20 mA, RL <

500 ohm

2 AGND

3 AO2

Motor current 0…20 mA, R

L

< 500 ohm

4 AGND

XD2D Drive-to-drive link

1 B

Drive-to-drive link

2 A

3 BGND

J3 J3 Drive-to-drive link termination switch

XRO1, XRO2, XRO3 Relay outputs

11 NC

Ready

250 V AC / 30 V DC

2 A

12 COM

13 NO

21 NC

Running

250 V AC / 30 V DC

2 A

22 COM

23 NO

31 NC

Faulted(-1)

250 V AC / 30 V DC

2 A

32 COM

33 NO

XD24 Digital interlock

1 DIIL Run enable

2 +24VD +24 V DC 200 mA

3 DICOM Digital input ground

4 +24VD +24 V DC 200 mA

5 DIOGND Digital input/output ground

J6 Ground selection switch

XDIO Digital input/outputs

1 DIO1 Output: Ready

2 DIO2 Output: Running

XDI Digital inputs

1 DI1 Stop (0) / Start (1)

2 DI2 Forward (0) / Reverse (1)

3 DI3 Reset

4 DI4 Acceleration & deceleration select

5 DI5 Constant speed 1 (1 = On)

6 DI6 By default not in use.

XSTO Safe torque off

1 OUT1

Safe torque off. Both circuits must be

closed for the drive to start.

2 SGND

3 IN1

4 IN2

X12 Safety functions module connection

X13 Control panel connection

X205 Memory unit connection

Wire sizes:

0.5 … 2.5 mm

2

(24…14 AWG)

Tightening

torques: 0.5 N·m

(0.4 lbf·ft) for

both stranded

and solid wiring.

Default IO connection diagram

EN

DA

DE

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 9

Declaration of Conformity (EU)

EN – Quick installation guide 9

EN

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 10

10 EN – Quick installation guide

EN

DA

DE

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 11

EN – USA quick installation guide 11

EN – USA quick installation guide

This guide briefly describes how to install the drive. For complete information on

installation, see ACS880-11 drives hardware manual (3AXD50000045932 [English]).

For start-up instructions, see ACS880 drives with primary control program quick

start-up guide (3AUA0000098062 [English]).

To read a manual, go to

abb.com/drives/documents

and search for the document number.

Obey the safety instructions

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur:

• Only qualified electrical professionals are allowed to install and maintain the

drive.

• Never work on the drive, motor cable or motor when main power is applied. If

the drive is already connected to the input power, wait for 5 minutes after

disconnecting the input power.

• Never work on the control cables when power is applied to the drive or to the

external control circuits.

• Do not connect the drive to a voltage higher than what is marked on the type

designation label.

• Always ground the drive, the motor and adjoining equipment to the protective

earth (PE) bus of the power supply.

•Frames R6

Use a lifting device for lifting. Do not tilt the drive. Manual lifting, or overturning due

to the tilting, can cause physical injury. Make sure that the wall and the fixing

devices can carry the weight.

• Make sure that debris from drilling, cutting and grinding does not enter the drive.

• Make sure that the floor below the drive and the wall where the drive is installed

are non-flammable.

and R8: The drive module is heavy and its center of gravity is high.

DE

USA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

Check if capacitors need to be reformed

If the drive has not been powered (either in storage or unused) for over three years,

you must reform the capacitors.

You can determine the manufacturing date from the serial number, which you find on

the type designation label attached to the drive. The serial number is of format

MYYWWRXXXX. YY and WW tell the manufacturing year and week as follows:

YY: 17, 18, 19, … for 2017, 2018, 2019,

WW: 01, 02, 03, … for week 1, week 2, week 3, …

…

ZH

Page 12

12 EN – USA quick installation guide

For information on reforming the capacitors, see Converter module capacitor

reforming instructions (3BFE64059629 [English]), available on the Internet at

abb.com/drives/documents

.

Data

UL (NEC) ratings

ACS880-11-

3-phase UN = 480 V (440, 460, 480 V)

EN

USA

DE

ES

FI

FR

FR

07A6-5 14 JJS-15 219

11A0-5 14 JJS-20 278

014A-5 10 JJS-25 321

021A-5 10 JJS-35 473

027A-5 8 JJS-40 625

034A-5 8 JJS-50 711

040A-5 6 JJS-60 807

052A-5 4 JJS-80 960

065A-5 2 JJS-90 1223

077A-5 2 JJS-110 1560

101A-5 1 JJS-150 1995

124A-5 2/0 JJS-200 2800

156A-5 3/0 JJS-225 3168

180A-5 250MCM JJS-300 3872

NL

Cu cable

(AWG/kcmil)

UL fuse Losses (W)

3AXD00000588487

Select the power cables

PL

See the Data table on page 12.

PT

Ensure cooling

RU

See the Data table on page 12. No condensation or frost is allowed. The allowed

operating temperature range of the drive without derating is -15 to +40 °C.

SV

Protect the drive and input power cable

TR

Check on the fuse time-current curve to ensure that the operating time of the fuse is

below0.1 seconds. Obey the local regulations.

ZH

A – Install the drive on the wall

See figure A on page 141.

Frames R6

the drive before you tighten the upper fastening screws. Place the vertical edge of the

hood in between the wall and the drive back plate. Then tighten the screws to fasten

the hood and drive on its place. See figure A (R6 , R 8) on page 141.

and R8 of UL Type 12 (option +B056): Install an additional hood on top of

Page 13

EN – USA quick installation guide 13

B – Remove the cover

Remove the cover(s). See figures B (R3) and B (R6, R8)... on page 141.

C – Check the compatibility with IT (ungrounded) and corner-grounded delta systems

See figure C on page 141.

WARNING!

grounded) system or on a corner-grounded delta system, disconnect the EMC

filter (option +E202) and ground-to-phase varistor. See the drive hardware manual.

If the drive will be connected on an IT (ungrounded or high-resistance

D – Check the insulation of the power cables and the motor

Check the insulation of motor and motor cable. See figure D on page 142. Note:

Moisture inside the motor casing will reduce the insulation resistance. If moisture is

suspected, dry the motor and repeat the measurement.

Check the insulation of the input cable before connecting it to the drive. Obey the local

regulations.

E – Attach the warning stickers in local languages

See figure E on page 142.

F – Connect the power cables

Procedure:

1. Frame R6

(R6, R8)… on page 142. Frame R8

plates.

2. Remove the rubber grommets from the bottom plate for the cable conduits to be

installed. See figure …F… on page 142.

and R8: Remove the shroud on the power cable terminals. See figure F

: For easier installation, remove the side

DE

USA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

3. Attach the cable conduits to the bottom plate holes. See figure …F… on

page 142.

4. Remove the cable shelves (4a). Reinstall the four screws to avoid moisture

exchange through the empty holes! (4b). See figure …F (R6, R8)… on page 142.

5. Strip the cable ends. (Note the extra length of the grounding conductors.) Slide

the cables through the connectors. See figure …F… on page 142.

ZH

Page 14

14 EN – USA quick installation guide

6. Connect the grounding conductors to the grounding terminals. Connect the

conductors of the input and motor cables. Tighten the screws. See figures …F

(R3)…, …F (R6)… and …F (R8)……on page 142.

Connect the phase conductors of the motor cable to the T1/U, T2/V and T3/W

terminals and the phase conductors of the input cable to the L1, L2 and L3

terminals.

If the protective PE conductor is smaller than 10 mm

earthing conductor (6a). See the hardware manual for more information.

2

, you must use a second

7. Frame R6 types bigger than -040A-x:

EN

USA

DE

ES

FR

FR

NL

PL

PT

RU

SV

TR

cables. Frame R8:

shroud for the input cables. See figure …F (R6, R8)… on page 143.

8. Frames R6

G – Connect the control cables

Procedure:

1. Remove the front cover(s) if not already removed.

FI

2. Frame R3

3. Remove the rubber grommets from the bottom plate for the cable conduits to be

installed.

4. Attach the cable conduits to the bottom plate holes.

5. Strip the cable ends and cut to suitable length (note the extra length of the

grounding conductors).

6. Route the cables. Frame R3:

Frame R6:

on page 144.

7. Secure the cables inside the drive with cable ties.

8. Frame R3

drive end, and ground them at the other cable end. Cut any unconnected wires at

the drive end. Frame R6 and R8:

wire under the clamp below the control unit.

: Lift the control panel holder up. See figure G (R3)… on page 143.

See figure …G (R6)… on page 144. Frame R8: See figure …G (R8)…

: Leave the pair cable shields and grounding wires unconnected at the

Install the side plates if removed. Knock out holes in the

and R8:; Install the shroud on the power cable terminals.

See figure …G (R3)… on page 143.

Cut tabs in the shroud for the installed

Ground the pair-cable shields and grounding

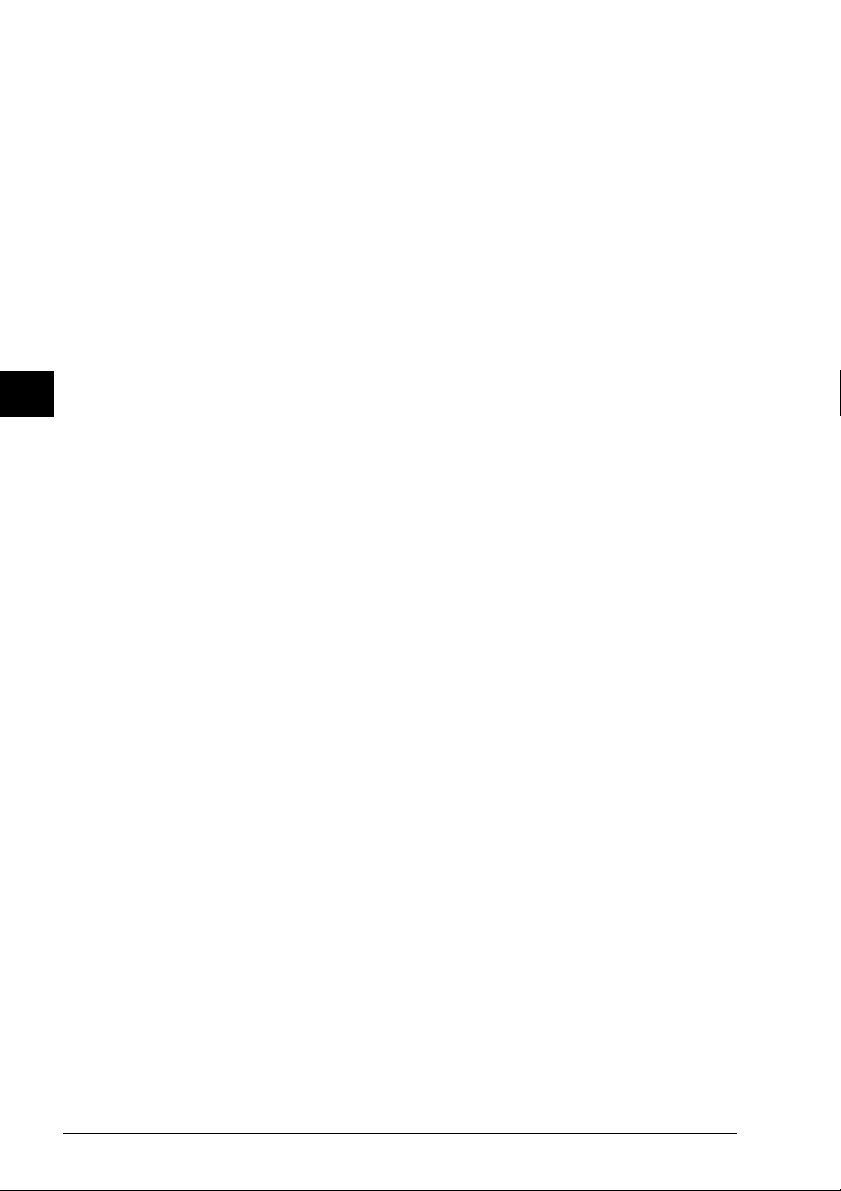

9. Connect the conductors to the appropriate terminals of the control unit. See

ZH

Default IO connection diagram on page 16.

10. Wire the optional modules if included in the delivery. See the option module user's

manual or installation guide.

Note:

• Leave the other ends of the control cable shields unconnected.

• Keep any signal wire pairs twisted as close to the terminals as possible.

Page 15

H – Reinstall cover(s)

See figures H (R3, R6, R8)... on page 145.

EN – USA quick installation guide 15

DE

USA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 16

16 EN – USA quick installation guide

Fault

XPOW External power input

1 +24VI

24 V DC, 2 A

2 GND

XAI Reference voltage and analog inputs

1 +VREF 10 V DC, RL 1…10 kohm

2 -VREF -10 V DC, RL 1…10 kohm

3 AGND Ground

4 AI1+ Speed reference 0(2)…10 V, Rin >

200 kohm

5 AI1-

6 AI2+ By default not in use. 0(4)…20 mA, Rin =

100 ohm

7 AI2-

J1 J1 AI1 current/voltage selection jumper

J2 J2 AI2 current/voltage selection jumper

XAO Analog outputs

1 AO1 Motor spee d rpm 0…20 mA, RL <

500 ohm

2 AGND

3 AO2

Motor current 0…20 mA, R

L

< 500 ohm

4 AGND

XD2D Drive-to-drive link

1 B

Drive-to-drive link

2 A

3 BGND

J3 J3 Drive-to-drive link termination switch

XRO1, XRO2, XRO3 Relay outputs

11 NC

Ready

250 V AC / 30 V DC

2 A

12 COM

13 NO

21 NC

Running

250 V AC / 30 V DC

2 A

22 COM

23 NO

31 NC

Faulted(-1)

250 V AC / 30 V DC

2 A

32 COM

33 NO

XD24 Digital interlock

1 DIIL Run enable

2 +24VD +24 V DC 200 mA

3 DICOM Digital input ground

4 +24VD +24 V DC 200 mA

5 DIOGND Digital input/output ground

J6 Ground selection switch

XDIO Digital input/outputs

1 DIO1 Output: Ready

2 DIO2 Output: Running

XDI Digital inputs

1 DI1 Stop (0) / Start (1)

2 DI2 Forward (0) / Reverse (1)

3 DI3 Reset

4 DI4 Acceleration & deceleration select

5 DI5 Constant speed 1 (1 = On)

6 DI6 By default not in use.

XSTO Safe torque off

1 OUT1

Safe torque off. Both circuits must be

closed for the drive to start.

2 SGND

3 IN1

4 IN2

X12 Safety functions module connection

X13 Control panel connection

X205 Memory unit connection

Wire sizes:

0.5 … 2.5 mm

2

(24…14 AWG)

Tightening

torques: 0.5 N·m

(0.4 lbf·ft) for

both stranded

and solid wiring.

Default IO connection diagram

EN

USA

DE

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 17

EN – USA quick installation guide 17

UL checklist

WARNING! Operation of this drive requires detailed installation and operation

instructions provided in the hardware and software manuals. The manuals are

provided in electric format in the drive package or on the Internet. Retain the manuals

with the drive at all times. Hard copies of the manuals can be ordered through the

manufacturer.

• Make sure that the drive type designation label includes the cULus Listed

marking.

• CAUTION - Risk of electric shock. After disconnecting the input power, always

wait for 5 minutes to let the intermediate circuit capacitors discharge before you

start working on the drive, motor or motor cable.

• The drive is to be used in a heated, indoor controlled environment. The drive must

be installed in clean air according to enclosure classification. Cooling air must be

clean, free from corrosive materials and electrically conductive dust. See the

hardware manual.

• The maximum surrounding air temperature is +55 °C (131 °F) at rated current.

The current is derated for 40 to 55 °C (104 to 131 °F).

• The drive is suitable for use in a circuit capable of delivering not more than

100,000 rms symmetrical amperes, 480 V maximum when protected by the UL

fuses on page 12. The ampere rating is based on tests done according to the

appropriate UL standard.

• The cables located within the motor circuit must be rated for at least 75 °C

(167 °F) in UL-compliant installations.

• The input cable must be protected with fuses. The fuses must provide branch

circuit protection in accordance with the national regulations (National Electrical

Code (NEC) or Canadian Electrical Code). Obey also any other applicable local

or provincial codes.

• Note: Circuit breakers must not be used without fuses in the USA. Contact your

local representative for suitable circuit breakers.

WARNING! The opening of the branch-circuit protective device may be an

indication that a fault current has been interrupted. To reduce the risk of fire

or electric shock, current-carrying parts and other components of the device

should be examined and replaced if damaged.

• The drive provides motor overload protection. For adjustments, see the firmware

manual.

• For the drive overvoltage category and pollution degree, see the hardware

manual.

DE

USA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 18

18 EN – USA quick installation guide

EN

USA

DE

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 19

DA – Hurtig installationsvejledning 19

DA – Hurtig installationsvejledning

Denne vejledning giver en kortfattet beskrivelse af, hvordan du installerer frekvensomformeren. Du finder fuldstændige oplysninger om installationen i ACS880-11

drives hardware manual (3AXD50000045932 (på engelsk)). Se opstartsinstruktionerne i ACS880 drives with primary control program quick start-up guide

(3AUA0000098062 (på engelsk)).

Du kan læse en manual ved at gå til www.abb.com/drives/documents

dokumentnummeret.

og søge efter

Overhold sikkerhedsinstruktionerne

ADVARSEL! Følg disse instruktioner. Hvis de ignoreres, kan det resultere i

personskader, dødsfald eller skade på udstyret:

• Kun autoriserede elinstallatører må udføre installation og vedligeholdelse af

frekvensomformeren.

• Undlad at arbejde med frekvensomformeren, motorkablet eller motoren, når tilslutning til nettet er foretaget. Hvis frekvensomformeren allerede er tilsluttet netforsyningen, skal du vente 5 minutter efter frakobling af netspændingen.

• Du må aldrig arbejde med signalkablerne, når netspændingen er tilsluttet

frekvensomformeren eller de eksterne styrekredse.

• Frekvensomformeren må ikke tilsluttes til en spænding, der er højere end den,

der er angivet på typebetegnelsesmærkaten.

• Frekvensomformeren, motoren og tilstødende udstyr skal altid jordes med

strømforsyningens beskyttelsesjordbus (PE).

• Modul R6

punkt. Brug en løfteanordning til at løfte med. Frekvensomformeren må ikke vippes. Manuelle løft eller væltning som følge af tipning af frekvensomformeren

kan forårsage fysiske skader. Sørg for, at væggen og fastgørelsesanordningerne kan understøtte vægten.

• Undgå, at der trænger smuds fra boringer, skæring eller slibning ind i

frekvensomformeren under installation.

• Sørg for, at gulvet under frekvensomformeren og den væg, hvor frekvensomformeren installeres, ikke er brændbare.

og R8: Frekvensomformermodulet er tungt og har et højt tyngde-

DA

DA

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Kontrollér, om det er nødvendigt at reformere kondensatorerne

Hvis frekvensomformeren ikke har været tilsluttet spænding (opbevaret eller ikke

anvendt) i over tre år, skal du reformere kondensatorerne.

Page 20

20 DA – Hurtig installationsvejledning

Du kan bestemme produktionsdatoen ud fra serienummeret, som du finder på

typebetegnelsesmærket på frekvensomformeren. Serienummeret har formatet

MYYWWRXXXX. YY og WW angiver produktionsåret og ugen på følgende måde:

YY: 17, 18, 19, … for 2017, 2018, 2019,

…

WW: 01, 02, 03, … for uge 1, uge 2, uge 3, …

Oplysninger om reformering af kondensatorer findes i Converter module capacitor

reforming instructions (3BFE64059629 (på engelsk)), som findes på internettet på

www.abb.com/drives/documents

Data

EN

IEC-klassificeringer

DA

ACS880-11-

DA

3-faset UN = 400 V (380…415 V)

09A4-3 3×1.5 170M1561 226

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

12A6-3 3×1.5 170M1561 329

017A-3 3×6 170M1563 395

025A-3 3×6 170M1563 579

032A-3 3×10 170M1565 625

038A-3 3×10 170M1565 751

045A-3 3×16 170M1566 912

061A-3 3×25 170M1567 1088

072A-3 3×35 170M1568 1502

087A-3 3×50 170M1569 1904

105A-3 3×50 170M3817 1877

145A-3 3×95 170M3817 2963

169A-3 3×120 170M5809 3168

206A-3 3×150 170M5810 3990

3-faset UN = 500 V (380…500 V)

07A6-5 3×1.5 170M1561 219

11A0-5 3×1.5 170M1561 278

014A-5 3×6 170M1563 321

021A-5 3×6 170M1563 473

027A-5 3×10 170M1565 625

034A-5 3×10 170M1565 711

040A-5 3×16 170M1566 807

052A-5 3×25 170M1567 960

065A-5 3×35 170M1568 1223

077A-5 3×35 170M1569 1560

101A-5 3×50 170M3816 1995

124A-5 3×95 170M3817 2800

156A-5 3×120 170M5808 3168

180A-5 3×150 170M5810 3872

Kabel (mm

.

2

) aR -sikring Tab (W)

3AXD00000588487

Page 21

DA – Hurtig installationsvejledning 21

Vælg effektkabler

Se Data på side 20.

Sørg for køling

Se Data på side 20. Kondensation eller frost er ikke tilladt. Frekvensomformerens

tilladte driftstemperaturområde uden reduktion er -15 til +40 °C.

Beskyt frekvensomformeren og netkablet

Se Data på side 20.

A – Installer frekvensomformeren på væggen

Se figur A på side 137.

B – Fjern dækslet

Fjern dækslet/dækslerne. Se figurerne B (R3) og B (R6, R8)... på side 137.

DA

DA

ES

FI

C – Kontrollér kompatibiliteten med IT-net (ujordede) og hjørnejordede deltasystemer

Se figur C på side 137.

ADVARSEL! Hvis frekvensomformeren tilsluttes på et It-net (ujordede eller

højmodstandsjordede) eller på et hjørnejordet deltasystem, skal du frakoble

EMC-filtret (ekstraudstyr +E202) og jord-til-fase-varistor. Se frekvensomforme-

rens hardwaremanual.

D – Kontrollér isoleringen på effektkablerne og motoren.

Tilslut motorkablet i motorenden. For at opnå mindst mulig radiofrekvensinterferens

jordes motorkabelskærmen 360 grader ved kabelindgangen i motorklemkassen. Se

figur D på side 137.

Kontrollér isoleringen af motor og motorkabel Se figur D på side 137. Bemærk! Fugt

inden i motorhuset reducerer isolationsmodstanden. Hvis der er mistanke om fugt,

skal motoren tørres, og målingen gentages.

Kontrollér isoleringen af indgangskablet, inden det tilsluttes frekvensomformeren.

Overhold de lokale bestemmelser.

E – Fastgør advarselsmærkaterne på de lokale sprog

Se figur E på side 138.

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 22

22 DA – Hurtig installationsvejledning

F – Tilslut effektkablerne

Anvend et skærmet symmetrisk kabel til motorkabling. Hvis kabelskærmen er den

eneste PE-leder, skal du sørge for, at den har tilstrækkelig ledeevne til PE'en.

Note til modul R3:

indgangen. Se hardwaremanualen for at få flere oplysninger.

Procedure:

Du skal sikre dig, at du har en ekstra PE-leder i effektkablet til

1. Modul R6

R8)… på side 138. Modul R8

EN

DA

DA

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

installere.

2. Fjern gummimufferne fra bundpladen, så kablerne kan tilsluttes. Se figur …F… på

side 138.

3. Skær et tilstrækkeligt stort hul i gummimufferne. Træk mufferne over på kablerne.

4. Forbered kabelenderne. Se figur …F… på side 138.

Afskærmningen jordes 360 grader. Markér det øje, der dannes af skærmen, som

en PE-leder med gult og grønt.

FI

Der er vist to alternative symmetriske trelederkabeltyper samt en

firlederkabeltype. Firlederkablet må kun bruges ved effektkablet til indgangen.

Hvis du bruger aluminiumskabler, skal du smøre fedt på det skrællede

aluminiumskabel, før du slutter det til frekvensomformeren.

5. Før kablerne gennem hullerne på indgangspladen, og sæt mufferne fast i

hullerne.

6. Tilslut kablerne (brug de momenter, der er defineret i figuren). Se figurerne …F…

på side 138 og 139:

• Jord skærmene 360 grader ved at spænde klemmen på netkablets

• Forbind den snoede del af kabelskærmen med jordterminalen.

• Brug et separat jordet PE-kabel (6a) eller et kabel med separat PE-leder (6b),

• Modul R3:

• Forbind motorkablets faseledere med terminalerne T1/U, T2/V og T3/W samt

7. Modul R6-typer større end -040A-x:

installerede kabler. Modul R8:

huller i afskærmningen til indgangskablerne. Se figur …F (R6, R8)… på side 139.

og R8: Fjern afdækningen på effektkabelterminalerne. Se figur F (R6,

: Fjern sidepladerne for nemmere at kunne

jordingsplint fast på den afisolerede del af kablet.

hvis skærmens ledeevne ikke opfylder kravene til PE-lederen. Hvis PElederen til beskyttelse er mindre end 10 mm

jordleder. Se hardwaremanualen for at få flere oplysninger.

Tilslut den ekstra PE-leder for effektkablet til indgangen.

indgangskablets faseledere med terminalerne L1, L2 og L3.

Skær tapper i afskærmningen til de

Montér sidepladerne, hvis de har været fjernet. Lav

2

, skal du bruge en ekstra

8. Modul R6

(R6, R8)… på side 139.

og R8: Installér afdækningen på effektkabelterminalerne. Se figur …F

Page 23

DA – Hurtig installationsvejledning 23

9. Fastgør kablerne mekanisk udvendigt på frekvensomformeren.

G – Tilslutning af styrekablerne

Procedure:

1. Fjern frontdækslet/-dækslerne, hvis det ikke allerede er gjort.

2. Modul R3

3. Klip et passende hul i gummimuffen, og skub muffen på kablet. Før kablet

gennem et hul i bundpladen, og sæt muffen fast i hullet.

4. Træk kablerne. Modul R3:

Modul R6:

side 140.

5. Jord den udvendige skærm på kablet 360 grader under jordingsklemmen. Kablet

skal være isoleret så tæt på terminalerne på styrekortet som muligt.

6. Fastgør kablerne mekanisk indvendigt på frekvensomformeren.

7. Modul R3

frekvensomformerens ende, og jord dem i den anden kabelende. Klip alle ikketilsluttede kabler ved frekvensomformerens ende. Modul R6 og R8:

skærmene på de parsnoede kabler og alle jordkabler under klemmen under

styreenheden.

8. Forbind kablets ledere til de korrekte klemmer på styreenheden. Se Diagram over

I/O-standardtilslutninger på side 24.

9. Forbind de valgfrie moduler, hvis de indgår i leverancen. Se ekstramodulets

brugermanual eller installationsvejledning.

10. Fastgør kablerne mekanisk udvendigt på frekvensomformeren.

Bemærk!

• Lad de andre ender af styrekabelskærmen være uforbundet.

• Lad parvise signalkabler være snoet så tæt på terminalerne som muligt.

: Løft betjeningspanelets holder op. Se figur G (R3)… på side 139.

Se figur …G (R3)… på side 139.

Se figur …G (R6)… på side 139. Modul R8: Se figur …G (R8)… på

: Undlad at tilslutte skærmene på de parsnoede kabler og jordkabler ved

Jord

H – Geninstallér dæksel eller dæksler.

Se figurerne H (R3, R6, R8)... på side 140.

DA

DA

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 24

24 DA – Hurtig installationsvejledning

Fejl

XPOW Ekstern strømforsyning

1 +24VI

24 V DC, 2 A

2 GND

XAI Referencespænding og analoge indgange

1 +VREF 10 V DC, RL 1…10 kohm

2 -VREF -10 V DC, RL 1…10 kohm

3 AGND Jord

4 AI1+ Hastighedsreference 0(2)…10 V, Rin >

200 kohm

5 AI1-

6 AI2+ Som standardindstilling ubenyttet.

0(4)…20 mA, R

in

= 100 ohm

7 AI2-

J1 J1 AI1-jumper til valg af strøm/spænding

J2 J2 AI2-jumper til valg af strøm/spænding

XAO Analoge udgange

1 AO1 Motorhastighed o/min 0…20 mA, RL <

500 ohm

2 AGND

3 AO2

Motorstrøm 0…20 mA, R

L

< 500 ohm

4 AGND

XD2D Drev-til-drev-forbindelse

1 B

Drev-til-drev-forbindelse

2 A

3 BGND

J3 J3 Afbryder til drev-til-drev-forbindelse

XRO1, XRO2, XRO3 Relæudgange

11 NC

Startklar

250 V AC / 30 V DC

2 A

12 COM

13 NEJ

21 NC

Kører

250 V AC / 30 V DC

2 A

22 COM

23 NEJ

31 NC

Fejl(-1)

250 V AC / 30 V DC

2 A

32 COM

33 NEJ

XD24 Digital interlock

1 DIIL Start frigiv

2 +24VD +24 V DC 200 mA

3 DICOM Jording af digital indgang

4 +24VD +24 V DC 200 mA

5 DIOGND Jording af digital indgang/udgang

J6 Afbryder til valg af jord

XDIO Digitale indgange/udgange

1 DIO1 Udgang: Startklar

2 DIO2 Udgang: Kører

XDI Digitale indgange

1 DI1 Stop (0) / Start (1)

2 DI2 Forlæns (0) / Baglæns (1)

3 DI3 Nulstil

4 DI4 Acceleration og deceleration vælg

5 DI5 Konstant hastighed 1 (1 = Til)

6 DI6 Som standardindstilling ubenyttet.

XSTO Safe torque off

1 OUT1

Safe torque off. Begge kredse skal være

lukkede, for at frekvensomformeren kan

starte.

2 SGND

3 IN1

4 IN2

X12 Modulforbindelse med sikkerhedsfunktioner

X13 Tilslutning til betjeningspanel

X205 Tilslutning til hukommelsesenhed

Ledningsstørrelse:

0,5 … 2,5 mm

2

(24…14 AWG)

Fastspændingsmomenter:

0,5 N·m

(0,4 lbf·ft) til

både trådledere

og stive ledere.

Diagram over I/O-standardtilslutninger

EN

DA

DA

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 25

DA – Hurtig installationsvejledning 25

Overensstemmelseserklæring (EU)

DA

DA

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 26

26 DA – Hurtig installationsvejledning

EN

DA

DA

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 27

DE – Kurzanleitung für die Installation 27

DE – Kurzanleitung für die Installation

Diese Kurzanleitung beschreibt die Installation des Frequenzumrichters. Vollständige

Informationen zur Installation siehe ACS880-11 drives hardware manual

(3AXD50000045932 [Englisch]). Inbetriebnahmeanweisungen siehe ACS880 drives

with primary control program quick start-up guide (3AUA0000098062 [Englisch]).

Die Handbücher finden Sie unter www.abb.com/drives/documents

Dokument mit seiner jeweiligen Dokumentennummer.

, und suchen Sie das

EN

DA

Befolgen Sie die Sicherheitsvorschriften

WARNUNG! Befolgen Sie diese Hinweise. Wenn diese nicht befolgt werden,

können Verletzungen, tödliche Unfälle oder Schäden an den Geräten auftreten:

• Installation und Wartung des Frequenzumrichters dürfen nur von qualifiziertem

Fachpersonal ausgeführt werden.

• Am Frequenzumrichter, dem Motorkabel oder dem Motor dürfen keinerlei Arbeiten ausgeführt werden, solange die Netzspannung anliegt. Wenn der Frequenzumrichter bereits an die Spannungsversorgung angeschlossen ist/war, warten

Sie 5 Minuten nach der Trennung von der Eingangsspannung.

• Führen Sie keine Arbeiten an den Steuerkabeln durch, wenn Spannung am

Frequenzumrichter oder den externen Steuerkreisen anliegt.

• Am Frequenzumrichter keine Spannung anlegen, die höher ist, als auf dem

Typenschild angegeben.

• Erden Sie immer den Frequenzumrichter, den Motor und die benachbarten

Geräte über die PE-Sammelschiene der Spannungsversorgung.

• Baugrößen R6

hoch liegenden Schwerpunkt. Verwenden Sie eine Hebevorrichtung. Der Frequenzumrichter darf nicht gekippt werden. Das manuelle Anheben oder ein

Umkippen kann zu Verletzungen führen. Stellen Sie sicher, dass die Wand und

die Montagemittel das Gewicht tragen können.

• Verhindern Sie, dass Bohrspäne, Schneidespäne oder Staub in den Frequenzumrichter eindringen.

• Stellen Sie sicher, dass der Boden unterhalb des Frequenzumrichters und die

Wand, an der der Frequenzumrichter montiert wird, aus nicht brennbarem Material bestehen.

und R8: Das Frequenzumrichtermodul ist schwer und hat einen

DE

DE

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 28

28 DE – Kurzanleitung für die Installation

Prüfen Sie, ob Kondensatoren nachformiert werden müssen

Wenn der Frequenzumrichter seit mehr als drei Jahren nicht an die Spannungsversorgung angeschlossen war (entweder gelagert oder nicht benutzt war), müssen die

Kondensatoren nachformiert werden.

Das Herstellungsdatum kann anhand der Seriennummer bestimmt werden, welche

auf dem am Frequenzumrichter angebrachten Typenschild angegeben ist. Die

Seriennummer hat das Format MJJWWRXXXX. JJ und WW geben das

Herstellungsjahr und die -woche an:

JJ: 17, 18, 19, … für 2017, 2018, 2019,

EN

WW: 01, 02, 03, … für Woche 1, Woche 2, Woche 3, …

Informationen zum Formieren der Kondensatoren enthält die Anleitung Converter

DA

module capacitor reforming instructions (3BFE64059629 [englisch]), verfügbar im

Internet auf www.abb.com/drives/documents

DE

DE

FI

FR

FR

NL

PL

PT

RU

SV

TR

…

.

ZH

Page 29

DE – Kurzanleitung für die Installation 29

Daten

IEC-Nenndaten

ACS880-11-

3-phasig, UN = 400 V (380…415 V)

09A4-3 3×1,5 170M1561 226

12A6-3 3×1,5 170M1561 329

017A-3 3×6 170M1563 395

025A-3 3×6 170M1563 579

032A-3 3×10 170M1565 625

038A-3 3×10 170M1565 751

045A-3 3×16 170M1566 912

061A-3 3×25 170M1567 1088

072A-3 3×35 170M1568 1502

087A-3 3×50 170M1569 1904

105A-3 3×50 170M3817 1877

145A-3 3×95 170M3817 2963

169A-3 3×120 170M5809 3168

206A-3 3×150 170M5810 3990

3-phasig, UN = 500 V (380…500 V)

07A6-5 3×1,5 170M1561 219

11A0-5 3×1,5 170M1561 278

014A-5 3×6 170M1563 321

021A-5 3×6 170M1563 473

027A-5 3×10 170M1565 625

034A-5 3×10 170M1565 711

040A-5 3×16 170M1566 807

052A-5 3×25 170M1567 960

065A-5 3×35 170M1568 1223

077A-5 3×35 170M1569 1560

101A-5 3×50 170M3816 1995

124A-5 3×95 170M3817 2800

156A-5 3×120 170M5808 3168

180A-5 3×150 170M5810 3872

Kabel (mm

2

) aR-Sicherung Verlustleistung (W)

Auswahl der Leistungskabel

Siehe Daten auf Seite 29.

3AXD00000588487

EN

DA

DE

DE

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Ausreichende Kühlung sicherstellen

Siehe Daten auf Seite 29. Kondensation und/oder Vereisung sind nicht zulässig. Der

zulässige Betriebstemperaturbereich für den Frequenzumrichter ohne

Leistungsminderung beträgt -15 bis +40 °C.

Page 30

30 DE – Kurzanleitung für die Installation

Schutz des Frequenzumrichters und der Einspeisekabel

Siehe Abschnitt Daten auf Seite 29.

A – Wandmontage des Frequenzumrichters

Siehe Abbildung A auf Seite 137.

B – Die Abdeckung abnehmen.

Die Abdeckung(en) abnehmen. Siehe Abbildungen B (R3) und B (R6, R8)... auf

Seite 137.

EN

DA

C – Prüfung der Kompatibilität mit IT- (ungeerdeten) und asymmetrisch geerdeten TN-Netzen

DE

Siehe Abbildung C auf Seite 137.

DE

FI

FR

FR

WARNUNG! Wenn der Frequenzumrichter an ein IT- (ungeerdetes oder

hochohmig geerdetes) Netz oder ein asymmetrisch geerdetes TN-Netz

angeschlossen wird, muss der EMV-Filter (Option +E202) abgetrennt und der ErdePhase-Varistor geerdet werden. Siehe das entsprechende Hardware-Handbuch des

Frequenzumrichters.

NL

D – Prüfung der Isolation der Einspeise- und Motorkabel und des Motors

PL

Das Motorkabel motorseitig anschließen. Für minimale HF-Störungen muss der

Motorkabelschirm an der Eingangsverschraubung des Motorklemmenkastens mit einer

PT

360-Grad-Erdung versehen werden. Siehe Abbildung D auf Seite 137.

RU

Prüfen Sie die Isolation des Motors und des Motorkabels. Siehe Abbildung D auf

Seite 137. Hinweis: Feuchtigkeit innerhalb des Motorgehäuses reduziert den

SV

Isolationswiderstand. Bei Verdacht auf Feuchtigkeit den Motor trocknen und die

Messung wiederholen.

TR

Prüfen Sie die Isolation des Eingangskabels vor dem Anschluss an den

Frequenzumrichter. Befolgen Sie die örtlichen Vorschriften.

ZH

E – Bringen Sie die Warnaufkleber in der Landessprache an

Siehe Abbildung E auf Seite 138.

Page 31

DE – Kurzanleitung für die Installation 31

F – Anschluss der Leistungskabel

Ein symmetrisch geschirmtes Motorkabel ist zu verwenden. Wenn der Kabelschirm

der einzige PE-Leiter ist, stellen Sie sicher, dass er eine ausreichend bemessene

Leitfähigkeit für PE hat.

Hinweis für Baugröße R3:

im Einspeisekabel haben. Weitere Informationen enthält das Hardware-Handbuch.

Vorgehensweise:

1. Baugrößen R6

entfernen. Siehe Abbildung F (R6, R8)… auf Seite 138. Baugröße R8

Sie für eine leichtere Montage die Seitenbleche.

2. Die Gummi-Kabeldurchführungen für die anzuschließenden Kabel aus dem

Bodenblech entfernen. Siehe Abbildung …F… auf Seite 138.

3. Eine passende Öffnung in die Gummidichtung schneiden. Kabeldurchführungen

auf die Kabel schieben.

4. Die Kabelenden vorbereiten. Siehe Abbildung …F… auf Seite 138.

Der blanke Schirm des Kabels wird 360 Grad geerdet. Kennzeichnen Sie das

verdrillte Schirmbündel als PE-Leiter mit einer gelb-grünen Markierung.

Es werden zwei alternative symmetrische Drei-Leiter-Kabeltypen und ein Vier-

Leiter-Kabeltyp gezeigt. Das Vier-Leiter-Kabel ist nur für die Eingangsverkabelung zulässig.

Wenn Sie Aluminiumkabel verwenden, versehen Sie den abisolierten Teil mit

Kontaktfett, bevor Sie das Kabel an den Frequenzumrichter anschließen.

5. Die Kabel durch die Öffnungen der Kabeleinführungsplatte stecken und die

Dichtungen in die Öffnungen drücken.

6. Die Kabel anschließen (verwenden Sie die in der Abbildung angegebenen

Anzugsmomente). Siehe Abbildungen …F… auf Seite 138 und 139:

• Den Schirm 360 erden, indem die Kabelschelle der Einspeisekabelerdung

über den abisolierten Teil gelegt und verschraubt wird.

• Den verdrillten Schirm des Kabels an die Erdungsklemme anschließen.

• Verwenden Sie ein separates PE-Erdungskabel (6a) oder ein Kabel mit

separatem PE-Leiter (6b), wenn die Leitfähigkeit des Schirms den

Anforderungen an den PE-Leiter nicht genügt. Wenn der PE-Leiter einen

kleineren Querschnitt als 10 mm

verwendet werden. Weitere Informationen enthält das Hardware-Handbuch.

• Baugröße R3:

• Die Phasenleiter des Motorkabels an die Klemmen T1/U, T2/V und T3/W und

die Phasenleiter des Eingangskabels an die Klemmen L1, L2 und L3

anschließen.

Stellen Sie sicher, dass sie einen zusätzlichen PE-Leiter

und R8: Die Abdeckung von den Leistungskabelklemmen

: Entfernen

2

aufweist, muss ein zweiter Erdleiter

Den zusätzlichen PE-Leiter des Eingangskabels anschließen.

EN

DA

DE

DE

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 32

32 DE – Kurzanleitung für die Installation

7. Bei Baugröße R6 und Typen größer als -040A-x

Abdeckung für die installierten Kabel. Baugröße R8:

Seitenbleche, falls diese entfernt wurden. Brechen Sie aus der Abdeckung

Öffnungen für die Eingangskabel heraus. Siehe Abbildung …F (R6, R8)… auf

Seite 139.

8. Baugrößen R6

montieren. Siehe Abbildung …F (R6, R8)… auf Seite 139.

9. Die Kabel außerhalb des Frequenzumrichters mechanisch sichern.

G – Anschluss der Steuerkabel

EN

Vorgehensweise:

DA

1. Entfernen Sie die Frontabdeckung(en), falls noch nicht geschehen.

DE

2. Baugröße R3: Den Bedienpanelhalter hochklappen. Siehe Abbildung G (R3)…

DE

FR

FR

NL

PL

PT

RU

SV

auf Seite 139.

3. Schneiden Sie eine passende Öffnung in die Gummi-Kabeldurchführung und

schieben Sie die Kabeldurchführung auf das Kabel. Das Kabel durch eine Öffnung

FI

der Bodenplatte stecken und die Kabeldurchführung in die Öffnung drücken.

4. Verlegen Sie die Kabel. Baugröße R3:

Baugröße R6:

Abbildung …G (R8)… auf Seite 140.

5. Eine 360-Grad-Erdung des Kabelschirms unter der Erdungsschelle durchführen.

Das Kabel mit durchgängigem Schirm so nahe wie möglich an die Klemmen der

Regelungseinheit führen.

6. Die Kabel innerhalb des Frequenzumrichters mechanisch sichern.

7. Baugröße R3

nicht an und erden Sie diese am anderen Ende der Leiterpaare des Kabels.

Schneiden Sie nicht angeschlossene Leiter auf der Antriebsseite ab. Baugröße

R6 und R8: Die Kabelschirme und den Erdleiter unter der Schelle unterhalb der

Regelungseinheit erden.

und R8: Die Abdeckung über den Leistungskabelklemmen

Siehe Abbildung …G (R3)… auf Seite 139.

Siehe Abbildung …G (R6)… auf Seite 139. Baugröße R8: Siehe

: Schließen Sie die Kabelschirme und die Erdleiter antriebsseitig

: Machen Sie Ausschnitte in die

Befestigen Sie wieder die

8. Schließen Sie die Leiter an die entsprechenden Klemmen der Regelungseinheit

TR

an. Siehe Standard-E/A-Anschlussplan auf Seite 34.

ZH

9. Die Optionsmodule, falls im Lieferumfang enthalten, verdrahten. Siehe das

Benutzerhandbuch des Optionsmoduls oder die Installationsanleitung.

10. Die Kabel außerhalb des Frequenzumrichters mechanisch sichern.

Hinweis:

• Schließen Sie die anderen Enden der Steuerkabelschirme nicht an

• Signalleiterpaare bis auf den kürzestmöglichen Abstand zu den Klemmen verdrillt

lassen.

Page 33

DE – Kurzanleitung für die Installation 33

H – Abdeckung(en) wieder installieren

Siehe Abbildungen H (R3, R6, R8)... auf Seite 140.

EN

DA

DE

DE

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 34

34 DE – Kurzanleitung für die Installation

Störung

XPOW Eingang für externe Spannungsversorgung

1 +24VI

24 V DC, 2 A

2 GND

XAI Referenzspannungs- und Analogeingänge

1 +VREF 10 V DC, RL 1…10 kOhm

2 -VREF -10 V DC, RL 1…10 kOhm

3 AGND Masse

4 AI1+ Drehzahl-Sollwert

0(2)…10 V, R

in

> 200 kOhm

5 AI1-

6 AI2+ Standardmäßig nicht benutzt.

0(4)...20 mA, R

in

= 100 Ohm

7 AI2-

J1 J1

AI1 Steckbrücke für Auswahl I/U Strom/Spannung

J2 J2

AI2 Steckbrücke für Auswahl I/U Strom/Spannung

XAO Analogausgänge

1 AO1 Motordrehzahl U/min

0…20 mA, R

L

< 500 Ohm

2 AGND

3 AO2 Motorstrom

0…20 mA, R

L

< 500 Ohm

4 AGND

XD2D Umrichter-Umrichter-Verbindung (D2D)

1 B

Umrichter-Umrichter-Verbindung (D2D)

2 A

3 BGND

J3 J3 Schalter Abschluss Drive-to-Drive

XRO1, XRO2, XRO3 Relaisausgänge

11 NC

Bereit

250 V AC / 30 V DC

2 A

12 COM

13 NO

21 NC

Läuft

250 V AC / 30 V DC

2 A

22 COM

23 NO

31 NC

Störung (-1)

250 V AC / 30 V DC

2 A

32 COM

33 NO

XD24 Digital-Startsperre

1 DIIL Reglerfreigabe

2 +24VD +24 V DC 200 mA

3 DICOM Digitaleingang Masse

4 +24VD +24 V DC 200 mA

5 DIOGND Digitaleingang/-ausgang Masse

J6 Schalter Masse-Auswahl

XDIO Digitaleingänge/-ausgänge

1 DIO1 Ausgang: Bereit

2 DIO2 Ausgang: Läuft

XDI Digitaleingänge

1 DI1 Stopp (0) / Start (1)

2 DI2 Vorwärts (0) /Rückwärts (1)

3 DI3 Rücksetzen

4 DI4 Auswahl Beschl./Verzög.-Rampen

5 DI5 Konstantdrehzahl 1 (1 = Ein)

6 DI6 Standardmäßig nicht benutzt.

XSTO Sicher abgeschaltetes Drehmoment

1 OUT1

Sicher abgeschaltetes Drehmoment

(STO). Beide Kreise müssen für den

Start des Antriebs geschlossen sein.

2 SGND

3 IN1

4 IN2

X12 Sicherheitsfunktionsmodul-Anschluss

X13 Bedienpanel-Anschluss

X205 Anschluss für Memory Unit

Leitergrößen:

0,5 … 2,5 mm

2

(24…14 AWG)

Anzugsmoment:

0,5 Nm

(0,4 lbf·ft) für

Litzen und

einadrige Leiter.

Standard-E/A-Anschlussplan

EN

DA

DE

DE

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 35

Konformitätserklärung (EU)

DE – Kurzanleitung für die Installation 35

EN

DA

DE

DE

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 36

36 DE – Kurzanleitung für die Installation

EN

DA

DE

DE

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 37

ES – Guía rápida de instalación 37

ES – Guía rápida de instalación

Esta guía describe brevemente cómo instalar el convertidor de frecuencia. Consulte

la documentación completa sobre la instalación en ACS880-11 drives hardware

manual (3AXD50000045932 [Inglés]). Consulte las instrucciones de puesta en

marcha en ACS880 drives with primary control program quick start-up guide

(3AUA0000098062 [Inglés]).

Para consultar un manual, entre en www.abb.com/drives/documents

número del documento.

y busque el

Siga estrictamente las instrucciones de seguridad

ADVERTENCIA: Siga estrictamente estas instrucciones. Si no lo hace, se

pueden producir daños en el equipo o en las personas, e incluso causar la

muerte:

• Sólo podrán efectuar la instalación y el mantenimiento del convertidor

electricistas cualificados.

• No intente trabajar con el convertidor, el cable de motor o el motor con la

alimentación principal conectada. Si el convertidor está conectado a la potencia

de entrada, espere 5 minutos tras desconectarlo.

• Nunca manipule los cables de control mientras el convertidor o los circuitos de

control externo reciban alimentación.

• No conecte el convertidor a una tensión superior a la indicada en la etiqueta de

designación de tipo.

• Conecte siempre el convertidor, el motor y los equipos auxiliares al embarrado

de conexión a tierra (PE) de la fuente de alimentación.

• Bastidores R6

está alto. Use un dispositivo de elevación para el izado. No incline el convertidor.

El izado manual o el vuelco al inclinarlo podrían producir lesiones. Asegúrese de

que la pared y los dispositivos de fijación puedan soportar el peso.

• Asegúrese de que no entren en el convertidor los restos resultantes de taladrar,

cortar y pulir.

• Asegúrese de que el suelo sobre el que se apoya el convertidor y la pared

sobre la que está instalado son ignífugos.

y R8: El módulo de convertidor es pesado y su centro de gravedad

EN

DA

DE

ES

ES

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Compruebe si es necesario reacondicionar los condensadores

Si el convertidor no ha recibido alimentación (estando almacenado o fuera de uso)

durante más de tres años, deberá reacondicionar los condensadores.

Page 38

38 ES – Guía rápida de instalación

Puede determinar la fecha de fabricación a partir del número de serie, que

encontrará en la etiqueta de designación de tipo adherida al convertidor. El número

de serie tiene el formato MAASSRXXXX. AA y SS indican el año y la semana de

fabricación, de la forma siguiente:

AA: 17, 18, 19… para 2017, 2018, 2019

…

SS: 01, 02, 03… para semana 1, semana 2, semana 3…

Para más información sobre el reacondicionamiento de los condensadores, consulte el

documento Converter module capacitor reforming instructions (3BFE64059629

[Inglés]), disponible en Internet en www.abb.com/drives/documents

EN

Datos técnicos

DA

Especificaciones IEC

DE

ES

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

ACS880-11-

Trifásico UN = 400 V (380…415 V)

09A4-3 3×1,5 170M1561 226

12A6-3 3×1,5 170M1561 329

017A-3 3×6 170M1563 395

025A-3 3×6 170M1563 579

032A-3 3×10 170M1565 625

038A-3 3×10 170M1565 751

045A-3 3×16 170M1566 912

061A-3 3×25 170M1567 1088

072A-3 3×35 170M1568 1502

087A-3 3×50 170M1569 1904

105A-3 3×50 170M3817 1877

145A-3 3×95 170M3817 2963

169A-3 3×120 170M5809 3168

206A-3 3×150 170M5810 3990

Trifásico UN = 500 V (380…500 V)

07A6-5 3×1,5 170M1561 219

11A0-5 3×1,5 170M1561 278

014A-5 3×6 170M1563 321

021A-5 3×6 170M1563 473

027A-5 3×10 170M1565 625

034A-5 3×10 170M1565 711

040A-5 3×16 170M1566 807

052A-5 3×25 170M1567 960

065A-5 3×35 170M1568 1223

077A-5 3×35 170M1569 1560

101A-5 3×50 170M3816 1995

124A-5 3×95 170M3817 2800

156A-5 3×120 170M5808 3168

180A-5 3×150 170M5810 3872

Cable (mm

2

) Fusible aR Pérdidas (W)

3AXD00000588487

.

Page 39

ES – Guía rápida de instalación 39

Selección de los cables de potencia

Véase Datos técnicos en la página 38.

Garantizar la refrigeración

Véase Datos técnicos en la página 38. No se permite condensación ni escarcha. El

rango de temperatura de funcionamiento permitido para el convertidor de frecuencia

sin pérdidas de potencia es de -15 a +40 °C.

Protección del convertidor y el cable de potencia de entrada

Véase Datos técnicos en la página 38.

A – Montaje del convertidor de frecuencia en la pared

Véase la figura A en la página 137.

B – Retirar la cubierta

Retire la/s cubierta/s. Consulte las figuras B (R3) y B (R6, R8)... en la página 137.

C – Comprobar la compatibilidad con las redes IT (sin conexión a tierra) y redes con conexión a tierra en un vértice

Véase la figura C en la página 137.

ADVERTENCIA: Si el convertidor se va a conectar a una red IT (sin conexión

a tierra o con conexión a tierra de alta resistencia) o a una red con conexión a

tierra en un vértice, desconecte el filtro EMC (opcional +E202) y el varistor tierrafase. Consulte el manual de hardware del convertidor.

D – Comprobar el aislamiento de los cables de potencia y del propio motor

Conecte el cable de motor del lado del motor. Para que las interferencias por

radiofrecuencia sean mínimas, conecte a tierra a 360 grados la pantalla del cable de

motor en la entrada de cable de la caja de terminales del motor. Véase la figura D en la

página 137.

EN

DA

DE

ES

ES

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Comprobar el aislamiento del motor y del cable de motor. Véase la figura D en la

página 137. Nota: La humedad en el interior de la carcasa del motor reduce la

resistencia de aislamiento. Si sospecha de la presencia de humedad, seque el motor

y repita la medición.

Page 40

40 ES – Guía rápida de instalación

Comprobar el aislamiento del cable de alimentación antes de conectarlo al convertidor.

Siga los reglamentos locales.

E – Fijar las etiquetas de advertencia disponibles en los idiomas locales

Véase la figura E en la página 138.

F – Conectar los cables de potencia

Use cable apantallado simétrico para el cableado al motor. Si la pantalla del cable es

EN

el único conductor de conexión a tierra, asegúrese de que tiene la conductividad

suficiente como para ofrecer una protección adecuada de este tipo.

DA

Nota acerca del bastidor R3:

adicional en el cableado de potencia de entrada. Consulte el manual de hardware

DE

para obtener más información.

ES

Procedimiento:

Asegúrese de tener un conductor de conexión a tierra

1. Bastidor R6

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

potencia. Véase la figura F (R6, R8)… en la página 138. Bastidor R8

facilitar la instalación, retire los paneles laterales.

2. Retire las arandelas de goma de la placa inferior para los cables que desee

conectar. Véase la figura …F… en la página 138.

3. Recorte un orificio adecuado en los pasacables de goma. Deslice los pasacables

por los cables.

4. Prepare los extremos de los cables. Véase la figura …F… en la página 138.

La pantalla pelada se conecta a tierra a 360 grados. Marque el extremo del cable

de la pantalla con colores verde y amarillo para indicar que es el conductor de

conexión a tierra.

Se muestran dos tipos alternativos cables de tres conductores simétricos y un

tipo de cable de cuatro conductores. Sólo se permite el uso del cable de cuatro

conductores para el cableado de potencia de entrada.

Si utiliza cables de aluminio, ponga grasa en el cable pelado de aluminio antes de

conectarlo al convertidor.

5. Pase los cables a través de los orificios de la placas de entrada de cables y fije

las arandelas a los orificios.

6. Conecte los cables (use los pares definidos en la figura). Véanse las figuras

…F… en la página 138 y 139:

• Conecte a tierra la pantalla a 360 grados apretando la abrazadera de la

pletina de conexión a tierra del cable de potencia en la parte pelada del cable.

y R8: Retire la cubierta protectora de los terminales del cable de

: Para

Page 41

ES – Guía rápida de instalación 41

• Conecte el apantallamiento trenzado del cable al terminal de conexión a

tierra.

• Use un cable PE con conexión a tierra separada (6a) o un cable con un

conductor PE separado (6b) si la conductividad de la pantalla no cumple los

requisitos del conductor de conexión a tierra. Si el conductor de conexión a

tierra de protección es de menos de 10 mm

conductor de conexión a tierra. Consulte el manual de hardware para obtener

más información.

• Bastidor R3:

de potencia de entrada.

• Conecte los conductores de fase del cable de motor a los terminales T1/U,

T2/V y T3/W y los conductores de fase del cable de alimentación a los

terminales L1, L2 y L3.

7. Tipos de bastidores R6 mayores que -040A-x:

protectora para los cables instalados. Bastidor R8:

móntelos. Practique orificios en la cubierta protectora para los conductores del

cable de alimentación. Véase la figura …F (R6, R8)… en la página 139.

8. Bastidores R6

potencia. Véase la figura …F (R6, R8)… en la página 139.

9. Fije los cables fuera del convertidor de forma mecánica.

Conecte el conductor de conexión a tierra adicional del cableado

y R8: Monte la cubierta protectora en los terminales del cable de

2

, deberá usar un segundo

Corte lengüetas en la cubierta

Si retiró los paneles laterales,

EN

DA

DE

ES

ES

FR

IT

G – Conexión de los cables de control

Procedimiento:

1. Retire la cubierta o cubiertas frontales si no lo ha hecho antes.

2. Bastidor R3

página 139.

3. Practique un orificio adecuado en el pasacables de goma y pase el cable a través

de él. Pase el cable a través de un orificio de la placa pasacables y fije el

pasacables en el orificio.

4. Enrutar los cables. Bastidor R3:

Bastidor R6:

figura …G (R8)… en la página 140.

5. Conecte a tierra la pantalla exterior del cable a 360 grados bajo la abrazadera de

conexión a tierra. Mantenga el cable apantallado lo más cerca posible de los

terminales de la tarjeta de control.

6. Fije los cables dentro del convertidor de forma mecánica.

7. Bastidor R3

pantallas de los cables de pares trenzados y los cables de conexión a tierra y

conéctelos a tierra en el otro extremo del cable. Corte los cables no conectados

: Eleve el soporte del panel de control. Véase la figura G (R3)… en la

Véase la figura …G (R3)… en la página 139.

Véase la figura …G (R6)… en la página 139. Bastidor R8: Véase la

: En el extremo del convertidor de frecuencia, deje sin conectar las

NL

PL

PT

RU

SV

TR

ZH

Page 42

42 ES – Guía rápida de instalación

del extremo del convertidor. Bastidor R6 y R8:

cables de par trenzado apantallados y el cable de conexión a tierra bajo la

abrazadera situada debajo de la unidad de control.

8. Conecte los conductores a los terminales apropiados de la unidad de control.

Véase Diagrama de conexiones de E/S por defecto en la página 43.

9. Cablee los módulos opcionales si están incluidos en el suministro. Consulte el

manual de usuario o la guía de instalación del módulo opcional.

10. Fije los cables fuera del convertidor de forma mecánica.

Nota:

EN

• Deje sin conectar los otros extremos de las pantallas de los cables de control.

DA

• Mantenga trenzados los pares de hilos de señal lo más cerca posible de los

terminales.

DE

conecte a tierra las pantallas de los

H – Montar de nuevo la(s) cubierta(s)

ES

Véanse las figuras H (R3, R6, R8)... en la página 140.

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 43

ES – Guía rápida de instalación 43

Fallo

XPOW Entrada de alimentación externa

1 +24 VI

24 V CC, 2 A

2 GND

XAI Tensión de referencia y entradas analógicas

1 +VREF 10 V CC, RL 1…10 kohmios

2 -VREF -10 V CC, RL 1…10 kohmios

3 AGND Tierra

4 AI1+ Ref. de velocidad 0(2)…10 V, Rin >

200 kohmios

5 AI1-

6 AI2+ Por defecto no se usa. 0(4)…20 mA, Rin

= 100 ohmios

7 AI2-

J1 J1

Puente de selección de Tensión/Corriente AI1

J2 J2

Puente de selección de Tensión/Corriente AI2

XAO Salidas analógicas

1 AO1 Régimen de motor rpm 0…20 mA, RL

< 500 ohmios

2 AGND

3 AO2 Intensidad de motor 0…20 mA, RL <

500 ohmios

4 AGND

XD2D Enlace de convertidor a convertidor

1 B

Enlace de convertidor a convertidor

2 A

3 BGND

J3 J3

Terminador de enlace de convertidor a convertidor

XRO1, XRO2, XRO3 Salidas de relé

11 NC

Listo

250 V CA / 30 V CC

2 A

12 COM

13 NA

21 NC

En marcha

250 V CA / 30 V CC

2 A

22 COM

23 NA

31 NC

Fallo(-1)

250 V CA / 30 V CC

2 A

32 COM

33 NA

XD24 Bloqueo de marcha

1 DIIL Permiso de marcha

2 +24 VD +24 V CC 200 mA

3 DICOM Tierra de entrada digital

4 +24 VD +24 V CC 200 mA

5 DIOGND Tierra de entrada/salida digital

J6 Interruptor de selección de tierra

XDIO Entradas/salidas digitales

1 DIO1 Salida: Listo

2 DIO2 Salida: En marcha

XDI Entradas digitales

1 DI1 Paro (0) / Marcha (1)

2 DI2 Avance (0) / Retroceso (1)

3 DI3 Restaurar

4 DI4 Selección de aceleración y deceleración

5 DI5 Velocidad constante 1 (1 = activado)

6 DI6 Por defecto no se usa.

XSTO Safe Torque Off

1 OUT1

Safe Torque Off. Ambos circuitos deben

estar cerrados para que el convertidor

pueda ponerse en marcha.

2 SGND

3 IN1

4 IN2

X12 Conexión de módulo de funciones de seguridad

X13 Conexión del panel de control

X205 Conexión de la unidad de memoria

Tamaños de

hilos:

0,5 … 2,5 mm

2

(24…14 AWG)

Pares de

apriete: 0,5 N·m

(0,4 lbf·ft) tanto

para los cables

flexibles como

para los rígidos.

Diagrama de conexiones de E/S por defecto

EN

DA

DE

ES

ES

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 44

44 ES – Guía rápida de instalación

Declaración de conformidad (UE)

EN

DA

DE

ES

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 45

ES – Guía rápida de instalación 45

EN

DA

DE

ES

ES

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Page 46

46 ES – Guía rápida de instalación

EN

DA

DE

ES

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Page 47

FI – Asennuksen pikaopas 47

FI – Asennuksen pikaopas

Tässä oppaassa on taajuusmuuttajan lyhyet asennusohjeet. Täydelliset tiedot

asennuksesta on annettu oppaassa ACS880-11 drives hardware manual

(3AXD50000045932, englanninkielinen). Käyttöönotto-ohjeet ovat oppaassa

ACS880 drives with primary control program quick start-up guide (3AUA0000098062,

englanninkielinen).

Voit lukea oppaita osoitteessa www.abb.com/drives/documents

asiakirjanumerolla.

. Löydät oikean oppaan

Noudata turvaohjeita

VAROITUS! Noudata näitä ohjeita. Ohjeiden laiminlyönti voi aiheuttaa

fyysisen vamman tai hengenvaaran tai vahingoittaa laitteistoa.

• Taajuusmuuttajan asennus- ja huoltotyöt saa suorittaa vain valtuutettu sähköalan

ammattilainen.

• Tee kaikki taajuusmuuttajan, moottorikaapelin ja moottorin asennus- ja huoltotyöt

jännitteen ollessa katkaistuna. Jos taajuusmuuttaja on jo kytketty syöttöverkkoon,

kytke se irti verkosta ja odota 5 minuuttia.

• Älä käsittele ohjauskaapeleita, kun taajuusmuuttajaan tai ulkoisiin ohjauspiireihin on

kytketty jännite.

• Älä kytke taajuusmuuttajaa tyyppikilpeen merkittyä jännitettä suurempaan

jännitteeseen.

• Maadoita taajuusmuuttaja, moottori ja niihin liittyvät laitteet aina syötön

suojamaakiskoon (PE).

• Runkokoot R6

Käytä nostamiseen asianmukaista nostolaitetta. Älä kallista taajuusmuuttajaa.

Taajuusmuuttajan nostaminen käsin voi johtaa loukkaantumiseen. Taajuusmuuttaja

voi myös kaatua, jos se pääsee kallistumaan. Varmista, että seinä ja

kiinnitysvälineet kestävät painon.

• Varmista, ettei poraus-, jyrsintä- tai hiontajätettä pääse laitteen sisään.

• Varmista, että taajuusmuuttajan alla oleva lattia ja seinä, johon taajuusmuuttaja on

asennettu, ovat syttymättömiä.

ja R8: Taajuusmuuttaja on raskas, ja sen painopiste on korkealla.

FI

DA

DE

ES

FI

FI

IT

NL

PL

PT

RU

SV

TR

ZH

Tarkista, täytyykö kondensaattorit elvyttää

Jos taajuusmuuttajaan ei ole kytketty virtaa (eli se on ollut varastossa tai

käyttämättömänä) yli kolmeen vuoteen, kondensaattorit on elvytettävä.

Voit selvittää valmistusajankohdan sarjanumeron perusteella. Sarjanumero on

taajuusmuuttajaan kiinnitetyssä tyyppikilvessä. Sarjanumero on muotoa

MYYWWRXXXX. YY ja WW ilmaisevat valmistusvuoden ja -viikon seuraavasti:

Page 48

48 FI – Asennuksen pikaopas

YY: 17, 18, 19,…, mikä tarkoittaa vuotta 2017, 2018, 2019,…

WW: 01, 02, 03,…, mikä tarkoittaa viikkoa 1, 2, 3,…

Lisätietoja kondensaattorien elvyttämisestä on Converter module capacitor

reforming instructions -oppaassa (3BFE64059629, englanninkielinen), joka on

saatavana osoitteesta www.abb.com/drives/documents

.

Tieto

IEC-nimellisarvot

EN

DA

DE

ES

FR

NL

PL

PT

RU

SV

TR

ZH

ACS880-11-

3-vaihe UN = 400 V (380…415 V)

09A4-3 3 × 1,5 170M1561 226

12A6-3 3 × 1,5 170M1561 329

017A-3 3 × 6 170M1563 395

025A-3 3 × 6 170M1563 579

032A-3 3 × 10 170M1565 625

038A-3 3 × 10 170M1565 751

045A-3 3 × 16 170M1566 912

FI

FI

061A-3 3 × 25 170M1567 1088

072A-3 3 × 35 170M1568 1502

087A-3 3 × 50 170M1569 1904

105A-3 3 × 50 170M3817 1877

145A-3 3 × 95 170M3817 2963

169A-3 3 × 120 170M5809 3168

206A-3 3 × 150 170M5810 3990

3-vaihe UN = 500 V (380…500 V)

07A6-5 3 × 1,5 170M1561 219

11A0-5 3 × 1,5 170M1561 278

014A-5 3 × 6 170M1563 321