Page 1

ABB industrial drives

User's manual

ACS880-1007LC liquid cooling unit

Page 2

Page 3

User's manual

ACS880-1007LC liquid cooling unit

Table of contents

3. Mechanical installation

4. Electrical installation

6. Start-up

© 2017 ABB Oy. All Rights Reserved. 3AXD50000129607 Rev A

EN

EFFECTIVE: 2017-12-22

Page 4

Page 5

Table of contents

1 Introduction to the manual

2 Operation basics and hardware description

Table of contents 5

11Contents of this chapter ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

11Applicability .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

11Safety instructions . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

11Target audience ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

11Categorization by option code ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

12Use of component designations ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

12Terms and abbreviations ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

12Related manuals . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

12Related single drive manuals ...... . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .

13Contents of this chapter ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

13Basics .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

14Layout drawing – ACS880-1007LC-0070 in cabinet line-up .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

15ACS880-1007LC-0070 component designations .... . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .

16Layout drawing – ACS880-1007LC-0195 in cabinet line-up .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

18ACS880-1007LC-0195 component designations ... . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

19Layout drawing – ACS880-1007LC-0195 stand-alone (option +C139) .. . . .. . . .. . . .. . .. . . .

20Swing out frame for electric devices in ACS880-1007LC-0070 ..... . . .. . .. . . .. . . .. . . .. . .. . .

21Swing out frame for electric devices in ACS880-1007LC-0195 ..... . . .. . .. . . .. . . .. . . .. . .. . .

22Control interfaces . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

22General .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

22Control panel . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

22IO interface of the control unit . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

23IO interface of the FAIO-01 analog interface module . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . ..

23Use of the control unit expansion slots .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

23PC connection . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

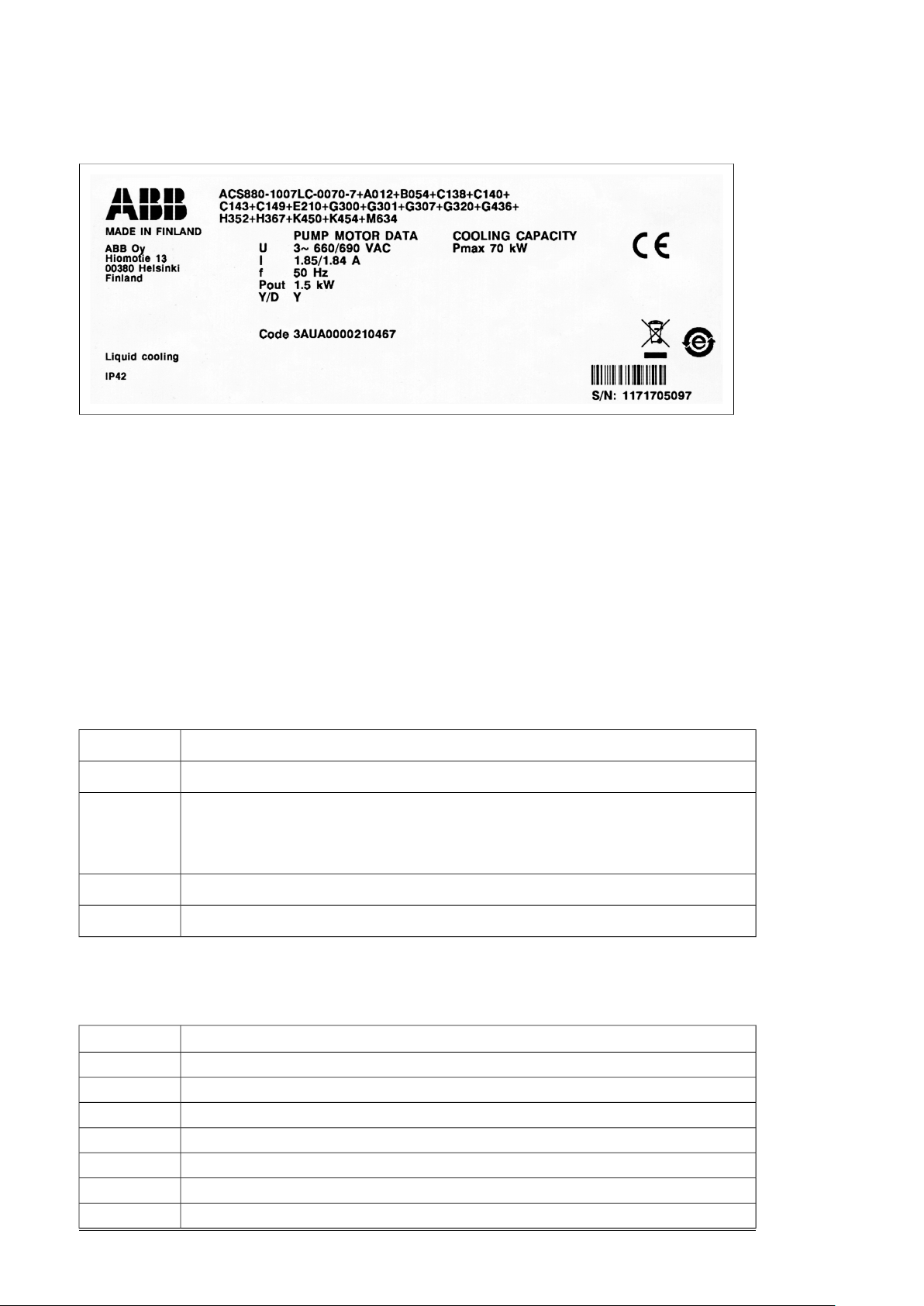

24Type designation label .. . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . ..

24Type designation key .. . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

24Basic code . . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . ..

24Option codes . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. .

3 Mechanical installation

4 Electrical installation

29What this chapter contains ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

29Safety .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. .

29Electrical safety precautions ... . . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

30Connecting the power cables ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

31Connection diagram – pump motors, auxiliary circuit and cubicle heater .. . . .. . . .. . .. .

31Connecting the control cables ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

32Control cable connection procedure ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

32Grounding the outer shields of the control cables at the cabinet entry ... . . .. . . .. . .

34Routing the control cables inside the cabinet .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

34Connecting control cabling ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

Page 6

6 Table of contents

5 Installation checklist

6 Start-up

7 Maintenance

39Contents of this chapter ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

39Safety .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. .

39Before start-up . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

40Adjusting air pressure of the expansion tank .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

40About the expansion tank ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .

40Pressure adjusting procedure ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

41Filling up the cooling circuit and starting the cooling unit .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

42Basic settings in the control program . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

43On-load settings . . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

45Safety .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. .

45Maintenance intervals . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

46Adding cooling liquid ... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

46Draining the cooling unit ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

47Storing the cooling unit ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

47Checking the quality of the coolant . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

47Cleaning and drying the leakage detector . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

48ACS880-1007LC-0070 replacing the pump motor .. . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

51ACS880-1007LC-0070 replacing the pump ...... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. .

53ACS880-1007LC-0195 replacing the pump motor .. . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

55ACS880-1007LC-0195 replacing the pump ...... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. .

8 Program features

57What this chapter contains ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

57Basics .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

57Start/stop control, and reset ...... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

57Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

58Pump control . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . ..

58Basic operation . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

58Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

58Alternation .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

58Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

58Redundancy .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

58Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

59Standby .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

59Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

59Delayed cooling . . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

59Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

59Pressure monitoring functions ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

59Operation of the Pressure difference monitoring function .... . . .. . . .. . . .. . .. . . .. . . .. . . .. .

60Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

60Temperature monitoring functions ...... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. .

60Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

60Leakage monitoring function ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

60Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

Page 7

9 Parameters

Table of contents 7

61Miscellaneous .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

61User lock . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .

61Settings and diagnostics ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . ..

63Terms and abbreviations ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

6301 Actual values ... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

6404 Warnings and faults . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

6606 Control and status words .. .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

6707 System info ... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .

6720 LCU control and settings .. .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

6931 Fault functions ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

7047 Data storage ... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

7049 Panel port communication ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

7150 Fieldbus adapter (FBA) ...... . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

7651 FBA A settings ...... . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

7852 FBA A data in .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

7953 FBA A data out .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

7954 FBA B settings ...... . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

8155 FBA B data in .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

8256 FBA B data out .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

8260 DDCS communication ... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

8461 D2D and DDCS transmit data . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

8562 D2D and DDCS receive data . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

8796 System . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

10 Fault tracing

11 Fieldbus control through a fieldbus adapter

91What this chapter contains ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

91Safety .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. .

91Indications .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .

91Warnings and faults ....... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

92Editable messages . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

92Warning/fault history and analysis .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. .

92Event logs . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . ..

92Factory data logger ... . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

92Other data loggers ... . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

92User data logger ... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

92Parameters that contain warning/fault information .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

92QR Code generation for mobile service application .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

93Warnings .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . ..

96Faults .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

97What this chapter contains ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

97System overview . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . ..

98Basics of the fieldbus control interface . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

100Control word and Status word .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

100Debugging the network words ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . .

100Actual values . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

100Debugging the network words ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . .

100Setting up the cooling unit for fieldbus control ..... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

Page 8

8 Table of contents

12 Internal cooling circuit

101Contents of this chapter ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

101Applicability .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

101Internal cooling system ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

102Connection to a cooling unit .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

102Connection to an ACS880-1007LC cooling unit . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

103Connection to a custom cooling unit . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

103General requirements . . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

103Coolant temperature control ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

103Filling up and bleeding the internal cooling circuit .... . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

103Drive line-ups with an ACS880-1007LC cooling unit .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

103Drive line-ups with a custom cooling unit .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . ..

104Draining the internal cooling circuit .. .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

105Maintenance intervals . . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

105Technical data ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

105Coolant specification . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .

105Coolant type . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

105Temperature limits ... . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

107Pressure limits . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .

107Cooling circuit materials ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . ..

13 Technical data

109What this chapter contains ...... . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

109Nominal cooling power, losses and pressure drop . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

109Dimensions .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

110Coolant flow and quantity ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . ..

110Pump and motor types, and motor ratings .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

110Filling pump . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .

110Fill/drain/bleed hoses . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .

110Auxiliary power supply for the control circuits .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

111Power supply for the cabinet heater (option +G300) ..... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

111Flanges for connecting the piping .. . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .

111Ambient conditions . . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. .

111Internal cooling circuit data ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

111External cooling circuit data ...... . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . ..

111Liquid quality for standard heat exchanger and piping .... . . .. . . .. . . .. . . .. . .. . . .. . . .. . . ..

112Temperature and pressure limits .. . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . ..

112Recommended pipe size and material .. .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

112Materials .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

113Compliance with the Pressure Equipment Directive (PED) .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . .

113Disclaimers .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. .

113Generic disclaimer . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . .

113Cybersecurity disclaimer . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . .

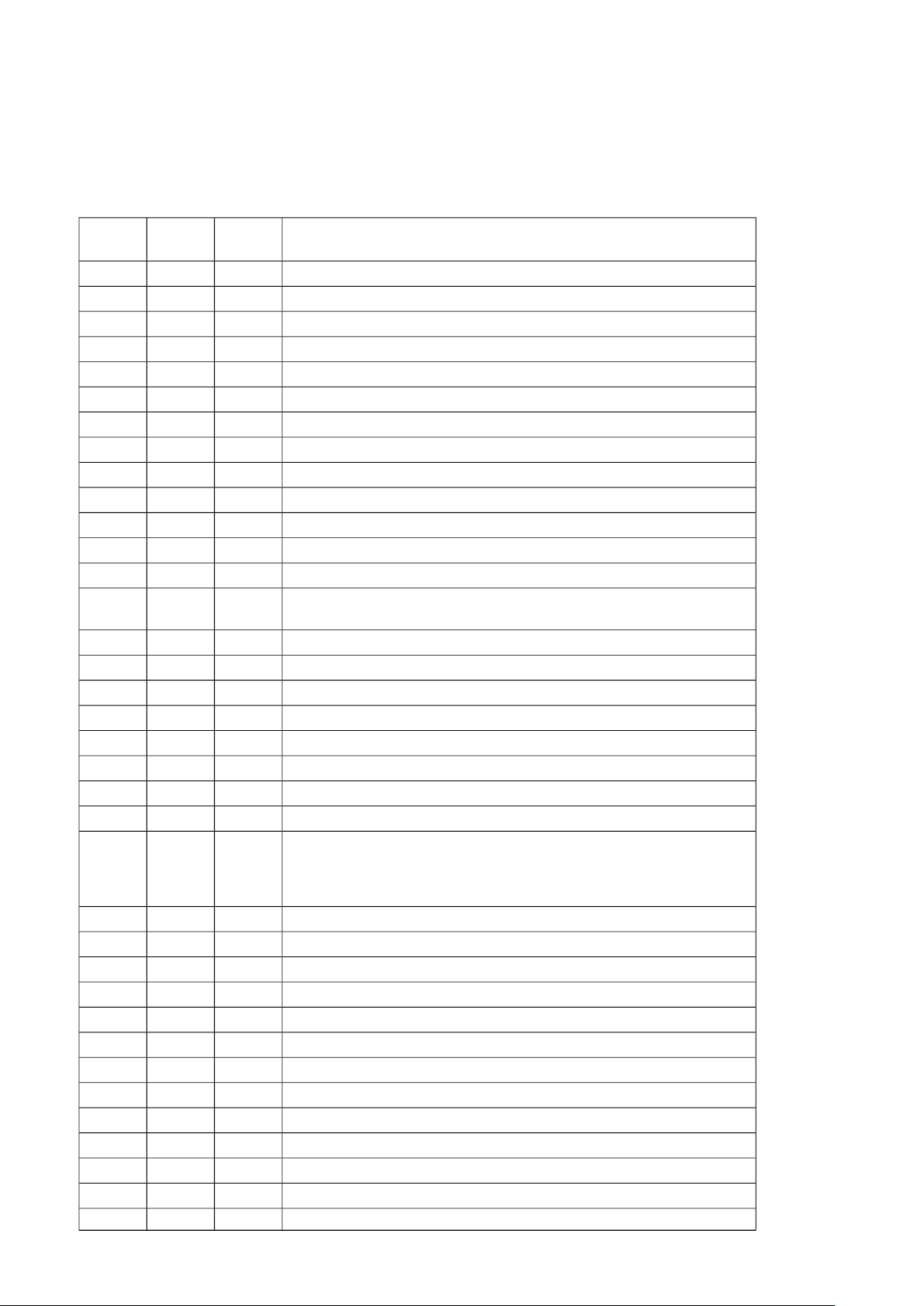

14 Piping and instrumentation diagrams

116ACS880-1007LC-0070 .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

117ACS880-1007LC-0070 component designations .... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

118ACS880-1007LC-0195 .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

119ACS880-1007LC-0195 component designations ... . . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

Page 9

15 Circuit diagrams

16 Dimension drawings

Further information

Table of contents 9

121What this chapter contains ...... . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

122ACS880-1007LC-0070 in cabinet line-up ...... . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .

129What this chapter contains ...... . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. .

129Cable entry (bottom) ... . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. . . .. . . .. . .. . . .. .

130ACS880-1007LC-0070 in cabinet line-up (at right), external cooling circuit from right . . .

131ACS880-1007LC-0070 stand-alone cooling unit, external cooling circuit from right .. .. .

132ACS880-1007LC-0195 in cabinet line-up (at right), external cooling circuit from right . . .

133ACS880-1007LC-0195 stand-alone cooling unit, external cooling circuit from right .. .. .

Page 10

10

Page 11

Introduction to the manual

Introduction to the manual 11

1

Contents of this chapter

This chapter contains general information of the manual, a list of related manuals, and a

list of terms and abbreviations.

Applicability

This manual applies to the ACS880-1007LC cooling units. The control program firmware

version is 2.60.0.0 or later (parameter 07.05).

Safety instructions

WARNING!

Read the complete safety instructions before you install, commission, or use the

drive. Obey the instructions. For a multidrive, see the separate safety instructions

manual. For a single drive, see the appropriate drive hardware manual.

Target audience

This manual is intended for people who plan the installation, install, start up, use and service

the cooling unit. Read the manual before working on the unit. You are expected to know

the fundamentals of electricity, wiring, electrical components and electrical schematic

symbols.

Categorization by option code

The information which only concerns certain optional selection is marked with the option

code in brackets. For example (option +E205). The options included in the unit are visible

Page 12

12 Introduction to the manual

on the type designation label. The type designation key in the manual describes the meaning

of the option codes.

Use of component designations

Some device names in the manual include the item designation in brackets, for example

[Q20], to make it possible to identify the components in the circuit diagrams of the drive.

Terms and abbreviations

DescriptionTerm

Control board built in a housing (often rail-mountable)Control unit

Frequency converter for controlling AC motorsDrive

Physical size of the drive or power moduleFrame, frame size

Inverter module

Inverter unit

Power module

Supply module

Inverter bridge, related components and drive DC link capacitors enclosed in a metal

frame or enclosure. Intended for cabinet installation.

Inverter module(s) under control of one control board, and related components. One

inverter unit typically controls one motor.

Liquid cooling unitLCU

Protective earth (ground)PE

Common term for drive module, inverter module, supply module, brake chopper

module etc.

Rectifier bridge and related components enclosed in a metal frame or enclosure. Intended for cabinet installation.

Supply module(s) under control of one control board, and related components.Supply unit

Type of control unitZCU

Related manuals

■ Related single drive manuals

ACS880-07CLC: See ACS880-07CLC hardware manual (3AXD50000131457 (English)).

Page 13

Operation basics and hardware description 13

2

Operation basics and hardware description

Contents of this chapter

This chapter describes the operation basics and the hardware of the cooling unit.

Basics

ACS880-1007LC is a liquid cooling unit (LCU) for the ACS880 drives. The cooling unit forms

a closed-loop cooling system (internal circuit) together with the piping and heat exchangers

in the drive. The unit pumps the coolant through the heat exchangers in the drive, and the

liquid-to-liquid heat exchanger in the LCU. The drive heat exchangers transfer the heat out

of the drive cubicles. The external cooling circuit conveys the heat out of the liquid-to-liquid

heat exchanger of the LCU.

The internal cooling circuit is equipped with an expansion tank which damps the pressure

variations due to liquid volume changes with temperature. The expansion tank is located

at the inlet of the pump to provide stable pressure for the pump.

The user must design, build and couple the external cooling circuit for the LCU. The user

must also balance the cooling capacity of the LCU with the drive losses in order to sustain

efficient cooling. The fine tuning is done by adjusting or controlling the flow in the external

cooling circuit typically.

There are two cooling unit types available: a one-pump unit and a two-pump unit. With the

two pump unit:

• only one pump is in operation at the time

• the cooling unit alternates the pump in duty automatically (reduces wear)

• the user can disconnect one pump from the system in case of a failure, and still continue

the operation (reduces downtime).

Page 14

14 Operation basics and hardware description

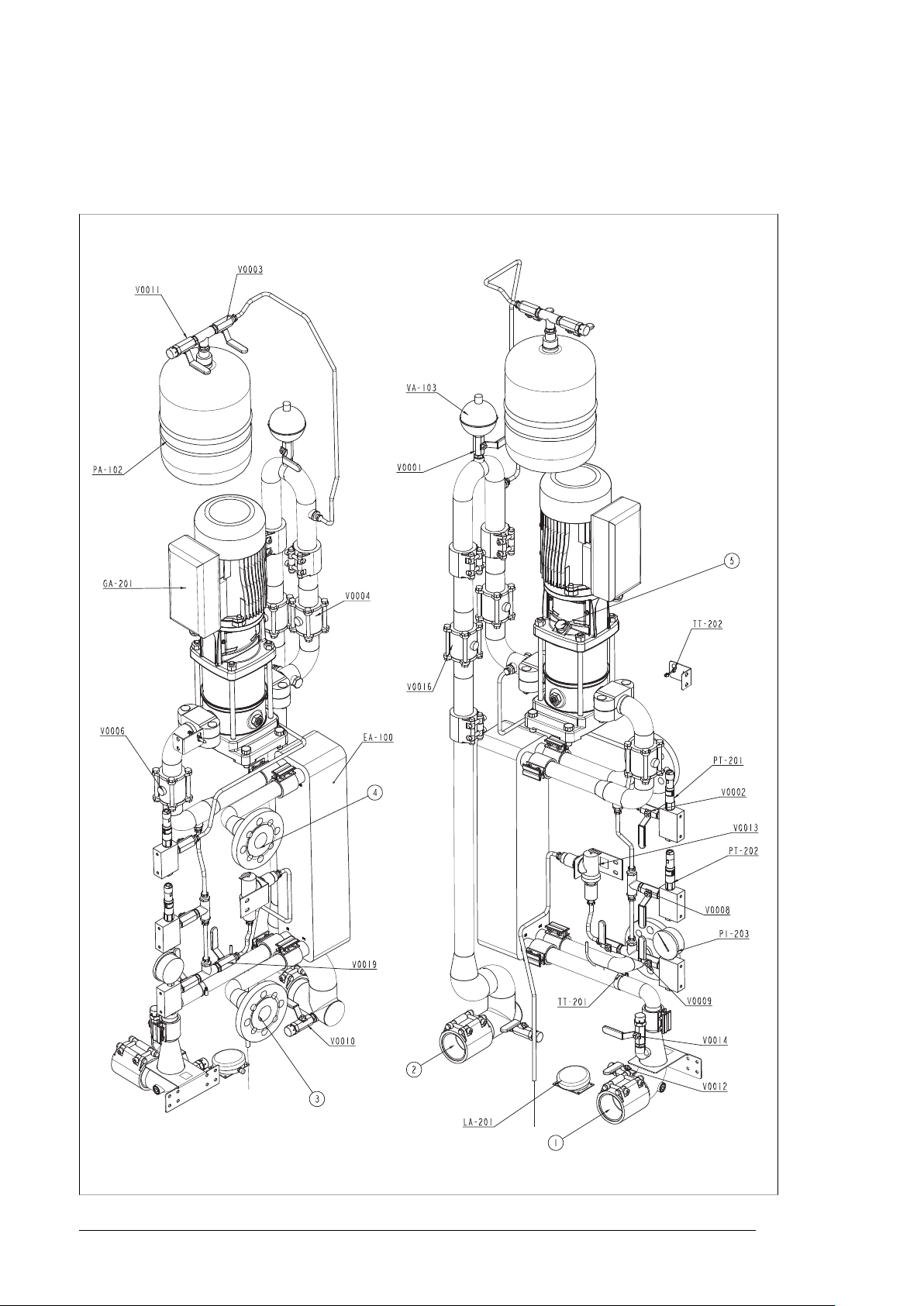

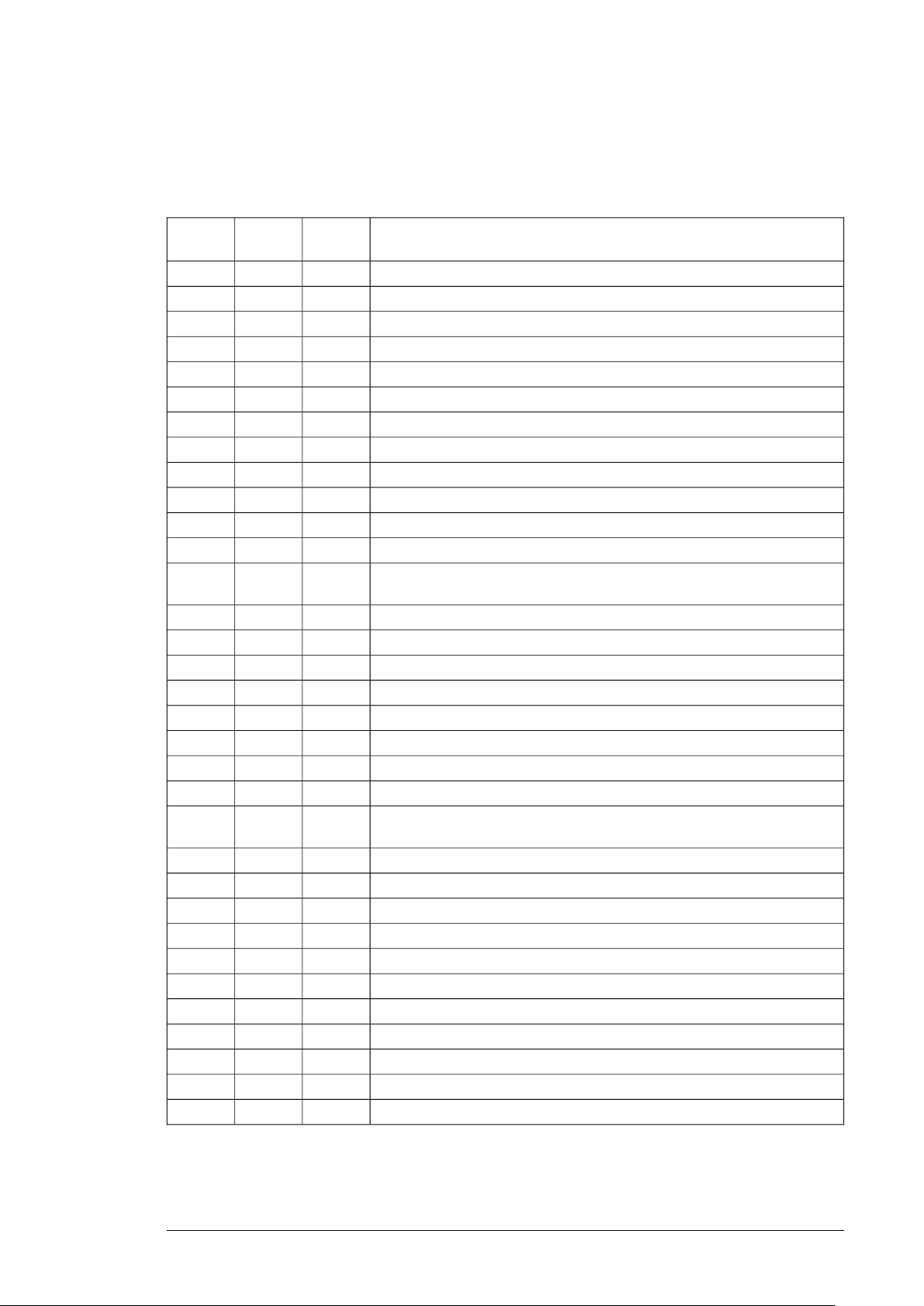

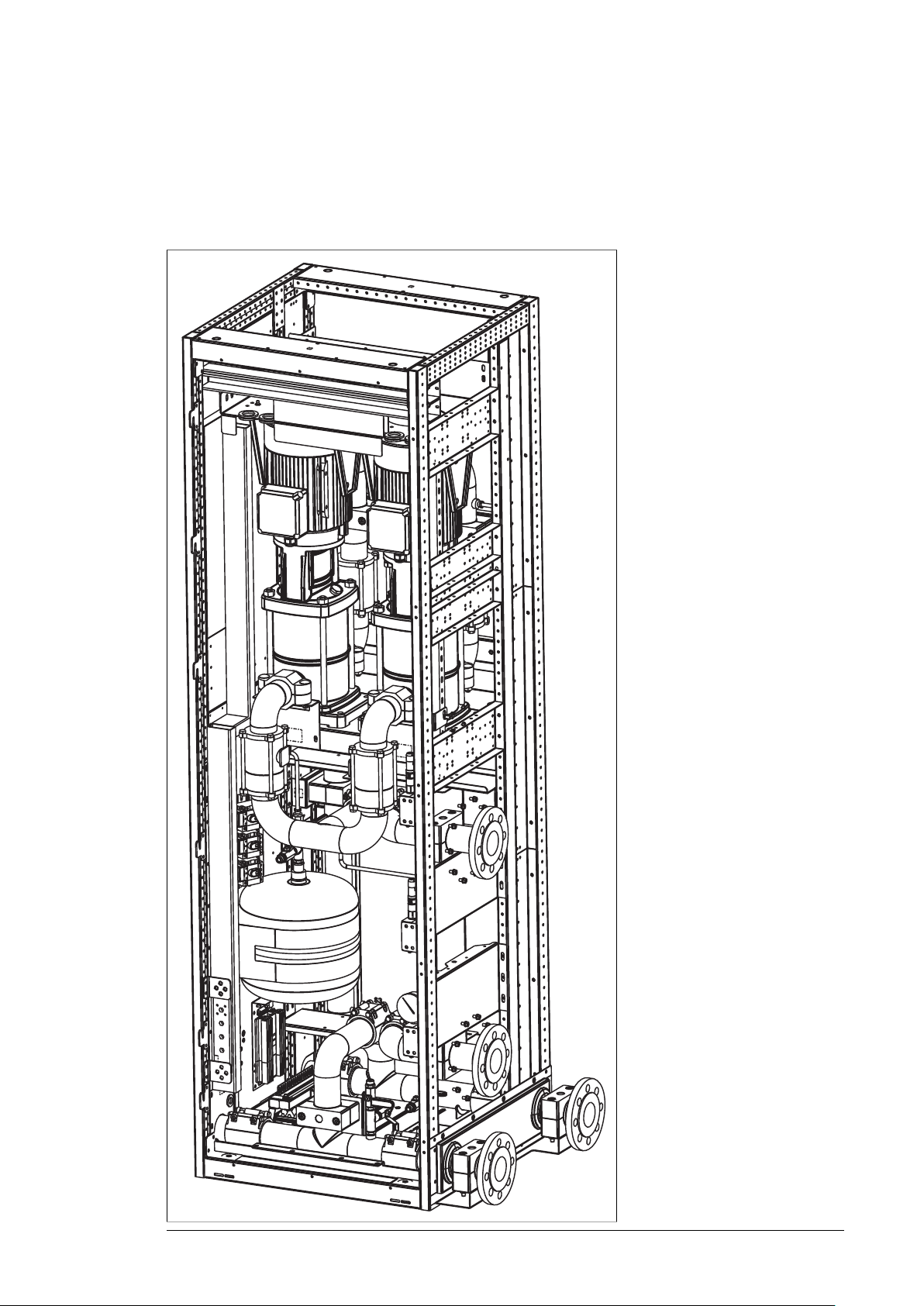

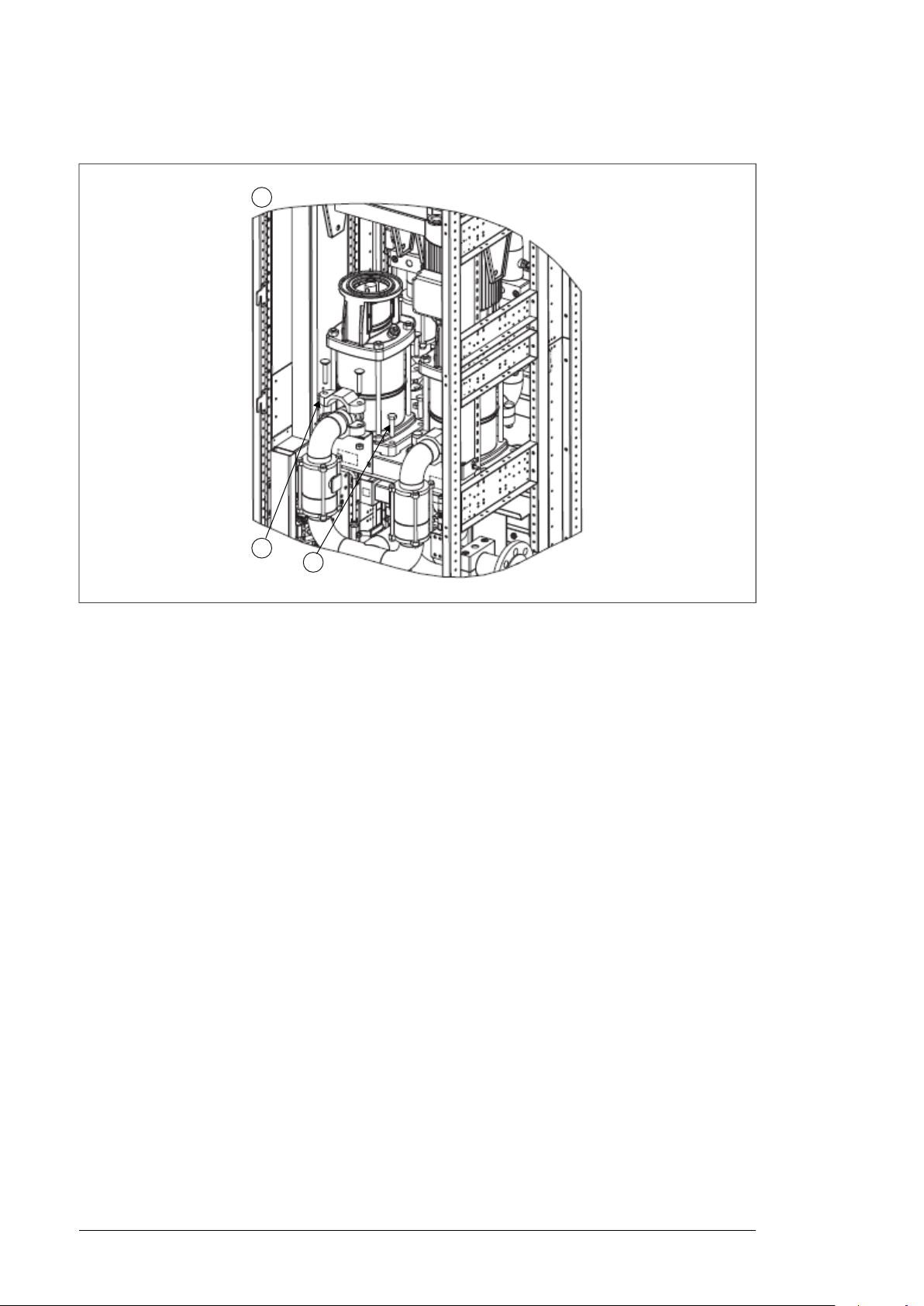

Layout drawing – ACS880-1007LC-0070 in cabinet line-up

This figure shows the interior of the cooling unit which is attached to the right end of the

drive cabinet line-up. The user connects the external cooling circuit from right.

Page 15

Operation basics and hardware description 15

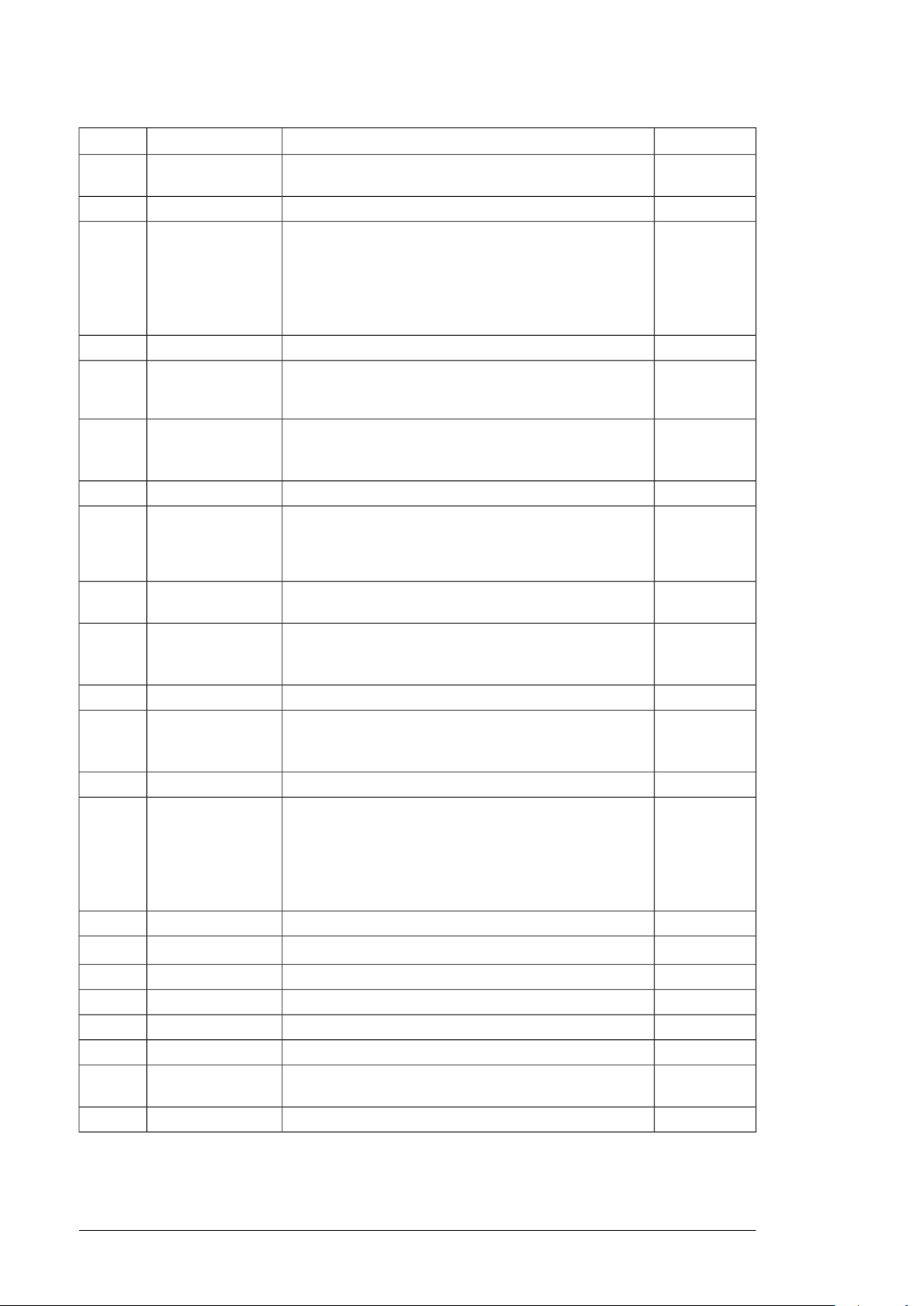

■ ACS880-1007LC-0070 component designations

The table below lists the component designations used in layout drawings, piping and

instrumentation (PI) diagrams, and circuit diagrams.

Layout

drawing

-

V0004,

V0006

PI diagram

210

V0006

diagram

-TIA(C)-

DescriptionCircuit

Outlet to internal cooling circuit--1

Inlet from internal cooling circuit--2

Inlet from external cooling circuit--3

Outlet to external cooling circuit--4

Pump de-airing screw--5

Coolant pump 1-M201GA-201GA-201

Heat exchanger-EA-100EA-100

Expansion tank-PA-102PA-102

Automatic float air vent-VA-103VA-103

Pump inlet pressure transmitter with low limit alarm-T201PT-201PT-201

Pump outlet pressure transmitter-T202PT-202PT-202

Coolant pressure gauge-PT-203PT-203

Coolant temperature indicator and alarm (and control, if optional 2-way valve

installed). This device is the LCU control unit.

Coolant temperature transmitter-B201TT-201TT-201

Ambient temperature transmitter-B202TT-202TT-202

Cabinet temperature transmitter(-A210)TT-210-

Shut-off valve for automatic float air vent-V0001V0001

Pressure transmitter (PT-201) shut-off valve-V0002V0002

Pressure transmitter (PT-202) shut-off valve-V0008V0008

Pressure gauge (PI-203) shut-off valve-V0009V0009

Expansion tank shut-off valve-V0003V0003

Pump shut-off valves-V0004,

Drain/fill valve (internal circuit LCU inlet)-V0010V0010

Expansion tank bleed valve-V0011V0011

Drain valve (internal circuit LCU outlet)-V0012V0012

Fill valve (Internal circuit LCU outlet)-V0014V0014

Safety relief valve (UL option only)-V0013V0013

Flow control valve-V0016V0016

Flow control valve (Optional, if 2-way valve installed)-V0018V0018

Shut off valve for the Safety relief valve-V0019V0019

Strainer (Optional, if 2-way valve installed)-SA-104-

LCU Leakage detectorS201LA-201LA-201

VAU Leakage detectorS211LA-211-

Page 16

16 Operation basics and hardware description

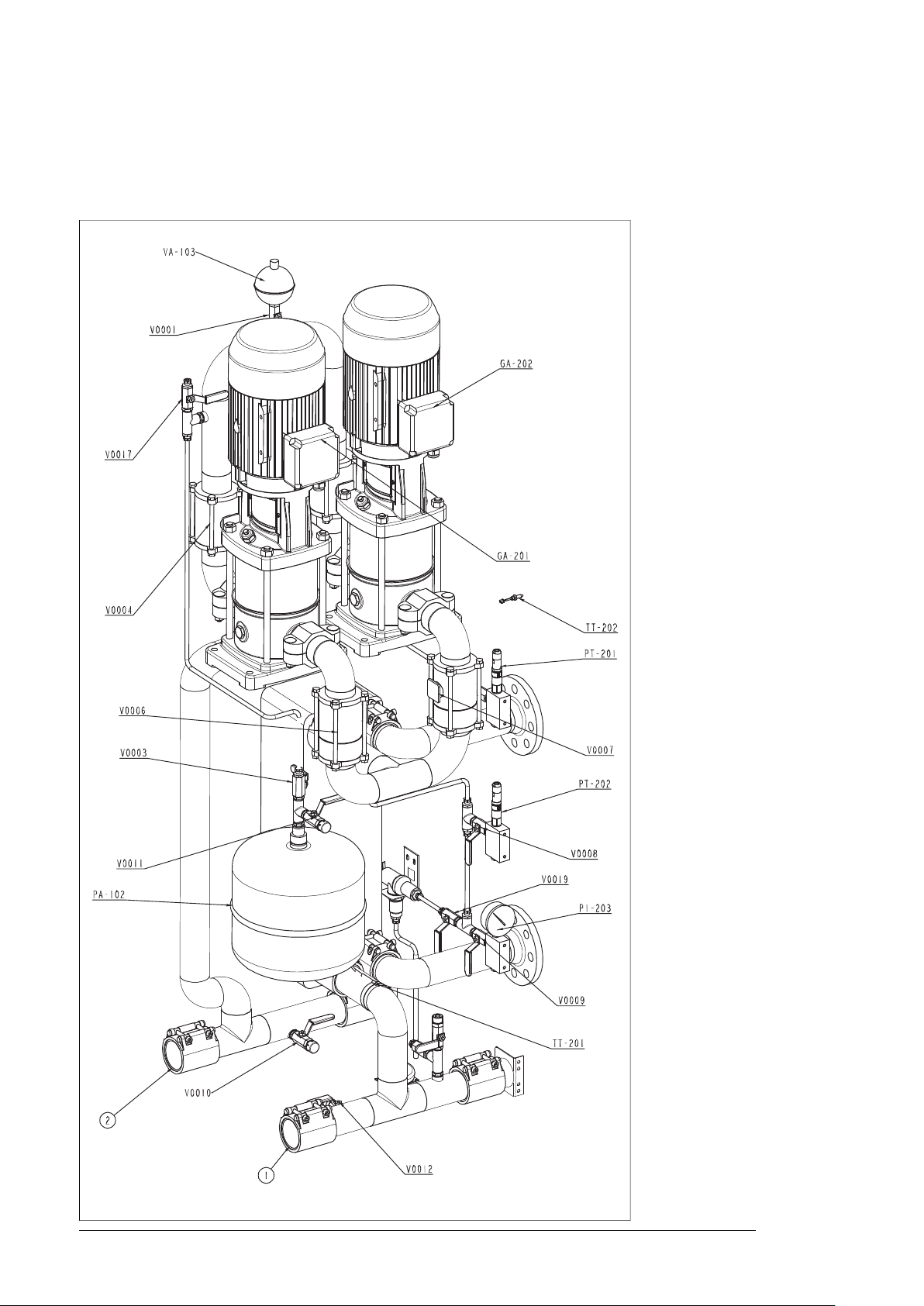

Layout drawing – ACS880-1007LC-0195 in cabinet line-up

These figures show the interior of the cooling unit which is attached to the right end of the

drive cabinet line-up. The user connects the external cooling circuit from right. Page 1/2:

Page 17

Page 2/2

Operation basics and hardware description 17

Page 18

18 Operation basics and hardware description

■ ACS880-1007LC-0195 component designations

The table below lists the component designations used in layout drawings, piping and

instrumentation (PI) diagrams, and circuit diagrams.

Layout

drawing

-

V0004,

V0005,

V0006,

V0007

PI diagram

210

V0005,

V0006,

V0007

diagram

-TIA(C)-

DescriptionCircuit

Outlet to internal cooling circuit--1

Inlet from internal cooling circuit--2

Inlet from external cooling circuit--3

Outlet to external cooling circuit--4

Pump de-airing screw--5

Coolant pump 1-M201GA-201GA-201

Coolant pump 2-M202GA-202GA-202

Heat Exchanger-EA-100EA-100

Expansion tank-PA-102PA-102

Automatic float air vent-VA-103VA-103

Pump inlet pressure transmitter with low limit alarm-T201PT-201PT-201

Pump outlet pressure transmitter-T202PT-202PT-202

Coolant pressure gauge-PT-203PT-203

Coolant temperature indicator and alarm (and control, if optional 2-way valve

installed)

Coolant temperature transmitter-B201TT-201TT-201

Ambient temperature transmitter-B202TT-202TT-202

Cabinet temperature transmitter(-A210)TT-210TT-210

Shut-off valve for automatic float air vent-V0001V0001

Pressure transmitters (PT-201) shut-off valve-V0002V0002

Pressure transmitter (PT-202) shut-off valve-V0008V0008

Pressure gauge (PI-203) shut-off valve-V0009V0009

Expansion tank shut-off valve-V0003V0003

Pump shut-off/check valves-V0004,

Drain/fill valve (internal circuit LCU inlet)-V0010V0010

Expansion tank bleed valve-V0011V0011

Drain/fill valve (internal circuit LCU outlet)-V0012V0012

Fill valve (internal circuit LCU outlet)-V0014V0014

Safety relief valve (UL option only)-V0013V0013

Flow control valve-V0016V0016

Shut off valve for extra LCU cubicle cooler (with option +C213 only)-V0015V0015

Shut off valve for extra LCU cubicle cooler (with option +C213 only)-V0017V0017

Flow control valve (Optional, if 2-way valve installed)-V0018V0018

Strainer (Optional, if 2-way valve installed)-SA-104-

Shut off valve for the Safety relief valve-V0019V0019

Leakage detectorS201LA-201LA-201

VAU Leakage detectorS211LA-211-

Page 19

Operation basics and hardware description 19

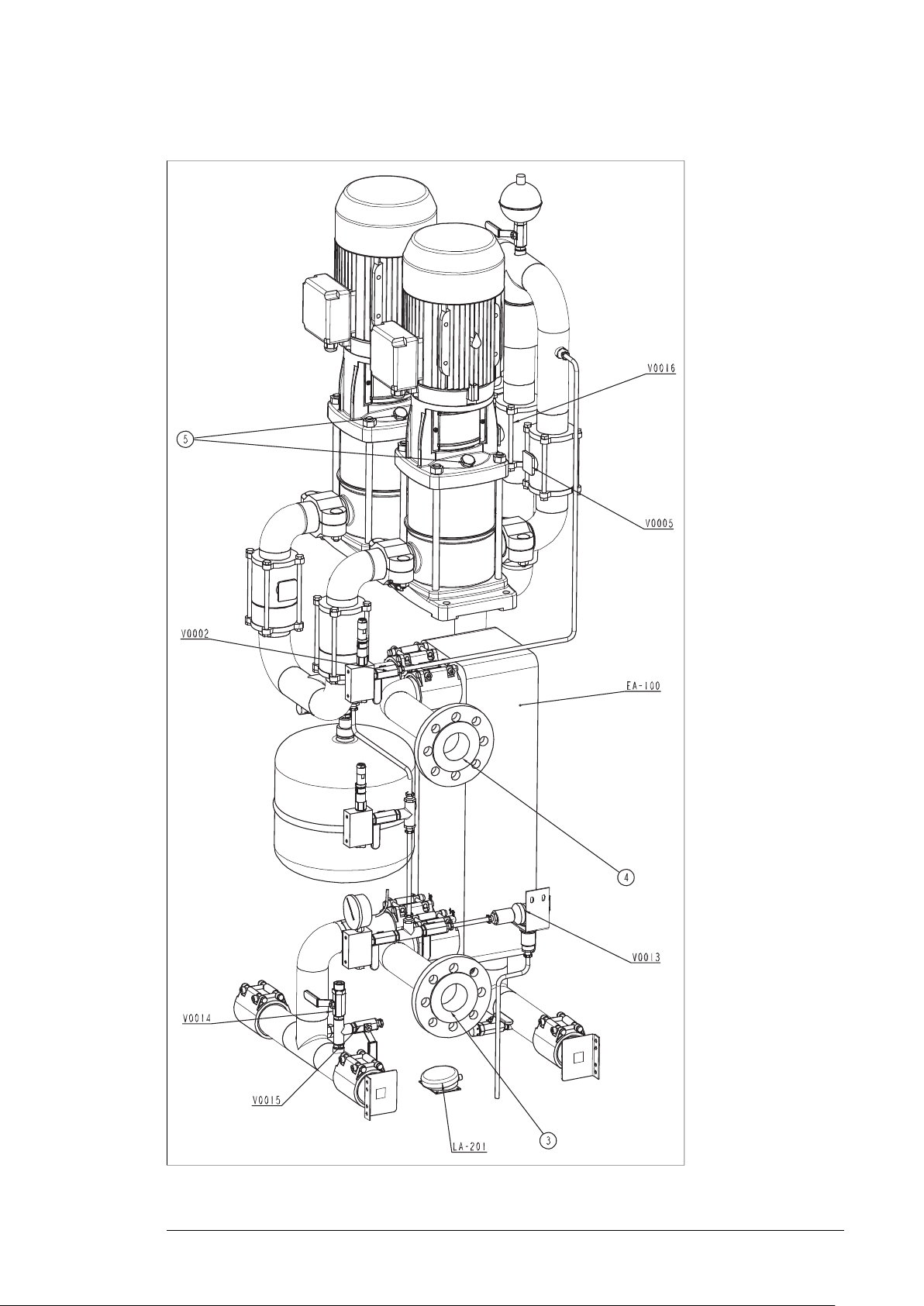

Layout drawing – ACS880-1007LC-0195 stand-alone (option +C139)

This figure shows a stand-alone cooling unit. The user connects both the internal and external

cooling circuits from right.

Page 20

20 Operation basics and hardware description

The components are described in section Layout drawing – ACS880-1007LC-0195 in cabinet

line-up (page 16).

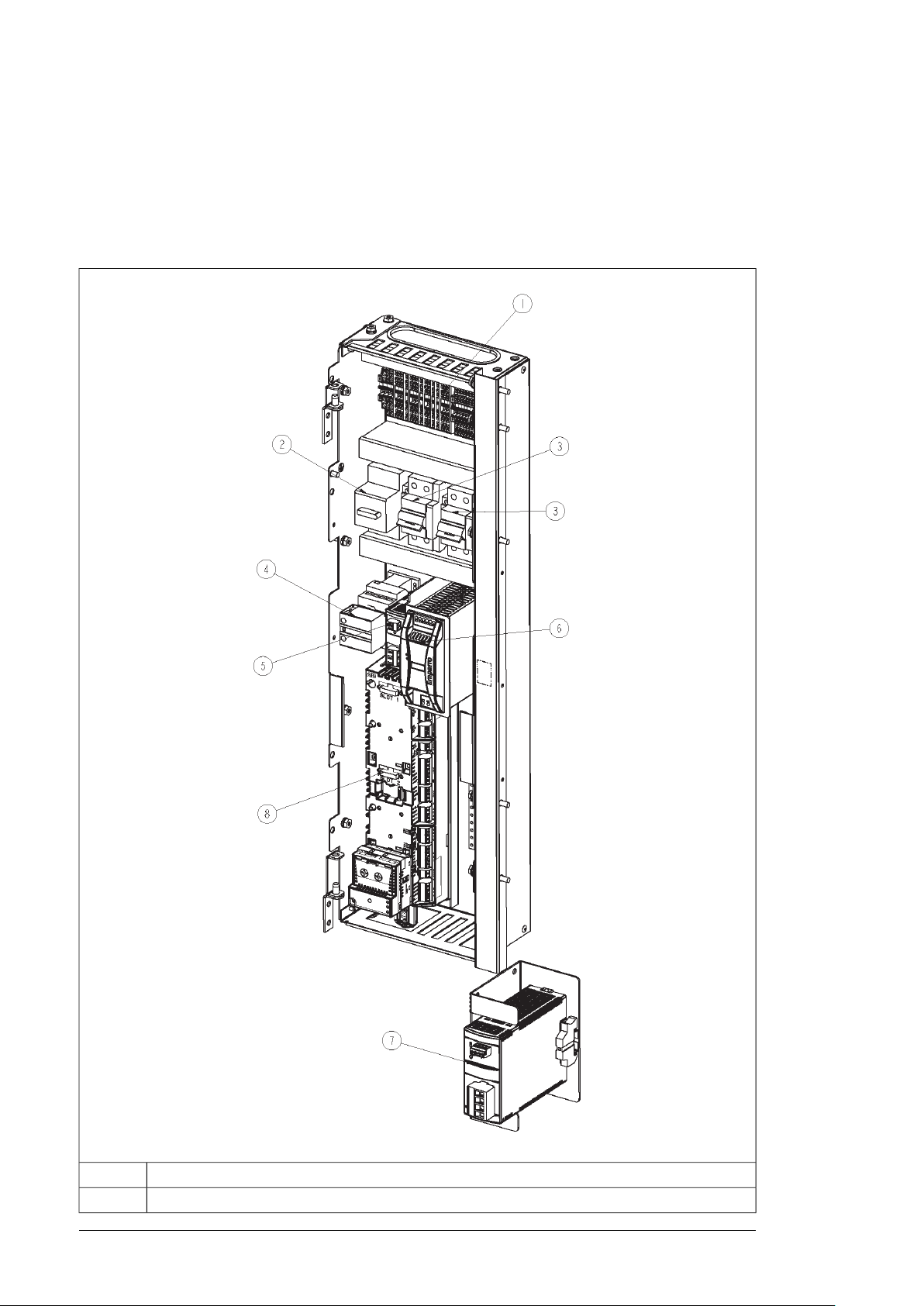

Swing out frame for electric devices in ACS880-1007LC-0070

Terminal block (X201)1.

Motor protective circuit breaker for pump (F201)2.

Page 21

Operation basics and hardware description 21

Circuit breakers for control voltage & cabinet heater (F210, F295)3.

Main contactor for pump (Q201)4.

Power supply for lighting (T130)5.

24 V DC power supply (for control board) (T210)6.

Buffer unit (C210)7.

ZCU control unit (A210)8.

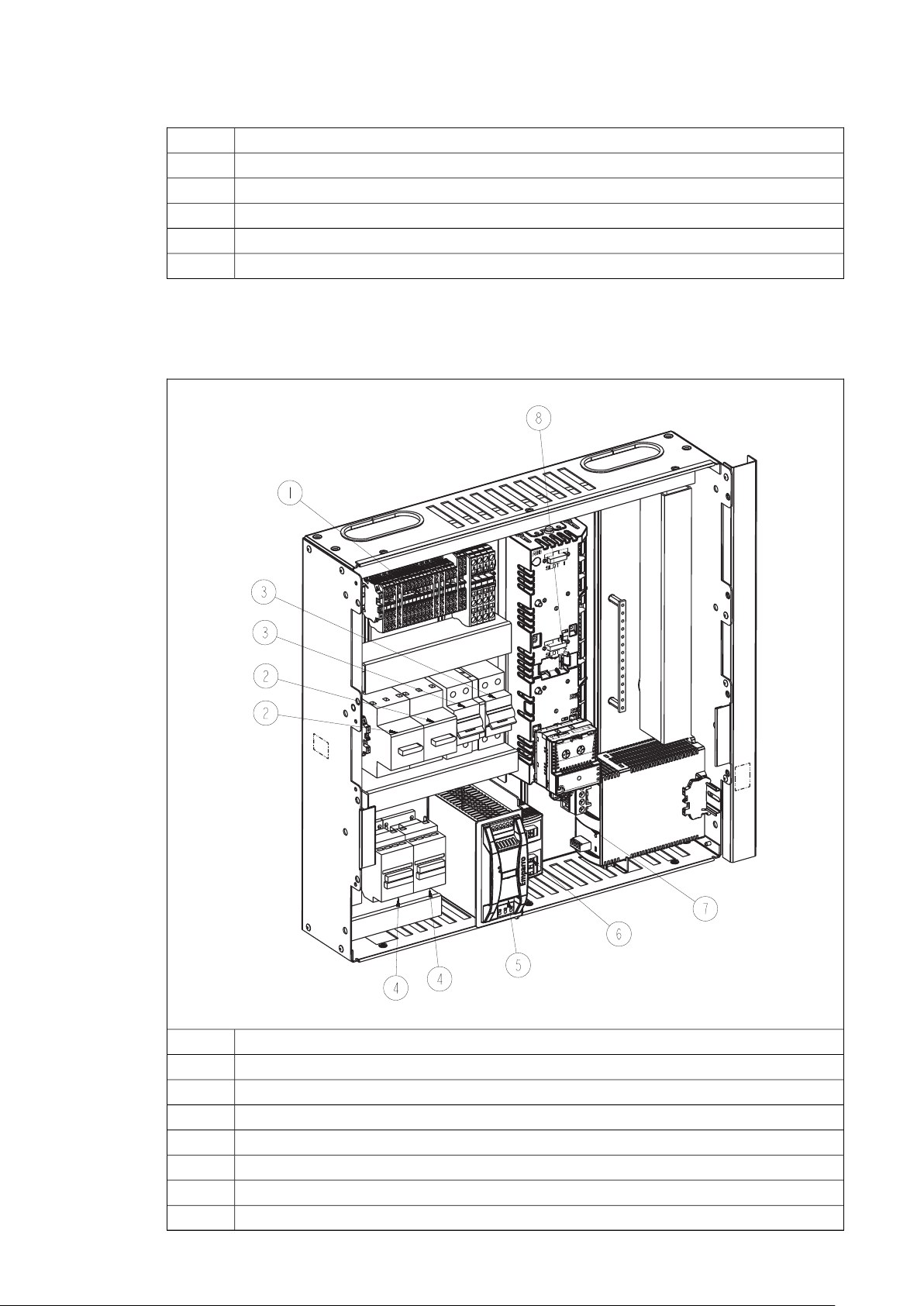

Swing out frame for electric devices in ACS880-1007LC-0195

Terminal block (X201)1.

Motor protective circuit breaker for pump (F201, F202)2.

Circuit breakers for control voltage & cabinet heater (F210, F295)3.

Main contactor for pump (Q201, Q202)4.

24 V DC power supply (for control board) (T210)5.

Power supply for lighting (T130)6.

Buffer unit (C210)7.

ZCU control unit (A210)8.

Page 22

22 Operation basics and hardware description

Control interfaces

■ General

The control program runs on the ZCU-14 control unit. The IO interface of the control unit is:

• the standard interface for the internal control and status signals (pump status, pressure

monitoring, pump on/off, etc.)

• the default interface for the external control signals (start, reset, fault indication).

User cannot change the interface for the internal signals. For the external signals, user can

use these signal interfaces also instead of the IO interface:

• a control panel (optional), or a PC with the Drive composer PC tool (optional)

• a fieldbus adapter module (optional)

• A DDCS communication adapter (optional).

User selects the external control interface by the control panel and a parameter (20.03):

• When the control panel is on the local control mode, the control panel is the control

interface (despite of any parameter value).

• When the control panel is on the remote control mode, the parameter selection defines

the control interface in use.

You can switch between local and remote control modes by the Loc/Rem key of the control

panel.

■ Control panel

Typically, there is a dedicated control panel in the stand-alone unit, and when the unit is in

the multidrive cabinet line-up. When the unit is part of the single drive line-up, there is no

dedicated panel for the cooling unit but the drive panel can also communicate with the

cooling unit.

■ IO interface of the control unit

This table shows the signals of the control unit IO interface.

IO

tion

XDI.2DI2

DescriptionDesigna-

Status of the pump 1 motor protective circuit breaker (1 = ON)XDI.1DI1

Status of the pump 2 motor protective circuit breaker (1 = ON). Not in use in one-pump

cooling unit.

Leakage detector (1 = LEAKAGE)XDI.3DI3

Reset (1 = RESET)XDI.4DI4

Not in useXDI.5DI5

Start signal (1 = START)XDI.6DI6

Not in useXDIO.1DIO1

Not in useXDIO.1DIO2

Not in useXD24.1DIIL

Pump 1 control (1 = RUN)XRO1RO1

Pump 2 control (1 = RUN). Not in use in one-pump cooling unit.XRO2RO2

Page 23

Operation basics and hardware description 23

IO

tion

DescriptionDesigna-

Fault indication (0 = Fault)XRO3RO3

Inlet pressure sensorXAI.4-5AI1

Outlet pressure sensorXAI.6-7AI2

2-way control valve control (optional)XAO.1-2AO1

Not in useXAO.3-4AO2

Ambient temperature sensorX209

■ IO interface of the FAIO-01 analog interface module

This table shows the signals of the FAIO-01 analog interface module. The module is attached

on the control unit as standard.

IO

tion

DescriptionDesigna-

Coolant temperature signal from the sensor (0…2 V)XA1AI1

Not in useXAI2AI2

Current source for the coolant temperature measurement sensor (0…20 mA)XAO1AO1

Not in useXAO2AO2

■ Use of the control unit expansion slots

The control unit has three expansion slots. This table shows the possible use of the slots.

DescriptionSlot

Slot 1

Slot 2

Slot 3

FAIO-01 analog interface module (standard). Interface for the internal coolant temperature monitoring.

FENA-11 Ethernet adapter module (optional). You can connect a PC with drive PC tool via Ethernet

to FENA adapter and further to the cooling unit.

Fieldbus adapter module (optional), or FDCO-01 DDCS adapter module and FDPI-02 for panel

bus adapter (optional)

■ PC connection

There is a USB connector on the front of the control panel that can be used to connect a

PC to the drive. When a PC is connected to the control panel, the control panel keypad is

disabled.

If the cooling unit is equipped with an Ethernet adapter module FENA-11 or -21 (option

+K473 or +K475), you can connect the PC with an Ethernet cable.

Page 24

24 Operation basics and hardware description

Type designation label

Type designation key

The type designation describes the composition of the module in short. The complete

designation code is divided in sub-codes:

• The first digits form the basic code. It describes the basic construction of the unit. The

fields in the basic code are separated by hyphens.

• The option codes (plus codes) follow the basic code. Each code starts with an identifying

letter (common for the whole product series), followed by descriptive digits. The plus

codes are separated by plus signs.

■ Basic code

The table below describes the fields of the basic code. ACS880-1007LC-0070-7 is used as

an example.

DescriptionFields

Product series. ACS880: Industrial drives.ACS880

1007LC

Unit identifier. 1007LC: Cooling unit. Standard features (if not defined otherwise by the option

codes): pipe connections from right, industrial water in external cooling circuit, 50 mm plinth

height, door hinges on right, standard cable entry plate, manuals on USB stick, coolant Antifrogen® L 25%.

Unit size. 0070: 0070 kW, 0195: 195 kW.0070

Voltage rating. 4: 380/400 V AC, 7: 660/690 V AC.7

■ Option codes

The table below describes the option codes (plus codes).

DescriptionCode

50 Hz supply frequencyA012

60 Hz supply frequencyA013

IP42, UL type 1B054

IP54, UL type 12B055

Marine constructionC121

UL-approvedC129

CSA-approvedC134

Page 25

Operation basics and hardware description 25

DescriptionCode

Line-up connected cooling unitC138

stand-alone cooling unitC139

Single pump cooling unitC140

Redundant pump cooling unitC141

Bottom pipe connectionC142

Pipe connection on leftC144

ANSI flangesC145

Sea waterC146

2-way valve in own cabinetC147

100 mmC164

200 mmC179

Door hinges on leftC176

Two pumps runningC213

100 kA short circuit ratingF274

Cabinet heaterG300

Cabinet lightingG301

115 VAC supply voltageG304

230 VAC supply voltageG320

External control voltage supplyG307

Halogen free wiringG330

Bottom power cable entryH352

Top power cable entryH353

Cable gland plates (Steel 3 mm, non-drilled)H358

Cable gland plates (Aluminum 3 mm, non-drilled)H364

Cable gland plates (Brass 6 mm, non-drilled)H365

Lead through, diameter 72 mmH390

Bottom control cable entryH367

Top control cable entryH368

Control panelJ400

Common control panelJ412

FDNA-01 fieldbus adapterK451

FLON-01 fieldbus adapterK452

FPBA-01 (PROFIBUS DP, DPV0/DPV1) fieldbus adapterK454

FCAN-01 fieldbus adapterK457

FSCA-01 fieldbus adapterK458

FCNA-01 fieldbus adapterK462

FECA-01 fieldbus adapterK469

FEPL-02 fieldbus adapterK470

FENA-11 (EtherNet/IP, Modbus/TCP, PROFINET) ethernet adapterK473

FENA-21 (EtherNet/IP, Modbus/TCP, PROFINET IO) Daisy chain ethernet adapterK475

Ethernet switch for PC tool and control networkK480

Ethernet switch with optical link for PC tool and control networkK483

Page 26

26 Operation basics and hardware description

DescriptionCode

Ethernet switch for PROFINETK493

Ethernet switch with optical link for PROFINETK494

FDCO-02, DDCS Communication 5/10 MBdL508

RDCO-04, DDCS CommunicationL509

Additional I/O terminal blockL504

Motor in delta connectionM633

Motor in star connectionM634

Special colorP913

Manuals in EnglishR700

R701

R702

R705

R706

R707

R708

R711

R712

R717

Manuals in German

Manuals in Italian

Manuals in Swedish

Manuals in Finnish

Manuals in French

Manuals in Spanish

Manuals in Russian

Manuals in Chinese

User´s manuals paper copy, one setR716

Paper copy of user's manual in A4, paper copy of dimensional drawings and circuit diagrams

in A3

1)

1)

1)

1)

1)

1)

1)

1)

1)

Some manuals are only available in English.

Page 27

Mechanical installation

Drive

2

LCU

4

3 3

Mechanical installation 27

3

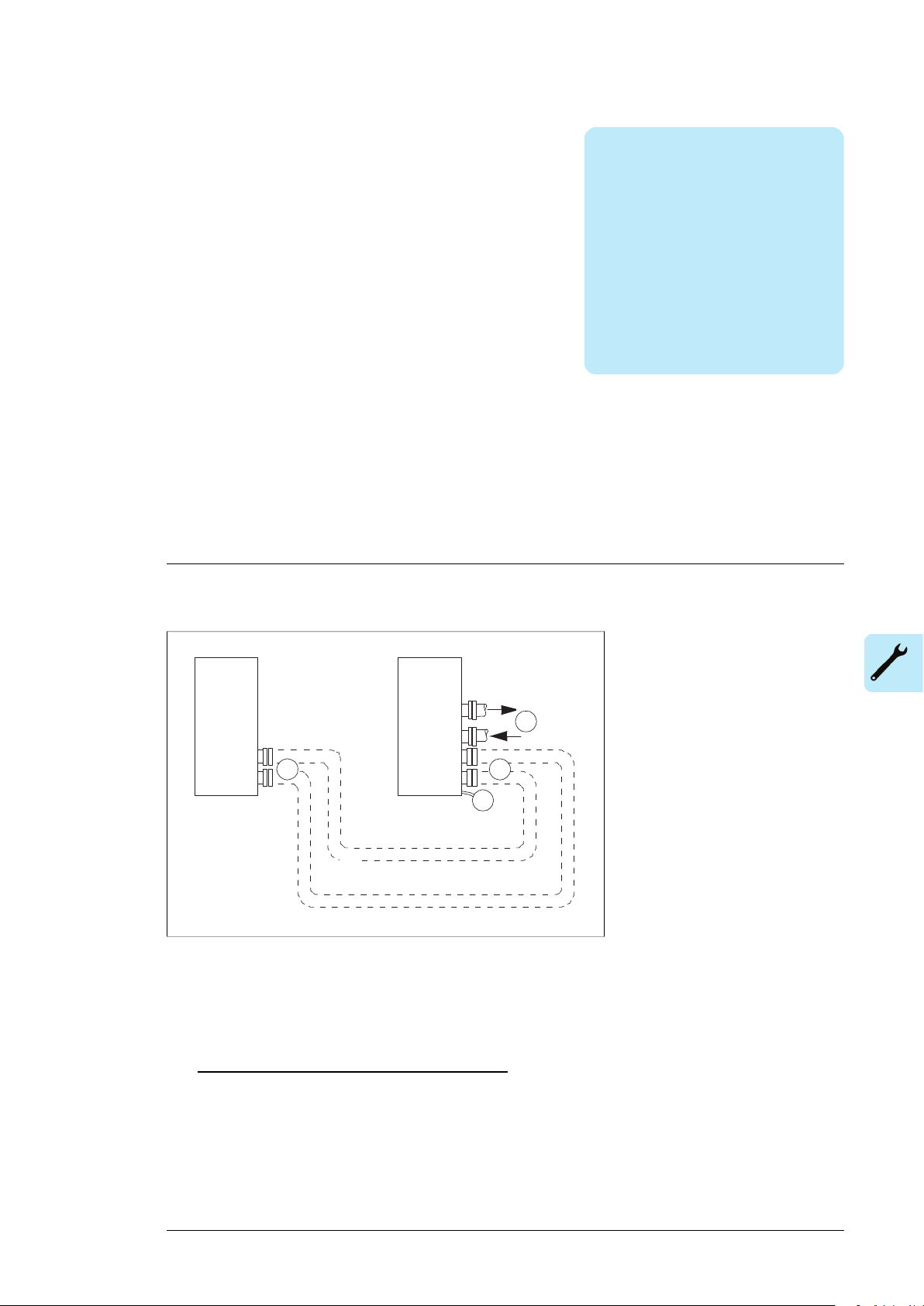

The figure below shows the internal and external cooling circuit connections of the

stand-alone cooling unit (option +C139).

Procedure:

1. Fasten the cooling unit to the floor. See the appropriate drive manual for the instructions.

In marine installation (or other cases where the unit will be subjected to vibration), fasten

the unit also from above.

2. Lead the bottom leakage hose to a sewer.

3. Stand-alone cooling unit (option +C139): Connect the drive internal cooling circuit to

the cooling unit. Use only the bolt and nut types, and tightening torque specified in

section Flanges for connecting the piping (page 111). Secure the pipes mechanically.

4. Connect the external cooling circuit to the cooling unit. Use only the bolt and nut types,

and tightening torque specified in section Flanges for connecting the piping (page 111).

Secure the pipes mechanically.

Page 28

28

Page 29

Electrical installation

Electrical installation 29

4

What this chapter contains

This chapter shows the user connections of the liquid cooling unit (LCU).

Safety

WARNING!

Read and obey the complete safety instruction of the drive. If you ignore them,

injury or death, or damage to the equipment can occur. Only a qualified electrician

may do the work described in this chapter.

■ Electrical safety precautions

These electrical safety precautions are for all personnel who do work on the drive, motor

cable or motor.

WARNING!

Obey these instructions. If you ignore them, injury or death, or damage to the

equipment can occur. If you are not a qualified electrician, do not do installation

or maintenance work. Go through these steps before you begin any installation or

maintenance work.

1. Keep the cabinet doors closed when the drive is powered. With the doors open, a risk

of a potentially fatal electric shock, arc flash or high-energy arc blast exists.

2. Clearly identify the work location.

3. Disconnect all possible voltage sources.

• Open the main disconnecting device of the drive.

• Open the charging switch if present.

Page 30

30 Electrical installation

• Open the auxiliary voltage switch-disconnector (if present), and all other possible

disconnecting devices that isolate the drive from dangerous voltage sources.

• In the liquid cooling unit (if present), open the motor protective circuit breaker(s) of

the cooling pumps.

• If you have a permanent magnet motor connected to the drive, disconnect the motor

from the drive with a safety switch or by other means.

• Make sure that re-connection is not possible. Lock the disconnectors to open position

and attach a warning notice to them.

• Disconnect any external power sources from the control circuits before you do work

on the control cables.

• After you disconnect the drive, always wait 5 minutes to let the intermediate circuit

capacitors discharge before you continue.

4. Protect any other energized parts in the work location against contact.

5. Take special precautions when close to bare conductors.

6. Measure that the installation is de-energized. If the measurement requires removal or

disassembly of shrouding or other cabinet structures, obey the local laws and regulations

applicable to live working (including – but not limited to – electric shock and arc

protection).

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive input power terminals and the

grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive DC busbars (+ and -) and the

grounding (PE) busbar is close to 0 V.

7. Install temporary grounding as required by the local regulations.

8. Ask the person in control of the electrical installation work for a permit to work.

Connecting the power cables

WARNING!

Read and obey the complete safety instruction of the drive. If you ignore them,

injury or death, or damage to the equipment can occur. Only a qualified electrician

may do the work described in this chapter.

WARNING!

Do the steps in section Electrical safety precautions (page 29) before you start

the work on drive and cooling unit. Go through the checklist together with another

person.

Page 31

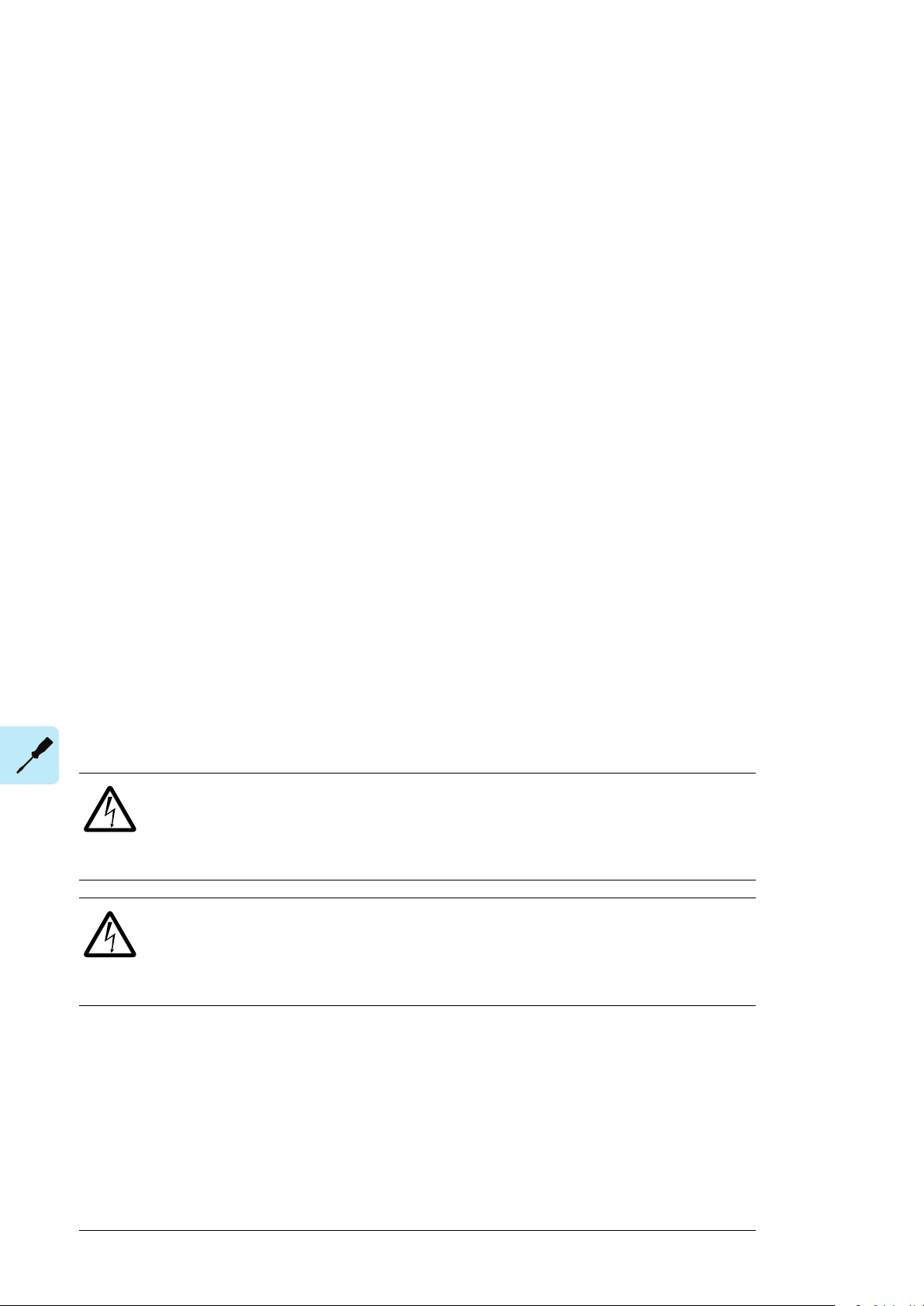

M

3~

L1

1~

2)

LN

L2 L3

3~

1)

ACS880-1007LC

PE

Q200

246

123

PE

4) 4)

Q210

246

123

1~ 3)

LN

4)

Q295

246

123

Electrical installation 31

■ Connection diagram – pump motors, auxiliary circuit and cubicle

heater

1

Three-phase power supply for the pump motor(s). User connects on site to a user-defined power supply.

Voltage, power rating and fuses: See the type designation label, chapter Technical data (page 109) and

the delivery-specific circuit diagrams.

One-phase auxiliary power supply for the control circuit.

2

Cooling unit in drive cabinet line-up: Connected to the drive auxiliary voltage supply at the factory. No

user connection on site needed. See the delivery-specific circuit diagrams.

Stand-alone cooling unit: User connects on site to a user-defined power supply. Voltage, power rating

and fuses: See the type designation label, chapter Technical data (page 109) and the delivery-specific

circuit diagrams.

One-phase auxiliary power supply for the cabinet heater (option +G300).

3

Cooling unit in drive cabinet line-up: Connected to the drive auxiliary voltage supply at the factory. No

user connection on site needed. See the delivery-specific circuit diagrams.

Stand-alone cooling unit: User connects on site to a user-defined power supply. Voltage, power rating

and fuses: See the type designation label, chapter Technical data (page 109) and the delivery-specific

circuit diagrams.

See the delivery-specific circuit diagrams.4

Connecting the control cables

WARNING!

Read and obey the complete safety instruction of the drive. If you ignore them,

injury or death, or damage to the equipment can occur. Only a qualified electrician

may do the work described in this chapter.

WARNING!

Do the steps in section Electrical safety precautions (page 29) before you start

the work on drive and cooling unit. Go through the checklist together with another

person.

Page 32

32 Electrical installation

Cooling unit in drive cabinet line-up (option +C138): As standard, there are no control

connections to be connected by the user. The supply unit of the drive controls the LCU, and

the connections are done at the factory. See the delivery-specific circuit diagrams.

Stand-alone cooling unit (option +C139): Connect the external control cabling according to

the delivery-specific circuit diagrams.

■ Control cable connection procedure

1.

Stop the drive (if running) and do the steps in section Electrical safety

precautions (page 29) before you start the work.

2.

Run the control cables into the cabinet as described in section Grounding the outer

shields of the control cables at the cabinet entry below.

3.

Route the control cables as described in section Routing the control cables inside the

cabinet (page 34).

4.

Connect the control cables as described in section Connecting control cabling (page 34).

Grounding the outer shields of the control cables at the cabinet entry

Ground the outer shields of all control cables 360 degrees at the EMI conductive cushions

as follows (example constructions are shown below, the actual hardware may vary):

1. Loosen the tightening screws of the EMI conductive cushions and pull the cushions

apart.

2. Cut adequate holes to the rubber grommets in the entry plate and put the cables through

the grommets and the cushions.

3. Strip off the cable plastic sheath above the entry plate just enough to ensure proper

connection of the bare shield and the EMI conductive cushions.

4. Tighten the two tightening screws so that the EMI conductive cushions press tightly

round the bare shield.

Page 33

2

1

4

1

4

3

2

4

1

4

1

3

grounding wire (if present).

uous.

A Stripped cable

B Conductive surface of the shield exposed

C Stripped part covered with copper foil

1 Cable shield

2 Copper foil

3 Shielded twisted pair

4 Grounding wire

1

A B C

2 2

3

4

Electrical installation 33

Note 1: Keep the shields continuous as close to the connection terminals as possible.

Secure the cables mechanically at the entry strain relief.

Note 2: If the outer surface of the shield is non-conductive:

• Cut the shield at the midpoint of the bare part. Be careful not to cut the conductors or

the grounding wire (if present).

• Turn the shield inside out to expose its conductive surface.

• Cover the turned shield and the stripped cable with copper foil to keep the shielding

continuous.

Stripped cableA

Conductive surface of the shield exposedB

Stripped part covered with copper foilC

Cable shield1

Copper foil2

Shielded twisted pair3

Grounding wire4

Page 34

Electrical installation 99

co

nductive cushions.

34 Electrical installation

Note for top entry of cables: When each cable has its own rubber grommet, sufficient IP

and EMC protection can be achieved. However, if very many control cables come to one

cabinet, plan the installation beforehand as follows:

1. Make a list of the cables coming to the cabinet.

2. Sort the cables going to the left into one group and the cables going to the right into

another group to avoid unnecessary crossing of cables inside the cabinet.

3. Sort the cables in each group according to size.

4. Group the cables for each grommet as follows ensuring that each cable has a proper

contact to the cushions on both sides.

Max. number of cables per grommetCable diameter in mm

4≤ 13

3≤ 17

2< 25

1≥ 25

5. Arrange the bunches according to size from thickest to the thinnest between the EMI

conductive cushions.

6. If more than one cable go through a grommet, seal the grommet by applying Loctite

5221 (catalogue number 25551) inside the grommet.

Routing the control cables inside the cabinet

Use the existing trunking in the cabinet wherever possible. Use sleeving if cables are laid

against sharp edges. When running cables to or from a swing-out frame, leave enough

slack at the hinge to allow the frame to open fully.

Connecting control cabling

Connect the conductors to the appropriate terminals. Refer to the wiring diagrams delivered

with the drive.

Connect the inner twisted pair shields and all separate grounding wires to the grounding

clamps closest to the terminals.

The drawing below represents the grounding of the control cabling when connecting to a

terminal block inside the cabinet. The grounding is done in the same way when connecting

directly to a component such as the control unit.

Notes:

• Do not ground the outer shield of the cable here since it is grounded at the lead-through.

• Keep any signal wire pairs twisted as close to the terminals as possible. Twisting the

wire with its return wire reduces disturbances caused by inductive coupling.

Page 35

100 Electrical installation

Electrical installation 35

At the other end of the cable, leave the shields unconnected or ground them indirectly via

a high-frequency capacitor with a few nanofarads, eg. 3.3 nF / 630 V. The shield can also

be grounded directly at both ends if they are in the same ground line with no significant

voltage drop between the end points.

Page 36

36

Page 37

Installation checklist

Installation checklist 37

5

Check the installation before start-up. Go through the checklist together with another person.

WARNING!

Read and obey the complete safety instruction of the drive. If you ignore them,

injury or death, or damage to the equipment can occur. Only a qualified electrician

may do the work described in this chapter.

WARNING!

Do the steps in section Electrical safety precautions (page 29) before you start

the work on drive and cooling unit. Go through the checklist together with another

person.

Task

The drive installation has been checked against the checklists in the drive manuals.

The cooling unit has been fixed properly to floor. In marine applications the unit has also been fastened

from above.

The bottom leakage hose has been led to a sewer.

The power supply voltage for the pump motor(s) matches the motor nominal voltage.

The power supply cable for the pump motor(s) has been connected to appropriate terminals and the

connection is tight. Pull conductors to check.

The PE (ground) conductor has been connected and the connection is tight. Pull conductor(s) to check.

Stand-alone cooling unit (option +C139): Auxiliary power supply for the control circuit has been connected

to appropriate terminals and the connection is tight. Pull conductors to check.

Stand-alone cooling unit with cabinet heater (option +G300): The power supply for the cabinet heater

has been connected to appropriate terminals and the connection is tight. Pull conductors to check.

The external control cabling (if any) has been connected to appropriate terminals and the connections

are tight. Pull conductors to check.

There are no tools, foreign objects or dust from drilling inside the cooling unit.

Page 38

38 Installation checklist

Task

All bleed valves and drain valves are closed (drive and cooling unit).

The external cooling circuit is connected and the connections are tight.

Stand-alone cooling unit (option +C139): The internal cooling circuit is connected and the connections

are tight.

Page 39

Start-up

Start-up 39

6

Contents of this chapter

This chapter contains a list for checking the installation.

Safety

WARNING!

Read and obey the complete safety instruction of the drive. If you ignore them,

injury or death, or damage to the equipment can occur. Only a qualified electrician

may do the work described in this chapter.

Before start-up

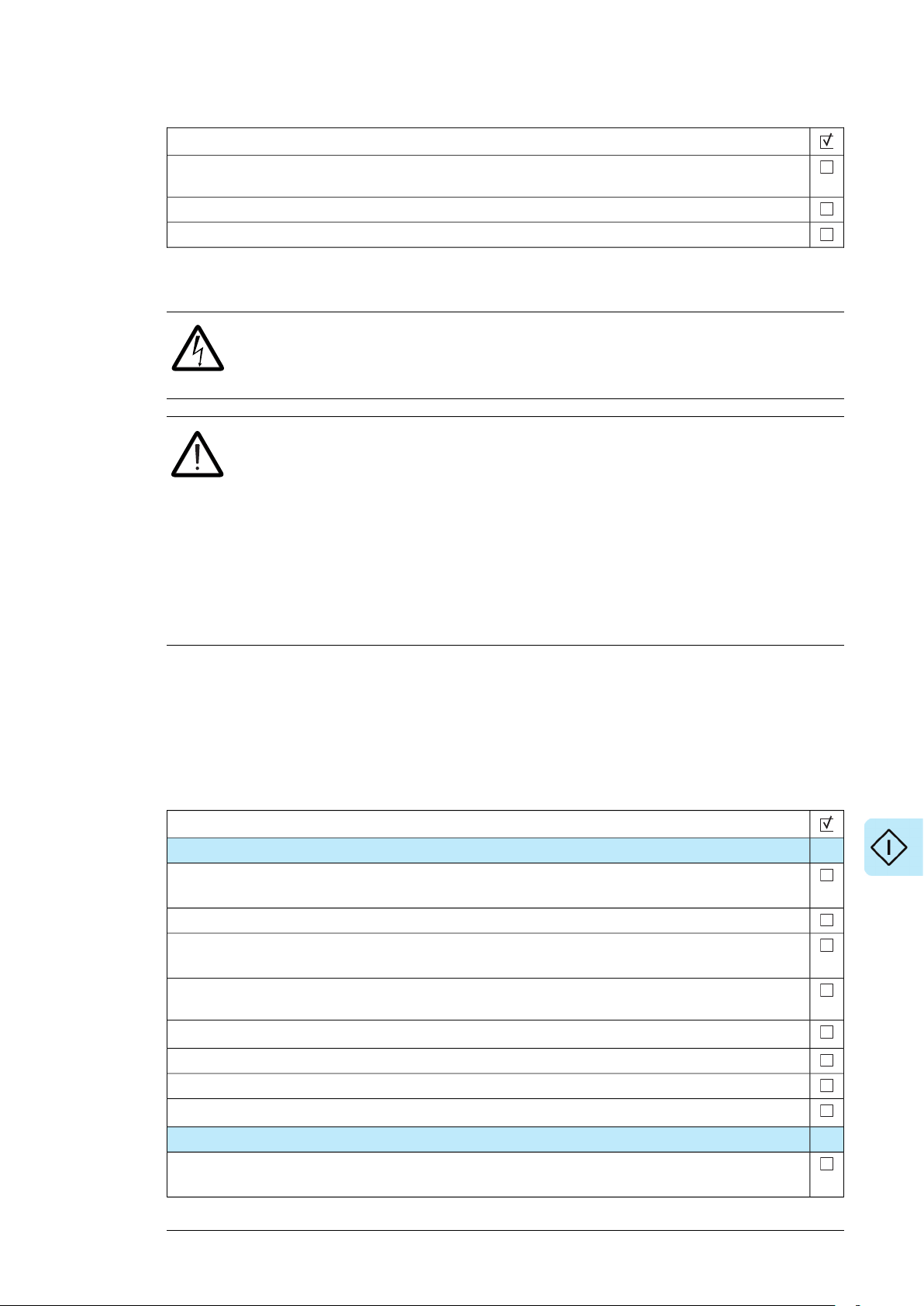

Task

Use the required personal protective equipment. See the Safety data sheet for Antifrogen® L coolant by

Clariant (www.clariant.com) for the instructions on the respiratory, hand and eye protection.

Make sure that you have enough of right type of coolant at hand. For the coolant type, see Technical

data (page 105). For the quantity of coolant in the drive cooling circuit: See the appropriate hardware

manual(s). Quantity in the cooling unit: See Technical data.

Check that the coolant temperature and the ambient temperature are within the limits. See Technical

data (page 105), and Ambient conditions (page 111).

Page 40

40 Start-up

Task

Check that you have at hand:

• tools

• air pump with a pressure gauge and standard tyre head for the air pressure adjustment of the expansion

tank

• container filled with coolant

• buckets for bleeding and draining of the system

• hoses for filling, draining and bleeding. Three hoses are included as standard in the cooling unit delivery.

See also Fill/drain/bleed hoses (page 110).

• pump for filling the coolant. We recommend a hand pump with max. 5 l/min capacity for slow and airfree fill up. See also Filling pump (page 110).

If the cooling unit has been stored in cold or damp environment, warm and dry it with the cabinet heater

or by some other means before the start.

Adjusting air pressure of the expansion tank

■ About the expansion tank

The expansion tank is divided into two sections: liquid and air section. The air section is the

reservoir into which the liquid section expands whenever a temperature rise increase the

volume of the liquid in the system. You must set the air counterpressure at the system

start-up.

■ Pressure adjusting procedure

The component designations refer to Piping and instrumentation diagrams (page 115) and

Operation basics and hardware description (page 13). Study the drawings before starting

the task and keep them at hand when performing it.

WARNING!

Do the steps in Electrical safety precautions (page 29) before you start the work

on drive and cooling unit. Go through the checklist together with another person.

WARNING!

Read and obey the safety instructions of the liquid cooling system. See the complete

safety instructions of the drive. If you ignore them, injury or death, or damage to

the equipment can occur.

Use the required personal protective equipment. See the Safety data sheet for

Antifrogen® L coolant by Clariant (www.clariant.com) for the instructions on the

respiratory, hand and eye protection.

Avoid skin contact with coolant. If liquid splashes into skin or eyes, rinse

immediately with plenty of water.

Task

Close the shut-off valve (V003) through which the expansion tank (PA-102) is coupled to the internal

cooling circuit.

Connect a hose to the bleed valve (V011) of the expansion tank and lead the hose to a bucket.

Open bleed valve to release pressure - if any - of the upper (liquid) section of the expansion tank.

Remove (unscrew by hand) the protective cap that covers the air valve at the bottom of the expansion

tank.

Page 41

Start-up 41

Task

Connect an air pump with a gauge to the air valve and measure the pressure in the lower section of the

expansion tank. Control the pressure to 40 kPa. Replace the cap onto the air valve.

Close the bleed valve (V011) and remove the hose from the valve.

Open the shut-off valve (V003).

Filling up the cooling circuit and starting the cooling unit

WARNING!

Do the steps in Electrical safety precautions (page 29) before you start the work

on drive and cooling unit. Go through the checklist together with another person.

WARNING!

Read and obey the safety instructions of the liquid cooling system. See the complete

safety instructions of the drive. If you ignore them, injury or death, or damage to

the equipment can occur.

Use the required personal protective equipment. See the Safety data sheet for

Antifrogen® L coolant by Clariant (www.clariant.com) for the instructions on the

respiratory, hand and eye protection.

Avoid skin contact with coolant. If liquid splashes into skin or eyes, rinse

immediately with plenty of water.

Keep the pump shutt-off valves closed until you start filling the internal cooling circuit. The

pumps are filled with a protective mixture at the factory. The mixture can be left in the cooling

circuit.

The component designations refer to the drawings in Piping and instrumentation

diagrams (page 115) and Operation basics and hardware description (page 13). Study the

drawings before starting the task and keep them at hand when performing it.

Task

Preparing the drive and cooling unit

Check and adjust the air pressure in the expansion tank if not done yet. See Adjusting air pressure of the

expansion tank (page 40).

Check that the drain valves in all cubicles of the drive cabinet line-up are closed.

Open the valves at the inlet and outlet of the pump(s) (V0004, V0006, V00051), V00071), GA-101, GA-

1021)).

Open inlet, outlet and bleed valves in one cubicle of the drive. Keep the valves still closed in the other

drive cubicles. (The cubicles will be filled one at a time.)

Connect a filling hose to the fill valve of the cooling unit (V0012 or V00141)).

Lead the bleed hose of the drive cubicle to bucket.

Open the shut-off valve (V0001) of the automatic float air vent (VA-103).

Open the fill valve of the cooling unit (V0012 or V00141)).

Filling

Fill the system by pumping coolant in through the fill valve (V0012 or V00141)). Pump slowly to keep air

out.

Page 42

42 Start-up

Task

When there is sufficient amount of coolant in the piping, coolant begins to overflow from the bleed hose

of the drive cubicle. Drain some coolant to get all air out of the system, then close the bleed, inlet and

outlet valves in the drive cubicle.

Lead the bleed hose of the next drive cubicle to a bucket, and open the inlet, outlet and bleed valves of

the cubicle. Fill and bleed the drive cubicle. Repeat the procedure for the remaining drive cubicles.

Open the inlet and outlet valves of all drive cubicles and let the remaining air come out through the

automatic float air vent (VA-103) of the cooling unit. The pressure in the internal circuit starts to rise.

Monitor the pressure on the pressure gauge (PT-203). Increase the pressure up to 100…150 kPa by

pumping coolant in from the fill valve (V0012 or V00141)). When the pressure has been reached, close

the fill valve and stop the fill-in pump. Keep the fill hose still coupled for later use.

Open the pump bleed valves somewhat and let the air out. Check the pressure again, and add some

coolant if necessary.

WARNING!

Do not fill in too much coolant. Ensure that the maximum permissible operating pressure (600 kPa,

indicated by pressure gauge PT-203) is not exceeded.

Starting the cooling unit and checking the pressure

Connect power to the cooling unit.

Close the door of the cooling unit.

Start the pump for one or two minutes.

• With the control panel: Switch the control panel to the Local control mode (Loc/Rem key). Start the

pump with the Start key of the panel.

• External control device: The remote start options depend on the control location selection. See parameter 20.03 and the delivery specific circuit diagrams.

Ensure that the flow control valve (V0016) is set to the design position which is shown on the label beside

the valve.

Monitor inlet and outlet liquid pressures of the pump (01.01, 01.02) on the control panel (Inside the cooling

unit, there is also pressure gauge PT-203).

Stop the pump by pressing the Stop key of the control panel: The pressure gauge should indicate pressure

100... 150 kPa when the pump is stopped.

Re-start the pump for couple of minutes.

Listen for a humming sound or feel the piping for vibration to find out if there is still air left. If these

symptoms appear:

• Make sure that the shut-off valve for automatic float air vent (VA-103) is open.

• Stop the pump, open the pump bleed valves and let air out. If necessary, add coolant (until pressure

of 150 kPa is reached). Repeat the procedure until all air is removed from the system.

Stop the pump. Check that all drain and bleed valves are closed. Remove the filling hose.

1)

Only in the two-pump cooling unit.

Basic settings in the control program

For more information on the use of the control panel, see ACX-AP-x Assistant control panels

user's manual (3AUA0000085685 (English)).

Task

Check that the number of pumps setting corresponds to actual number of pumps (20.04).

Two-pump unit ACS880-1007LC-0195: Activate and tune the delays of the automatic pump alternation

function (20.01, 20.05, 20.06).

If the drive and the cooling unit will be out of use for long time periods, activate the Standby function

(20.08).

Page 43

Start-up 43

Task

Start/stop settings when the LCU will be controlled through the IO

Make sure that:

•

Parameter 20.03 = Local. (That is: The control interface selection defines a digital input DI6 as the

source for the start/stop signal in the remote control mode.)

• Control panel, if any, is in Remote control mode. Change with the Loc/Rem key when necessary.

Give start-command (and stop) command via digital input DI6. Verify that the cooling unit starts and stops

accordingly.

Start/stop settings when the LCU will be controlled through a serial link

Make sure that:

- Parameter 20.03 = Fieldbus A. (That is: The control interface selection defines fieldbus adapter A as

the source for the start/stop signal in the remote control mode.)

- Control panel, if any, is in Remote control mode. Change with the Loc/Rem key when necessary.

Give start-command and stop command from the overriding control system via Main control word bit b0.

Verify that the cooling unit starts and stops accordingly. You can monitor the command status from the

bits of parameter 06.01.

On-load settings

Task

Define the warning limit for the minimum pump inlet pressure (31.01). Set the warning limit 20 kPa below

the pressure value during normal operation. Parameter 01.01 shows the measured actual value.

Define the warning limit for the maximum coolant temperature at internal circuit outlet (31.10). If the

measured temperature during normal operation is below +36°C, decrease the default warning limit accordingly. Parameter 01.23 shows the measured actual value.

Define the warning limit for the maximum coolant pressure at the pump outlet with parameter 31.03. A

rule of thumb value: 50 kPa above the value measured during normal operation. Parameter 01.02 shows

the measured actual value.

Note: The higher the liquid temperature the higher the pressure.

Check the coolant temperature in the internal circuit as the load varies. Adjust/control the external cooling

circuit flow when necessary.

Page 44

44

Page 45

Maintenance

Maintenance 45

7

Safety

WARNING!

Read and obey the complete safety instruction of the drive. If you ignore them,

injury or death, or damage to the equipment can occur. Only a qualified electrician

may do the work described in this chapter.

Maintenance intervals

The tables below show the maintenance tasks which can be done by the end user. The

complete maintenance schedule is available on the Internet (www.abb.com/drivesservices).

For more information, consult your local ABB Service representative

www.abb.com/searchchannels).

Maintenance tasks, every year:

Tasks

Spare parts

ISpare parts

Inspections by user

ITightness of terminals

IDustiness, corrosion and temperature

ICooling liquid pipe connections

PCoolant antifreeze concentration

Page 46

46 Maintenance

Maintenance tasks, every 2nd year:

Maintenance tasks, every 3 to 9 years:

Coolant

Coolant pump

Aging

(Real-time clock)

clock)

Tasks

PInspection of coolant quality

Tasks and intervals (years from start-up)

21181512963

RRRCoolant draining and refill

RRRPump

RRRPump motor

RRRExpansion tank

RRRZCU/BCU control unit battery

RRControl panel battery (Real-time

Legend:

Inspection (visual inspection and maintenance action if needed)I

Performance of on/off-site work (commissioning, tests, measurements or other work)P

ReplacementR

Note:

• Maintenance and component replacement intervals are based on the assumption that

the equipment is operated within the specified ratings and ambient conditions. ABB

recommends annual drive inspections to ensure the highest reliability and optimum

performance.

• Long term operation near the specified maximum ratings or ambient conditions may

require shorter maintenance intervals for certain components. Consult your local ABB

Service representative for additional maintenance recommendations.

Adding cooling liquid

See Filling up the cooling circuit and starting the cooling unit (page 41).

Draining the cooling unit

The designations refer to the drawings in Piping and instrumentation diagrams (page 115).

Study the drawings before starting the task and keep them at hand when performing it.

WARNING!

Do the steps in Electrical safety precautions (page 29) before you start the work

on drive and cooling unit. Go through the checklist together with another person.

Page 47

Maintenance 47

WARNING!

Read and obey the safety instructions of the liquid cooling system. See the complete

safety instructions of the drive. If you ignore them, injury or death, or damage to

the equipment can occur.

Use the required personal protective equipment. See the Safety data sheet for

Antifrogen® L coolant by Clariant (www.clariant.com) for the instructions on the

respiratory, hand and eye protection.

Avoid skin contact with coolant. If liquid splashes into skin or eyes, rinse

immediately with plenty of water.

1. Stop the cooling unit and disconnect it from power line. Make sure by measuring that

the unit is de-energized.

2. Connect hoses to the drain/fill valves (V0010, V0012) and lead them into to a bucket.

3. Open the inlet and outlet valves of all drive cubicles, and make sure that the pump

shut-off valves (V004, V005, V0006, V007) are open.

4. Open the drain/fill valves (V0010, V0012) and let the liquid flow out of the system.

5. Open the expansion tank bleed valve (V0011) to let air displace the liquid.

6. Dry the piping with compressed oil free air if the system will be empty for long period.

Pressure may not exceed 600 kPa.

Storing the cooling unit

Fill the cooling circuit with coolant before the storing. See the procedure in Filling up the

cooling circuit and starting the cooling unit (page 41).

Checking the quality of the coolant

The manufacturer checks the quality of coolant free of charge. Send a 250 milliliter sample

to Clariant. See www.clariant.com.

Antifreeze on-site testers are available from the Antifrogen® Distributors. See

www.clariant.com.

Cleaning and drying the leakage detector

WARNING!

Do the steps in Electrical safety precautions (page 29) before you start the work

on drive and cooling unit. Go through the checklist together with another person.

WARNING!

Read and obey the safety instructions of the liquid cooling system. See the complete