ABB machinery drives

Hardware manual

ACS850-04 drive modules (160 to 560 kW, 200 to 700 hp)

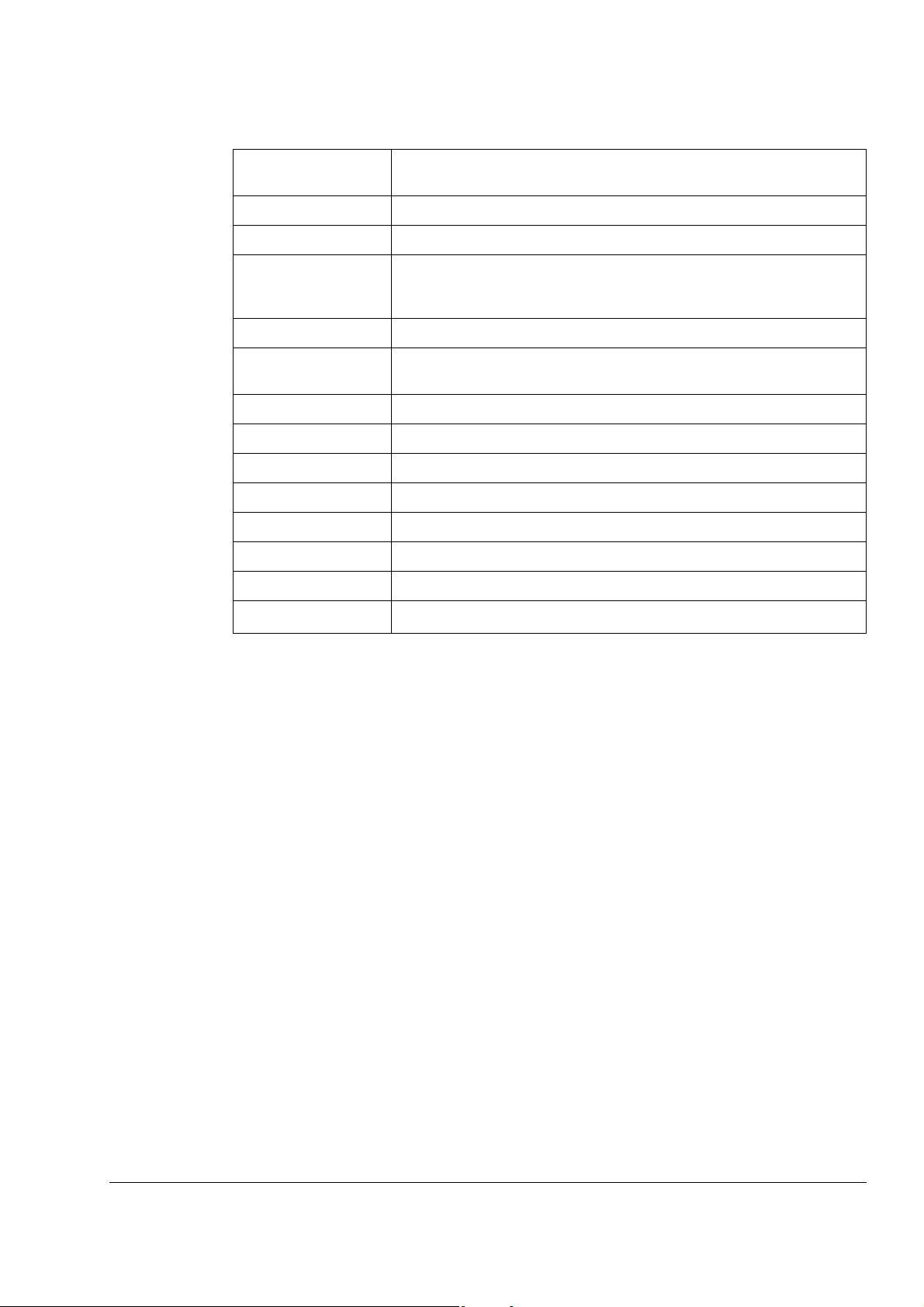

List of related manuals

ACS850-04 manuals

Drive hardware manuals and guides Code (English)

ACS850-04 drive modules (160 to 560 kW, 200 to 700 hp) hardware manual 3AUA0000081249

Safe torque off function for ACSM1, ACS850 and ACQ810 drives application

guide

Drive firmware manuals and guides

ACS850 standard control program quick start-up guide 3AUA0000045498

ACS850 standard control program firmware manual 3AUA0000045497

ACS850 crane control program supplement (to std ctrl prg) 3AUA0000081708

ACS850-04 drives with SynRM motors (option +N7502) supplement 3AUA0000123521

Option manuals and guides

ACS-CP-U Control Panel IP54 Mounting Platform Kit (+J410) Installation

Guide

ACS850 Common DC configuration for ACS850-04 drives application guide 3AUA0000073108

ATEX-certified Safe disconnection function for ACS850 drives (+Q971)

application guide

Application programming for ACS850 and ACQ810 drives application guide 3AUA0000078664

Manuals and quick guides for I/O extension modules, fieldbus adapters, etc.

You can find manuals and other product documents in PDF format on the Internet. See section

Document library on the Internet on the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

3AFE68929814

3AUA0000049072

3AUA0000074343

ACS850-04 drive modules

160 to 560 kW (200 to 700 hp)

Hardware manual

2013 ABB Oy. All Rights Reserved.

3AUA0000081249 Rev C

EN

EFFECTIVE: 2013-04-11

Table of contents

List of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of contents

Safety instructions

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Use of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety in installation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Permanent magnet motor drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fiber optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Safe start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Permanent magnet motor drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5

Introduction to the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Categorization by frame size and option code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Quick installation, commissioning and operating flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operation principle and hardware description

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power connections and control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

External control unit connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Type designation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Type designation key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Planning the cabinet installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Basic requirements for the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Planning the layout of the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table of contents

6

Layout examples, door closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Layout example, door open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Arranging the grounding inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Selecting the busbar material and preparation of the joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Planning the fastening of the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Planning the cabinet placement on a cable channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Planning the electromagnetic compatibility (EMC) of the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . .41

Planning the grounding of the cable shields at the cabinet lead-through . . . . . . . . . . . . . . . . . . . . .43

Planning the cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Preventing the recirculation of hot air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Required free space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Free space at the top of the drive module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Free space around the drive module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Other installation positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Planning the placement of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Planning the use of the cubicle heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Planning the electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Selecting the supply disconnecting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Other regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Selecting and dimensioning the main contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Protecting the motor insulation and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Checking the compatibility of the motor and drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Requirements table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Additional requirements for explosion-safe (EX) motors . . . . . . . . . . . . . . . . . . . . . . . .53

Additional requirements for HXR and AMA motors . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Additional requirements for ABB motors of types other than M2_, M3_, M4_, HX_

and AM_ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Additional requirements for the braking applications . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Additional requirements for ABB high-output motors and IP23 motors . . . . . . . . . . . . .53

Additional requirements for non-ABB high-output and IP23 motors . . . . . . . . . . . . . . .54

Additional data for calculating the rise time and the peak line-to-line voltage . . . . . . . .55

Additional note for sine filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Additional note common mode filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Typical power cable sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Motor cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Additional US requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Armored cable / shielded power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Signals in separate cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Signals allowed to be run in the same cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Table of contents

Relay cable type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Control panel cable length and type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Separate control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Continuous motor cable shield or enclosure for equipment in the motor cable . . . . . . . . . . . 62

Implementing thermal overload and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Protecting the drive and input power cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Protecting the motor and motor cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Protecting the drive and the input power and motor cables against thermal overload . . . . . 63

Protecting the motor against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Protecting the drive against ground faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Residual current device compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Implementing the Emergency stop function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Implementing the Safe torque off function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Implementing the ATEX-certified Safe motor disconnection function (option +Q971) . . . . . . . . . . 64

Implementing the Power loss ride-through function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Using power factor compensation capacitors with the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Implementing a safety switch between the drive and motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Using a contactor between the drive and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Implementing a bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Example bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Switching the motor power supply from drive to direct-on-line . . . . . . . . . . . . . . . . . . . 67

Switching the motor power supply from direct-on-line to drive . . . . . . . . . . . . . . . . . . . 67

Protecting the contacts of relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connecting a motor temperature sensor to the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Example circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7

Installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Checking the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Moving and unpacking the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Input cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Brake resistor and resistor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Overall flowchart of the installation process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installing the mechanical accessories into the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Assembly drawing (frame G1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Assembly drawing (frame G2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Assembly drawing (air baffles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Power cable connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Mounting the drive module into the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table of contents

8

Mounting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Assembly drawing of installing the drive module to the cabinet (frame G1) . . . . . . . . . . . . . .93

Assembly drawing of installing the drive module to the cabinet (frame G2) . . . . . . . . . . . . . .94

Removing the protective covering from the module air outlet . . . . . . . . . . . . . . . . . . . . . . . . .95

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Flowchart of the control cable installation process (external control unit) . . . . . . . . . . . . . . . .95

Flowchart of the control cable installation process (internal control unit, option +P905) . . . . .95

Removing the cover assembly of the external control unit . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Fastening the control cable clamp plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Connecting the external control unit to the drive module . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Mounting the external control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Mounting the external control unit to wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Mounting the external control unit vertically on a DIN rail . . . . . . . . . . . . . . . . . . . . . .100

Mounting the control unit horizontally on a DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Installing optional modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Wiring the modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Connecting the control cables to the terminals of the control unit . . . . . . . . . . . . . . . . . . . . .102

Default I/O connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

External power supply for the JCU control unit (XPOW) . . . . . . . . . . . . . . . . . . . . . . .106

DI6 (XDI:6) as a thermistor input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Drive-to-drive link (XD2D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Safe torque off (XSTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Control cable connection procedure of units with internal control unit (option +P905) . . . . . . . . . .108

Connecting a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Installation checklist

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Start-up

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Warning and fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Maintenance

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Table of contents

Cleaning the interior of the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Cleaning the interior of the heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Replacing the circuit board compartment cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Replacing the main cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Replacing the drive module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Reforming the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Memory unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Technical data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Ambient temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Fuses (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Ultrarapid (aR) fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

aR fuses with flush end contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Fuses (UL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

UL recognised Class T / Class L fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Dimensions, weights and free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Losses, cooling data and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Terminal and lead-through data for the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Units with optional common mode filter (+E208) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Units with optional cabling panels (+H381 or +H383) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Units without optional cabling panels (no +H381 or +H383) . . . . . . . . . . . . . . . . . . . . . . . . 130

Terminal data for the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Electrical power network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Motor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Brake resistor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

DC connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Control unit (JCU-11) connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Compliance with the European Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Compliance with the European EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Compliance with the European Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Compliance with EN 61800-3:2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Category C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Category C4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

UL checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9

Table of contents

10

CSA marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

“C-tick” marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

GOST R certificate of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Dimension drawings

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Frame G1 – Drive module dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Frame G1 – Drive module dimensions with optional cabling panels (+H381) . . . . . . . . . . . . . . . .143

Frame G1 – Cabling panels (+H383) installed into a Rittal TS 8 cabinet . . . . . . . . . . . . . . . . . . . .145

Frame G2 – Drive module dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Frame G2 – Drive module dimensions with optional cabling panels (+H381) . . . . . . . . . . . . . . . .147

Frame G2 – Cabling panels (+H383) installed into a Rittal TS 8 cabinet . . . . . . . . . . . . . . . . . . . .149

Frames G1 and G2 – Bottom plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Frames G1 and G2 – Air baffles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Example circuit diagram

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Example circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Resistor braking

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Availability of brake choppers and resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

When is resistor braking needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Planning the braking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Selecting the brake circuit components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Placing the brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Protecting the system in fault situations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Thermal overload protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Selecting and routing the brake circuit cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Minimizing electromagnetic interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Maximum cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

EMC compliance of the complete installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Brake circuit commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Brake resistor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

SAFUR resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Maximum resistor cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Table of contents

11

du/dt filters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

du/dt filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

When is du/dt filter needed? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Selection table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Description, installation and technical data of the FOCH filters . . . . . . . . . . . . . . . . . . . . . . 161

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Table of contents

12

Table of contents

Safety instructions

What this chapter contains

This chapter contains the safety instructions which you must follow when installing,

operating and servicing the drive. If ignored, physical injury or death may follow, or

damage may occur to the drive, motor or driven equipment. Read the safety

instructions before you work on the unit.

Use of warnings

Warnings caution you about conditions which can result in serious injury or death

and/or damage to the equipment and advise on how to avoid the danger. The

following warning symbols are used in this manual:

Electricity warning warns of hazards from electricity which can cause

physical injury and/or damage to the equipment.

13

General warning warns about conditions, other than those caused by

electricity which can result in physical injury and/or damage to the

equipment.

Electrostatic sensitive devices warning warns of electrostatic

discharge which can damage the equipment.

Hot surface warning warns of component surfaces that may become

hot enough to cause burns if touched.

Safety instructions

14

Safety in installation and maintenance

Electrical safety

These warnings are intended for all who work on the drive, motor cable or motor.

WARNING! Ignoring the following instructions can cause physical injury or death, or

damage to the equipment:

Only qualified electricians are allowed to install and maintain the drive.

•

Never work on the drive, motor cable or motor when main power is applied.

•

After disconnecting the input power, always wait for 5 min to let the intermediate

circuit capacitors discharge before you start working on the drive, motor or

motor cable.

Always ensure by measuring with a multimeter (impedance at least 1 Mohm)

that:

1. voltage between drive input phases U1, V1 and W1 and the frame is close to

0V.

2. voltage between terminals UDC+ and UDC- and the frame is close to 0 V.

Do not work on the control cables when power is applied to the drive or to the

•

external control circuits. Externally supplied control circuits may cause

dangerous voltages inside the drive even when the main power on the drive is

switched off.

Do not make any insulation or voltage withstand tests on the drive or drive

•

modules.

Note:

The motor cable terminals on the drive are at a dangerously high voltage when

•

the input power is on, regardless of whether the motor is running or not.

The brake control terminals (UDC+, UDC-, R+ and R- terminals) carry a

•

dangerous DC voltage (over 500 V).

Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V)

•

may be present on the terminals of relay outputs (X2) or Safe torque off (X6).

The Safe torque off function does not remove the voltage from the main and

•

auxiliary circuits.

Safety instructions

Grounding

These instructions are intended for all who are responsible for the grounding of the

drive.

WARNING! Ignoring the following instructions can cause physical injury, death,

increased electromagnetic interference and equipment malfunction:

Ground the drive, motor and adjoining equipment to ensure personnel safety in

•

all circumstances, and to reduce electromagnetic emission and interference.

Make sure that grounding conductors are adequately sized as required by

•

safety regulations.

In a multiple-drive installation, connect each drive separately to protective

•

earth (PE).

Where EMC emissions must be minimized, make a 360° high frequency

•

grounding of cable entries at the cabinet lead-through in order to suppress

electromagnetic disturbances. In addition, connect the cable shields to

protective earth (PE) in order to meet safety regulations.

15

Note:

Power cable shields are suitable for equipment grounding conductors only

•

when adequately sized to meet safety regulations.

As the normal leakage current of the drive is higher than 3.5 mA AC or 10 mA

•

DC, a fixed protective earth connection is required by EN 61800-5-1, 4.3.5.5.2.

Safety instructions

16

Permanent magnet motor drives

These are additional warnings concerning permanent magnet motor drives.

WARNING! Ignoring the instructions can cause physical injury or death, or damage

to the equipment.

• Do not work on the drive when the permanent magnet motor is rotating. Also,

when the supply power is switched off and the drive is stopped, a rotating

permanent magnet motor feeds power to the intermediate circuit of the drive and

the supply connections become live.

Before installation and maintenance work on the drive:

• Stop the motor.

• Ensure that there is no voltage on the drive power terminals according to step 1 or

2, or if possible, according to the both steps.

1. Disconnect the motor from the drive with a safety switch or by other means.

Measure that there is no voltage present on the drive input, output or DC

terminals (U1, V1, W1, U2, V2, W2, UDC+, UDC-).

2. Ensure that the motor cannot rotate during work. Make sure that no other system,

like hydraulic crawling drives, is able to rotate the motor directly or through any

mechanical connection like felt, nip, rope, etc. Measure that there is no voltage

present on the drive input, output or DC terminals (U1, V1, W1, U2, V2, W2,

UDC+, UDC-). Ground the drive output terminals temporarily by connecting them

together as well as to the PE.

Safety instructions

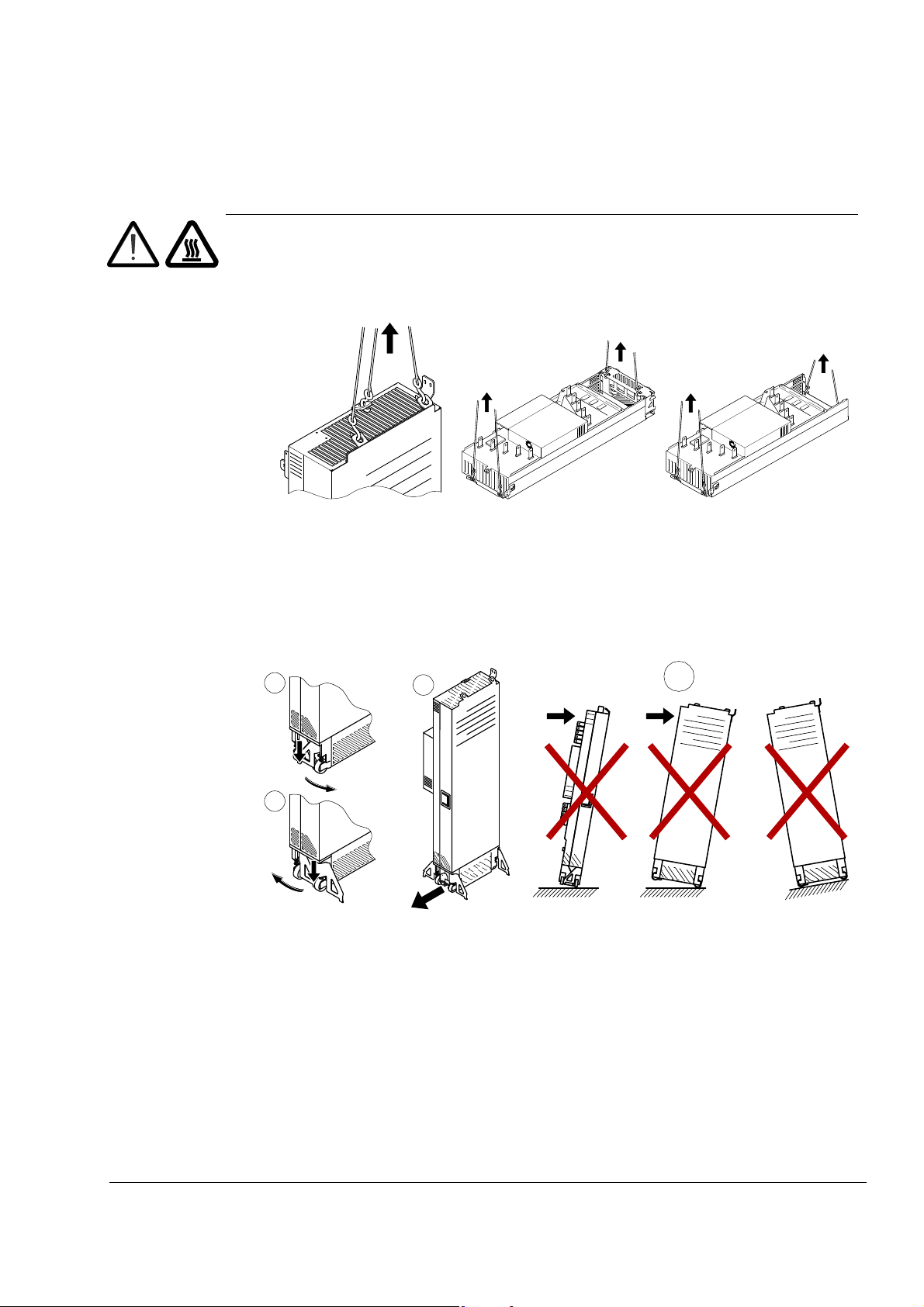

General safety

1

2

3

3AUA0000086323

A

These instructions are intended for all who install and service the drive.

WARNING! Ignoring the following instructions can cause physical injury or death,

or damage to the equipment:

- Lift the drive module using the lifting lugs attached to the top and base of the

•

unit.

- Handle the drive module carefully. Make sure that the module does not fall

down when moving it on the floor and during installation and maintenance

work: Open the support legs by pressing each leg a little down (1, 2) and

turning it aside. When ever possible secure the module also with chains.

- Do not tilt the drive module (A). It is heavy (over 160 kg [350 lb]) and its

center of gravity is high. The module will overturn from a sideways tilt of 5

degrees. Do not leave the module unattended on a sloping floor.

17

Safety instructions

18

3AUA0000086323

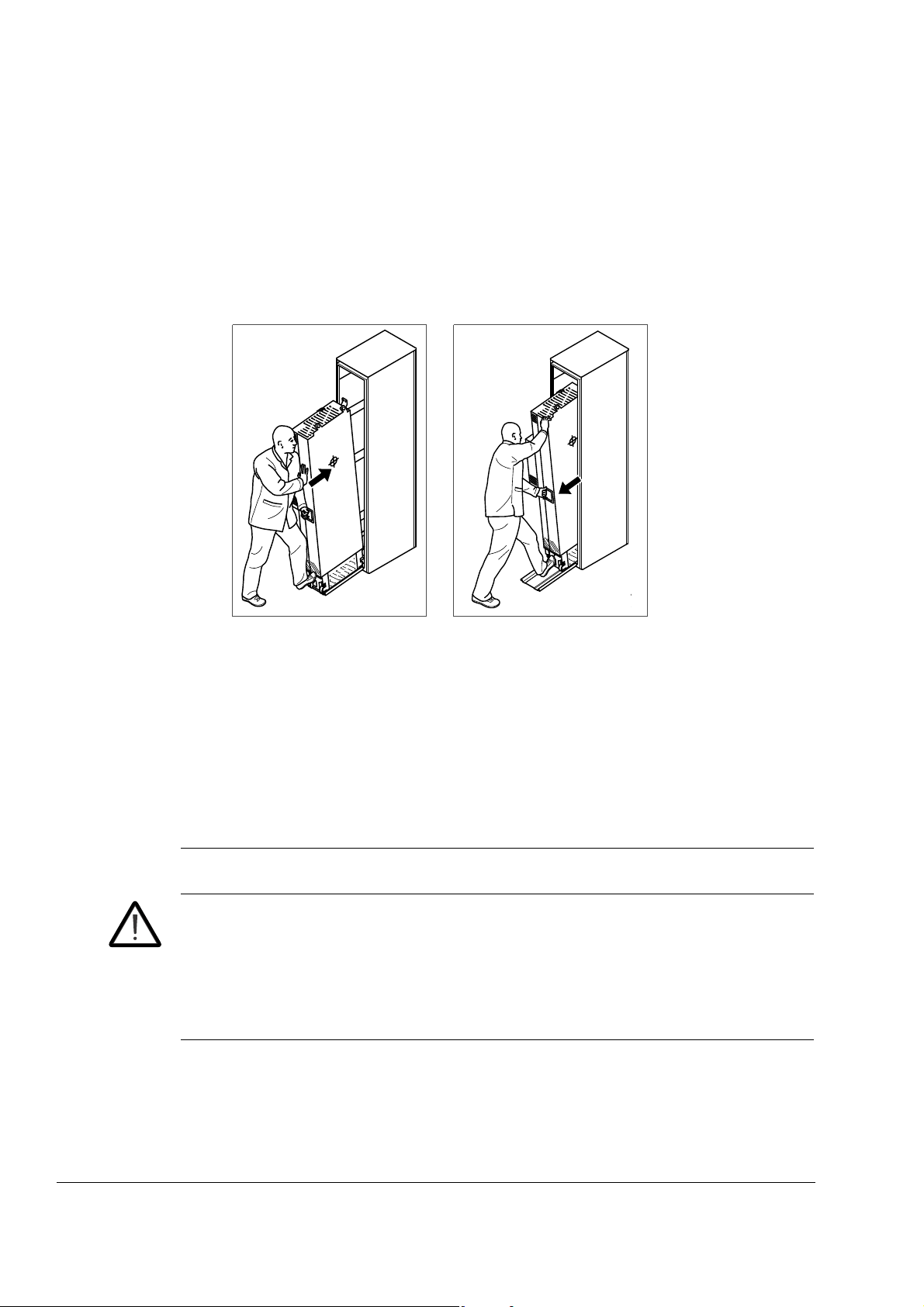

- Push the drive module into the cabinet and pull it from the cabinet carefully

preferably with help from another person as shown below. Keep a constant

pressure with one foot on the base of the module to prevent the module from

falling on its back. Use safety shoes with metal toe cap to avoid foot injury.

Do not use the ramp with plinth heights which exceed the maximum height

marked on the ramp next to the fastening screw. (The maximum plinth height

is 50 mm when the telescopic ramp is shortest and 150 mm when the ramp is

longest.) Tighten the two fastening bolts of the ramp carefully.

Beware of hot surfaces. Some parts, such as heatsinks of power

•

semiconductors, remain hot for a while after disconnection of the electrical

supply.

Make sure that dust from borings and grindings does not enter the drive when

•

installing. Electrically conductive dust inside the unit may cause damage or

malfunctioning.

Ensure sufficient cooling.

•

Do not fasten the drive by riveting or welding.

•

Fiber optic cables

WARNING! Ignoring the following instructions can cause equipment malfunction

and damage to the fiber optic cables:

Handle the fiber optic cables with care. When unplugging optic cables, always

•

grab the connector, not the cable itself. Do not touch the ends of the fibers with

bare hands as the fiber is extremely sensitive to dirt. The minimum allowed

bend radius is 35 mm (1.4 in.).

Safety instructions

Printed circuit boards

WARNING! Ignoring the following instructions can cause damage to the printed

circuit boards:

Wear a grounding wrist band when handling the boards. Do not touch the

•

boards unnecessarily. The printed circuit boards contain components sensitive

to electrostatic discharge.

Safe start-up and operation

General safety

These warnings are intended for all who plan the operation of the drive or operate

the drive.

WARNING! Ignoring the following instructions can cause physical injury or death,

or damage to the equipment:

Before adjusting the drive and putting it into service, make sure that the motor

•

and all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at

speeds above and below the speed provided by connecting the motor directly

to the power line.

19

Do not activate any automatic fault reset functions of the drive control program

•

if dangerous situations can occur. When activated, these functions will reset

the drive and resume operation after a fault.

Do not control the motor with an AC contactor or disconnecting device;

•

instead, use the control panel keys and , or commands via the I/O

board of the drive. The maximum allowed number of charging cycles of the DC

capacitors, ie, power-ups by applying power, is five in ten minutes.

Note:

If an external source for start command is selected and it is ON, the drive will

•

start immediately after an input voltage break or fault reset unless the drive is

configured for 3-wire (a pulse) start/stop.

When the control location is not set to local, the stop key on the control panel

•

will not stop the drive.

Permanent magnet motor drives

WARNING! Do not run the motor over the rated speed. Motor overspeed leads to

overvoltage which may damage or explode the capacitors in the intermediate circuit

of the drive.

Safety instructions

20

Safety instructions

Introduction to the manual

What this chapter contains

This chapter describes the intended audience and contents of the manual. It

contains a flowchart of steps in checking the delivery, installing and commissioning

the drive. The flowchart refers to chapters/sections in this manual and other

manuals.

Target audience

This manual is intended for persons who

• plan the cabinet assembly of the drive module and install the module into a userdefined cabinet

• plan the electrical installation of the drive cabinet

• make instructions for the end user of the drive concerning the mechanical

installation of the drive cabinet, connection of power and control cables to the

cabinet-installed drive and maintenance of the drive.

21

Read the manual before working on the drive. You are expected to know the

fundamentals of electricity, wiring, electrical components and electrical schematic

symbols.

The manual is written for readers worldwide. Both SI and imperial units are shown.

Contents of the manual

This manual contains the instructions and information for the basic drive module

configuration. The chapters of the manual are briefly described below.

Safety instructions give safety instructions for the installation, commissioning,

operation and maintenance of the drive module.

Introduction to the manual introduces the manual.

Operation principle and hardware description describes the drive module.

Planning the cabinet installation guides in planning drive cabinets and installing the

drive module into a user-defined cabinet. The chapter gives cabinet layout examples

and free space requirements around the module for cooling.

Planning the electrical installation instructs in the motor and cable selection,

protections and cable routing.

Installation describes how to install the drive module into a cabinet and connect the

cables to the drive.

Installation checklist contains lists for checking the mechanical and electrical

installation of the drive.

Introduction to the manual

22

Start-up refers to the start-up instructions of the cabinet-installed drive.

Fault tracing describes the LED indications and refers to the fault tracing instructions

of the drive.

Maintenance contains preventive maintenance instructions.

Technical data contains the technical specifications of the drive module, eg, the

ratings, sizes and technical requirements, provisions for fulfilling the requirements for

CE and other markings.

Dimension drawings contains dimension drawings of the drive module installed into

a Rittal TS 8 cabinet.

Example circuit diagram shows an example circuit diagram for a cabinet-installed

drive module.

Resistor braking describes how to select, protect and wire brake resistors.

du/dt filters describes how to select du/dt filters for the drive.

Categorization by frame size and option code

The instructions, technical data and dimension drawings which concern only certain

drive frame sizes are marked with the symbol of the frame size (G1 or G2). The

frame size is marked on the type designation label.

The instructions and technical data which concern only certain optional selections

are marked with option codes, eg, +H381. The options included in the drive can be

identified from the option codes visible on the type designation label. The option

selections are listed in section Type designation key on page 35.

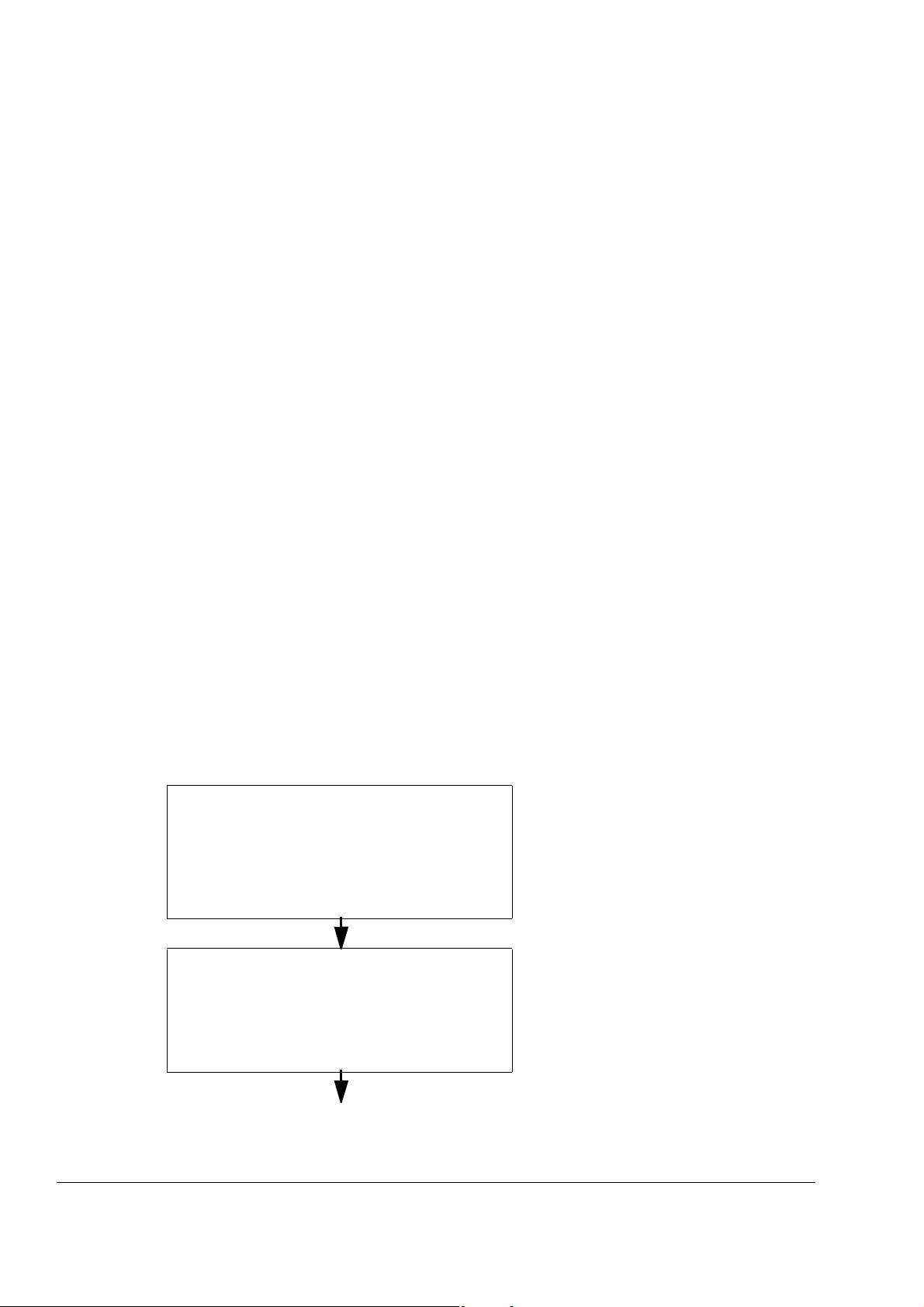

Quick installation, commissioning and operating flowchart

Task See

Plan the installation.

Check the ambient conditions, ratings, required

cooling air flow, input power connection, compatibility

of the motor, motor connection, and other technical

data.

Select the cables.

Unpack and check the units.

Check that all necessary optional modules and

equipment are present and correct.

Only intact units may be started up.

Planning the cabinet installation (page 37)

Planning the electrical installation (page 49)

Technical data (page 125)

Resistor braking (page 155)

Option manual (if optional equipment is

included)

Moving and unpacking the unit (page 74)

Checking the delivery (page 76)

If the drive module has been non-operational

for more than one year, the converter DC link

capacitors need to be reformed. (Reforming the

capacitors, page 124)

Introduction to the manual

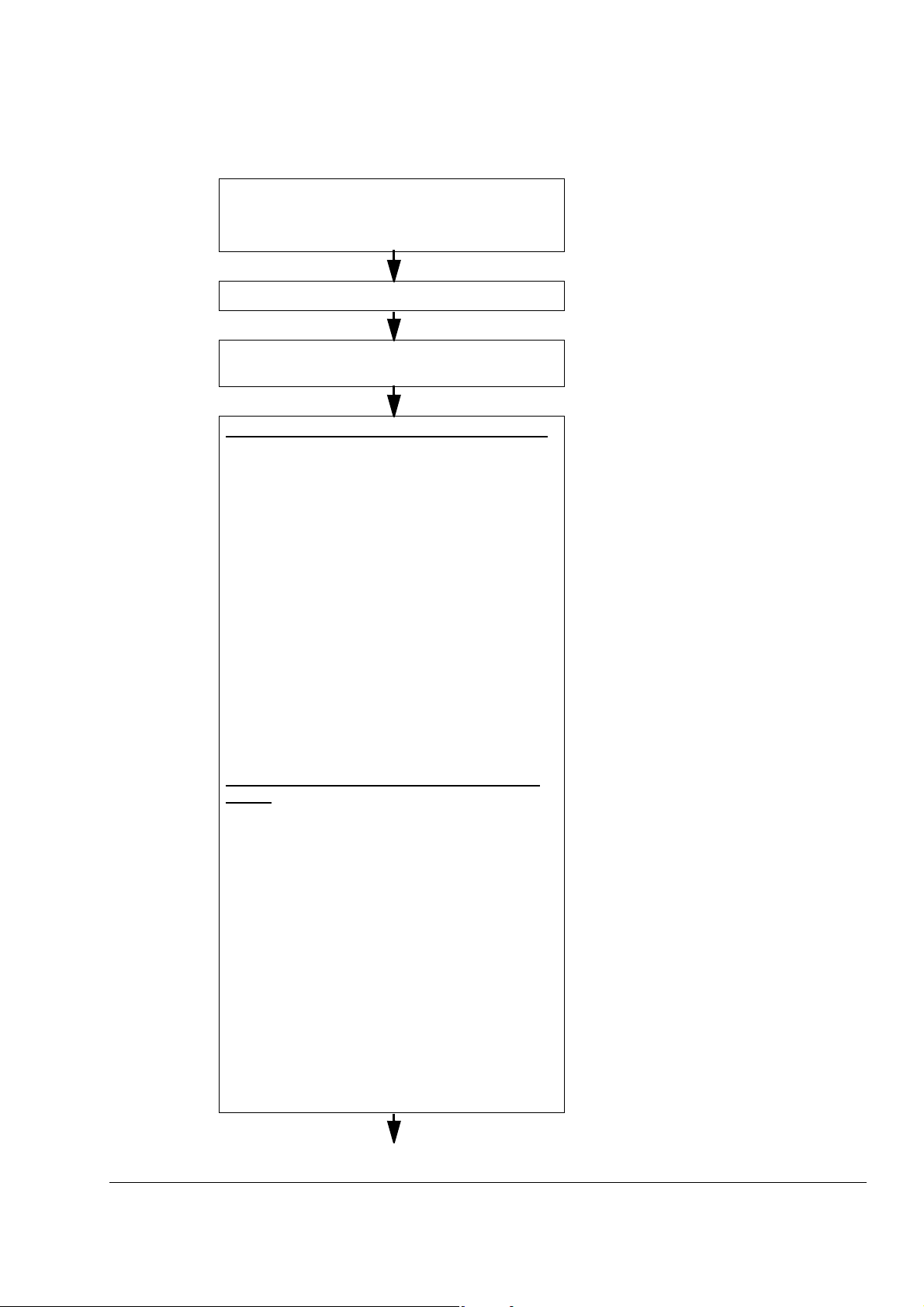

Task See

23

Check the installation site. Fasten the base of the

cabinet to floor.

Route the cables. Routing the cables (page 60)

Check the insulation of the supply cable, the motor

and the motor cable and the resistor cable (if present).

Units with optional cabling panels (+H

• Install the cabling panels into the cabinet.

• Install the additional components into the cabinet

(composition varies, for example: main disconnector,

main contactor, main AC fuses, etc.).

• If the main disconnector is installed into the cabinet,

connect the input power cabling to it.

• Connect the input power cables and motor cables to

the cabling panel terminals.

• Connect the brake resistor and DC connection

cables (if any) to the cabling panel terminals.

• Install the drive module into the cabinet.

• Fasten the cabling panel busbars to the drive module

busbars.

• If external drive control unit, connect the power

supply and fiber optic cables from the drive module to

the control unit and install the control unit into the

cabinet.

Units without optional cabling panels (no +H

+H383)

• Install the additional components into the cabinet

(composition varies, for example: main PE busbar,

main disconnector, main contactor, main AC fuses,

etc.).

• Install the drive module into the cabinet.

• Connect the power cabling between the drive module

and the rest of the main circuit components in the

cabinet (if any).

• Connect the input power cables and motor cables to

the drive cabinet.

• Connect the brake resistor and DC connection

cables to the drive cabinet.

• If external drive control unit, connect the power

supply and fiber optic cables from the drive module to

the control unit and install the control unit into the

cabinet.

381 or +H383)

381 or

Checking the installation site (page 73)

Ambient conditions (page 134)

Planning the cabinet installation (page 37)

Checking the insulation of the assembly (page

76)

Installing the mechanical accessories into the

cabinet (page 79)

Connecting the power cables (page 84)

Mounting the drive module into the cabinet

(page 89)

Connecting the external control unit to the drive

module (page 97)

Mounting the external control unit (page 99)

Manuals for any optional equipment

Introduction to the manual

24

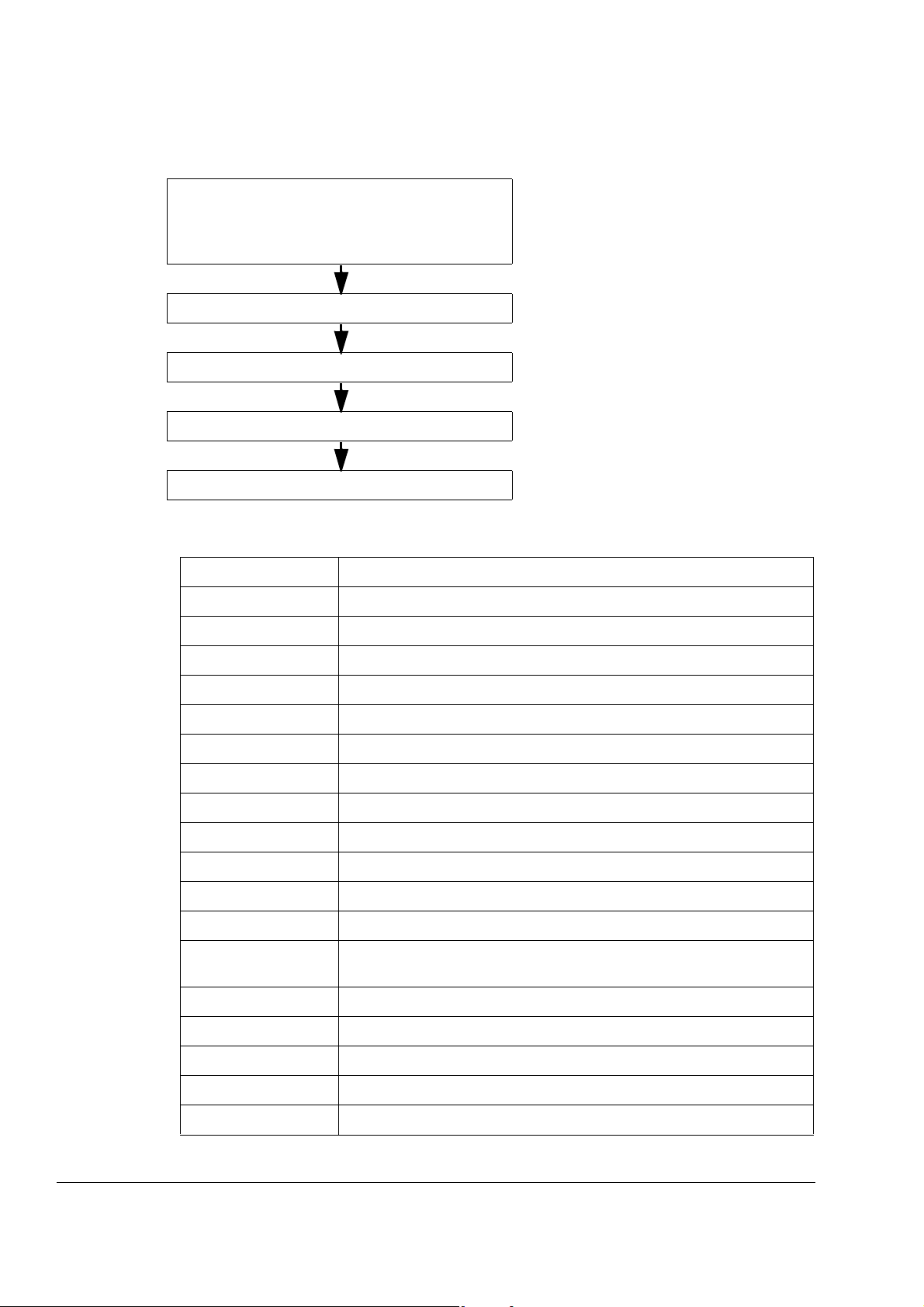

Task See

Connect the external control cables to the drive control

unit.

Check the installation. Installation checklist (page 109)

Commission the drive. Start-up (page 113)

Commission the brake chopper (if used). Resistor braking (page 155)

Operating of the drive: start, stop, speed control etc. Appropriate firmware manual

Terms and abbreviations

Term/Abbreviation Explanation

AIBP Input bridge protection board

APOW Power supply board

Connecting the control cables (page 95)

Control cable connection procedure of units

with internal control unit (option +P905), page

108

BFPS Power supply board

EMC Electromagnetic compatibility

EMI Electromagnetic interference

FCAN-01 Optional CANopen adapter module

FDNA-01 Optional DeviceNet™ adapter module

FECA-01 Optional EtherCAT

FEN-01 Optional TTL encoder interface module

FEN-11 Optional absolute encoder interface module

FEN-21 Optional resolver interface module

FEN-31 Optional HTL encoder interface

FENA-11 Optional Ethernet/IP™, Modbus/TCP and PROFINET IO fieldbus adapter

module

FIO-01 Optional digital I/O extension module

FIO-11 Optional analog I/O extension module

FIO-21 Optional analog and digital I/O extension module

FLON-01 Optional LonWorks

®

adapter module

®

adapter module

FPBA-01 Optional PROFIBUS DP adapter module

Introduction to the manual

Frame (size) Size of the drive module. The drive modules described in this manual are

of frame size G1 and G2.

FSCA-01 Optional Modbus adapter

HTL High-threshold logic

IGBT Insulated gate bipolar transistor; a voltage-controlled semiconductor type

widely used in converters due to their easy controllability and high

switching frequency.

I/O Input/Output

JCU The control unit of the drive module. The external I/O control signals are

connected to the JCU, or to optional I/O extension modules mounted on it.

JGDR Gate driver board

JINT Main circuit board

JMU-xx The memory unit attached to the control unit (JCU)

JRIB Adapter board connected to the control board in the control unit (JCU)

STO Safe torque off

25

SynRM Synchronous reluctance motor

RFI Radio-frequency interference

TTL

Transistor-transistor logic

Introduction to the manual

26

Introduction to the manual

Operation principle and hardware description

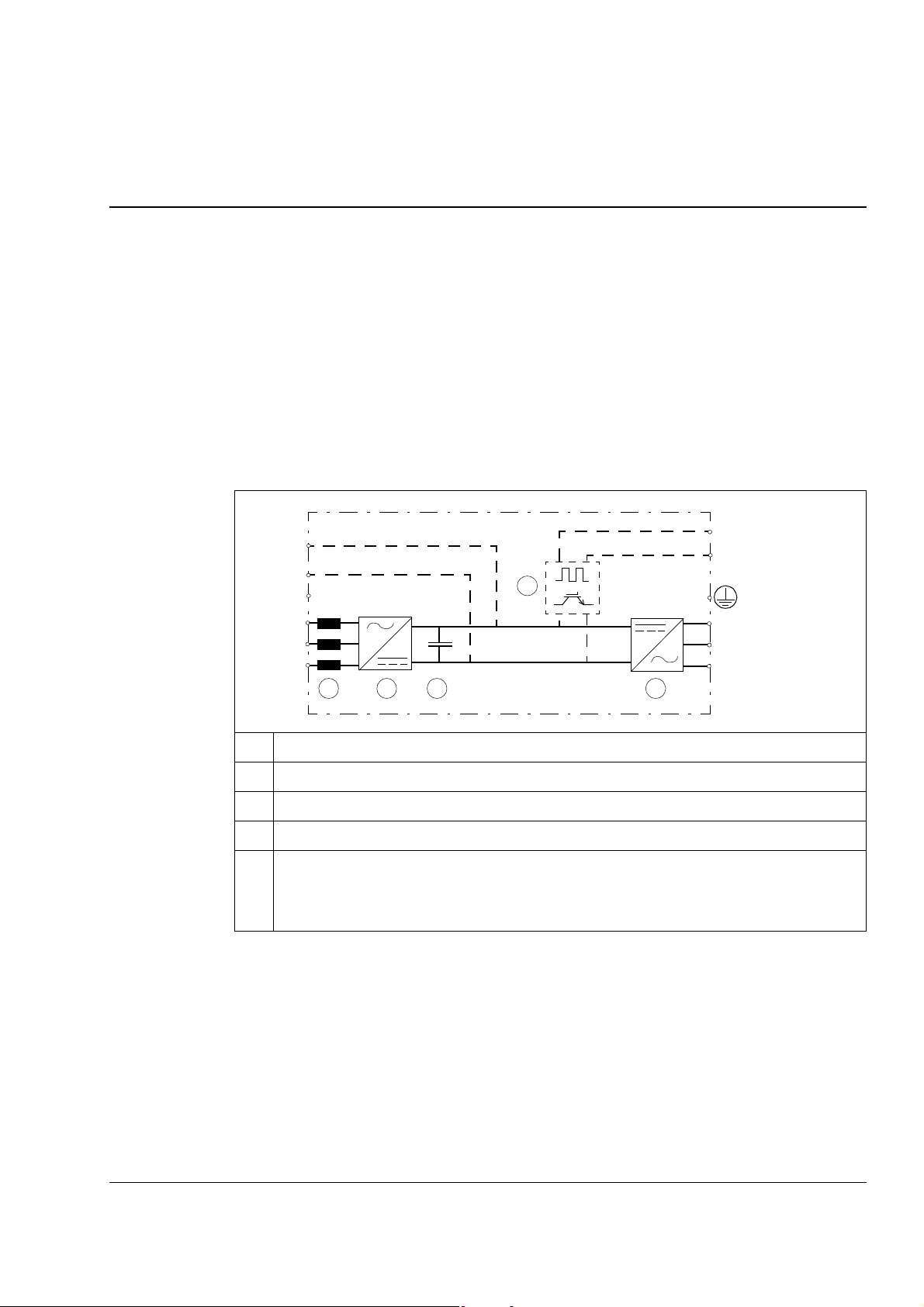

U1

V1

W1

U2

V2

W2

ACS850-04

R-

R+

421

5

3

UDC-

UDC+

PE

What this chapter contains

This chapter describes the operating principle and construction of the drive module

in short.

Product overview

The ACS850-04 is a drive module for controlling asynchronous AC induction motors,

permanent magnet motors and ABB synchronous reluctance motors (SynRM

motors).

The main circuit of the drive module is shown below.

27

1 AC choke

2 Rectifier. Converts alternating current and voltage to direct current and voltage.

3 DC link. DC circuit between rectifier and inverter

4 Inverter. Converts direct current and voltage to alternating current and voltage.

5 Brake chopper (option +D150). Conducts the surplus energy from the intermediate circuit of

the drive to the brake resistor when necessary. The chopper operates when the DC link

voltage exceeds certain maximum limit. The voltage rise is typically caused by deceleration

(braking) of a high inertia motor.

Operation principle and hardware description

28

9

6

3

2

1

8

4

A

5

7

B

1

2

3

8

W1, V1, U1

W2, V2, U2

11

12

13

14 15

10

17

16

18

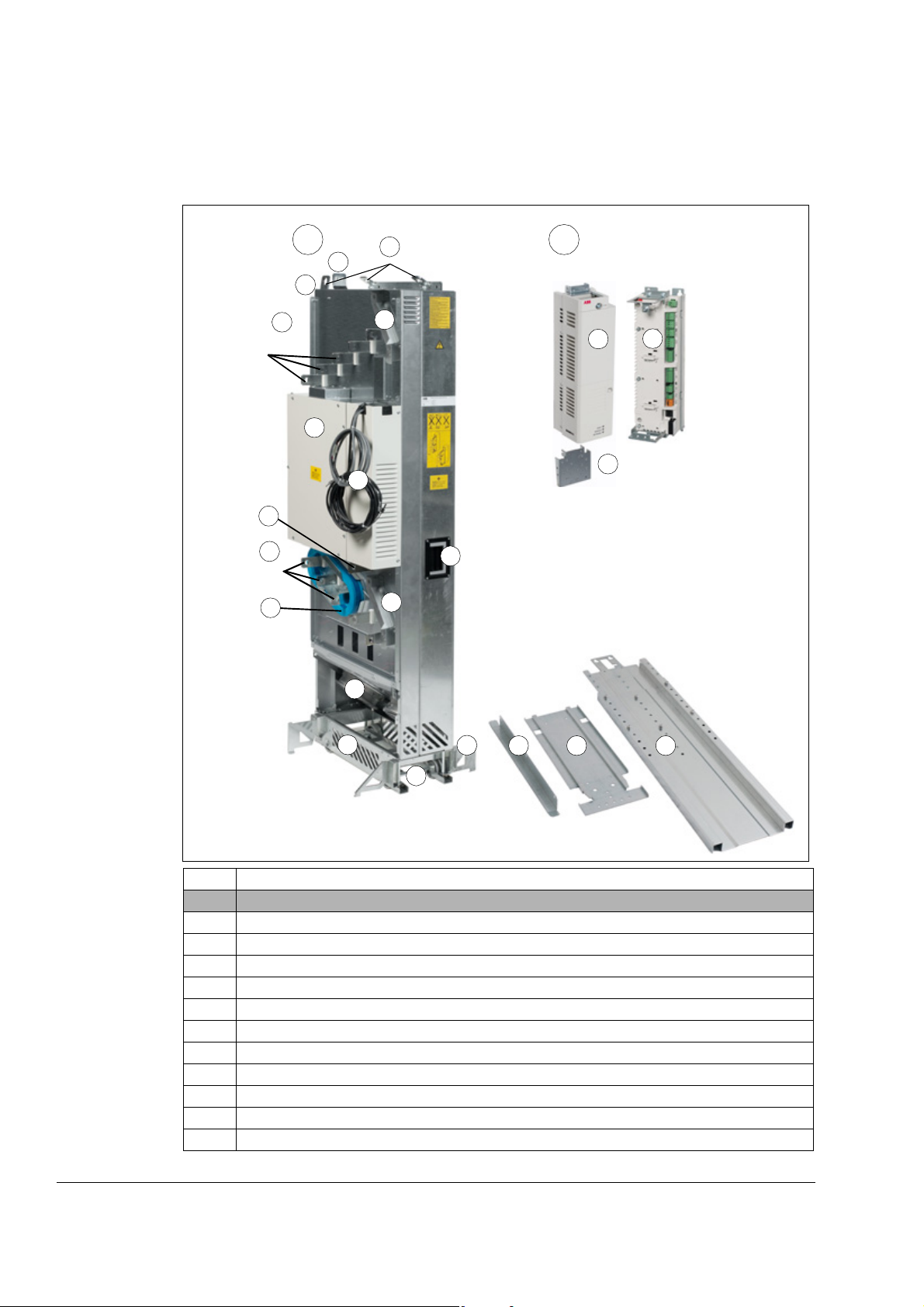

Layout

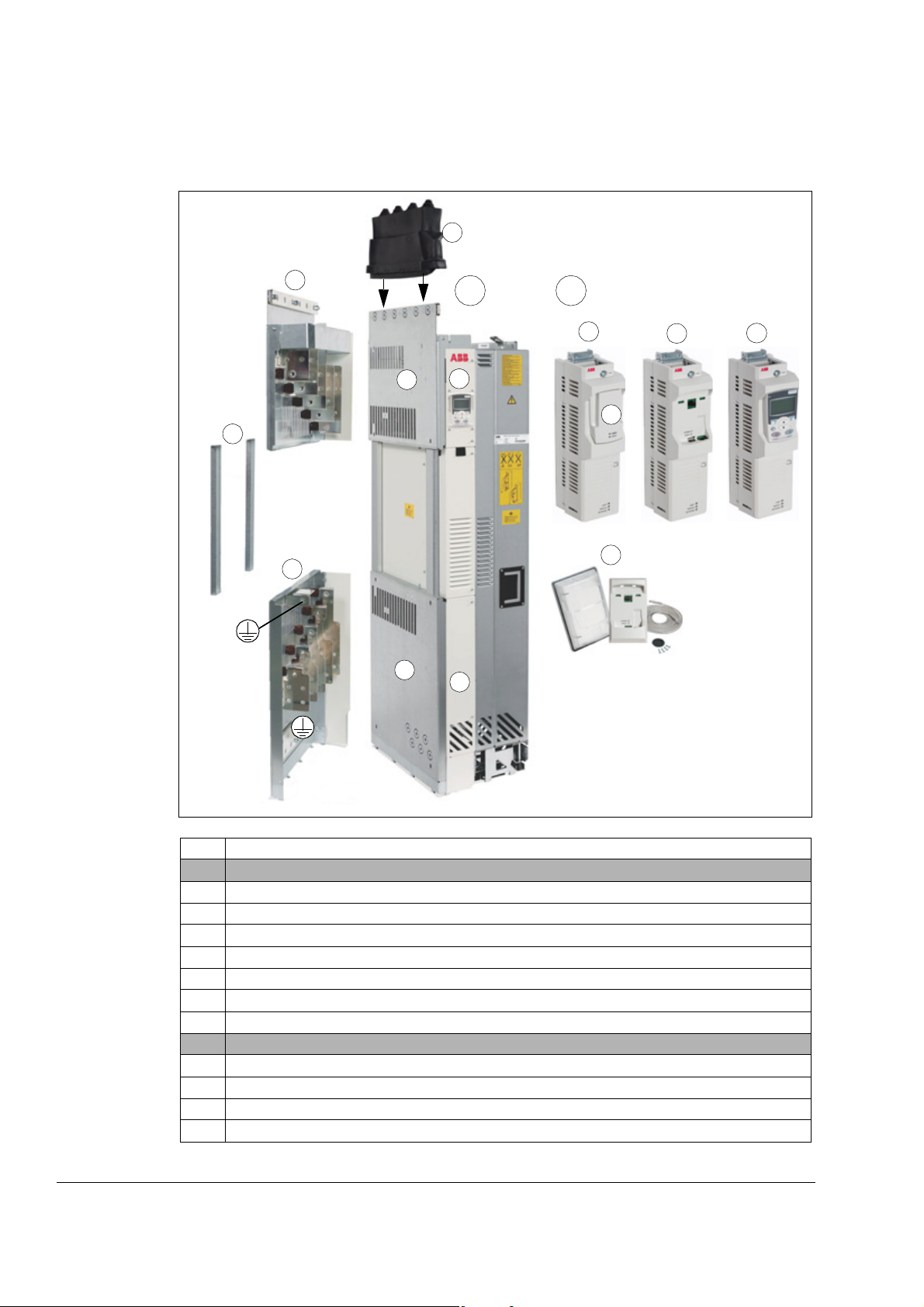

The components of the standard unit are shown below.

Item Description

A Drive module

1 Lifting lugs

2 Fastening bracket

3 Input cable connection busbars and optional DC+ and DC- busbars (+H356)

4 Circuit board compartment

5 Power supply and fiber optic cables to be connected to the external control unit

6 Output cable connection busbars and optional brake resistor connection busbars (+D150)

7 PE terminal

8 Control cable duct

9 Main cooling fans

10 Pedestal

11 Retractable support legs

Operation principle and hardware description

Item Description

12 Base fastening screws

13 Handle for pulling the drive module out of the cabinet

14 Pedestal guide plate

15 Telescopic extraction and insertion ramp

16 Top guide plate

17 Optional common mode filter (+E208)

18 Grounding busbar

B Control unit (JCU)

1 Control unit with front cover

2 Control unit with front cover removed

3 Control cable clamp plate

29

Operation principle and hardware description

30

3

1

2

3

a

A B

1

2

3

4

4

6

5

7

The drive module and optional selections are shown below: control unit and control

panel variations and cabling panels.

Item Description

A Drive module

1 Input power cabling panel to be fastened to the cabinet (+H381 or +H383)

2 Output power cabling panel to be fastened to the cabinet (+H381 or +H383)

3 Front cover. With option +P905, the control panel is placed on this cover.

4 Input power cabling panel (+H381 or +H383)

5 Side guides (+H381 or +H383)

6 Output power cabling panel (+H381 or +H383)

7 Rubber grommet (+H381)

B Control unit variants

1 Control unit with control panel holder (+J414)

2 Control unit with control panel holder (+J414) when cover (a) is removed

3 Control unit with control panel (+J400)

4 Control panel door mounting kit (+J410)

Operation principle and hardware description

31

Slots 1 and 2 for

optional I/O extension

and encoder/resolver

interface modules

Slot 3 for optional

fieldbus adapter

module

Relay outputs

+24VD

Digital inputs

Digital input/outputs

Analog inputs

Analog outputs

Drive-to-drive link

Control panel / PC connection

Memory unit (JMU) connection

External 24 V power input

Safe torque off connection

The control unit layout is shown below (cover assembly and protective coverings of

the slots removed).

Operation principle and hardware description

32

Slot 1

Slot 2

Slot 3

F

X

X

X

F

X

X

U2

V2

W2

UDC-

X7

M

3 ~

XPOW

XRO1…3

XD24

XDI

XDIO

XAI

XAO

XD2D

XSTO

2

4

U1

V1

W1

L1

L2

L3

PE

PE

UDC+

R-

R+

t°

3

1

F

X

X

Power connections and control interfaces

The diagram shows the power connections and control interfaces of the drive

module.

Slot 1 and

Slot 2

Operation principle and hardware description

Slot 3 Fieldbus adapter modules (FCAN-01, FDNA-01,

XPOW External power input

XRO1…3 * Relay outputs (3 pcs)

XD24 24 V DC output

XDI * Digital inputs (6 pcs)

XDIO * Digital input/outputs (2 pcs)

XAI * Analog inputs

XAO * Analog outputs

XD2D Drive-to-drive link

XSTO Safe torque off

I/O extension modules (FIO-01, FIO-11, FIO-21)

and/or encoder or resolver interface modules

(FEN-01, FEN-11, FEN-21, FEN-31)

FENA-11, FECA-01, FLON-01, FSCA-01,

FPBA-01)

1) For information on the default

connections, see page 104. For the

specifications, see page 131.

* programmable

2) Memory unit, see page 124.

3) Brake resistor (optional)

4) du/dt or sine filter (optional, see

page 161)

External control unit connection cables

3 m (9.8 ft)

JINT

APOW

3 m (9.8 ft)

2560 mm (8.4 ft)

Category 5e cable

JRIB

8

0

(

3

.

1

5

”

)

JCU

ACS850-04

JGDR

The cables for connecting the drive module and control panel to the control unit are

shown below. See sections Connecting the external control unit to the drive module

(page 97) and Connecting a PC (page 108) for the actual connections.

33

Operation principle and hardware description

34

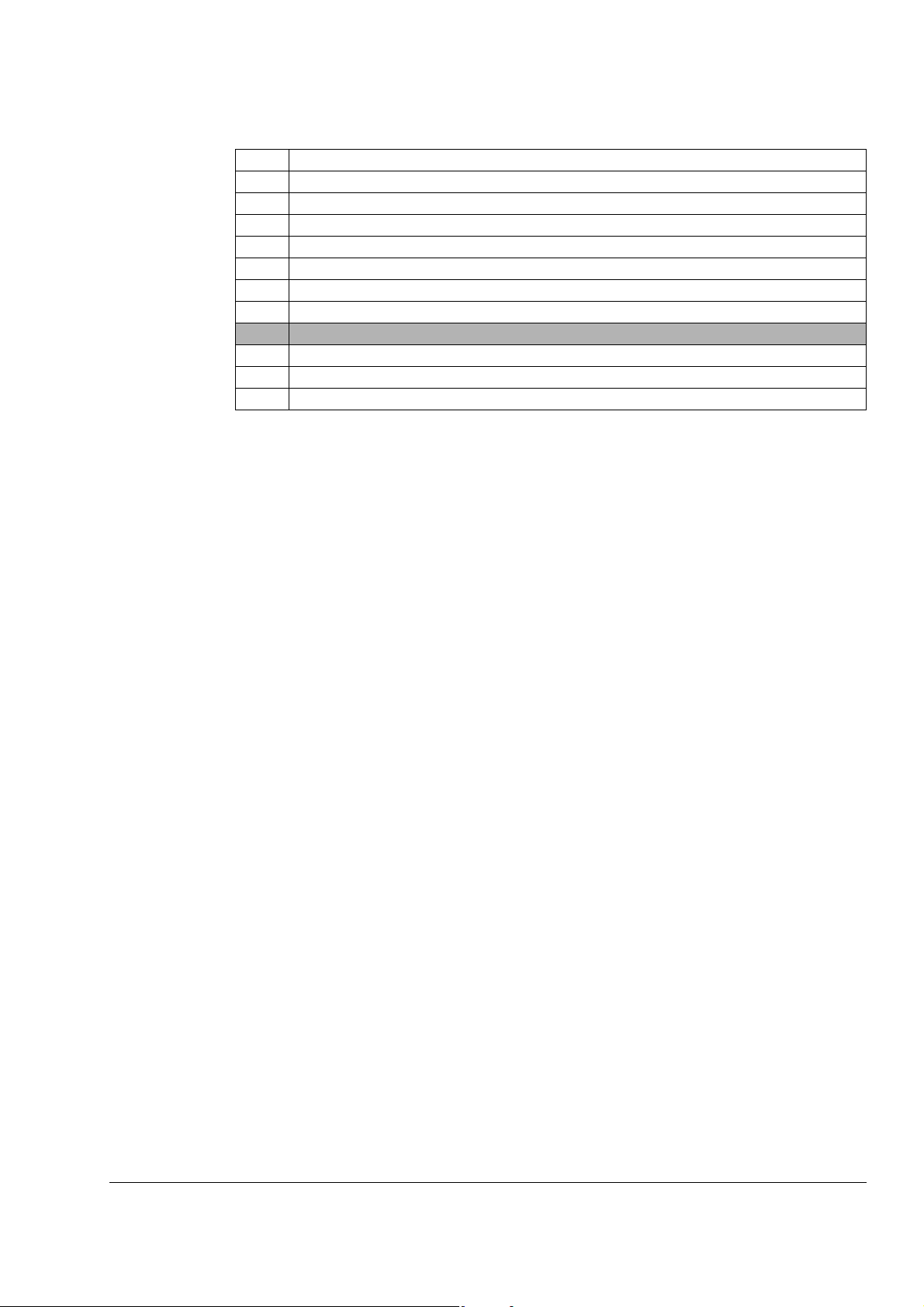

No. Description

1 Type designation, see section Type designation key on page 35.

2Frame size

3Ratings

4 Valid markings

5 Serial number. The first digit of the serial number refers to the manufacturing plant. The next

four digits refer to the unit’s manufacturing year and week, respectively. The remaining

digits complete the serial number so that there are no two units with the same number.

1

2

3

4

5

Type designation label

The type designation label includes an IEC and NEMA rating, CE and cULus, and

CSA markings, a type designation and a serial number, which allow individual

recognition of each unit. The type designation label is located on the front cover. An

example label is shown below.

Operation principle and hardware description

Type designation key

The type designation contains information on the specifications and configuration of

the drive module. The first digits from left express the basic configuration. The

optional selections are given thereafter, separated by plus signs, eg, +E208. The

main selections are described below. Not all selections are available for all types.

For more information, refer to ACS850-04 Ordering Information

(3AXD00000579470), available on request.

Code Description

Basic code, eg, ACS850-04-710A-5

Product series

ACS850 ACS850 product series

Type

04 Air-cooled drive module. When no options are selected: IP00 (UL type open), top entry and

bottom exit for cables (terminals at the side of the module), external JCU control unit with a

front cover but no control panel, Standard Control Program, AC choke, coated boards, Safe

torque off function, pedestal guide plate, extraction and insertion ramp, module fastening

bracket and screws, hardware manual, multilingual quick start-up guide and CD containing

all manuals.

Size

xxxA Refer to the rating tables, page 125.

Voltage range

5 380…500 V AC

Option codes (plus codes)

Resistor braking

D150 Brake chopper and brake resistor connection busbars, and R+ and R- terminals in the power

cabling panel (+H381 or +H383) if the power cabling panels are ordered

Filters

E208 Common mode filter. Includes three extension busbars to the drive module output busbars

with units without option +H381 or +H383.

Cabling panels

H381 Power cabling panels (U1, V1, W1, U2, V2, W2 terminals) to be installed in the cabinet,

rubber grommet that gives the unit an IP20 protection class.

H383 Power cabling panels (U1, V1, W1, U2, V2, W2 terminals) to be installed in the cabinet,

degree of protection: IP00.

DC busbars

H356 DC output busbars, and DC+ and DC- terminals in the power cabling panel (+H381 or

+H383) if the power cabling panels are ordered

Pedestal

0H354 No pedestal

Control panel and control unit

J400 Control panel inserted onto the JCU control unit. Includes control panel mounting platform

and internal cable.

J410 Control panel with a door mounting kit. Includes control panel mounting platform, IP54 cover

and a 3-meter panel connection cable.

J414 Control panel holder with cover and internal cable but no control panel. Not to be used with

+J400.

0C168 Without front cover for the JCU control unit

P905 JCU control unit inside the circuit board compartment of drive module.

35

Operation principle and hardware description

36

Code Description

Fieldbus adapter modules

K451 FDNA-01 DeviceNet™ fieldbus adapter module

®

K452 FLON-01 LonWorks

fieldbus adapter module

K454 FPBA-01 PROFIBUS DP fieldbus adapter module

K457 FCAN-01 CANopen fieldbus adapter module

K458 FSCA-01 Modbus fieldbus adapter module

®

K469 FECA-01 EtherCAT

fieldbus adapter module

K473 FENA-11 Ethernet/IP™, Modbus/TCP and PROFINET IO fieldbus adapter module

I/O extension and feedback interface modules

L500 FIO-11 analog I/O extension module

L501 FIO-01 digital I/O extension module

L502 FEN-31 HTL incremental encoder interface module

L516 FEN-21 resolver interface module

L517 FEN-01 TTL incremental encoder interface module

L518 FEN-11 TTL absolute encoder interface module

L519 FIO-21 analog and digital I/O extension module

Control programs

N2007 Standard control program version UIFI2110 (frame G2 only)

N2008 Standard control program version UIFI2200 (frame G2 only)

N2009 Standard control program version UIFI2210 (frame G2 only)

N2010 Standard control program version UIFI2300 (frame G2 only)

N3050 Crane technology library

N5050 Crane control program. Requires option +N3050.

N7502 SynRM control program

Warranty

P904 Extended warranty

ATEX-certified function

Q971 ATEX-certified Safe motor disconnection function using the drive Safe torque off function

Paper manuals. Note: The delivered manual set may include manuals in English if the translation is

not available.

R700 English

R701 German

R702 Italian

R703 Dutch

R704 Danish

R705 Swedish

R706 Finnish

R707 French

R708 Spanish

R709 Portuguese

R710 Portuguese spoken in Brazil

R711 Russian

R714 Turkish

Operation principle and hardware description

Planning the cabinet installation

What this chapter contains

This chapter guides in planning drive cabinets and installing the drive module into a

user-defined cabinet so that the front of the module faces the cabinet door. The

chapter gives cabinet layout examples and free space requirements around the

module for cooling. The issues discussed are essential for the safe and trouble-free

use of the drive system.

Limitation of liability

The installation must always be designed and made according to applicable local

laws and regulations. ABB does not assume any liability whatsoever for any

installation which breaches the local laws and/or other regulations.

Basic requirements for the cabinet

37

Use a cabinet which:

• has a frame sturdy enough to carry the weight of the drive components, control

circuitry and other equipment installed in it

• protects the user and drive module against contact and meets the requirements

for dust and humidity

• has sufficient air inlet and outlet gratings that allow free flow of cooling air through

the cabinet. This is critical for proper cooling of the drive module.

Planning the layout of the cabinet

Design a spacious layout to ensure easy installation and maintenance. Sufficient

cooling air flow, obligatory clearances, cables and cable support structures all

require space.

Place the control board(s) away from:

• main circuit components such as contactor, switches and power cables

• hot parts (heat sink, air outlet of the drive module).

Planning the cabinet installation

38

1a

4

3

2a2b

5

6

1a*)Air inlet for the drive module

1b Air inlet for the other equipment. An extra fan is not necessary if an

extra air baffle is used on the cabinet roof (see next page).

1c*

)

Air inlet for circuit boards and DC and output busbars

2a*

)

Air outlet with an extra exhaust fan for the drive module

2b*

)

Air outlet for the other equipment

2c*

)

Air outlet for the drive module and other equipment on the cabinet

roof. An exhaust fan if needed. We recommend this alternative

instead of 2a.

3 Drive control panel with DPMP-01 mounting platform (option

+J410). The control panel is connected to the JCU control unit

inside the cabinet.

4 Contactor control switch and emergency stop switch (connected to

the contactor control circuit inside the cabinet)

5 Operating handle of the disconnector

6 Rubber grommets for degree of protection

7 Roof air flow viewed from top

*

)

Note: The sizes of the air inlet and outlet gratings are critical for

proper cooling of the drive module. For losses and cooling data

requirements, see page 129.

7

1c

1b

2c

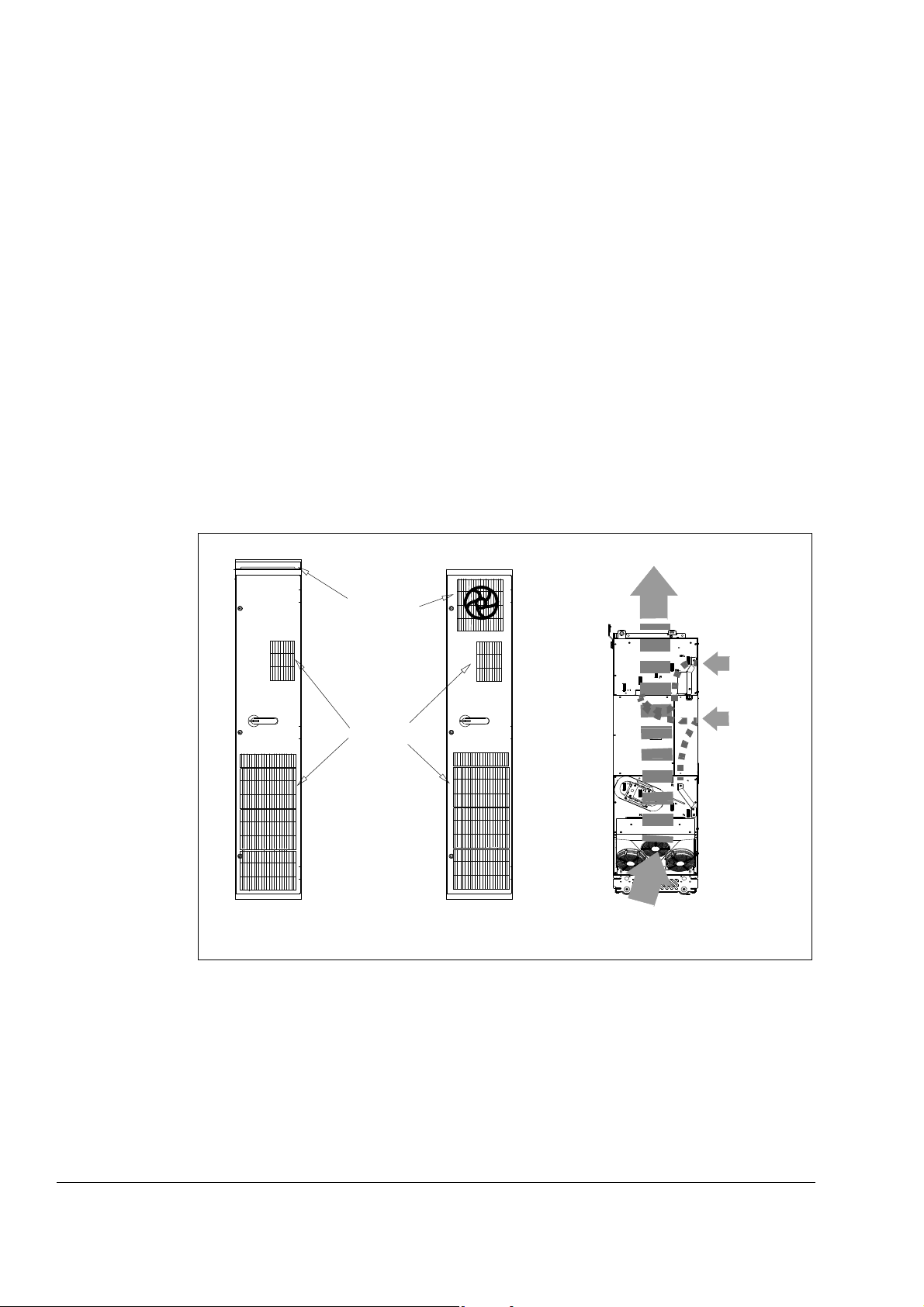

Layout examples, door closed

This diagram shows a cabinet layout example with the input power cable leadthrough from top and the motor cable lead-through from bottom.

Layout example, door open

Planning the cabinet installation

This diagram shows a layout example when optional cabling panels are not used.

39

1 Supporting frame of the cabinet 9 JCU control unit.

2 Vertical (2a, 2b) and horizontal (2c, 2d) air

baffles that separate the cool and hot

areas (leak-proof lead-throughs). See also

page 46.

Note: With an internal control unit (option +P905), the

air inlet 17 is critical for proper cooling of the control

board.

2e Optional air baffle that is needed when 10 External control cables

there is no fan on the lower part of the 11 Grounding screws

cabinet door (see 1b on page 38). 12 Alternative to grounding screws (11)

3 Cabinet grounding busbar (PE) 13 Air flow to the roof

4 Input power cable including the protective 14 Air flow through the drive module (side view)

ground conductor (PE) of the drive 15 Air inlet gratings in the cabinet door

5 Disconnector and fuses 16 Air inlet for the brake option

6 Contactor 17 Air inlet for circuit boards and DC and output busbars

7 Drive module

8 Motor cable including the protective

ground conductor of the drive

PE

U1

V1

W1

W2

V2

U2

1

4

5

6

7

8

3

2a

11

2a

12

13

14

9

10

2b

3

2c

2d

15

2e

2e

16

17

Planning the cabinet installation

40

Note 1: The power cable shields can also be grounded to the drive module

grounding terminals.

Note 2: See also section Required free space, page 47.

Arranging the grounding inside the cabinet

Arrange the grounding of the drive module by leaving the contact surfaces of the

fastening points unpainted (bare metal-to-metal contact). The module frame will be

grounded to the PE busbar of the cabinet via the fastening surfaces, screws and the

cabinet frame. Alternatively, use a separate grounding conductor between the PE

terminal of the drive module and the PE busbar of the cabinet.

Ground also the other components in the cabinet according to the principle above.

Selecting the busbar material and preparation of the joints

If planning the use of busbars, note the following:

• Tin-plated copper is recommended but aluminium can also be used.

• The oxide layer from aluminium busbar joints must be removed and suitable antioxidant joint compound applied.

Tightening torques

Apply the following torques to grade 8.8 screws (with or without joint compound) that

tighten electric contacts.

Screw size Torque

M5 3.5 N·m (2.6 lbf·ft)

M6 9 N·m (6.6 lbf·ft)

M8 20 N·m (14.8 lbf·ft)

M10 40 N·m (29.5 lbf·ft)

M12 70 N·m (52 lbf·ft)

M16 180 N·m (133 lbf·ft)

Planning the fastening of the cabinet

Note the following when planning the fastening of the cabinet:

• Fasten the cabinet to the floor from the front and to the floor or wall from the back.

• Always fasten the drive module from its fastening points to the cabinet. For

details, see the module installation instructions.

WARNING! Do not fasten the cabinet by electric welding. ABB does not assume any

liability for damages caused by electric welding as the welding circuit may damage

electronic circuits in the cabinet.

Planning the cabinet installation

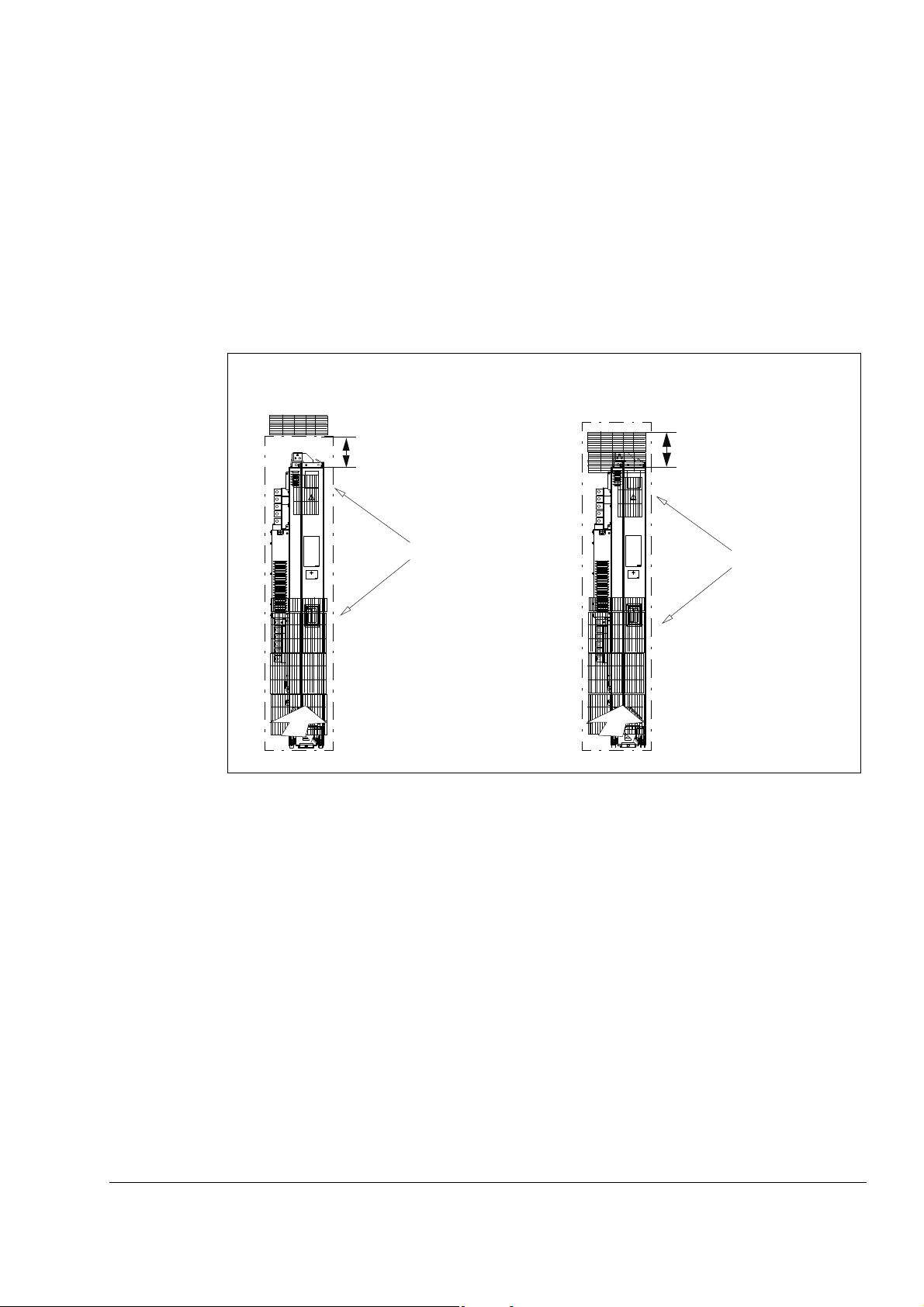

Planning the cabinet placement on a cable channel

The carrying structure on a cable channel Cabinet side view with a bottom plate

Note the following when planning to place the cabinet on a cable channel:

• The cabinet structure must be sturdy enough. If the whole cabinet base will not be

supported from below, the cabinet weight will lie on the sections that the floor

carries.

• Equip the cabinet with a sealed bottom plate and cable lead-throughs to ensure

the degree of protection and to prevent the cooling air flow from the cable channel

into the cabinet.

41

Planning the electromagnetic compatibility (EMC) of the cabinet

Note following when planning the electromagnetic compatibility of the cabinet:

• Generally, the fewer and smaller the holes in the cabinet, the better the

interference attenuation. The maximum recommended diameter of a hole in

galvanic metal contact in the covering cabinet structure is 100 mm. Pay special

attention to the cooling air inlet and outlet gratings.

• The best galvanic connection between the steel panels is achieved by welding

them together as no holes are necessary. If welding is not possible, the seams

between the panels are recommended to be left unpainted and equipped with

special conductive EMC strips to provide adequate galvanic connection. Usually,

reliable strips are made of flexible silicon mass covered with a metal mesh. The

non-tightened touch-contact of the metal surfaces is not sufficient, so a

conductive gasket between the surfaces is required. The maximum

recommended distance between assembly screws is 100 mm.

• Construct sufficient high-frequency grounding network in the cabinet to avoid

voltage differences and forming of high-impedance radiator structures. A good

high-frequency grounding is made with short flat copper braids for low

inductance. One-point high-frequency grounding cannot be used due to the long

distances inside the cabinet.

Planning the cabinet installation

42

Cable ties

Knitted wire mesh

Bare cable shield

Cabinet bottom plate

Lead-through plate

Cable

Shielding cushion

(conductive)

Cable

Cable grommet

Bare cable shield

Cabinet bottom plate

• 360° high frequency grounding of the cable shields at the cable lead-throughs

improves the EMC shielding of the cabinet.

• 360° high frequency grounding of the motor cable shields at their entries is

recommended. The grounding can be implemented by a knitted wire mesh

screening as shown below.

• 360° high frequency grounding of the control cable shields is recommended at

their entries. The shields can be grounded by means of conductive shielding

cushions pressed against the cable shield from both directions:

Planning the cabinet installation