ABB ACS850 Firmware Manual

ACS850

Firmware Manual

ACS850 Standard Control Program

List of related manuals

ACS850-04 manuals

Drive hardware manuals a

CS850-04 Drive Modules (0.37 to 45 kW) Hardware

A

Manual

ACS850-04 Drive Modules (0.37 to 45 kW) Quick

Installation Guide

ACS850-04 Drive Modules (55 to 200 kW, 60 to 200 hp)

Hardware Manual

ACS850-04 Drive Modules (55 to 200 kW, 60 to 200 hp)

Quick Installation Guide

ACS850-04 Drive Modules (200 to 500 kW, 250 to

600 hp) Hardware Manual

ACS850-04 Drive Modules (160 to 560 kW, 200 to

700 hp) Hardware Manual

Drive firmware manuals and guides

ACS850 Standard Control Program Firmware Manual 3AUA0000045497

ACS850 Standard Control Program Quick Start-up

Guide

ACS850-04 drives with SynRM motors (option +N7502)

supplement

nd guides Code (English)

3AUA0000045496

3AUA0000045495

3AUA0000045487

3AUA0000045488

3AUA0000026234

3AUA0000081249

3AUA0000045498

3AUA0000123521

Option manuals and guides

Application programming for ACS850 and ACQ810

drives application guide

ATEX-certified Safe disconnection function for ACS850

drives (+Q971) application guide

Common DC configuration for ACS850-04 drives

application guide

Safe torque off function for ACSM1, ACS850 and

ACQ810 drives application guide

Manuals and quick guides for I/O extension modules,

fieldbus adapters, etc.

You can find manuals and other product documents in PDF format on the Internet. See section

Document library on the Internet on the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

3AUA0000078664

3AUA0000074343

3AUA0000073108

3AFE68929814

Firmware Manual

ACS850 Standard Control Program

Table of contents

3AUA0000045497 Rev H

EN

EFFECTIVE: 2013-01-15

© 2013 ABB Oy. All Rights Reserved.

Table of contents 5

Table of contents

1. About the manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. The ACS850 control panel

Safety

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Status line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Basics of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

List of tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Help and panel version – Any mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Basic operations – Any mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Output mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Assistants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Changed Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fault Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Time & Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Parameter Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

I/O Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Reference Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Drive Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Parameter Change Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3. Control locations and operating modes

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Local control vs. external control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Operating modes of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Speed control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Torque control mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Special control modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 Table of contents

4. Program features

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Drive configuration and programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Programming via parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Application programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Control interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Programmable analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Programmable analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Programmable digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Programmable I/O extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Programmable relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Constant speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Critical speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Speed controller tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Encoder support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Scalar motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

User-definable load curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

User-definable U/f curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Autophasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Flux braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Application control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Application macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Mechanical brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

DC voltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Overvoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Undervoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Voltage control and trip limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Safety and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Thermal motor protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Programmable protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Automatic fault resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Signal supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Maintenance counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Energy saving calculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Backup and restore of drive contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Data storage parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Drive-to-drive link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table of contents 7

5. Application macros

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Default control connections for the Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Default control connections for the Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

PID control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Default control connections for the PID control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Torque control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Default control connections for the Torque control macro . . . . . . . . . . . . . . . . . . . . . . . . 99

Sequential control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Default control connections for the Sequential control macro . . . . . . . . . . . . . . . . . . . . . 102

6. Parameters

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Summary of parameter groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Parameter listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

01 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

02 I/O values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

03 Control values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

04 Appl values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

06 Drive status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

08 Alarms & faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

09 System info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

10 Start/stop/dir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11 Start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

12 Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

13 Analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

14 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

15 Analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

16 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

19 Speed calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

20 Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

21 Speed ref . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

22 Speed ref ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

23 Speed ctrl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

24 Torque ref . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

25 Critical speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

26 Constant speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

27 Process PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

30 Fault functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

31 Motor therm prot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

32 Automatic reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

33 Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

34 User load curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

35 Process variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

36 Timed functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

8 Table of contents

38 Flux ref . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

40 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

42 Mech brake ctrl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

44 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

45 Energy optimising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

47 Voltage ctrl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

48 Brake chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

49 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

50 Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

51 FBA settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

52 FBA data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

53 FBA data out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

56 Panel display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

57 D2D communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

58 Embedded Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

64 Load analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

74 Appl programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

90 Enc module sel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

91 Absol enc conf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

92 Resolver conf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

93 Pulse enc conf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

94 Ext IO conf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

95 Hw configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

97 User motor par . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

99 Start-up data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

7. Additional parameter data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Fieldbus equivalents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Pointer parameter format in fieldbus communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

32-bit integer value pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

32-bit integer bit pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Parameter groups 1…9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Parameter groups 10…99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

8. Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

How to reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Alarm messages generated by the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Fault messages generated by the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

9. Control through the embedded fieldbus interface

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Connecting the embedded fieldbus to the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Table of contents 9

Setting up the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Setting the drive control parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Basics of the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Control Word and Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Data inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Register addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

About the EFB communication profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

ABB Drives classic profile and ABB Drives enhanced profile . . . . . . . . . . . . . . . . . . . . . . . . 330

Control Word for the ABB Drives profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Status Word for the ABB Drives profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

State transition diagram for the ABB Drives profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

References for the ABB Drives profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Actual values for the ABB Drives profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Modbus register addresses for the ABB Drives classic profile . . . . . . . . . . . . . . . . . . . . 337

Modbus register addresses for the ABB Drives enhanced profile . . . . . . . . . . . . . . . . . . 338

DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Control and Status words for the DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Status Word for the DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

State transition diagram for the DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

References for the DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Actual signals for the DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Modbus register addresses for the DCU 16-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . 340

DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Control and Status words for the DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Status word for the DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

State transition diagram for the DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

References for the DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Actual signals for the DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Modbus register addresses for the DCU 32-bit profile . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Modbus function codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Modbus exception codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

10. Control through a fieldbus adapter

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Setting up communication through a fieldbus adapter module . . . . . . . . . . . . . . . . . . . . . . . 349

Setting the drive control parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Basics of the fieldbus adapter interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Control Word and Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

FBA communication profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Fieldbus references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

State diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

10 Table of contents

11. Drive-to-drive link

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Datasets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Types of messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Master point-to-point messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Read remote messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Follower point-to-point messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Standard multicast messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Broadcast messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Chained multicast messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

12. Control chain and drive logic diagrams

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Speed feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Speed reference modification and ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Speed error handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Torque reference modification, operating mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Process PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Start/stop logic of the drive – I/O and D2D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Start/stop logic of the drive – Fieldbus interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Direct torque control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

1

About the manual

About the manual 11

What this chapter contains

The chapter describes the contents of the manual. It also contains information on the

compatibility, safety and intended audience.

Compatibility

The manual is compatible with:

• ACS850 standard control program version UIFI2500 and later

• ACS850 synchronous reluctance motor control program (option +N7502).

Safety instructions

Follow all safety instructions delivered with the drive.

• Read the complete safety instructions before you install, commission, or use

the drive. The complete safety instructions are given at the beginning of the

Hardware Manual.

• Read the software function specific warnings and notes before changing the

default settings of the function. For each function, the warnings and notes are

given in this manual in the section describing the related user-adjustable

parameters.

Reader

The reader of the manual is expected to know the standard electrical wiring practices,

electronic components, and electrical schematic symbols.

12 About the manual

Contents

The manual consists of the following chapters:

• The ACS850 control panel provides a description and instructions for use of the

control panel.

• Control locations and operating modes describes the control locations and

operation modes of the drive.

• Program features contains descriptions of the features of the ACS850 standard

control program.

• Application macros contains a short description of each macro together with a

connection diagram.

• Parameters describes the parameters of the drive.

• Additional parameter data contains further information on the parameters.

• Fault tracing lists the alarm (warning) and fault messages with possible causes

and remedies.

• Control through the embedded fieldbus interface describes the communication to

and from a fieldbus network using an embedded fieldbus interface.

• Control through a fieldbus adapter describes the communication to and from a

fieldbus network using an optional fieldbus adapter module.

• Drive-to-drive link describes the communication between drives connected

together by the drive-to-drive link.

• Control chain and drive logic diagrams.

Related manuals

The delivery of the drive includes a multilingual Quick Start-up Guide.

A complete list of related manuals is printed on the inside of the front cover.

Terms and abbreviations

Term/abbreviation Definition

AI Analog input; interface for analog input signals

AO Analog output; interface for analog output signals

DC link DC circuit between rectifier and inverter

DI Digital input; interface for digital input signals

DO Digital output; interface for digital output signals

DTC Direct torque control

EFB Embedded fieldbus

FBA Fieldbus adapter

FEN-01 Optional TTL encoder interface module for the ACS850

FEN-11 Optional absolute encoder interface module for the ACS850

FEN-21 Optional resolver interface module for the ACS850

About the manual 13

Term/abbreviation Definition

FEN-31 Optional HTL encoder interface module for the ACS850

FIO-01 Optional digital I/O extension module for the ACS850

FIO-11 Optional analog I/O extension module for the ACS850

FIO-21 Optional analog/digital I/O extension module for the ACS850

FCAN-0x Optional CANopen adapter for the ACS850

FDNA-0x Optional DeviceNet adapter for the ACS850

FECA-01 Optional EtherCAT® adapter for the ACS850

FENA-0x Optional Ethernet/IP adapter for the ACS850

FLON-0x Optional L

ONWORKS

FPBA-0x Optional PROFIBUS DP adapter for the ACS850

FSCA-0x Optional Modbus adapter for the ACS850

HTL High-threshold logic

ID run Motor identification run. During the identification run, the drive will identify

the characteristics of the motor for optimum motor control.

IGBT Insulated gate bipolar transistor; a voltage-controlled semiconductor type

widely used in inverters due to their easy controllability and high

switching frequency

®

adapter for the ACS850

I/O Input/Output

JCU Control unit of the drive module. The JCU is installed on top of the power

unit. The external I/O control signals are connected to the JCU, or

optional I/O extensions mounted on it.

JMU Memory unit attached to the control unit of the drive

JPU Power unit; see the definition below.

LSB Least significant bit

LSW Least significant word

MSB Most significant bit

MSW Most significant word

Parameter User-adjustable operation instruction to the drive, or signal measured or

calculated by the drive

PI controller Proportional-integral controller

PID controller Proportional–integral–derivative controller. Drive speed control is based

on PID algorithm.

PLC Programmable logic controller

Power unit Contains the power electronics and connections of the drive module. The

JCU is connected to the power unit.

PTC Positive temperature coefficient

RFG Ramp Function Generator

RO Relay output; interface for a digital output signal. Implemented with a

relay.

SSI Synchronous serial interface

STO Safe torque off

TTL Transistor-transistor logic

UIFI xxxx Firmware of the ACS850 drive

14 About the manual

Term/abbreviation Definition

UPS Uninterruptible power supply; power supply equipment with battery to

maintain output voltage during power failure

The ACS850 control panel 15

2

The ACS850 control panel

What this chapter contains

This chapter describes the features and operation of the ACS850 control panel.

The control panel can be used to control the drive, read status data, and adjust

parameters.

Features

• alphanumeric control panel with an LCD display

• copy function – parameters can be copied to the control panel memory for later

transfer to other drives or for backup of a particular system.

• context sensitive help

• real time clock.

16 The ACS850 control panel

Installation

Mechanical installation

For mounting options, see the Hardware Manual of the drive.

Instructions for mounting the control panel onto a cabinet door are available in

ACS-CP-U Control Panel IP54 Mounting Platform Kit Installation Guide

(3AUA0000049072 [English]).

Electrical installation

Use a CAT5 straight-through network cable with a maximum length of 3 meters.

Suitable cables are available from ABB.

For the control panel connector location on the drive, see the Hardware Manual of the

drive.

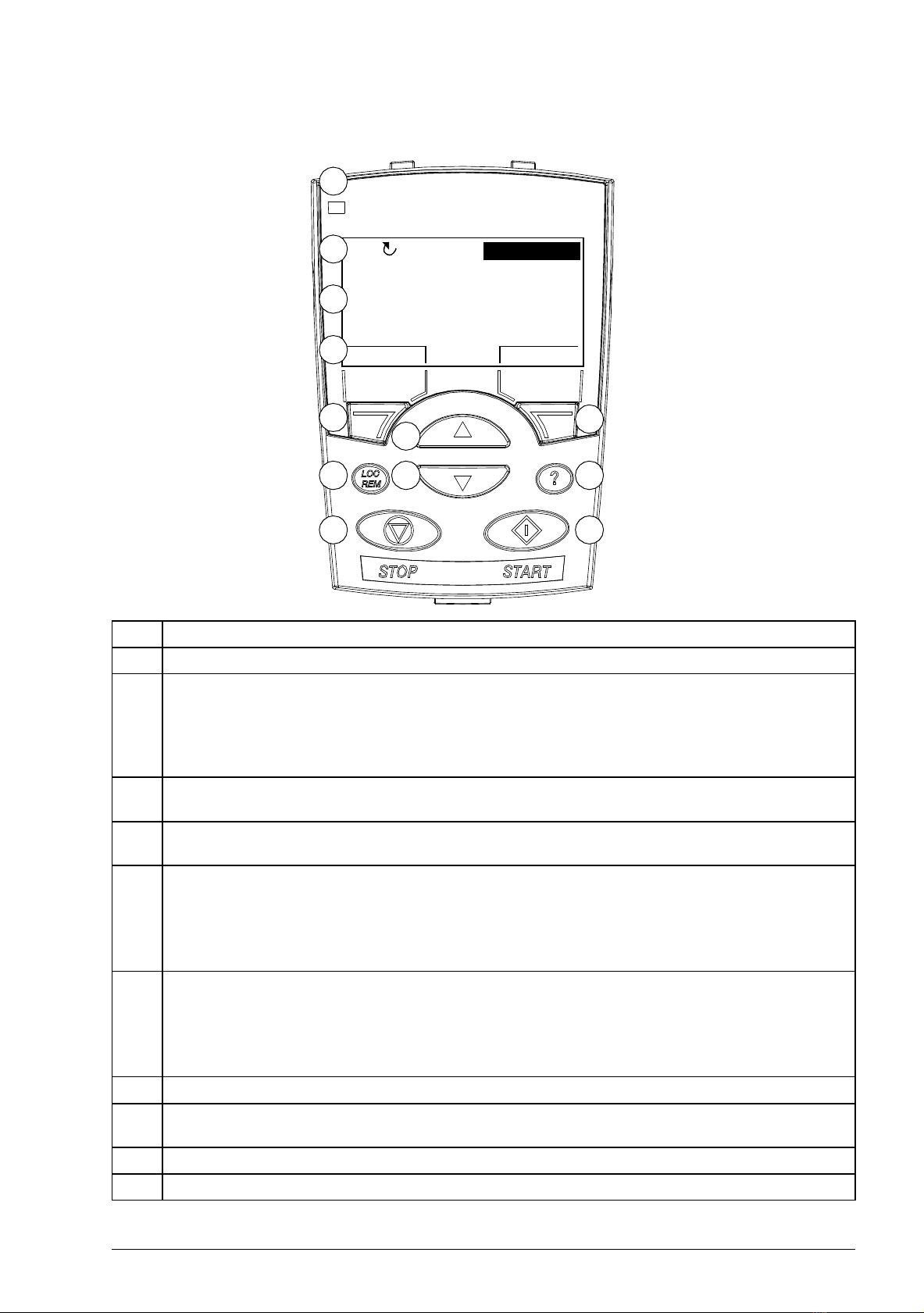

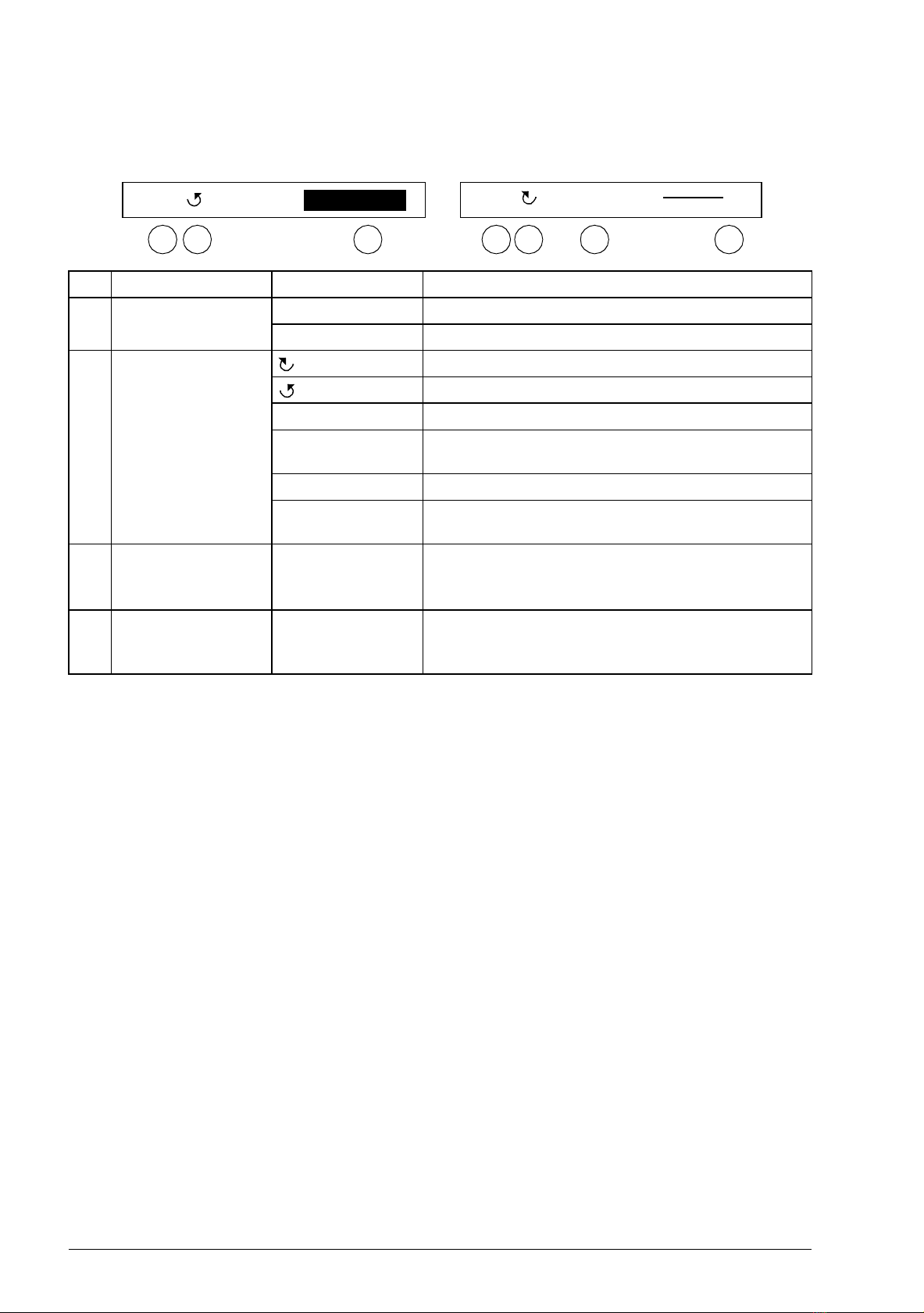

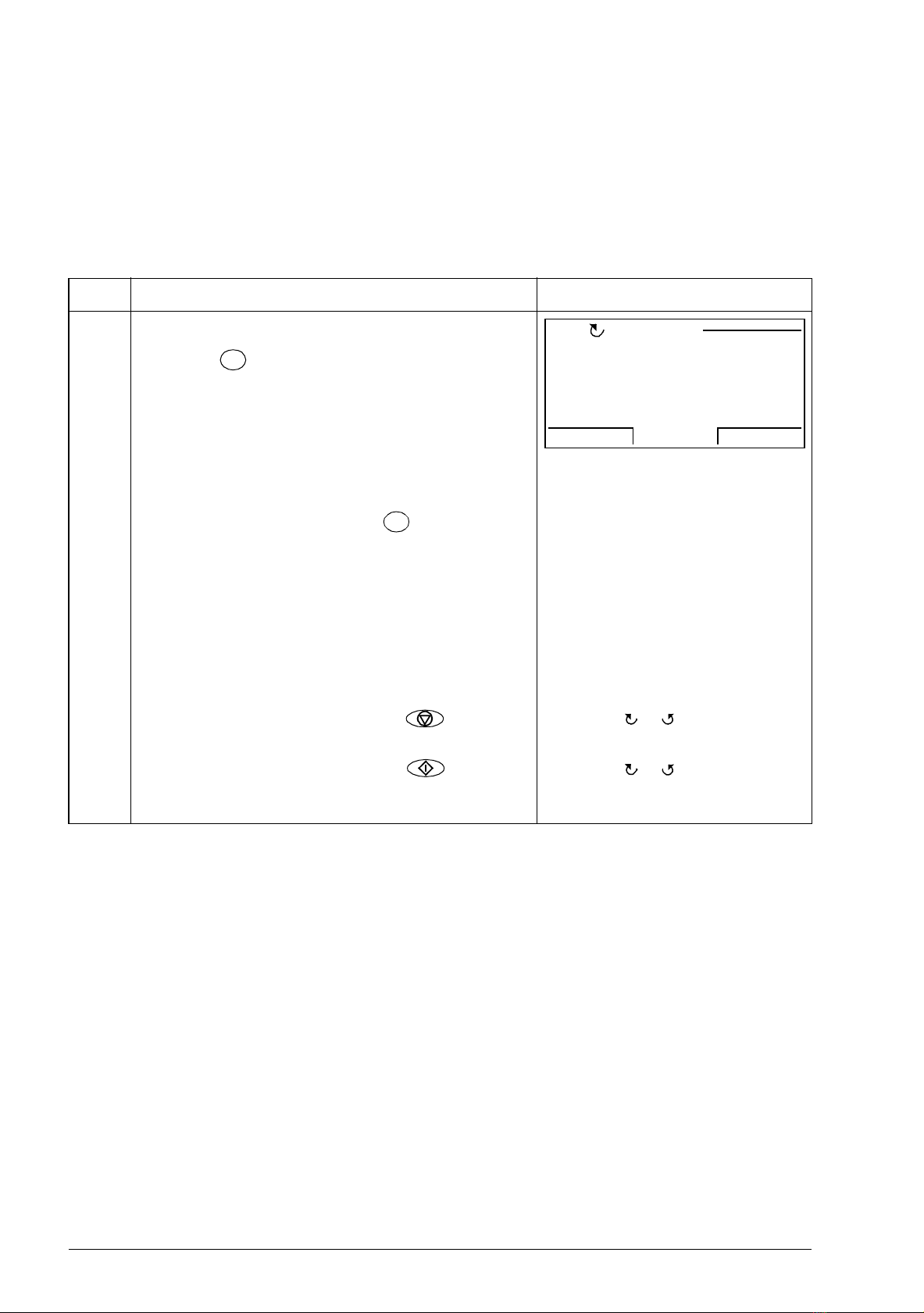

Layout

30.10Hz

LOC

DIR 12:45 MENU

400RPM

1200 RPM

12.4 A

405 dm3/s

3

4

5

67 8

9 10

30.00rpm

50 A

10 Hz

7 %10

.

0

.

49

.

LOC

DIR

MENU00:00

1

2a

2b

2c

30.00rpm

The ACS850 control panel 17

No. Use

1 Status LED – Green = normal operation; blinking green = an alarm is active; red = a fault is active.

2 LCD display – Divided into three main areas:

Status line – variable, depending on the mode of operation, see section Status line on page 18.

Center – variable; in general, shows signal and parameter values, menus or lists. Shows also faults

and alarms.

Bottom line – shows current functions of the two soft keys and, if enabled, the clock display.

3 Soft key 1 – Function depends on the context. The text in the lower left corner of the LCD display

indicates the function.

4 Soft key 2 – Function depends on the context. The text in the lower right corner of the LCD display

indicates the function.

5 Up –

Scrolls up through a menu or list displayed in the center of the LCD display.

Increments a value if a parameter is selected.

Increments the reference value if the upper right corner is highlighted.

6 Down –

7 LOC/REM – Changes between local and remote control of the drive.

8 Help – Displays context sensitive information when the key is pressed. The information displayed

9 STOP – Stops the drive in local control.

10 START – Starts the drive in local control.

Holding the key down changes the value faster.

Scrolls down through a menu or list displayed in the center of the LCD display.

Decrements a value if a parameter is selected.

Decrements the reference value if the upper right corner is highlighted.

Holding the key down changes the value faster.

describes the item currently highlighted in the center of the display.

18 The ACS850 control panel

30.00rpmLOC

1 2 4

LOC MAIN MENU 1

1 2 3 4

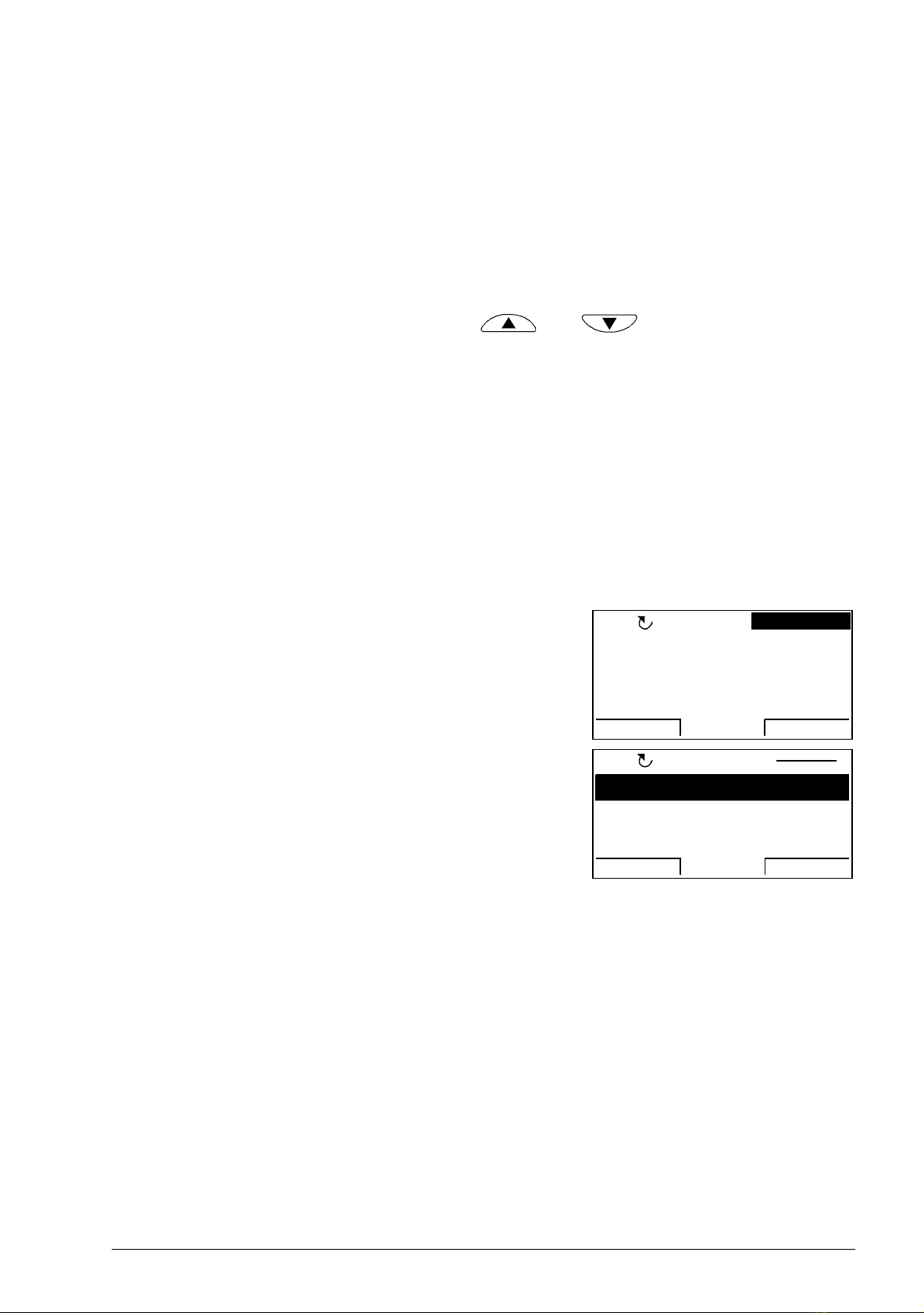

Status line

The top line of the LCD display shows the basic status information of the drive.

No. Field Alternatives Significance

1 Control location LOC Drive control is local, that is, from the control panel.

REM Drive control is remote, such as the drive I/O or fieldbus.

2 State Forward shaft direction

Reverse shaft direction

Rotating arrow Drive is running at reference.

Dotted rotating

arrow

Stationary arrow Drive is stopped.

Dotted stationary

arrow

3 Panel operation mode • Name of the current mode

4 Reference value or

number of the

selected item

Drive is running but not at reference.

Start command is present, but the motor is not running,

e.g. because start enable signal is missing.

• Name of the list or menu shown

• Name of the operation state, e.g. REF EDIT.

• Reference value in the Output mode

• Number of the highlighted item, e.g mode, parameter

group or fault.

The ACS850 control panel 19

PARAMETERS

ASSISTANTS

CHANGED PAR

EXIT ENTER00:00

MAIN MENU 1

LOC

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU00:00

30.00rpm

Operating instructions

Basics of operation

You operate the control panel with menus and keys. The keys include two contextsensitive soft keys, whose current function is indicated by the text shown in the

display above each key.

You select an option, e.g. operation mode or parameter, by entering the MENU state

using soft key 2, and then by scrolling the and arrow keys until the

option is highlighted and then pressing the relevant soft key. With the right soft key

you usually enter a mode, accept an option or save the changes. The left soft key is

used to cancel the made changes and return to the previous operation level.

The Control Panel has ten options in the Main menu: Parameters, Assistants,

Changed Par, Fault Logger, Time & Date, Parameter Backup, I/O Settings, Reference

Edit, Drive Info and Parameter Change Log. In addition, the control panel has an

Output mode, which is used as default. Also, when a fault or alarm occurs, the panel

goes automatically to the Fault mode showing the fault or alarm. You can reset the

fault in the Output or Fault mode. The operation in these modes and options is

described in this chapter.

Initially, the panel is in the Output mode, where you

can start, stop, change the direction, switch between

local and remote control, modify the reference value

and monitor up to three actual values. To do other

tasks, go first to the Main menu and select the

appropriate option on the menu. The status line (see

section Status line on page 18) shows the name of

the current menu, mode, item or state.

20 The ACS850 control panel

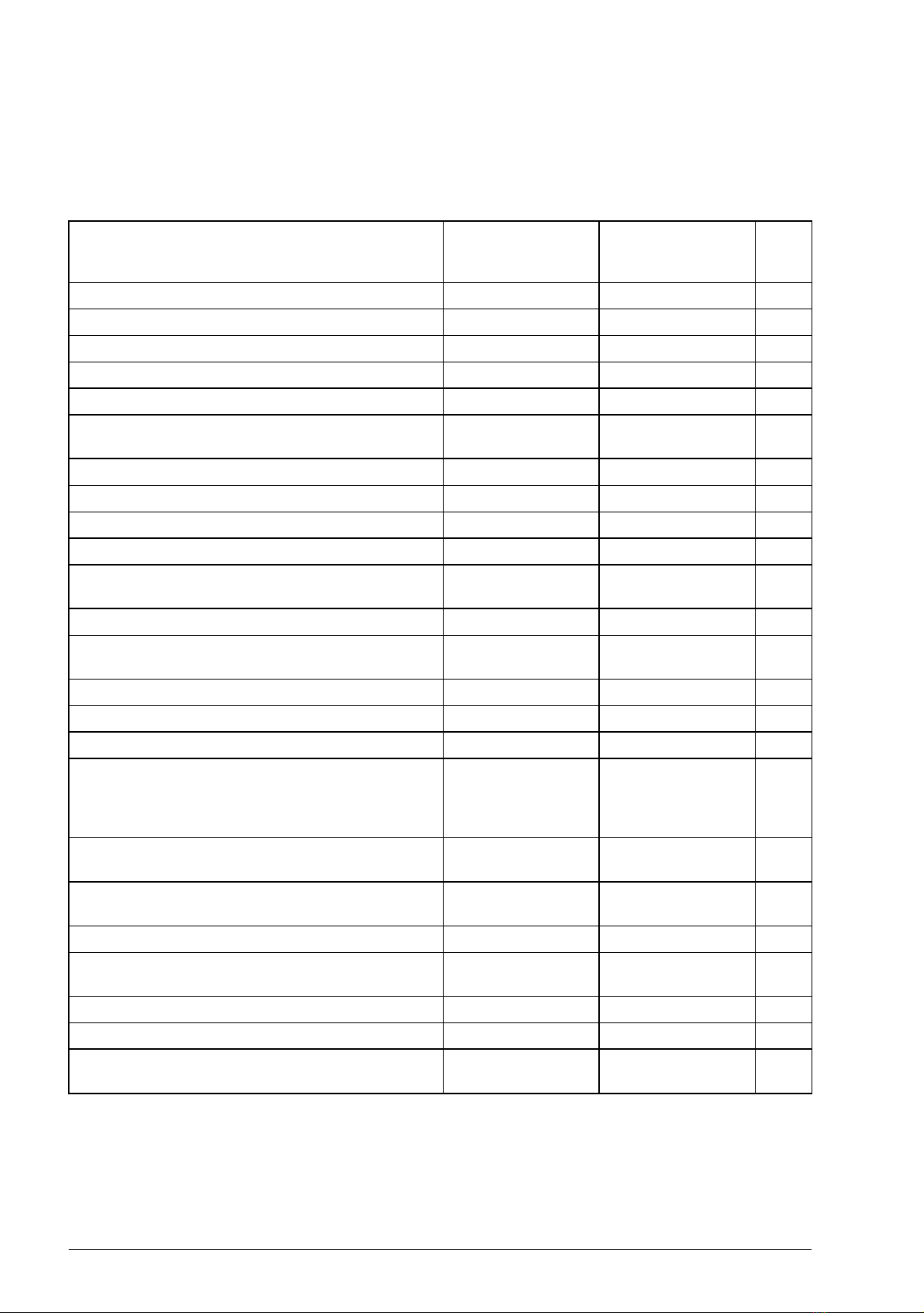

List of tasks

The table below lists common tasks, the mode in which you can perform them,

abbreviations of the options in the Main menu and the page number where the steps

to do the task are described in detail.

Task Mode / Main menu

option

How to get help Any - 21

How to find out the panel version Any - 21

How to start and stop the drive Output - 22

How to switch between local and remote control Any - 22

How to change the direction of the motor rotation Any - 23

How to set the speed, frequency or torque reference

in the Output mode

How to adjust the display contrast Output - 24

How to change the value of a parameter Parameters PARAMETERS 25

Output - 23

Abbreviations of

the Main menu

options *

Page

How to change the value of value pointer parameters Parameters PARAMETERS 26

How to change the value of bit pointer parameters Parameters PARAMETERS 28

How to change the value of bit pointer parameter to

fixed 0 (FALSE) or 1 (TRUE)

How to select the monitored signals Parameters PARAMETERS 31

How to do guided tasks (specification of related

parameter sets) with assistants

How to view and edit changed parameters Changed Parameters CHANGED PAR 33

How to view faults Fault Logger FAULT LOGGER 35

How to reset faults and alarms Fault Logger FAULT LOGGER 36

How to show/hide the clock, change date and time

formats, set the clock and enable/disable automatic

clock transitions according to the daylight saving

changes

How to copy parameters from the drive to the control

panel

How to restore parameters from the control panel to

the drive

How to view backup information Parameter Backup PAR BACKUP 45

How to edit and change parameter settings related to

I/O terminals

How to edit reference value Reference Edit REF EDIT 49

Parameters PARAMETERS 30

Assistants ASSISTANTS 32

Time & Date TIME & DATE 37

Parameter Backup PAR BACKUP 39

Parameter Backup PAR BACKUP 39

I/O Settings I/O SETTINGS 47

How to view drive info Drive Info DRIVE INFO 50

How to view and edit recently changed parameters Parameter Change

Log

* Main menu options actually shown in the control panel.

PAR CHG LOG 51

The ACS850 control panel 21

?

TIME FORMAT

DATE FORMAT

SET TIME

SET DATE

DAYLIGHT SAVING

TIME & DATE 6

EXIT

SEL00:00

LOC

EXIT 00:00

Use Daylight saving

to enable or disable

automatic clock

adjustment according

to daylight saving

HELP

LOC

EXIT 00:00

to enable or disable

automatic clock

adjustment according

to daylight saving

changes

HELPLOC

EXIT

TIME FORMAT

DATE FORMAT

SET TIME

SET DATE

DAYLIGHT SAVING

TIME & DATE 6

EXIT SEL00:00

LOC

?

?

Panel SW: x.xx

Rom CRC: xxxxxxxxxx

Flash Rev: x.xx

xxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxx

PANEL VERSION INFO

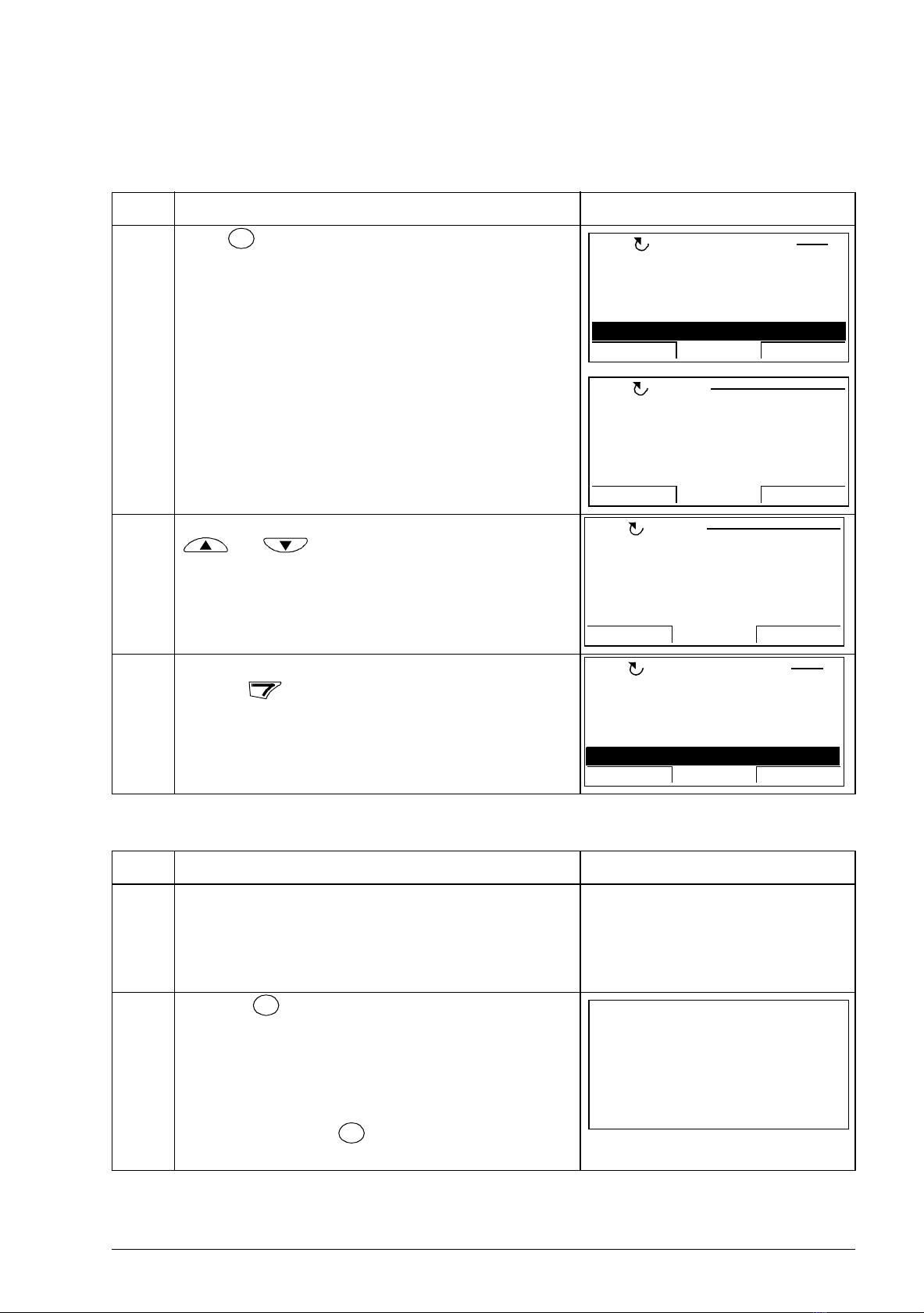

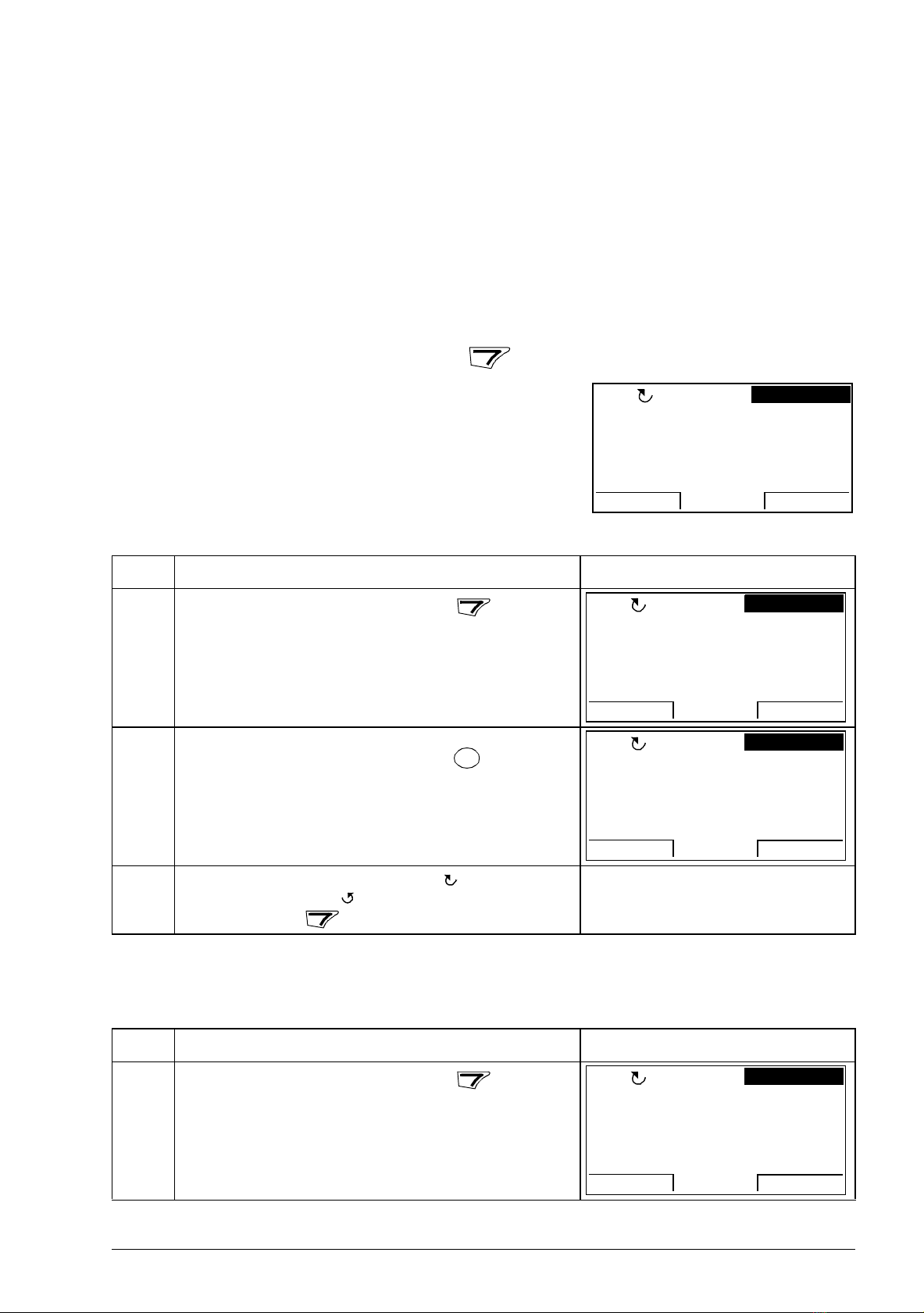

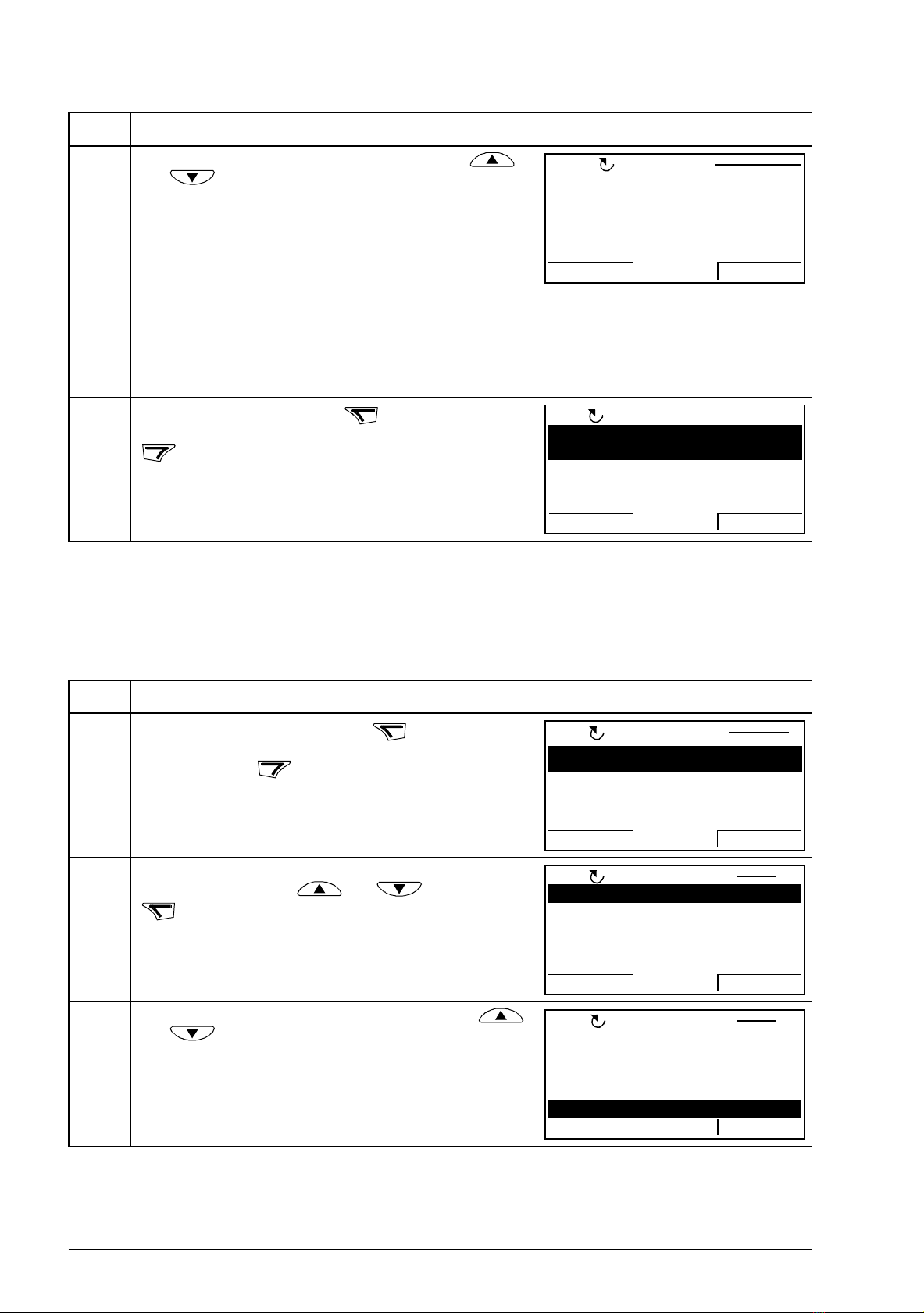

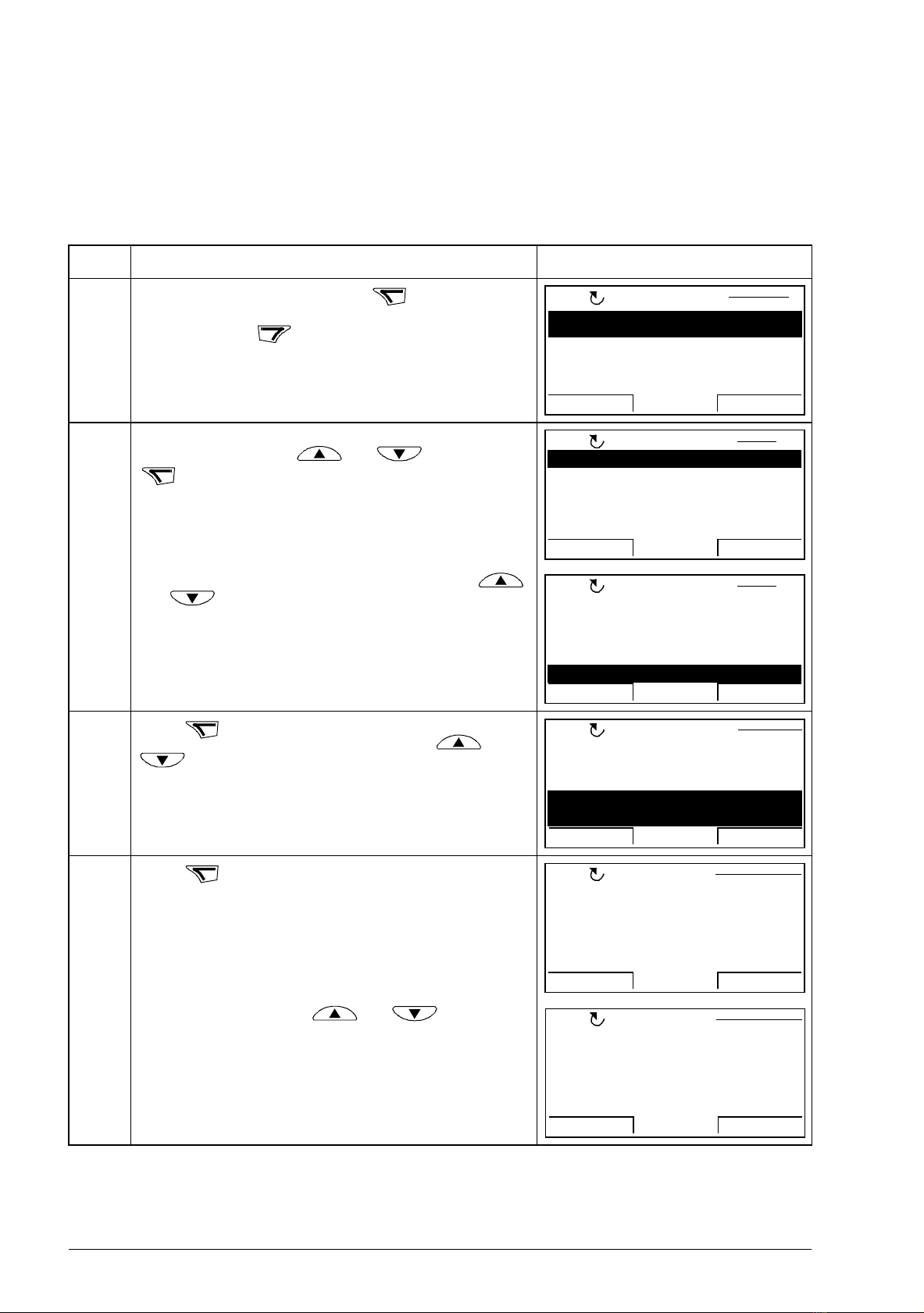

Help and panel version – Any mode

How to get help

Step Action Display

1. Press to read the context-sensitive help text for the

item that is highlighted.

If help text exists for the item, it is shown on the display.

2. If the whole text is not visible, scroll the lines with keys

and .

3. After reading the text, return to the previous display by

pressing .

How to find out the panel version

Step Action Display

1. If the power is switched on, switch it off.

- If the panel cable can be disconnected easily, unplug

the panel cable from the control panel, OR

- if the panel cable can not be disconnected easily, switch

off the control board or the drive.

2. Keep key depressed while you switch on the power

and read the information. The display shows the

following panel information:

Panel SW: Panel firmware version

ROM CRC: Panel ROM check sum

Flash Rev: Flash content version

Flash content comment.

When you release the key, the panel goes to the

Output mode.

22 The ACS850 control panel

LOC

REM

00:00

Switching to the

local control mode.

MESSAGE

LOC

LOC

REM

Basic operations – Any mode

How to start, stop and switch between local and remote control

You can start, stop and switch between local and remote control in any mode. To be

able to start or stop the drive by using the control panel, the drive must be in local

control.

Step Action Display

1. To switch between remote control (REM shown on the

status line) and local control (LOC shown on the status

line), press .

Note: Switching to local control can be prevented with

parameter 16.01 Local lock.

The very first time the drive is powered up, it is in remote

control (REM) and controlled through the drive I/O

terminals. To switch to local control (LOC) and control the

drive using the control panel, press . The result

depends on how long you press the key:

If you release the key immediately (the display flashes

“Switching to the local control mode”), the drive stops.

Set the local control reference as instructed on page 23.

If you press the key until the text “Keep running” appears,

the drive continues running as before. The drive copies

the current remote values for the run/stop status and the

reference, and uses them as the initial local control

settings.

To stop the drive in local control, press . The arrow ( or ) on the status line

stops rotating.

To start the drive in local control, press . The arrow ( or ) on the status line

starts rotating. It is dotted until the

drive reaches the setpoint.

The ACS850 control panel 23

EXIT

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU00:00

30.00rpm

EXIT

50 A

10 Hz

7 %10.

0.

49.

REM

DIR

MENU00:00

30.00rpm

LOC

REM

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU

00:00

30.00rpm

DIR

EXIT

50 A

10 Hz

7 %10.

0.

49.

REM

DIR

MENU00:00

30.00rpm

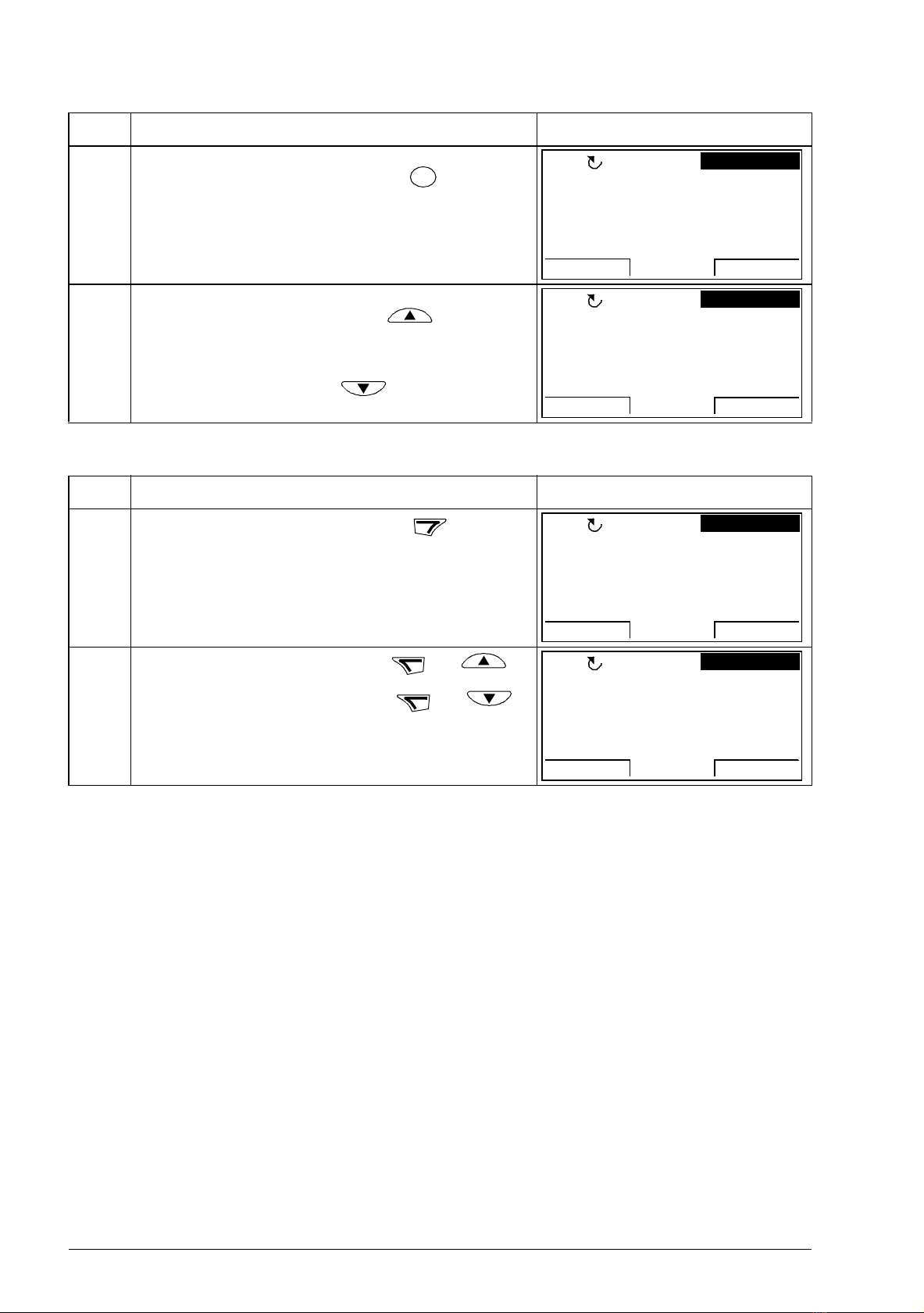

Output mode

In the Output mode, you can:

• monitor actual values of up to three signals

• change the direction of the motor rotation

• set the speed, frequency or torque reference

• adjust the display contrast

• start, stop, change the direction and switch between local and remote control.

You get to the Output mode by pressing repeatedly.

The top right corner of the display shows the

reference value. The center can be configured to

show up to three signal values or bar graphs; see

page 31 for instructions on selecting and modifying

the monitored signals.

How to change the direction of the motor rotation

Step Action Display

1. If you are not in the Output mode, press repeatedly

until you get there.

2. If the drive is in remote control (REM shown on the status

line), switch to local control by pressing . The display

briefly shows a message about changing the mode and

then returns to the Output mode.

3. To change the direction from forward ( shown on the

status line) to reverse ( shown on the status line), or

vice versa, press .

How to set the speed, frequency or torque reference in the Output mode

See also section Reference Edit on page 49.

Step Action Display

1. If you are not in the Output mode, press repeatedly

until you get there.

24 The ACS850 control panel

LOC

REM

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU00:00

30.00rpm

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU00:00

31.00rpm

EXIT

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU00:00

30.00rpm

MENU

MENU

50 A

10 Hz

7 %10.

0.

49.

LOC

DIR

MENU00:00

30.00rpm

Step Action Display

2. If the drive is in remote control (REM shown on the status

line), switch to local control by pressing . The display

briefly shows a message about changing the mode and

then returns to the Output mode.

3. To increase the highlighted reference value shown in the

top right corner of the display, press . The value

changes immediately. It is stored in the permanent

memory of the drive and restored automatically after

power switch-off.

To decrease the value, press .

How to adjust the display contrast

Step Action Display

1. If you are not in the Output mode, press repeatedly

until you get there.

2. To increase the contrast, press keys and

simultaneously.

To decrease the contrast, press keys and

simultaneously.

The ACS850 control panel 25

MENU

EXIT

PARAMETERS

ASSISTANTS

CHANGED PAR

EXIT ENTER00:00

MAIN MENU 1

LOC

ENTER

01 Actual values

02 I/O values

03 Control values

04 Appl values

06 Drive status

EXIT

SEL00:00

PAR GROUPS 01LOC

99 Start-up data

01 Actual values

02 I/O values

03 Control values

04 Appl values

EXIT

SEL00:00

PAR GROUPS 99LOC

SEL

9901 Language

English

9904 Motor type

9905 Motor ctrl mode

9906 Mot nom current

PARAMETERS

EXIT EDIT00:00

LOC

9901 Language

9904 Motor type

9905 Motor ctrl mode

9906 Mot nom current

0.0 A

PARAMETERS

EXIT EDIT00:00

LOC

EDIT

9906 Mot nom current

PAR EDIT

0.0 A

CANCEL SAVE00:00

LOC

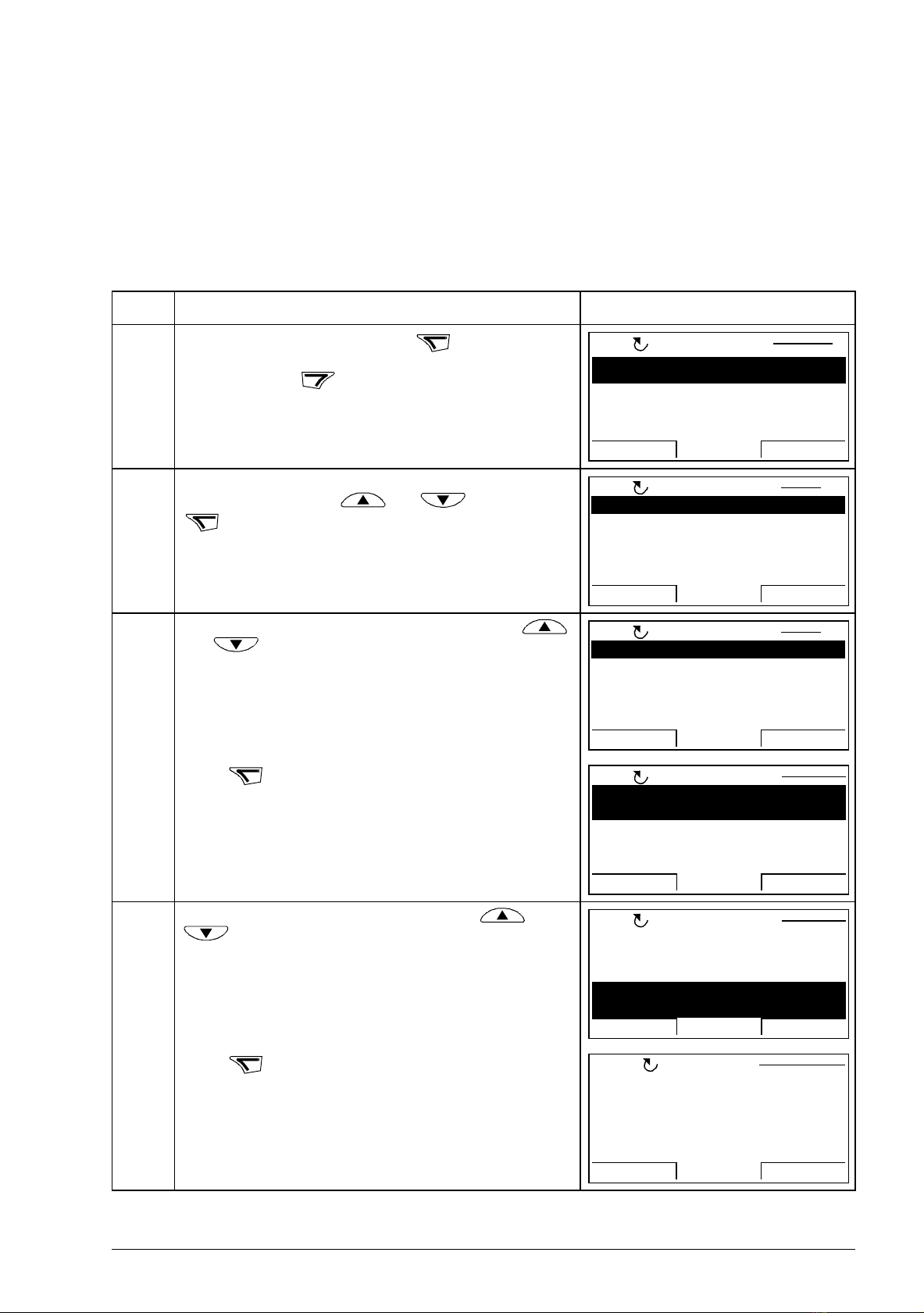

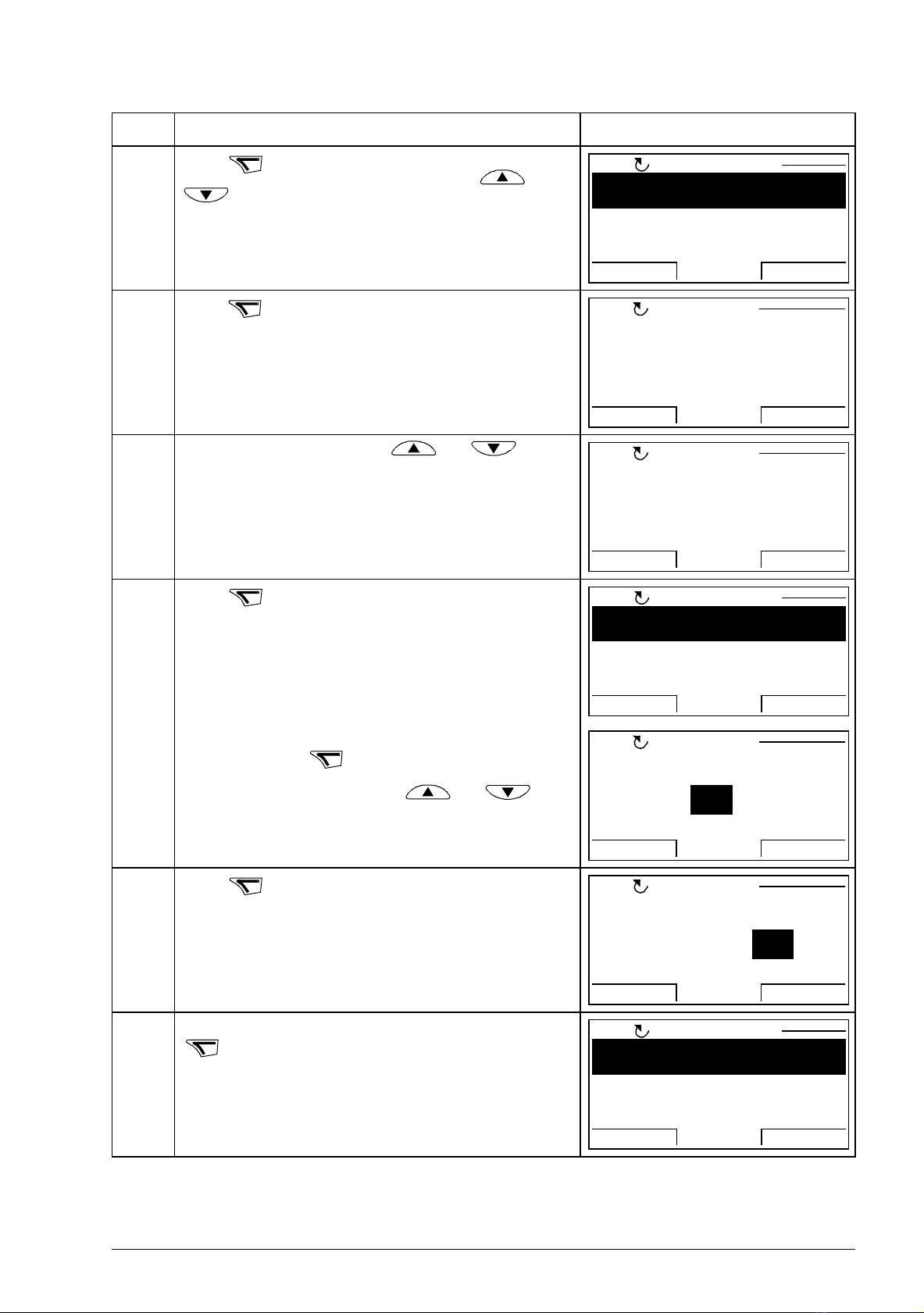

Parameters

In the Parameters option, you can:

• view and change parameter values

• start, stop, change the direction and switch between local and remote control.

How to select a parameter and change its value

Step Action Display

1. Go to the Main menu by pressing if you are in the

Output mode.

Otherwise press repeatedly until you get to the

Main menu.

2. Go to the Parameters option by selecting PARAMETERS

on the menu with keys and , and pressing

.

3. Select the appropriate parameter group with keys

and .

Press .

4. Select the appropriate parameter with keys and

. The current value of the parameter is shown

below the selected parameter. Here the parameter 99.06

Mot nom current is used as an example.

Press .

26 The ACS850 control panel

9906 Mot nom current

PAR EDIT

3.5 A

CANCEL SAVE00:00

LOC

SAVE

CANCEL

9906 Mot nom current

3.5 A

9907 Mot nom voltage

9908 Mot nom freq

9909 Mot nom speed

PARAMETERS

EXIT EDIT

00:00

LOC

MENU

EXIT

PARAMETERS

ASSISTANTS

CHANGED PAR

EXIT ENTER00:00

MAIN MENU 1

LOC

ENTER

01 Actual values

02 I/O values

03 Control values

04 Appl values

06 Drive status

EXIT

SEL00:00

PAR GROUPS 01LOC

15 Analogue outputs

16 System

19 Speed calculation

20 Limits

21 Speed ref

EXIT

SEL00:00

PAR GROUPS 21LOC

Step Action Display

5. Specify a new value for the parameter with keys

and .

Pressing an arrow key once increments or decrements

the value. Keeping the key depressed for a while first

quickly changes the current digit until the cursor moves

left one position. This is repeated until the key is

released.

After the key is released, step-by-step adjustment of the

current digit is possible. If neither key is pressed for a

while, the cursor returns to the right one position at a

time.

Pressing both keys simultaneously replaces the

displayed value with the default value.

6. To save the new value, press .

To cancel the new value and keep the original, press

.

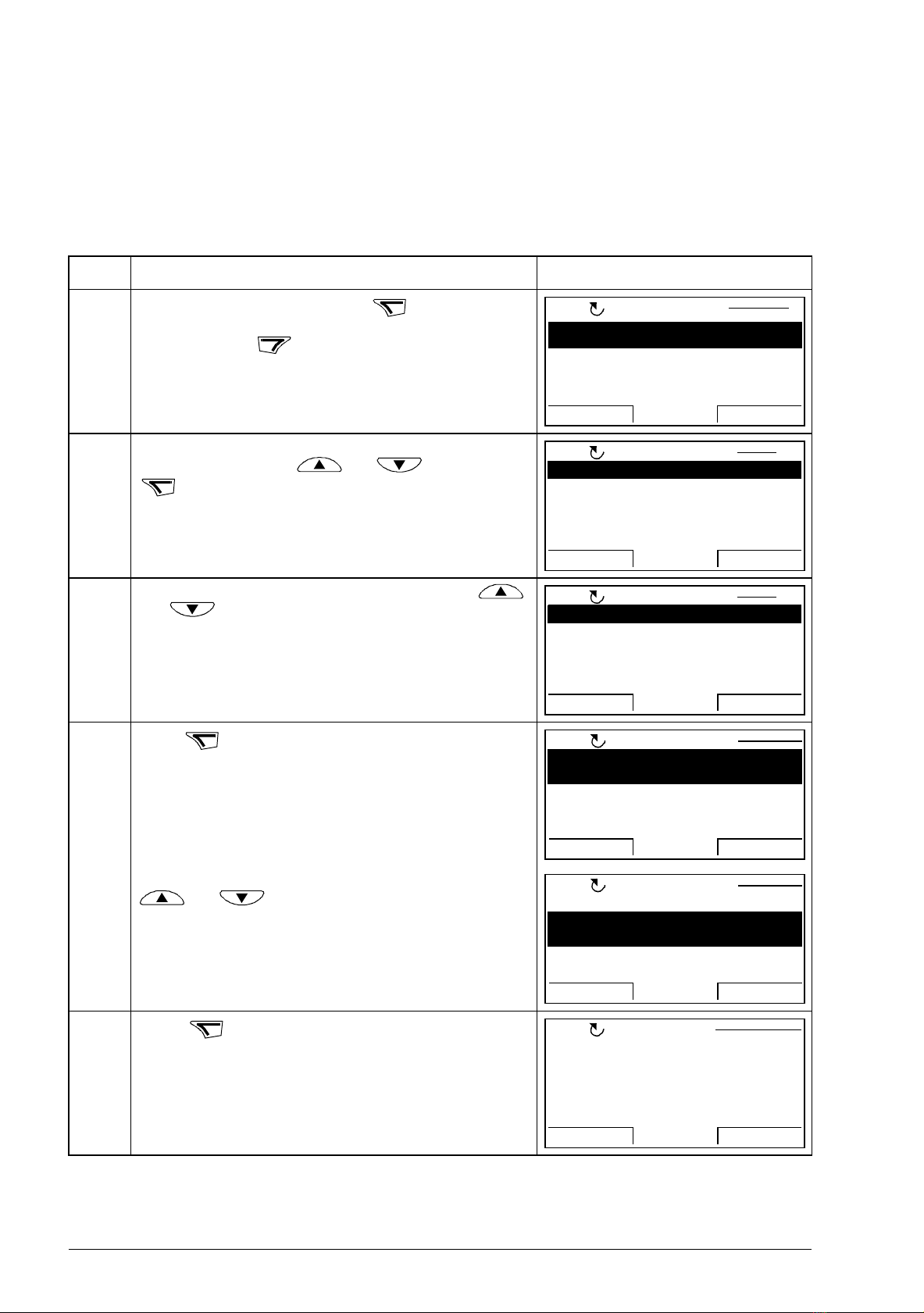

How to change the value of value pointer parameters

In addition to the parameters shown above, there are two kinds of pointer

parameters; value pointer parameters and bit pointer parameters. A value pointer

parameter points to the value of another parameter.

Step Action Display

1. Go to the Main menu by pressing if you are in the

Output mode.

Otherwise press repeatedly until you get to the

Main menu.

2. Go to the Parameters option by selecting PARAMETERS

on the menu with keys and , and pressing

.

3. Select the appropriate parameter group with keys

and . Here the value pointer parameter 21.01

Speed ref1 sel is used as an example.

The ACS850 control panel 27

SEL

2101 Speed ref1 sel

AI2 scaled

2102 Speed ref2 sel

2103 Speed ref1 func

2104 Speed ref1/2 sel

PARAMETERS

EXIT EDIT00:00

LOC

EDIT

2101 Speed ref1 sel

AI1 scaled

PAR EDIT

CANCEL SEL00:00

[P.02.05]

LOC

2101 Speed ref1 sel

FBA ref1

PAR EDIT

CANCEL SEL00:00

[P.02.26]

LOC

SEL

2101 Speed ref1 sel

FBA ref1

2102 Speed ref2 sel

2103 Speed ref1 func

2104 Speed ref1/2 sel

PARAMETERS

EXIT EDIT00:00

LOC

NEXT

2101 Speed ref1 sel

P.02.05

PAR EDIT

CANCEL

SAVE

00:00

02 I/O values

LOC

NEXT

2101 Speed ref1 sel

P.02.07

PAR EDIT

CANCEL SAVE

00:00

0207 AI2 scaled

LOC

SAVE

2101 Speed ref1 sel

AI2 scaled

2102 Speed ref2 sel

2103 Speed ref1 func

2104 Speed ref1/2 sel

PARAMETERS

EXIT EDIT00:00

LOC

Step Action Display

4. Press to select the appropriate parameter group.

Select the appropriate parameter with keys and

, current value of each parameter is shown below

it.

5. Press . Current value of the value pointer parameter

is shown, as well as the parameter it points to.

6. Specify a new value with keys and . The

parameter the value pointer parameter points to changes

respectively.

7. Press to accept any of the preselected values and

to return to the parameters list.

The new value is shown in the parameters list.

To freely define an analog signal as the value, choose

Pointer and press . The parameter group and index

will be shown.

Select the parameter group with and . The

text below the cursor displays the currently-selected

parameter group.

8. Press to select the parameter index.

Again, the text below the cursor reflects the current

setting.

9. To save the new value for the pointer parameter, press

.

The new value is shown in the parameters list.

28 The ACS850 control panel

MENU

EXIT

PARAMETERS

ASSISTANTS

CHANGED PAR

EXIT ENTER00:00

MAIN MENU 1

LOC

ENTER

01 Actual values

02 I/O values

03 Control values

04 Appl values

06 Drive status

EXIT

SEL00:00

PAR GROUPS 01LOC

10 Start/stop/dir

11 Start/stop mode

12 Operating mode

13 Analogue inputs

14 Digital I/O

EXIT

SEL00:00

PAR GROUPS 10LOC

SEL

1001 Ext1 start func

In1

1002 Ext1 start in1

1003 Ext1 start in2

1004 Ext2 start func

PARAMETERS

EXIT EDIT00:00

LOC

1001 Ext1 start func

1002 Ext1 start in1

DI1

1003 Ext1 start in2

1004 Ext2 start func

PARAMETERS

EXIT EDIT00:00

LOC

EDIT

1002 Ext1 start in1

DI1

PAR EDIT

CANCEL SEL00:00

[P.02.01.00]

LOC

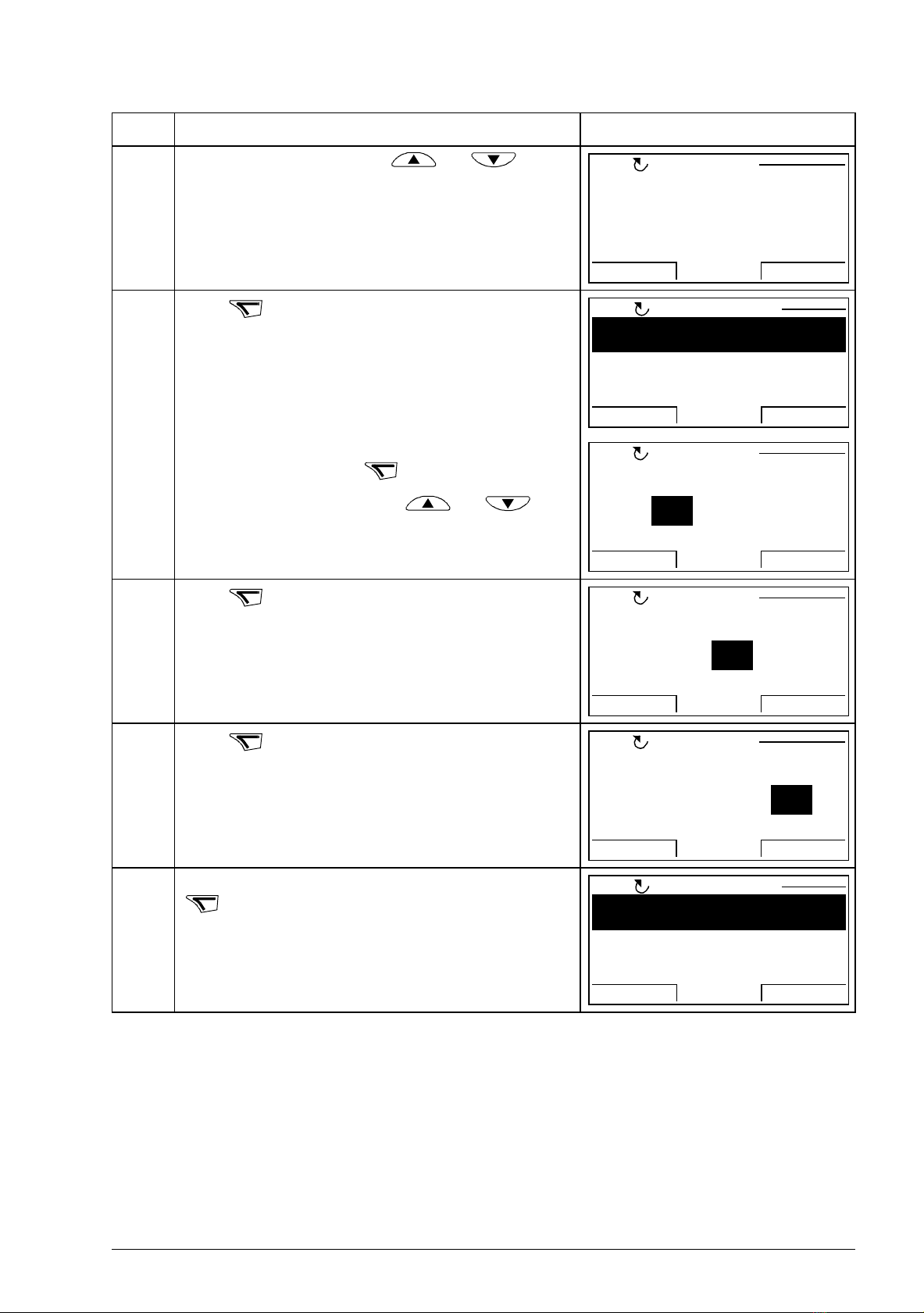

How to change the value of bit pointer parameters

The bit pointer parameter points to the value of a bit in another signal, or can be fixed

to 0 (FALSE) or 1 (TRUE). For the latter option, see page 30. A bit pointer parameter

points to a bit value (0 or 1) of one bit in a 32-bit signal. The first bit from the left is bit

number 31, and the first bit from the right is bit number 0.

Step Action Display

1. Go to the Main menu by pressing if you are in the

Output mode.

Otherwise press repeatedly until you get to the

Main menu.

2. Go to the Parameters option by selecting PARAMETERS

on the menu with keys and , and pressing

.

3. Select the appropriate parameter group with keys

and . Here the bit pointer parameter 10.02 Ext1

start in1 is used as an example.

4. Press to select the appropriate parameter group.

Current value of each parameter is shown below its

name.

Select the parameter 10.02 Ext1 start in1 with keys

and .

5. Press .

The ACS850 control panel 29

1002 Ext1 start in1

DI6

PAR EDIT

CANCEL SEL00:00

[P.02.01.05]

LOC

SEL

1002 Ext1 start in1

DI6

1003 Ext1 start in2

1004 Ext2 start func

1005 Ext2 start in1

PARAMETERS

EXIT EDIT00:00

LOC

NEXT

1002 Ext1 start in1

P.02.01.00

PAR EDIT

CANCEL SAVE00:00

02 I/O values

LOC

NEXT

1002 Ext1 start in1

P.02.01.00

PAR EDIT

CANCEL SAVE00:00

0201 DI status

LOC

NEXT

1002 Ext1 start in1

P.02.01.01

PAR EDIT

CANCEL

SAVE

00:00

01 DI2

LOC

SAVE

1002 Ext1 start in1

P.02.01.01

1003 Ext1 start in2

1004 Ext2 start func

1005 Ext2 start in1

PARAMETERS

EXIT

EDIT00:00

LOC

Step Action Display

6. Specify a new value with keys and . The

text below the cursor shows the corresponding

parameter group, index and bit.

7. Press to accept any of the preselected values and

to return to the parameters list.

To freely define a bit of a binary parameter as the value,

choose Pointer and press . The parameter group,

index and bit will be shown.

Select the parameter group with and . The

text below the cursor displays the currently-selected

parameter group.

8. Press to select the parameter index.

Again, the text below the cursor reflects the current

setting.

9. Press to select the bit.

Again, the text below the cursor reflects the current

setting.

10. To save the new value for the pointer parameter, press

.

The new value is shown in the parameters list.

30 The ACS850 control panel

MENU

EXIT

PARAMETERS

ASSISTANTS

CHANGED PAR

EXIT ENTER

00:00

MAIN MENU 1LOC

ENTER

01 Actual values

02 I/O values

03 Control values

04 Appl values

06 Drive status

EXIT

SEL00:00

PAR GROUPS 01

LOC

10 Start/stop/dir

11 Start/stop mode

12 Operating mode

13 Analogue inputs

14 Digital I/O

EXIT

SEL

00:00

PAR GROUPS 14

LOC

SEL

1404 DIO1 Ton9901

1405 DIO1 Toff

1406 DIO2 conf

1407 DIO2 out src

P.06.02.03

PARAMETERS

EXIT EDIT00:00

LOC

EDIT

1407 DIO2 out src

PAR EDIT

Pointer

CANCEL NEXT00:00

LOC

1407 DIO2 out src

PAR EDIT

Const

CANCEL NEXT00:00

LOC

How to change the value of bit pointer parameter to fixed 0 (FALSE) or 1 (TRUE)

The bit pointer parameter can be fixed to constant value of 0 (FALSE) or 1 (TRUE).

When adjusting a bit pointer parameter on the control panel, CONST is selected in

order to fix the value to 0 (displayed as C.FALSE) or 1 (C.TRUE).

Step Action Display

1. Go to the Main menu by pressing if you are in the

Output mode.

Otherwise press repeatedly until you get to the

Main menu.

2. Go to the Parameters option by selecting PARAMETERS

on the menu with keys and , and pressing

.

Select the appropriate parameter group with keys

and . Here the bit pointer parameter 14.07 DIO2

out src is used as an example.

3. Press to select the appropriate parameter group.

Select the appropriate parameter with keys and

. Current value of each parameter is shown below

its name.

4. Press .

Select CONST with keys and .

Loading...

Loading...