Page 1

ACH550-UH User’s Manual 1-1

ACH550-UH HVAC Drives

1…550 HP

User’s Manual

ACH550-UH_UM (3AUA0000004092) Rev I

EN

EFFECTIVE: 2010-04-01

SUPERSEDES: ACH550-UH_UM (3AUA0000004092) Rev H 2008-04-01

2010 ABB. All Rights Reserved.

Page 2

Page 3

ACH550-UH User’s Manual 1-3

Safety

Use of warnings and notes

There are two types of safety instructions throughout this manual:

• Notes draw attention to a particular condition or fact, or give information on a

subject.

• Warnings caution you about conditions which can result in serious injury or death

and/or damage to the equipment. They also tell you how to avoid the danger. The

warning symbols are used as follows:

Electricity warning warns of hazards from electricity which can cause physical

injury and/or damage to the equipment.

General warning warns about conditions, other than those caused by electricity,

which can result in physical injury and/or damage to the equipment.

WARNING! The ACH550 adjustable speed AC drive should ONLY be installed by a

qualified electrician.

WARNING! Even when the motor is stopped, dangerous voltage is present at the

power circuit terminals U1, V1, W1 (L1, L2, L3) and U2, V2, W2 (T1, T2 T3) and,

depending on the frame size, UDC+ and UDC-, or BRK+ and BRK-.

WARNING! Dangerous voltage is present when input power is connected. After

disconnecting the supply, wait at least 5 minutes (to let the intermediate circuit

capacitors discharge) before removing the cover.

WARNING! Even when power is switched off from the input terminals of the

ACH550, there may be dangerous voltage (from external sources) on the terminals

of the relay outputs.

WARNING! When the control terminals of two or more drives are connected in

parallel, the auxiliary voltage for these control connections must be taken from a

single source which can either be one of the drives or an external supply.

Safety

Page 4

1-4 ACH550-UH User’s Manual

WARNING! Disconnect the internal EMC filter when installing the drive on an IT

system (an ungrounded power system or a high-resistance-grounded [over 30 ohm]

power system).

WARNING! Do not attempt to install or remove EM1, EM3, F1 or F2 screws while

power is applied to the drive’s input terminals.

WARNING! Do not control the motor with the disconnecting device (disconnecting

means); instead, use the control panel keys or commands via the I/O board of the

drive. The maximum allowed number of charging cycles of the DC capacitors (i.e.

power-ups by applying power) is five in ten minutes.

WARNING! Never attempt to repair a malfunctioning ACH550; contact the factory or

your local Authorized Service Center for repair or replacement.

WARNING! The ACH550 will start up automatically after an input voltage

interruption if the external run command is on.

WARNING! The heat sink may reach a high temperature.

Note: For more technical information, contact the factory or your local ABB

representative.

Safety

Page 5

ACH550-UH User’s Manual 1-5

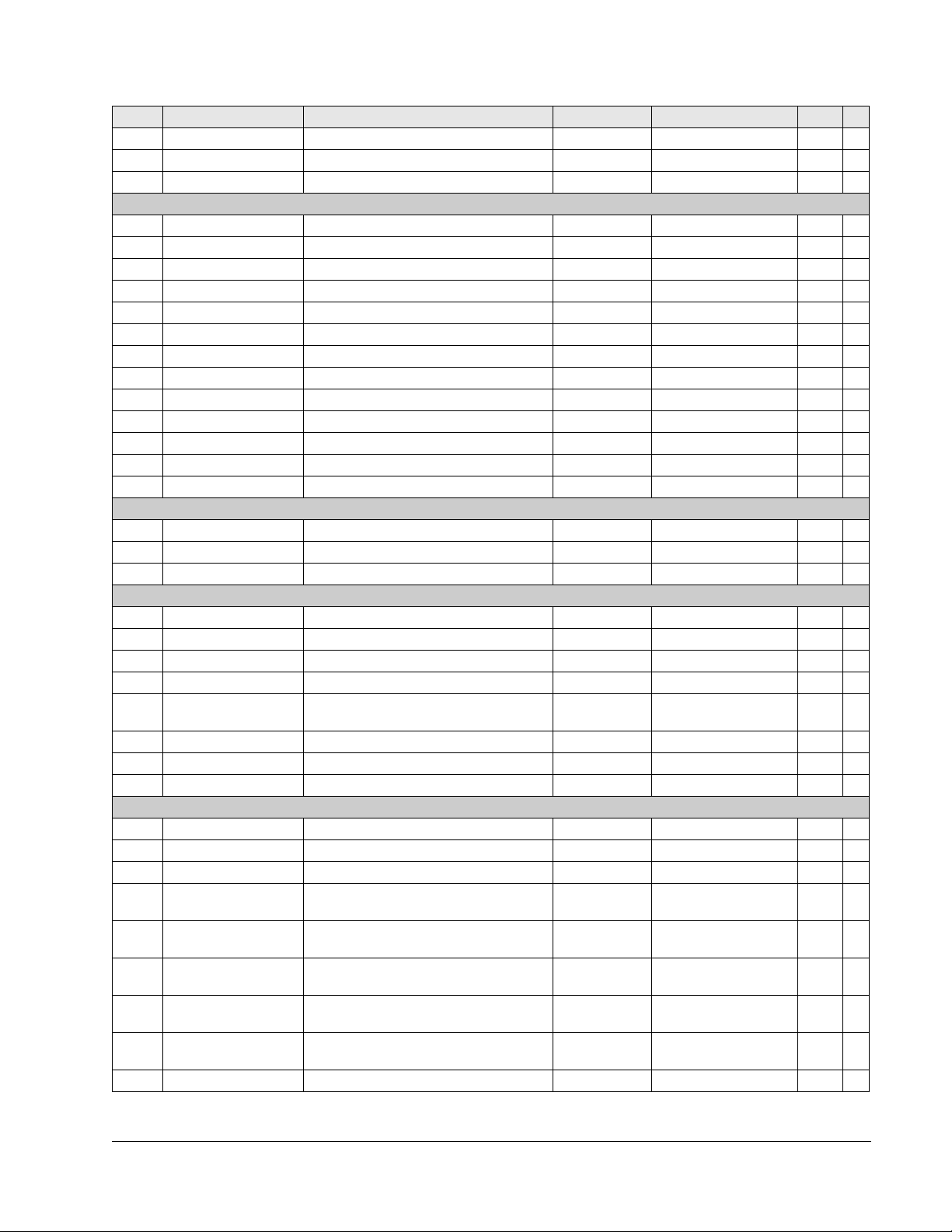

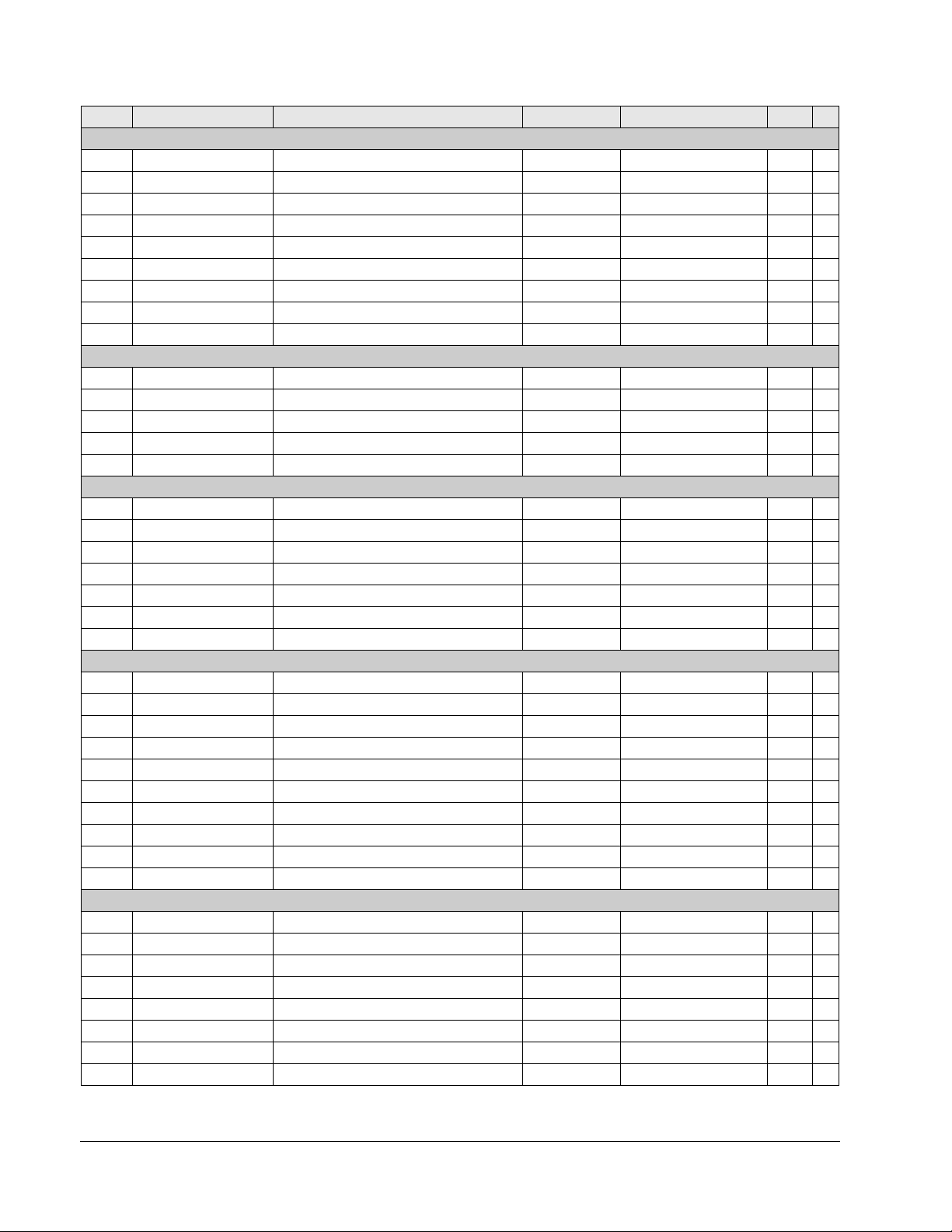

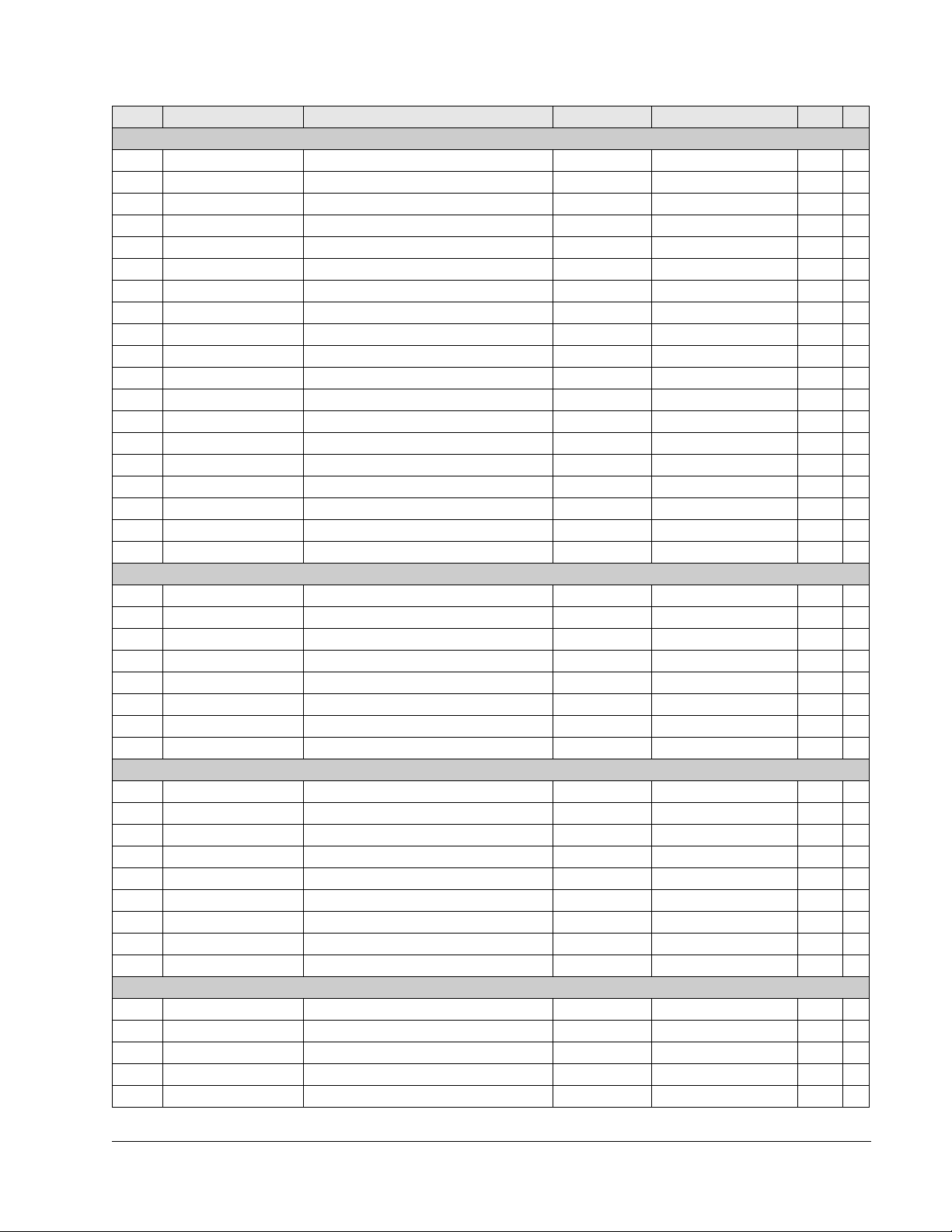

Table of contents

Safety

Use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table of contents

Installation

Installation flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Installing the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Control panel

HVAC control panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

HVAC control panel modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Start-up

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

Application macros

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

HVAC Default macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-51

Supply Fan macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-52

Return Fan macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

Cooling Tower Fan macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-54

Condenser macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

Booster Pump macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-56

Pump Alternation macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

Internal Timer macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

Internal Timer with Constant Speeds / PRV macro . . . . . . . . . . . . . . . . . . . 1-59

Floating Point macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-60

Dual Setpoint with PID macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

Dual Setpoint with PID and Constant Speeds . . . . . . . . . . . . . . . . . . . . . . . 1-62

E-bypass macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-63

Hand Control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

E-Clipse macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-65

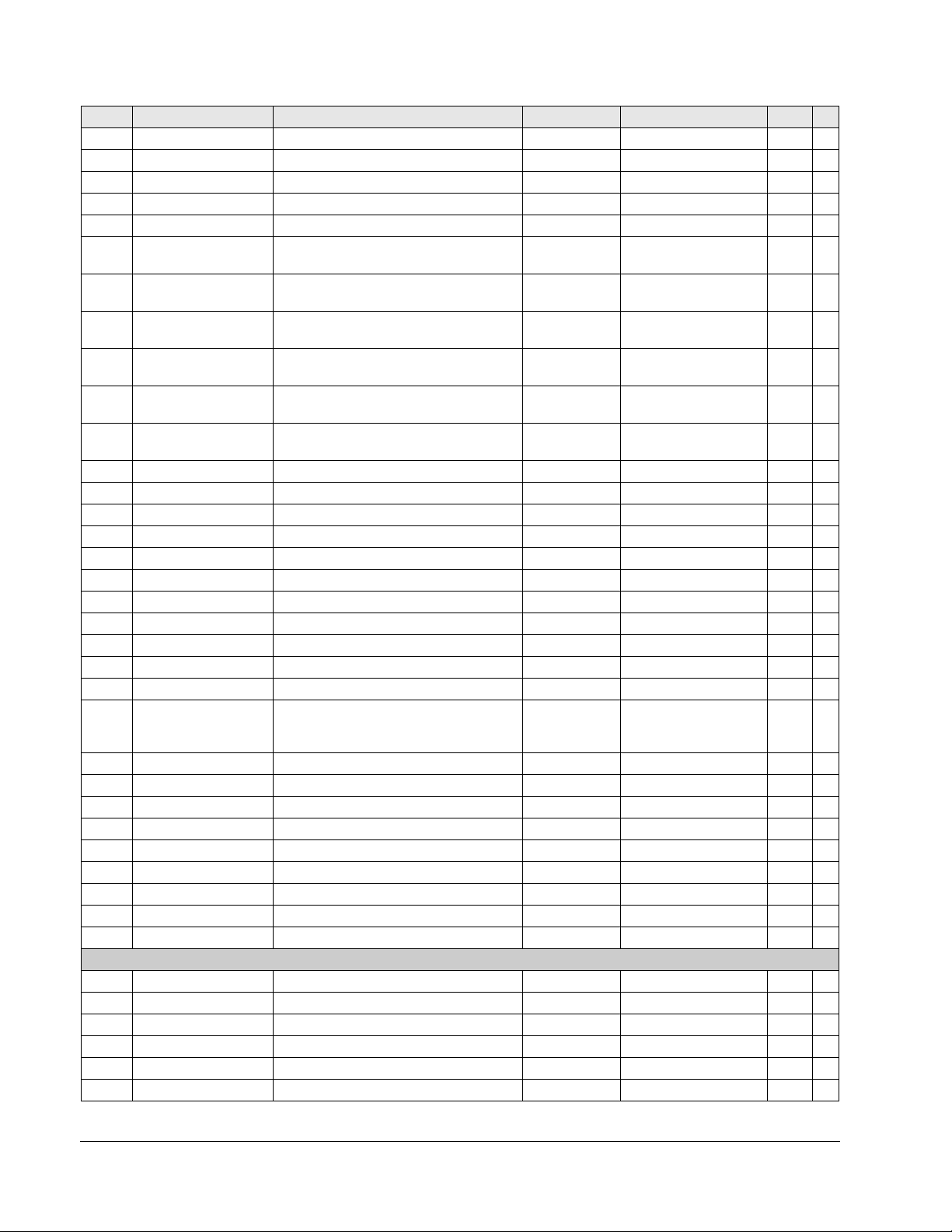

Parameters

Complete parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-67

Complete parameter descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-80

Table of contents

Page 6

1-6 ACH550-UH User’s Manual

Embedded fieldbus

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-187

Mechanical and electrical installation – EFB . . . . . . . . . . . . . . . . . . . . . . . 1-189

Communication setup – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-191

Activate drive control functions – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-195

Feedback from the drive – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-200

Diagnostics – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-202

N2 protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-207

FLN protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-215

BACnet protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-229

Modbus protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-241

ABB control profiles technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-249

Fieldbus adapter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-261

Mechanical and electrical installation – FBA . . . . . . . . . . . . . . . . . . . . . . . 1-264

Communication setup – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-265

Activate drive control functions – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-265

Feedback from the drive – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-268

Diagnostics – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-269

ABB drives profile technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-271

Generic profile technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-279

Diagnostics

Diagnostic displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-281

Correcting faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-282

Correcting alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-288

Maintenance

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-291

Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-291

Drive module fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-292

Enclosure fan replacement – UL Type 12 enclosures . . . . . . . . . . . . . . . . 1-293

Enclosure air filter replacement – UL Type 12 enclosures . . . . . . . . . . . . . 1-295

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-298

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-298

Table of contents

Page 7

ACH550-UH User’s Manual 1-7

Technical data

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-299

Input power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-303

Motor connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-311

Control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-317

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-320

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-320

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-322

Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-327

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-328

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-329

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-330

Liability limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-332

Index

Table of contents

Page 8

1-8 ACH550-UH User’s Manual

Table of contents

Page 9

ACH550-UH User’s Manual 1-9

Installation

Study these installation instructions carefully before proceeding. Failure to observe

the warnings and instructions may cause a malfunction or personal hazard.

WARNING! Before you begin read Safety on page 1-3.

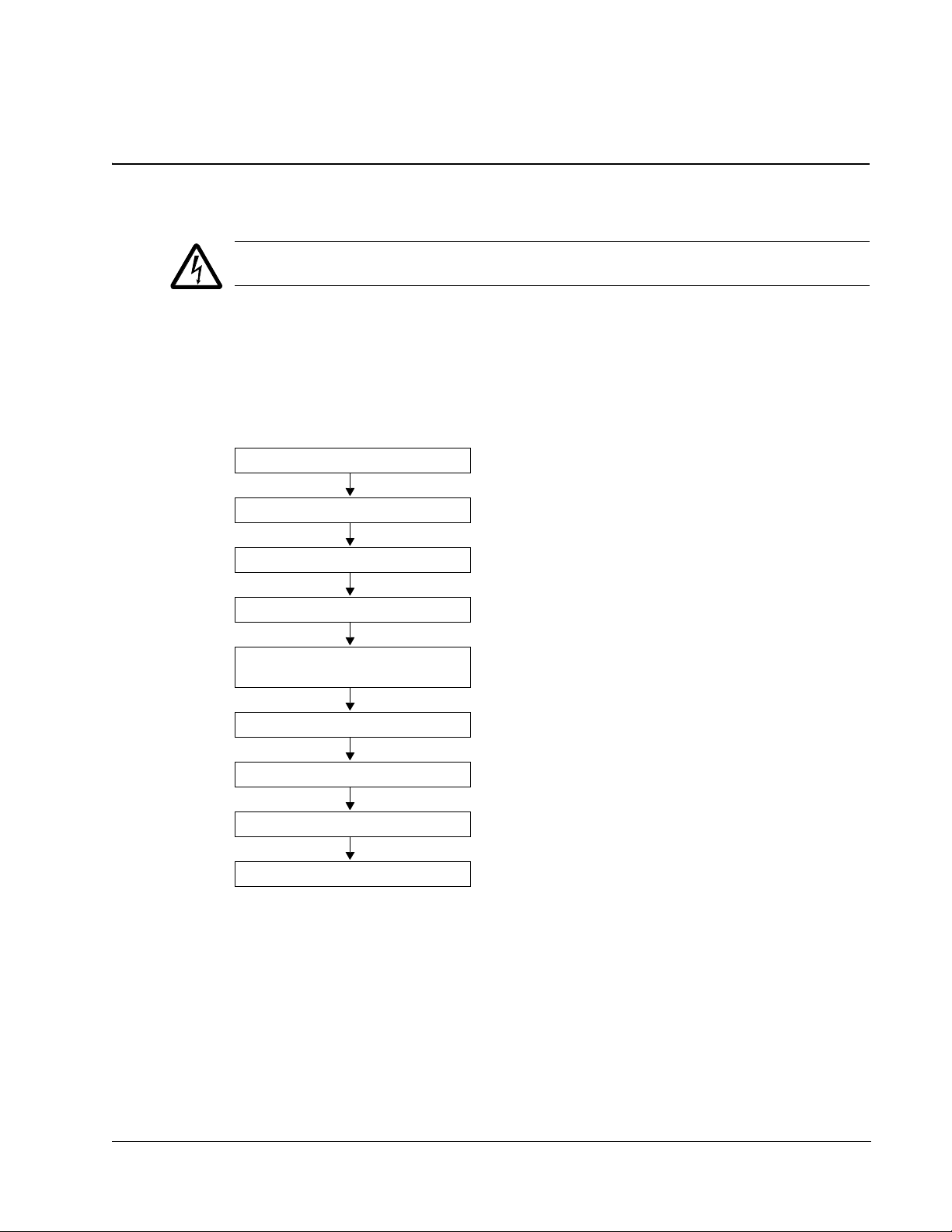

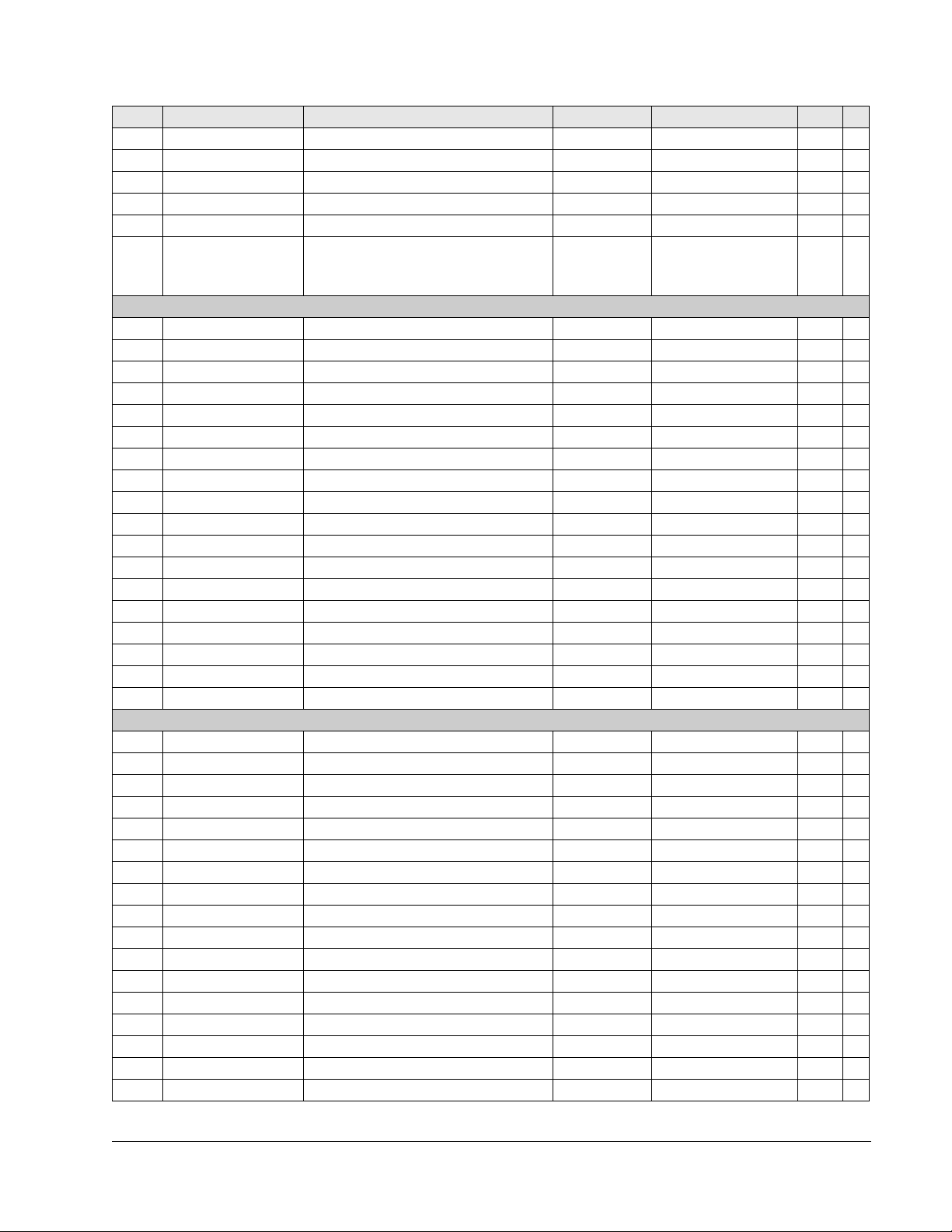

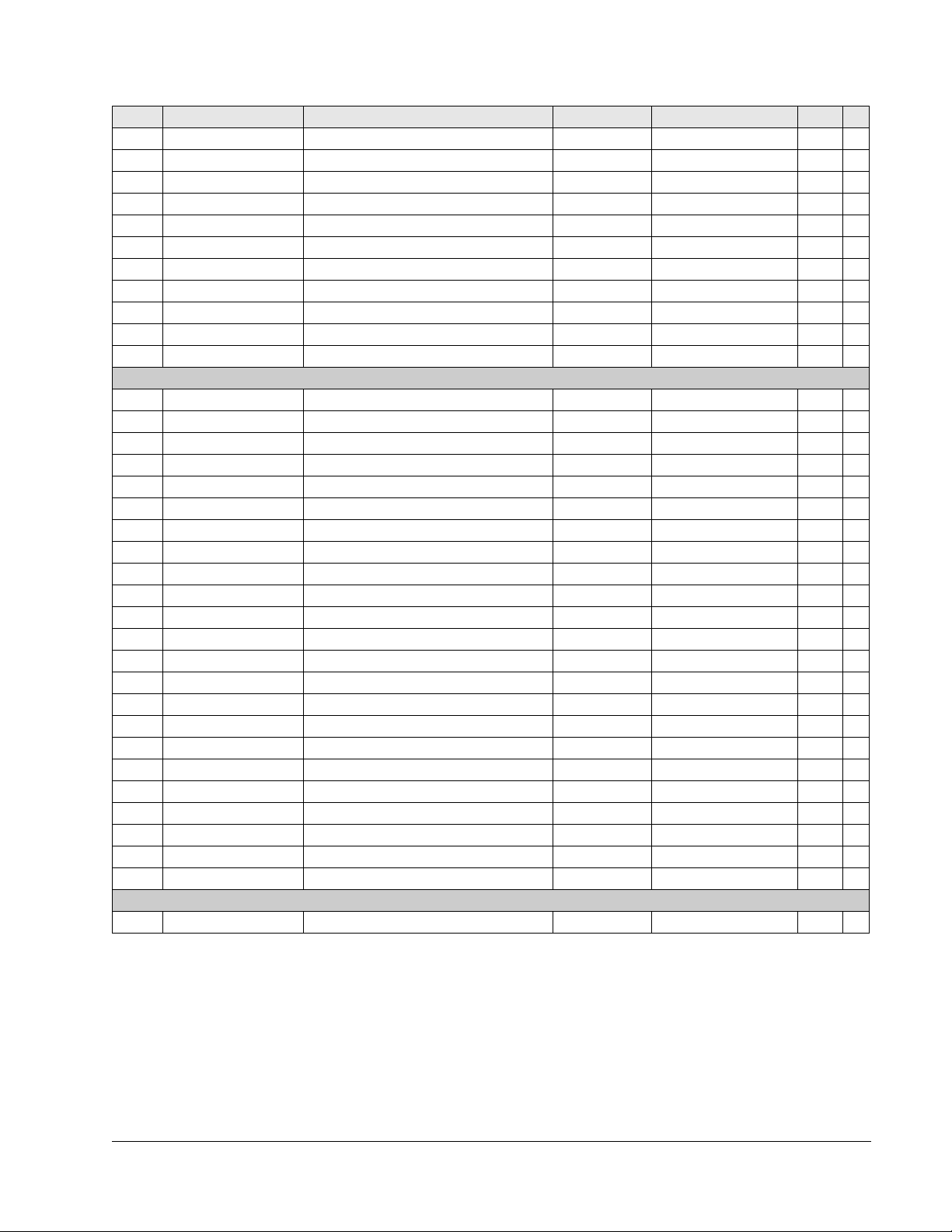

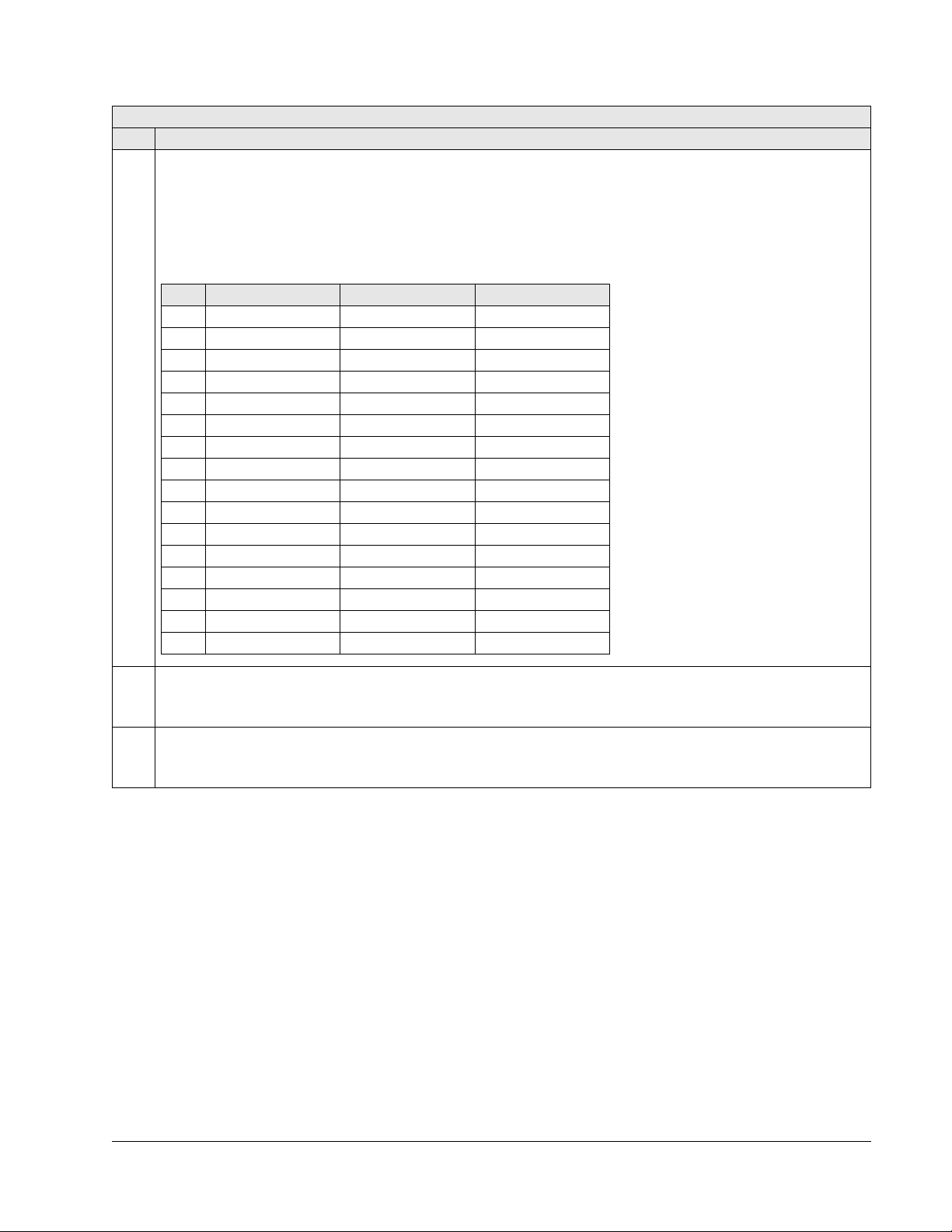

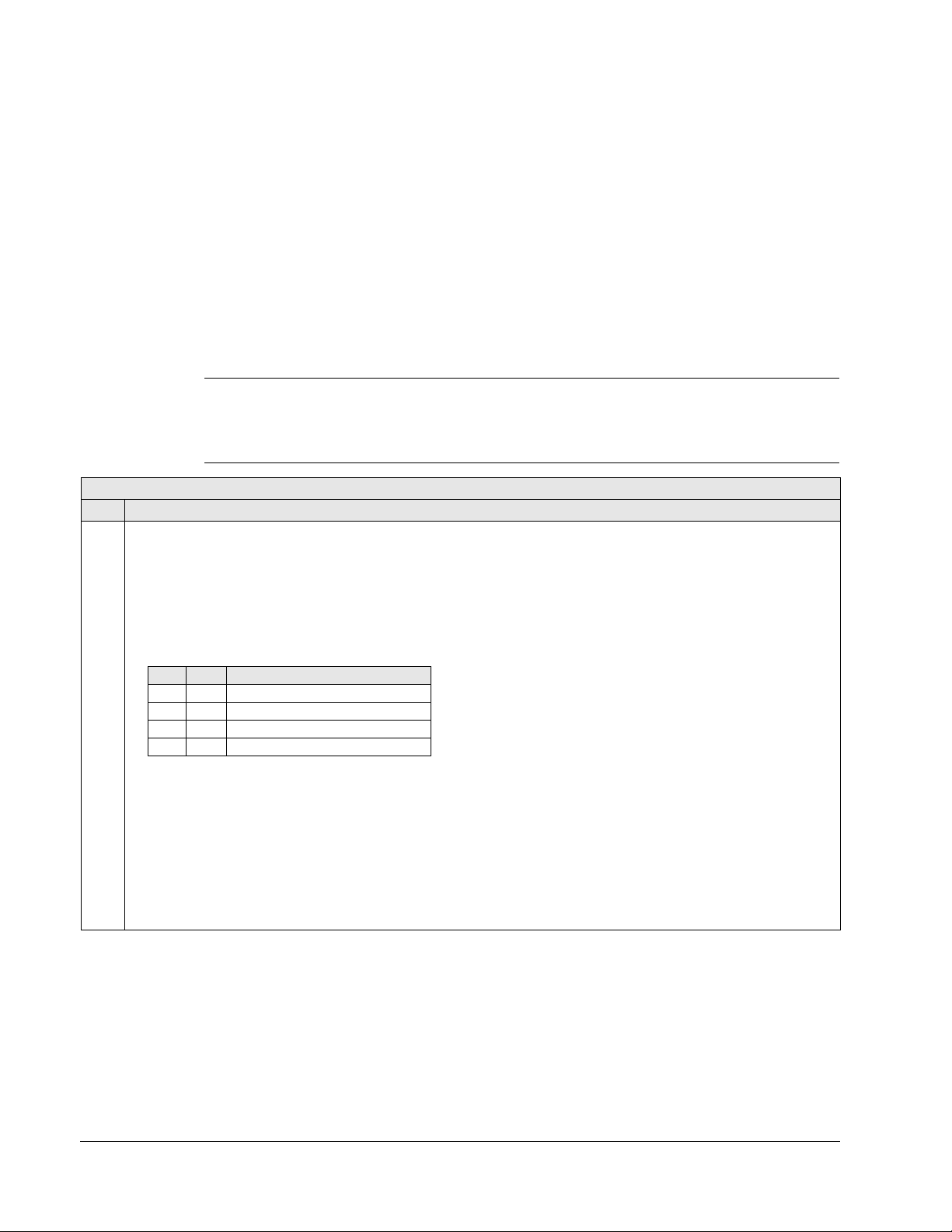

Installation flow chart

The installation of the ACH550 adjustable speed AC drive follows the outline below.

The steps must be carried out in the order shown. At the right of each step are

references to the detailed information needed for the correct installation of the unit.

Task Se e

PREPARE for installation Preparing for installation on page 1-10.

PREPARE the mounting location Prepare the mounting location on page 1-14.

REMOVE the front cover Remove front cover on page 1-16.

MOUNT the drive Mount the drive on page 1-17.

INSTALL wiring Wiring overview on page 1-18 and

CHECK installation Check installation on page 1-27.

REINSTALL the cover Re-install cover on page 1-27.

APPLY power Apply power on page 1-29.

START-UP Start-up on page 1-30.

Install the wiring on page 1-23.

Installation

Page 10

1-10 ACH550-UH User’s Manual

IP2040

PC00005

R70010

2

PC00003

30

o

Preparing for installation

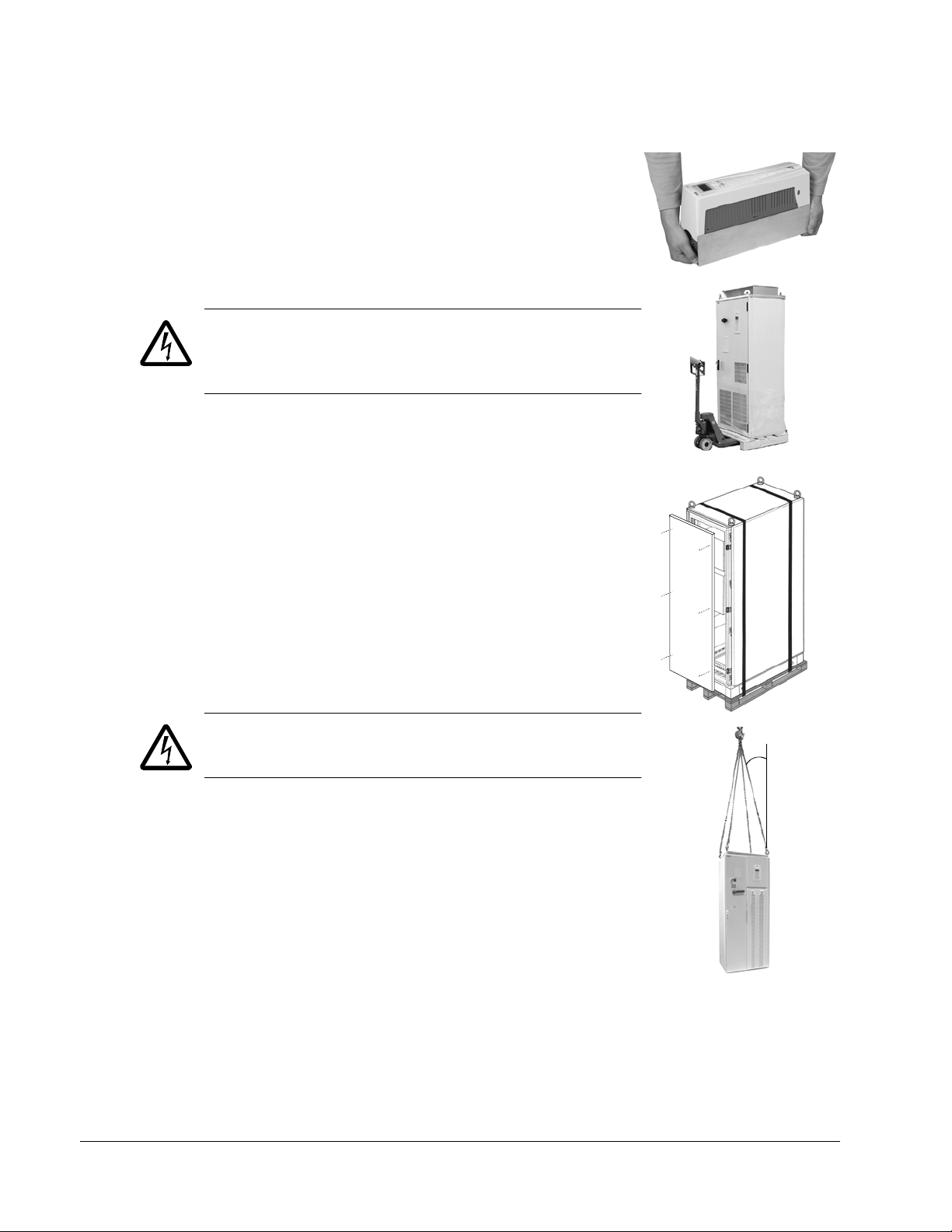

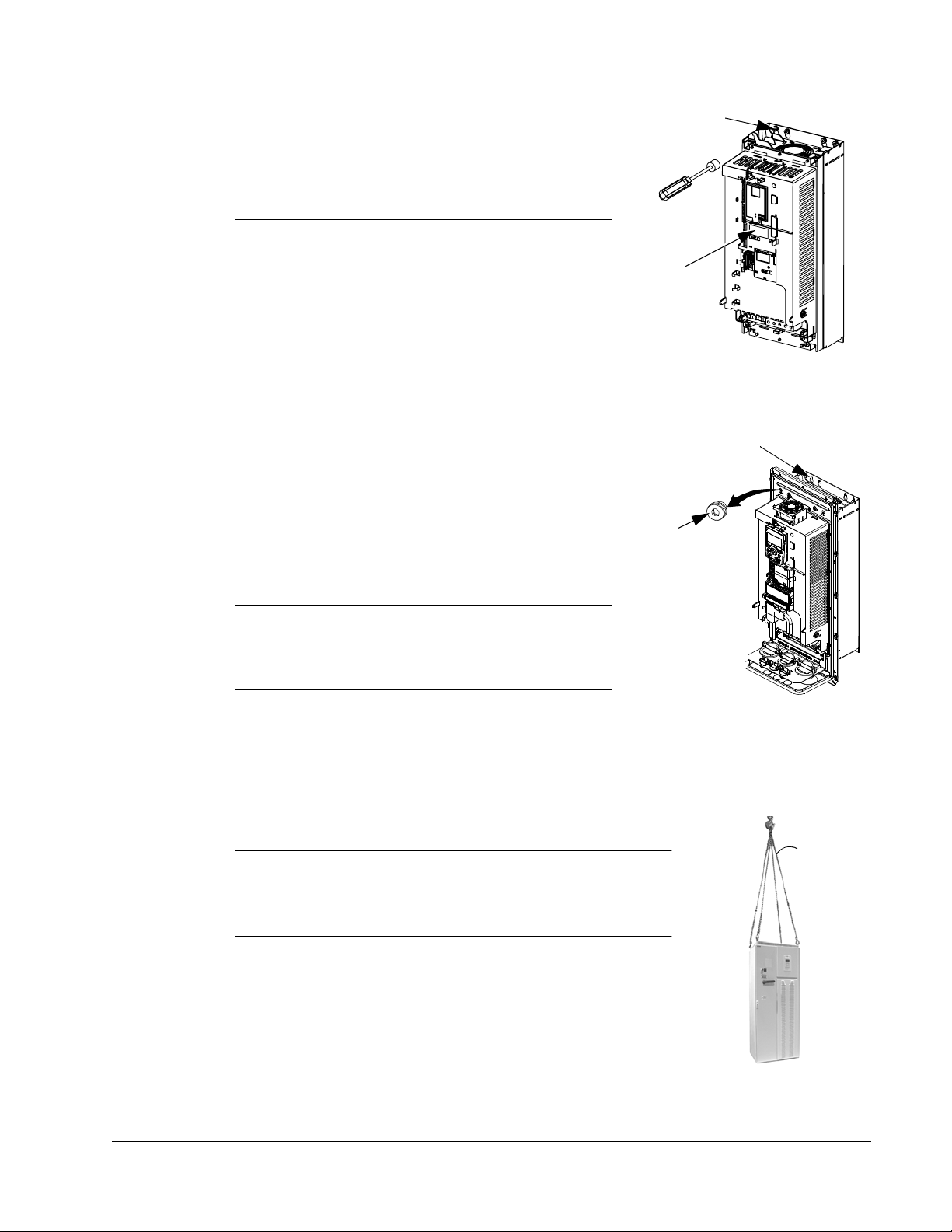

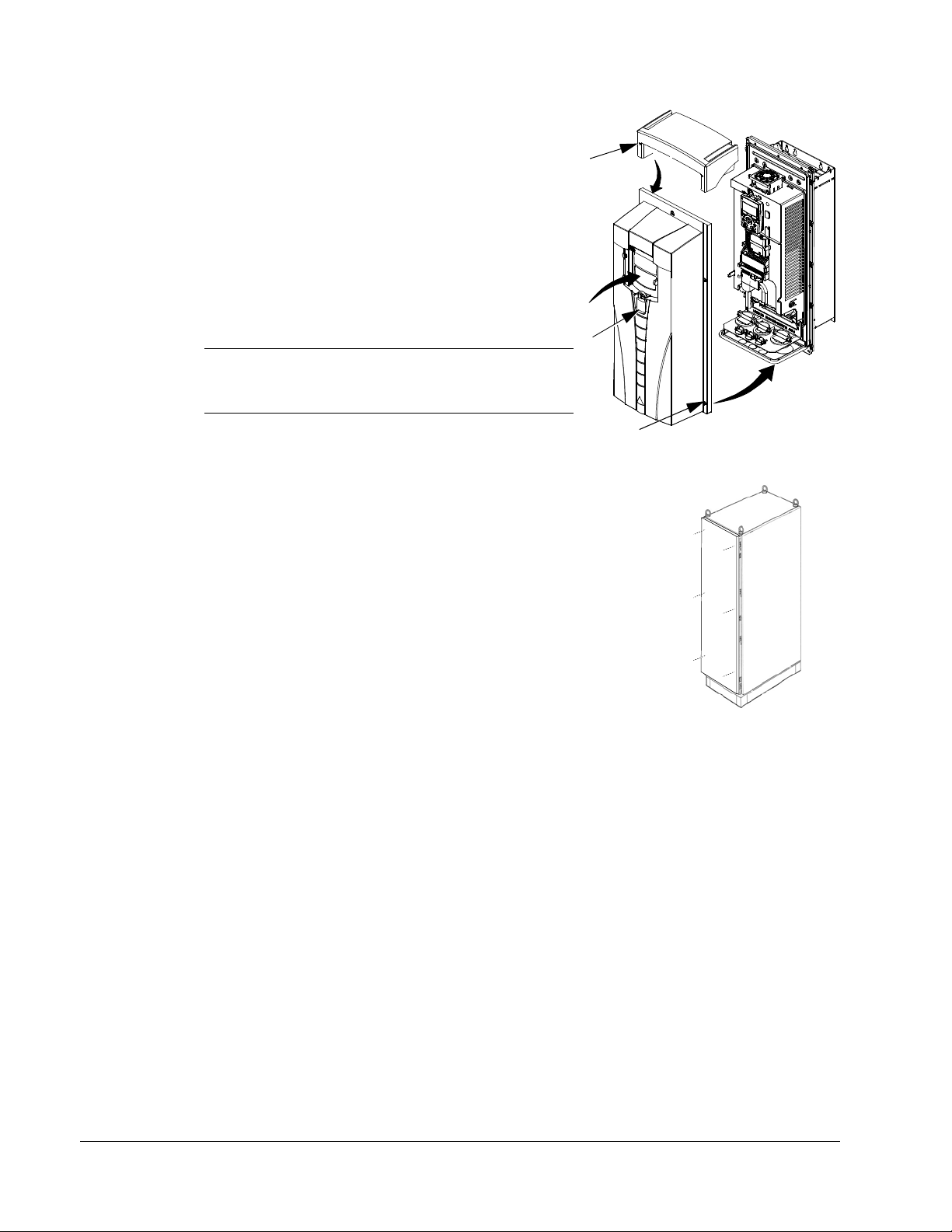

Lifting the drive

R1…R6

Lift the drive only by the metal chassis.

R7…R8

WARNING! Handle and ship floor mounted enclosures

only in the upright position. These units are not designed

to be laid on their backs.

1. Use a pallet truck to move the transport package/

enclosure to the installation site.

2. Remove the cabinet side panels for access to the

cabinet/pallet mounting bolts. (6 torx screws hold each

cabinet side panel in place. Leave the side panels off

until later.)

3. Remove the 4 bolts that secure the cabinet to the

shipping pallet.

WARNING! Use the lifting lugs/bars at the top of the unit

to lift R7/R8 drives.

4. Use a hoist to lift the drive. (Do not place drive in final

position until mounting site is prepared.)

Unpack the drive

1. Unpack the drive.

2. Check for any damage and notify the shipper

immediately if damaged components are found.

3. Check the contents against the order and the shipping

label to verify that all parts have been received.

Installation

Page 11

ACH550-UH User’s Manual 1-11

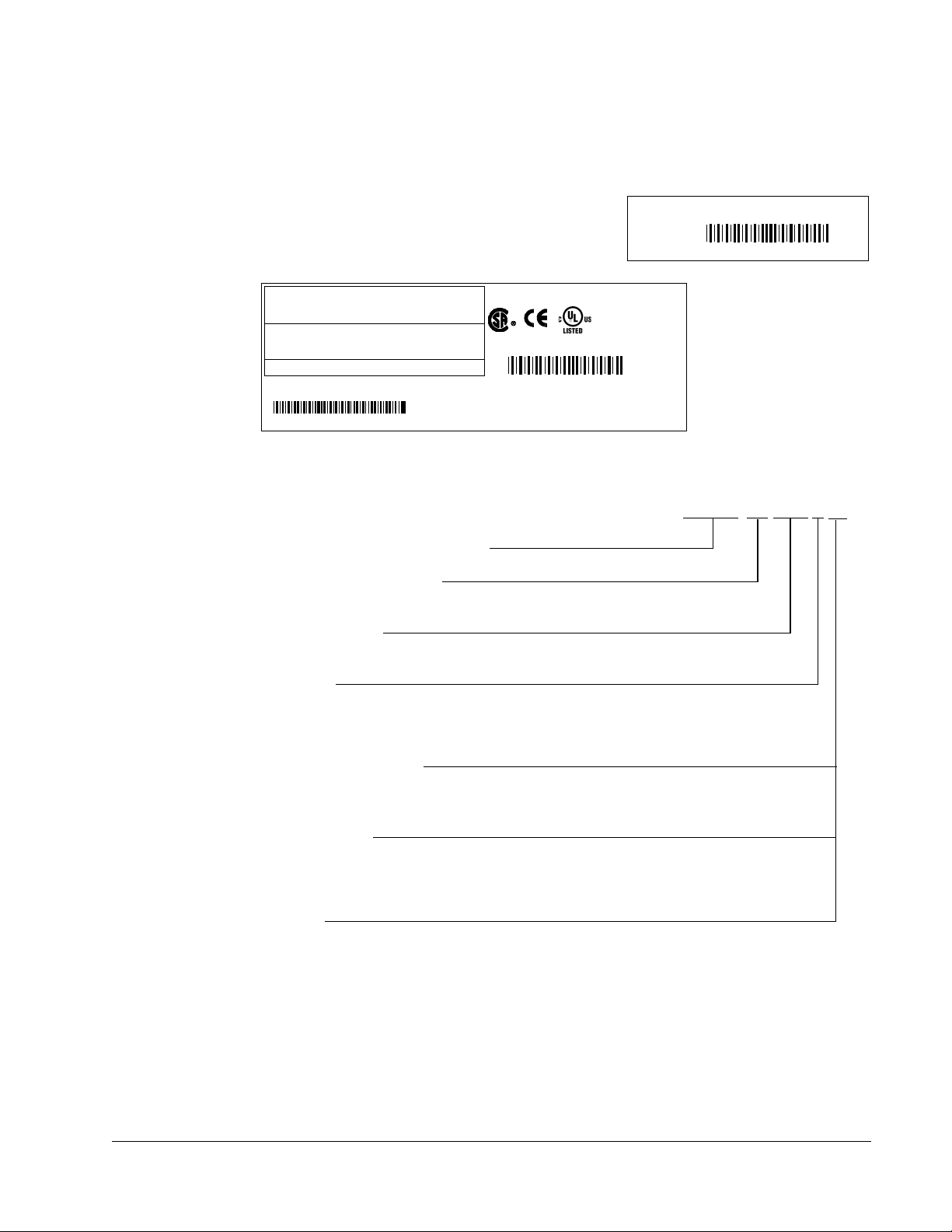

S/N

ACH550-UH-059A-2

2030700001

SW:

V.2. 06B

2030700001

Input

Voltage (U1)

Current (I1n)

3 PH 48…63 Hz

200…240 Vac

59.4 A

1 PH 4…63 Hz

200…240 Vac

59.4 A

Output

Voltage (U2)

Current (I2n)

3 PH 0…500 Hz

0…U1 Vac

59.4 A

3 PH 0…500 Hz

0…U1 Vac

28 A

ACH550-UH-059A-2

Power (Pn)

Mfg. Date: 01-December-2005

Org. Firmware: V.2.06B

ABB Inc.

Made in USA of foreign parts

10 HP20 HP

kAIC

S/N

2030700001

AC, HVAC Drive – 550 product series

Construction (region specific)

UH = Setup and parts specific to US installation and NEMA compliance

Output current rating

e.g. 08A8 = 8.8A See section Ratings for details on page 1-299

Volta g e r a ting

2 = 208…240 VAC

4 = 380…480 VAC

6 = 500…600 VAC

Enclosure protection class

No specification = UL type 1 / NEMA 1 / IP 21

+B055 = UL type 12 / NEMA 12 / IP 54

Fieldbus Adapter

+K451 = DeviceNet Adapter +K462 = ControlNet Adapter

+K452 = LonWorks Adapter +K466 = EtherNet Adapter

+K454 = Profibus Adapter

I/O Options

+L511 = Relay Output Extension

+L512 = 115/230 V Digital Input Interface

ACH550-UH-08A8-4+...

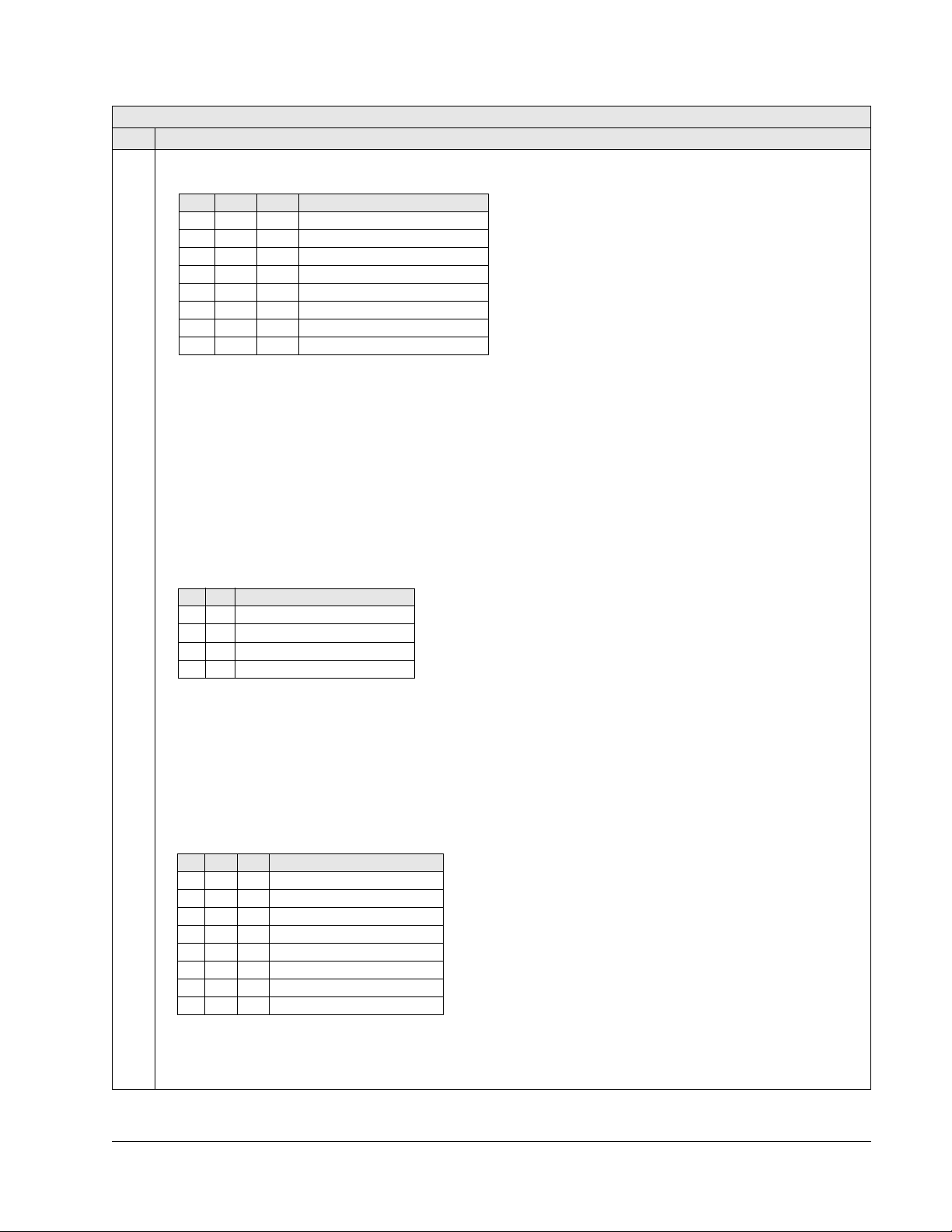

Drive identification

Drive labels

To determine the type of drive you are installing, refer to either:

• Serial number label attached on upper part of

the chokeplate between the mounting holes.

• Type code label attached on the heat sink – on

the side of the enclosure.

Type code

Use the following chart to interpret the type code found on either label.

Ratings and frame size

The chart in section Ratings on page 1-299 lists technical specifications, and

identifies the drive’s frame size. To read the Ratings table, you need the “Output

current rating” entry from the type code (see above). Also, when using the Ratings

tables, note that there are different tables for each drive “Voltage rating”.

Installation

Page 12

1-12 ACH550-UH User’s Manual

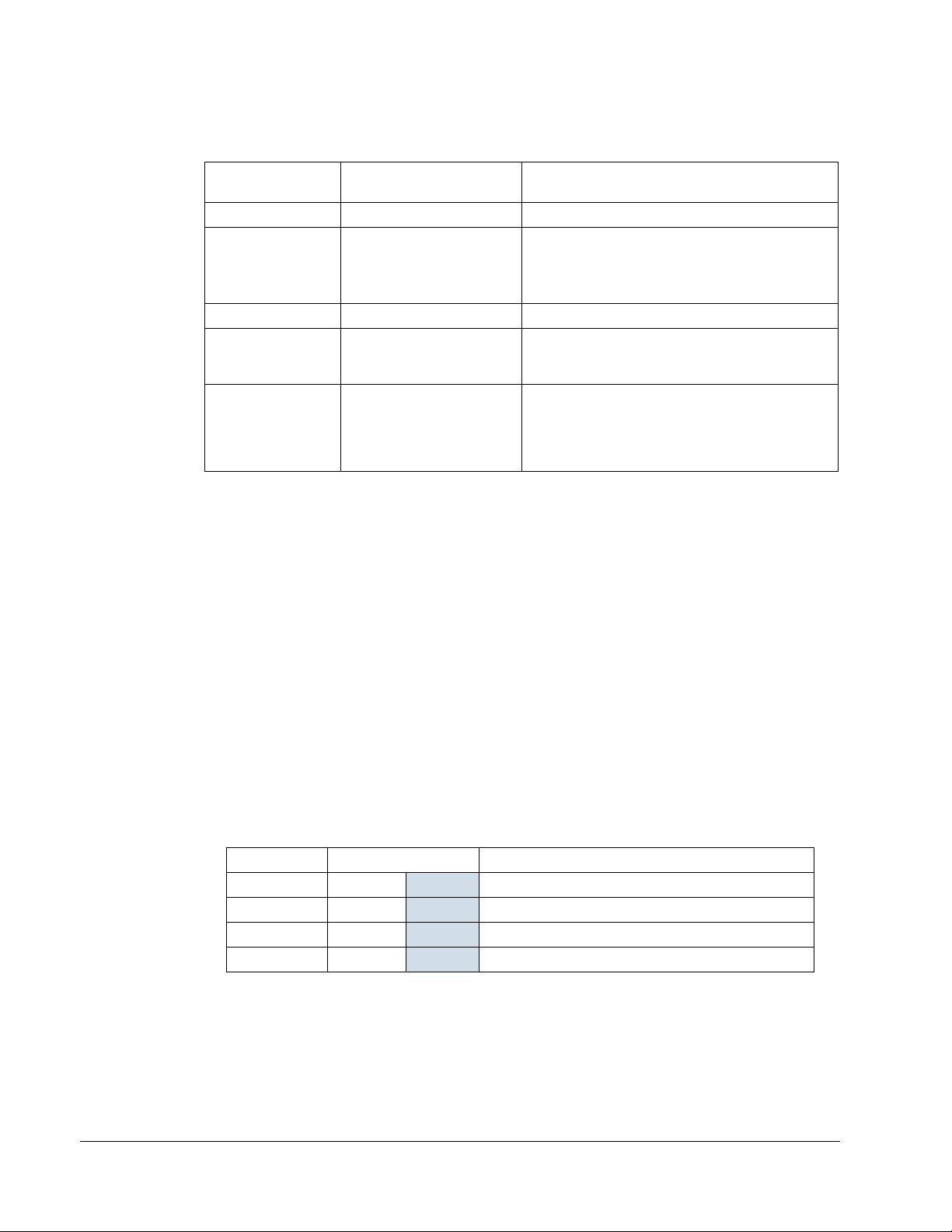

Motor compatibility

The motor, drive, and supply power must be compatible:

Motor

Specification

Motor type 3-phase induction motor –

Nominal current Motor value is within this

range: 0.15…1.5 * I

(I

2N

Nominal frequency 10…500 Hz –

Voltage range Motor is compatible with

Insulation 500…600 V drives: Either

the ACH550 voltage range.

the motor complies with

NEMA MG1 Part 31, or a

du/dt filter is used between

the motor and drive.

Verify Reference

• Type code label on drive, entry for Output I

= normal use current)

2N

or

• Type code on drive and rating table in

Technical data on page 1-299.

208…240 V (for ACH550-xx-xxxx-2) or

380…480 V (for ACH550-xx-xxxx-4)

500…600 V (for ACH550-xx-xxxx-6)

For ACH550-xx-xxxx-6

Tools required

To install the ACH550 you need the following:

• Screwdrivers (as appropriate for the mounting hardware used)

• Wire stripper

• Tape measure

2N

,

•Drill

• Frame sizes R5…R8 with UL type 12 enclosure: Punch for conduit mounting

holes

• Frame sizes R7/R8: pallet truck and hoist

• For installations involving frame size R6…R8: The appropriate crimping tool for

power cable lugs. See Power terminal considerations – R6 Frame size.

• Mounting hardware: screws or nuts and bolts, four each. The type of hardware

depends on the mounting surface and the frame size:

Frame Size Mounting Hardware Note

R1…R4 M5

R5 M6

R6 M8

R7…R8 M10

#10

1/4 in

5/16 in

7/16 Secures free standing cabinets if required.

• For installations involving frame size R7…R8: Hoist.

Installation

Page 13

ACH550-UH User’s Manual 1-13

Suitable environment and enclosure

Confirm that the site meets the environmental requirements. To prevent damage

prior to installation, store and transport the drive according to the environmental

requirements specified for storage and transportation. See Ambient conditions on

page 1-328.

Confirm that the enclosure is appropriate, based on the site contamination level:

• UL type 1 enclosure. The site must be free of airborne dust, corrosive gases or

liquids, and conductive contaminants such as condensation, carbon dust, and

metallic particles.

• UL type 12 enclosure. This enclosure provides protection from airborne dust and

light sprays or splashing water from all directions.

Suitable mounting location

Confirm that the mounting location meets the following constraints:

• R1…R6: The drive must be mounted vertically on a smooth, solid surface, and in

a suitable environment as defined above.

• The drive must be located in a suitable environment as defined above.

• The minimum space requirements for the drive are the outside dimensions (see

Outside dimensions – R1…R6 on page

on page 1-326), plus air flow space around the unit (see Cooling

• The distance between the motor and the drive is limited by the maximum motor

cable length. See either Motor connection specifications on page 1-311, or

EN 61800-3 compliant motor cables on page 1-314.

• The mounting site must support the drive’s weight. See Weight on page 1-324.

Installing the drive

WARNING! Before installing the ACH550, ensure the input power supply to the drive

is off.

WARNING! Metal shavings or debris in the enclosure can damage electrical

equipment and create a hazardous condition. Where parts, such as conduit plates

require cutting or drilling, first remove the part. If that is not practical, cover nearby

electrical components to protect them from all shavings or debris.

1-325 or Outside dimensions – R7…R8

on page 1-320).

Installation

Page 14

1-14 ACH550-UH User’s Manual

X0002

1

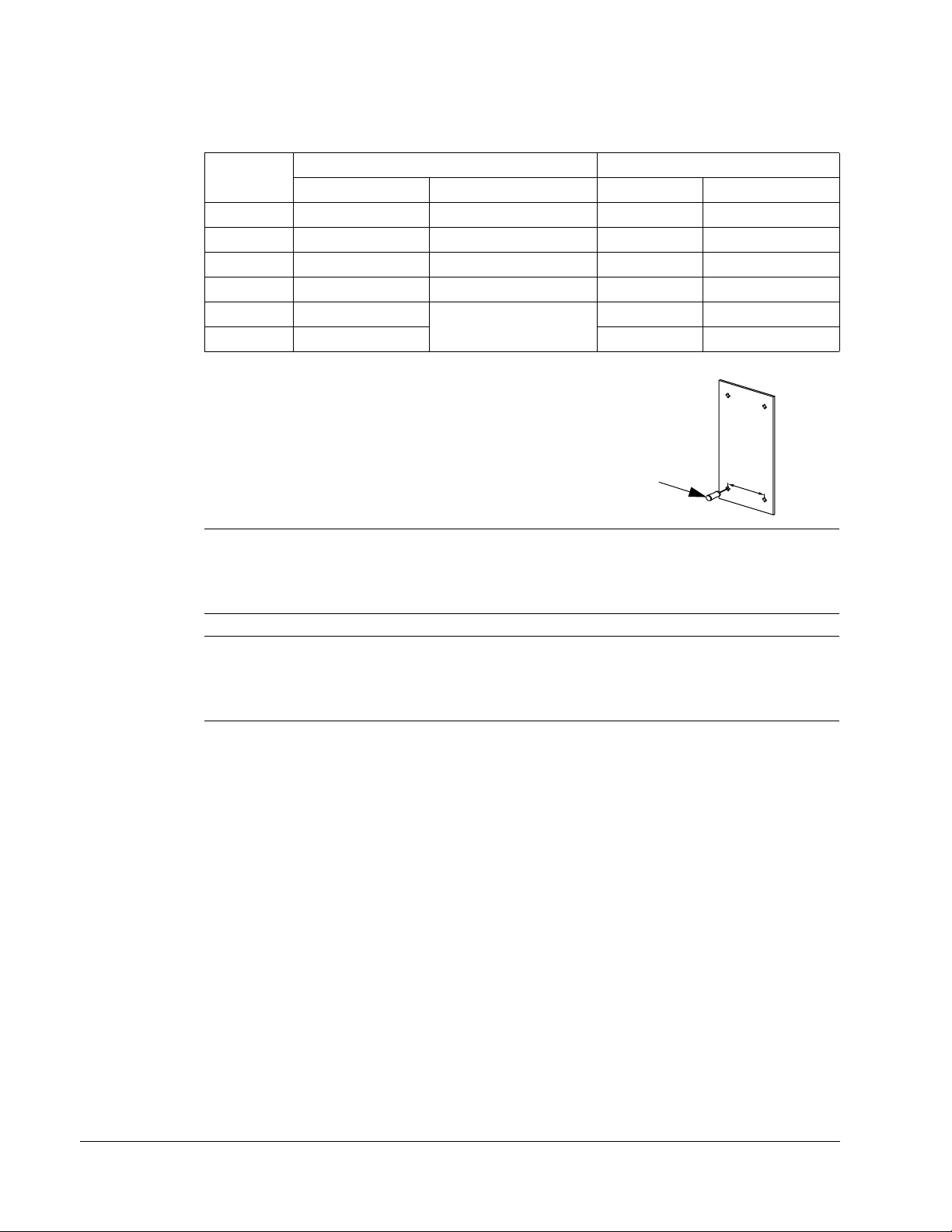

For flange mounting (mounting the drive in a cooling air duct), see the appropriate

Flange Mounting Instructions:

Frame size

R1 FMK-A-R1 100000982 FMK-B-R1 100000990

R2 FMK-A-R2 100000984 FMK-B-R2 100000992

R3 FMK-A-R3 100000986 FMK-B-R3 100000994

R4 FMK-A-R4 100000988 FMK-B-R4 100000996

R5 AC8-FLNGMT-R5 ACS800-PNTG01U-EN - R6 AC8-FLNGMT-R6 - -

IP21 / UL type 1 IP54 / UL type 12

Kit Code (English) Kit Code (English)

Prepare the mounting location

The ACH550 should only be mounted where all of the

requirements defined in Preparing for installation on

page 1-10 are met.

1. Mark the position of the mounting holes.

Note: Frame sizes R3 and R4 have four holes along the top. Use only two. If

possible, use the two outside holes (to allow room to remove the fan for

maintenance).

Note: ACH400 drives can be replaced using the original mounting holes. For R1 and

R2 frame sizes, the mounting holes are identical. For R3 and R4 frame sizes, the

inside mounting holes on the top of ACH550 drives match ACH400 mounts.

Installation

Page 15

ACH550-UH User’s Manual 1-15

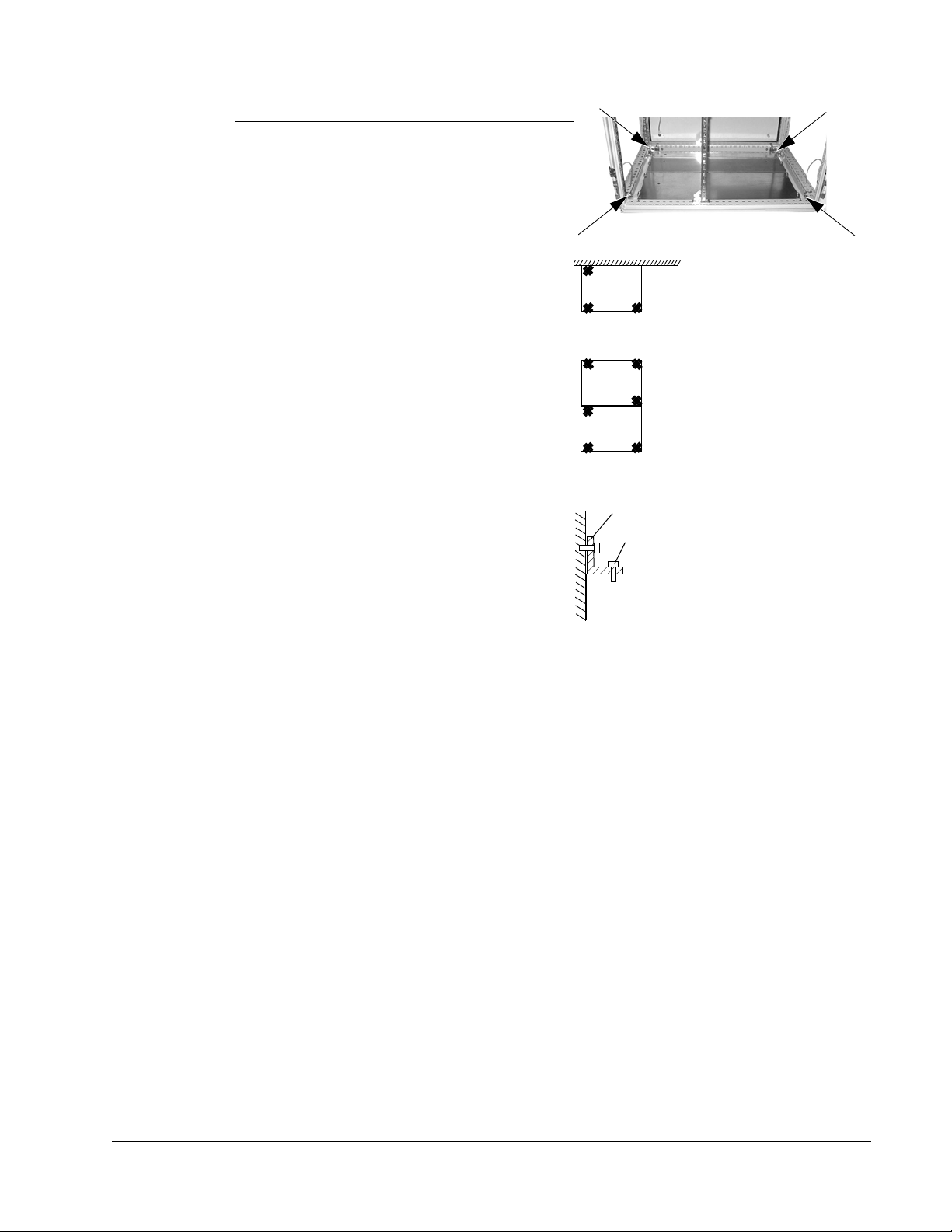

PC00023

Fastening points when installed

back against a wall (Top view)

Fastening points when installed

back against back

Cabinet top

M12 bolt (1/2 to 9/16 in)

L-bracket

Fastening the cabinet at the top

using L-brackets (side view)

Note: Frame sizes R7 and R8 have

mounting holes inside the enclosure base.

See Mounting dimensions on page 1-323.

Where it is not possible to use either

mounting hole at the back of the base, use

an L-bracket at the top of the enclosure to

secure the cabinet to a wall or to the back of

another enclosure. Bolt the L-bracket to the

enclosure using the lifting lug bolt hole on

the top of the enclosure.

2. Drill holes of appropriate size in the

mounting location.

Installation

Page 16

1-16 ACH550-UH User’s Manual

3

IP2000

1

2

3

4

1

2

FM

1

R70020

Remove front cover

R1…R6, UL type 1

1. Remove the control panel, if attached.

2. Loosen the captive screw at the top.

3. Pull near the top to remove the cover.

R1…R6, UL type 12

1. If hood is present: Remove screws (2) holding

the hood in place.

2. If hood is present: Slide hood up and off of the

cover.

3. Loosen the captive screws around the edge of

the cover.

4. Remove the cover.

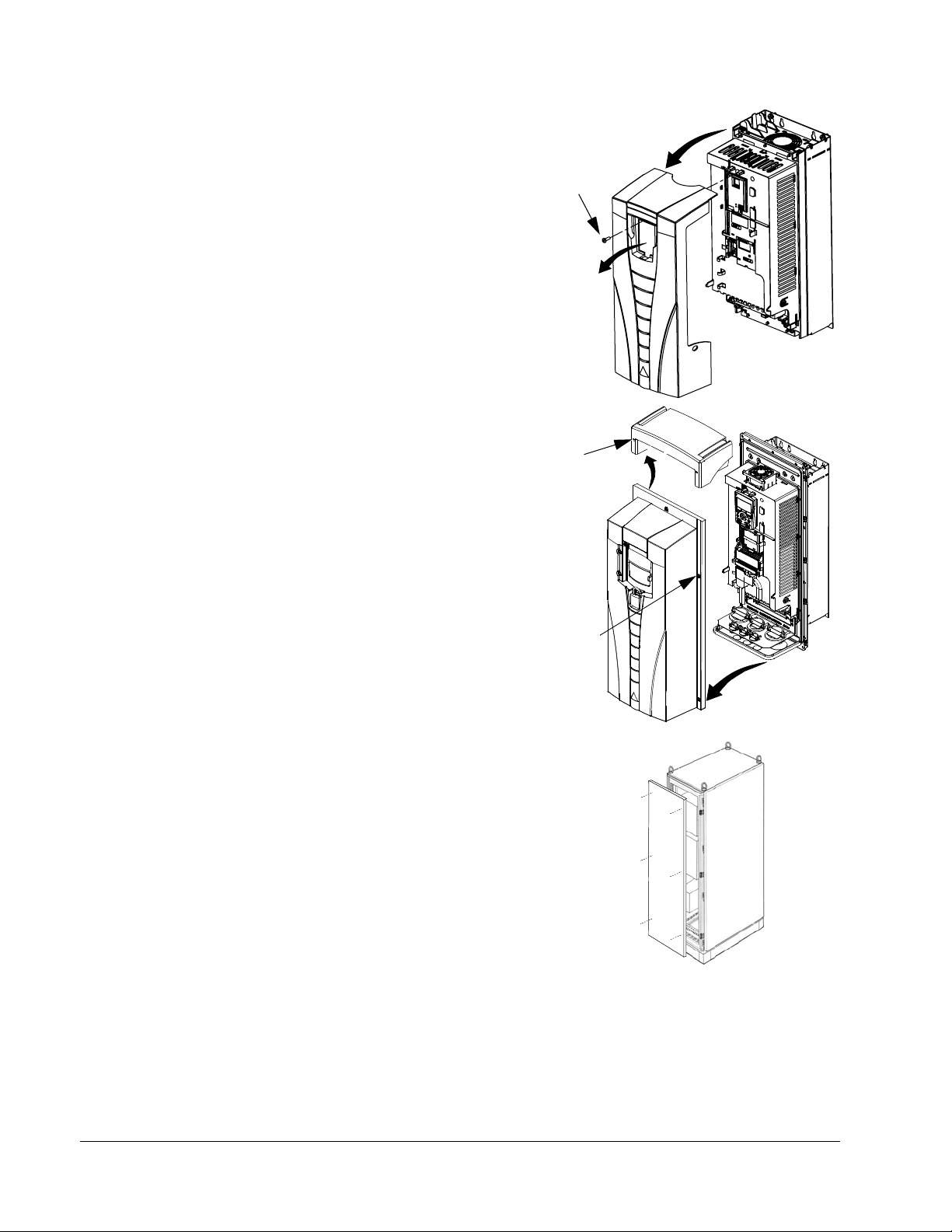

R7…R8, Cabinet Door

1. To open the cabinet door, loosen the quarterturn screws that hold the cabinet door closed.

R7…R8, Side Panels

The side panels were removed to take the

cabinet off the pallet. Installation access is

easier if these panels are kept off throughout

the installation.

Installation

Page 17

ACH550-UH User’s Manual 1-17

IP2002

1

2

2

1, 3

FM

PC00003

30

o

Mount the drive

R1…R6, UL type 1

1. Position the ACH550 onto the mounting screws

or bolts and securely tighten in all four corners.

Note: Lift the ACH550 by its metal chassis.

2. Non-English speaking locations: Add a warning

sticker in the appropriate language over the

existing warning on the top of the module.

R1…R6, UL type 12

For the UL type 12 enclosures, rubber plugs are required in the holes provided for

access to the drive mounting slots.

1. As required for access, remove the rubber plugs.

Push plugs out from the back of the drive.

2. R5 & R6: Align the sheet metal hood (not shown)

in front of the drive’s top mounting holes. (Attach

as part of next step.)

3. Position the ACH550 onto the mounting screws

or bolts and securely tighten in all four corners.

Note: Lift the ACH550 by its metal chassis

(frame size R6 by the lifting holes on both sides

at the top).

4. Re-install the rubber plugs.

5. Non-English speaking locations: Add a warning sticker in the appropriate language

over the existing warning on the top of the module.

R7…R8

1. Use a hoist to move the cabinet into position.

Note: If the cabinet location does not provide access to

the cabinet sides, be sure to re-mount side panels before

positioning cabinet.

2. Install and tighten mounting bolts.

Installation

Page 18

1-18 ACH550-UH User’s Manual

Wiring overview

Conduit kit

Wiring R1…R6 drives with the UL type 1 Enclosure requires a conduit kit with the

following items:

• conduit box

• screws

• cover

The kit is included with UL type 1 Enclosures.

Wiring requirements

WARNING! Ensure the motor is compatible for use with the ACH550. The ACH550

must be installed by a competent person in accordance with the considerations

defined in Preparing for installation on page 1-10. If in doubt, contact your local ABB

sales or service office.

As you install the wiring, observe the following:

• There are two sets of wiring instructions – one set for each enclosure type (UL

type 1 and UL type 12). Be sure to select the appropriate procedure.

• For the power connection points on the drive see the Connection diagrams

section below.

• Use separate, metal conduit runs to keep these three classes of wiring apart:

– Input power wiring.

– Motor wiring. (Use a separate, metal conduit run for each drive)

– Control/communications wiring.

• When installing input power and motor wiring, refer to the following, as

appropriate:

Terminal Description Specifications and Notes

U1, V1, W1* 3-phase power supply input Input power connections on page 1-303.

PE Protective Ground Ground connections on page 1-307.

U2, V2, W2 Power output to motor Motor connections on page 1-311.

* The ACH550 -xx-xxxx-2 (208…240V series) can be used with a single phase supply, if output

current is derated by 50%. For single phase supply voltage connect power at U1 and W1.

• To locate input power and motor connection terminals, see Connection diagrams

starting on page 1-20. For specifications on power terminals, see Drive’s power

connection terminals on page 1-309.

Installation

• For corner grounded TN systems, see section Unsymmetrically grounded

networks on page 1-307.

• For IT systems, see section Floating networks on page 1-308.

• For frame size R6, see Power terminal considerations – R6 Frame size on page

1-309 to install the appropriate cable lugs.

Page 19

ACH550-UH User’s Manual 1-19

• For details on control connections, refer to the following sections:

– Drive’s control connection terminals on page 1-318.

– Control connections on page 1-317.

– Application macros starting on page 1-49.

– Complete parameter descriptions on page 1-80.

– Embedded fieldbus on page 1-187.

– Fieldbus adapter on page 1-261.

• For electro-magnetic compliance (EMC), follow local codes and the requirements

in Motor cable requirements for CE & C-Tick compliance on page 1-313. For

example:

– Properly ground the wire screen cable shields.

– Keep individual un-screened wires between the cable clamps and the screw

terminals as short as possible.

– Route control cables away from power cables.

Installation

Page 20

1-20 ACH550-UH User’s Manual

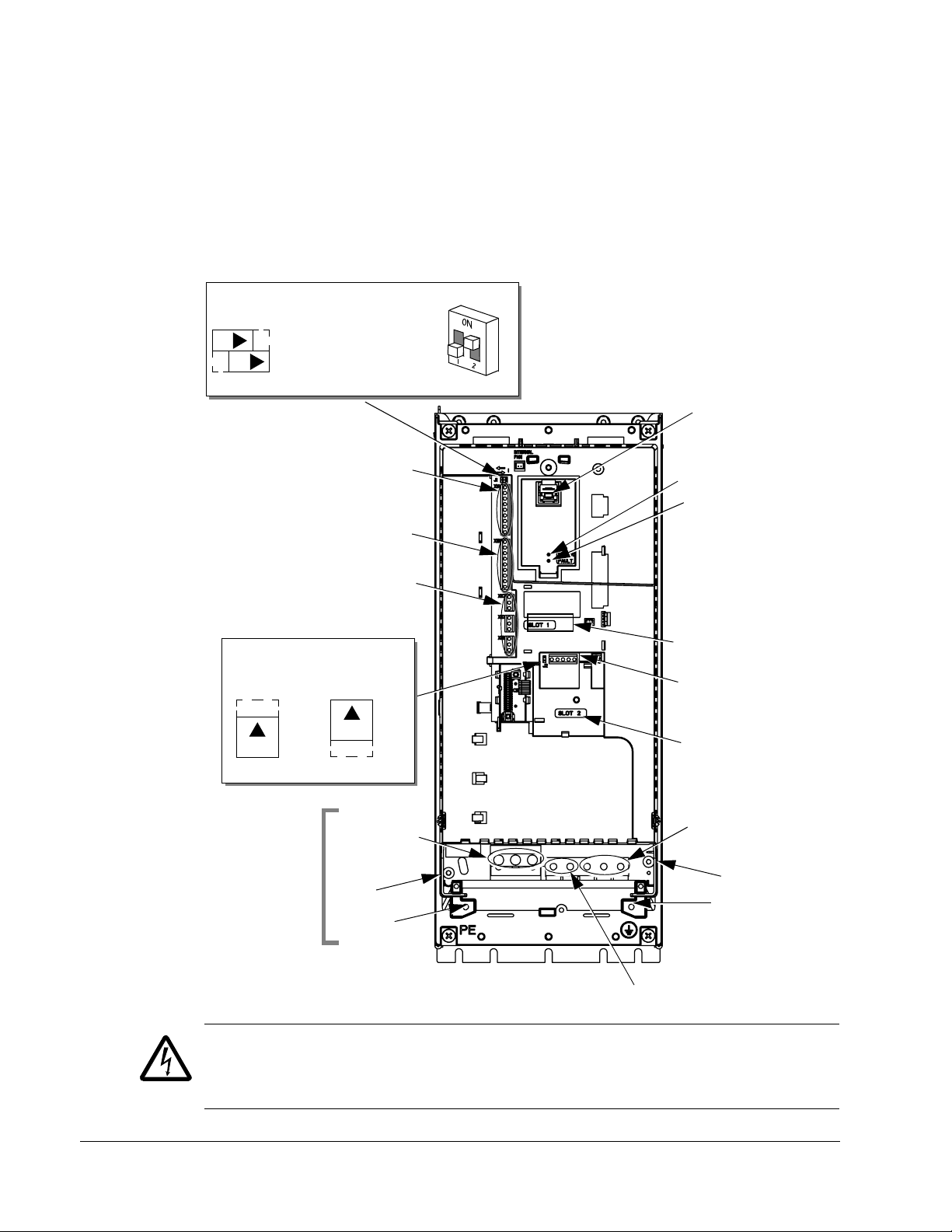

Panel Connector

Power LED (Green)

Fault LED (Red)

Optional Module 1

X1 – Communications

Optional Module 2

GND

Power Output to Motor

Power Input

EM1

X1 – Analog Inputs and Outputs

X1 – Digital Inputs

X1 – Relay Outputs

(and 10 V Ref. Voltage Output)

(and 24 V Aux. Voltage Output)

EM3

PE

(U1, V1, W1)

(U2, V2, W2)

X0003

(RS485)

R5/R6 differ.

See next page.

Frame Sizes

R1…R4 (Diagram shows the R3 frame.)

J2 – DIP Switches

J2

ON

off position on position

for RS485 Termination

J2

ON

Terminals Not Used

J1 – DIP Switches for Analog Inputs

AI1: (in Voltage Position)

AI2: (in Current Position)

ON

ON

The switch is one of two types:

Alternate

Original

Illustration of available switch

positions; not default settings

Illustration of available switch

positions; not default settings

Connection diagrams

The following diagrams show:

• The terminal layout for frame size R3, which, in general, applies to frame sizes

R1

• The R5/R6 power and ground terminals.

• The terminal layout for R7/R8.

…R6, except for the R5/R6 power and ground terminals.

Installation

WARNING! To avoid danger, or damage to the drive, on IT systems and corner

grounded TN systems, see section Disconnecting the internal EMC filter on

page 1-22.

Page 21

ACH550-UH User’s Manual 1-21

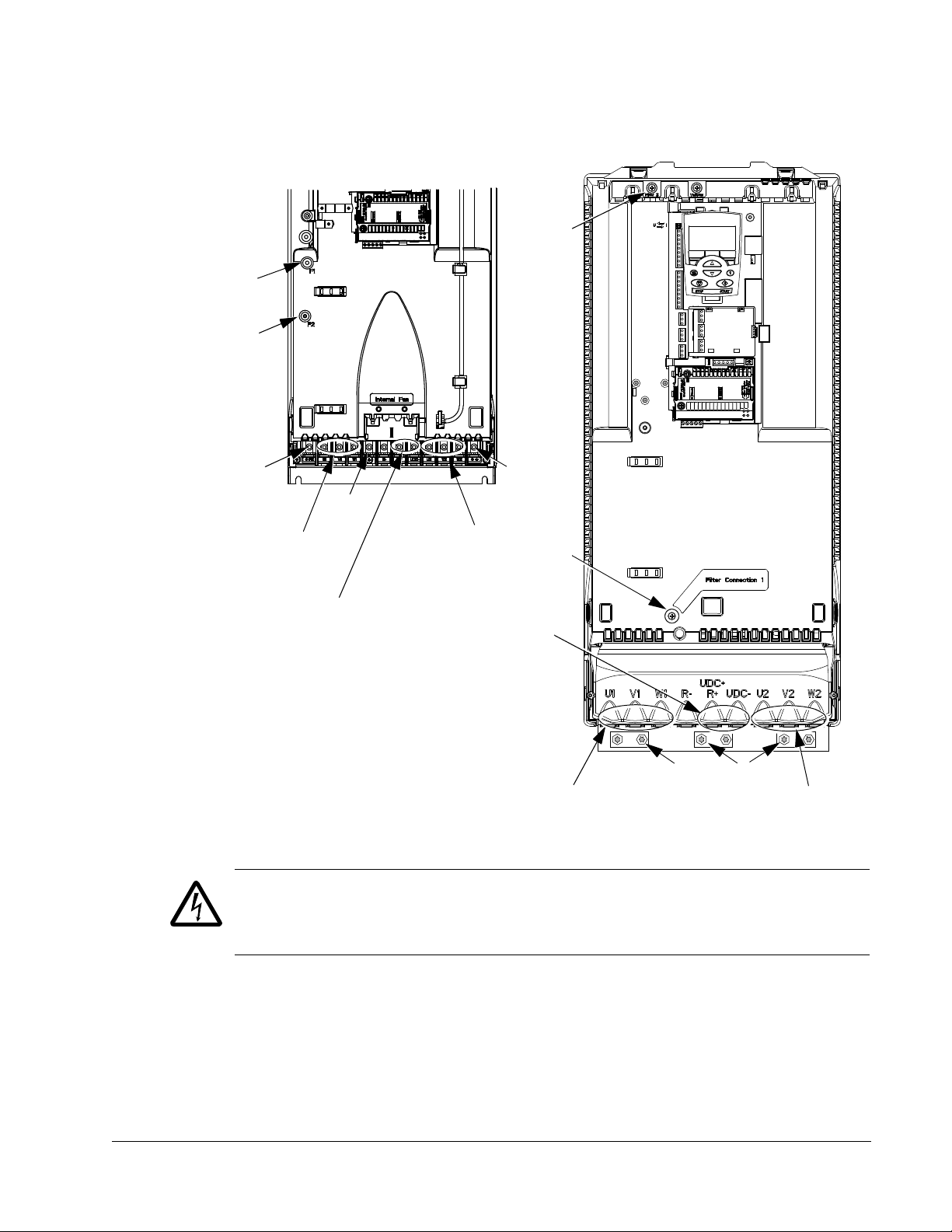

GND

Power Input

PE

(U1, V1, W1)

X0011

F1

F2

Power Input

PE

(U1, V1, W1)

F1

F2

X0013

Power Output to Motor

(U2, V2, W2)

R5 R6

GND

GND

Power Output to Motor

(U2, V2, W2)

Terminals Not Used

Terminals Not Used

The following diagram shows the power and ground terminal layout for frame sizes

R5 and R6.

WARNING! To avoid danger, or damage to the drive, on IT systems and corner

grounded TN systems, see section Disconnecting the internal EMC filter on

page 1-22.

Installation

Page 22

1-22 ACH550-UH User’s Manual

Ground Lug

Bar

ACH550

R7

Motor

Terminals

Input Power

Te rm in a ls

Control Wires

(X1)

Terminal Strip

Only on

ACH550-UH

The following diagram shows the power and ground terminal layout for frame size

R7 (R8 is similar).

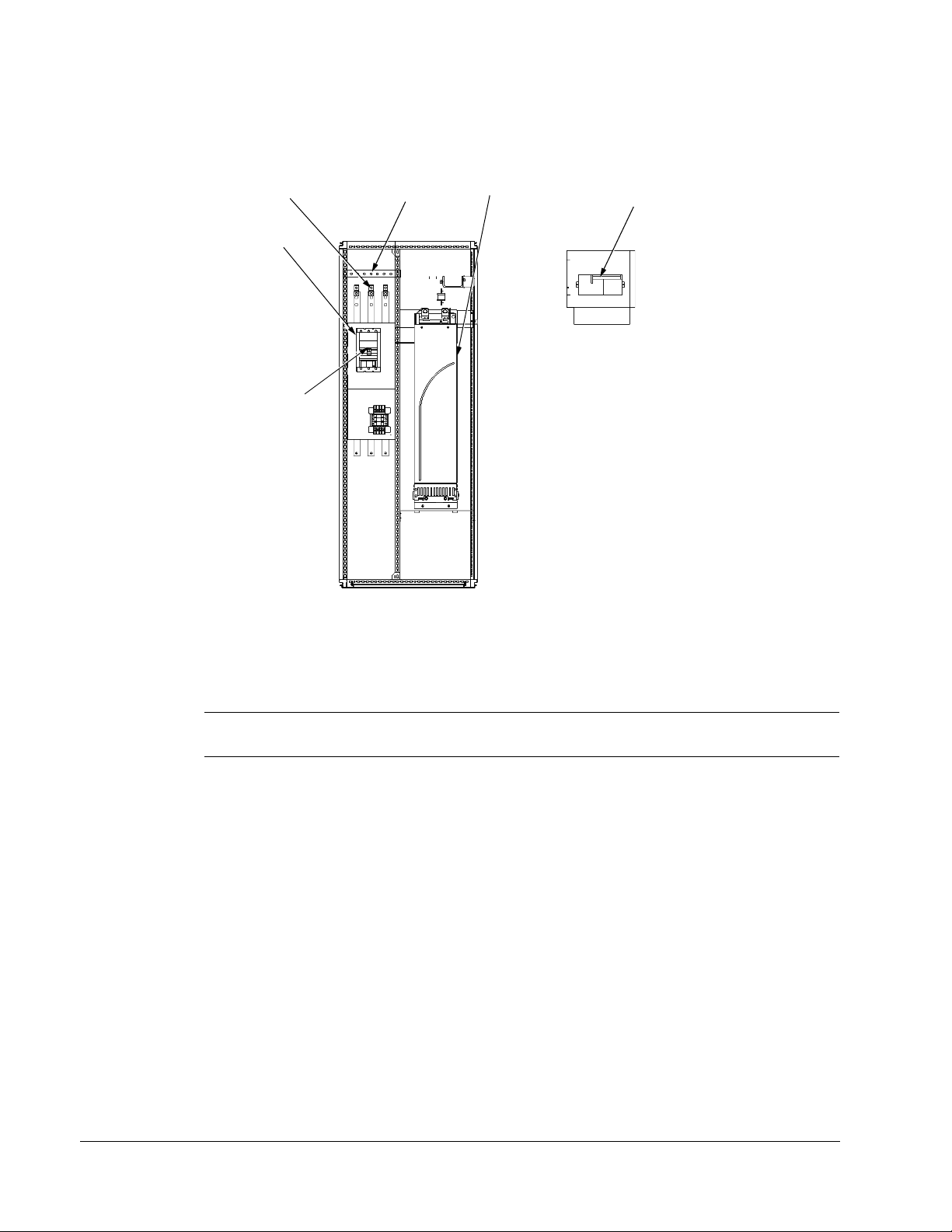

Disconnecting the internal EMC filter

On certain types of systems, you must disconnect the internal EMC filter, otherwise

the system will be connected to ground potential through the EMC filter capacitors,

which might cause danger, or damage the drive.

Note: When the internal EMC filter is disconnected, the drive is not EMC compatible.

The following table shows the installation rules for the EMC filter screws in order to

connect or disconnect the filter, depending on the system type and the frame size.

For more information on the different system types, see Floating networks on page

1-308 and Unsymmetrically grounded networks on page 1-307.

Installation

Page 23

ACH550-UH User’s Manual 1-23

PE

M

ohm

The locations of screws EM1 and EM3 are shown in the diagram on page 1-20. The

locations of screws F1 and F2 are shown in the diagram on page 1-21.

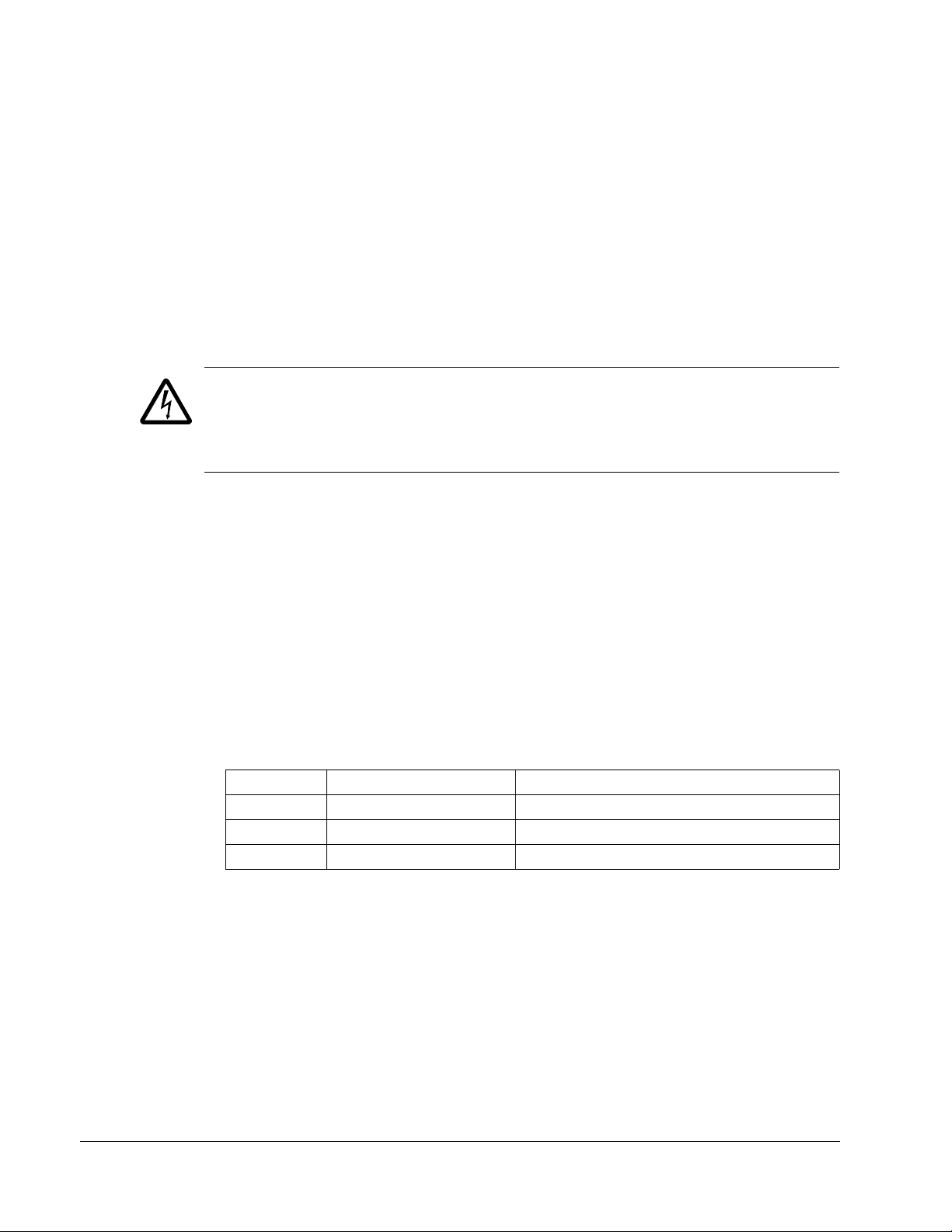

Frame

sizes

R1…R3

R4

R5…R6

x = Install the screw. (EMC filter will be connected.)

= Replace the screw with the provided polyamide screw. (EMC filter will be disconnected.)

–

= Remove the screw. (EMC filter will be disconnected.)

Screw

EM1 x x

EM3 x

EM1 x x –

EM3 x ––

F1 x x –

F2 x x –

Symmetrically

grounded TN systems

(TN-S systems)

Corner grounded

TN systems

IT systems (ungrounded

or high-resistance-

grounded [> 30 ohm])

Install the wiring

Checking motor and motor cable insulation

WARNING! Check the motor and motor cable insulation before connecting the drive

to input power. For this test, make sure that motor cables are NOT connected to the

drive.

1. Complete motor cable connections to the motor, but NOT to the drive output

terminals (U2, V2, W2).

2. At the drive end of the motor cable, measure the insulation

resistance between each motor cable phase and Protective

Earth (PE): Apply a voltage of 1 kV DC and verify that

resistance is greater than 1 Mohm.

Installation

Page 24

1-24 ACH550-UH User’s Manual

2

X0007

3

X0005

4

IP2004

7

7

5

10

8

IP2005

12

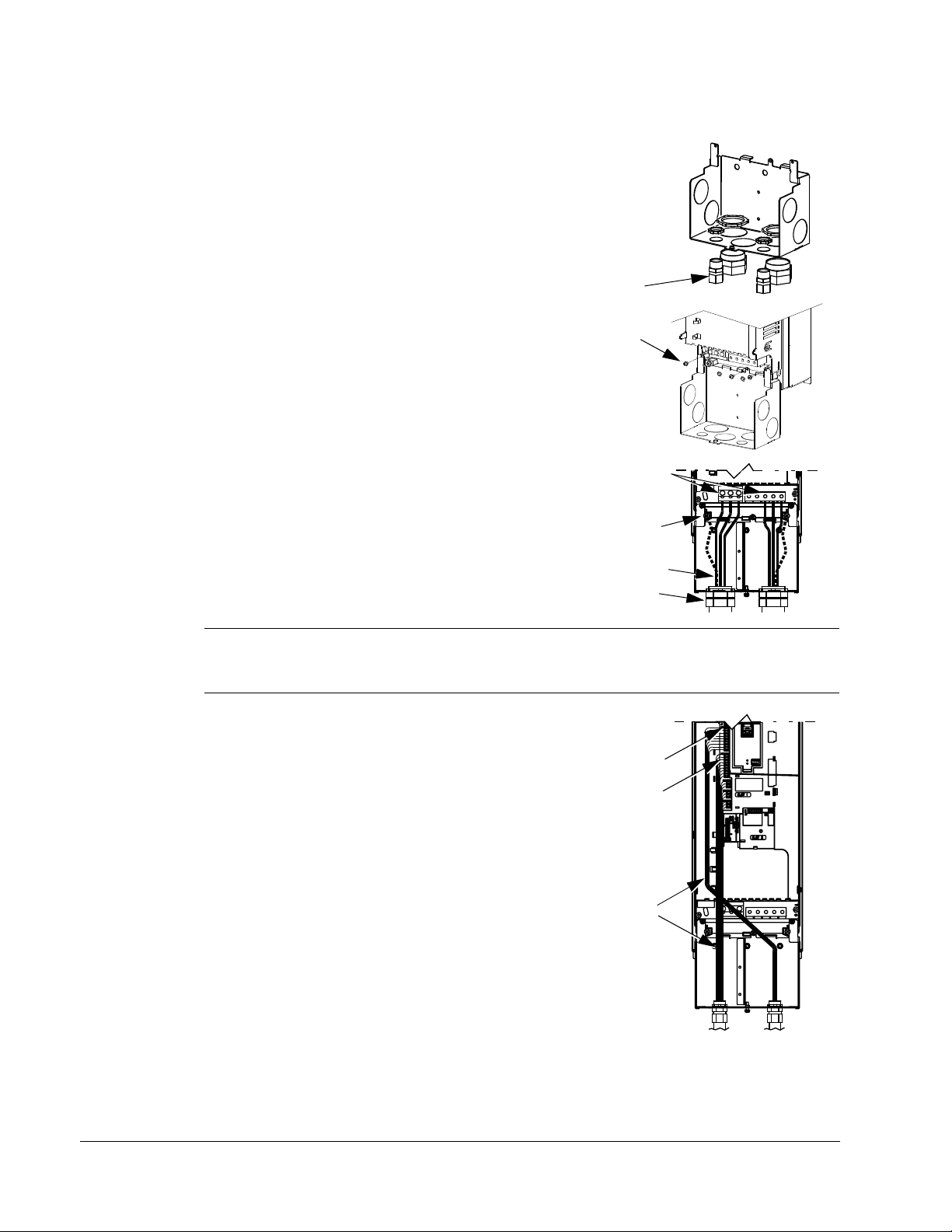

R1…R6, wiring UL type 1 enclosure

1. Open the appropriate knockouts in the

conduit box. (See Conduit kit on page 1-18.)

2. Install thin-wall conduit clamps (not supplied).

3. Install conduit box.

4. Connect conduit runs for input power, motor

and control cables to the box.

5. Route input power and motor wiring through

separate conduits.

6. Strip wires.

7. Connect power, motor, and ground wires to

the drive terminals. See Wiring requirements

on page 1-18 and table on the tightening

torques on page 1-309.

Note: For R5 frame size, the minimum power cable size is 25 mm2 (4 AWG). For R6

frame size, refer to Power terminal considerations – R6 Frame size on page 1-309.

8. Route the control cables through the conduit

(not the same conduit as either input power or

motor wiring).

9. Use available secure points and tie strap

landings to permanently secure control wiring

at a minimum distance of 6 mm (1/4") from

power wiring.

10. Strip the control cable sheathing and twist the

copper screen into a pig-tail.

11. Connect the ground screen pig-tail for digital

and analog I/O cables at X1-1. (Ground only

at drive end.)

12. Connect the ground screen pig-tail for RS485

cables at X1-28 or X1-32. (Ground only at

drive end.)

Installation

13. Strip and connect the individual control wires to the drive terminals. See Wiring

requirements on page 1-18.

14. Install the conduit box cover (1 screw).

Page 25

ACH550-UH User’s Manual 1-25

IP50131

R1…R4

IP5023

1

R5, R6

2

IP5006

3

IP5007

6

4

7

IP5008

9…11

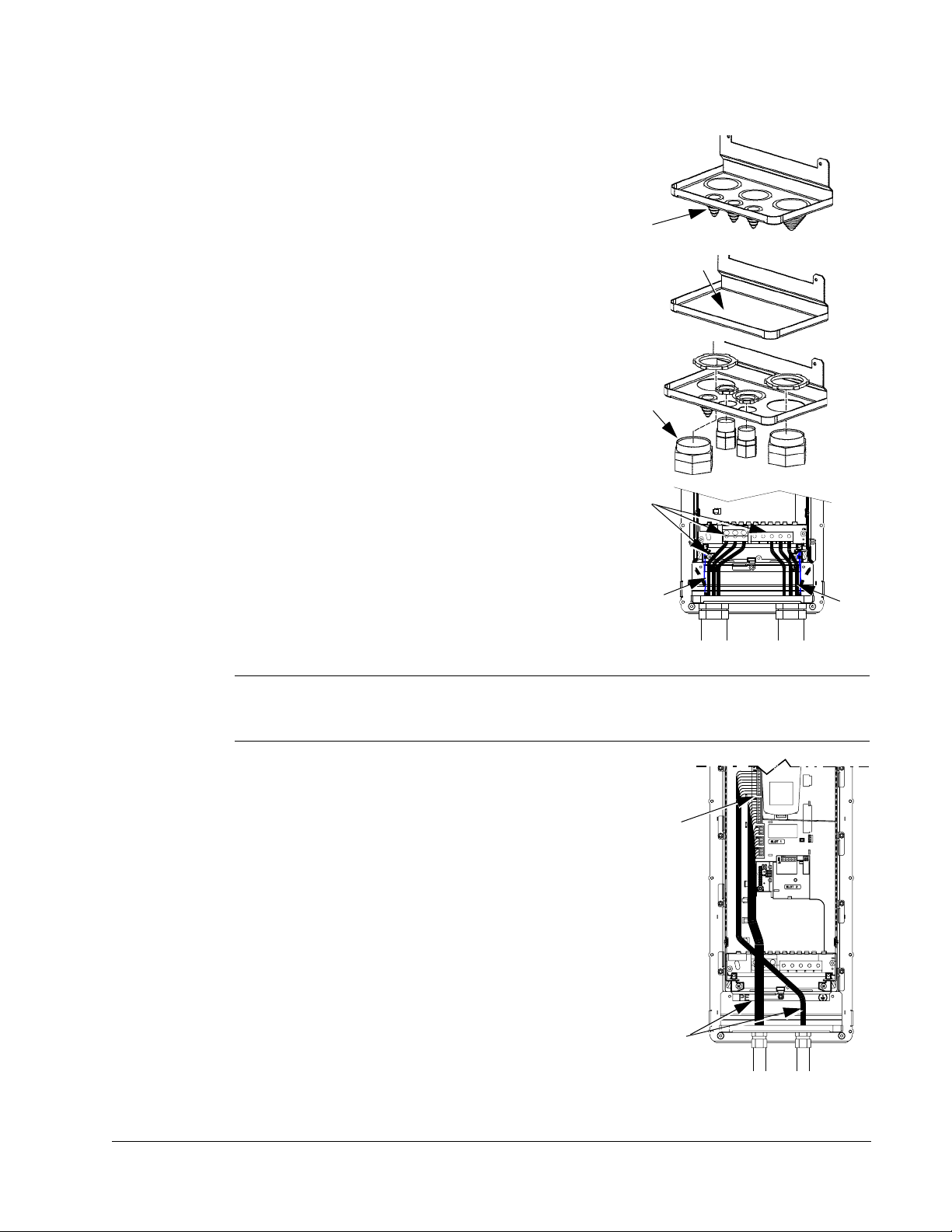

R1…R6, wiring UL type 12 enclosure

1. Step depends on Frame Size:

• Frame Sizes R1…R4: Remove and discard the

cable seals where conduit will be installed. (The

cable seals are cone-shaped, rubber seals on

the bottom of the drive.)

• Frame Sizes R4 and R5: Use punch to create

holes for conduit connections as needed.

2. For each conduit run (input power, motor and

control wiring must be separate), install water tight

conduit connectors (not supplied).

3. Route the power wiring through conduit.

4. Route the motor wiring through conduit (not the

same conduit as input power wiring run).

5. Strip the wires.

6. Connect the power, motor, and ground wires to

the drive terminals. See Wiring requirements on

page 1-18, Connection diagrams on page 1-20 and

table for tightening torques on page 1-309.

Note: For R5 frame size, the minimum power cable size is 25 mm2 (4 AWG). For R6

frame size, refer to Power terminal considerations – R6 Frame size on page 1-309.

7. Route the control cables through the conduit (not

the same conduit as either input power or motor

wiring runs).

8. Use available secure points and tie strap landings to

permanently secure control wiring at a minimum

distance of 6 mm (1/4") from power wiring.

9. Strip the control cable sheathing and twist the

copper screen into a pig-tail.

10. Connect the ground screen pig-tail for digital and

analog I/O cables at X1-1. (Ground only at drive

end.)

11. Connect the ground screen pig-tail for RS485 cables

at X1-28 or X1-32. (Ground only at drive end.)

12. Strip and connect the individual control wires to the drive

terminals. See Wiring requirements on page 1-18.

13. Install the conduit box cover (1 screw).

Installation

Page 26

1-26 ACH550-UH User’s Manual

BP0054

Input Power

Gnd

Cable

Term in al St r ip

Only on

ACH550-UH

BP0054

Motor

Gnd

Cable

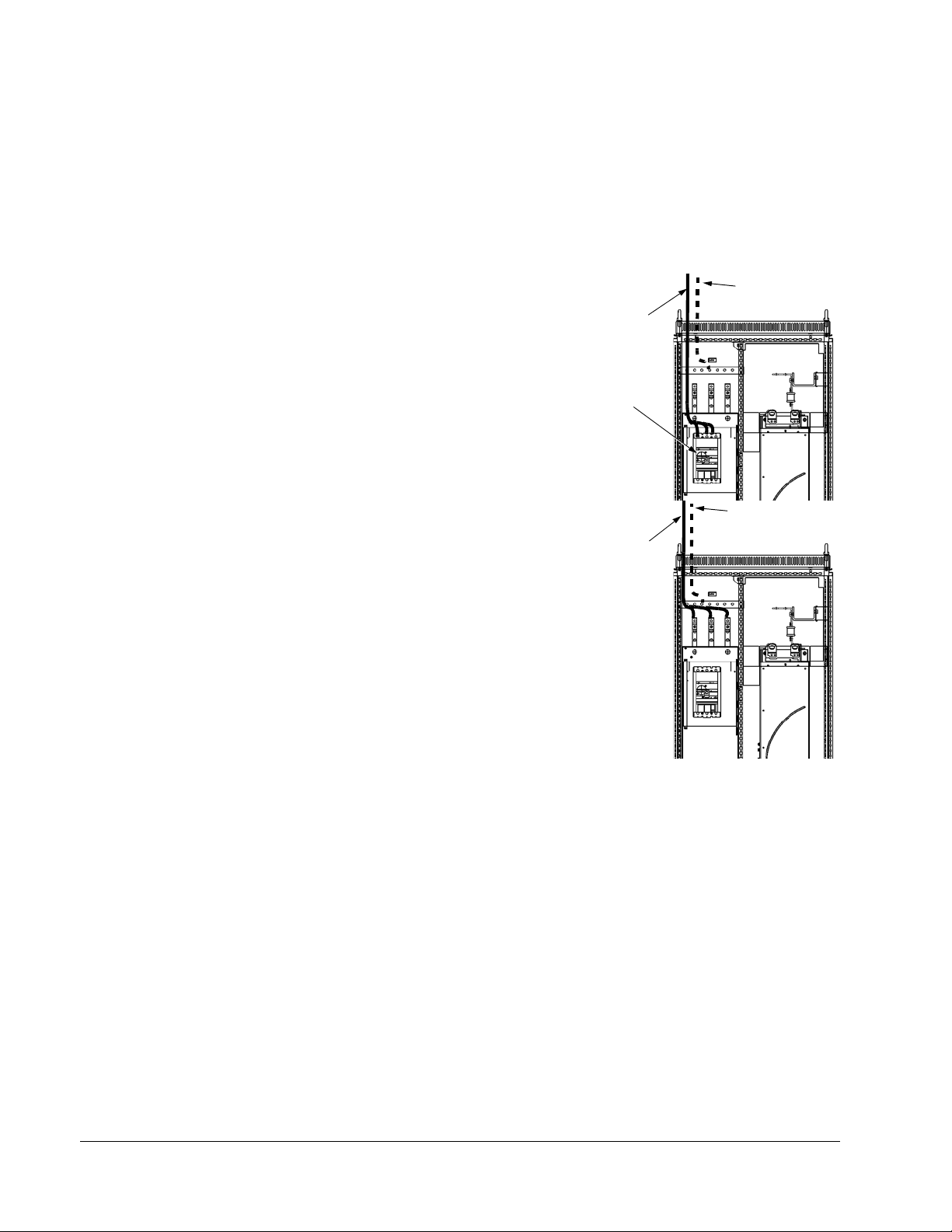

R7…R8, wiring (both enclosure types)

The figures show connections in the R7 cabinet, the R8 cabinet is similar.

1. Remove the conduit connection plate from the top of the left bay.

2. Route the input power, motor and control cables to the top of the cabinet. Each cable

type (input power, motor, and control) must be in separate conduit.

3. Use punch to create holes for conduit connections as needed.

4. UL type 12 Enclosure: For each conduit

run (input power, motor and control wiring

must be separate), install water tight

conduit connectors (not supplied).

5. Connect input power and motor cables to

the bus terminals. See Wiring requirements

on page 1-18, Connection diagrams on

page 1-20.

6. Connect grounds to ground bar.

7. Use available secure points and tie strap

landings to permanently secure control

wiring at a minimum distance of 6 mm

(1/4") from power wiring.

8. Strip the control cable sheathing and twist

the copper screen into a pig-tail.

9. Connect the ground screen pig-tail for

digital and analog I/O cables at X1-1.

(Ground only at drive end.)

10. Connect the ground screen pig-tail for

RS485 cables at X1-28 or X1-32. (Ground

only at drive end.)

11. Strip and connect the individual control wires to the drive terminals. See Wiring

requirements on page 1-18.

Installation

Page 27

ACH550-UH User’s Manual 1-27

3

1

2

IP2009

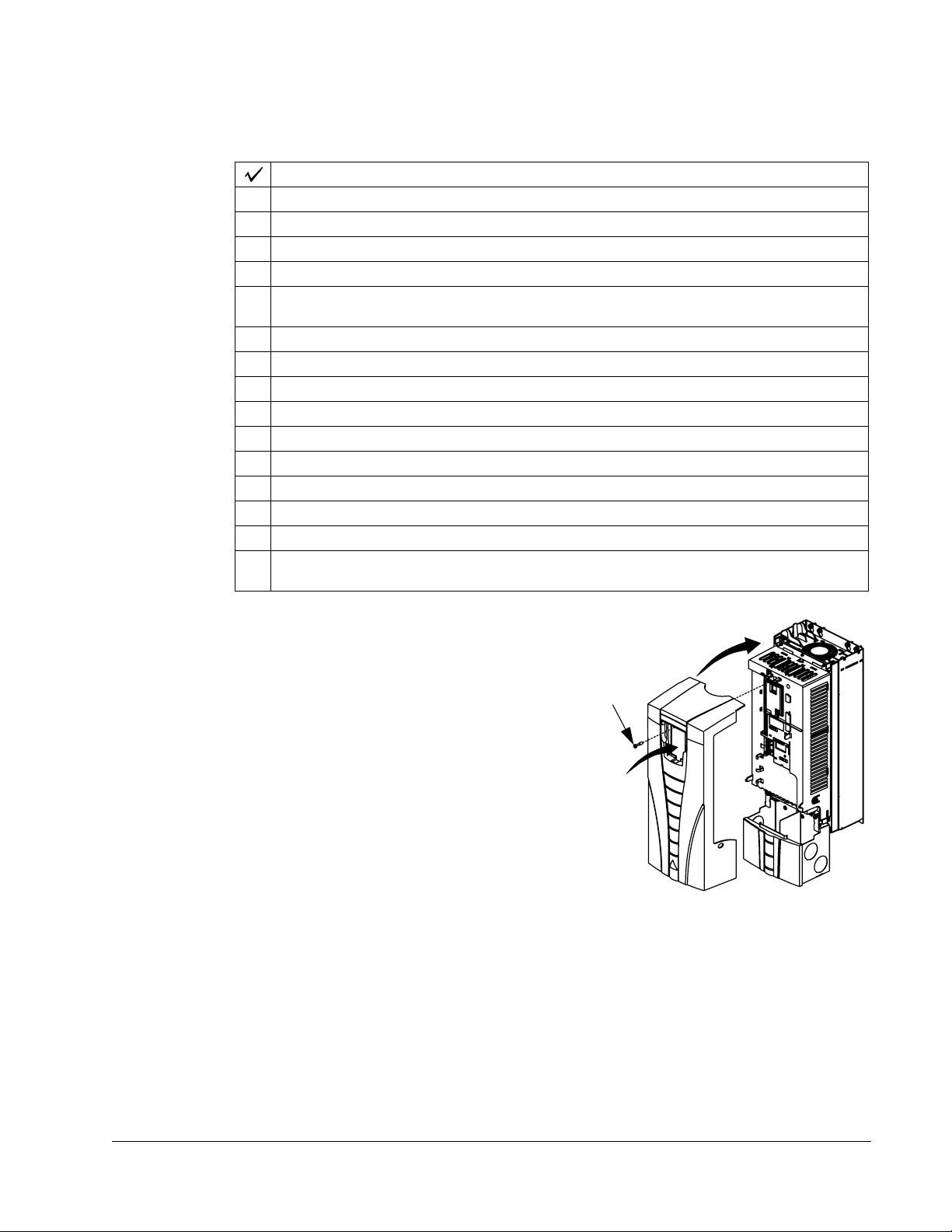

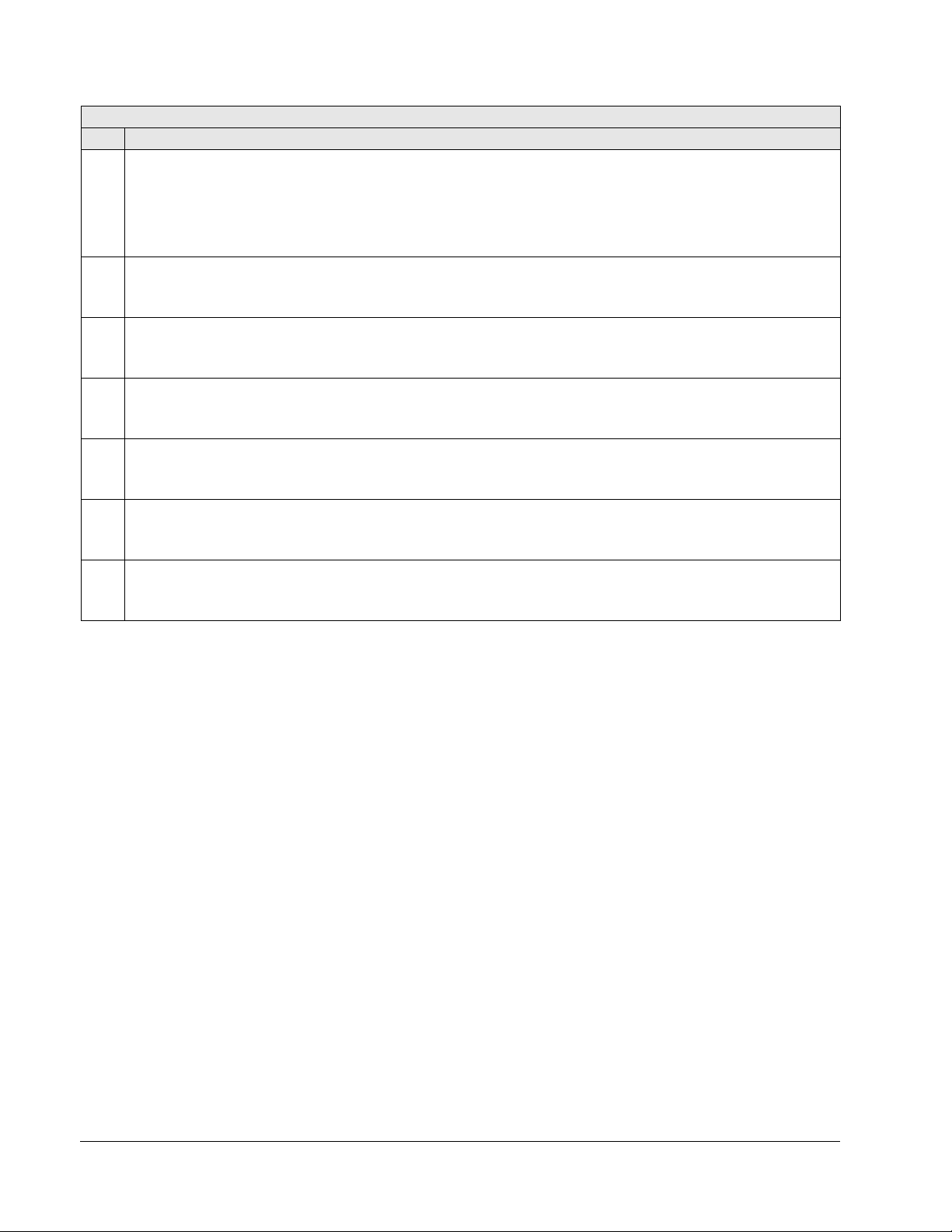

Check installation

Before applying power, perform the following checks.

Check

Installation environment conforms to the drive’s specifications for ambient conditions.

The drive is mounted securely.

Space around the drive meets the drive’s specifications for cooling.

The motor and driven equipment are ready for start.

For floating networks (R1…R6): The internal RFI filter is disconnected (screws EM1 & EM3 or

F1 & F2).

The drive is properly grounded.

The input power voltage matches the drive nominal input voltage range.

The input power connections at U1, V1, and W1 are connected and tightened as specified.

The input power branch circuit protection is installed.

The motor connections at U2, V2, and W2 are connected and tightened as specified.

The input power, motor and control wiring are routed through separate conduit runs.

NO power factor compensation capacitors are in the motor cable.

The control connections are connected and tightened as specified.

NO tools or foreign objects (such as drill shavings) are inside the drive.

NO alternate power source for the motor (such as a bypass connection) is connected – no

voltage is applied to the output of the drive.

Re-install cover

R1…R6, UL type 1

1. Align the cover and slide it on.

2. Tighten the captive screw.

3. Re-install the control panel.

Installation

Page 28

1-28 ACH550-UH User’s Manual

2

1

4

3

5

6

FM

1

R70020

R1…R6, UL type 12

1. Align the cover and slide it on.

2. Tighten the captive screws around the edge of

the cover.

3. R1…R4: Slide the hood down over the top of

the cover.

4. R1…R4: Install the two screws that attach the

hood.

5. Re-install the control panel.

Note: The control panel window must be closed

to comply with UL type 12.

6. Optional: Add a lock (not supplied) to secure

the control panel window.

R7…R8, Covers

1. If side panels were removed and not remounted,

mount them now. Each panel requires 6 torx

screws.

2. Re-mount all high voltage shields.

3. Close all internal swing-out panels and secure in

place with the quarter-turn screws.

4. Close the cabinet door and secure in place with

the quarter-turn screws.

Installation

Page 29

ACH550-UH User’s Manual 1-29

U1 V1 W1 U2 V2 W2

L1

L2

L3

Motor

Drive

Input

FM

U1 V1 W1 U2 V2 W2

L1

L2

L3

Motor

Drive

Input

To change rotation direction,

switch motor leads

GND

GND

GND

GND

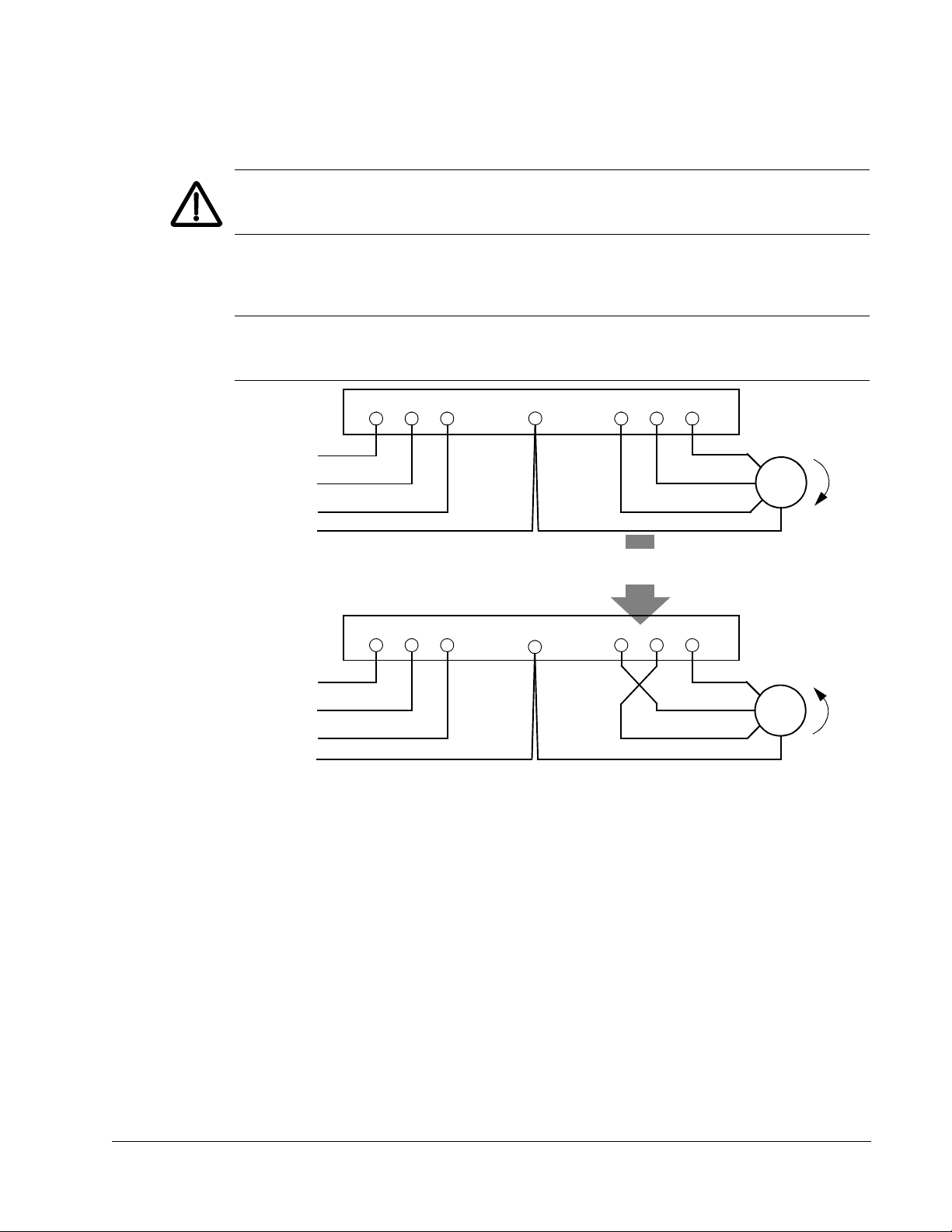

Apply power

Always re-install the covers before turning power on.

WARNING! The ACH550 will start up automatically at power up, if the external run

command is on.

1. Apply input power.

When power is applied to the ACH550, the green LED comes on.

Note: Before increasing motor speed, check that the motor is running in the desired

direction. To change rotation direction, switch motor leads as shown below.

Installation

Page 30

1-30 ACH550-UH User’s Manual

Start-up

The ACH550 has default parameter settings that are sufficient for many situations.

However, review the following situations. Perform the associated procedures as

appropriate.

Spin motor

When first installed and started the control panel displays a welcome screen with the

following options.

• Press Exit to commission the drive as described in section Start-up by changing

the parameters individually on page 1-47.

• Press Enter to move to the following options:

– Select “Commission Drive” to commission the drive as described in section

Start-Up by Start-up by using the Start-Up Assistant on page 1-47.

– Select “Spin Motor” to operate the motor prior to commissioning. This option

operates the motor without any commissioning, except entry of the motor data

as described below. Spin Motor is useful, for example, to operate ventilation

fans prior to commissioning.

Note: When using Spin Motor, the motor speed is limited to the range 1/3…2/3 of

maximum speed. Also, no interlocks are activated. Finally, once the drive is

commissioned, the welcome screen and this option no longer appear.

Motor data

The motor data on the ratings plate may differ from the defaults in the ACH550. The

drive provides more precise control and better thermal protection if you enter the

rating plate data.

1. Gather the following from the motor ratings plate:

• Voltage

• Nominal motor current

• Nominal frequency

• Nominal speed

• Nominal power

2. Edit parameters 9905…9909 to the correct values.

• Assistant Control Panel: The Start-Up Assistant walks you through this data entry

(see page 1-37).

• Basic Control Panel: Refer to Parameters Mode on page 1-35, for parameter

editing instructions.

Installation

Page 31

ACH550-UH User’s Manual 1-31

Macros

Note: Selecting the appropriate macro should be part of the original system design,

since the control wiring installed depends on the macro used.

1. Review the macro descriptions in Application macros on page 1-49. Use the macro

that best fits system needs.

2. Edit parameter 9902 to select the appropriate macro. Use either of the following:

• Use the Start-up Assistant, which displays the macro selection immediately after

motor parameter setup.

• Refer to Parameters Mode on page 1-35, for parameter editing instructions.

Tuning – parameters

The system can benefit from one or more of the ACH550 special features, and/or

fine tuning.

1. Review the parameter descriptions in Complete parameter descriptions starting on

page 1-80. Enable options and fine tune parameter values as appropriate for the

system.

2. Edit parameters as appropriate.

Fault and alarm adjustments

The ACH550 can detect a wide variety of potential system problems. For example,

initial system operation may generate faults or alarms that indicate set-up problems.

1. Faults and alarms are reported on the control panel with a number. Note the number

reported.

2. Review the description provided for the reported fault/alarm:

• Use the fault and alarm listings on pages 1-282 and 1-288 respectively, or

• Press the help key (Assistant Control Panel only) while fault or alarm is displayed.

3. Adjust the system or parameters as appropriate.

Installation

Page 32

1-32 ACH550-UH User’s Manual

Installation

Page 33

ACH550-UH User’s Manual 1-33

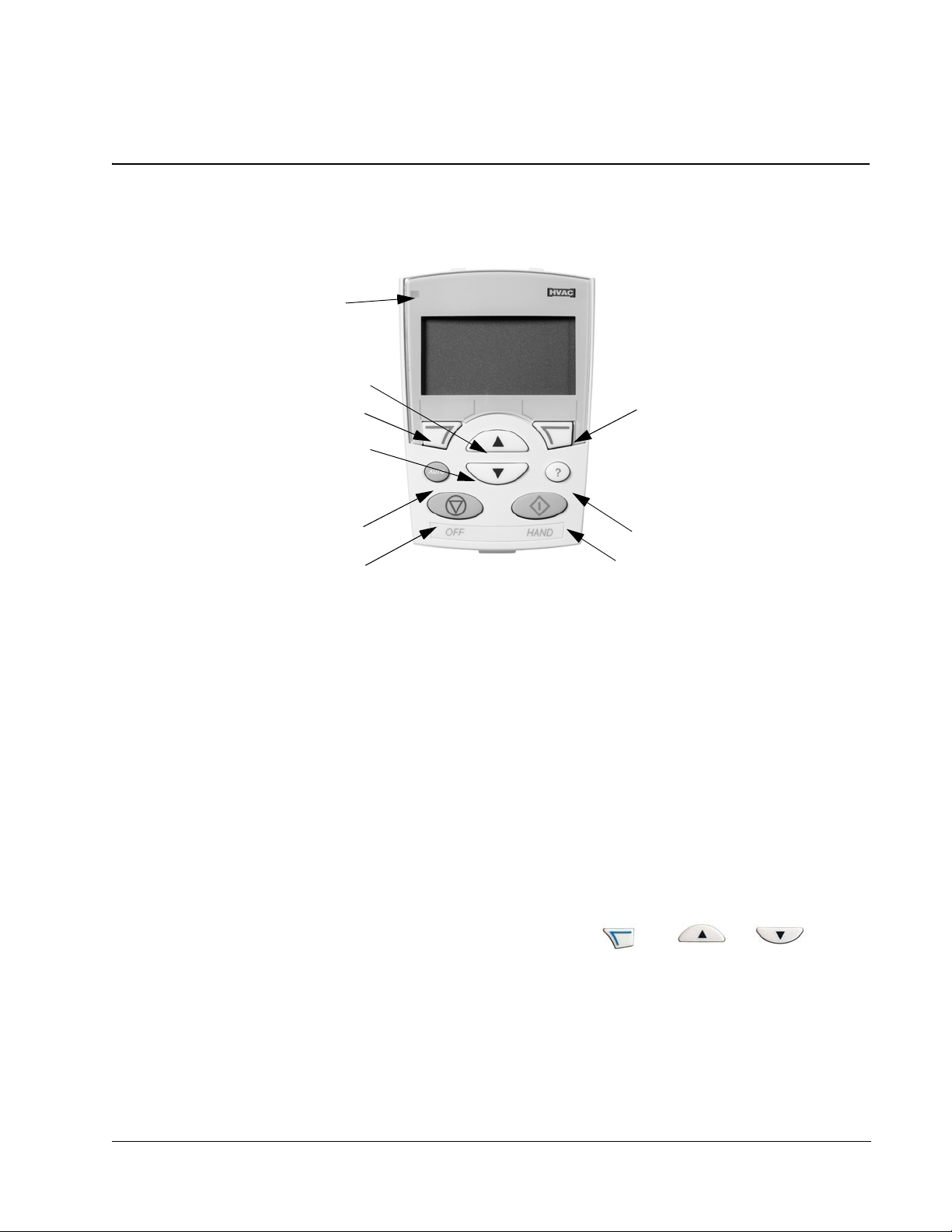

Status LED

UP

SOFT

KEY 1

DOWN

OFF

SOFT

KEY 2

HELP (always available)

HAND

AUTO

(Green when normal,

if flashing or red,

see Diagnostics.)

X0201

Control panel

HVAC control panel features

The ACH550 HVAC control panel (ACS-CP-B) features:

• Language selection for the display

• Drive connection that can be made or detached at any time

• Start-up assistant to facilitate drive commissioning

• Copy function for moving parameters to other ACH550 drives

• Backup function for saving parameter sets

• Context sensitive help

• Real-time clock

General display features

Soft key functions

The soft key functions are defined by text displayed just above each key.

Display contrast

To adjust display contrast, simultaneously press and or , as

appropriate.

Control panel

Page 34

1-34 ACH550-UH User’s Manual

HVAC control panel modes

The HVAC control panel has several different modes for configuring, operating and

diagnosing the drive. The modes are:

• Standard Display Mode – Shows drive status information and operates the drive.

• Parameters Mode – Edits parameter values individually.

• Start-up Assistant Mode – Guides the start-up and configuration.

• Changed Parameters Mode – Shows changed parameters.

• Fault Logger Mode – Shows the drive fault history.

• Drive Parameter Backup Mode – Stores or uploads the parameters.

• Clock Set Mode – Sets the time and date for the drive.

• I/O Settings Mode – Checks and edits the I/O settings.

• Alarm Mode – Reporting mode triggered by drive alarms.

Standard Display Mode

Use the Standard Display Mode to read information on the drive’s status and to

operate the drive. To reach the Standard Display Mode, press EXIT until the LCD

display shows status information as described below.

Status information

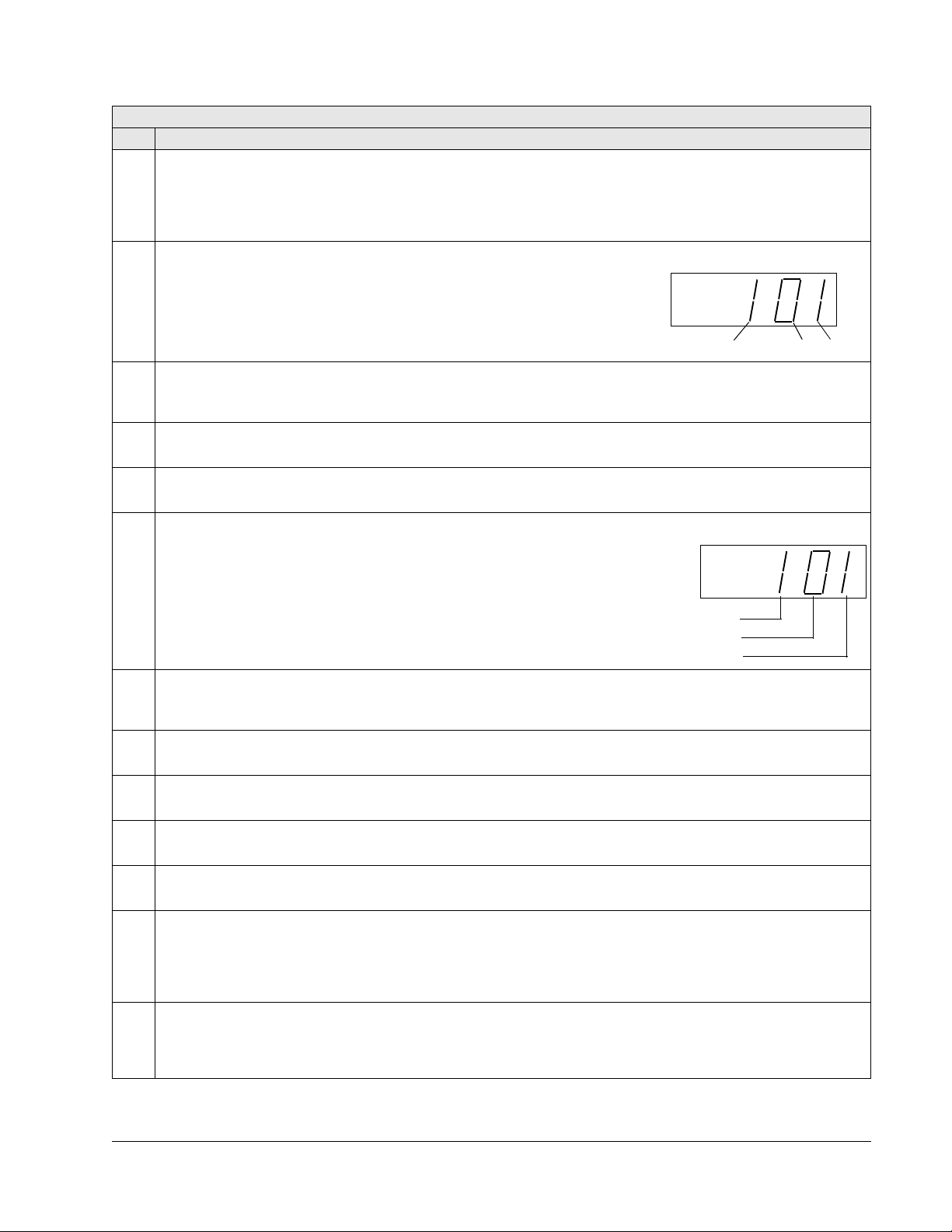

Top. The top line of the LCD display shows the basic status information of the drive.

• HAND – Indicates that the drive control is local, that is, from the control panel.

•AUTO – Indicates that the drive control is remote, such as the basic I/O (X1) or

fieldbus.

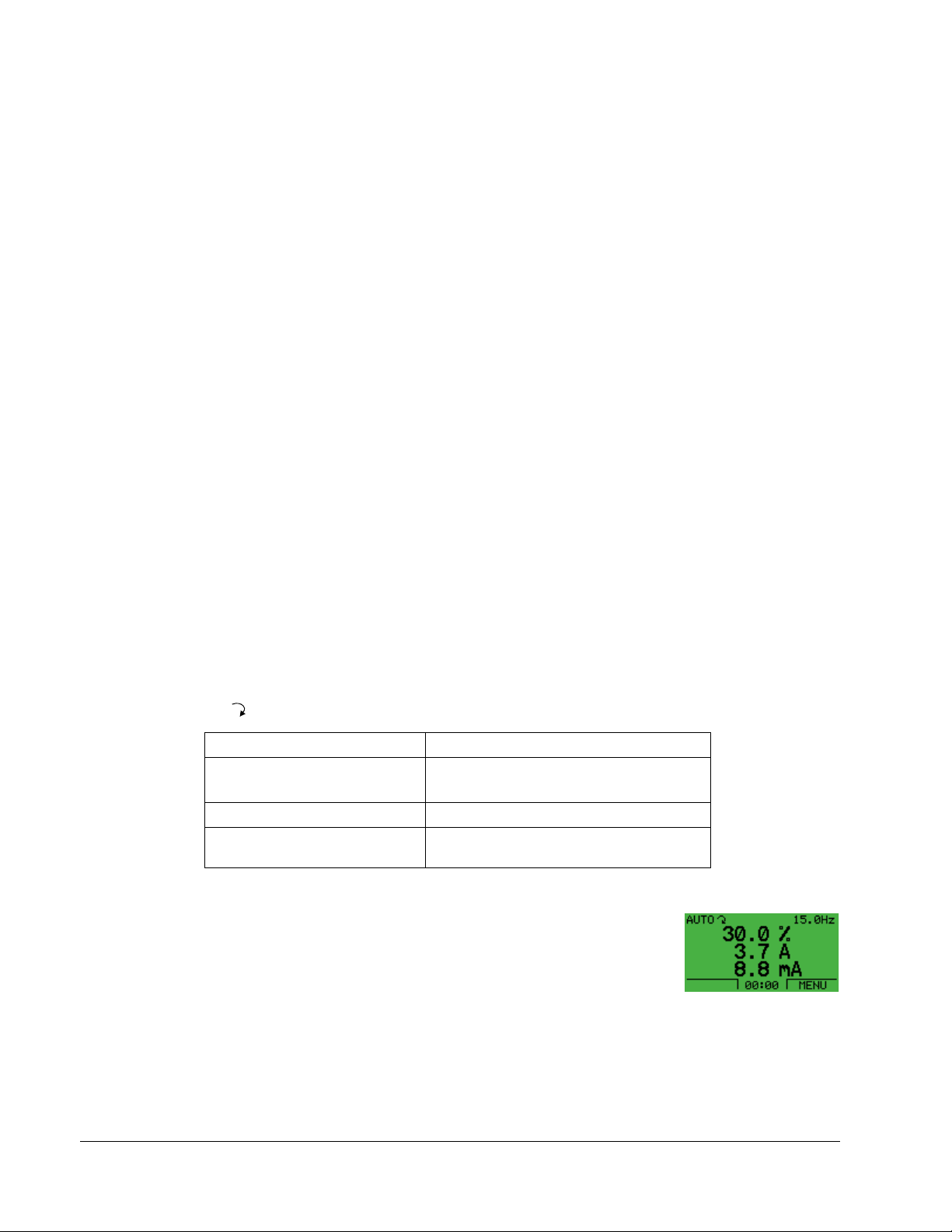

• – Indicates the drive and motor rotation status as follows:

Control panel display Significance

Rotating arrow (clockwise or

counterclockwise)

Rotating dotted arrow blinking Drive is running but not at setpoint

Stationary dotted arrow Start command is present, but motor is not

• Drive is running and at setpoint

• Shaft direction is forward or reverse

running. E.g. start enable is missing.

• Upper right – shows the active reference.

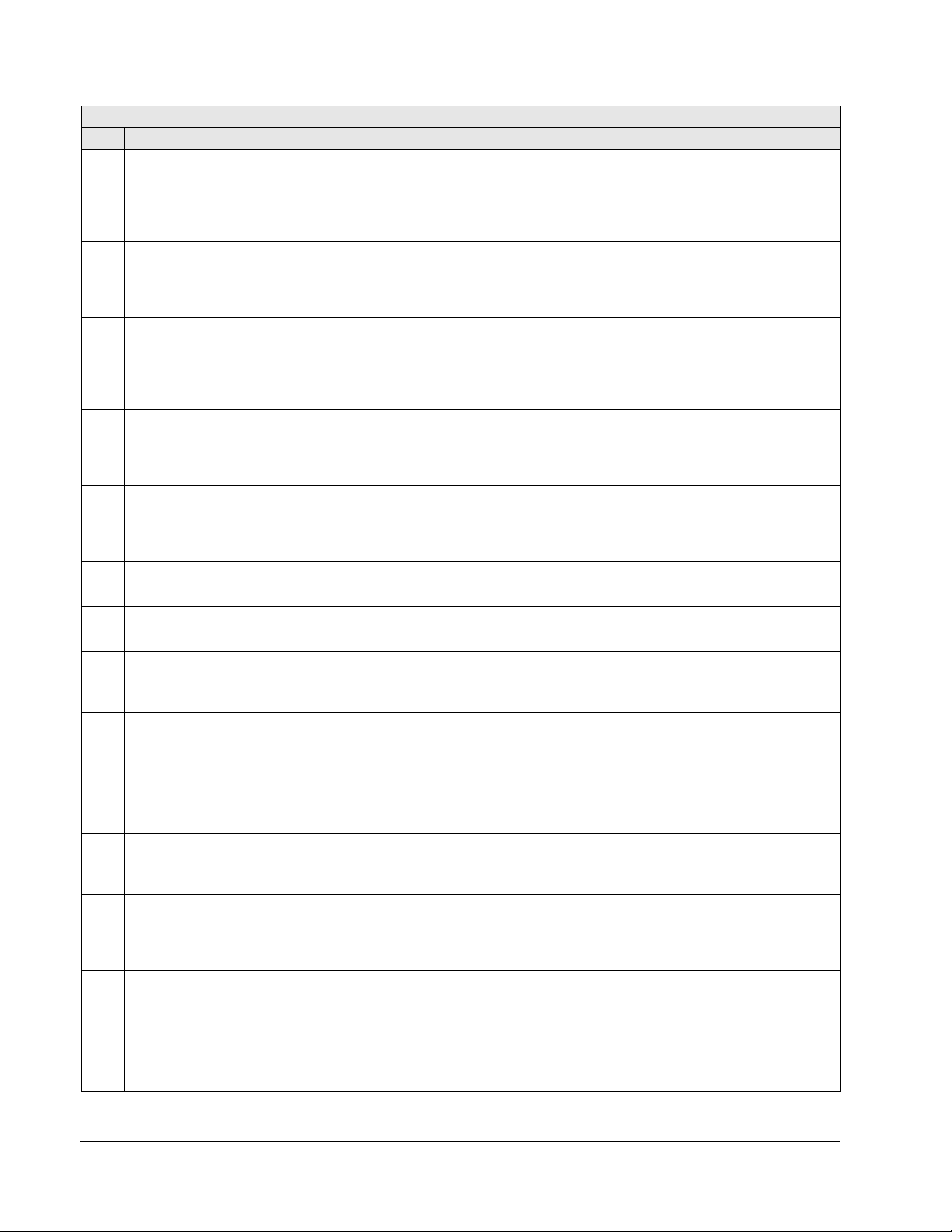

Middle. Using parameter group 34, the middle of the LCD

display can be configured to display:

• One to three parameter values – The default display shows

parameters 0103 (OUTPUT FREQ) in percentages, 0104

(CURRENT) in amperes and 0120 (AI1) in milliamperes.

Control panel

– Use parameters 3401, 3408, and 3415 to select the parameters (from Group

01) to display. Entering “parameter” 0100 results in no parameter displayed.

For example, if 3401 = 0100 and 3415 = 0100, then only the parameter

specified by 3408 appears in the Control Panel display.

Page 35

ACH550-UH User’s Manual 1-35

– You can also scale each parameter in the display, for example, to convert the

motor speed to a display of conveyor speed. Parameters 3402…3405 scale

the parameter specified by 3401, parameters 3409…3412 scale the parameter

specified by 3408, etc.

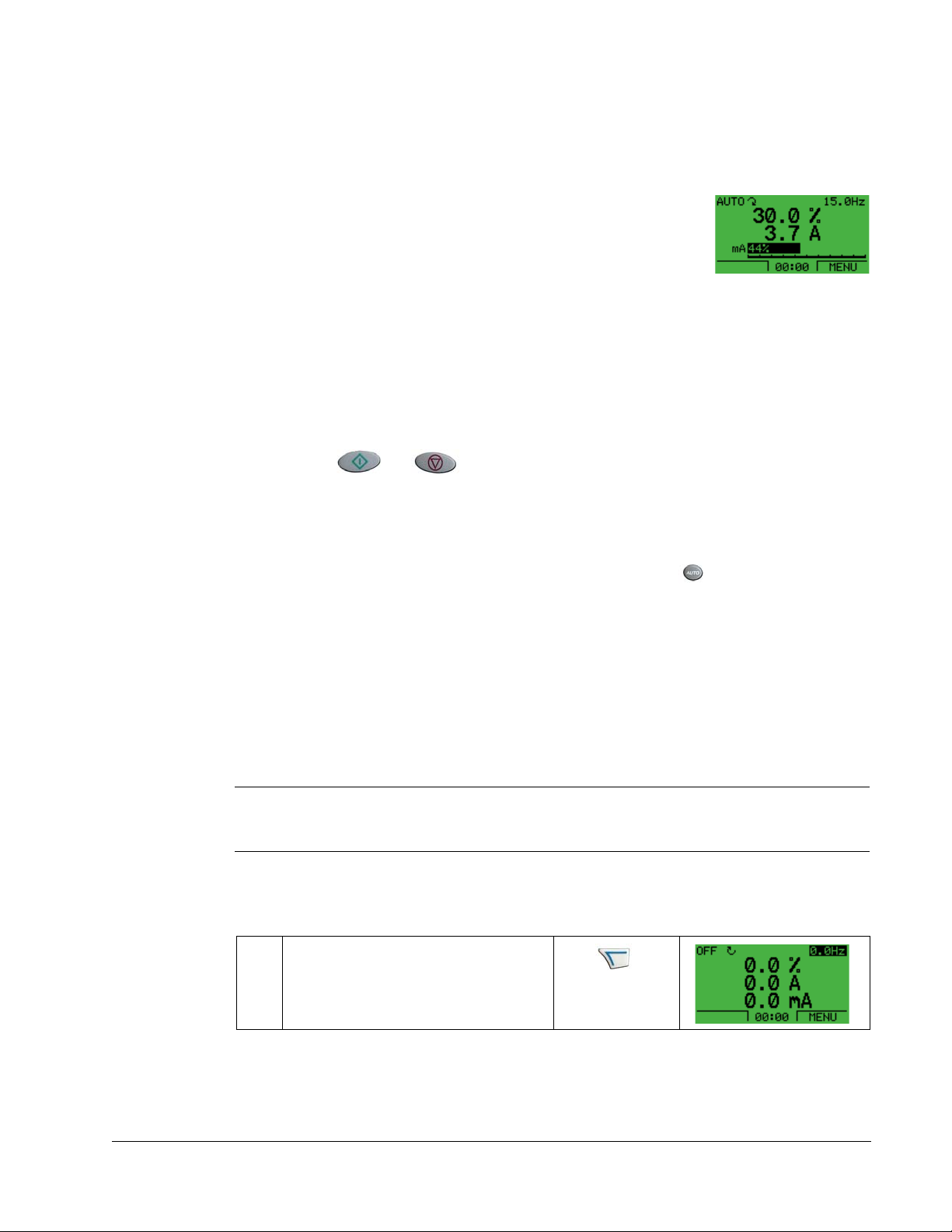

• A bar meter rather than one of the parameter values.

– Enable bar graph displays using parameters 3404, 3411

and 3418.

Bottom. The bottom of the LCD display shows:

• Lower corners – show the functions currently assigned to the two soft keys.

• Lower middle – displays the current time (if configured to show the time).

Operating the drive

AUTO/HAND – The very first time the drive is powered up, it is in the auto control

(AUTO) mode, and is controlled from the Control terminal block X1.

To switch to hand control (HAND) and control the drive using the control panel, press

and hold the or button.

• Pressing the HAND button switches the drive to hand control while keeping the

drive running.

• Pressing the OFF button switches to hand control and stops the drive.

To switch back to auto control (AUTO), press and hold the button.

Hand/Auto/Off – To start the drive press the HAND or AUTO buttons, to stop the

drive press the OFF button.

Reference – To modify the reference (only possible if the display in the upper right

corner is in reverse video) press the UP or DOWN buttons (the reference changes

immediately).

The reference can be modified in the local control mode (HAND/OFF), and can be

parameterized (using Group 11 reference select) to also allow modification in the

remote control mode.

Note: The Start/Stop, Shaft direction and Reference functions are only valid in local

control (HAND/OFF) mode.

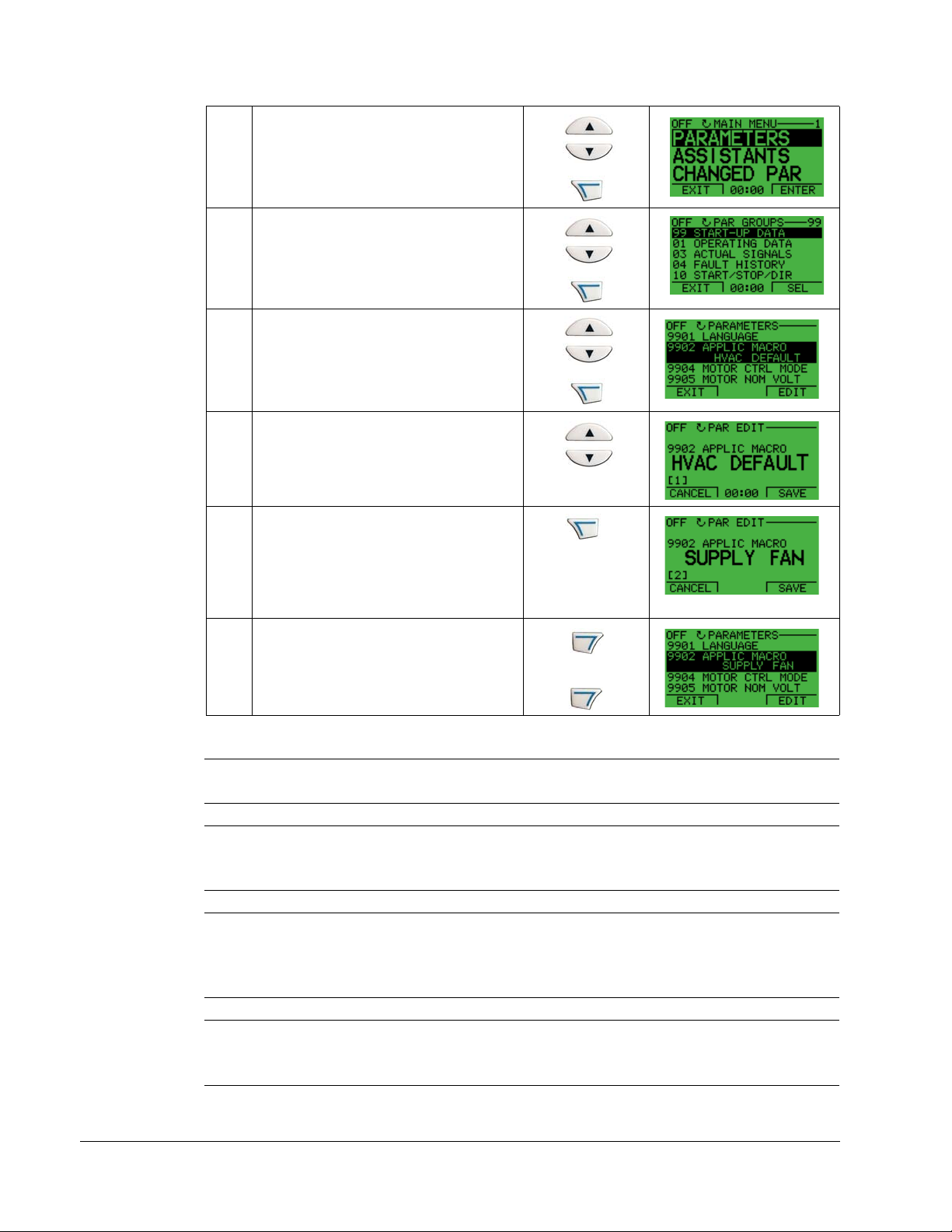

Parameters Mode

To change the parameters, follow these steps:

Select MENU to enter the main menu.

1

Control panel

Page 36

1-36 ACH550-UH User’s Manual

Select the Parameters mode with the UP/

DOWN buttons, and select ENTER to

select the Parameters Mode.

2

Select the appropriate parameter group

with the UP/DOWN buttons and select

SEL.

3

Select the appropriate parameter in a

group with the UP/DOWN buttons. Select

EDIT to change the parameter.

4

Press the UP/DOWN buttons to change

the parameter value.

5

Select SAVE to store the modified value

or select CANCEL to leave the set mode.

• Any modifications not saved are

6

7

cancelled.

• Each individual parameter setting is

valid immediately after pressing SAVE.

Select EXIT to return to the listing of

parameter groups, and again to return to

the main menu.

For detailed hardware description, see the Appendix.

Note: The current parameter value appears below the highlighted parameter.

Note: To view the default parameter value, press the UP/DOWN buttons

simultaneously.

Note: The most typical and necessary parameters to change are parameter groups

99 Start-up data, 10 Start/Stop/Dir, 11 Reference Select, 20 Limits, 21 Start/Stop, 22

Accel/Decel, 26 Motor Control and 30 Fault Functions.

Control panel

Note: To restore the default factory settings, select the application macro HVAC

Default.

Page 37

ACH550-UH User’s Manual 1-37

Start-Up Assistant Mode

To start the Start-Up Assistant, follow these steps:

Select MENU to enter the main menu

1

Select ASSISTANTS with the UP/DOWN

buttons and select ENTER.

2

Scroll to COMMISSION DRIVE with the

UP/DOWN buttons and select SEL.

3

Change the values suggested by the

assistant to your preferences and then

press SAVE after every change.

4

The Start-Up Assistant will guide you through the start-up.

The Start-Up Assistant guides you through the basic programming of a new drive.

(You should familiarize yourself with basic control panel operation and follow the

steps outlined above.) At the first start, the drive automatically suggests entering the

first task, Language Select.The assistant also checks the values entered to prevent

entries that are out of range.

The Start-Up Assistant is divided into tasks. You may activate the tasks one after the

other, as the Start-Up Assistant suggests, or independently.

Note: If you want to set the parameters independently, use the Parameters Mode.

The order of tasks presented by the Start-up Assistant depends on your entries. The

following task list is typical.

Task name Description

Spin the motor • Prompts for control panel display language selection.

• Prompts for motor data.

• Guides user through rotation check.

Commission drive Prompts for motor data.

Application Prompts for application macro selection.

References 1 & 2 • Prompts for the source of speed references 1 and 2.

• Prompts for reference limits.

• Prompts for frequency (or speed) limits.

Control panel

Page 38

1-38 ACH550-UH User’s Manual

Task name Description

Start/Stop Control • Prompts for the source for start and stop commands.

• Prompts for start and stop mode definition.

• Prompts for acceleration and deceleration times.

Protections • Prompts for current and torque limits.

• Prompts for the use of Run enable and Start enable signals.

• Prompts for the use of emergency stop.

• Prompts for Fault function selection.

• Prompts for Auto reset functions selection.

Constant Speeds • Prompts for the use of constant speeds.

• Prompts for constant speed values.

PID Control • Prompts for PID settings.

• Prompts for the source of process reference.

• Prompts for reference limits.

• Prompts for source, limits and units for the process actual value.

• Defines the use of Sleep function.

Low Noise Setup • Prompts for switching frequency.

• Prompts for definition of Flux optimization.

• Prompts for the use of Critical speeds.

Panel Display Prompts for display variable and unit settings.

Timed Functions Prompts for the use of Timed functions.

Output • Prompts for the signals indicated through the relay outputs.

• Prompts for signals indicated through the analog outputs AO1 and AO2.

Sets the minimum, maximum, scaling and inversion values.

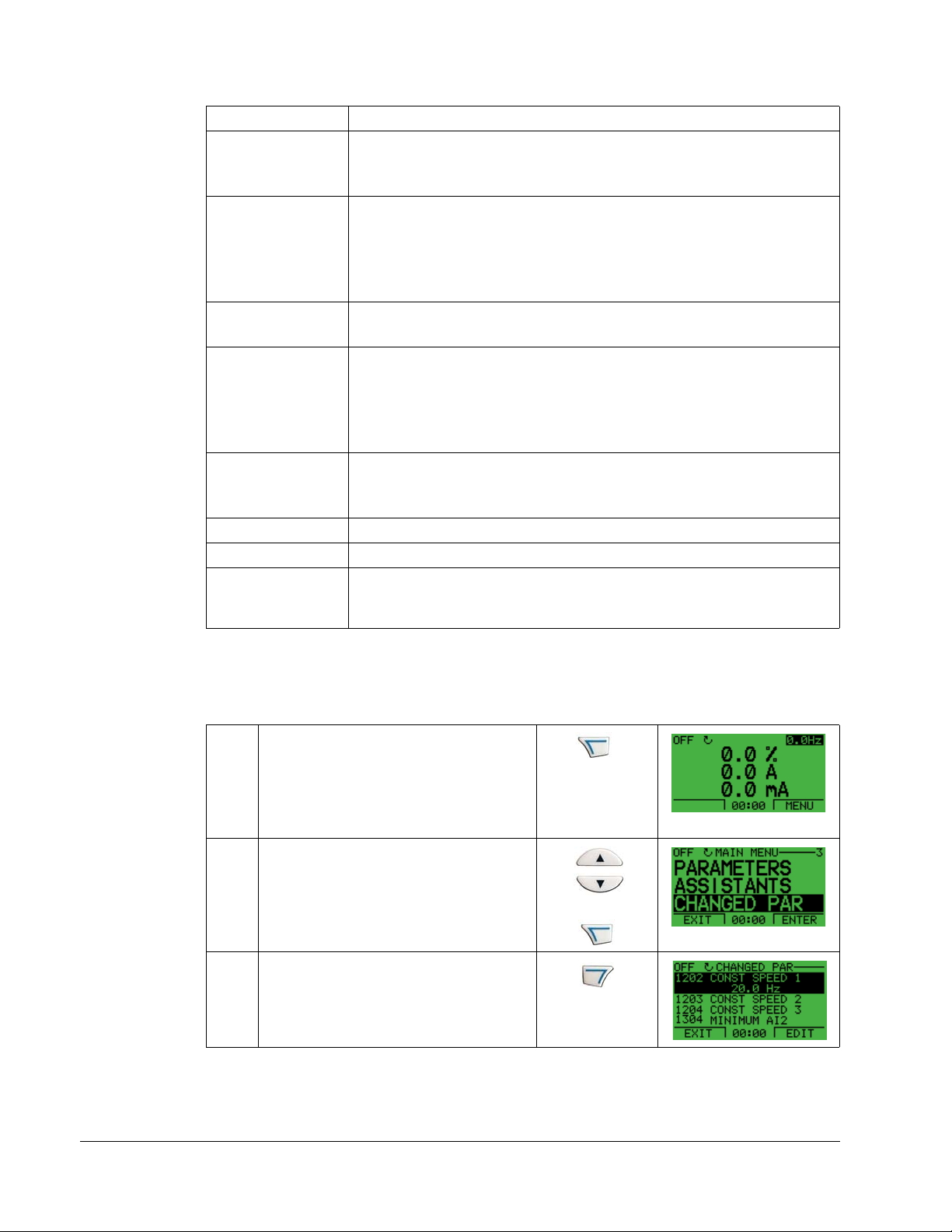

Changed Parameters Mode

To view (and edit) a listing of all parameters that have been changed from macro

default values, follow these steps:

Select MENU to enter the menu.

1

Select CHANGED PAR with the UP/

DOWN buttons and select ENTER.

2

A list of changed parameters is displayed.

Select EXIT to exit the Changed

Parameters Mode.

3

Control panel

Page 39

ACH550-UH User’s Manual 1-39

Fault Logger Mode

Use the Fault Logger Mode to see drive fault history, fault state details and help for

the faults.

1. Select FAULT LOGGER in the Main Menu.

2. Press ENTER to see the latest faults (up to 10 faults, maximum).

3. Press DETAIL to see details for the selected fault.

• Details are available for the three latest faults.

4. Press DIAG to see the help description for the fault. See Diagnostics section.

Note: If a power off occurs, only the three latest faults will remain (with details only in

the first fault).

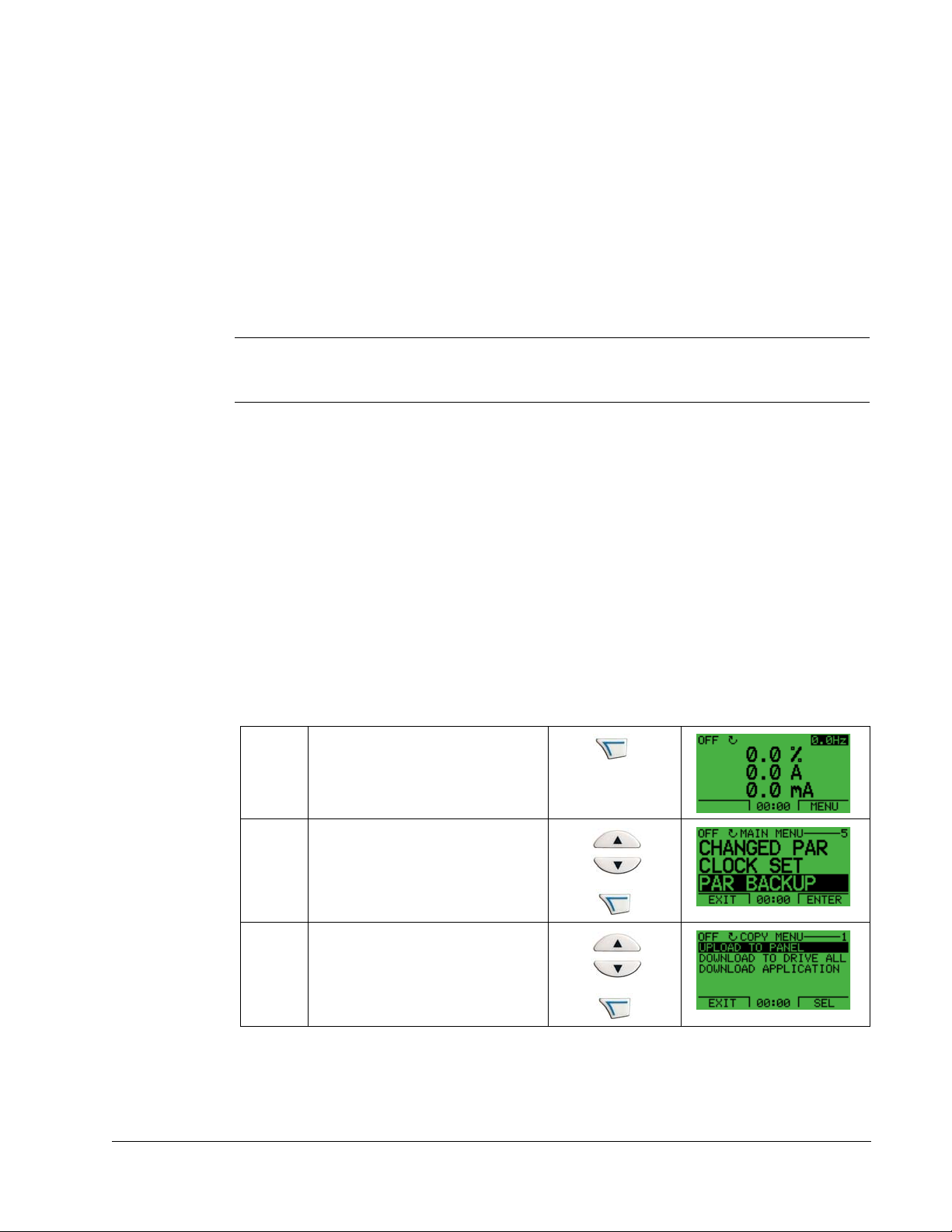

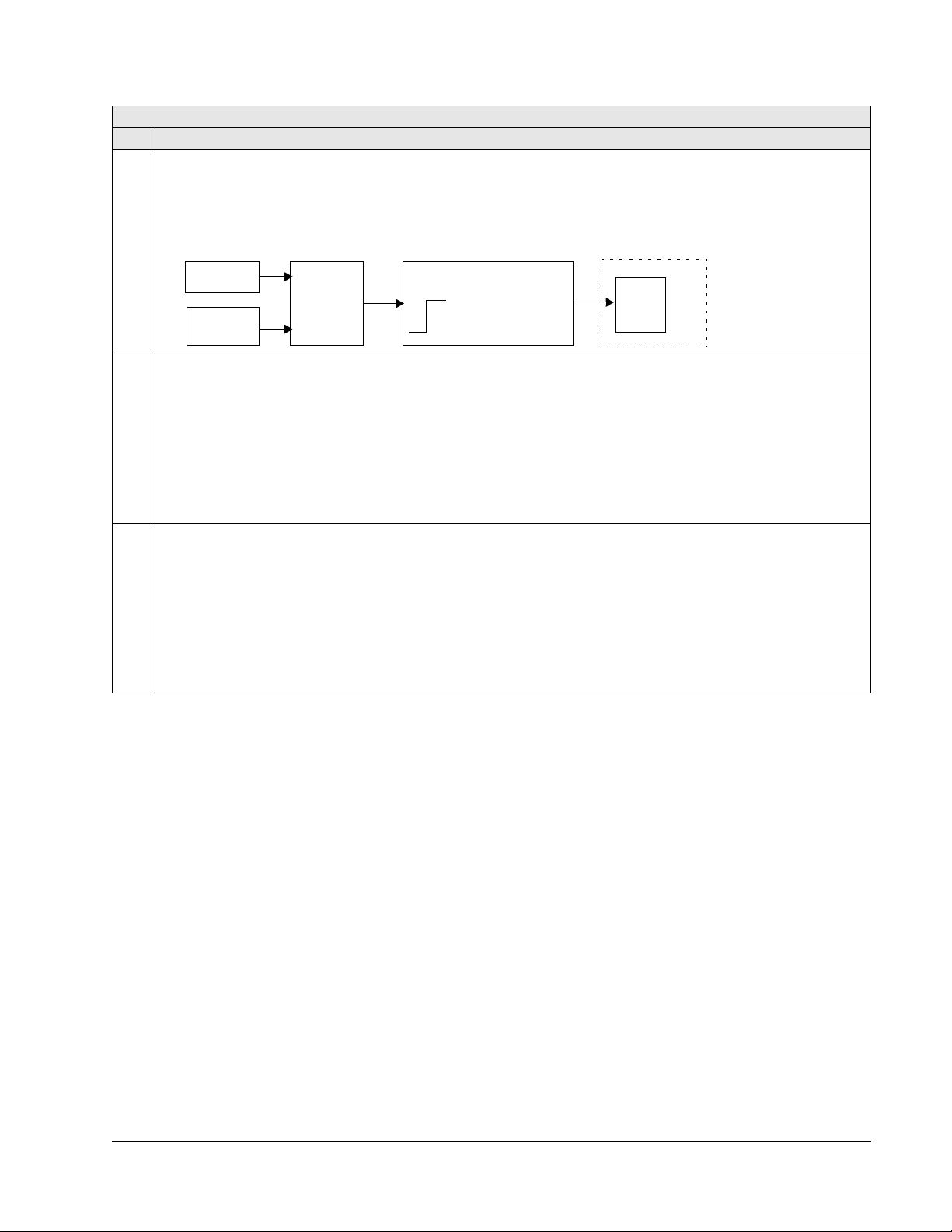

Drive Parameter Backup Mode

Use the Drive Parameter Backup Mode to export parameters from one drive to

another. The parameters are uploaded from a drive to the control panel and

downloaded from the control panel to another drive. Two options are available:

Par Backup Mode

The Assistant Control Panel can store a full set of drive parameters.

The Par Backup Mode has these functions:

• Upload to Panel – Copies all parameters from the drive to the Control Panel.

This includes user sets of parameters (if defined) and internal parameters such as

those created by the Motor Id Run. The Control Panel memory is non-volatile and

does not depend on the panel’s battery. To upload parameters to control panel,

follow these steps:

Select MENU to enter the main

menu.

1

Select PAR BACKUP with the UP/

DOWN buttons and select ENTER.

2

Scroll to Upload to Panel and select

SEL.

3

Control panel

Page 40

1-40 ACH550-UH User’s Manual

Control

Download

all

X0202

Upload

to panel

IP2100

Panel

IP2100

The text “Copying parameters” and a

progress diagram is displayed.

Select ABORT if you want to stop

4

the process.

The text “Parameter upload

successful” is displayed and the

control panel returns to the PAR

BACKUP menu. Select EXIT to

return to the main menu. Now you

can disconnect the panel.

5

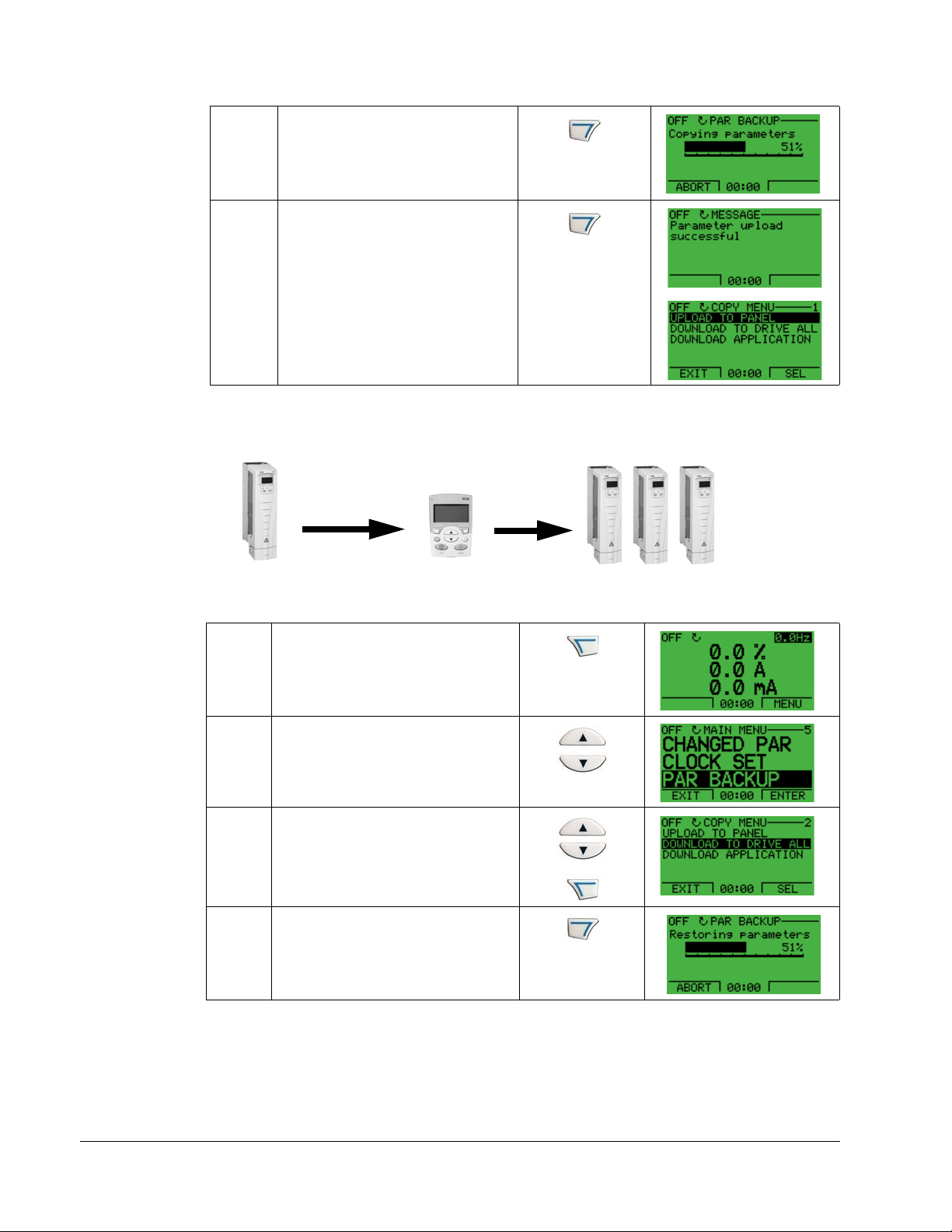

• Download Full Set – Restores the full parameter set from the Control Panel to

the drive. Use this option to restore a drive, or to configure identical drives. This

download does not include user sets of parameters.

To download all parameters to drive, follow these steps:

Select MENU to enter the menu.

1

Select PAR BACKUP with the UP/

DOWN buttons.

2

Scroll to Download to drive all and

select SEL.

3

The text “Restoring parameters” is

displayed. Select ABORT if you want

to stop the process.

4

Control panel

Page 41

ACH550-UH User’s Manual 1-41

Upload

to panel

Download

application

IP2100

Control

X0202

IP2101

Panel

After the download stops, the

message “Parameter download

successful” is displayed and the

control panel goes back to PAR

BACKUP menu. Select EXIT to return

to the main menu.

5

Note: Download Full Set writes all parameters to the drive, including motor

parameters. Only use this function to restore a drive, or to transfer parameters to

systems that are identical to the original system.

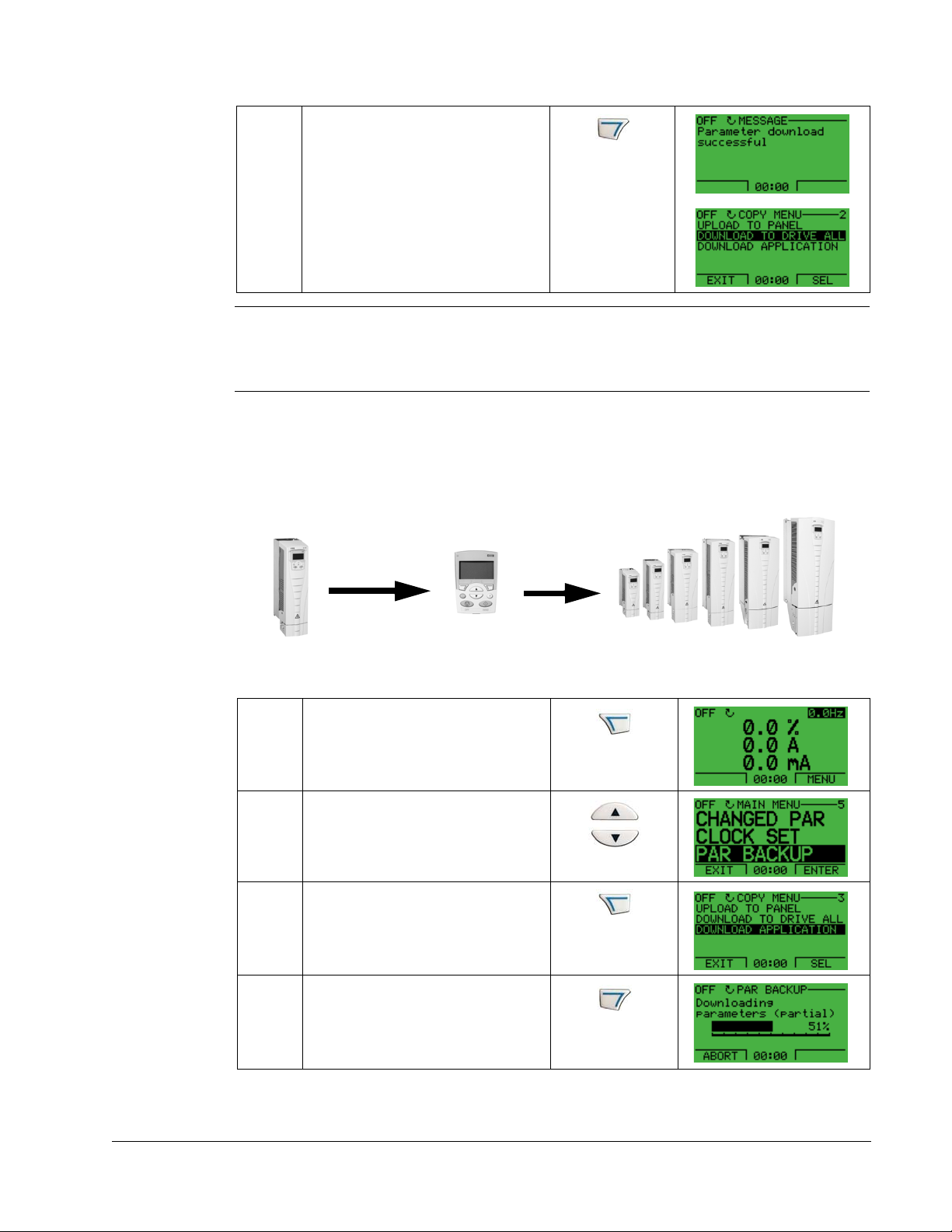

• Download Application – Copies a partial parameter set from the Control Panel

to a drive. The partial set does not include internal motor parameters, parameters

9905…9909, 1605, 1607, 5201, nor any Group 51 and 53 parameters. Use this

option to transfer parameters to systems that use similar configurations – the

drive and motor sizes do not need to be the same.

To download application to drive, follow these steps:

Select MENU to enter the menu.

1

Select PAR BACKUP with the UP/

DOWN buttons.

2

Scroll to DOWNLOAD APPLICATION

and select SEL.

3

The text “Downloading parameters

(partial)” is displayed. Select ABORT

if you want to stop the process.

4

Control panel

Page 42

1-42 ACH550-UH User’s Manual

LOC DIFFERENCES ----

VALUES UNDER MIN

VALUES OVER MAX

INVALID VALUES

EXTRA PARS

MISSING VALUES

READY SEL

3

2

1

5

7

LOC DIFFERENCES ---VALUES UNDER MIN

VALUES OVER MAX

INVALID VALUES

EXTRA PARS

MISSING VALUES

READY SEL

3

2

1

5

7

LOC INVALID VAL

9902 APLIC MACRO

2606*SWITCHING FREQ

12 kHz

8 kHz

3401*DISP 1 SEL

EXIT EDIT

The text “Parameter download

successful” is displayed and the

control panel returns to PAR BACKUP

menu. Select EXIT to return to the

main menu.

5

• Download User Set 1 - Copies USER S1 parameters (user sets are saved using

parameter 9902

APPLIC MACRO) from the Control Panel to the drive.

• Download User Set 2 - Copies

USER S2 parameters from the Control Panel to the

drive.

Handling inexact downloads

In some situations, an exact copy of the download is not appropriate for the target

drive. Some examples:

• A download to an old drive specifies parameters/values that are not available on

the old drive.

• A download (from an old drive) to a new drive does not have definitions for the

new parameters – parameters that did not originally exist.

• A download can include an illegal value for the target drive, e.g. a backup from a

small drive can have a switching frequency of 12 kHz whereas a big drive can

only handle 8k Hz.

As a default, the control panel handles these situations by:

• Discarding parameters/values not available on

the target drive.

• Using parameter default values when the

download provides no values or invalid values.

• Providing a Differences List – A listing of the

type and number of items that the target cannot

accept exactly as specified.

You can either accept the default edits by pressing

READY, or view and edit each item as follows:

1. Highlight an item type in the Differences List (left screen below) and press SEL to

see the details for the selected type (right screen below).

Control panel

Page 43

ACH550-UH User’s Manual 1-43

In the above-right “details” screen:

• The first item that requires editing is automatically highlighted and includes

details: In general, the first item listed in the details is the value defined by the

backup file. The second item listed is the “default edit.”

• For tracking purposes, an asterisk initially appears by each item. As edits are

made, the asterisks disappear.

2. In the illustrated example, the backup specifies a switching frequency of 12 kHz, but

the target drive is limited to 8 kHz.

3. Press EDIT to edit the parameter. The display is the target drive’s standard edit

screen for the selected parameter.

4. Highlight the desired value for the target drive.

5. Press SAVE to save setting.

6. Press EXIT to step back to the differences view and continue for each remaining

exception.

7. When your editing is complete, press READY in the Differences List and then select

“Yes, save parameters.”

Download failures

In some situations, the drive may be unable to accept a download. In those cases,

the control panel display is: “Parameter download failed” plus one of the following

causes:

• Set not found – You are attempting to download a data set that was not defined in

the backup. The remedy is to manually define the set, or upload the set from a

drive that has the desired set definitions.

• Par lock – The remedy is to unlock the parameter set (parameter 1602).

• Incompat drive/model – The remedy is to perform backups only between drives of

the same type (ACS/industrial or ACH/HVAC) and the same model (all ACH550).

• Too many differences – The remedy is to manually define a new set, or upload the

set from a drive that more closely resembles the target drive.

Note: If upload or download of parameters is aborted, the partial parameter set is not

implemented.

Clock Set Mode

The Clock Set Mode is used for setting the time and date for the internal clock of the

ACH550. In order to use the timer functions of the ACH550, the internal clock has to

be set first. Date is used to determine weekdays and is visible in Fault logs.

Control panel

Page 44

1-44 ACH550-UH User’s Manual

To set the clock, follow these steps:

Select MENU to enter the main menu.

1

Scroll to Clock Set with the UP/DOWN

buttons and select ENTER to enter the

Clock Set Mode.

2

Scroll to Clock Visibility with the UP/

DOWN buttons and select SEL to change

the visibility of the clock.

3

Scroll to Show Clock with the UP/DOWN

buttons and select SEL to make the clock

visible.

4

Scroll to Set Time with the UP/DOWN

buttons and select SEL.

5

Change the hours and minutes with the

UP/DOWN buttons and select OK to save

the values. The active value is displayed

6

in inverted color.

Scroll to Time Format with the UP/DOWN

buttons and select SEL.

7

The different formats are displayed.

Select a format with the UP/DOWN

buttons and select SEL to confirm the

8

selection.

Scroll to Set Date with the UP/DOWN

buttons and select SEL.

Control panel

9

Page 45

ACH550-UH User’s Manual 1-45

Change the days, months and year with

the UP/DOWN buttons and select OK to

save the values. The active value is

10

displayed in inverted color.

Scroll to Date Format with the UP/DOWN

buttons and select SEL.

11

The Date formats are displayed. Select a

date format with the UP/DOWN buttons

and select OK to confirm the selection.

12

Select EXIT twice to return to the main

menu.

13

Control panel

Page 46

1-46 ACH550-UH User’s Manual

I/O Settings Mode

To view and edit the I/O settings, follow these steps:

Select MENU to enter the main menu.

1

Scroll to I/O Settings with the UP/DOWN

buttons and select ENTER.

2

Scroll to the I/O setting you want to view

with the UP/DOWN buttons and select

SEL.

3

Select the setting you want to view with

the UP/DOWN buttons and select OK.

4

You can change the value with the UP/

DOWN buttons and save it by selecting

SAVE.

5

If you do not want to change the setting,

select CANCEL.

Select EXIT to return to the main menu.

6

Control panel

Page 47

ACH550-UH User’s Manual 1-47

Start-up

Start-up

Start-up can be performed in two ways:

• Using the Start-Up Assistant.

• Changing the parameters individually.

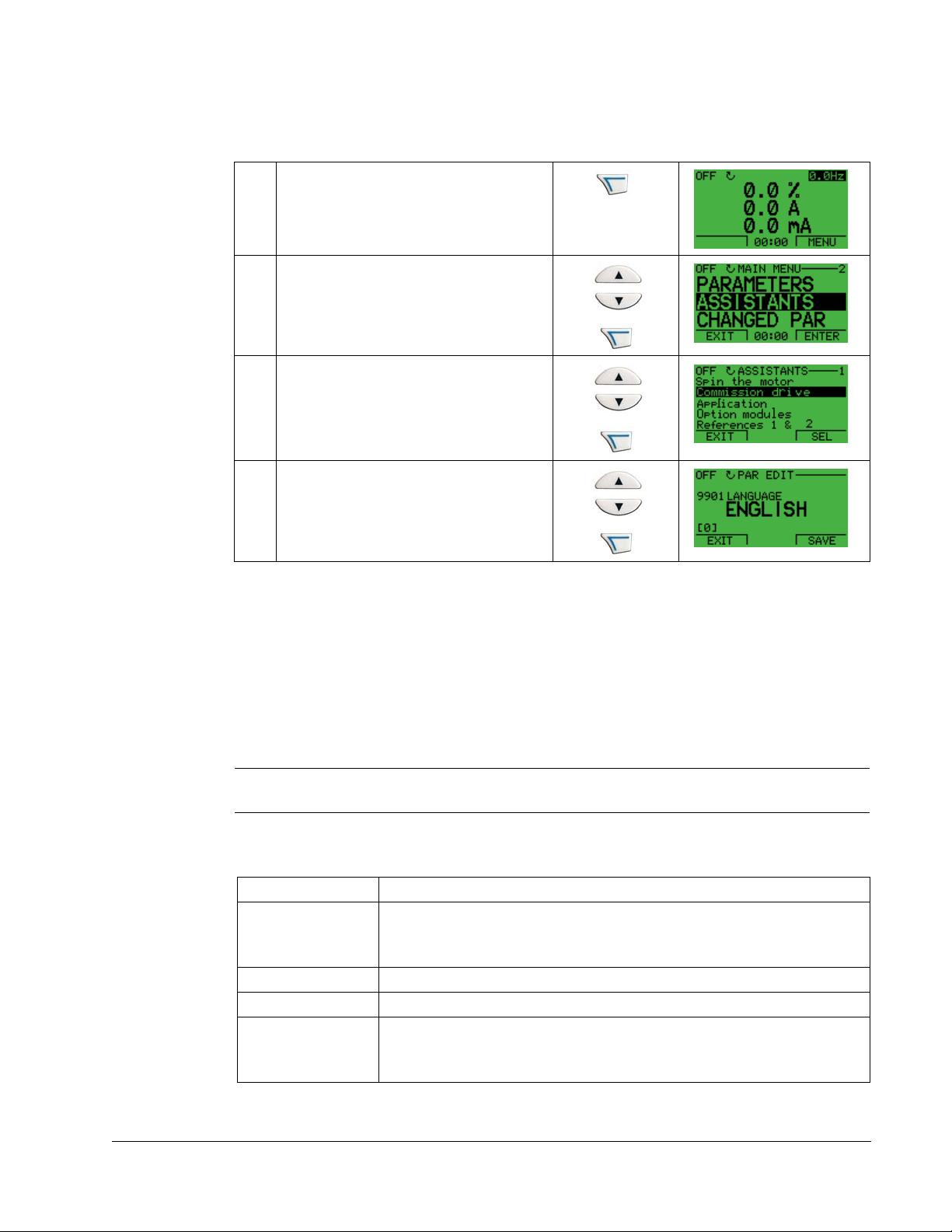

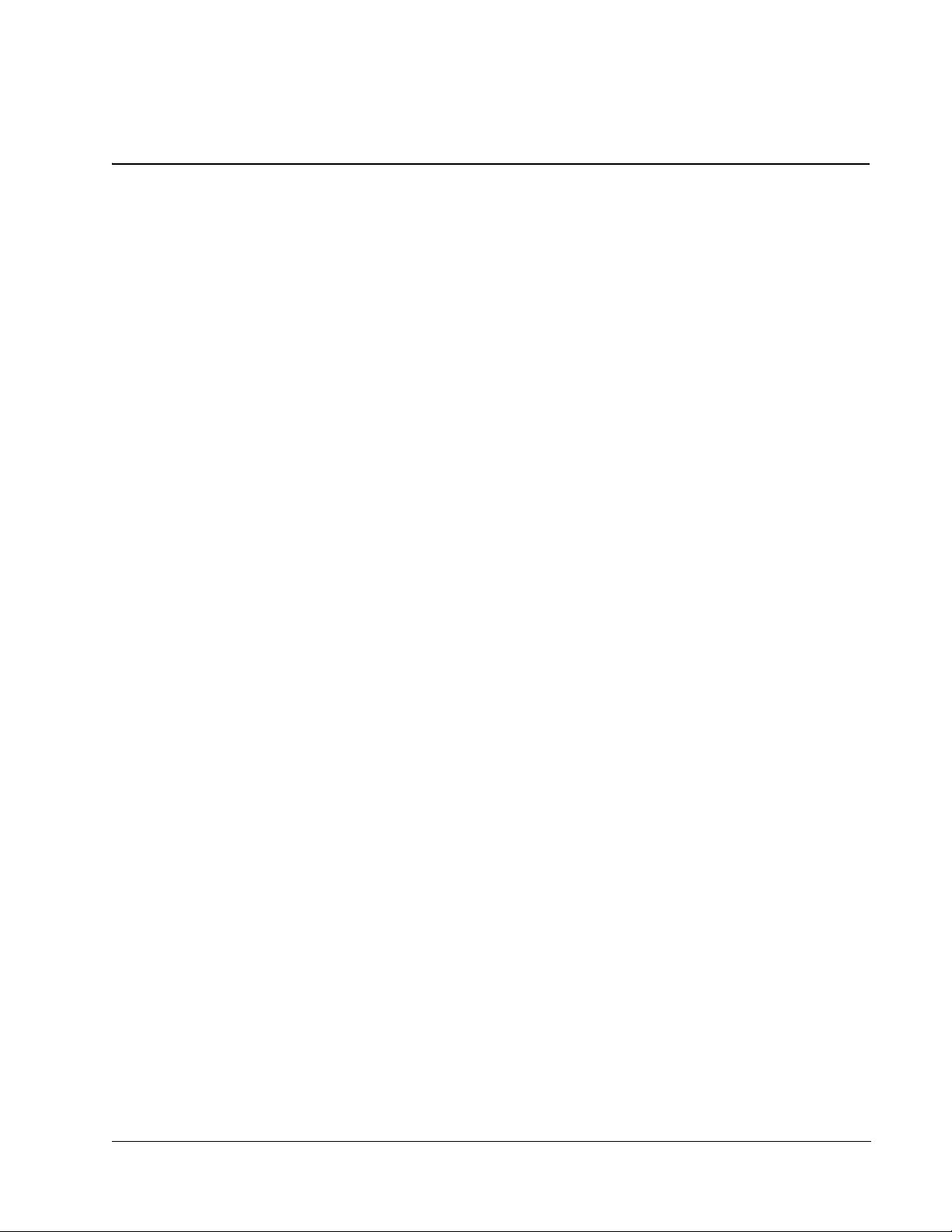

Start-up by using the Start-Up Assistant

To start the Start-Up Assistant, follow these steps:

Select MENU to enter the main menu.

1

Select ASSISTANTS with the Up/Down

buttons and select ENTER.

2

Scroll to COMMISSION DRIVE with the

Up/Down buttons.

3

Change the values suggested by the

assistant to your preferences and then

press SAVE after every change.

4

The Start-Up Assistant will guide you through the start-up.

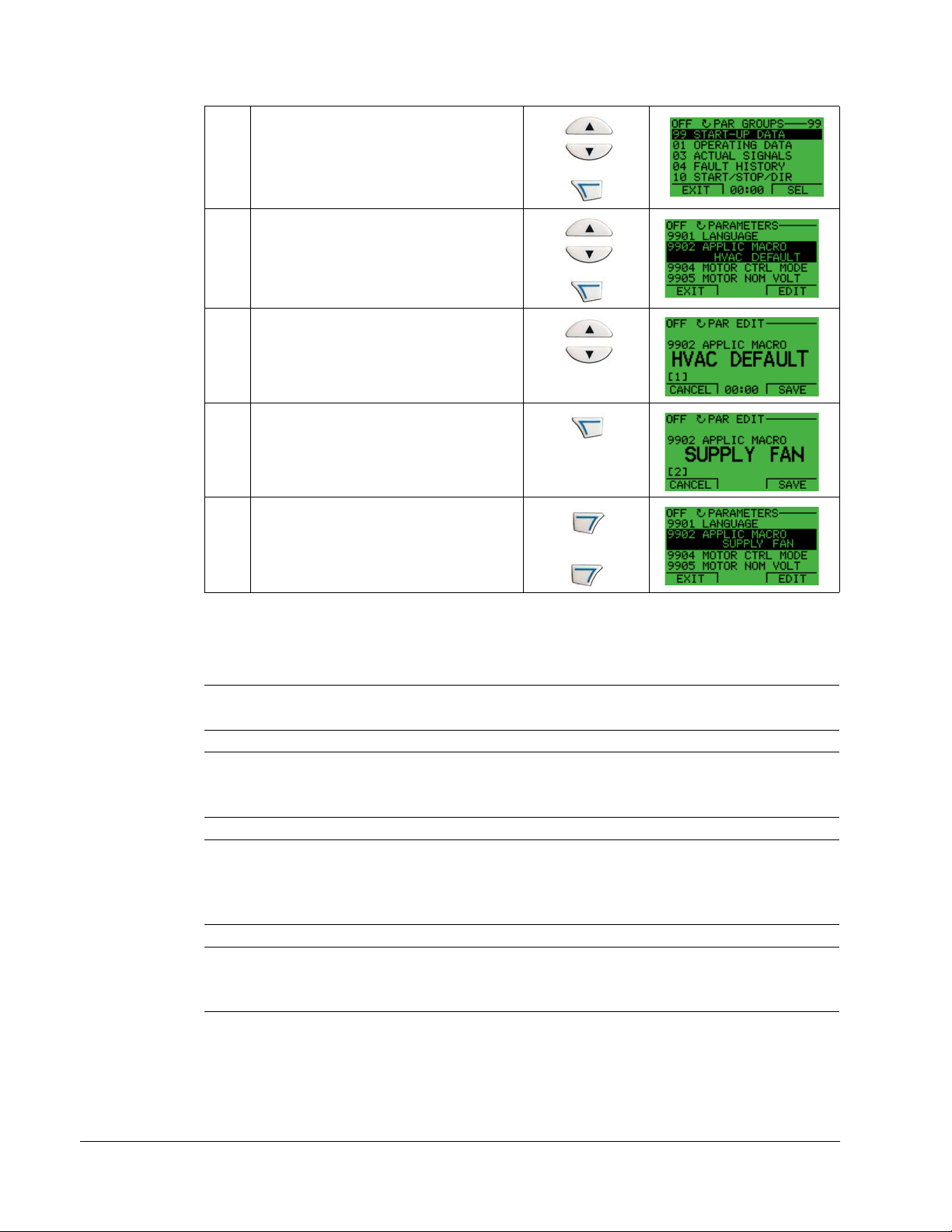

Start-up by changing the parameters individually

To change the parameters, follow these steps:

Select MENU to enter the main menu.

1

Select the Parameters mode with the UP/

DOWN buttons and select ENTER to

select the Parameters mode.

2

Start-up

Page 48

1-48 ACH550-UH User’s Manual

Select the appropriate parameter group

with the UP/DOWN buttons and select

SEL

3

Select the appropriate parameter in a

group with the UP/DOWN buttons. Select

EDIT to change the parameter value.

4

Press the UP/DOWN buttons to change

the parameter value.

5

Select SAVE to store the modified value or

select CANCEL to leave the set mode.

Any modifications not saved are

6

cancelled.

Select EXIT to return to the listing of

parameter groups, and again to return to

the main menu.

7

To complete the control connections by manually entering the parameters, see

Parameters Mode on page 1-35.

For detailed hardware description, see the Technical data section on page 1-299.

Note: The current parameter value appears below the highlighted parameter.

Note: To view the default parameter value, press the UP/DOWN buttons

simultaneously.

Note: The most typical and necessary parameters to change are parameter groups

99 Start-up data, 10 Start/Stop/Dir, 11 Reference Select, 20 Limits, 21 Start/Stop, 22

Accel/Decel, 26 Motor Control and 30 Fault Functions.

Note: To restore the default factory settings, select the application macro HVAC

Default.

Start-up

Page 49

ACH550-UH User’s Manual 1-49

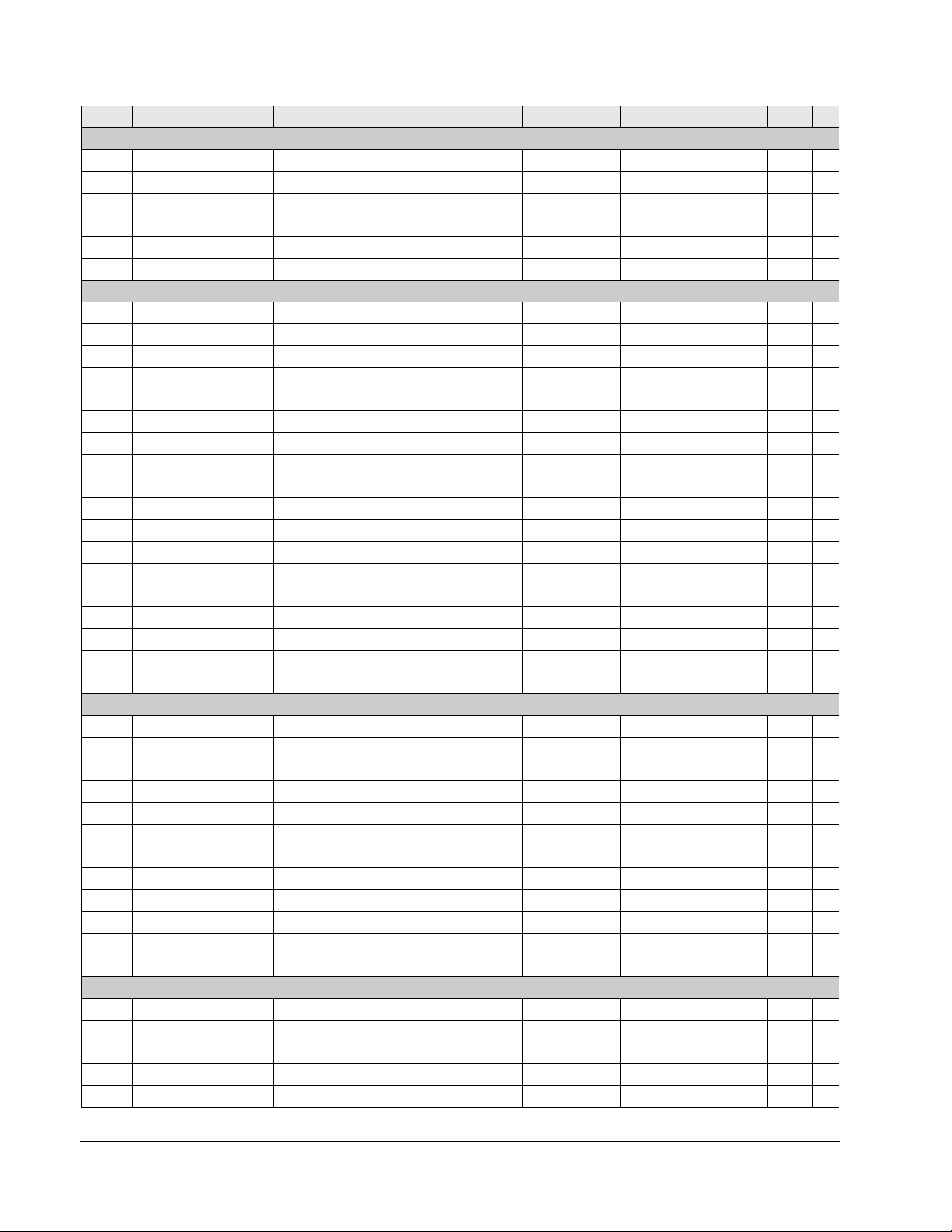

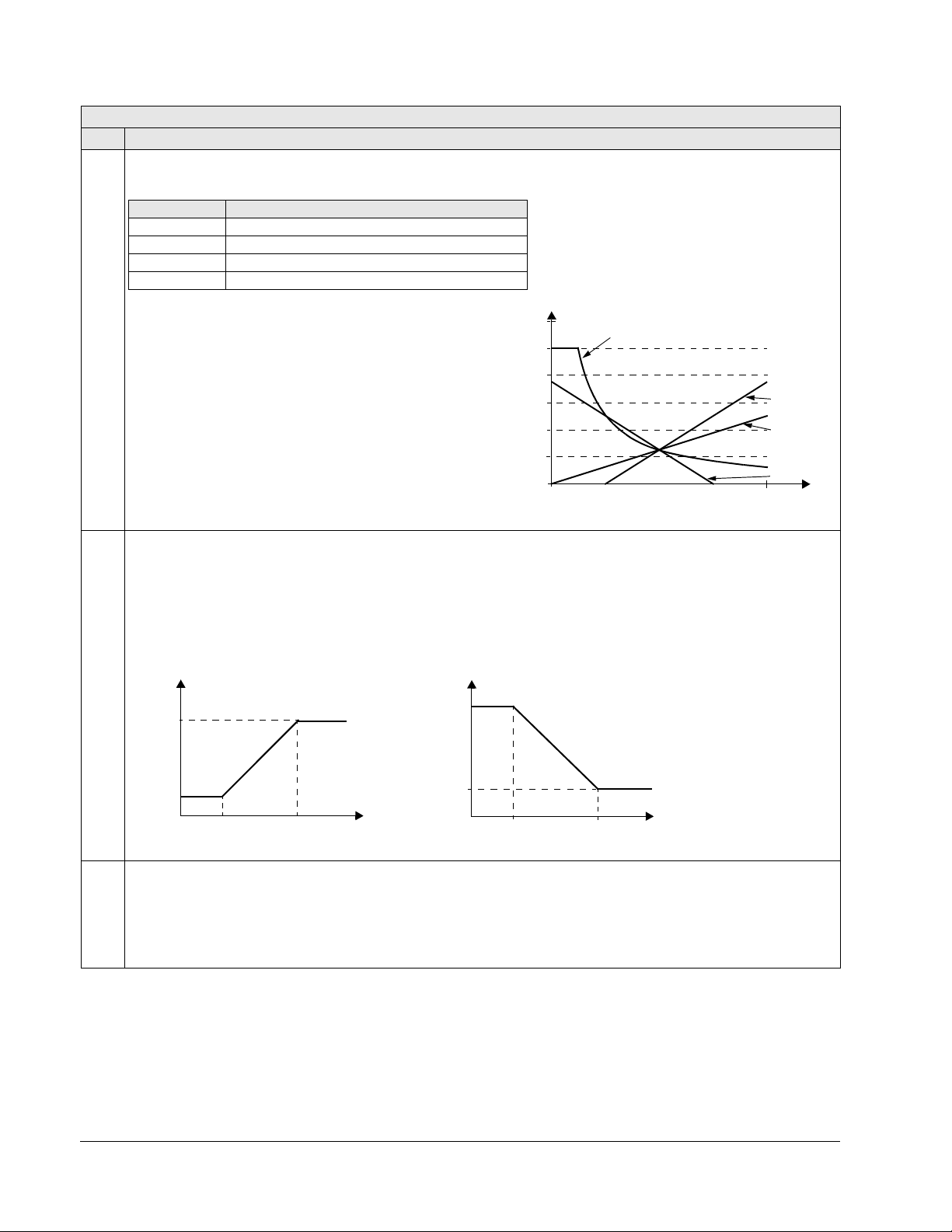

Application macros

Overview

Macros change a group of parameters to new, predefined values designed for

specific applications. Use macros to minimize the need for manual editing of

parameters. Selecting a macro sets all other parameters to their default values,

except:

• Group 99: Start-up Data parameters (except parameter 9904)

• The

• The

• The

• The

PARAMETER LOCK 1602

PARAM SAVE 1607

COMM FAULT FUNC 3018 and COMM FAULT TIME 3019

COMM PROT SEL 9802

• Groups 51…53 serial communication parameters

• Group 29: Maintenance triggers

After selecting a macro, additional parameter changes can be made manually using

the control panel.

Application macros are enabled by setting the value for parameter 9902

MACRO. By default, HVAC Default (value 1) is the enabled macro.

APPLIC

General considerations

The following considerations apply for all macros:

• When using a direct speed reference in AUTO mode, connect the speed

reference to analog input 1 (AI1), and provide the START command using digital

input 1 (DI1). In HAND/OFF mode, the control panel provides the speed

reference and START command.

• When using process PID, connect the feedback signal to analog input 2 (AI2). As

a default, the control panel sets the Setpoint, but analog input 1 can be used as

an alternate source. You can set up process PID using parameters (Group 40) or

using the PID control assistant (recommended).

Application macros

Page 50

1-50 ACH550-UH User’s Manual

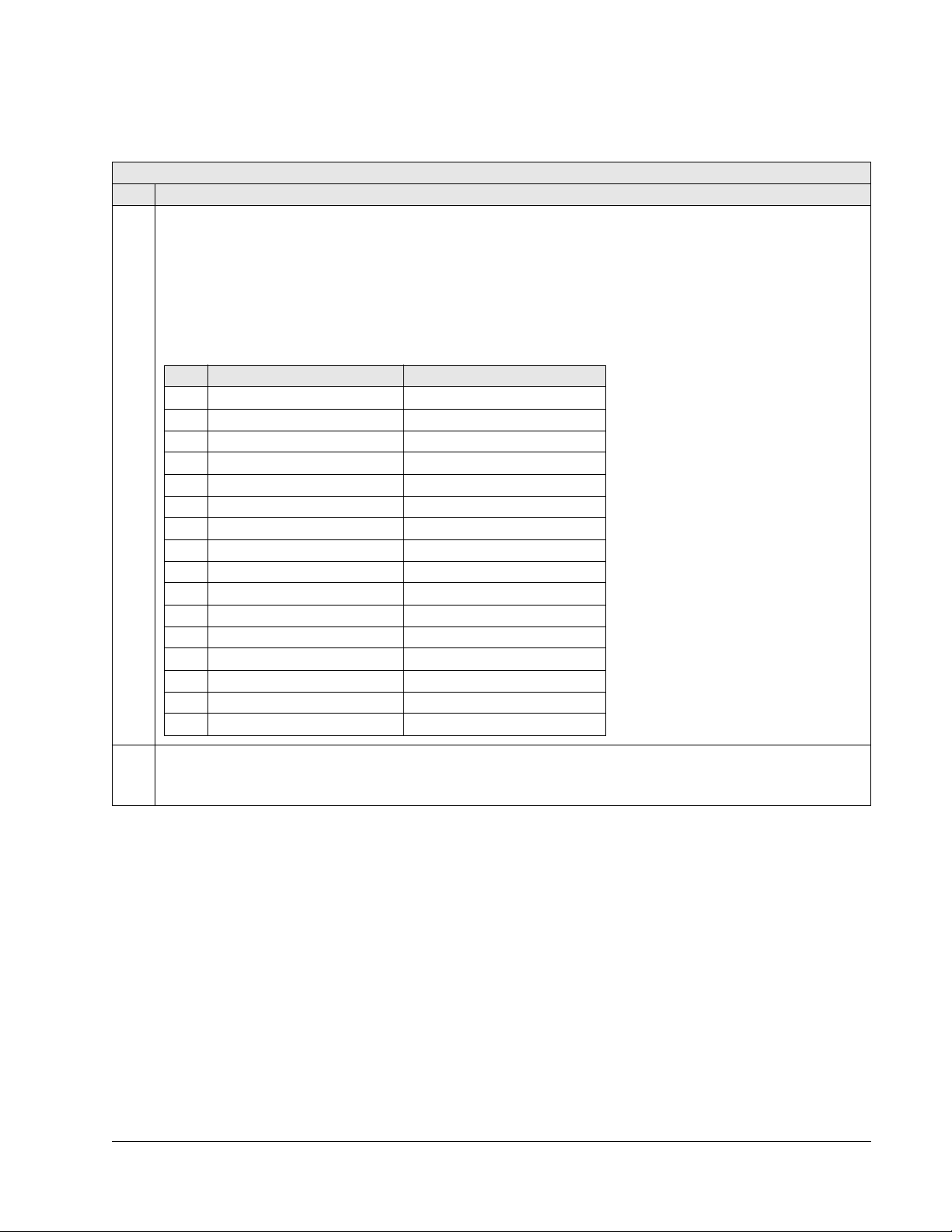

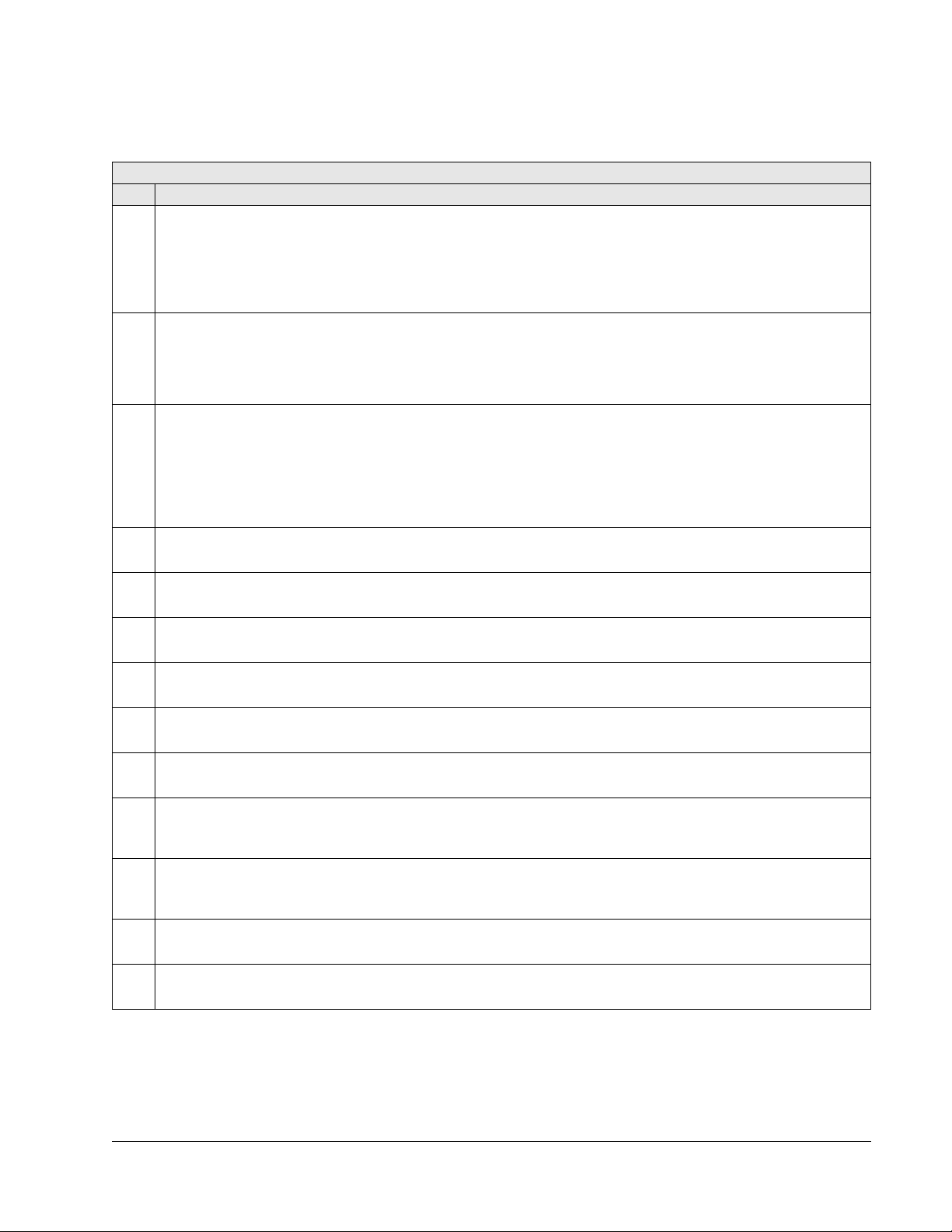

Application / macro listing

This section describes the following macros:

9902

Value

1 HVAC Default

2 Supply Fan

3 Return Fan

4 Cooling Tower Fan

5 Condenser

6Booster Pump

7 Pump Alternation

8 Internal Timer

Macro

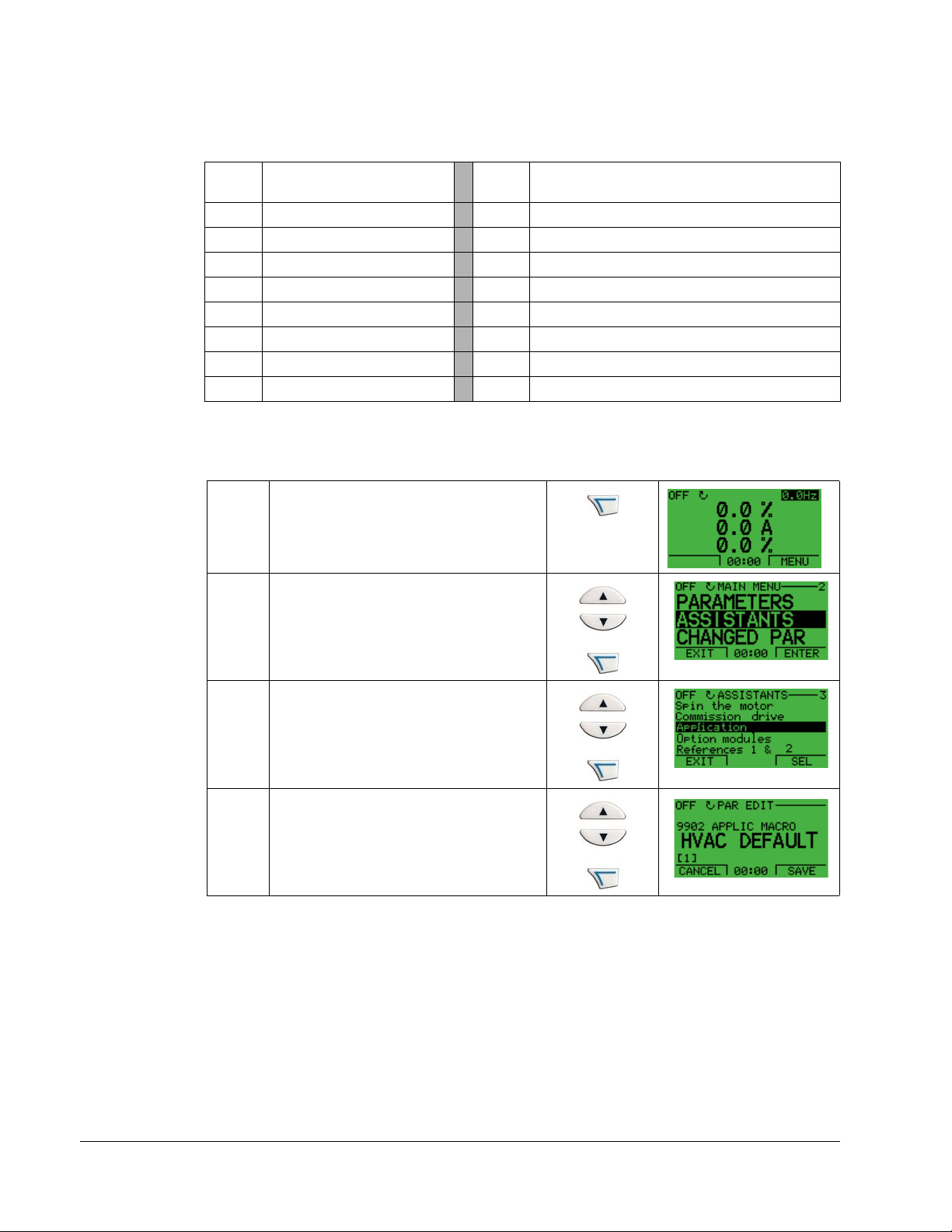

Selecting an application macro

To select a macro, follow these steps:

Select MENU to enter the main menu.

1

Select ASSISTANTS with the UP/DOWN

buttons and select ENTER.

2

9902

Value

9 Internal Timer with Constant Speeds

10 Floating Point

11 Dual Setpoint PID

12 Dual Setpoint PID with Constant Speeds

13 E-bypass

14 Hand Control

15 E-Clipse

Macro

Scroll to APPLICATION and select

ENTER.

3

Select a macro with the UP/DOWN buttons

and select SAVE.

4

Restoring defaults

To restore the factory default settings, select the application macro HVAC Default.

Control wiring

Each macro has specific requirements for control wiring. For general details

about the ACH550 control wiring terminals, see Control terminal descriptions on

page 1-318. Specific wiring requirements are included with each macro description.

Application macros

Page 51

ACH550-UH User’s Manual 1-51

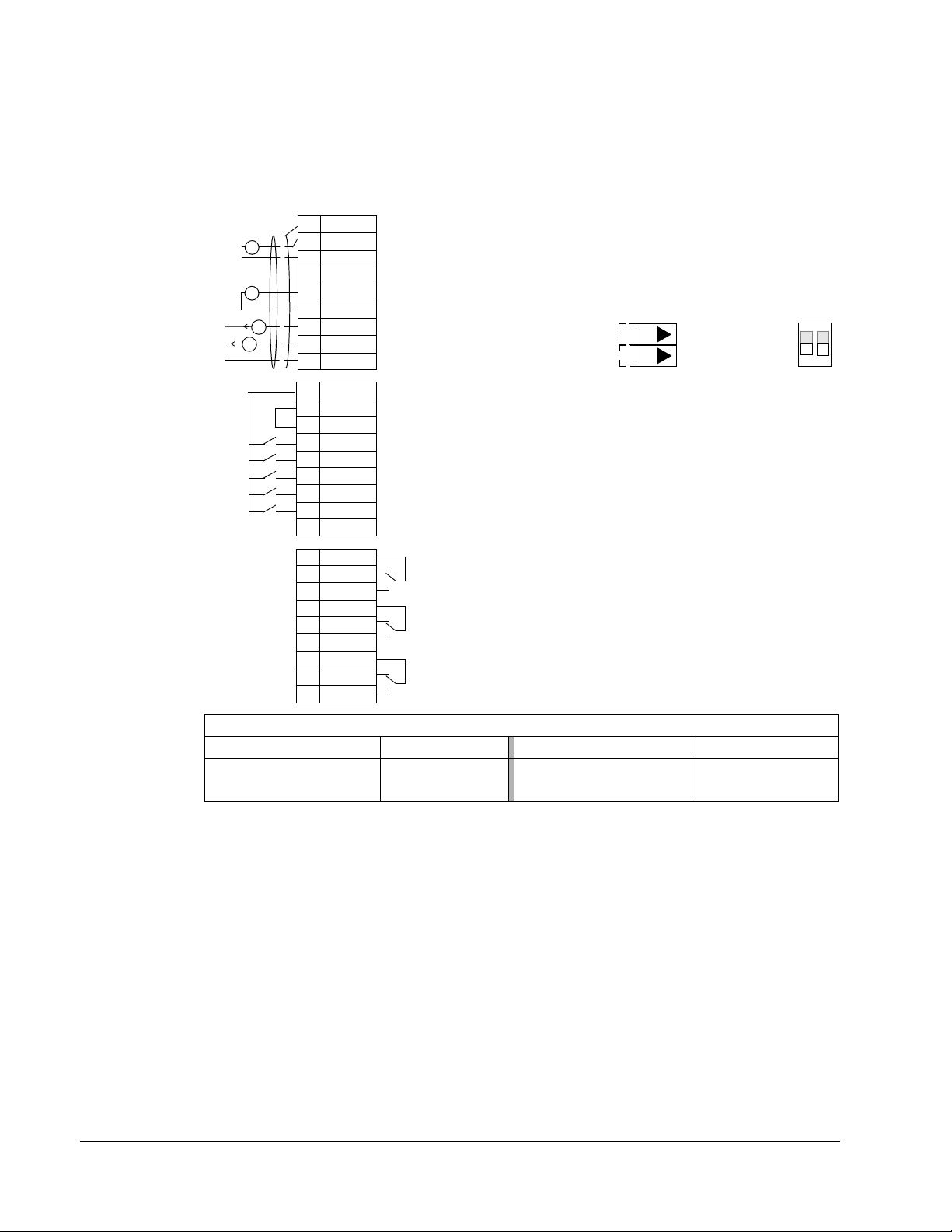

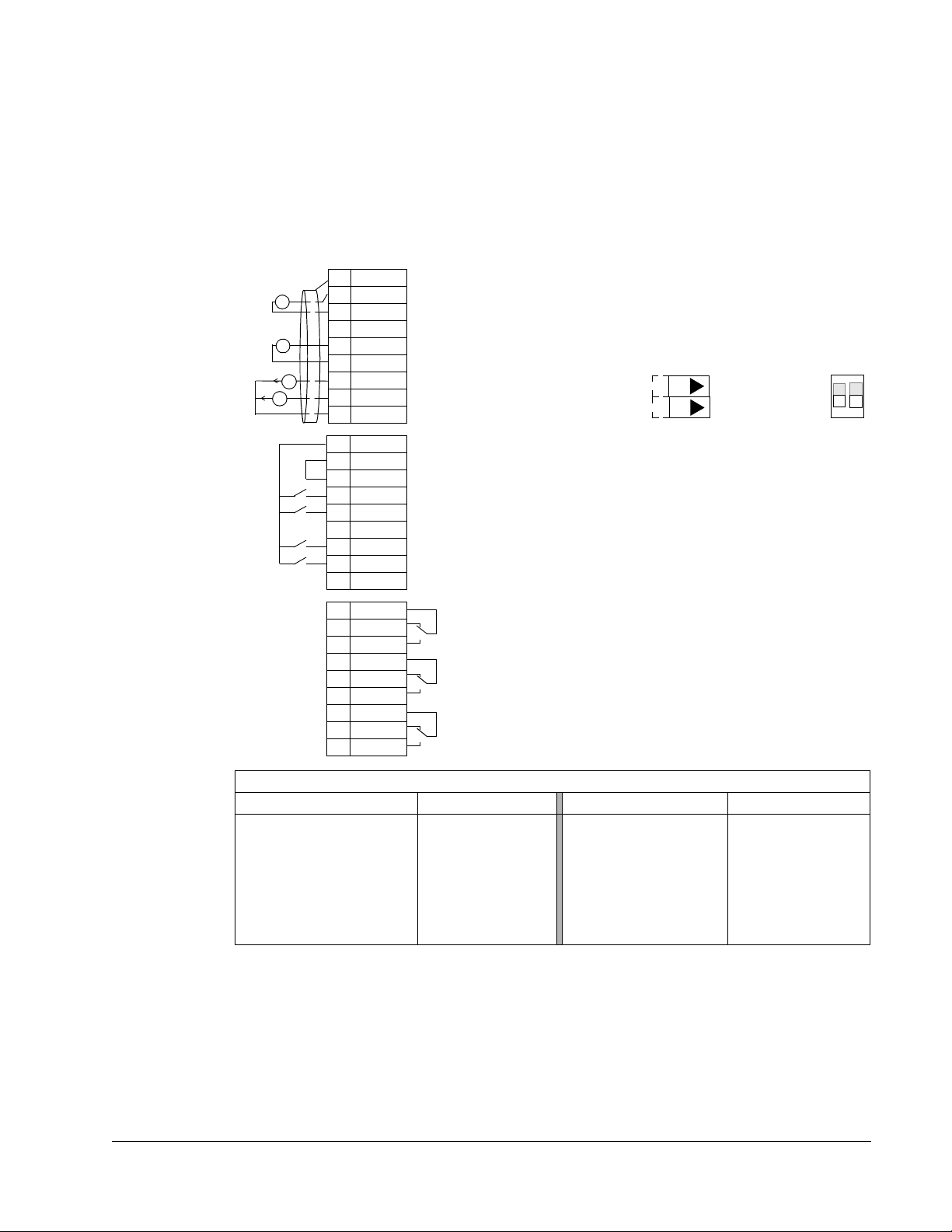

1SCR

2AI1

3AGND

410V

5AI2

6AGND

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

21 RO1B

22 RO2C

23 RO2A

24 RO2B

25 RO3C

26 RO3A

27 RO3B

External reference 0(2)…10 V or 0(4)…20 mA

Reference voltage 10 VDC

Output frequency: 0(4)…20 mA

Start/Stop: Activate to start drive

Not configured

Constant (Preset) speed 1 (P 1202)

Safety interlock: Deactivate to stop drive (P 1608)

Not configured

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

X1

Output current: 0(4)…20 mA

Not configured

Analog input circuit common

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog output circuit common

Auxiliary voltage output +24 VDC

Auxiliary voltage output common

Digital input common for all

Signal cable shield (screen)

Analog input circuit common

(Fault => 25 connected to 26)

+

mA

mA

+

J1

AI1: 0(4)

…20 mA

AI2: 0(4)

…20 mA

ON

Jumper Settings

ON

1

2

ON

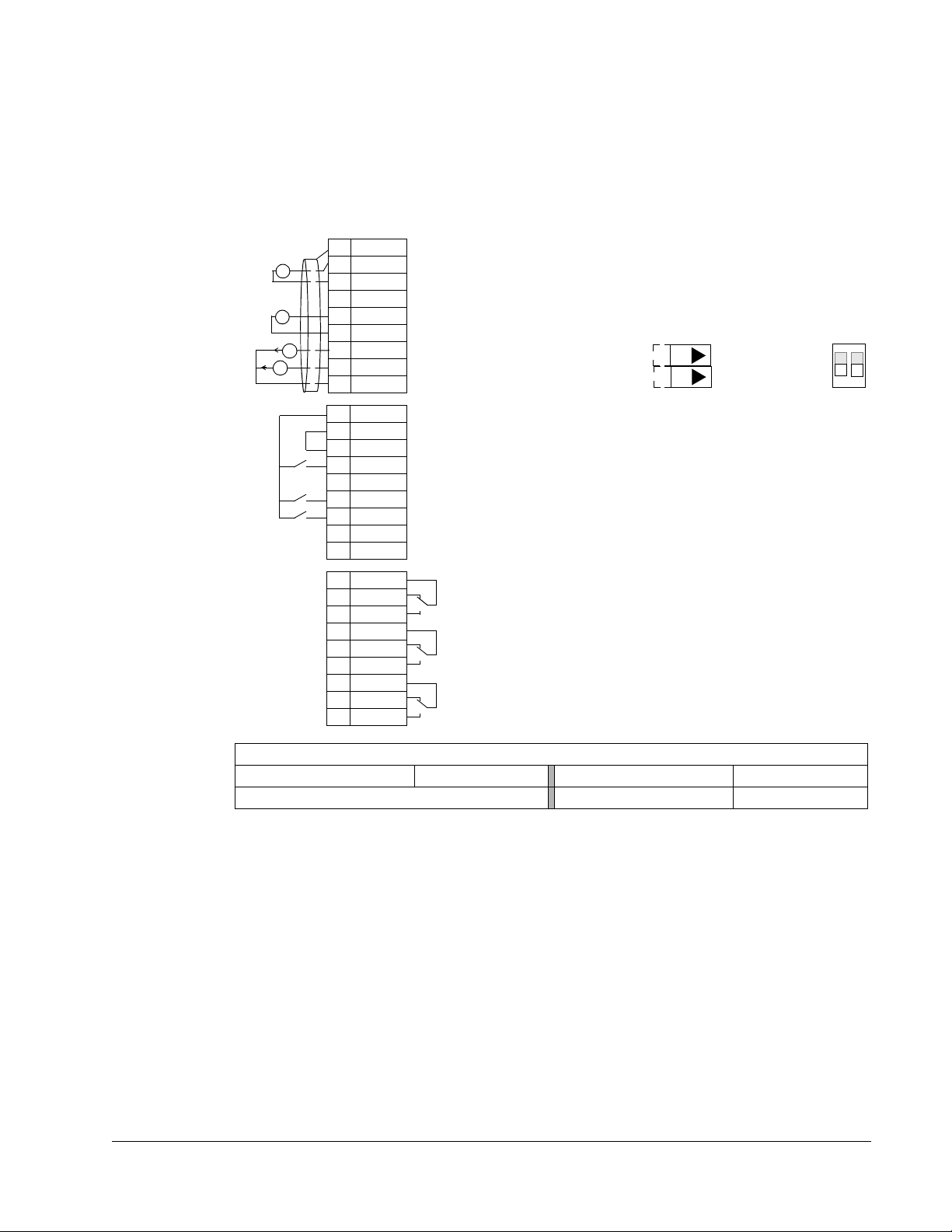

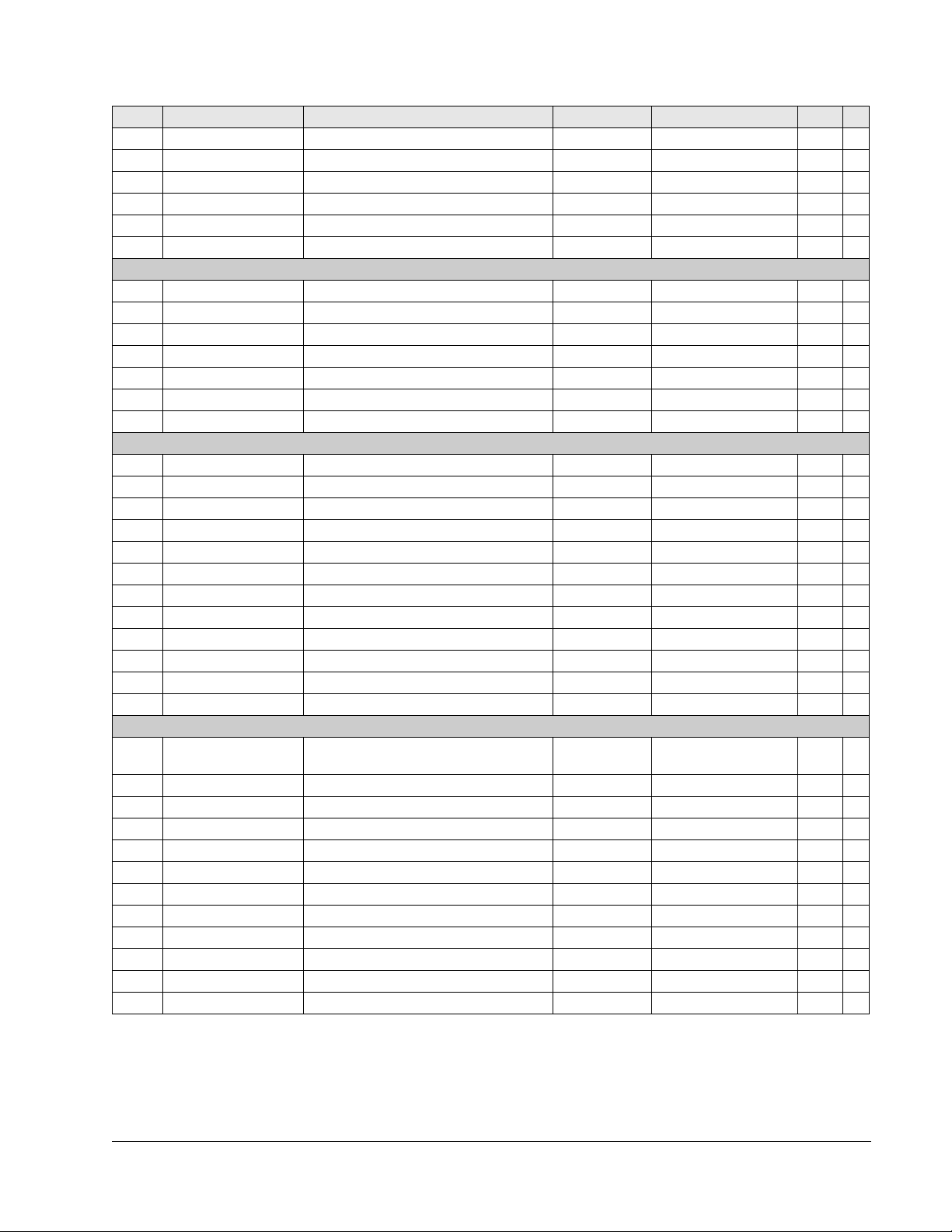

HVAC Default macro

This macro provides the factory default parameter settings for the ACH550-UH.

Factory defaults can be restored at any time by setting parameter 9902 to 1. The

diagram below shows typical wiring using this macro. When using direct speed

reference in AUTO mode or process PID, see General considerations on page 1-49.

None (Default macro)

Parameter Value

Parameters Changed Relative to HVAC Default

Parameter Value

Application macros

Page 52

1-52 ACH550-UH User’s Manual

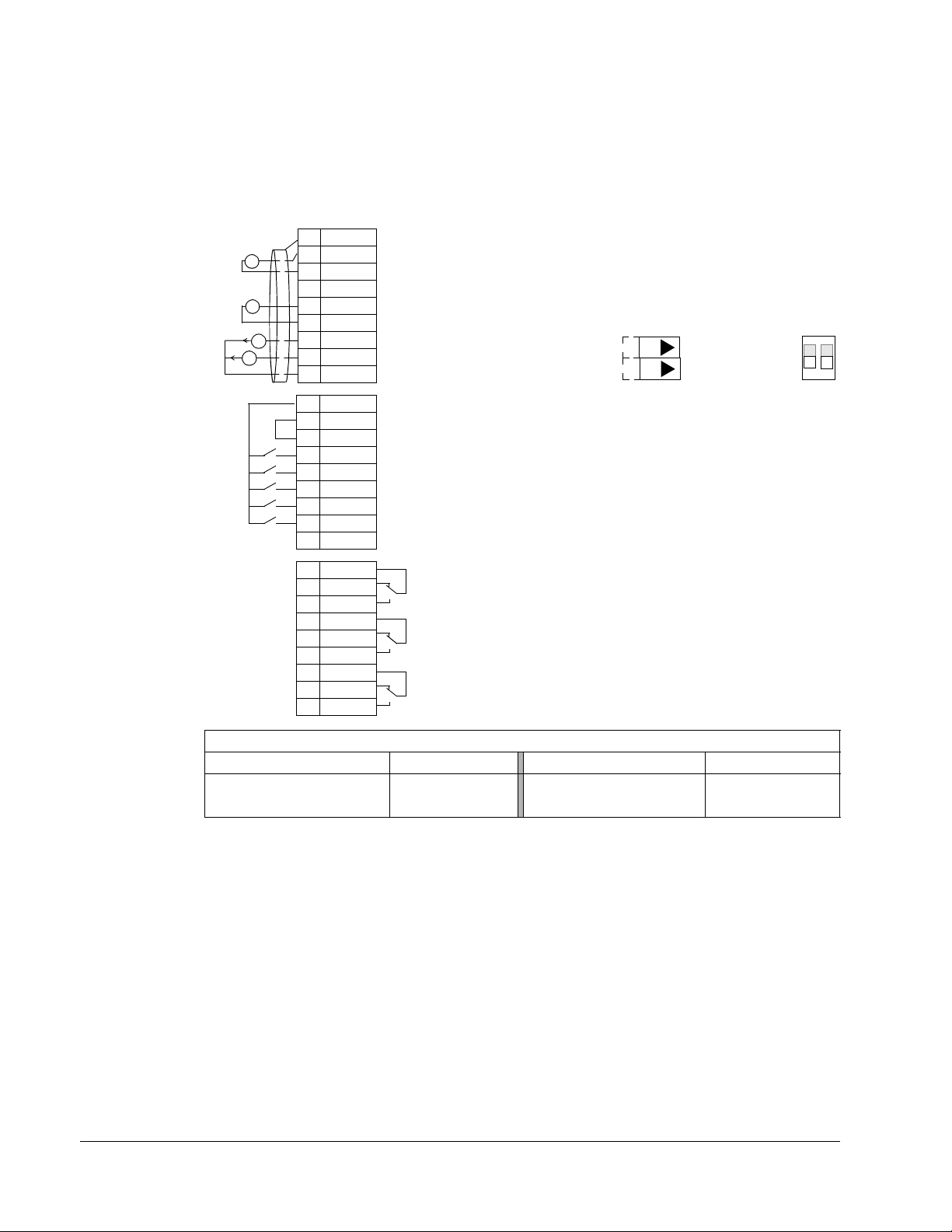

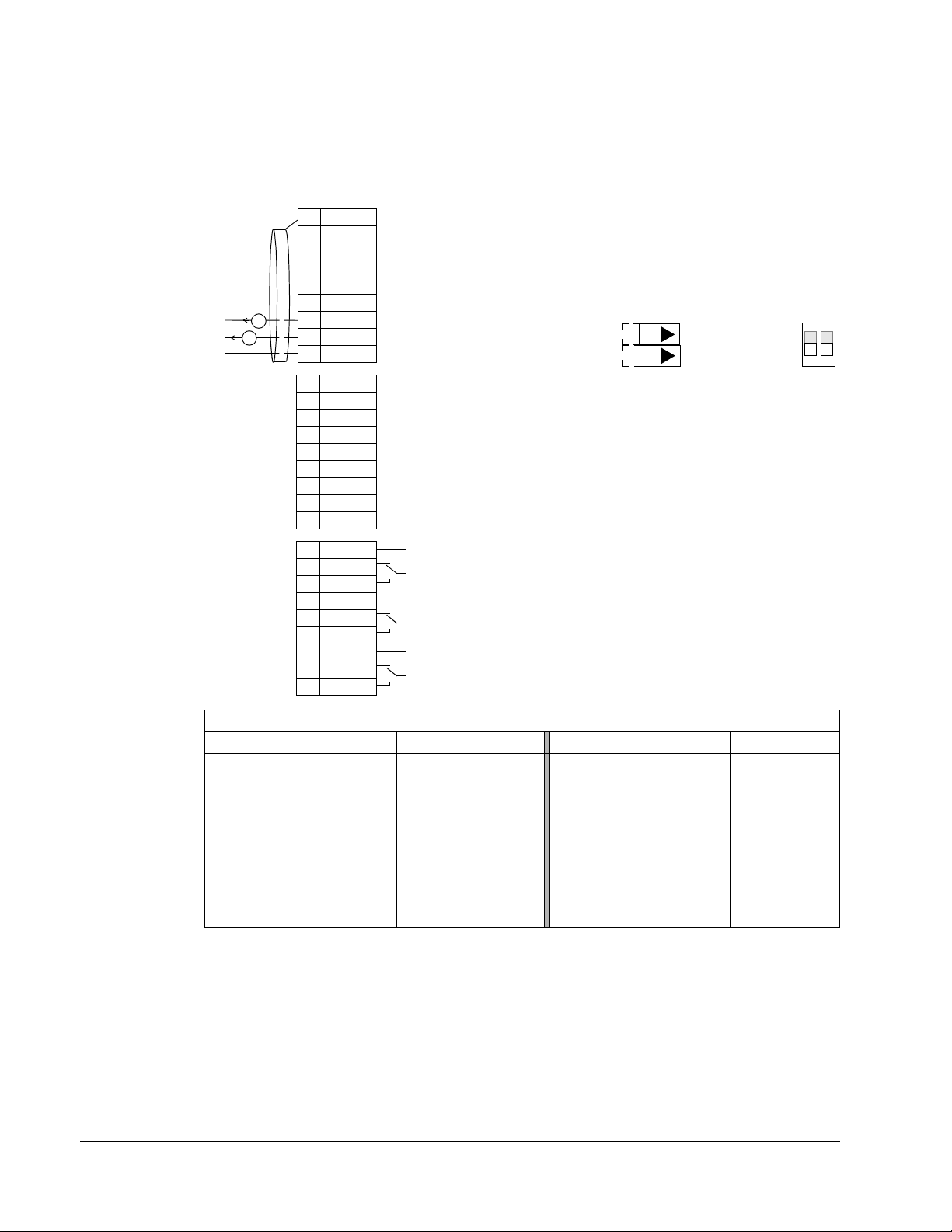

1SCR

2AI1

3AGND

4 10V

5AI2

6AGND

7AO1

8AO2

9AGND

10 24V

11 GN D

12 DCOM

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

21 RO1B

22 RO2C

23 RO2A

24 RO2B

25 RO3C

26 RO3A

27 RO3B

X1

+

mA

mA

External reference 0(2)…10 V or 0(4)…20 mA

Reference voltage 10 VDC

Output frequency: 0(4)…20 mA

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202

1

)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Relay output 1 (P 1401)

Default operation: Started =>19 connected to 21

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

Output current: 0(4)…20 mA

Not configured

Analog input circuit common

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog output circuit common

Auxiliary voltage output +24 VDC

Auxiliary voltage output common

Digital input common for all

Signal cable shield (screen)

Analog input circuit common

(Fault => 25 connected to 26)

+

J1

AI1: 0(4)

…20 mA

AI2: 0(4)

…20 mA

ON

Jumper Settings

ON

1

2

ON

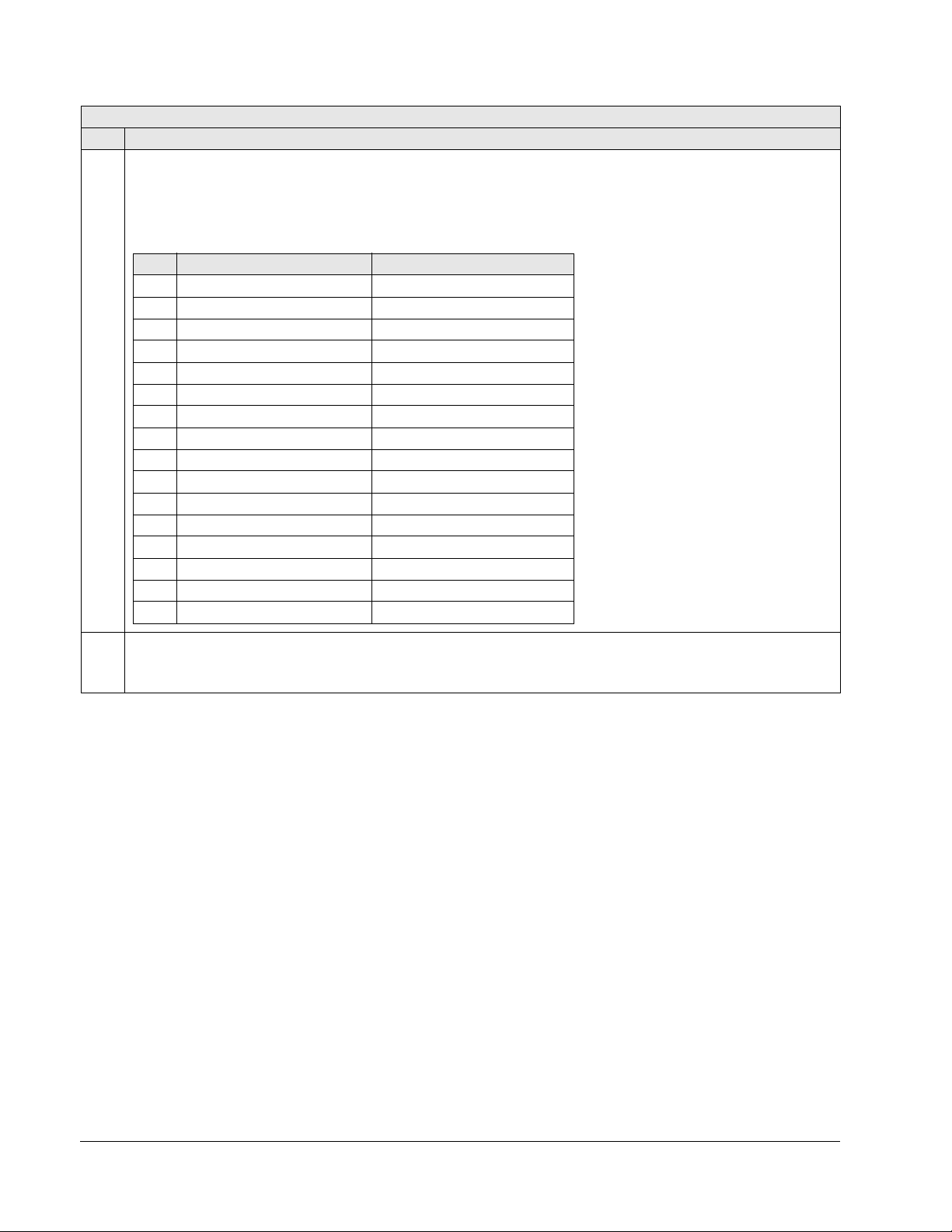

Supply Fan macro

This macro configures for supply fan applications where the supply fan brings fresh

air in according to signals received from a transducer. When using direct speed

reference in AUTO mode or process PID, see General considerations on page 1-49.

Application macros

Parameters Changed Relative to HVAC Default

9902

1401

Parameter Value Parameter Value

APPLIC MACRO 2 (SUPPLY FAN) 1601 RUN ENABLE 2 (DI2)

RELAY OUTPUT 17 (STARTED) 1609 START ENABLE 25 (DI5)

Page 53

ACH550-UH User’s Manual 1-53

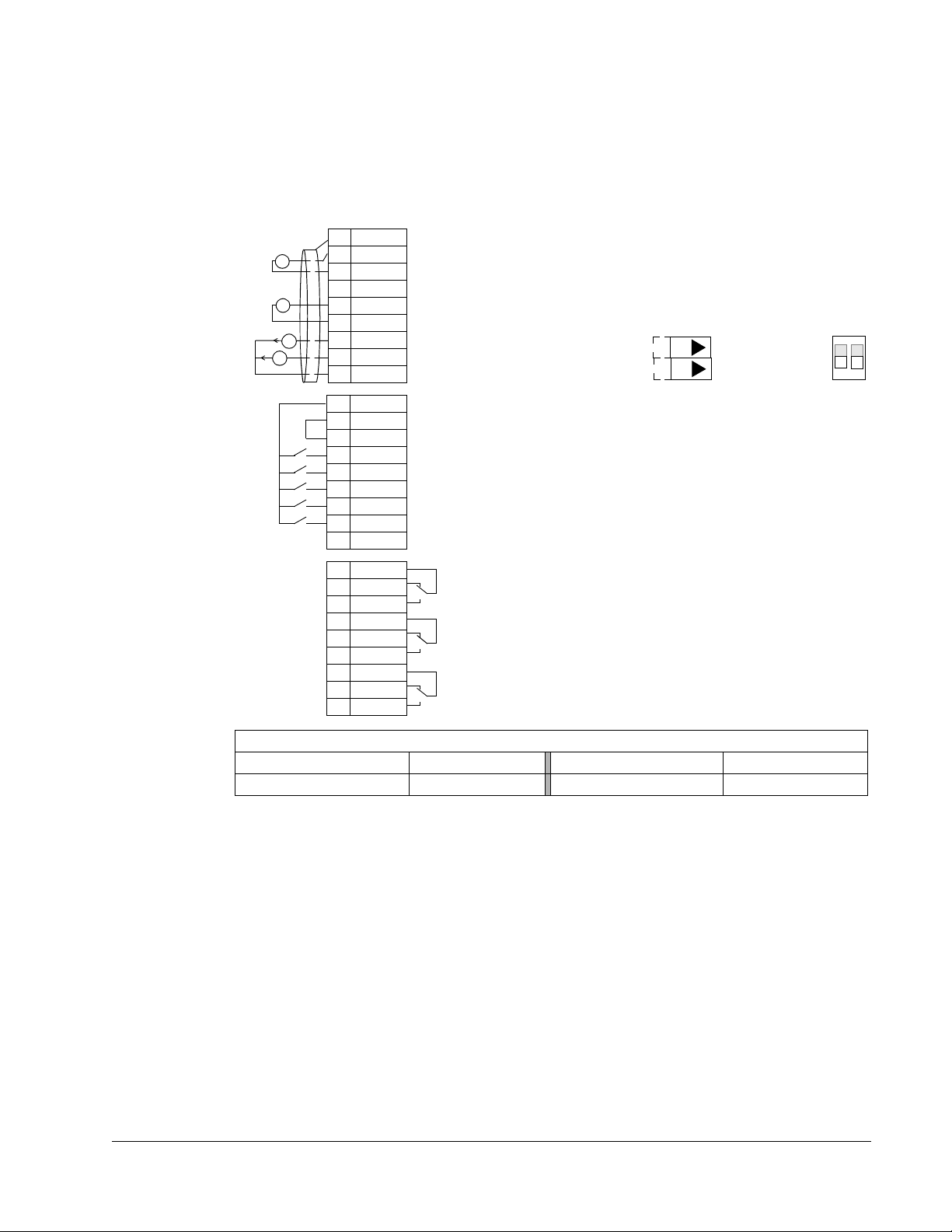

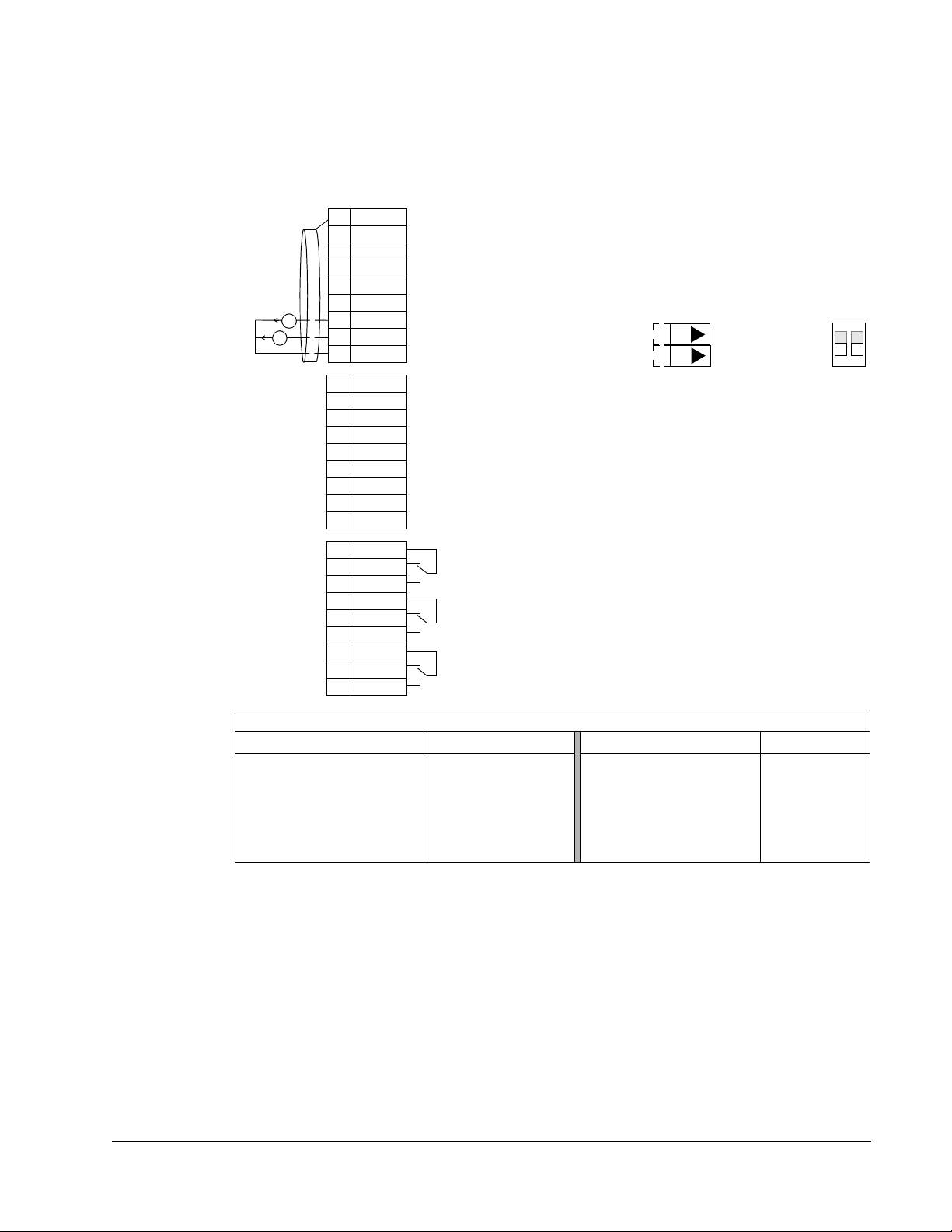

1SCR

2AI1

3AGND

4 10V

5AI2

6AGND

7AO1

8AO2

9AGND

10 24V

11 GN D

12 DCOM

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

21 RO1B

22 RO2C

23 RO2A

24 RO2B

25 RO3C

26 RO3A

27 RO3B

X1

+

mA

mA

External reference 0(2)…10 V or 0(4)…20 mA

Reference voltage 10 VDC

Output frequency: 0(4)…20 mA

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202

1

)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Relay output 1 (P 1401)

Default operation: Started =>19 connected to 21

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

Output current: 0(4)…20 mA

Not configured

Analog input circuit common

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog output circuit common

Auxiliary voltage output +24 VDC

Auxiliary voltage output common

Digital input common for all

Signal cable shield (screen)

Analog input circuit common

(Fault => 25 connected to 26)

+

J1

AI1: 0(4)

…20 mA

AI2: 0(4)

…20 mA

ON

Jumper Settings

ON

1

2

ON

Return Fan macro

This macro configures for return fan applications where the return fan removes air

according to signals received from a transducer. When using direct speed reference

in AUTO mode or process PID, see General considerations on page 1-49.

Parameters Changed Relative to HVAC Default

Parameter Value Parameter Value

APPLIC MACRO 3 (RETURN FAN) 1609 START ENABLE 25 (DI5)

9902

RELAY OUTPUT 17 (STARTED)

1401

Application macros

Page 54

1-54 ACH550-UH User’s Manual

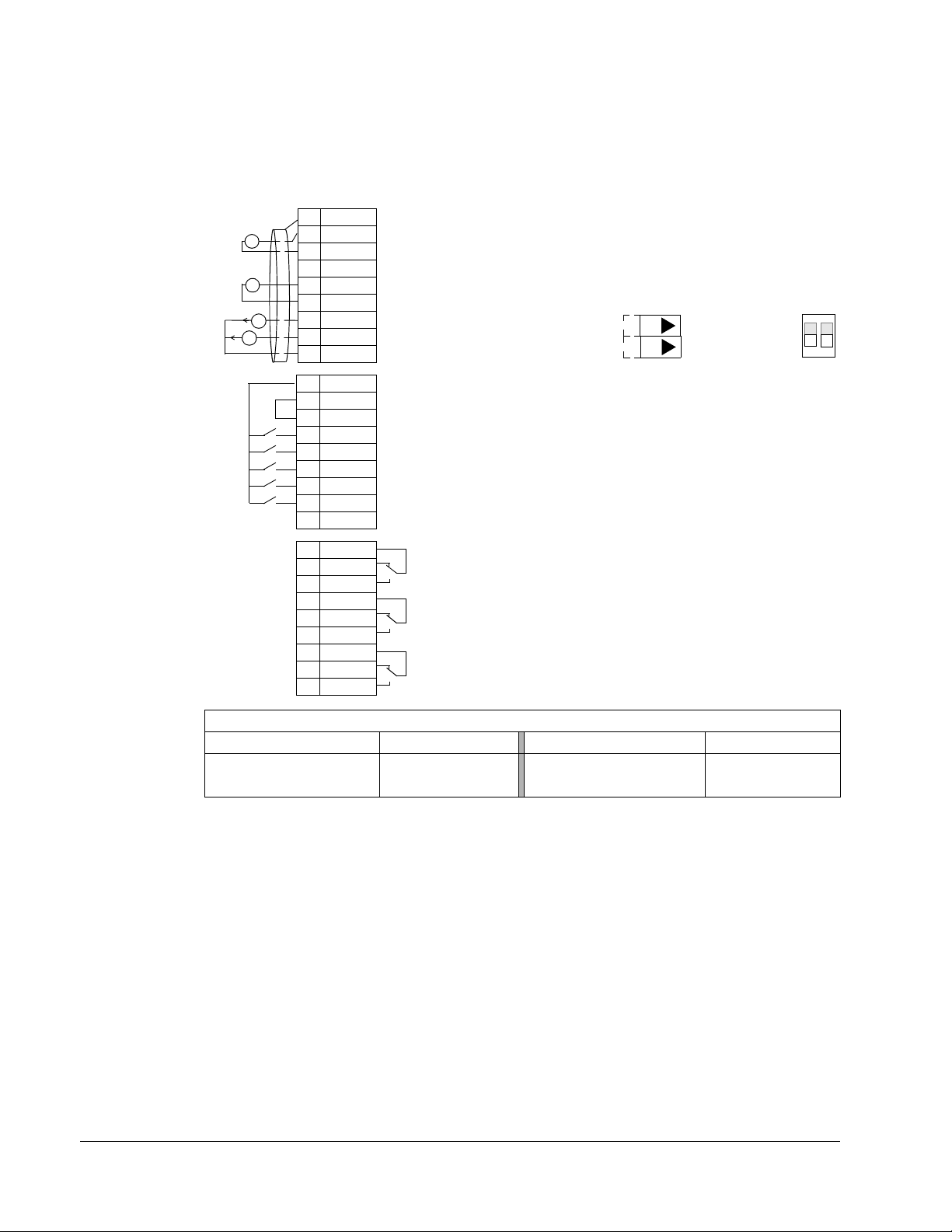

1SCR

2AI1

3AGND

410V

5AI2

6AGND

7AO1

8AO2

9AGND

10 24V

11 GN D

12 DCOM

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

21 RO1B

22 RO2C

23 RO2A

24 RO2B

25 RO3C

26 RO3A

27 RO3B