Page 1

3M Separation and Purication Sciences

™

3M

Zeta Plus

Depth Filters

High Performance, Scalable,

Single-Use System

™

Page 2

3M™ Zeta Plus™ Encapsulated System

The System of Choice for Single-Use Depth Filtration

High Performance

Filter Media

The 3M™ Zeta Plus™ Encapsulated

System utilizes the high performing

Zeta Plus depth lter series

media, including the single and

dual layer.

• Positive charge is capable of

reducing negatively charged

DNA, endotoxins and other host

cell proteins

™

• The 3M

media enhances the contaminant

holding capacity of the lter media.

This allows for larger particles to

be trapped in the upstream zone

of the more open lter media and

smaller particles to be trapped in

the downstream zone, reducing

premature plugging and helping

extend service life of the media.

• Can be used for post fermentation

cell culture clarication or

downstream impurity removal

• Can be employed independently or

in conjunction with centrifugation or

tangential ow ltration (TFF)

Zeta Plus™ dual layer

3M™ Zeta Plus™ Depth Filter Quick Start Guide

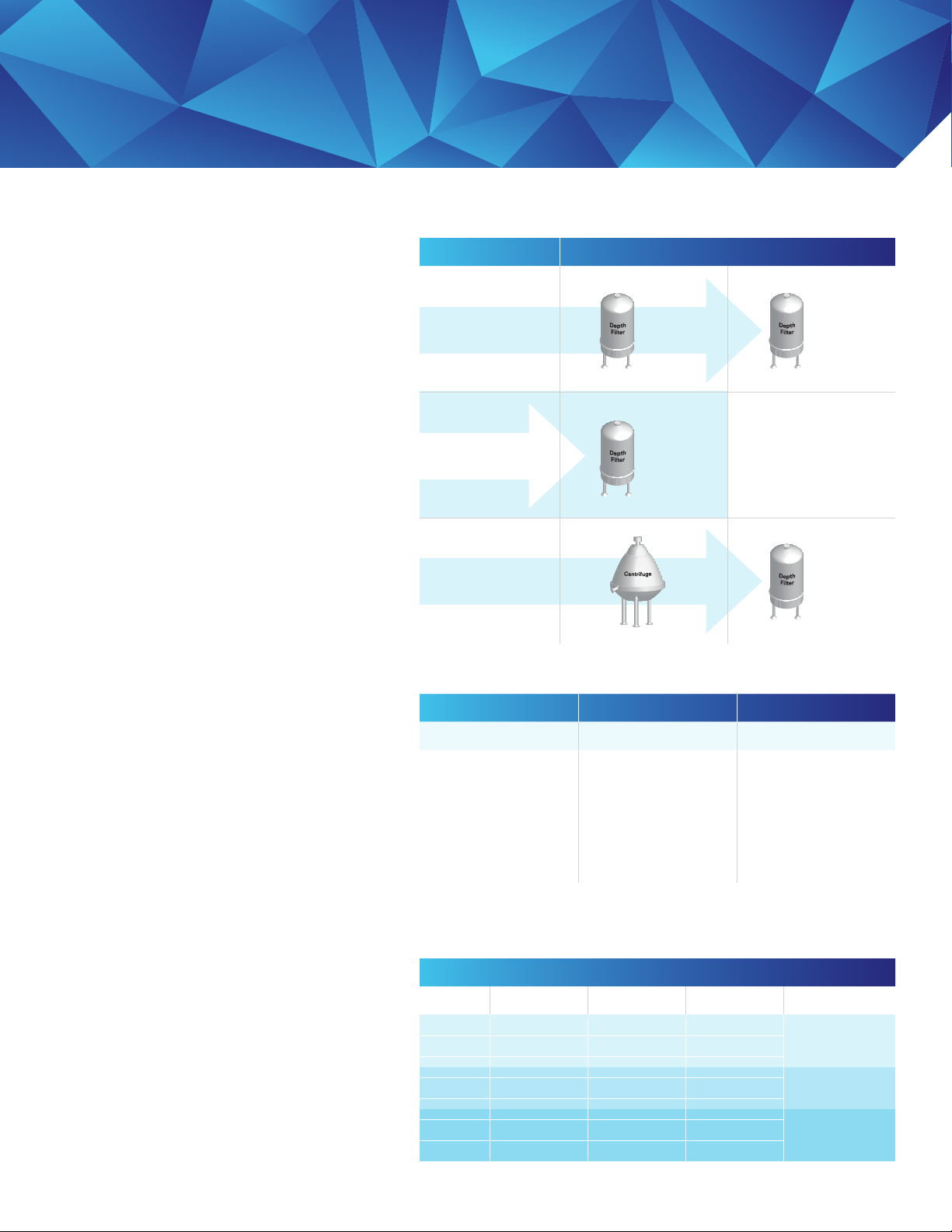

Application Stage / Product

First Stage Second Stage

Two Stage

Operations

Single Stage

Operations

Post Centrifuge

Operations

05SP01

10SP02

60SP02

90ZB08

90SP08

60ZB05

60SP05

90ZB08

90SP08

60ZB05

60SP05

Media Series

SP Media LA Media ZB Media

Widest Range Cleanest Highly Charged

SP has the widest nominal

pore size range relative to

other 3M Zeta Plus media

oerings, including a

greater number of grades

as well as grades with

larger nominal pore sizes

than LA or ZB media.

LA is the cleanest

3M Zeta Plus media family

offered. 3M

series low aluminum (LA)

filter media are designed

to provide low levels of

extractables, especially

aluminum.

™

Zeta Plus™ LA

ZB media offers a higher

charge level than SP or LA

media, and offers single

layer and dual layer grades

with a smaller nominal

pore size than either the

SP media family or the LA

media family.

• Activated carbon and lipid removal

media also available

2 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

Sizing Guide

Pore Size Options: 3M™ Zeta Plus™ SP, LA and ZB Media

Media Family

Grades SP ZB LA Application

5 X

10 X

30 X X X

50 X

60 X X X

90 X X X

120 X

For reference only. Retention ratings may vary depending on application.

Primary

Secondary

Centrate

Page 3

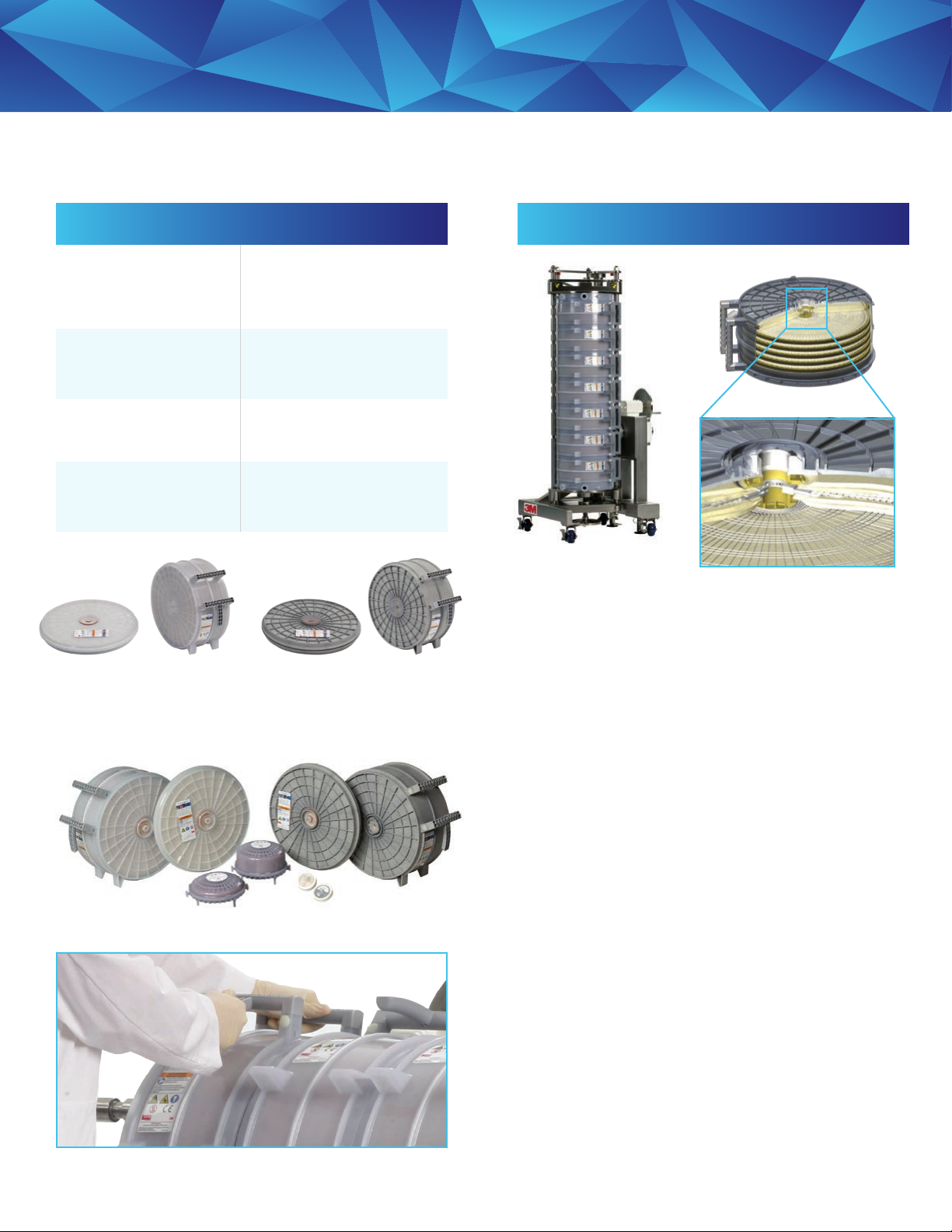

Features & Benets

Capsule/Manifold Design

Translucent plastic shell

(standard capsules,

polycarbonate shells)

Fully encapsulated shell

around solid core

Self guiding locking

mechanism

Lenticular style capsule

design

3M™ Zeta Plus™ Capsules:

Encapsulated Standard Capsule

with Polycarbonate Shells

• Easy detection of the liquid

level inside, providing real time

monitoring of the filtration

process.

• Eliminates the need for a

stainless steel housing and the

cleaning step after filtration.

• Fast and reliable capsule-to-

capsule connectivity.

• Consistency between

single-use and conventional

depth filtration.

3M™ Zeta Plus™ Capsules: Encapsulated

Capsule with Alkaline Resistant*

Polyphenylene Oxide/Polystyrene

3M™ Zeta Plus™ Filter Media

Model# 16EZB

• Both single and dual layer Zeta Plus filter

media are available.

• Excellent performance in throughput and

filtration efficiency with proper media

selection and sizing.

3M™ Zeta Plus™ Capsule Family

* Based on testing with 1M NaOH and 5% NaClO (Bleach).

• The 3M

a single use depth filtration system

• The complete system is comprised of a

holder, two manifolds and the desired number

of capsules

• The polycarbonate capsules feature a

translucent shell that allows for easy fluid

level observation

• A self-guiding locking mechanism ensures fast

and reliable connections between capsules

Self Guiding Locking

Mechanism Enables

Fast and Reliable

Capsule-To-Capsule

Connection

™

Zeta Plus™ Encapsulated System is

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 3

Page 4

3M™ Zeta Plus™ Encapsulated System

The System of Choice for Single-Use Depth Filtration

Ergonomically Designed

Large Filter Holders

Traditional depth ltration systems utilize lenticular style

cartridge lters and a vertical ltration ow path to allow

easy access to process liquids and ecient utilization of

lter media. However, stacking cartridges from bottom

to top can be cumbersome, and dismantling the spent

cartridges is often labor intensive.

Features & Benets

Ergonomically Designed Holder System

3M™ Encapsulated System

Holder, Large (Model

#16EZB): holder is pivoted

between horizontal and

vertical positions

Vertical flow path

• Enables loading and unloading at

waist height.

• Central inlets and outlets minimize

fluid spills during post use handing.

• Holder and capsule design

allows the combination of multiple

3M Zeta Plus media types or even

multiple 3M filtration products

in a single holder.

• Reduced footprint during operation.

4 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

Page 5

Recognizing the need for a depth ltration system that is fast, easy and clean, 3M designed lter holders

(Model# 16EZB) that can be pivoted between the horizontal position for loading and unloading the

capsules and manifolds, and the vertical position for ltration. Allowing loading and unloading at waist

height eliminates the need for operators to lift capsules above their heads and reduces the risk of uid

spills when handling spent capsules. The use of the vertical ow path allows for full media utilization and

a small system footprint during ltration.

3M™ Encapsulated System Holders, Small

(Model# 16EZA)

The small holder is available for laboratory and pilot scale-up

studies, in addition to low volume production ltration. The

1-high holder can accommodate from one to four 0.23 m²

capsules, or one 1.6 m² (dual layer) or 2.5 m² (single layer)

capsule. The 2-high holder can accommodate up to two 1.6 m²

(dual layer) or 2.5 m² (single layer) capsules. The 3 high holder

can accommodate up to three 1.6 m² (dual layer) or 2.5 m²

(single layer) capsules. Either single stage or two-stage depth

ltration can be performed within the same holder. The 1-high

small holder has a built-in torque limiter that will signal the

operator when the holder assembly is properly sealed. All

small holders have been designed to be fully autoclavable for

applications where that may be required.

3M™ Encapsulated System Holders, Large

(Model# 16EZB)

The large holder can accommodate up seven 1.6 m² (dual layer)

or 2.5 m² (single layer) capsules. This holder is best suited for

use in small to large production scale purication processes.

However, this holder can also accommodate a single 1.6 m²

(dual layer) or 2.5 m² (single layer) capsule should choose to use

it for scale up studies.

Two Stage Operations

For two stage purication operations a

second pair of manifolds is required between

each stage of multistage operations.

Manifold and capsule materials should

always be the same.

Figure 1. 3M™ Zeta Plus™ Encapsulated System

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 5

Page 6

Innovative Capsule/Manifold Design

Two capsule congurations are available for use

™

with the 3M

Zeta Plus™ Encapsulated System.

05SP01A

• Single cell and multicell capsules are available

2

• Single cells have 0.23 m

• Multicells have 1.6 m

2

or 2.5 m

of single layer media

of ltration media

2

of dual layer media

• Alkaline resistant capsules available

• Dual stage ltration can be performed in

the same holder by using an additional set

of manifolds

*Based on testing with 1M NaOH and 5% NaClO (Bleach).

10SP02A

30SP02A

60SP02A

60SP05A

60ZB05A

90SP05A

90ZB05A

90ZB08A

120ZB08A

0.1 0.5 1 2 4 6 10

Micron

Figure 2. Nominal Retention Ratings for

3M™ Zeta Plus™ Dual Layer Grades

(For reference only. Retention ratings may vary depending on application.)

Additional Formats Available

In addition to the 3M™ Zeta Plus™ Encapsulated system, cartridge and sheet options are also available in most media types and grades.

Zeta Plus Cartridges:

• Produced in 8 inch, 12 inch and 16 inch sizes

• Multiple lenticle and construction configurations

• Dual Layer cartridges are available in SP, ZB and LA

media families

• Stainless steel housings for each size available

• Uses the same media as encapsulated systems

6 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

Page 7

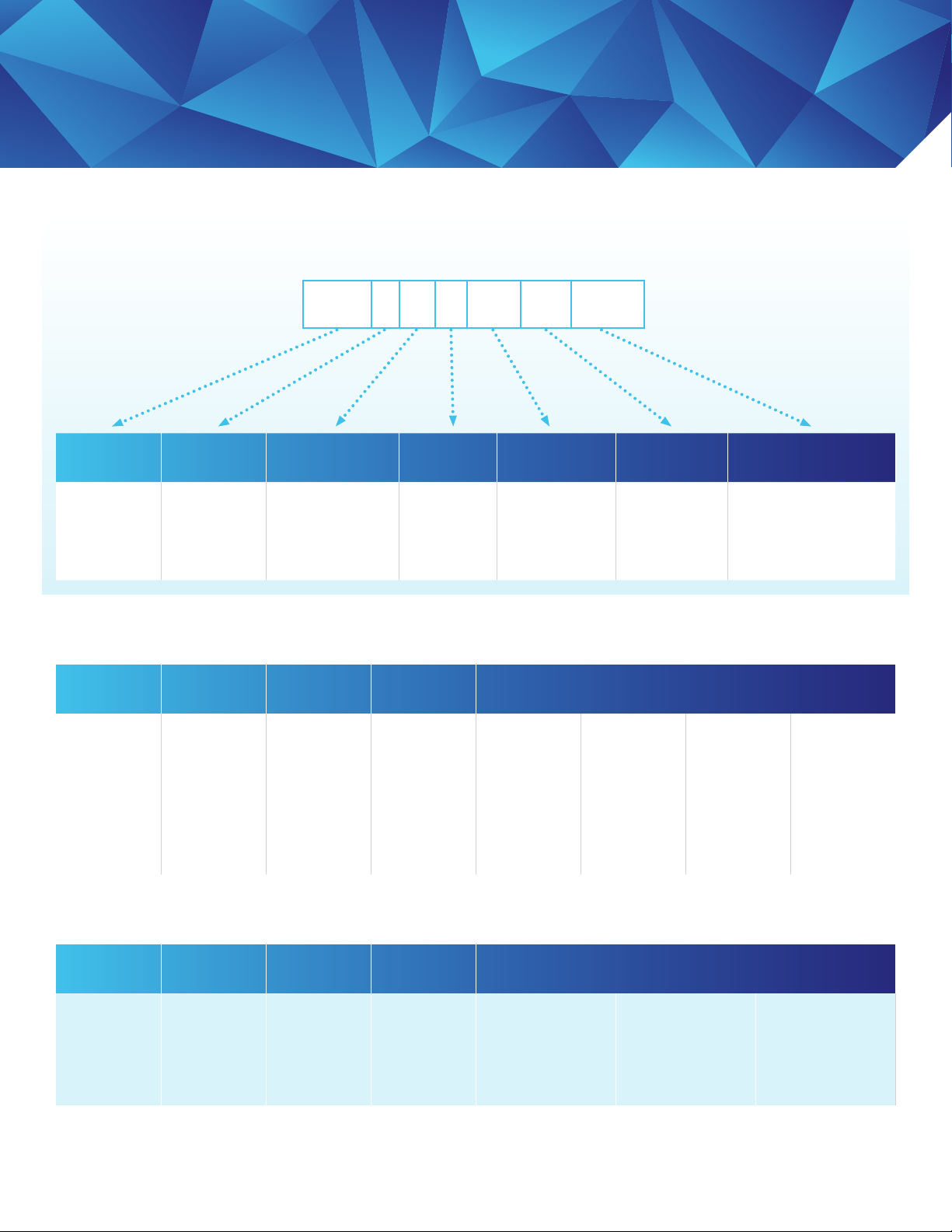

Scalability

The 3M™ Zeta Plus™ Encapsulated System retains the lenticular lter design and vertical ow path that

™

are characteristics of traditional depth ltration systems. A full range of 3M

available from benchtop to production scale, which allows for lab scale, pilot testing and scale-up with

the same ltration media.

Figure 3. The 3M™ Zeta Plus™

Encapsulated System

Zeta Plus™ capsules is

Capacity

Single-Use Depth Filtration

Product Portfolio

BC25 (25 cm2)

E0170 (170 cm²) and

E0340 (340 cm²)

E01020 (1020 cm²)

16EZA

Double layer: 1.6 m²

Single layer: 2.5 m²

16EZB

Double layer: 11.2 m²

Single layer: 17.5 m²

Process Volume

Zeta Plus Sheets:

• Available in SP, ZB and LA media families

• Activated carbon and lipid removal media

available on request

• May be die cut to match specific requirements

• Designed for use with commercially available

filter presses

Contact your local sales rep for additional information about these formats.

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 7

Page 8

Table 2a. 3M™ Zeta Plus™ Laboratory Capsules: Filter Specifications

BC25, Luer BC25, Sanitary

Dimensions

Single Layer (height by diameter)

Dual Layer (height by diameter)

Weight

Dry - Single Layer ≈ 60 g ≈ 64 g

Dry - Dual Layer ≈ 69 g ≈ 75 g

Wet Post Blow-Down - Single Layer ≈ 70 g ≈ 75 g

Wet Post Blow-Down - Dual Layer ≈ 86 g ≈ 93 g

Materials of Construction

Shells Polypropylene

Ring Seal (dual layer media) Polypropylene

Edge Seal Overmold Glass Fiber Filled Polypropylene

Luer Cap & Luer-barb Connector Polypropylene

Volume

Capsule Fill Volume¹ - Single Layer ≈ 17 mL

Capsule Fill Volume¹ - Dual Layer ≈ 25 mL

Post Blow-Down Hold-up Volume² - Single Layer ≈ 11 mL

Post Blow-Down Hold-up Volume² - Dual Layer ≈ 17 mL

Miscellaneous

Effective Filtration Area 25 cm² 25 cm²

Connector Luer

1

Volume of liquid required to fill capsule (experimentally measured).

2

Capsule Post blow-down hold-up volume. Estimated volume of residual preconditioning flush liquid after air/gas blow-down, using water as the flush

fluid and calculated by post-blow-down weight and flush fluid density. Actual amount depends upon exact blow-down conditions, media type in

capsule, the number of capsules in the system, the process fluid, and loading level of the capsule.

6.5 cm × 7.6 cm

(2.6 inches × 3 inches)

6.9 cm × 7.6 cm

(2.7 inches × 3 inches)

Can accommodate both ½" and ¾"

7.9 cm × 7.6 cm

(3.1 inches × 3 inches)

8.3 cm × 7.6 cm

(3.3 inches × 3 inches)

Sanitary Style

Laboratory Capsule Filter Schematics

Inlet

Vent

Outlet

BC-25 Sanitary Lab Capsule

8 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

Vent

BC-25 Luer Lab Capsule

Inlet

Outlet

Page 9

Table 2b. 3M™ Zeta Plus™ Scale-Up Capsules: Filter Specifications

170 cm² Capsule 340 cm² Capsule 1020 cm² Capsule

Dimensions

Height × Diameter

Weight

Dry - Single Layer 1.0 kg (2.2 lb) 1.0 kg (2.2 lb) 1.4 kg (3.0 lb)

Dry - Dual Layer 1.0 kg (2.2 lb) 1.0 kg (2.3 lb) 1.6 kg (3.5 lbs)

Wet Post Blow-Down - Single Layer 1.1 kg (2.4 lb) 1.1 kg (2.5 lb) 1.8 kg (4.0 lb)

Wet Post Blow-Down - Double Layer 1.2 kg (2.6 lb) 1.3 kg (2.9 lb) 2.4 kg (5.2 lb)

Materials of Construction

Capsule Shells Polysulfone

Separator, Spacer, Vent Cap Polypropylene

O-ring Fluorocarbon

Endcap & Edge Seals

Hold-up Volume

Capsule Fill Volume

Post Blow-Down Hold-up

2

Volume

1

Single Layer ≈ 0.67 L (≈ 1.5 gal) ≈ 0.69 L (≈ 1.5 gal) ≈ 1.7 L (≈ 3.7 gal)

Dual Layer ≈ 0.63 L (≈ 1.4 gal) ≈ 0.65 L (≈ 1.4 gal) ≈ 1.6 L (≈ 3.5 gal)

Single Layer ≈ 0.12 L (≈ 0.26 gal) ≈ 0.16 L (≈ 0.35 gal) ≈ 0.46 L (≈ 1.0 gal)

Dual Layer ≈ 0.15 L (≈ 0.34 gal) ≈ 0.26 L (≈ 0.58 gal) ≈ 0.80 L (≈ 1.8 gal)

Miscellaneous

Effective Filtration Area 170 cm² (0.18 ft²) 340 cm² (0.37 ft²) 1020 cm² (1.10 ft²)

Connector

1

Volume of liquid required to fill capsule (experimentally measured).

2

Capsule Post blow-down hold-up volume. Estimated volume of residual preconditioning flush liquid after air/gas blow-down, using water as the flush

fluid and calculated by post-blow-down weight and flush fluid density. Actual amount depends upon exact blow-down conditions, media type in

capsule, the number of capsules in the system, the process fluid, and loading level of the capsule.

IMPORTANT NOTICE: Always operate the filter system within the maximum differential pressure of 2.4 bar (35 psig).

4.1" × 8.5" (10.3 cm × 21.6 cm) 6.0" × 8.5" (15.2 cm × 21.6 cm)

Thermoplastic Elastomer

1/2" Sanitary Style

Scale-Up Capsule Filter Schematics

Outlet not shown

VentInlet

170 cm2 & 340 cm2 Capsules

Vent

Inlet Outlet

1020 cm2 Capsule

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 9

Page 10

Table 2c. 3M™ Zeta Plus™ Production Capsules: Filter Specifications

Configuration

Single Cell Capsule Multi-Cell Capsule

Standard Alkaline Resistant

Dimensions (Height × Diameter)

5.7 cm × 45.2 cm (2.2" × 17.8") 20.3 cm × 45.2 cm (8.0" × 17.8")

Weight

Dry 3.3 kg (7 lbs) 3.4 kg (8 lbs) 10.0 kg (22 lbs) 10.7 kg (24 lbs)

Wet (post Blow-Down) 4.4 kg (10 lbs) 4.8 kg (11 lbs) 19.3 kg (43 lbs) 19.7 kg (43 lbs)

Materials of Construction

Filter Media Filter aids, cellulose, binding resin Filter aids, cellulose, binding resin

Outer Shell Polycarbonate

Polyphenylene oxide /

Polystyrene

O-rings Silicone Silicone

Separators, Spacers and Connectors

Polypropylene Polypropylene

Edge Seals Thermoplastic Elastomer Thermoplastic Elastomer

Handles N/A Nylon

Hold-up Volume

Single Layer E16E01 & E16R01: ≈ 3.8 L (≈ 1.0 gal) E16E11 & E16R11: ≈ 18.8 L (≈ 5.0 gal)

Capsule Fill Volume

Post Blow-Down

Hold-up Volume³

2

Dual Layer E16E01 & E16R01: ≈ 3.4 L (≈ 0.9 gal) E16E07 & E16R07: ≈ 18.1 L (≈ 4.8 gal)

Single Layer E16E01 & E16R01: ≈ 0.7 L (≈ 0.2 gal) E16E11 & E16R11: ≈ 7.5 L (≈ 2.0 gal)

Dual Layer E16E01 & E16R01: ≈ 1.3 L (≈ 0.4 gal) E16E07 & E16R07: ≈ 9.0 L (≈ 2.4 gal)

Maximum Operating Line Pressure 3.4 bar (50 psig) 3.4 bar (50 psig)

Maximum Differential Pressure

Forward 2.4 bar (35 psid) 2.4 bar (35 psid)

Effective Filtration Area 0.23 m² (2.4 ft²)

1

Based on testing with 1M NaOH and 5% NaClO (Bleach).

² Volume of liquid required to fill capsule (experimentally measured).

³ Capsule Post blow-down hold-up volume. Estimated volume of residual preconditioning flush liquid after air/gas blow-down, using water as the

flush fluid and calculated by post-blow-down weight and flush fluid density. Actual amount depends upon exact blow-down conditions, media type

in capsule, the number of capsules in the system, the process fluid, and loading level of the capsule.

1

Standard Alkaline Resistant

Polycarbonate

Polyphenylene oxide /

Polystyrene

Double layer: 1.6 m² (17.2 ft²)

Single layer: 2.5 m² (27.0 ft²)

1

Single-Use Capsule Filter Schematic

Female Connector Female Connector

Plastic Shell

E16 Single-Cell Capsule

(with double layer or single layer media)

10 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

0.23 m

2

Capsule

Straight Handle

T Handle

Capsule Stop

E16 Multi-Cell Capsule

1.6 m2 Capsule

(with double layer media)

2.5 m2 Capsule

(with single layer media)

Page 11

Table 2d. 3M™ Encapsulated System Manifold Specifications

Configuration

Standard Alkaline Resistant

Dimensions (Height × Diameter)

Connector

Material Polycarbonate Polyphenylene oxide / Polystyrene

Weight 4.4 kg (9.6 lbs) 4.7 kg (10.4 lbs)

Hold up Volume Per Set < 250 mL (<0.07 gal)

5.2 cm × 45.2 cm ( 2.0" × 17.8" )

1.5" Sanitary Style

1

Single-Use Manifold Filter Schematic

Upstream Vent

Downstream Vent

Manifold Stop

O-Rings

Male Connector

Top Manifold Bottom Manifold

Female Connector

Outlet

Inlet

Manifold Stop

Table 3. 3M™ Encapsulated System Holder Specifications

Holder Model

Small Holder

(Model# 16EZA)

Maximum Operating Pressure

Materials of Construction

Frame 304 Stainless Steel 304 Stainless Steel

End Plates 304 Stainless Steel 304 Stainless Steel

Support Rods 440 Stainless Steel 316 Stainless Steel

Stand 304 Stainless Steel 304 Stainless Steel

Hand Wheels 300 Series Stainless Steel 300 Series Stainless Steel

Gear Box N/A

Locking Bar N/A 304 Stainless Steel

Casters Stainless Steel Stainless Steel

Wheels Phenolic Polyurethane

Material

Standard Mechanical Polish Finish (4552601) Mechanical Polish Finish (6123502)

Special Electropolish Finish (4552602) N/A

5.2 cm × 45.2 cm ( 2.0" × 17.8" )

Epoxy Coated Cast Iron Cover

Shrouded in 304 Stainless Steel

Large Holder

(Model# 16EZB)

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 11

Page 12

Table 4. 3M™ Encapsulated System Holder Capacity

Model

16EZA 4 1 2 N/A

16EZB N/A 7 N/A 6

E16E01 Capsule E16E07/E16E11 Capsule E16E01 Capsule E16E07/E16E11 Capsule

Table 4a. 3M™ Single Cell Capsule Capacities

Single Stage Two Stage

Holder

Single Stage Filtration (one set of manifolds) Two Stage Filtration* (two sets of manifolds)

Small, 1-high (Part #4552601) up to 4 2 to 3

Small, 2-high (Part #4552603) up to 9 5 to 8

Small, 3-high (Part #4552604) up to 11 6 to 9

Large (Part #6123502) 4 to 26 2 to 23

Single Cell Capsules (E16E01, E16R01, BV800)

Table 4b. 3M™ Multi-Cell Capsule Capacities

Holder

Single Stage Filtration (one set of manifolds) Two Stage Filtration* (two sets of manifolds)

Small, 1-high (Part #4552601) 1 n/a

Small, 2-high (Part #4552603) 2 2

Small, 3-high (Part #4552604) 3 2

Large (Part #6123502) up to 7 2 to 6

Multi-Cell Capsules (E16E07, E16R07, E16E11, E16R11, BV5600)

* Number of 3M production capsules which will fit in a 3M holder along with two sets of 3M manifolds. For example, 2 single cell production

capsules in the first stage followed by 1 single cell production capsule in the second stage meets the maximum of 3 single cell production capsules

for Part Number 4552601.

Figure 9. Small Holder Family (Model# 16EZA) Dimensions

121 cm

(47.48”)

Max

98 cm

(38.48”)

Min

Depth (z)

64.5 cm (25.4”)

65.6 cm

(25.81”)

3M™ Encapsulated System Holder,

Small, One-High Part #4552601

148 cm

(58.38”)

Max

120 cm

(47.38”)

Min

Depth (z)

64.5 cm (25.4”)

65.6 cm

(25.81”)

3M™ Encapsulated System Holder,

Small, Two-High Part #4552603

169 cm

(65.38”)

Max

141 cm

(55.38”)

Min

Depth (z)

64.5 cm (25.4”)

65.6 cm

(25.81”)

3M™ Encapsulated System Holder,

Small, Three-High Part #4552604

12 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

Page 13

Figure 10. Large Holder (Model# 16EZB) Dimensions

205.9 cm (81.1”)

Maximum

86.4 cm

(34.0”)

Horizontal Position

113.9 cm

(45.5”)

Z = depth = 109 cm (42.75”).

Depth includes the handle.

3M™ Encapsulated System Holder, Large, Part #6123502

109 cm

(42.75”)

Vertical Position

210.7 cm

(83”)

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 13

Page 14

Capsule Ordering Guide

Capsule Product Naming Convention

E16 E 11 A 30 SP 01A

Diameter Configuration Number of Cells

16"

Production

E - Standard

R - Alkaline

Resistant

1, 7 or 11 Cells

1 or 11 = Single

1 or 7 = Dual

Gasket

Material

A-Silicone 05, 10, 30,

Grade Media Second Layer

50, 60, 90

are available

for SP

DELI or DELP

Capsule Filter Ordering Information - Double Layer (U.S. Customers)

Catalog

Number

E16

Configuration

E - Standard

R - Alkaline

Resistant

*

Number of

Cells

01 - 1 Cell

07 - 7 Cell

Gasket

Material

A-Silicone

05SP01A

10SP02A

30SP02A

30SP03A

60SP01A

60SP02A

60SP03A

60SP05A

90SP05A

90SP08A

60LA05A

90LA05A

90LA08A

SP, ZB, LA,

Grade

01A, 02A, 03A, 05A

indicate grade of

second layer

120ZB05A

120ZB08A

120ZB10A

60ZB05A

90ZB05A

90ZB08A

DELP08A

Capsule Filter Ordering Information - Single Layer (U.S. Customers)

*

Number of

Cells

01 - 1 Cell

11 - 11 Cell

Catalog

Number

E16

14 | 3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio

Configuration

E - Standard

R - Alkaline

Resistant

Gasket

Material

A-Silicone

30LA

60LA

90LA

Grade

10SP

30SP

50SP

60SP

90SP

30ZB

60ZB

90ZB

120ZB

DELP

Page 15

Manifold Ordering Information

Manifold Part 3M PI Part Number 3M ID

Manifold Set (Standard) 6128901 70020256221

Manifold Set (Alkaline Resistant*) 6129001 70020262369

Filter Holder Ordering Information

Model Name 3M Catalog ID (U.S. Customers) Description 3M ID

™

Encapsulated System Holder,

3M

Small, One-High

™

Encapsulated System Holder,

3M

Small, Two-High

™

Encapsulated System Holder,

3M

Small, Three-High

™

Encapsulated System Holder,

3M

Large

16EZA

16EZB

4552601

4552603

4552604

6123502

Scale-Up Capsules - Dual Layer

70020310846

70020310861

70020310879

70020252899

3M Catalog ID

(U.S. Customers)

E

EFA cm

2

0170

0340

1020

Scale-Up Capsules - Single Layer

3M Catalog ID

(U.S. Customers)

E

EFA cm

2

0170

0340

1020

Material

Code

FSA

Material

Code

FSA

05SP01A

10SP02A

30SP02A

30SP03A

60SP01A

60SP02A

60SP03A

60SP05A

90SP05A

90SP08A

05SP

10SP

30SP

50SP

60SP

90SP

Grade

60LA05A

90LA05A

90LA08A

60ZB05A

90ZB05A

90ZB08A

120ZB05A

120ZB08A

120ZB10A

Grade

30LA

50LA

60LA

90LA

DELI08A

DELP08A

30ZB

60ZB

90ZB

120ZB

DELI

DELP

* Based on testing with 1M NaOH and 5% NaClO (Bleach). See Chemical Compatibility Guide (70-0202-2023-5/LITPHG03) for more information.

3M™ Zeta Plus™ Single-Use Depth Filtration Product Portfolio | 15

Page 16

Intended Use: 3M™ Zeta Plus™ single-use lter products are intended for use in biopharmaceutical processing applications of aqueous and chemical

based pharmaceuticals (drugs) and vaccines in accordance with the product instructions and specications, and cGMP requirements, where applicable.

Since there are many factors that can aect a product’s use, the customer and user remain responsible for determining whether the 3M product is

suitable and appropriate for the user’s specic application, including user conducting an appropriate risk assessment and evaluating the 3M product in

user’s application.

Restricted Use: 3M advises against the use of these 3M products in any application other than the stated intended use(s), since other applications have

not been evaluated by 3M and may result in an unsafe or unintended condition. Do not use in any manner whereby the 3M product, or any leachable

from the 3M product, may become part of or remains in a medical device that is regulated by any agency, and/or globally exemplary agencies, including

but not limited to: a) FDA, b) European Medical Device Directive (MDD), c) Japan Pharmaceuticals and Medical Devices Agency (PMDA) or in

applications involving permanent implantation into the body; Life-sustaining medical applications; Applications requiring food contact compliance.

Product Selection and Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can aect the use and performance of

a 3M product in a particular application. As a result, end-user is solely responsible for evaluating the product and determining whether it is appropriate

and suitable for end-user’s application, including completing a risk assessment that considers the product leachable characteristics and its impact on

drug safety conducting a workplace hazard assessment and reviewing all applicable regulations and standards (e.g., OSHA, ANSI, etc.). Failure to

properly evaluate, select, and use a 3M product and appropriate safety products, or to meet all applicable safety regulations, may result in injury,

sickness, death, and/or harm to property.

Warranty, Limited Remedy, and Disclaimer: Unless a dierent warranty is specically stated on the applicable 3M product packaging or product

literature (in which case such warranty governs), 3M warrants that each 3M product meets the applicable 3M product specication at the time 3M ships

the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED

WARRANTY OR CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ARISING OUT OF A COURSE OF DEALING,

CUSTOM, OR USAGE OF TRADE. If a 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement

of the 3M product or refund of the purchase price.

Limitation of Liability: Except for the limited remedy stated above, and except to the extent prohibited by law, 3M will not be liable for any loss or damage

arising from or related to the 3M product, whether direct, indirect, special, incidental, or consequential (including, but not limited to, lost prots or

business opportunity), regardless of the legal or equitable theory asserted, including, but not limited to, warranty, contract, negligence, or strict liability.

3M Separation and Purification Sciences Division

400 Research Parkway

Meriden, CT 06450 USA

Phone: 1-800-243-6894

1-203-237-5541

Web: www.3M.com/bioprocessing

Please recycle. Printed in U.S.A. © 3M 2019.

3M and Zeta Plus are trademarks of 3M Company.

All rights reserved. 70-0202-3967-2 Rev 12/2019

Loading...

Loading...