Page 1

Transportation Safety Division

3M™ Liquid Pavement Marking Series 5000

Product Bulletin Series 5000

March 2021

Replaces Product Bulletin 5000 Dated April 2016

1 Description

3M™ Liquid Pavement Marking Series 5000 (“Series 5000”) has been designed for use as a durable pavement

marking on roadways and highways. Series 5000 is a 2:1 ratio two-component, 100 percent solid polyurea coating

material that cures rapidly to hardness after application. Series 5000 can be configured to provide desired levels of

retroreflective performance using a number of different optics packages.

Applied to properly prepared road surfaces, Series 5000 markings can be used for long-lines (center, skip, and

contrast), channelizing lines, gore markings, and intersection markings.

Series 5000 can also be applied over any type of well-adhered pavement marking. The required application

thickness for Series 5000 is determined by the application surface or marking use, and discussed in Section 5

below. See 3M Information Folder 5.28

for detailed surface preparation recommendations.

For long line markings, Series 5000 is applied using a specialized mobile, truck-mounted or self-contained,

pavement marking machine. This pavement marking machine applies the two-component liquid materials and

reflective media simultaneously in continuous or skip patterns.

Page 2

2 3M™ Liquid Pavement Marking Series 5000 March 2021

2 Product Features

• Track-free in less than two minutes over entire application temperature range.

• Low temperature application, down to 30 ºF (-1 ºC).

• Excellent adhesion to asphalt cement concrete (ACC) and properly prepared Portland cement concrete

(PCC).

• Good dry and wet weather performance when Connected Roads All Weather Elements (“Elements”) are

used.

• Very low shrinkage, which enables quality installations on most common pavement surfaces.

• Resists discoloration caused by ultraviolet exposure and dirt pickup.

• Elements are colored, which helps provide a true yellow color under nighttime illumination.

• Typical volatile organic compound (VOC) content is 2.1 grams/liter or less.

• No intentional use of heavy metals, lead chromate pigments, or other similar lead-containing materials.

• Good color retention (Per MUTCD color requirements).

3 Component References

Components available from 3M:

• 5000 Part A White

• 5001 Part A Yellow

• 5050 Part B

• Series 90, Series 50, and Dry White Elements

• Series 91, Series 51, and Dry Yellow Elements

Components available from other suppliers

• Non-reflective Black Particles.

• Glass beads specifically designed for Series 5000 markings are available from a number of suppliers.

Contact 3M Technical Service at 1-800-553-1380 for sources and specifications.

4 Specifications

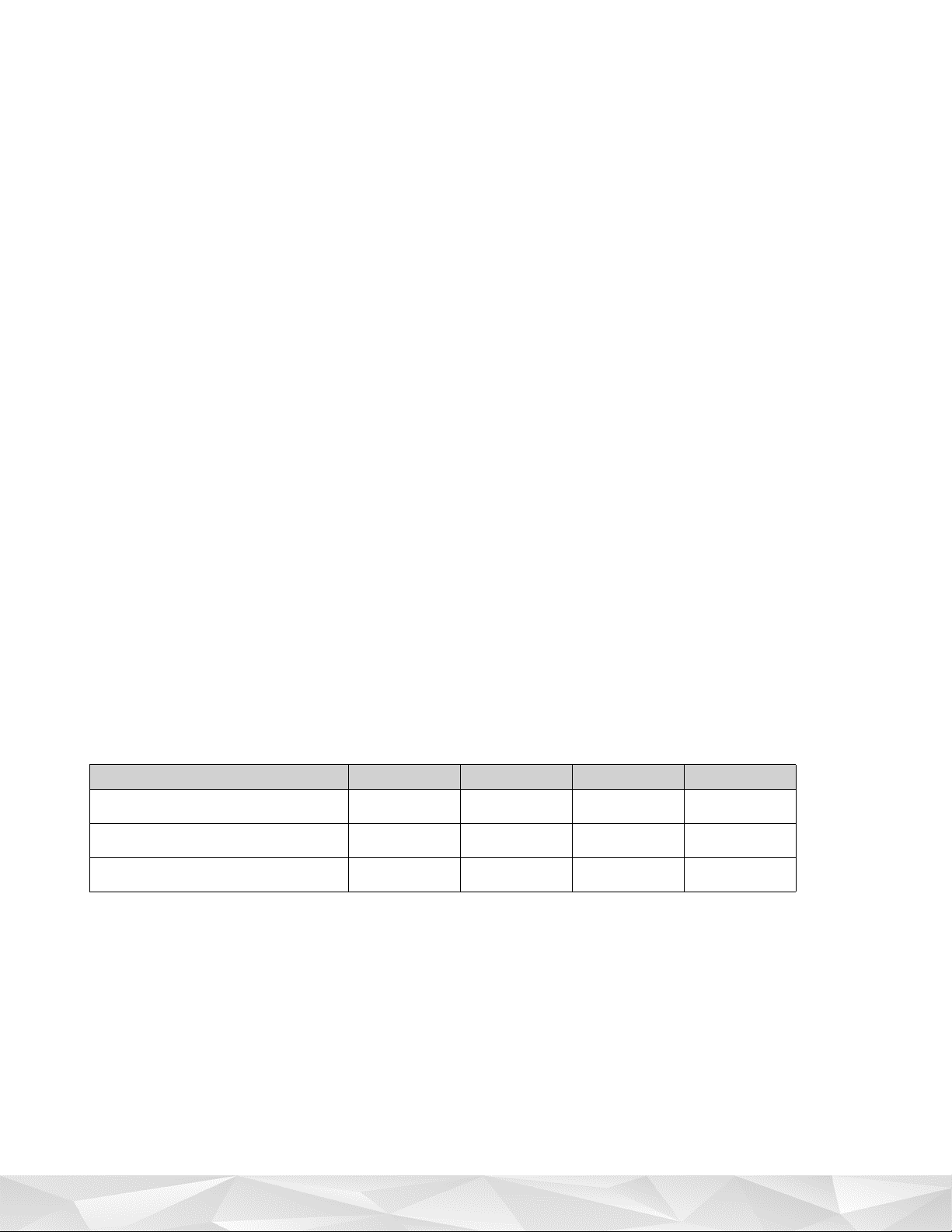

Table 1 presents typical retroreflectivity values for Series 5000 pavement markings Elements. Some variance

should be expected across applications, and all values represent initial properties unless otherwise noted.

Table 1. Typical average initial coefficients of retroreflected luminance

Property/test method Series Dry Series 50 Series 90 Series Wet

Retroreflectivity, Dry Average

ASTM E1710

Retroreflectivity, Wet Recovery Average

ASTM E2177

Retroreflectivity, Wet Continuous Average

ASTM E2832

a.Typical retroreflectivity results represent average performance for smooth pavement surfaces. Results may vary due

to differences in pavement type and surface roughness. Increased Elements drop rate may be necessary to

compensate for increased surface area characteristic of rough pavement surfaces. Wet retroreflectivity testing of

markings applied in grooved or recessed surfaces is difficult since water pools in recesses. In such cases, consider

installing sections of pavement markings for testing on either a smooth section of the pavement surface, or on rigid

panels (50 mil aluminum). If markings are applied to panels, allow them to cure, then move them carefully for

retroreflectivity testing - make sure to protect the optics when transporting.

White: 1250

Yellow: 900

N/A

N/A

White: 700

Yellow: 525

White: 275

Yellow: 225

White: 200

Yellow: 150

a

[mcd/m2/lx].

White: 500

Yellow: 375

White: 375

Yellow: 300

White: 275

Yellow: 225

N/A

White: 400

Yellow: 325

White: 300

Yellow: 250

Page 3

3 3M™ Liquid Pavement Marking Series 5000 March 2021

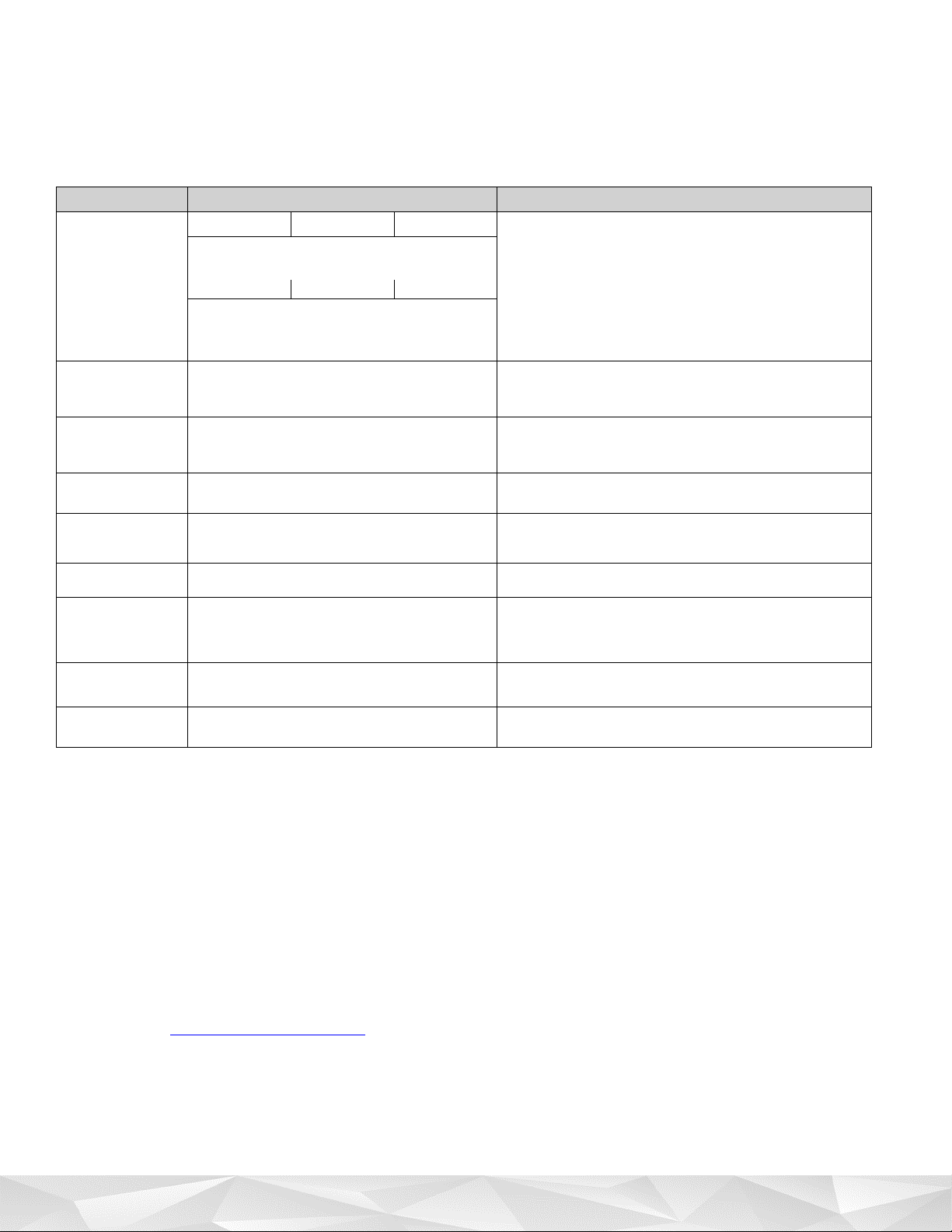

Table 2 presents typical initial properties for Series 5000 markings. Some variance should be expected across

applications, and all values represent initial properties unless otherwise noted.

Table 2. Typical initial properties of Series 5000 pavement markings.

Property Specification Test Details

Initial After 1000 hrs

White Cap Y

Color

Adhesion to

Portland Cement

Concrete

Adhesion to

Asphalt Cement

Concrete

No Track Time

(Laboratory)

No Track Time

(On the Road)

Skid Resistance

Volatile Organic

Compound (VOC)

Content

TiO2 Content

(White)

Acid Resistance of

Glass

Coating only >90 >89

With beads >63

Yellow Cap Y

Coating only 54–60 54–60

With beads 39–45

Portland cement concrete failure: PASS

Asphalt cement concrete failure: PASS

No pick-up condition within two minutes

No track condition within two minutes; insensitive

to temperature

Greater than or equal to 45 BPN beads only >60

beads and Elements

Upon mixing liquid components in appropriate ratio,

the VOC content is equal to 2.1 grams/liter or less.

>16% By weight.

No more than 15% of beads showing distinct opaque

surface upon microscopic examination (20x)

ASTM E1349 -45/0 (0/45) and CIE Illuminant D65 and CIE1931

(2°) Standard Observer.

ACI Method 503. Samples should be conditioned at room temperature (75 ± 2 °F) for 24–72 hours prior to testing.

ACI Method 503. Samples should be conditioned at room temperature (75 ± 2 °F) for 24–72 hours prior to testing.

ASTM D711; 15 mil binder thickness, insensitive to temperature,

AASHTO Type 1 beads coated at 0.099 pounds per square foot.

ASTM D711 with 77 °F air temperature; 15 mil thick binder

coated with normal bead and Element loading; no visible tracking from a distance of 50 feet.

ASTM E303

Testing of mixed liquid components should be conducted in

accordance with EPA Reference Method 24 - determination of

volatile architectural coatings and paints. Matter content, density, volume solids.

Expose microcrystalline ceramic beads to 1% solution (by

weight) of sulfuric acid.

5 Application

5.1 Required Weather and Pavement Conditions

o Dry weather only.

o Minimum 24 hour dry period.

o Air/road temperature of at least 30 ºF (-1 ºC).

o Road surface completely dry with no dew or frost.

o Road surface free of dirt, sand, dust, oil, grease, and all other contaminants.

o Curing compound and latents removed from new PCC surfaces.

o Users are encouraged to evaluate the substrate for intersection markings. The recommended substrate

for intersection markings is ACC.

o Poorly adhered pavement marking must be removed to expose 80% of the pavement surface prior to

application of Series 5000.

oSee 3M Information Folder 5.28

for additional application guidelines.

Page 4

4 3M™ Liquid Pavement Marking Series 5000 March 2021

5.2 Requirements

The marking installer is responsible for meeting all application requirements presented in Table 3.

Table 3. Binder application requirements.

Application Surface Description or Marking Use

Smooth (variation ≤ 0.125") pavement (asphalt, concrete, grooved or surface

treatment)

Textured or variation ≥ 0.125" (open graded, large stone mixes, tined or sawn

concrete, chip seal)

Well-worn and well adhered existing markings, see Information Folder 5.28

For use as temporary markings (prior to durable marking application)

a. Application rates calculated using a conversion of 231 cubic inches per US liquid gallon.

Recommended Series 5000 Liquid Binder Thickness

(1 inch = 1000 mils) & Usage Rates

20 to 22 mils

(240–220 linear feet for 4-inch line width per gallon)

25 to 30 mils

(190–160 linear feet for 4-inch line width per gallon)

20 to 22 mils

(240–220 linear feet for 4-inch line width per gallon)

10 to 15 mils

(480–320 linear feet for 4-inch line width per gallon)

a

5.3 Application Rates

Elements, or other first drop glass beads, and second drop glass beads must be applied at the rates shown in

Table 4 and Table 5, respectively. The preferred second drop glass bead type for use with Series 5000 is

Missouri Type P or 18/50 (Utah).

Table 4. 3M Connected Roads All Weather Elements application rates.

Units

Pounds per 4-inch lineal foot 0.018

Pounds per mile, 4-inch width 93

Grams per 4-inch lineal foot 8

Grams per square foot 24

Grams per square meter 260

Pounds per gallon - 20 mils ~240 ft/gal 4.2

Pounds per gallon - 25 mils ~190 ft/gal 3.4

Pounds/100 Sq ft 5.3

Minimum for Durable Markings

on Smooth Surface

Table 5. Second drop glass bead (Missouri Type P or 18/50 (Utah) preferred) or black particle application rates.

Units Application Rate

Grams per 4-inch

lineal foot

Grams per square

meter

Pounds per 4-inch

lineal foot

Pounds/100 Sq ft 9.92–13.23

Pounds per gallon -

20 mils ~240 ft/gal

Pounds per gallon -

25 mils ~ 190 ft/gal

15–20

485–646

0.033–0.044

8.0–10.7

6.4–8.5

Page 5

5 3M™ Liquid Pavement Marking Series 5000 March 2021

5.4 Bead Types

Many different glass bead gradations are currently used for pavement markings. Table 6 presents glass bead

gradations of several bead types commonly used with liquid pavement markings.

Table 6. Bead gradations of bead types commonly used with liquid pavement markings.

Common bead types with liquid pavement markings

Bead gradations - mass percent passing (ASTM D1214)

US Mesh Micron

10 2000 100

12 1700 100 95–100

14 1410 95–100 80–95

16 1180 100 80–95 10–40

18 1000 65–80 10–40 0–5

20 850 95–100 90–97 0–5 0–2

25 710 0–2

30 600 75–95 60–87 0–30

40 425

50 300 15–35 0–15 0–5

70 212 0.5

80 180

100 150 0–5

a. A minimum of 15% of the total weight will be from direct melt glass. All +30 US Mesh beads will be 85% minimum

rounds and minimum crush strength of 30 lbs. in accordance with ASTM D1213.

b. Bead types used as in double drop or in triple drop optics package.

AASHTO M247

b

Type I

Missouri

Specification

Type P

18/50 Blend

(former Utah

Performance

Specification)

AASHTO M247

b

Type 3

a

AASHTO M247

b

Type 4

5.5 Marking Dimensions

Marking dimensions must be in accordance with the “Manual on Uniform Traffic Control Devices” and the

project plans.

5.6 Proportioning and Mixing

Ensure that application equipment provides continuous proportioning at two volumes of Part A to every one

volume of Part B, and sufficient mixing to ensure that markings are hardened throughout and free of soft and

uncured or “blackened” areas and streaks. See 3M Information Folder 5.28

for detailed recommendations.

5.7 Control of Overspray

Series 5000 markings must not exhibit excessive overspray.

5.8 Placement of Beads and Elements

Elements and beads must be dropped onto Series 5000 such that their upper exposed portions are free of

binder material. Target embedment for beads and Elements is 40–60%.

6 Equipment

The installer is responsible for procuring equipment suitable for applying Series 5000 markings, as well as

maintaining and operating the equipment in a manner that ensures that the application requirements are met.

Equipment for applying Series 5000 markings is available from suppliers independent of 3M. The application

machines pump the two binder components in the correct volumetric ratio through a mixing device and airless

spray nozzle. Prior to mixing, the two liquids are heated and filtered. Elements, and then beads, are dropped onto

the binder immediately after it is sprayed. Some application machines are capable of applying multiple lines at the

same time, and can stripe at speeds of up to eight miles per hour, depending upon application dimensions

(thickness and width).

Page 6

6 3M™ Liquid Pavement Marking Series 5000 March 2021

7Storage

Store Series 5000 binder components in a cool, dry, well ventilated, indoor area, at a temperature of 40–100 ºF

(4–38 ºC). Use within six months of receipt. If Part A has been exposed to high temperature, and/or stored for an

extended period of time, it may require remixing. Inspect Part A before use. If separation is noted, remix. If Part B is

exposed to high heat for an extended period, the container can pressurize and possibly rupture. Proper disposal of

empty drums is the responsibility of the user. For more information, see 3M Information Folder 5.28

Series 5000 Safe Handling Procedures.

Note: 3M fills containers with Series 5000 liquid components by weight. This is done to ensure the accuracy and

consistency of shipped quantities, regardless of temperature. 3M has shown this filling method to be more

accurate than the volume markings on the product containers. Volume markings on containers are for reference

only.

Appendix B,

8 Health and Safety Information

Read all health hazard, precautionary, and first aid statements found in the Safety Data Sheets (SDSs),

3M Information Folder 5.28

the SDSs during the filling, use, or cleaning of application equipment. This product is intended for outdoor use only.

Application in tunnels or enclosed areas may necessitate the use of additional precautions. Purchaser

acknowledges and agrees to follow recommended safety and handling procedures as provided in the SDSs. To

obtain SDSs and Article Information Sheets for 3M products, go to 3M.com/SDS, contact 3M by mail, or for urgent

requests call 1-800-364-3577.

Appendix B and/or product labels prior to handling or use. Follow all precautions on

9 Quality Policy and Warranty Information

9.1 3M Basic Product Warranty

3M has no control over application methods or the quality of the surface to which materials are applied.

Therefore, 3M's warranty for Series 5000 shall be limited to the quality of materials supplied.

Series 5000 are warranted (“Basic Warranty”) to be free of defects in materials and manufacture at the time of

shipment and to meet the specifications stated in this product bulletin. If the Series 5000 is proven not to have

met the Basic Warranty on their shipment date, then a buyer's exclusive remedy, and 3M's sole obligation, at

3M's option, will be refund or replacement of Series 5000.

9.2 Disclaimer

THE 3M WARRANTY IS MADE IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE, OR ANY IMPLIED WARRANTY ARISING

OUT OF A COURSE OF DEALING OR OF PERFORMANCE, CUSTOM, OR USAGE OF TRADE.

9.3 Limitation of Liability

Except for the limited remedy stated above, and except where prohibited by law, 3M will not be liable for any

loss or damage arising from the use of or the inability to use Series 5000 or any 3M product, whether direct,

indirect, special, incidental, or consequential damages (including but not limited to lost profits, business, or

revenue in any way), regardless of the legal theory asserted including warranty, contract, negligence, or strict

liability. Before using, the user shall determine the suitability of Series 5000 for his/her intended use and the

user assumes all risk and liability whatsoever in connection therewith.

3M assumes no responsibility for any injury, loss, or damage arising out of the use of a product that is not of

our manufacture. Where reference is made in our literature to a commercially available product made by

another manufacturer (for example, application equipment), it shall be the user's responsibility to ascertain its

effectiveness and to take any precautionary measures required for its use, as outlined by the product's

manufacturer.

Page 7

7 3M™ Liquid Pavement Marking Series 5000 March 2021

10 Other Product Information

Always confirm that you have the most current version of the applicable product bulletin, information folder, or

other product information from 3M’s Website at http://www.3M.com/roadsafety

.

11 Literature References

3M IF 5.18 3M™ Stamark™ Pavement Marking Tape and Liquid Pavement Markings Application Guidelines

for Pavement Markings in Grooved Pavement Surfaces

3M IF 5.23

3M IF 5.28

3M PB CR AWE

ASTM Test Methods are available from ASTM International, West Conshohocken, PA.

3M™ Connected Roads All Weather Elements Application Guidelines for 3M Connected Roads

All Weather Elements

Liquid Pavement Marking Application Guidelines Series 5000

3M™ Connected Roads All Weather Elements

Page 8

For Information or Assistance

Call:

In Canada

1

Interne

http://www.3M.com/roadsafety

3M, Science. Applied to Life., and Stamark are trademarks of 3M. Used under license in Canada.

All other trademarks are the property of their respective owners.

3M assumes no responsibility for any injury, loss, or damage arising out of the use of a product that is not of our

manufacture. Where reference is made in literature to a commercially available product, made by another

manufacturer, it shall be the user’s responsibility to ascertain the precautionary measures for its use outlined by

the manufacturer.

1-800-553-1380

Call:

-800-3M HELPS (1-800-364-3577)

t:

Important Notice

All statements, technical information and recommendations contained herein are based on tests we believe to be

reliable at the time of this publication, but the accuracy or completeness thereof is not guaranteed, and the

following is made in lieu of all warranties, or conditions express or implied. Seller's and manufacturer's only

obligation shall be to replace such quantity of the product proved to be defective. Neither seller nor manufacturer

shall be liable for any injury, loss, or damage, direct, indirect, special, or consequential, arising out of the use of or

the inability to use the product. Before using, user shall determine the suitability of the product for his/her

intended use, and user assumes all risk and liability whatsoever in connection therewith. Statements or

recommendations not contained herein shall have no force or effect unless in an agreement signed by officers of

seller and manufacturer.

Transportation Safety Division

3M Center, Building 0225-04-N-14

St. Paul, MN 55144-1000 USA

Phone 1-800-553-1380

3M.com/roadsafety

Web

Please recycle. Printed in USA © 3M 2021.

All rights reserved. Electronic Only

Loading...

Loading...