Page 1

Low Range Shortening Monitor

LRSM

Technical Data TD 250

Date : Nov 2005

Supersedes : April 2004

Author : EK/CB

Introduction :

Shortening continually

breaks down through normal

use. This process is characterized by a modification of

the structure of the constituent molecules (Triglycerides). The by-products that

are formed are mainly Polar

Compounds, among others

are Free Fatty Acids

(F.F.A.). The 3M Low

Range Shortening Monitor

utilizes the free fatty acid

concentration as an indicator

to the degree of shortening

breakdown.

Product Description :

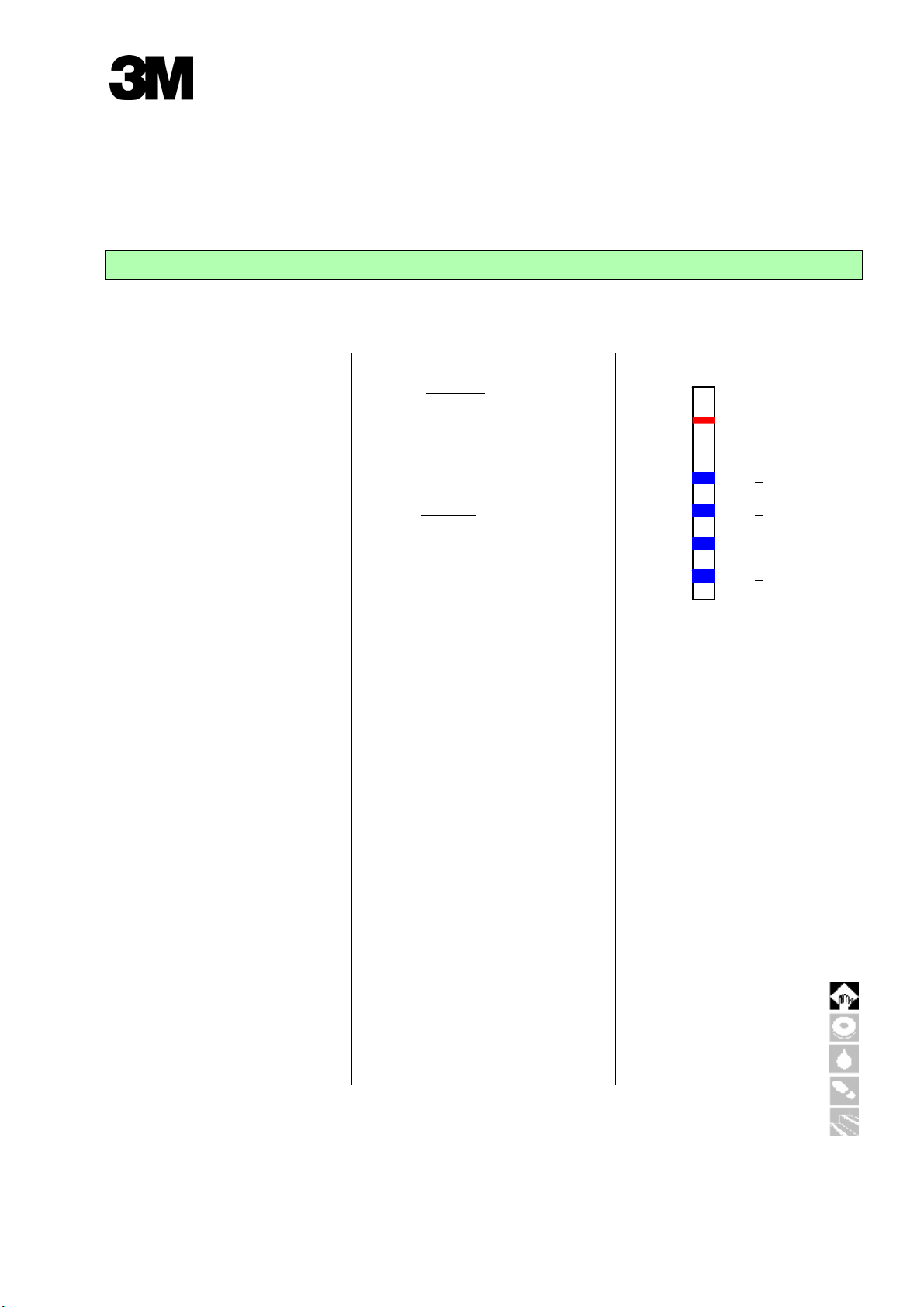

A test is a stiff white paper strip

(0,7 x 9.5 cm), having near one

end of the strip, four blue bands

across its width. A red line will

differentiate the Low Range

Shortening Monitor from Standard Shortening Monitor.

Packaging :

• Per 200

20 tests strips/plastic tube

1 plastic tube/box

10 boxes/case

(i.e. 200 strips/case)

or

• Per 200

50 tests strips/plastic tube

4 plastic tubes/case

(i.e. 200 strips/case)

Product Use :

The 3M LRSM strip is dipped

into shortening at operating

temperature. By simply counting the number of yellow

bands, the stage of shortening

breakdown is indirectly determined.

As shortening breaks down, the

free fatty acid concentration

increases, causing a greater

number of bands on the 3M

LRSM strip to change color. A

blue band will change completely to yellow at a specific

free fatty acid concentration

(see diagram).

FFA >

FFA >

FFA >

2,5 %

2,0 %

1,5 %

FFA > 1,0 %

Applications :

The product can be used in all

types of frying oils and fats

(animal, vegetable, and blends)

and fryers, provided the test is

done at operating temperature

(between 160°C and 185°C).

Product advantages :

• Easy to use : no need for

skilled people.

• Quick : immediate results.

Determination is made 30

seconds after dipping the

test strip into shortening.

_______________________________________________________________________________________________

3M B&CS Laboratory Europe Page 1 / 2

3M France Customer Application Center

Avenue Boulé PO box 28

F-95250 Beauchamp (France)

Page 2

Low Range Shortening Monitor

LRSM

Technical Data TD 250

Date : Nov 2005

Supersedes : April 2004

Author : EK/CB

Objective : results are inde-

•

pendent from people who

are doing the test.

• Hygienic : the test strip will

not contaminate the shortening.

• Accurate : the test provides

a specific discard point and

will minimize shortening

underuse and optimize fried

food quality (no overuse of

shortening).

• Safe : once the discard point

is set, the test will help the

user make sure that local

regulation is not infringed

Instructions for use :

1. Open the bottle and remove

one test strip.

2. Tightly close the tube with

unused strips.

3. Hold test strip by longest

white end (top, with red

line)

4. Dip the test strip into the

shortening so that all blue

bands are submerged during

1-2 seconds.

5. Remove and allow excess

shortening to drain back into

the vat (5 seconds)

6. After 30 seconds, read the

test strip by counting the

number of bands that have

completely or mostly

changed from blue to yellow. The reading is even

_____________________________________________________________________________________________

3M B&CS Laboratory Europe Page 2 / 2

3M France Customer Application Center

Avenue Boulé PO box 28

F-95250 Beauchamp (France)

easier if the test strip is

looked at when facing a

light source.

7. Based on this count, con-

tinue to use or discard shortening according to predetermined discard point.

8. Discard used test strip after

reading.

9. Use a new strip for each vat.

Storage conditions :

IMPORTANT : store the test

strips in their closed tube at 4°

C or cooler. Cold storage can

result in a light discoloration of

the low side reactive bands

(may turn to light blue color

with light green shading). This

discoloration is not detrimental

to the product quality and the

bands will turn back to the initial blue color after some time

at room temperature.

Setting discard point :

Each customer should determine their own discard point

depending on type of shortening, type of food, local regulations, habits…

Testing frequency :

Each vat should be tested daily.

The rate of which F.F.A is produced will depend on many

factors, including type and

quantity of food fried, type of

shortening used, frying temperature, seasonal weather

change and amount of moisture

of food. The rate will not be

constant from day to day if any

of these factors change.

Shelf life :

Low range Shortening Monitor

strips should be used by expiration date (printed on bottles,

cartons and case).

Caution :

Test strip will only measure

F.F.A concentration. 3M B&CS

Laboratory located in

Beauchamp (France) should be

consulted for the measurement

of other products resulting from

shortening breakdown (esp.

Polar Compounds).

Loading...

Loading...