Page 1

User Manual

3

Clean-Trace™ Luminometer

LM1

Page 2

3

Clean-Trace™ Luminometer

CONTENTS

INTENDED USE......................................................................... 1

PRODUCT DESCRIPTION ..................................................... 3

Using ATP Detection for Hygiene Monitoring

and Management ...................................................... 3

USING THIS MANUAL ........................................................... 3

OPERATING THE

3M™ CLEAN‑TRACE™ LUMINOMETER ..................... 4

Battery usage and maintenance ..................................... 4

Charging the battery ......................................................... 4

When the battery is charged ........................................... 4

Using the battery level indicator .................................... 4

Managing the battery ...................................................... 4

Switching the Power on .................................................. 4

Switching the Power o ....................................................5

Controlling the Software ...................................................5

Operating Controls of the

3M Clean-Trace Luminometer ................................5

Using the Base .................................................................. 6

Logging in on the 3M Clean-Trace Luminometer ........ 6

Logging in on the 3M Clean-Trace Luminometer

with a PIN ....................................................................7

Waking the 3M Clean-Trace Luminometer

from Sleep Mode ........................................................7

Using the Swab Sensor and Vertical

Position Sensor ...........................................................7

Logging out from the

3M Clean-Trace Luminometer .................................7

PERFORMING TESTS ON TEST POINTS WITHIN

SAMPLE PLANS ................................................................ 8

Performing an ATP Test on a Test Point

within a Sample Plan ................................................ 8

Performing a Retest on an ATP Test Point

with a Caution or a Fail Test Status

before Moving to a Dierent Test Point ................ 8

Performing a Retest on an ATP Test Point

with a Caution or a Fail Test Status after

Moving to a Dierent Test Point ............................. 9

Performing a Visual Inspection Test

on a Test Point within a Sample Plan ..................... 9

(English)

EN

Issue Date: 2016-06

Recording Temperature or pH for a Test Point

within a Sample Plan ............................................... 10

Adding Optional Comments to a Caution

or Fail ATP Test Result ..............................................10

Changing Temperature or pH Recording

for a Test Point within a Sample Plan ....................11

Moving to a Dierent Test Point

in the Same Sample Plan .......................................... 11

Moving to a Dierent Test Point

in a Dierent Sample Plan ........................................11

Viewing Test Results ........................................................ 11

Setting Up a Custom Test Type

on a Test Point within a Sample Plan ....................12

Performing a Retest on a Custom Test Type ................ 12

PERFORMING TESTING ON UNPLANNED

TEST POINTS .................................................................... 13

Performing an Unplanned ATP Test .............................. 13

Performing an Unplanned Visual Inspection Test ....... 13

SYNCHRONIZING THE 3M CLEAN‑TRACE

LUMINOMETER WITH THE COMPUTER

DATABASE ......................................................................... 14

Setting Up Synchronization

with a USB Connection ..........................................14

Setting Up Synchronization

with a Bluetooth Connection .................................14

Setting Up Synchronization

with a WiFi Connection ..........................................14

Changing the Connection Type .....................................16

Setting Synchronization Time ........................................16

PERFORMING ADMINISTRATIVE TASKS ......................... 16

Setting the Date and Time on the

3M Clean-Trace Luminometer ............................... 16

Performing a Diagnostic Check .....................................16

Changing the Screen Brightness ...................................16

Restarting the 3M Clean-Trace Luminometer ............. 16

Exporting a Log File ......................................................... 16

Displaying Software Versions ......................................... 17

Troubleshooting ...............................................................17

APPENDIX ............................................................................... 19

ii

Page 3

(English)

EN

INTENDED USE

The 3M Clean-Trace Luminometer is a battery operated Luminometer utilized primarily for objective and sensitive

determination of the end result of Adenosine Tri-Phosphate (ATP) tests. The 3M Clean-Trace Luminometer power supply

is provided to charge the battery. The 3M™ Clean-Trace™ Hygiene Management Software is designed for the transfer,

organization, and storage of data generated from the 3M™ Clean-Trace™ ATP Tests.

3M has not designed nor documented the 3M Clean-Trace Luminometer, and its power supply, or 3M Clean-Trace

Hygiene Management Software for use with other manufacturers’ products, use with other manufacturers’ designs, or use

in any other application that has not been evaluated or documented by 3M and may lead to an unsafe condition. The 3M

Clean-Trace Luminometer is not intended to be used in potentially ammable or explosive environments. Although the 3M

Clean-Trace Hygiene Monitoring and Management System is very sensitive, surfaces or solutions should not be considered

sterile based on results. The 3M Clean-Trace Hygiene Monitoring and Management System is not intended to be used in the

diagnosis of conditions in humans or animals. The user is responsible to know and follow applicable workplace regulations.

3M anticipates that the 3M Clean-Trace ATP Tests, equipment, and software will be utilized by technicians that have been

properly trained on the 3M Clean-Trace ATP Test methods.

If this product is used in a manner not specied, the protection provided by the product may be impaired.

USER RESPONSIBILITY

Users are responsible for familiarizing themselves with product instructions and information. Visit our website at

www.3M.com/foodsafety, or contact your local 3M representative or distributor for more information.

When selecting a test method, it is important to recognize that external factors such as sampling methods, testing

protocols, sample preparation, handling, and laboratory technique may inuence results.

It is the user’s responsibility in selecting any test method or product to evaluate a sucient number of samples with the

appropriate matrices and microbial challenges to satisfy the user that the chosen test method meets the user’s criteria.

It is also the user’s responsibility to determine that any test methods and results meet its customers’ and suppliers’

requirements.

As with any test method, results obtained from use of any 3M Food Safety product do not constitute a guarantee of the

quality of the matrices or processes tested.

Explanation of Safety Related Symbols

Attention: Read Accompanying Documentation

CAUTION: Recycle 3M Clean-Trace Luminometer to

avoid environmental contamination. This product contains

recyclable parts. For information on recycling - please

contact your nearest 3M Service Center for advice.

WEEE mark - This product contains electrical and

electronic components and must not be disposed of using

standard refuse collection. Please consult local directives

for disposal of electrical and electronic equipment.

UL NRTL mark (US and Canada electrical safety)

CE mark (conforms to applicable requirements for

European Economic Area).

RCM mark (Australia electrical safety and EMC)

The 3M Clean-Trace Luminometer model number, which is

LM1.

The 3M Clean-Trace Luminometer serial number

1

Page 4

EN

ENVIRONMENTAL OPERATING CONDITIONS

Environmental Condition Operating Condition Units

Indoor Use only - only connect the data connections to a computer that

conforms to IEC/EN/UL/CSA 60950-1

- keep 3M Clean-Trace Luminometer away from liquids

and high humidity when connected to the computer

Altitude 3000 maximum meters

Operating Temperature Range +5 to +40 (+41 to +104) °C (°F)

Relative Humidity 10 - 90 Non-condensing %

Storage Temperature Range -40 to +70 (-40 to +158) °C (°F)

AC Voltage for power supply

Mains Supply voltage uctuations up

to + 10% of nominal voltage

Temporary overvoltages occurring on

the mains supply

Frequency 50-60 Hertz

AC Current for power supply 300 mA

Power supply output voltage 5 Volts DC

Power supply output current 1.2 Amps

Luminometer input current 850 mAmps

Overvoltage Category II

Pollution Degree 2

100 -240 Volts

(English)

INSTRUMENT SPECIFICATIONS

Specication Units

Length 59.27 (2.33) mm (in)

Width 88.47 (3.48) mm (in)

Height 268.17 (10.56) mm (in)

Weight 517.83 (18.26) g (oz.)

External Connectors USB 2.0 type mini-AB receptacle

LIMITED WARRANTY

3M Food Safety Hardware (“Hardware”) includes the 3M Clean-Trace Luminometer and any associated Software and other

components supplied by 3M which are described in the applicable Installation and Use Guides (“User Documentation”).

LIMITED WARRANTY AND DISCLAIMER

3M warrants that for one year from the date of shipment that the Hardware will substantially perform in accordance

with the User Documentation. THIS WARRANTY IS VOID IF: (A) THE HARDWARE HAS BEEN REPAIRED BY PERSONS

NOT AUTHORIZED BY 3M; OR (B) THE HARDWARE HAS BEEN ALTERED, MODIFIED, OR MISUSED; OR (C) THE

HARDWARE IS USED WITH PRODUCTS, SUPPLIES, COMPONENTS OR SOFTWARE NOT SUPPLIED BY 3M FOR USE

WITH THE HARDWARE; OR (D) THE HARDWARE OR A COMPONENT IS USED FOR OTHER USES (FOR EXAMPLE

USE WITH OTHER CIRCUIT BOARDS OR SOFTWARE) OR (E) THE HARDWARE HAS NOT BEEN MAINTAINED OR

USED IN ACCORDANCE WITH THE USER DOCUMENTATION. UNLESS PROHIBITED BY LAW, THIS WARRANTY IS

MADE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, THE IMPLIED WARRANTY OF MERCHANTABILITY, OR ANY

IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING OR OF PERFORMANCE, CUSTOM OR USAGE OF

TRADE. 3M DOES NOT WARRANT THAT THE SOFTWARE WILL FUNCTION ERROR FREE.

If within one year after shipment, the Hardware does not conform to the express warranty set forth above, 3M’s sole

obligation and User’s sole remedy shall be, at 3M’s option: 1) to repair or replace the non-conforming component; or, 2)

refund the purchase price.

2

Page 5

(English)

?

EN

LIMITATION OF LIABILITY

UNLESS PROHIBITED BY LAW, 3M WILL NOT BE LIABLE TO USER OR OTHERS FOR ANY OTHER DIRECT, INDIRECT,

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES INCLUDING, FOR EXAMPLE, LOST PROFITS, BUSINESS,

INVESTMENTS, OR OPPORTUNITIES EVEN IF 3M HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. The

parties agree that 3M’s total cumulative liability to User for direct damages for all causes shall not exceed One Hundred

Dollars, or the price paid for the Hardware, whichever is higher. Some states or countries may have laws which require

liability rights dierent from those stated above. In such state or countries, the minimum required liability terms shall apply.

To request service, you must request a Returned Material Authorization (RMA) number from the service center. Please call

1-800-328-1671.

PRODUCT DESCRIPTION

Using ATP Detection for Hygiene Monitoring and Management

The 3M Clean-Trace Hygiene Monitoring and Management System consists of the following: 3M Clean-Trace

Luminometer, 3M™ Clean-Trace™ Tests, and 3M Clean-Trace Hygiene Management Software. This system is used to

detect ATP on surfaces or in water samples to measure levels of contamination for the purpose of hygiene monitoring

and management.

The detection technology used is Adenosine Triphosphate (ATP) bioluminescence. ATP is present in all animal and

vegetable material, including most food debris, living and dead bacteria, fungi and other microorganisms. The 3M

Clean-Trace Tests use Luciferin/Luciferase enzyme to produce light that is proportional to the amount of ATP present. The

3M Clean-Trace Luminometer measures the intensity of the light emitted from a sample, and it displays the test result in

Relative Light Units (RLU). Users do a validation study on their surface or water samples to determine the RLU test result

pass, caution and fail thresholds.

The rapid test results provided by the 3M Clean-Trace Luminometer allow users to take immediate remedial action in

response to a fail test result. The Test Point with a fail test result can be re-cleaned and retested before production,

ensuring that hygiene management goals are achieved. The results provide data that can be used in part to make the

decision to begin food or beverage production.

Read the Instructions for Use documents for 3M Clean-Trace Tests before using them along with a 3M Clean-Trace

Luminometer.

USING THIS MANUAL

1. The 3M Clean-Trace Luminometer User Manual is provided in electronic format only. There are two ways to access it:

• Click Help

• Go to www.3M.com/CleanTraceLM1manual

2. Click any heading in the Table of Contents to immediately go to that section, or scroll or page through the User Manual

to the desired section.

3. 3M Clean-Trace Software updates will include updates to this User Manual, which will automatically be installed along

with the software updates.

4. This User Manual describes the operation and behavior of the 3M Clean-Trace Luminometer. It is organized so that you

can search the Table of Contents for a specic task and follow step-by-step instructions.

5. In the step-by-step instructions for using the software, the following style guidelines were used:

a. Italic type is the name of a section in this User Manual.

b. Bold type is the exact text for a term that appears on a screen.

c. [Bold type with brackets] is the name of a button that you can tap or select using the cursor control button on a screen.

on the menu bar in the 3M Clean-Trace Hygiene Management Software, then click [User Manual].

3

Page 6

(English)

EN

OPERATING THE 3M CLEAN‑TRACE LUMINOMETER

Battery usage and maintenance

• A 3M Clean-Trace Luminometer has an internal rechargeable lithium ion battery that must be charged to use a 3M

Clean-Trace Luminometer.

Charging the battery

• Select the charger adapter that is appropriate for power in your country.

• Connect the charger to a 3M Clean-Trace Luminometer.

• Connect the charger to a power outlet.

• The battery becomes fully charged in approximately 2 hours.

• To monitor the charge status, turn on the 3M Clean-Trace Luminometer. A lightning bolt icon appears in the battery

charge level.

When the battery is charged

• Disconnect the charger from the power outlet.

• Unplug the charger from the 3M Clean-Trace Luminometer.

Using the battery level indicator

• The battery level indicator is located in the upper right corner of the screen.

• When a 3M Clean-Trace Luminometer is on, the indicator shows the remaining battery level.

• In Figure 1, the indicator shows the battery is fully charged

• As the battery charge decreases, the blue segment of the indicator becomes smaller.

• When the battery level is less than 10%, the indicator becomes red, showing the battery should be recharged.

• When the battery level is less than 5%, the 3M Clean-Trace Luminometer automatically shuts down.

Managing the battery

• In normal usage, the battery provides up to eight hours of charge capacity.

• As the battery ages, it will provide less than eight hours of charge capacity.

• The battery must be charged when the indicator is red, indicating less than 10% charge capacity.

• The battery does not need to be fully discharged before recharging.

• When storing a 3M Clean-Trace Luminometer for more than a month, the battery level should be at 50% charge. Do

not store a 3M Clean-Trace Luminometer with a fully discharged battery because the battery may lose the ability to be

recharged. Do not store a 3M Clean-Trace Luminometer with a fully charged battery because it may lose the ability to

recharge to full power.

• Battery replacement is recommended after two years of normal use. For battery replacement, the 3M Clean-Trace

Luminometer must be sent to a 3M Service Center.

Switching the Power on

Before switching on the 3M Clean-Trace Luminometer, check the chamber to ensure it is empty.

1. Press and hold the gray on/o button located below the cursor control buttons. The red 3M logo appears to

conrm the power on process has started, then the 3M logo Lockup appears and repeats several times.

2. The Welcome screen displays instructions for installing the 3M Clean-Trace Hygiene Management Software on

your computer using the software installation wizard provided on the segment of memory in the 3M Clean-Trace

Luminometer that appears on your computer as a ash drive.

• To prevent this display from appearing in the future, tap the Do not display again checkbox.

3. The screen goes black for a few seconds, then the Diagnostic Check screen appears. During the diagnostic check, a

progress bar is visible. Tap [Continue] when it’s no longer grayed out.

4. The 3M Clean-Trace Luminometer attempts to synchronize with a computer.

• Refer to the Synchronizing the 3M Clean‑Trace Luminometer with the Computer Database section in this User

Manual for more information.

• To skip the synchronize, tap [Skip Sync].

5. The log in screen appears. Refer to the Logging in on the 3M Clean‑Trace Luminometer section of this User Manual

for instructions.

Figure 1

4

Page 7

(English)

EN

Switching the Power o

1. Press the on/o button for 3 seconds.

2.

[Power o] appears to conrm the power o process has started.

3. Tap [Power o].

4. A conrmation message Your luminometer will shut down appears.

5. Tap [OK]. The display screen goes black to conrm the power o process has completed.

6. Or, tap [Cancel] to cancel the power o process.

Controlling the Software

To control the 3M Clean-Trace Luminometer software, use either the touch screen or the cursor control pad.

• To use the touch screen, use common gestures such as tap and swipe.

• Or, you can use the cursor control pad

on the front of the 3M Clean-Trace Luminometer. Simply press the arrows

on the cursor control pad to move the cursor to the option on the screen you want to select:

Press the up arrow to move the cursor up

Press the down arrow to move the cursor down

Press the left arrow to move the cursor left

Press the right arrow to move the cursor right

• Press the select button on the cursor control pad to select the option on the screen to which you have moved

the cursor.

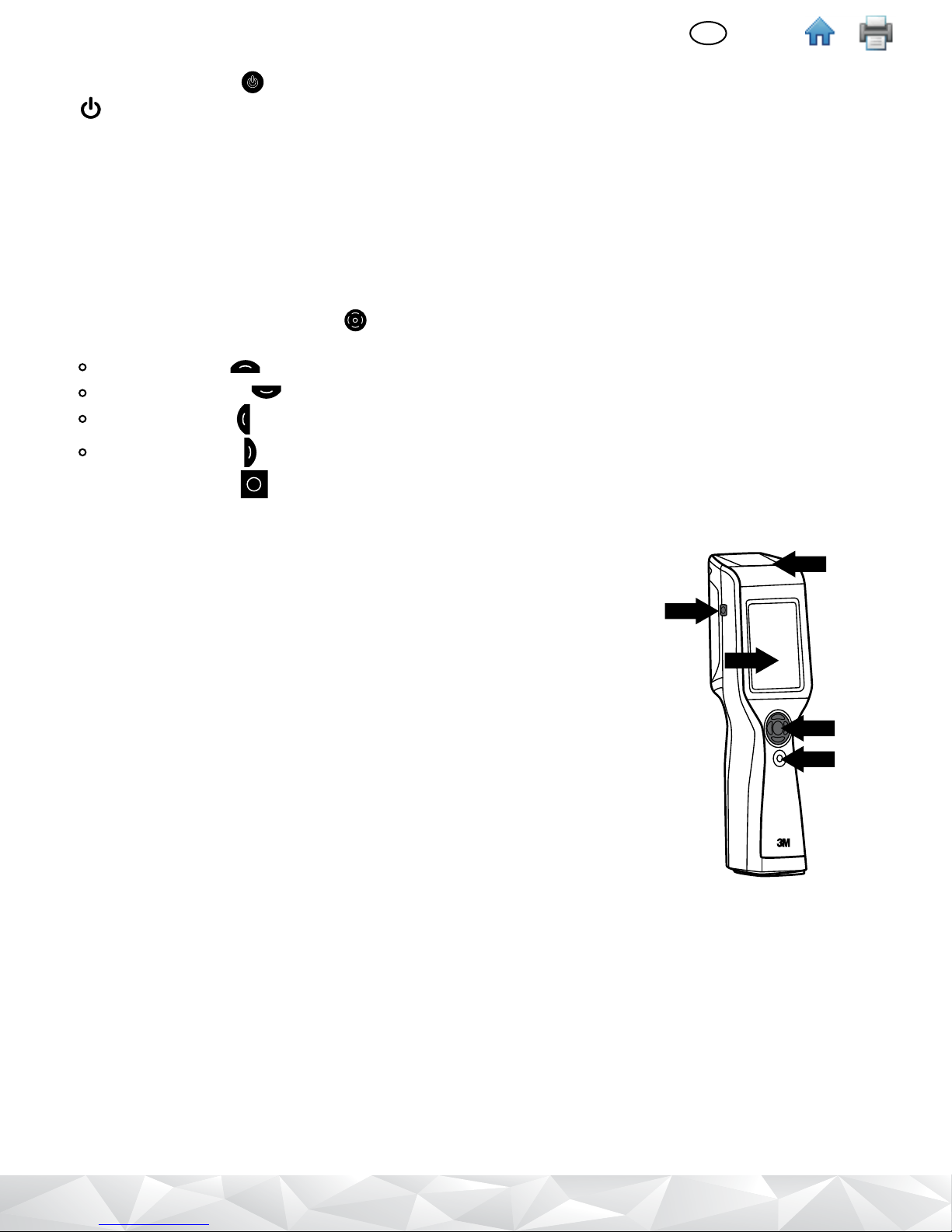

Operating Controls of the 3M Clean‑Trace Luminometer

Figure 2 shows the operating controls on the 3M Clean-Trace Luminometer.

5

1. On/O Switch - For instructions see Switching the Power On.

2. Cursor Control Buttons - For instructions see Controlling the Software.

4

3. Display/Touch Screen - For instructions see Controlling the Software.

4. USB/Power Port - For instructions see Charging the battery and Setting Up

3

Synchronization with a USB Connection.

5. Rocker Cap - For instructions see Figure 3.

2

1

Figure 2

5

Page 8

Figure 3 shows the step-by-step procedure for inserting a 3M Clean-Trace

Test into a 3M Clean-Trace Luminometer for testing, and removing it after testing

is completed.

1. Open the 3M Clean-Trace Luminometer by pressing the rocker cap.

2. Insert an activated 3M Clean-Trace Test into the chamber, making sure the

cuvette is at the bottom of the chamber.

3. The 3M Clean-Trace Test handle should be visible at the top of the chamber.

4. Release the rocker cap. Now you can do an ATP test with the 3M Clean-Trace

Test that’s inside the chamber.

5. After the ATP test is completed, open the chamber by pressing the rocker cap.

6. To remove the 3M Clean-Trace Test, grasp the top of the test and pull

upwards. Follow the instructions for disposal in the 3M Clean-Trace Test

Instructions for Use. Consult with local regulations for any additional

regulations regarding disposal.

Using the Base

For extra stability and convenience, the 3M Clean-Trace Luminometer can be

placed on the 3M™ Clean-Trace™ Base. The 3M Clean-Trace Base also holds the

3M Clean-Trace Luminometer at an optimum working and viewing angle.

(See Figure4).

(English)

EN

1. 2.

3. 4.

5. 6.

Figure 3

Figure 4

The 3M Clean-Trace Luminometer also has a fold-out stand built into the bottom

of the instrument. (See Figure 5).

Figure 5

Logging in on the 3M Clean‑Trace Luminometer

When the 3M Clean-Trace Luminometer is turned on, it automatically does a diagnostic check. If the diagnostic check is

within the required limits, the login screen appears.

1. The Default User is automatically logged in. Tap [Login].

• Or, if you set up Users using 3M Clean-Trace Hygiene Management Software, to select your User name, tap select

User

and tap your User name. Tap [Login].

2. Unplanned Test automatically appears. Sample Plans appear if you have created and synchronized them using the 3M

Clean-Trace Hygiene Management Software. You can start a new run of a sample plan or start new unplanned testing.

To return to this screen at any time, tap Home

.

• For more information, refer to the Performing Unplanned Testing or the Performing Tests on Test Points in Sample

Plans sections in this User Manual for more information.

6

Page 9

(English)

EN

Logging in on the 3M Clean‑Trace Luminometer with a PIN

When the 3M Clean-Trace Luminometer is turned on, it automatically does a diagnostic check. If the diagnostic check is

within the required limits, the login screen appears.

1. The Default User is automatically logged in. Tap [Login].

• Or, if you set up Users using 3M Clean-Trace Hygiene Management Software, to select your User name, tap select

User

• Use the number pad to enter your 4 digit PIN. As you enter each number, an asterisk (*) appears on the screen. Then

tap Enter

• If you enter a number incorrectly, tap Delete

• If you fail to enter your PIN correctly, you can make two more attempts. After three failed attempts, your user name

and PIN are locked out. Wait 5 minutes for your user name and PIN to clear automatically.

• If your user name does not appear or your PIN does not work, contact your supervisor.

• When you have correctly entered your user name and PIN, tap Enter

2. The New Testing screen displays Unplanned Test and the Sample Plans. You can start a new run of a sample plan or

start new unplanned testing. To return to this screen at any time, tap Home

• For more information, refer to the Performing Unplanned Testing or the Performing Tests on Test Points in Sample

Plans sections in this User Manual for more information.

Waking the 3M Clean‑Trace Luminometer from Sleep Mode

The 3M Clean-Trace Luminometer conserves battery power if the touch screen or the cursor control buttons are inactive.

After 5 minutes of inactivity, the 3M Clean-Trace Luminometer goes into Sleep mode and the screen darkens. After 2

additional hours of inactivity, the 3M Clean-Trace Luminometer automatically shuts down and must be powered on again

before use. Refer to the Switching the Power on section of this User manual for more information.

1. To wake the 3M Clean-Trace Luminometer from Sleep mode, press and hold the up arrow button on the cursor

control pad for 3 seconds.

2. The screen displays the information that appeared before the Sleep mode began so you can continue working.

• If the 3M Clean-Trace Luminometer does not wake from the Sleep mode:

The 3M Clean-Trace Luminometer might be turned o. Press and hold the on/o button for 3 seconds to

The battery might be completely discharged. Refer to the Charging the Battery section in this User Manual for

The 3M Clean-Trace Luminometer might need repair. Contact your 3M Representative for more information.

and tap your User name. Tap [Login].

.

to remove the number, and then enter a correct number.

.

.

turn it on. Refer to the Switching the Power on section in this User Manual for more information.

more information.

Using the Swab Sensor and Vertical Position Sensor

As soon as measurement of a 3M Clean-Trace Test is complete, remove the 3M Clean-Trace Test from the Luminometer

chamber. If a test remains in the 3M Clean-Trace Luminometer chamber for more than 30 seconds, the Swab Sensor

noties you to remove it.

• Keep the 3M Clean-Trace Luminometer upright whenever a test is in the chamber to ensure accurate results and

avoid spillage of reagents, which could damage the sensitive components of the instrument. If the 3M Clean-Trace

Luminometer is held at greater than 68 degrees from vertical when a test is in the chamber, a tilt symbol

you the test measurement was cancelled. Tap [OK], then hold the 3M Clean-Trace Luminometer in a vertical position

and measure the test again.

Logging out from the 3M Clean‑Trace Luminometer

1. Tap Settings

2. Tap [Log Out]. The Login screen appears. Refer to the Logging in on the 3M Clean‑Trace Luminometer section in this

User Manual for more information.

.

noties

7

Page 10

(English)

EN

PERFORMING TESTS ON TEST POINTS WITHIN SAMPLE PLANS

Performing an ATP Test on a Test Point within a Sample Plan

1. To start a new run, tap the Sample Plan, then tap [New Test Run…].

• If a Sample Plan does not appear, tap scroll up

additional Sample Plans.

Or, if you are restarting a Sample Plan that you did not complete, tap the Sample Plan, then tap the starting date and

time you want to restart.

• If a starting date and time does not appear, tap scroll up

• The List View appears, showing a list of the Test Points in the Sample Plan, and the number of Test Points in each

result category:

or scroll down or swipe the list up or down to display

or scroll down or swipe the list up or down.

Total number of

Test Points

• To select a Test Type, tap [Test types…] then tap the Test Type to be performed.

2. To select a Test Point to be tested, tap the Test Point.

• You can test the Test Points in sequence or in any order.

• If a Test Point does not appear, tap scroll up

additional Test Points.

• To display a dierent Test Point, tap Next Test Point Name

appears.

• To display a picture and a description of the test point, tap information

to return to the previous screen.

3. Follow the Instructions for Use for the 3M Clean-Trace Tests. Collect a sample, activate the test and shake it for at least

5 seconds.

a. Open the 3M Clean-Trace Luminometer by pressing the rocker cap. Then insert the activated test into the chamber.

Keep the 3M Clean-Trace Luminometer upright whenever a test is in the chamber to ensure accurate results and

avoid spillage of reagents, which could damage the sensitive components of the instrument.

b. Tap [Start]

c. The test result appears and is stored in the memory so it can be synchronized with the 3M Clean-Trace Hygiene

Management Software. The result is also interpreted using your established pass/fail limits and is displayed on the

screen as PASS

d. To remove the 3M Clean-Trace Test from the 3M Clean-Trace Luminometer, press the rocker cap, grasp the top of

the test and pull upwards. Follow the instructions for disposal in the 3M Clean-Trace Test Instructions for Use.

4. To test another Test Point, tap Next Test Point

• Or, to do a retest, tap [Retest]

• Or, to display the list of Test Points, tap [List View]

to begin measuring. A progress bar appears and moves from left to right.

, CAUTION , or FAIL .

then tap [Start] .

Number in

Pass

category

or scroll down or swipe the list up or down to display

or Previous Test Point until the Test Point you want appears.

.

Number in

Caution

category

or Previous Test Point until the Test Point you want

Number in

Fail

category

next to the Test Point name. Tap Back

Performing a Retest on an ATP Test Point with a Caution or a Fail Test Status before Moving to a Dierent Test Point

1. Before moving to a dierent Test Point, follow the Instructions for Use for the 3M Clean-Trace Test to collect a sample,

activate the test, and shake it for at least 5 seconds.

2. Open the 3M Clean-Trace Luminometer by pressing the rocker cap. Then insert the activated test into the chamber.

Keep the 3M Clean-Trace Luminometer upright whenever a test is in the chamber, to ensure accurate results and avoid

spillage of reagents, which could damage the sensitive components of the instrument.

3. Tap [Retest]

4. The test result appears and is stored in the memory so it can be synchronized with the 3M Clean-Trace Hygiene

Management Software. The result is also interpreted using your established pass/fail limits and is displayed on the

screen as PASS

then tap [Start] to begin measuring. A progress bar appears and moves from left to right.

, CAUTION or FAIL .

8

Page 11

(English)

EN

5. To remove the test from the 3M Clean-Trace Luminometer, press the rocker cap, grasp the top of the test and pull

upwards. Follow the instructions for disposal in the 3M Clean-Trace Test Instructions for Use.

Performing a Retest on an ATP Test Point with a Caution or a Fail Test Status after Moving to a Dierent Test Point

To select the Test Point you want to retest while in the same Sample Plan, tap Next

• Or, to use a dierent Sample Plan, tap Home , then tap the Sample Plan, then tap the date and time of the run.

• Or, tap Scroll down

1. Follow the Instructions for Use for the 3M Clean-Trace Test to collect a sample, activate the test and shake it for at least

5 seconds.

2. Open the 3M Clean-Trace Luminometer by pressing the rocker cap. Then insert the activated test into the chamber.

Keep the 3M Clean-Trace Luminometer upright whenever a test is in the chamber, to ensure accurate results and avoid

spillage of reagents, which could damage the sensitive components of the instrument.

3. Tap [Retest]

4. The test result appears on the screen and is stored in the memory so it can be synchronized with the 3M Clean-Trace

Hygiene Management Software. The result is also interpreted using your established pass/fail limits and is displayed on

the screen as PASS

5. To remove the test from the 3M Clean-Trace Luminometer, press the rocker cap, grasp the top of the test and pull

upwards. Follow the instructions for disposal in the 3M Clean-Trace Test Instructions for Use.

Performing a Visual Inspection Test on a Test Point within a Sample Plan

1. To start a new run, tap the Sample Plan, then tap [New Test Run…].

• If a Sample Plan does not appear, tap scroll up

additional Sample Plans.

Or, if you are restarting a Sample Plan that you did not complete, tap the Sample Plan, then tap the starting date and

time you want to restart.

• If a Sample Plan does not appear, tap scroll up

additional Sample Plans.

• The List View appears, showing a list of the Test Points in the Sample Plan, and the number of Test Points in each

result category:

then tap [Start] to begin measuring. A progress bar appears and moves from left to right.

or Scroll up then tap the Test Point you want to retest.

, CAUTION or FAIL .

or scroll down or swipe the list up or down to display

or scroll down or swipe the list up or down to display

or Previous .

Total number of

Test Points

• To select a Test Type, tap [Test types…] then tap the Test Type to be performed.

2. To select a Test Point to be tested, tap the Test Point.

• If a Test Point includes an ATP test and a Visual Inspection test, the Visual Inspection test appears immediately after

the ATP test.

• You can test the Test Points in sequence or in any order.

• If a Test Point does not appear, tap scroll up

additional Test Points.

• To display a dierent Test Point, tap Next Test Point Name

want appears.

• To display a picture and a description of the test point, tap information

to return to the previous screen.

• Tap [Pass] for a Pass result or tap [Fail] for a Fail result.

• If you selected Pass, the Pass display

• To redo a test, tap [Retest]

then tap [Start] .

appears. If you entered Fail, the Fail display appears.

Number in

Pass

category

or scroll down or swipe the list up or down to display

Number in

Caution

category

or Previous Test Point until the Test Point you

Number in

Fail

category

next to the Test Point name. Tap [Back]

9

Page 12

(English)

EN

• To add a comment to the result, tap Add Comment . The Add Comments screen and any previously added

comments appears. Tap [Add Comments] then tap comment to add. Tap [OK]. Tap [Back]. If you decide not to add a

comment, tap [Back] to return to the previous screen.

3. To test another Test Point, tap Next Test Point

• Or, to do a retest, tap [Retest]

• Or, to display the list of Test Points, tap List View

Recording Temperature or pH for a Test Point within a Sample Plan

1. To start a new run, tap the Sample Plan, then tap [New Test Run…].

• If a Sample Plan does not appear, tap scroll up or scroll down or swipe the list up or down to display

additional Sample Plans.

• If you are restarting a Sample Plan that you did not complete, tap the Sample Plan with the starting date and time

you want. If that Sample Plan does not appear, tap scroll up

Plan names.

• The List View appears, showing a list of the Test Points in the Sample Plan, and the number of Test Points in each

result category:

then tap [Start] .

or Previous Test Point until the Test Point you want appears.

.

or scroll down to display additional Sample

Total number of

Test Points

• To select a Test Type, tap [Test types…] then tap the Test Type to be performed. Tap [Done].

2. To select a Test Point to be tested, tap the Test Point.

• If a Test Point includes an ATP test and a Temperature or pH recording, the Temperature or pH recording appears

immediately after the ATP test.

• You can test points in the Sample Plan in sequence or in any order. The rst Test Point in the Sample Plan appears on

the screen. If you want to test a dierent Test Point, tap Next Test Point

can display a previous test point by tapping Previous Test Point .

• To display an image and a description of the Test Point, tap information

to return to the previous screen.

3. Tap the eld. Use the number pad to enter the Temperature test result or pH test result.

4. The test result appears and is stored in the memory so it can be synchronized with the 3M Clean-Trace Hygiene

Management Software. The result is also interpreted using your established pass/fail limits and is displayed on the

screen as PASS

• To add a comment to the result, tap the Add Comment

previously-selected comments will appear. Tap [Add Comments], and then tap the comment to add. Tap [OK].

Tap [Back].

• If you decide not to add a comment, tap Back

5. To test another Test Point, tap Next Test Point

• Or, to do a retest, tap [Retest]

• Or, to display the list of Test Points, tap List View

, or FAIL .

then tap [Start] .

Number in

Pass

category

to go to the previous screen.

or Previous Test Point until the Test Point you want appears.

.

Number in

Caution

category

symbol . The Add Comments screen and any

Number in

Fail

category

until the test point you want appears. You

next to the Test Point name. Tap [Back]

Adding Optional Comments to a Caution or Fail ATP Test Result

1. To view or add comments for a displayed test result, tap Add Comment

previously-selected comments appear.

2. Tap [Add Comments], and then tap the comment to add. Tap [OK]. Tap [Back].

3. If you decide not to add a comment, tap [Back]

. The Add Comments screen and any

to go to the previous screen.

10

Page 13

(English)

EN

Changing Temperature or pH Recording for a Test Point within a Sample Plan

1. To select the Test Point you want to retest if you are still in the same Sample Plan, tap Next or Previous .

2. To use a dierent Sample Plan, tap Home

3. Tap Scroll down

4. Use the number pad to enter the Temperature test result or pH test result.

• The test result appears and is stored in the memory so it can be synchronized with the 3M Clean-Trace Hygiene

Management Software. The result is also interpreted using your established pass/fail limits and is displayed on the

screen as PASS

• To add a comment to the result, tap the Add Comment

• Tap [Add Comments].

• Tap the comment. Tap [OK]. Tap [Back].

Moving to a Dierent Test Point in the Same Sample Plan

1. To move to the next Test Point in a Sample Plan, tap Next

displays. Tap Next again to move to the following Test Point in the Sample Plan until you reach the last Test Point in

the Sample Plan.

2. To move to a previous Test Point in a Sample Plan, tap Previous

Plan displays. Tap Previous again to move to the preceding Test Point in the Sample Plan until you reach the rst Test

Point in the Sample Plan.

3. When the Test Point you want is displayed, follow the instructions in this manual for Performing an ATP Test on a Test

Point within a Sample Plan, starting with step 5.

or Scroll up then tap the Test Point you want to retest.

, CAUTION or FAIL .

, then tap the Sample Plan, then tap the date and time of the run.

symbol. Any previously-selected comments appear.

. The name of the next Test Point in the Sample Plan

. The name of the previous Test Point in the Sample

Moving to a Dierent Test Point in a Dierent Sample Plan

1. Tap Home to move to the Sample Plan screen.

2. To do an ATP test on a Test Point in a Sample Plan you already started, tap the Sample Plan with the starting date and

time you want. If that Sample Plan does not appear, tap scroll up

display additional Sample Plans.

3. To move to the next Test Point in a Sample Plan, tap Next

displays. Tap Next again to move to the following Test Point in the Sample Plan until you reach the last Test Point in

the Sample Plan.

4. To move to a previous Test Point in a Sample Plan, tap Previous

Plan displays. Tap Previous again to move to the preceding Test Point in the Sample Plan until you reach the rst Test

Point in the Sample Plan.

5. When the Test Point you want is displayed, follow the instructions in this manual for Performing an ATP Test on a Test

Point within a Sample Plan, starting with step 5.

Viewing Test Results

1. To move to the Sample Plan screen, tap Results .

2. To display results with a fail Test Status, tap [Failed Tests]. To display the most recent results, tap [Last Test]. To display

results for the selected Sample Plan, tap [Sample Plan].

3. Test results are displayed using color coding: red for fail test results, yellow for caution test results and green for pass

test results. The display also includes the Sample Plan name, the Test Point name, the date and time of the test, and the

name of the person who did the testing.

4. To display additional test results, tap Scroll down

motion on the touch screen.

or Scroll up . You can also scroll up and down using a swiping

. The name of the next Test Point in the Sample Plan

or scroll down or swipe the list up or down to

. The name of the previous Test Point in the Sample

11

Page 14

(English)

EN

Setting Up a Custom Test Type on a Test Point within a Sample Plan

If a Sample Plan does not appear, tap scroll up or scroll down or swipe the list up or down to display additional

Sample Plans.

• If you are restarting a Sample Plan that you did not complete, tap the Sample Plan with the starting date and time

you want. If that Sample Plan does not appear, tap scroll up or scroll down to display additional Sample

Plan names.

• The List View appears, showing a list of the Test Points in the Sample Plan, and the number of Test Points in each

result category:

Total number of

Test Points

• To select a Test Type, tap [Test types…] then tap the Test Type to be performed. Tap [Done].

1. To select a Test Point to be tested, tap the Test Point

• If a Test Point includes an ATP test and a Custom Test Type, the Custom Test Type appears immediately after the

ATP test.

• You can test points in the Sample Plan in sequence or in any order. The rst Test Point in the Sample Plan appears on

the screen. If you want to test a dierent Test Point, tap Next Test Point

can display a previous test point by tapping Previous Test Point .

• To display an image and a description of the Test Point, tap information

to return to the previous screen.

2. Tap the gray bar that appears below the test type. Tap [Enter value] . Use the number pad to enter the test result. To

remove a number you entered incorrectly, tap backspace

3. The test result appears on the screen and is stored in the memory so it can later be synchronized with the 3M

Clean-Trace Hygiene Management Software. The test result is also interpreted using the pass/fail limits and the test

result status is displayed on the screen as PASS

4. The next Test Point in the Sample Plan you selected appears on the screen. You can repeat the process starting with

step 5 to enter a test result for the Test Point that’s displayed on the screen.

Performing a Retest on a Custom Test Type

1. To select the Test Point you want to retest, tap Next or Previous . To use a dierent Sample Plan, tap Home ,

then tap Next or Previous to move to the Test Point you want to retest.

a. To display a picture and a description of the Test Point, tap information

to return to the previous screen.

2. Tap the eld. Use the number pad to enter the test result. To remove a number you entered incorrectly, tap backspace

, then enter the correct number. Tap [Done].

3. The test result appears on the screen and is stored in the memory so it can be synchronized with the 3M Clean-Trace

Hygiene Management Software. The result is also interpreted using your established pass/fail limits and is displayed on

the screen as PASS

, CAUTION , or FAIL .

Number in

Pass

category

, CAUTION , or FAIL .

Number in

Caution

category

, then enter the correct number. Tap [Done].

Number in

Fail

category

until the test point you want appears. You

next to the Test Point name. Tap [Back]

next to the Test Point name. Tap back

12

Page 15

(English)

EN

PERFORMING TESTING ON UNPLANNED TEST POINTS

Performing an Unplanned ATP Test

1. Tap [Unplanned Test] .

To start a new run, tap [New Test Run…].

• Or, if you are restarting a run of unplanned tests that you did not complete, tap the starting date and time you

want to restart.

2. Tap Select Test Type

• UXL100(Surface ATP)

• AQF100

• AQT200(water total)

3. Tap [OK].

4. Follow the Instructions for Use for the 3M Clean-Trace Test to collect a sample, activate the test and shake it for at least

5 seconds.

5. Open the 3M Clean-Trace Luminometer by pressing the rocker cap. Then insert the activated test into the chamber.

Keep the 3M Clean-Trace Luminometer upright whenever a test is in the chamber, to ensure accurate results and avoid

spillage of reagents, which could damage the sensitive components of the instrument.

6. Tap [Start]

and is stored in the memory so it can be synchronized with the 3M Clean-Trace Hygiene Management Software.

7. To remove the test from the 3M Clean-Trace Luminometer, press the rocker cap, grasp the top of the test and pull

upwards. Follow the instructions for disposal in the 3M Clean-Trace Test Instructions for Use.

8. To do another unplanned ATP test, tap [New] and repeat this process.

• Or, to do a retest, tap [Retest]

to begin measuring. A progress bar appears and moves from left to right. The test result appears

then tap the test type:

then tap [Start] .

Performing an Unplanned Visual Inspection Test

1. Tap [Unplanned Test]

2. To start a new run, tap [New Test Run…].

Or, if you are restarting a run of unplanned tests that you did not complete, tap the starting date and time you want

to restart.

• If a starting date and time does not appear, tap scroll up

display additional Sample Plans.

3. Tap Select Test Type

4. Tap [OK].

5. Tap [PASS] for a Pass result or tap [FAIL] for a Fail result.

6. If you selected Pass, the Pass

symbol appears and [Retest] appears.

7. To do another Visual Inspection test, tap [New].

• To add a comment, tap Add Comment

appear. Tap [Add Comments], then tap the comment to add. Tap [OK]. Tap [Back].

• If you decide not to add a comment, tap [Back]

.

or scroll down or swipe the list up or down to

then tap [Visual Inspection].

display appears. If you entered Fail, the Fail display appears, and the add comment

. The Add Comments screen and any previously added comments

to return to the previous screen.

13

Page 16

(English)

EN

SYNCHRONIZING THE 3M CLEAN‑TRACE LUMINOMETER WITH THE COMPUTER DATABASE

Use the Sync Manager software to initiate a synchronization between the 3M Clean-Trace Luminometer and your

computer. Refer to the Using the Sync Manager section of the 3M Clean-Trace Hygiene Management Software User

Manual for more information.

• You must synchronize the rst time using the USB connection.

• A Diagnostic Check is automatically done when a synchronization is initiated.

• If you start a synchronization less than two minutes after completing the last previous synchronization, a warning

message appears. Wait at least two minutes, then start a synchronization again.

• If you synchronize a 3M Clean-Trace Luminometer that already contains Sample Plans that are dierent than the Sample

Plans on the computer you are currently synchronizing with, a warning message appears.

o Tap Settings. Tap [Synchronize]. The progress bar shows when the synchronization is complete.

o To cancel the synchronization, tap [Skip Sync]

o To continue the synchronization, tap [Continue]. This option removes the Sample Plans and test results from the 3M

Clean-Trace Luminometer and replaces the Sample Plans with the Sample Plans on the computer with which you are

currently synchronizing.

• Synchronizing the 3M Clean-Trace Luminometer with the computer sends information in both directions:

Sent from Computer to 3M Clean-Trace Luminometer:

- User names and PINs

- Sample Plans and Test Points including pass/fail limits and images of the Test Points if available

- Organization congurations such as number of days to retain synchronized test results

Sent from 3M Clean-Trace Luminometer to Computer:

- Test Results including date and time of test, User who did the test and comments if available

- The 3M Clean-Trace Luminometer provides three modes of communication: USB cable, Wi-Fi connection and

Bluetooth connection

Setting Up Synchronization with a USB Connection

To use a USB cable connection: connect one end of the 3M provided USB cable to the USB/Power port and connect the

other end of the USB cable to a USB port on your computer.

• To register a 3M Clean-Trace Luminometer the rst time you synchronize it, log in to the Sync Manager. Refer to the

Logging in Your User Name on the Sync Manager section of the 3M Clean-Trace Hygiene Management Software User

Manual.

• 1. Tap [Settings]

Setting Up Synchronization with a Bluetooth Connection

• You must synchronize the rst time using the USB connection to register the 3M Clean-Trace Luminometer.

• To use a Bluetooth connection: set up the Bluetooth connection for the 3M Clean-Trace Luminometer. This procedure

requires simultaneous use of both a 3M Clean-Trace Luminometer and the Sync Manager software, which is installed

on your computer by the software installation wizard for the 3M Clean-Trace Hygiene Management Software. For

instructions on pairing a Bluetooth connection, refer to the Setting Up a Bluetooth Connection section of the 3M

Clean-Trace Hygiene Management Software User Manual.

Setting Up Synchronization with a WiFi Connection

• You must synchronize the rst time using the USB connection to register the 3M Clean-Trace Luminometer.

• To use a Wi-Fi connection: set up Web Service on the 3M Clean-Trace Luminometer, which then sends the web service

information you set up to the computer the rst time you synchronize using the Sync Manager software.

1. Touch the top of the screen for 1 second, then swipe down.

2. Tap Connections

3. Tap WiFi

.

. Tap [Preferred Connection – (connection type)]. Tap [USB]. Tap [Select].

.

14

Page 17

(English)

EN

4. Turn WiFi on, and select your WiFi network. If it’s a secure WiFi, enter your security credential. Obtain this information

from your IT support.

5. Tap Return

6. Tap Settings

7. Tap [Preferred Connection - (connection type)]

8. Tap [WiFi]

9. Tap [Web Service Setup].

10. Conrm the Host Name, Common Services Port Number, Device Services Port Number are correct. Obtain this

information from your IT support. If this information is correct, tap OK. If not, use the following instructions to update

this information.

• Tap [Enter Host Name] and use the keyboard to enter the name of your webserver. Obtain this information from your

IT support.

• Or, to nd the name of your webserver for this computer:

a. Click the Windows Start button on the computer.

b. Select Computer

c. Select System Properties

d. The name of your webserver is listed on the screen as Full Computer Name.

e. Tap [Done]

• Tap [Common Services Port Number] and use the keyboard to enter the IIS port number for Common Service Port

No. To nd the Common Services Port No. for the computer that has the Sync Manager Software:

a. Click the Windows Start button on the computer.

b. Click Run….

c. Type inetmgr into the Open: eld then click OK.

d. Expand the computer name in the Connections column.

e. Expand Sites.

f. Click Clean-TraceCommonServices. The Common Services Port No. is the 4 digit number that appears in the

Browse Web Site area in the Actions column. For example, 9003.

g. Tap [Done]

• Tap [Device Services Port Number] and use the keyboard to enter the IIS port number for Device Service Port No.

To nd the Device Services Port No. for the computer that has the Sync Manager Software:

a. Click the Windows Start button on the computer.

b. Click Run….

c. Type inetmgr into the Open: eld then click OK.

d. Expand the computer name in the Connections column.

e. Expand Sites.

f. Click Clean-TraceDeviceServices. The Device Services Port No. is the 4 digit number that appears in the Browse

Web Site area in the Actions column. For example, 9004.

g. Tap [Done].

h. Tap [OK].

• To display the current Web Service information on the 3M Clean-Trace Luminometer without changing it, tap

[Settings]

• To change the Connection Type to WiFi, refer to the Changing the Connection Type section in this User Manual.

• The 3M Clean-Trace Luminometer WiFi software uses the following ports by default on your computer: 9002, 9003,

9004, 9005. Ensure that these ports are enabled by your antivirus software or rewall.

.

.

, then tap [Web Service Setup]. To return to Settings, tap [OK].

15

Page 18

(English)

EN

Changing the Connection Type

1. Tap Settings .

2. Tap [Preferred Connection - (connection type)]

3. Tap the connection type you prefer:

• USB

• WiFi

• Bluetooth

• Skip Sync – This selection disables the sync process

4. Tap [Select].

Setting Synchronization Time

1. Tap Settings

2. Tap [Synchronization Time].

3. Rotate the hour and minute wheels until the time you want is highlighted.

4. Tap [Done].

.

PERFORMING ADMINISTRATIVE TASKS

Setting the Date and Time on the 3M Clean‑Trace Luminometer

1. Touch the top of the screen for 1 second, then swipe down.

2. Tap the date and time that’s displayed.

3. To enable [Set date] and [Set time], tap [Automatic date & time]

4. To set the date, tap [Set date] then rotate the month, day, and year wheels until the correct date is displayed.

Tap [Done].

5. To set the time, tap [Set time] then rotate the hour, minute, and AM/PM wheels until the correct time is displayed.

Tap [Done].

6. Tap Return

.

Performing a Diagnostic Check

1. Tap Settings

2. Tap [Diagnostic Check] to do the same diagnostic check the 3M Clean-Trace Luminometer does automatically when

the power is switched on. For more information, refer to the Switching the Power on section in this User Manual

Changing the Screen Brightness

1. Tap Settings .

2. Tap [Screen Brightness].

3. To increase the screen brightness, drag the slider to the right. To decrease the screen brightness drag the slider to the left.

Restarting the 3M Clean‑Trace Luminometer

1. Tap Settings

2. Tap [Restart Device].

Exporting a Log File

1. Tap Settings

2. To generate a log le, tap [Export Log File]

• To view the log le:

a. Connect the 3M Clean-Trace Luminometer to your computer by USB cable.

b. Browse to 3M Clean-Trace\Luminometer Main Storage\Logs

c. To open the log le, use Microsoft® Notepad®.

.

.

16

Page 19

(English)

EN

Displaying Software Versions

1. Tap Settings .

2. Tap [About].

3. Swipe the list of software versions up to display the complete list.

4. Tap [Continue].

Troubleshooting

This section is intended to help you solve problems that you might encounter when using the 3M Clean-Trace

Luminometer. Contact 3M or your local 3M distributor for more information.

Problem Probable Cause Solution

Battery Low

message

Diagnostic Check

Failed Message

Incorrect Swab

Detected

No Display a. Instrument in Sleep mode

No Swab

Detected

Results Lower

than Expected

Rocker Cap Open

message

Swab Left in

Chamber

Swab Not

Recognized

The Luminometer

was dropped

The Luminometer

might have

experienced a

mechanical shock

Test Cancelled Luminometer tilted during test

Battery needs to be charged Turn the 3M Clean-Trace Luminometer o. DO NOT do

testing if a BATTERY LOW warning is displayed. Connect

the charging cable to the 3M Clean-Trace Luminometer

and to the power mains.

Tap [Try Again] to repeat the Diagnostic Check. If the

Diagnostic Check fails again, contact 3M or your local

distributor.

Insert a 3M Clean-Trace Test.

a. Press the up arrow button on the control panel for

b. Battery fully discharged

c. Instrument malfunction

a. Sample / reagent problem

b. Instrument malfunction

Rocker cap was open while you

attempted to start the reading process

measurement

3 seconds

b. Recharge the battery.

c. Contact 3M or your local distributor.

Insert a 3M Clean-Trace Test.

a. Check with a new 3M Clean-Trace Test and known

positive samples such as a 3M™ Clean-Trace™

Surface Positive Control or 3M™ Clean-Trace™ Water

Positive Control.

b. Contact 3M or your local distributor.

Close the rocker cap after you insert a 3M Clean-Trace Test

and before you start the reading process.

To prevent leakage into the chamber, if a 3M Clean-Trace

Test is left in the chamber for more than 30 seconds

following the completion of a measurement, this message

along with an audible tone reminds you to remove the test

from the chamber after the measurement is complete.

Insert a 3M Clean-Trace Test.

Turn power o and wait for 5 minutes. Restart the

Luminometer. If there is no error message, the

Luminometer is OK to use.

Turn power o and wait for 5 minutes. Restart the

Luminometer. If there is no error message, the

Luminometer is OK to use.

The test was cancelled. Please hold the Luminometer rmly

and pointed at most 68 degrees from vertical.

17

Page 20

EN

(English)

Synchronization

Failure

Instrument

becomes

unresponsive

Unexpectedly

high test results

Error: 7 Firmware upgrade problem 1. Turn o the 3M Clean-Trace Luminometer, and turn it

Error: 9 Cap was open while reading a test 1. Close the cap.

Error: 11

Error: 15

Error: 12

Error: 16

Error: 1

Error: 2

Error: 4

Error: 6

Error: 8

Error: 10

Error: 13

Error: 14

Error: 28

Error: 17

Error: 31

Error: 18 - 30

Error: 33 - 123

Instrument not registered To register an instrument the rst time you synchronize

it, log in to the Sync Manager on your computer, then

synchronize the instrument. Refer to the Using the

Sync Manager section of the 3M Clean-Trace Hygiene

Management Software User Manual for more information.

Temporary software malfunction To do a hard reset, press the on/o button for 15 seconds.

To start the instrument again, press the on/o button for

3 seconds.

Instrument was dropped or subjected

to a physical shock

Instrument temperature is >40°C 1. Use the 3M Clean-Trace Luminometer at ambient

Instrument temperature is <5°C 1. Use the 3M Clean-Trace Luminometer at ambient

Switch o the power for 5 minutes, then switch the power

on again.

on again.

2. Repeat the rmware upgrade.

3. If the problem persists, contact 3M or your local

distributor.

2. Repeat reading the test.

3. If the problem persists, contact 3M or your local

distributor.

temperature less than or equal to 40°C.

2. If the problem persists, contact 3M or your local

distributor.

temperatures greater than or equal to 5°C.

2. If the problem persists, contact 3M or your local

distributor.

1. Turn o the 3M Clean-Trace Luminometer, and turn it

on again.

2. Repeat the task using the 3M Clean-Trace Luminometer.

3. If the problem persists, contact 3M or your local

distributor.

18

Page 21

(English)

EN

APPENDIX

The 3M Clean-Trace Luminometer display screen is laminated, bonded and shatter-resistant. It is designed to hold together

in the event of breakage.

The 3M Clean-Trace Luminometer allows for gloved operation. Gloves need to be 4 mil thick or less and cannot be woven

with metallic substances.

Cleaning and Decontaminating the 3M Clean‑Trace Luminometer

WARNING: To reduce the risks associated with hazardous voltage, always turn the instrument o and disconnect from

outlet before cleaning the instrument.

Clean and decontaminate the instrument immediately if any spills occur.

Clean the external surfaces of the instrument regularly once per month.

Cleaning and Decontaminating the External surfaces:

1. Turn o the power by pressing and holding the on/o button for 3 seconds (1, see gure below), and then disconnect

the USB cable (2, see gure below) on the side of the instrument.

2. Use a disposable towel lightly dampened with a solution of mild, non-staining disinfectant/cleaner such as mild

dishwashing soap to gently wipe the outer surfaces of the instrument. Wring out the disposable towel thoroughly so

it is damp, but not dripping. Avoid the USB cable connection on the side of the instrument when cleaning the exterior

surfaces.

3. Use another disposable towel to repeat the procedure with DI water (distilled water or deionized water).

4. Allow the exterior surfaces of the instrument to air dry for at least 1 hour. Do not reconnect the power cable and the

USB cable until you have allowed the instrument to air dry for at least 1 hour.

5. Connect the USB cable (2), and turn on the power by pressing and holding the on/o button for 3 seconds (1).

2

1

19

Page 22

3M Food Safety

3M United States

3M Center

Bldg. 275-5W-05

St. Paul, MN 55144-1000

USA

1-800-328-6553

3M Canada

Post Oce Box 5757

London, Ontario N6A 4T1

Canada

1-800-563-2921

3M Latin America

3M Center

Bldg. 275-5W-05

St. Paul, MN 55144-1000

USA

1-954-340-8263

3M Europe and MEA

3M Deutschland GmbH

Carl-Shurz - Strasse 1

D41453 Neuss/Germany

+49-2131-14-3000

3M United Kingdom PLC

Morley Street,

Loughborough

Leicestershire

LE11 1EP

United Kingdom

+(44) 1509 611 611

3M Österreich GmbH

Euro Plaza

Gebaude J, A-1120 Wien

Kranichberggasse 4

Austria

+(43) 1 86 686-0

3M Asia Pacic

No 1, Yishun Avenue 7

Singapore, 768923

65-64508869

3M Japan

3M Health Care Limited

6-7-29, Kita-Shinagawa

Shinagawa-ku, Tokyo

141-8684 Japan

81-570-011-321

3M Australia

Bldg A, 1 Rivett Road

North Ryde, NSW 2113

Australia

61 1300 363 878

3

3M Health Care

2510 Conway Ave

St. Paul, MN 55144 USA

www.3M.com/foodsafety

© 2016, 3M. All rights reserved.

3M and Clean-Trace are trademarks of 3M. Used under license in Canada.

All other trademarks are the property of their respective companies.

34-8718-2963-5

Loading...

Loading...