Page 1

ANSI Z359.18

Type A

OSHA 1926.502

OSHA 1910.140

1

TROLLEY ANCHOR

Anchorage Connector

USER INSTRUCTIONS

5902145 REv. H

2103143

2103143C

2103147

2103149

2103152

ANSI

Z359.18

OSHA A B C D E

11.63 in.

(29.54 cm)

11.63 in.

(29.54 cm)

11.63 in.

(29.54 cm)

11.63 in.

(29.54 cm)

11.63 in.

(29.54 cm)

8.81 in.

(22.38 cm)

8.81 in.

(22.38 cm)

8.81 in.

(22.38 cm)

8.81 in.

(22.38 cm)

8.81 in.

(22.38 cm)

5.56 in.

(14.38 cm)

5.56 in.

(14.38 cm)

5.56 in.

(14.38 cm)

5.56 in.

(14.38 cm)

5.56 in.

(14.38 cm)

8.42 in.

(21.39 cm)

8.42 in.

(21.39 cm)

8.42 in.

(21.39 cm)

8.42 in.

(21.39 cm)

8.42 in.

(21.39 cm)

3.0 in. - 8.0 in.

(7.6 cm - 20.3 cm)

3.0 in. - 8.0 in.

(7.6 cm - 20.3 cm)

3.0 in. - 8.0 in.

(7.6 cm - 20.3 cm)

3.0 in. - 8.0 in.

(7.6 cm - 20.3 cm)

3.0 in. - 8.0 in.

(7.6 cm - 20.3 cm)

B

A

D

C

E

© 3M 2020

Page 2

2

D

A

E

G

B

C

A

H

H

F

3 4

A

FC

B

C

FC

B

C

2

Page 3

5 6

A. B. C. D.

A B C

1

3

4

5

1

6

2

A

B

C

D

D

E.

F.

G.

7

2

4

3

6

A

B

C

2

1

5

3 4

3

Page 4

7

5

A

B

8 9

D

C

≤ 1/16 in.

(1.6 mm)

30°

30°

30°

30°

10

A

A

4

Page 5

11

X

X

12

A

2103143

2103147

2103149

Y

2103152

2103143C

1

WARNING

Y

A B C

2

3 4 6

5

B

1

2

4

3

C

1

2

3 4

5

5

Page 6

SAFETY INFORMATION

EN

Please read, understand, and follow all safety information contained in these instructions prior to the use of this Anchorage Connector.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY OR DEATH.

These instructions must be provided to the user of this equipment. Retain these instructions for future reference.

Intended Use:

This Anchorage Connector is intended for use as part of a complete personal fall protection system.

Use in any other application including, but not limited to, material handling, recreational or sports related activities, or other activities not described in

the User Instructions, is not approved by 3M and could result in serious injury or death.

This device is only to be used by trained users in workplace applications.

! WARNING

This Anchorage Connector is part of a personal fall protection system. It is expected that all users be fully trained in the safe installation and operation

of their personal fall protection system. Misuse of this device could result in serious injury or death. For proper selection, operation, installation,

maintenance, and service, refer to these User Instructions and all manufacturer recommendations, see your supervisor, or contact 3M Technical Service.

• To reduce the risks associated with working with an Anchorage Connector which, if not avoided, could result in serious injury or

death:

- Inspect the device before each use, at least annually, and after any fall event. Inspect in accordance with the User Instructions.

- If inspection reveals an unsafe or defective condition, remove the device from service and repair or replace according to the User Instructions.

- Any device that has been subject to fall arrest or impact force must be immediately removed from service and destroyed.

- The device must only be installed in the specied substrates or on structures detailed in the User Instructions. Installations and use outside the

scope of this instruction must be approved by 3M Fall Protection.

- The substrate or structure to which the anchorage connector is attached must be able to sustain the static loads specied for the anchor in the

orientations permitted in the User Instructions.

- Only connect other fall protection subsystems to the designated anchorage connection point on the device.

- Prior to drilling or fastening, ensure no electric lines, gas lines, or other critical embedded systems will be contacted by the drill or the device.

- Ensure that fall protection systems/subsystems assembled from components made by dierent manufacturers are compatible and meet the

requirements of applicable standards, including the ANSI Z359 or other applicable fall protection codes, standards, or requirements. Always

consult a Competent or Qualied Person before using these systems.

• To reduce the risks associated with working at height which, if not avoided, could result in serious injury or death:

- Ensure your health and physical condition allow you to safely withstand all of the forces associated with working at height. Consult with your

doctor if you have any questions regarding your ability to use this equipment.

- Never exceed allowable capacity of your fall protection equipment.

- Never exceed maximum free fall distance of your fall protection equipment.

- Do not use any fall protection equipment that fails pre-use or other scheduled inspections, or if you have concerns about the use or suitability

of the equipment for your application. Contact 3M Technical Services with any questions.

- Some subsystem and component combinations may interfere with the operation of this equipment. Only use compatible connections. Consult

3M prior to using this equipment in combination with components or subsystems other than those described in the User Instructions.

- Use extra precautions when working around moving machinery (e.g. top drive of oil rigs) electrical hazards, extreme temperatures, chemical

hazards, explosive or toxic gases, sharp edges, or below overhead materials that could fall onto you or your fall protection equipment.

- Use Arc Flash or Hot Works devices when working in high heat environments.

- Avoid surfaces and objects that can damage the user or equipment.

- Ensure there is adequate fall clearance when working at height.

- Never modify or alter your fall protection equipment. Only 3M or parties authorized in writing by 3M may make repairs to the equipment.

- Prior to use of fall protection equipment, ensure a rescue plan is in place which allows for prompt rescue if a fall incident occurs.

- If a fall incident occurs, immediately seek medical attention for the worker who has fallen.

- Do not use a body belt for fall arrest applications. Use only a Full Body Harness.

- Minimize swing falls by working as directly below the anchorage point as possible.

- If training with this device, a secondary fall protection system must be utilized in a manner that does not expose the trainee to an unintended

fall hazard.

- Always wear appropriate personal protective equipment when installing, using, or inspecting the device/system.

FORM NO: 5908299 REV: A

6

Page 7

Prior to installation and use of this equipment, record the product identication information from the ID label in the

;

Inspection and Maintenance Log (Table 2) at the back of this manual.

Always ensure you are using the latest revision of your 3M instruction manual. Visit the 3M website or contact 3M

;

Technical Services for updated instruction manuals.

PRODUCT DESCRIPTION:

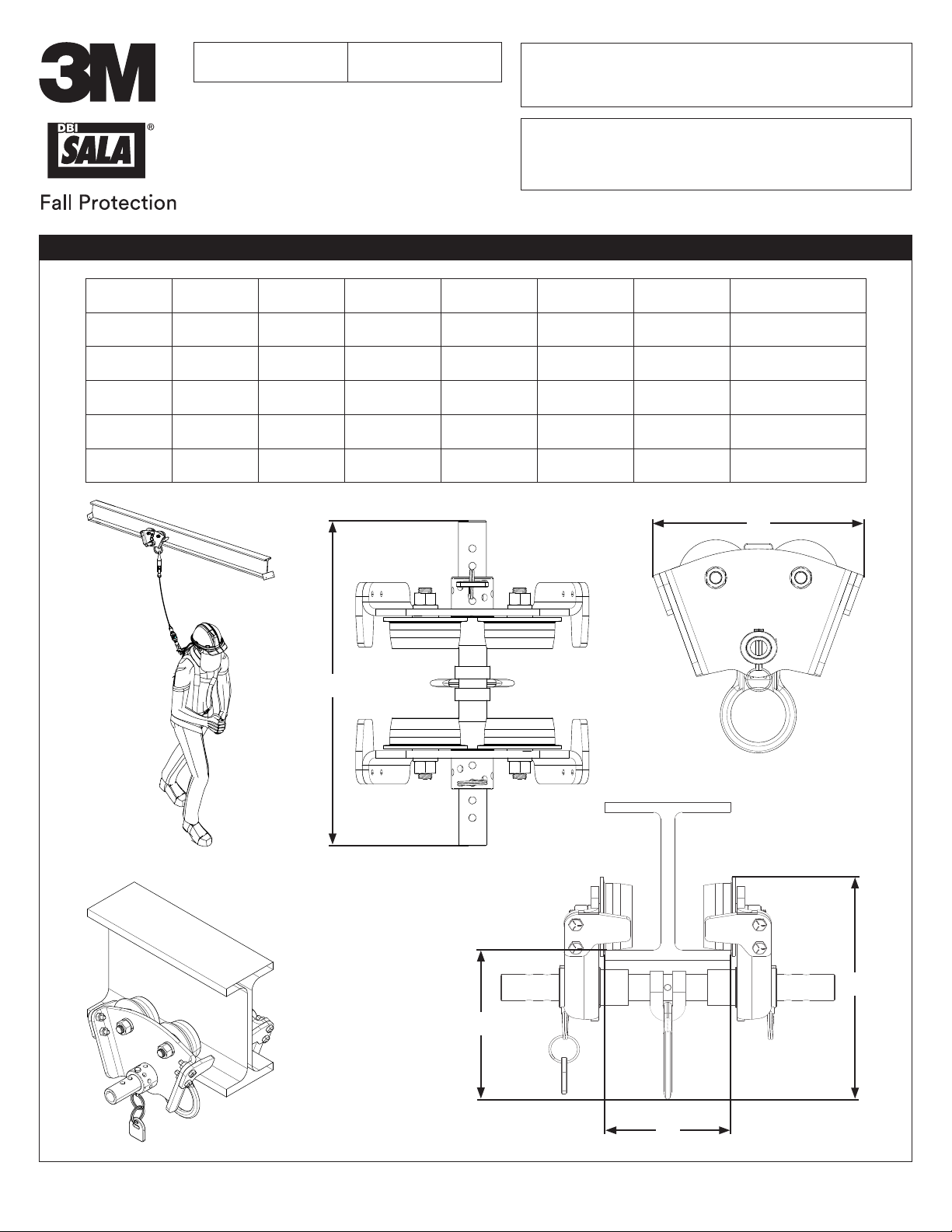

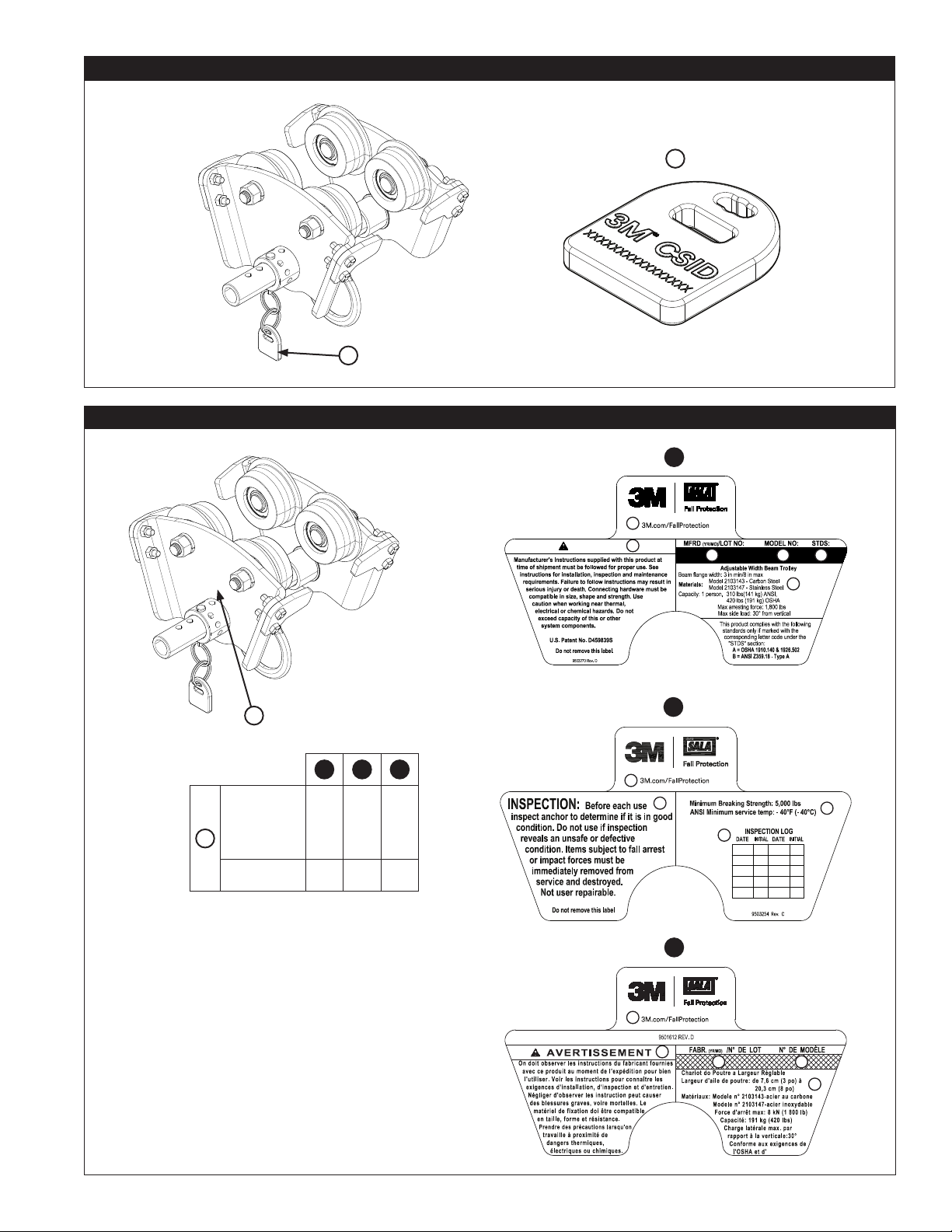

Figure 1 illustrates the 3M™ DBI-SALA® Trolley Anchor. The Trolley Anchor is a single point anchorage connector for a Fall Arrest

system designed to be installed overhead on the bottom ange of a beam and to roll along a horizontal beam.

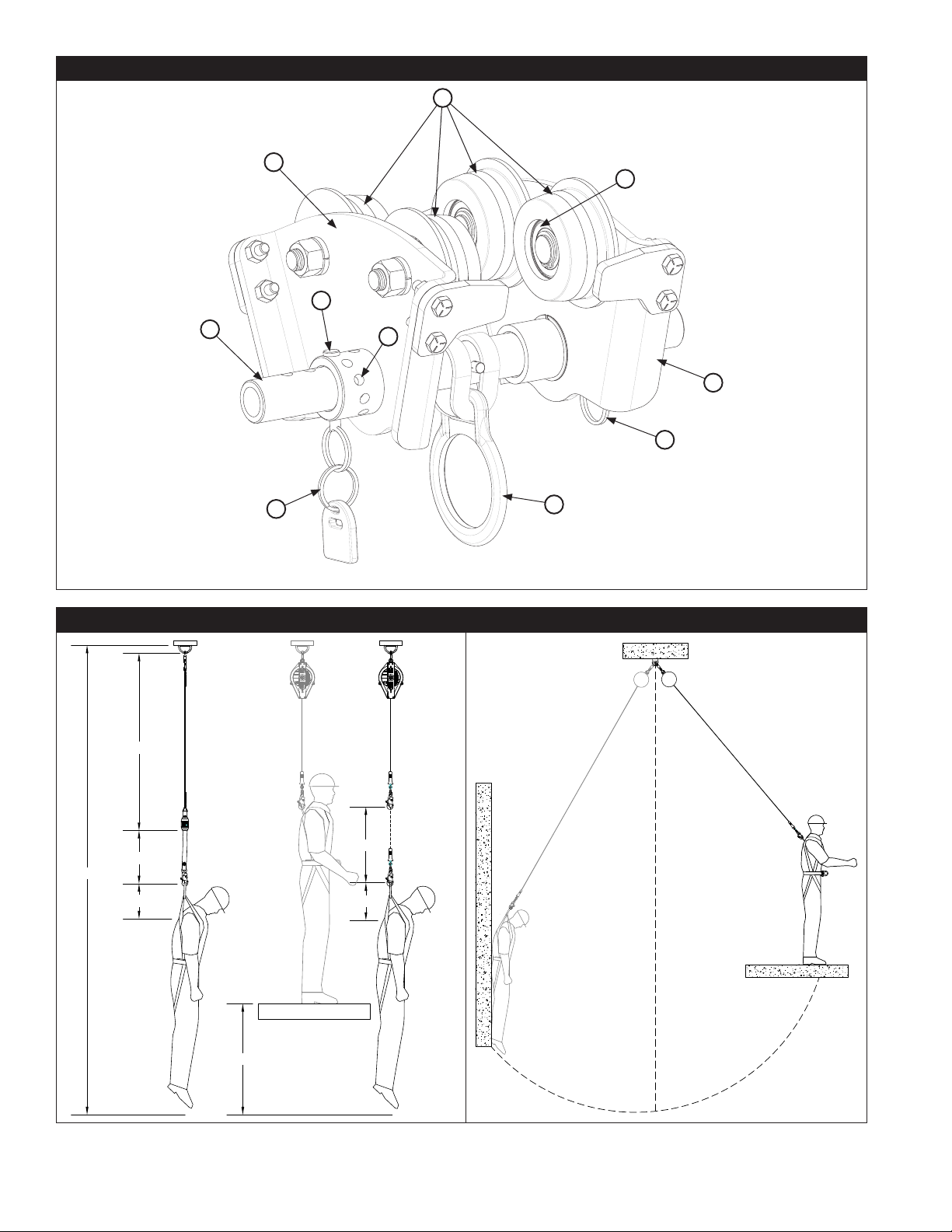

Figure 2 illustrates components of the Trolley Anchor. See Table 1 for Component Specications. The Trolley Anchor is comprised

of two Side Plates (A). The Load Bar (B) that connects the Side Plates adjusts to various beam ange widths with Adjuster Dials

(C) built into the outside of each Side Plate. The Side Plates can be adjusted by removing the Pull Ring (H) and Clevis Pin (G)

and then reinstalling. The four Wheels (D) are intended to roll smoothly along the beam, aided by Bearings (E). The Fall Arrest

subsystem connects to the Connector Ring (F) in the center of the Load Bar. A typical Fall Arrest system consists of a Fully Body

Harness and an Energy-Absorbing Lanyard or Self-Retracting Device (SRD).

Table 1 – Specications

System Specications:

Capacity: One person with a combined weight (clothing, tools, etc.) of no more than 310 lb. (140 kg) for ANSI, or no more

Anchorage

Strength:

than 420 lb. (191 kg) for OSHA.

The structure to which the anchorage connector is mounted must be capable of sustaining force in the anticipated

directions of loading. See Section 2.1 for values.

Only one Fall Arrest system may be attached to an individual Trolley Anchor at a time. The trolley may be used on

beam flanges 3.0 in. to 8.0 in. (7.6 cm to 20.3 cm) wide and up to 11/16 in. (1.75 cm) thick. The minimum radius the

trolley can follow is 48 in. (122 cm). The beam structure must meet the strength requirements specified in this section.

The beam must be horizontal and level.

Loads imposed on the trolley by the Fall Arrest system must remain within 30 degrees of the vertical center

;

line of the beam. See Figure 9 for reference.

If the user is unable to determine whether the anchorage structure meets product requirements, then the

;

user should either seek a Qualified Person or professional engineer who is able to do so or contact 3M Technical

Services.

Allowable Flange

Width:

Allowable Flange

Thickness:

Service

Temperature:

Minimum Breaking

Strength:

Dimensions: See Figure 1 for the dimensions of each Trolley Anchor model.

Weight: 15.0 lb. (6.8 kg)

Standards: The Trolley Anchor has been tested in compliance with the requirements of ANSI Z359.7, in addition to those

3.0 in. to 8.0 in. (7.6 cm to 20.3 cm). See Figure 1 for more information.

≤ 11/16 in (1.75 cm)

-40°F (-40°C) Minimum Service Temperature

5,000 lbf (22 kN) Minimum Breaking Strength

standards listed on the front cover.

ANSI compliance and testing covers only the product and does not extend to the anchorage structure or

;

substrate to which the product is attached.

Component Specications:

Figure 2

Reference Component

Materials

(Model 2103147)

Materials

(All other models)

A Side Plates Stainless Steel Zinc Plated Steel

B Load Bar Stainless Steel Alloy Steel

C Adjuster Dials with Adjustment Holes Stainless Steel Zinc Plated Steel

Zinc Plated Steel

D Wheels Stainless Steel

(Model 2103149 - Rubber coating on

wheels)

E Bearings Stainless Steel Stainless Steel

F Connector Ring Stainless Steel Zinc Plated Steel

G Clevis Pin Stainless Steel Stainless Steel

H Pull Ring Stainless Steel Stainless Steel

7

Page 8

1.0 PRODUCT APPLICATION

1.1 PURPOSE: Anchorage Connectors are designed to provide anchorage connection points for Fall Arrest1, Fall Restraint2,

Work Positioning3, or Rescue4 systems.

Fall Protection Only: This Anchorage Connector is for connection of Fall Protection equipment. Do not connect

;

Lifting Equipment to the Anchorage Connector.

1.2 STANDARDS: Your Anchorage Connector conforms to the national or regional standard(s) identied on the front cover

of these instructions. If this product is resold outside the original country of destination, the re-seller must provide these

instructions in the language of the country in which the product will be used.

1.3 SUPERVISION: Use of this equipment must be supervised by a Competent Person5.

1.4 TRAINING: This equipment must be installed and used by persons trained in its correct application. This manual is to be

used as part of an employee training program as required by national, regional, or local standards. It is the responsibility

of the users and installers of this equipment to ensure they are familiar with these instructions, trained in the correct care

and use of this equipment, and are aware of the operating characteristics, application limitations, and consequences of

improper use of this equipment.

1.5 RESCUE PLAN: When using this equipment and connecting subsystem(s), the employer must have a rescue plan and

the means at hand to implement and communicate that plan to users6, authorized persons7, and rescuers8. A trained,

on-site rescue team is recommended. Team members should be provided with the equipment and techniques to perform a

successful rescue. Training should be provided on a periodic basis to ensure rescuer prociency.

1.6 AFTER A FALL: If the product is subjected to fall arrest or impact force, remove the product from service immediately.

Clearly tag the product “DO NOT USE”. See Section 5 for more information.

2.0 SYSTEM REQUIREMENTS

2.1 ANCHORAGE: Anchorage structure requirements vary with the system application and whether it is a certied

anchorage9 or non-certied anchorage10. The structure to which a Fall Arrest, Restraint, Work Positioning, or Rescue

system is attached must sustain static loads applied in the directions permitted as shown in the following table. Anchorage

strength requirements, along with system applications, are specied below, unless noted or dened otherwise in Table 1:

Fall Protection System Certied Anchorage

9

Non-Certied Anchorage

10

Dened by

Fall Arrest 2 times maximum arresting force 5,000 lbf (22.2 kN) OSHA, ANSI

Restraint/Travel Restraint 2 times foreseeable force

1,000 lbf (4.4 kN) per ANSI

5,000 lbf (22.2 kN) per OSHA

OSHA, ANSI

Work Positioning 2 times foreseeable force 3,000 lbf (13.3 kN) OSHA, ANSI

Rescue 5 times applied load 3,000 lbf (13.3 kN) ANSI

When more than one system is attached to an anchorage, the strengths stated above must be multiplied by the number

of systems attached to the anchorage. See ANSI Z359.2 for more information.

2.2 PERSONAL FALL ARREST SYSTEM: Figure 1 illustrates the application of this Anchorage Connector. Personal Fall

Arrest Systems (PFAS) used with the system must meet applicable Fall Protection standards, codes, and requirements.

The PFAS must incorporate a Full Body Harness and limit Arresting Force to the following values:

Maximum Arresting Force Free Fall

PFAS with Shock Absorbing Lanyard 1800 lbf (8 kN)

PFAS with Self Retracting Device (SRD) 1800 lbf (8 kN)

Refer to the instruction(s) included with your

Lanyard or SRD for Free Fall limitations.

2.3 FALL PATH AND SRD LOCKING SPEED: A clear path is required to assure positive locking of an SRD. Situations

which do not allow for an unobstructed fall path should be avoided. Working in confined or cramped spaces may not allow

the body to reach sufficient speed to cause the SRD to lock if a fall occurs. Working on slowly shifting material, such as

sand or grain, may not allow enough speed buildup to cause the SRD to lock.

1 Fall Arrest System: A collection of Fall Protection Equipment congured to arrest a free fall. Protects the user in the event of a fall. Free fall is permitted up to

the limits allowed by the connecting device (either an Energy Absorbing Lanyard or Self-Retracting Device (SRD)).

2 Restraint System: A collection of Fall Protection Equipment congured to prevent the person’s center of gravity from reaching a fall hazard.Prevents the user

from reaching a hazard. No verical free fall is permitted.

3 Work Positioning System: A collection of Fall Protection Equipment congured to support a user at a work position. Must include a back-up personal fall

arrest system. Maximum permissible free fall is 2 feet.

4 Rescue System: A collection of Fall Protection Equipment congured to remove a person from danger, harm, or connement to a safe location. No vertical free

fall is permitted.

5 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary,

hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

6 User: A person who performs activities while protected by a Fall Protection system.

7 Authorized Person: A person assigned by the employer to perform duties at a location where the person will be exposed to a fall hazard.

8 Rescuer: Person or persons other than the rescue subject acting to perform an assisted rescue by operation of a rescue system.

9 Certied Anchorage: An anchorage for fall arrest, positioning, restraint, or rescue systems that a Qualied Person certies to be capable of meeting the

criteria for a certied anchorage according to Section 2.1.

10 Non-Certied Anchorage: A fall arrest anchorage that a Competent Person can judge to be capable of supporting the predetermined anchorage forces

listed in Section 2.1.

8

Page 9

2.4 HAZARDS: Use of this equipment in areas with environmental hazards may require additional precautions to prevent

injury to the user or damage to the equipment. Hazards may include, but are not limited to: heat, chemicals, corrosive

environments, high voltage power lines, explosive or toxic gases, moving machinery, sharp edges, or overhead materials

that may fall and contact the user or Personal Fall Arrest System.

2.5 FALL CLEARANCE: Figure 3 illustrates the components of a Fall Arrest. There must be sucient Fall Clearance (FC)

to arrest a fall before the user strikes the ground or other obstruction. Clearance is aected by a number of factors

including: Anchorage Location, (A) Lanyard Length, (B) Lanyard Deceleration Distance or SRD Maximum Arrest Distance,

(C) Harness Stretch and D-Ring/Connector Length and Settling. Refer to the instructions included with your Fall Arrest

subsystem for specics regarding Fall Clearance calculation.

2.6 SWING FALLS: Swing Falls occur when the anchorage point is not directly above the point where a fall occurs (see Figure

4). The force of striking an object in a swing fall may cause serious injury or death. Minimize swing falls by working as directly

below the anchorage point as possible. Do not permit a swing fall if injury could occur. Swing falls will signicantly increase the

clearance required when a Self-Retracting Device or other variable length connecting subsystem is used.

2.7 COMPONENT COMPATIBILITY: 3M equipment is designed for use with 3M approved components and subsystems

only. Substitutions or replacements made with non-approved components or subsystems may jeopardize compatibility of

equipment and may aect the safety and reliability of the complete system.

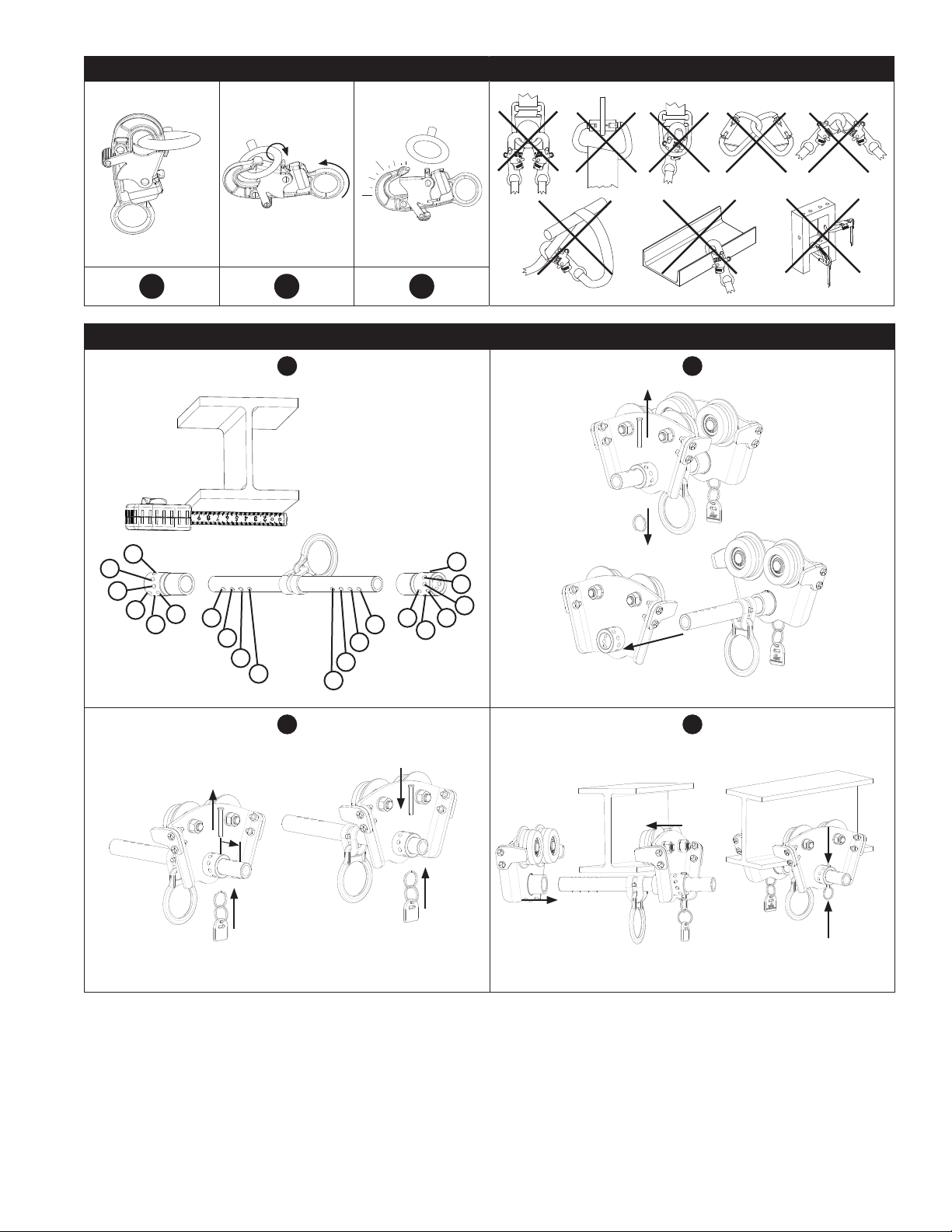

2.8 CONNECTOR COMPATIBILITY: Connectors are considered to be compatible with connecting elements when they

have been designed to work together in such a way that their sizes and shapes do not cause their gate mechanisms to

inadvertently open regardless of how they become oriented. Contact 3M if you have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable of supporting at least 5,000 lbf (22.2 kN). Connectors

must be compatible with the anchorage or other system components. Do not use equipment that is not compatible.

Non-compatible connectors may unintentionally disengage (see Figure 5). Connectors must be compatible in size, shape,

and strength. If the connecting element to which a snap hook or carabiner attaches is undersized or irregular in shape, a

situation could occur where the connecting element applies a force to the gate of the snap hook or carabiner (A). This force

may cause the gate to open (B), allowing the snap hook or carabiner to disengage from the connecting point (C).

Self-locking snap hooks and carabiners are required by ANSI Z359 and OSHA.

2.9 MAKING CONNECTIONS: Snap hooks and carabiners used with this equipment must be self-locking. Ensure all

connections are compatible in size, shape and strength. Do not use equipment that is not compatible. Ensure all

connectors are fully closed and locked.

3M connectors (snap hooks and carabiners) are designed to be used only as specied in each product’s user’s instructions.

See Figure 6 for examples of inappropriate connections. Do not connect snap hooks and carabiners:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate. Large throat snap hooks should not be connected to standard

size D-rings or similar objects which will result in a load on the gate if the hook or D-ring twists or rotates, unless the

snap hook complies is equipped with a 3,600 lbf (16 kN) gate. Check the marking on your snap hook to verify that it

is appropriate for your application.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the anchor, and

without visual conrmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the lanyard and

connector specically allows such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and lock, or that

roll-out could occur.

G. In a manner that does not allow the connector to align properly while under load.

9

Page 10

3.0 INSTALLATION

The owner of this equipment may contact 3M Technical Services with any questions regarding equipment installation, use,

;

or inspection.

Installation of the DBI-SALA Trolley Anchor must be performed or supervised by a Competent Person1.

;

1

2

3.1 PLANNING: Plan your Fall Protection system prior to installation of the Trolley Anchor. Account for all factors that may

affect your safety before, during, and after a fall. Consider all requirements, limitations, and specications dened in

Section 2 and Table 1.

3M shall make available upon request information that is necessary for the design and planning of systems.

;

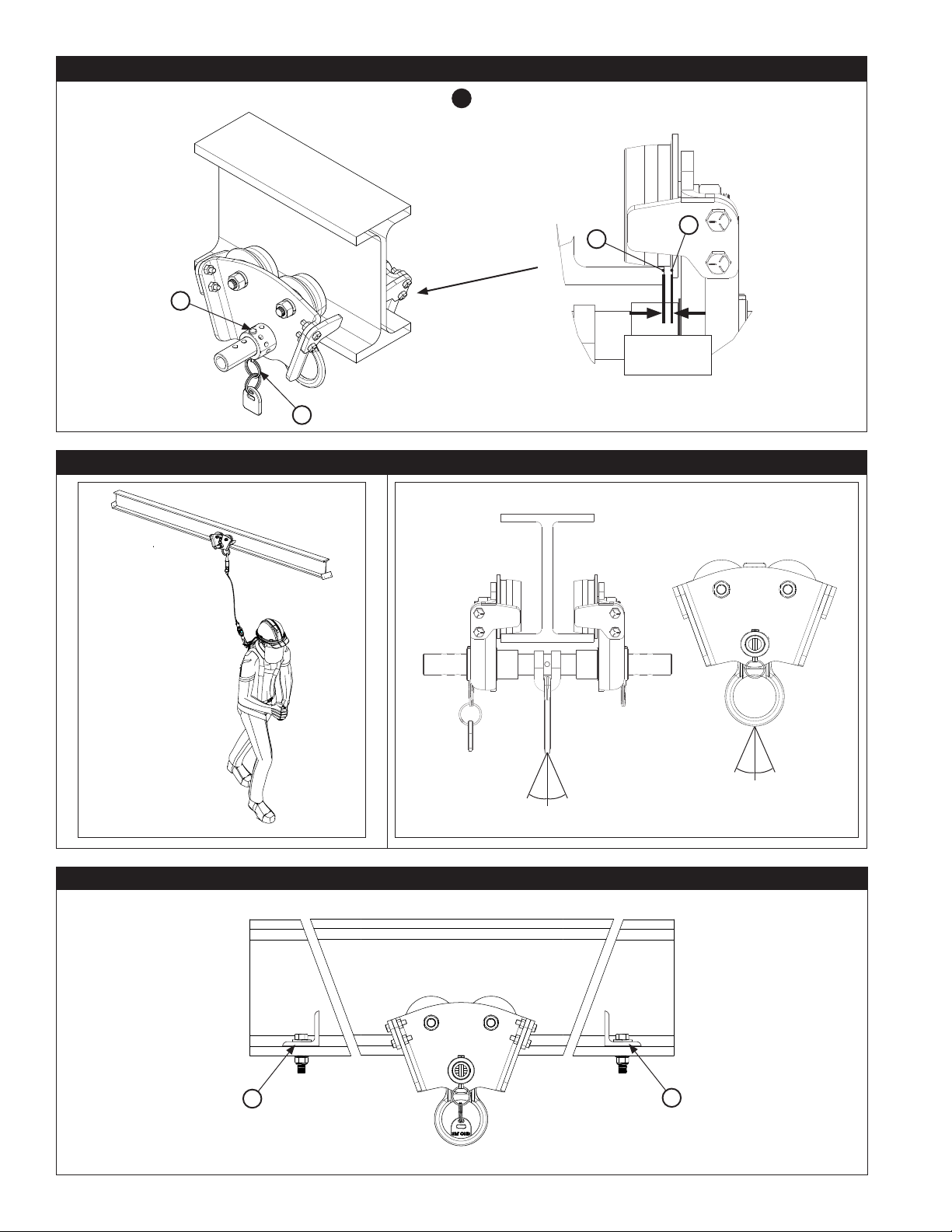

3.2 SELECTING AN ANCHORAGE BEAM: The Trolley Anchor may be installed on horizontal and level beams meeting the

anchorage requirements specied in Table 1. The beam must have End Stops (A) at each end to prevent the trolley from

rolling off the beam. See Figure 10 for reference. The end stops must be sized and positioned such that they are able to

safely stop the trolley. The trolley should not catch or hang on the end stop; the trolley must be able to freely return in

the opposite direction after touching the end stop.

Joints between beam sections must be ush to allow the Trolley Anchor to pass over smoothly.

;

3.3 INSTALLING THE TROLLEY ANCHOR: The Trolley Anchor can be installed on beams meeting the anchorage

requirements specied in Table 1. See Figure 1 for the Beam Trolley measurements. Figure 7 illustrates installation of the

Trolley Anchor. To install the Trolley Anchor:

1. Measure the beam ange width to determine the Adjustment Hole settings on the Trolley. Figure 7.1 and Table 2

illustrate the hole positions on the left and right Adjuster Dials and the Load Bar that correspond with Table 2. Record

these Adjustment Hole settings and use them for Step 3 and 4.

2. To open one side of the trolley, remove the Pull Ring from the Clevis Pin and pull the Clevis Pin up out of the Adjuster

Dial. Slide the Side Plate off the Load Bar.

3. On the still assembled side of the Trolley, remove the Pull Ring and Clevis Pin from the Side Plate, and adjust the

width to the required Adjustment Hole settings determined in Step 1 and from Table 2. Lock the adjustment into

place by re-installing the Clevis Pin vertically with the Clevis Pin Head on top through the appropriate Adjustment Dial

and Load Bar holes and installing the Pull Ring.

4. Place the partially assembled Side Plate and Load Bar onto the bottom ange of the beam with the Connector Ring

hanging down. Slide the un-assembled Side Plate onto the Load Bar and align with the required Adjuster Dial and

Load Bar holes as determined in Step 1. Install a Clevis Pin vertically, with the Clevis Pin head on top, through the

Adjuster Dial and Load Bar holes and secure with the Pull Ring.

Trolley width settings specified in Table 2 must be followed. Adjustments on the Load Bar must use the same

;

setting on both sides (e.g. A - A, B - B, etc.). Adjustments on the Adjuster Dial must be within one unit. Failure to

use correct settings may improperly load the Trolley. If the beam ange is too wide to install the Clevis Pin through

the correct holes, adjust the Trolley to the next larger beam ange size as specified in Table 2. The D-Ring must

always be centered between the two Side Plates.

5. Conrm the distance from the Trolley Wheel face (C) to the edge of the beam ange (D) is no more than 1/16 in.

(1.6 mm). If the distance is greater than 1/16 in. (1.6 mm), change the Adjuster Dials to the next narrower setting in

Table 2. Also, visually conrm the Clevis Pins (A) are installed with the pin heads on top of the Adjuster Dials and that

the Pull Rings (B) are fully installed through the Clevis Pin holes.

If the trolley is moved to another beam, or if the Pull Rings are removed, the circle type pull rings are reusable.

;

If a cotter pin is used, a new cotter pin is to be used for each new installation. Use 5/64 x 3/4”, 18-8 stainless

steel Pull Rings or Pivot Point bow-tie™ clip Pull Rings. If you are using Pivot Point bow-tie™ clips, they are also

reusable. Only use the original clevis pins. Do not make substitutes.

4.0 USE

4.1 BEFORE EACH USE: Verify that your work area and Fall Arrest system meet all criteria dened in these instructions.

Verify that a formal Rescue Plan is in place. Inspect the product per the ‘User’ inspection points dened in the “Inspection

and Maintenance Log”. If inspection reveals an unsafe or defective condition, or if there is any doubt about its condition

for safe use, remove the product from service immediately. Clearly tag it “DO NOT USE”. See Section 5 for more

information.

4.2 FALL ARREST CONNECTIONS: The Trolley Anchor is used with a Full Body Harness and Energy Absorbing Lanyard or

Self-Retracting Device (SRD). Figure 9 illustrates connection of the Lanyard (A) or SRD (B) between the Harness and

Trolley Anchor. Connect the Lanyard or SRD between the D-Ring on the Trolley Anchor and the back Dorsal D-Ring on the

Harness as instructed in the instructions included with the Lanyard or SRD.

Horizontal Lifeline Connections: The Beam Trolley Anchor cannot be used as an end anchor point for a

;

Horizontal Lifeline (HLL).

1 Qualied Person: An individual with a recognized degree or professional certificate, and extensive experience in Fall Protection. This individual must be capable

of design, analysis, evaluation, and specification in Fall Protection.

2 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazard-

ous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

10

Page 11

5.0 INSPECTION

After equipment has been removed from service, it may not be returned to service until a Competent Person confirms in

;

writing that it is acceptable to do so.

5.1 INSPECTION FREQUENCY: The product shall be inspected before each use by an authorized person and, additionally,

by a Competent Person other than the user at intervals of no longer than one year. A higher frequency of equipment use

and harsher conditions may require increasing the frequency of Competent Person inspections. The frequency of these

inspections should be determined by the Competent Person per the specic conditions of the worksite.

5.2 INSPECTION PROCEDURES: Inspect this product per the procedures listed in the “Inspection and Maintenance Log”.

Documentation of each inspection should be maintained by the owner of this equipment. An inspection and maintenance

log should be placed near the product or be otherwise easily accessible to users. It is recommended that the product is

marked with the date of next or last inspection.

Alternative inspection criteria may be set by the owner of this equipment. Alternative criteria must be equal to or

;

exceed those established by 3M in the “Inspection and Maintenance Log” and other official documents.

5.3 DEFECTS: If the product cannot be returned to service because of an existing defect or unsafe condition, or because it

has been subjected to a fall arrest, either destroy the product or contact 3M regarding possible replacement or repair.

5.4 PRODUCT LIFE: The functional life of the product is determined by work conditions and maintenance. As long as the

product passes inspection criteria, it may remain in service.

6.0 MAINTENANCE, SERVICE, and STORAGE

Equipment that is in need of maintenance or scheduled for maintenance should be tagged “DO NOT USE”. These

;

equipment tags should not be removed until maintenance is performed.

6.1 CLEANING: Periodically clean the metal components of the Trolley Anchor with a soft brush, warm water, and a mild soap

solution. Ensure parts are thoroughly rinsed with clean water.

6.2 SERVICE: Only 3M or parties authorized in writing by 3M may make repairs to this equipment.

6.3 STORAGE AND TRANSPORT: When not in use, store and transport the Trolley Anchor and associated Fall Protection

equipment in a cool, dry, clean environment out of direct sunlight. Avoid areas where chemical vapors may exist.

Thoroughly inspect components after extended storage.

7.0 RFID TAG

7.1 LOCATION: 3M product covered in these user instructions is equipped with a Radio Frequency Identication (RFID) Tag.

RFID Tags may be used in coordination with an RFID Tag Scanner for recording product inspection results. See Figure 11

for where your RFID Tag is located.

7.2 DISPOSAL: Prior to disposing of this product, remove the RFID Tag and dispose/recycle in accordance with local

regulations. For more information, please visit our website: http://www.3M.com/FallProtection/RFID

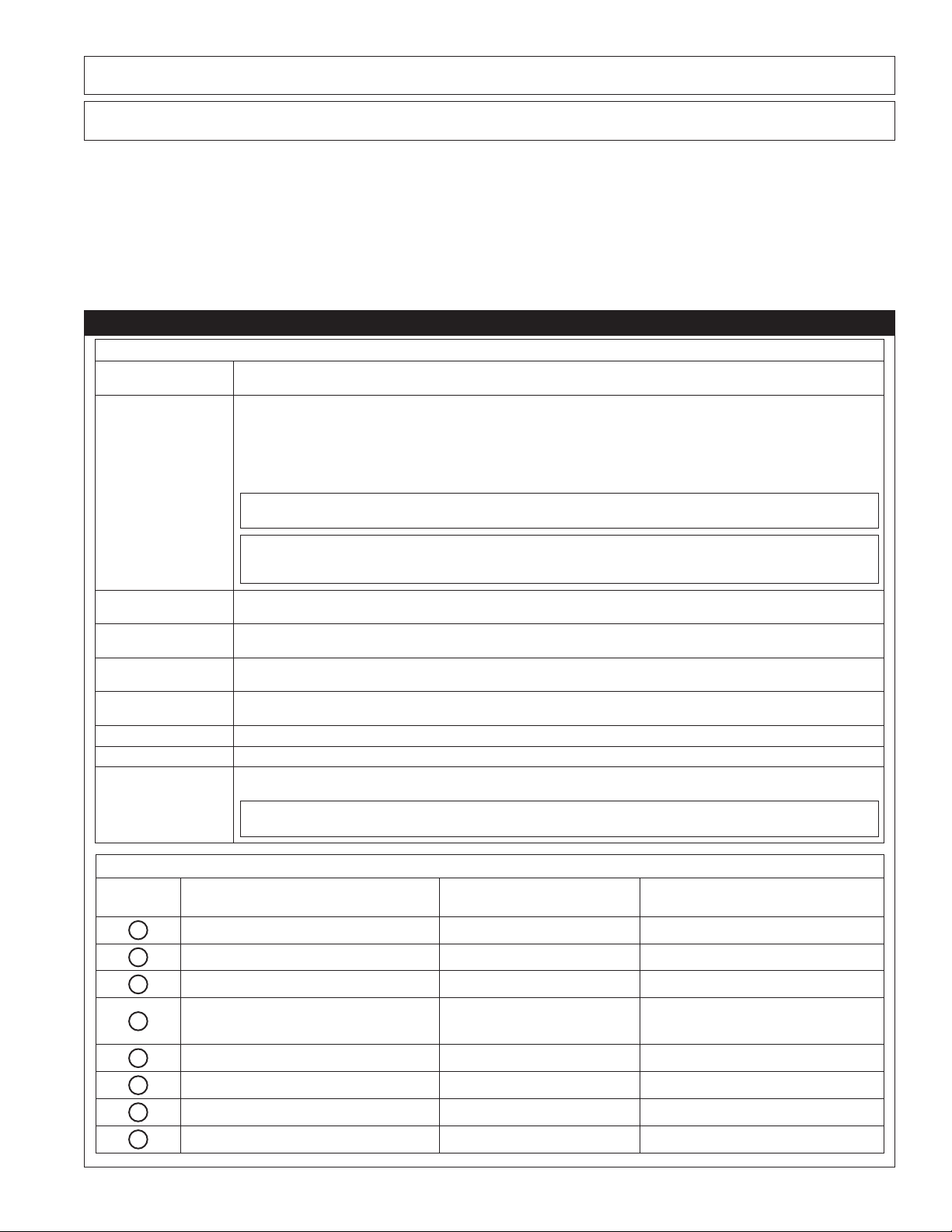

8.0 LABELS and MARKINGS

8.1 LABELS: Figure 12 illustrates labels on the Trolley Anchor. All labels must be present and fully legible. Information

provided on each label is as follows:

1) Company Website

2) Warning Statement

3) Manufactured (Year/Month) and Lot Number

A

4) Model Number

5) Product Specications

6) Applicable Standards

1) Company Website

2) Inspection Requirements - See Section 5 for more information.

B

3) Minimum Breaking Strength and Minimum Service Temperature

4) Inspection Log

1) Company Website

2) Warning Statement

C

3) Manufactured (Year/Month) and Lot Number

4) Model Number

5) Product Specications

11

Page 12

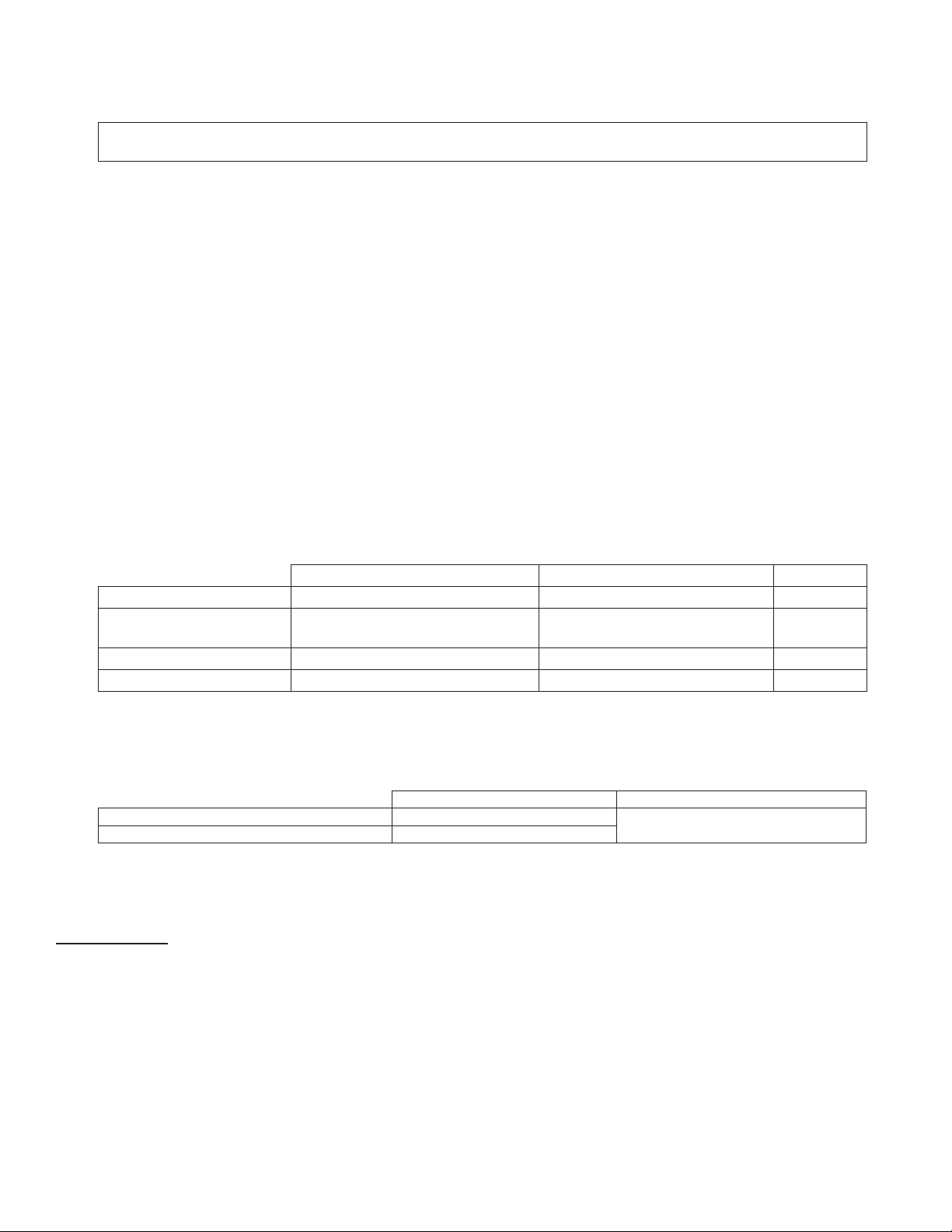

Table 2 - Trolley Width Adjustment

Beam Flange Width in inches (mm)

From

3.0 (76.2) 3.13 (79.38) D 1 1

3.13 (79.38) 3.25 (82.55) D 1 2

3.25 (82.55) 3.38 (85.73) D 2 2

3.38 (85.73) 3.50 (88.90) D 2 3

3.50 (88.90) 3.63 (92.08) D 3 3

3.63 (92.08) 3.75 (95.25) D 3 4

3.75 (95.25) 3.88 (98.43) D 4 4

3.88 (98.43) 4.0 (101.40) D 4 5

4.0 (101.40) 4.13 (104.78) D 5 5

4.13 (104.78) 4.25 (107.95) D 5 6

4.25 (107.95) 4.38 (111.13) C 1 1

4.38 (111.13) 4.5 (114.3) C 1 2

4.5 (114.3) 4.63 (117.48) C 2 2

4.63 (117.48) 4.75 (120.65) C 2 3

4.75 (120.65) 4.88 (123.83) C 3 3

4.88 (123.83) 5.0 (127.0) C 3 4

5.0 (127.0) 5.13 (130.18) C 4 4

5.13 (130.18) 5.25 (133.35) C 4 5

5.25 (133.35) 5.38 (136.53) C 5 5

5.38 (136.53) 5.5 (139.7) C 5 6

5.5 (139.7) 5.63 (142.88) B 1 1

5.63 (142.88) 5.75 (146.05) B 1 2

5.75 (146.05) 5.88 (149.23) B 2 2

5.88 (149.23) 6.0 (152.4) B 2 3

6.0 (152.4) 6.13 (155.58) B 3 3

6.13 (155.58) 6.25 (158.75) B 3 4

6.25 (158.75) 6.38 (161.93) B 4 4

6.38 (161.93) 6.5 (165.1) B 4 5

6.5 (165.1) 6.63 (168.28) B 5 5

6.63 (168.28) 6.75 (171.45) B 5 6

6.75 (171.45) 6.88 (174.63) A 1 1

6.88 (174.63) 7.0 (177.8) A 1 2

7.0 (177.8) 7.13 (180.98) A 2 2

7.13 (180.98) 7.25 (184.15) A 2 3

7.25 (184.15) 7.38 (187.33) A 3 3

7.38 (187.33) 7.5 (190.5) A 3 4

7.5 (190.5) 7.63 (193.68) A 4 4

7.63 (193.68) 7.75 (196.85) A 4 5

7.75 (196.85) 7.88 (200.03) A 5 5

7.88 (200.03) 8.0 (203.2) A 5 6

8.0 (203.2) --- A 6 6

Up to, but not

including

Load Bar Holes

(Both Sides)

Left Adjuster Dial

Hole

Right Adjuster Dial

Hole

12

Page 13

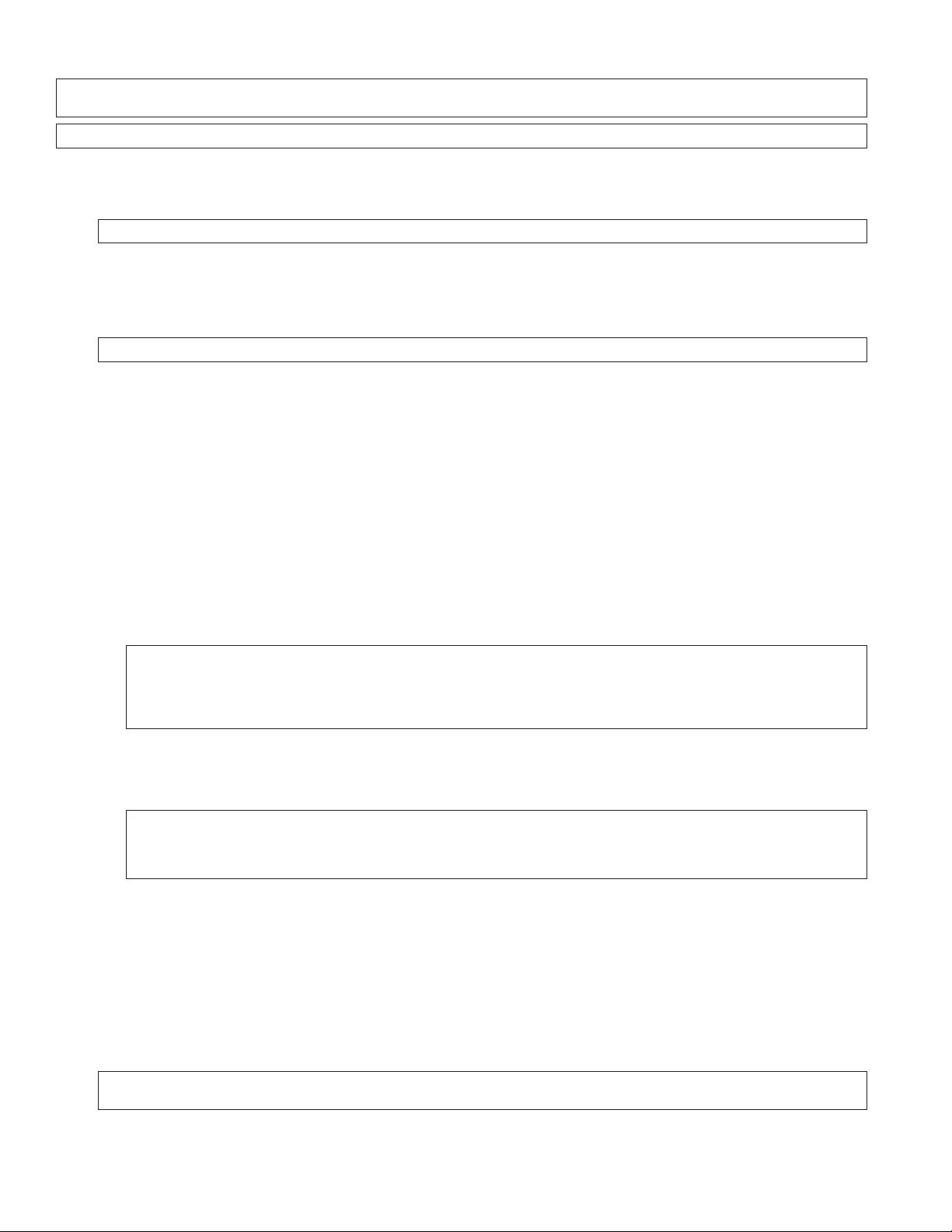

Table 3 – Inspection and Maintenance Log

Inspection Date: Inspected By:

Components: Inspection: (See Section 1 for Inspection Frequency) User

Trolley Anchor

(Figure 2)

Structure Verify the structure meets the requirements of Table 2, the beam has the end stops

Labels (Figure 12) Verify that all labels are present and fully legible.

Fall Protection

Equipment

Inspect Trolley for damage. Look for cracks or deformation. Look for excessive wear

or damage to the anchorage connection point. All fasteners must be secure.

Inspect the Trolley Wheels. All wheels should turn freely and be undamaged.

Inspect the entire unit for corrosion.

Ensure the Clevis Pin (G) can be inserted through the holes in the Support Tube

(A). Ensure both the Clevis Pins are installed in the Support Tube and that both Key

Rings are fully secured. Only use the provided Clevis Pins with the Trolley Anchor.

Inspect already-installed Trolley Anchors and conrm they are installed correctly

per Section 3.

at each end of the beam, and the beam is undamaged in any way.

Additional Fall Protection equipment used with the system should be installed and

inspected per the manufacturer’s instructions.

Competent

Serial Number(s): Date Purchased:

Model Number: Date of First Use:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Person

Page 14

INFORMATION DE SÉCURITÉ

FR-C

Veuillez lire, comprendre et suivre toutes les informations de sécurité contenues dans ces instructions avant d’utiliser ce connecteur

d’ancrage. LE NON-RESPECT DE CES INSTRUCTIONS PEUT ENTRAÎNER DES BLESSURES GRAVES, VOIRE LA MORT.

Ces instructions doivent être transmises à l’utilisateur de cet équipement. Veuillez conserver ces instructions pour une utilisation ultérieure.

Utilisation prévue :

Ce connecteur d’ancrage est prévu pour être utilisé comme partie intégrante d’un système de protection antichute personnel complet.

L’utilisation dans le cadre d’autres applications comme, sans en exclure d’autres, des activités récréatives ou liées au sport, ou d’autres activités non

décrites dans les instructions destinées à l’utilisateur, n’est pas approuvée par 3M et peut entraîner des blessures graves voire la mort.

Ce dispositif doit être utilisé uniquement par des usagers formés sur les applications du lieu de travail.

! AVERTISSEMENT

Ce connecteur d’ancrage fait partie intégrante d’un système de protection antichute personnel complet. Il est attendu que tous les usagers sont

entièrement formés sur l’installation sécuritaire et le fonctionnement de leur système de protection antichute personnel. Une mauvaise utilisation de

ce dispositif peut entraîner des blessures graves, voire la mort. Pour s’assurer d’un choix, d’un fonctionnement, d’une installation, de travaux

d’entretien et de réparation appropriés, reportez-vous à ces instructions de l’utilisateur ainsi qu’à toutes les recommandations du fabricant, consultez

votre superviseur ou communiquez avec les services techniques de 3M.

• Pour réduire les risques associés au travail en hauteur avec un connecteur d’ancrage qui, s’ils ne sont pas évités, pourraient

entraîner de graves blessures, voire la mort :

- Inspectez le dispositif avant chaque utilisation, au moins annuellement, et après chaque cas de chute. Réalisez l’inspection conformément aux

instructions de l’utilisateur.

- Si l’inspection révèle l’existence d’une défectuosité ou d’un problème aectant la sécurité, mettez l’équipement hors service et faites-le réparer

ou remplacez-le conformément à ces instructions.

- Tout dispositif ayant été soumis à un arrêt de chute ou à une force d’impact doit être immédiatement retiré du service et détruit.

- Ce dispositif ne doit être installé que sur les structures ou dans les substrats spéciés, comme il est précisé dans les instructions de l’utilisateur.

Toute installation ou utilisation qui est hors de la portée de ces instructions doit être approuvée par le service de protection antichute de 3M.

- La structure ou le substrat auquel le connecteur d’ancrage est xé doit pouvoir résister aux charges statiques précisées pour le dispositif

d’ancrage dans les sens permis indiqués dans les instructions de l’utilisateur.

- Ne connectez les autres sous-systèmes de protection antichute qu’au point de connexion d’ancrage désigné sur le dispositif.

- Avant de procéder au perçage ou à une xation, assurez-vous que la perceuse ou le dispositif n’entrera pas en contact avec des lignes

électriques, des conduites de gaz ou d’autres systèmes intégrés critiques.

- Assurez-vous que les systèmes/sous-systèmes de protection antichute assemblés à partir de composants fabriqués par diérents fabricants

sont compatibles et répondent aux exigences des normes applicables, y compris la norme ANSI Z359 ou d’autres codes, normes ou exigences

de protection antichute applicables. Consultez toujours une personne qualiée ou compétente avant d’utiliser ces systèmes.

• Pour réduire les risques associés au travail en hauteur qui, s’ils ne sont pas évités, pourraient entraîner des blessures graves, voire la mort :

- Assurez-vous que votre condition physique et votre état de santé vous permettent de supporter en toute sécurité toutes les forces associées au

travail en hauteur. Consultez votre médecin en cas de questions sur votre capacité à utiliser cet équipement.

- Ne dépassez jamais la capacité maximale permise de votre équipement de protection antichute.

- Ne dépassez jamais la distance maximale de chute libre de votre équipement de protection antichute.

- N’utilisez jamais un équipement de protection antichute qui échoue à une inspection préalable à son utilisation ou à toute autre inspection

programmée ou encore si vous vous inquiétez de l’utilisation ou de la pertinence de l’équipement pour votre application. En cas de questions,

n’hésitez pas à communiquer avec les services techniques de 3M.

- Certaines combinaisons de sous-systèmes et de composants peuvent gêner le fonctionnement de cet équipement. N’utilisez que des

connecteurs compatibles. Consultez 3M avant d’employer cet équipement conjointement avec des composants ou des sous-systèmes autres

que ceux décrits dans les instructions à l’utilisateur.

- Prenez des précautions supplémentaires lorsque vous travaillez à proximité d’une machinerie mobile (p. ex. l’entraînement supérieur d’une

plateforme pétrolière), risques électriques, températures extrêmes, risques chimiques, gaz explosifs ou toxiques, bords tranchants ou

matériaux en suspension pouvant endommager l’usager ou l’équipement.

- Lorsque vous travaillez dans un environnement où la chaleur est élevée, utilisez des appareils dont l’usage se fait en environnement chaud ou

en présence d’arc électrique.

- Évitez les surfaces et les objets qui pourraient endommager l’équipement de l’utilisateur.

- Lorsque vous travaillez en hauteur, vériez d’abord que la distance d’arrêt est adéquate.

- Ne modiez jamais votre équipement de protection antichute. Seules 3M ou les parties autorisées par écrit par 3M sont en droit d’eectuer des

réparations sur cet équipement.

- Avant d’utiliser un équipement de protection antichute, assurez-vous qu’un plan de sauvetage est en place et permet un sauvetage rapide en

cas de chute.

- Si un tel incident devait se produire, obtenez des soins médicaux immédiats pour le travailleur tombé.

- N’utilisez pas de ceinture de travail dans les applications de protection antichute. N’utilisez qu’un harnais de sécurité complet.

- Vous pouvez réduire les chutes oscillantes en travaillant aussi près que possible de l’ancrage.

- Si ce dispositif est utilisé en formation, un second système de protection antichute doit être utilisé aussi de façon à ne pas exposer le stagiaire

à un danger de chute involontaire.

- Portez toujours un équipement de protection individuelle approprié lors de l’installation, de l’utilisation ou de l’inspection du dispositif/système.

Nº DE FORMULAIRE : 5908299 RÉV : A

14

Page 15

Avant d’installer et d’utiliser ce matériel, consigner l’information d’identication de produit de l’étiquette d’identication

;

dans le Registre d’inspection et d’entretien (tableau 2) à la n de ce manuel.

Toujours s’assurer d’utiliser la dernière révision du manuel d’utilisation de 3M. Consulter le site Web de 3M ou

;

communiquer avec le Service technique de 3M pour obtenir des manuels d’utilisation mis à jour.

DESCRIPTION DU PRODUIT :

La gure 1 illustre l’ancrage à chariot DBI-SALA® 3MMC. L’ancrage à chariot est un connecteur d’ancrage à un seul point conçu

pour un système antichute; il doit être installé en hauteur sur la bride inférieure d’une poutre et doit rouler le long d’une poutre

horizontale.

La gure 2 illustre les composants de l’ancrage à chariot. Consulter le tableau 1 pour les spécications des composants.

L’ancrage à chariot est composé de deux plaques latérales (A). La traverse support (B) qui connecte les plaques latérales s’ajuste

à différentes largeurs de brides de poutre à l’aide de boutons de réglage (C) intégrés sur la face extérieure de chaque plaque

latérale. Les plaques latérales s’ajustent en enlevant l’anneau de traction (H) et l’axe à épaulement (G), puis en les réinstallant.

Les quatre roues (D) sont conçues pour rouler en douceur le long de la poutre à l’aide de paliers (E). Le sous-système antichute

se connecte à l’anneau connecteur (F) au centre de la traverse support. Un système antichute typique est composé d’un harnais

de sécurité complet et d’une longe amortisseur de choc ou d’un dispositif autorétractable.

Tableau 1 – Spécications

Spécications du système :

Capacité : Une seule personne dont le poids combiné (vêtements, outils, etc.) est d’au plus 140 kg (310 lb) pour l’ANSI ou

Résistance

d’ancrage :

d’au plus 191 kg (420 lb) pour l’OSHA.

La structure à laquelle le connecteur d’ancrage est xé doit être en mesure de supporter la force appliquée, dans le

sens de chargement anticipé. Voir la section 2.1 pour connaître les valeurs.

Un ancrage à chariot individuel ne peut accueillir qu’un seul système antichute à la fois. Le chariot peut être utilisé

sur des brides de poutre d’une largeur allant de 7,6 à 20,3 cm (3,0 à 8,0 po) et d’une épaisseur allant jusqu’à 1,75 cm

(11/16 po). Le rayon minimal que peut suivre le chariot est de 122 cm (48 po). La structure de la poutre doit respecter

les exigences en matière de résistance indiquées dans la présente section. La poutre doit être horizontale et à niveau.

Les charges imposées sur le chariot par le système antichute doivent rester dans une limite de 30 degrés par

;

rapport à la ligne centrale verticale de la poutre. Voir la figure 9 aux fins de référence.

Si l’utilisateur n’est pas en mesure de déterminer si la structure de l’ancrage répond aux exigences du

;

produit, il doit alors trouver une personne qualifiée ou un ingénieur professionnel en mesure de le faire ou

communiquer avec le Service technique de 3M.

Largeur de bride

permise :

Épaisseur de bride

permise :

Températures de

service :

Force de rupture

minimale :

Dimensions : Voir la gure 1 pour connaître les dimensions de chaque modèle d’ancrage à chariot.

Poids : 6,8 kg (15,0 lb)

Normes : L’ancrage à chariot a été mis à l’essai conformément aux exigences de la norme Z359.7 de l’ANSI en plus des normes

7,6 à 20,3 cm (3,0 à 8,0 po). Voir la gure 1 pour obtenir de plus amples renseignements.

≤ 1,75 cm (11/16 po)

Température de service minimale de -40 °C (-40 °F)

22 kN (5 000 lb)

indiquées sur la couverture.

La conformité aux normes de l’ANSI et les essais en vertu de ces dernières ne couvrent que le produit et ne

;

s’étendent pas à la structure d’ancrage ou au substrat auquel le produit est fixé.

Spécications des composants :

Figure 2

Référence Composant

Matériaux

(Modèle 2103147)

Matériaux

(Tous les autres modèles)

A Plaques latérales Acier inoxydable Acier zingué

B Traverse support Acier inoxydable Alliage d’acier

C Boutons de réglage et trous de réglage Acier inoxydable Acier zingué

Acier zingué

D Roues Acier inoxydable

(Modèle 2103149 – Roues avec

revêtement en caoutchouc)

E Paliers Acier inoxydable Acier inoxydable

F Anneau connecteur Acier inoxydable Acier zingué

G Axe à épaulement Acier inoxydable Acier inoxydable

H Anneau de traction Acier inoxydable Acier inoxydable

15

Page 16

1.0 APPLICATION DU PRODUIT

1.1 OBJECTIF : Les connecteurs d’ancrage sont conçus pour fournir des points de raccordement d’ancrage pour les systèmes

antichute1, systèmes de restriction du déplacement2, système de positionnement pour le travail3 ou systèmes de4 sauvetage.

Pour la protection contre les chutes seulement : Ce connecteur d’ancrage est conçu pour le raccordement du

;

matériel de protection contre les chutes. Ne pas raccorder de matériel de levage au connecteur d’ancrage.

1.2 NORMES : Votre connecteur d’ancrage est conforme à la ou aux normes nationales ou régionales identiées sur la

couverture avant de ces directives. Si ce produit est revendu en dehors du pays d’origine de destination, le revendeur doit

fournir ces directives dans la langue du pays dans lequel le produit est utilisé.

1.3 SUPERVISION : L’utilisation de ce matériel doit être supervisée par une personne compétente5.

1.4 FORMATION : Ce matériel doit être installé et utilisé par des personnes formées pour que son application soit

appropriée. Ce manuel doit être utilisé dans le cadre d’un programme de formation pour les employés, comme l’exigent

les normes nationales, régionales ou locales. L’utilisateur et l’installateur de ce matériel sont tenus de se familiariser

avec les présentes directives, de suivre une formation an de maintenir et d’utiliser correctement ce matériel et de bien

connaître les caractéristiques opérationnelles, les limites des applications ainsi que les conséquences d’une utilisation

inappropriée de ce matériel.

1.5 PLAN DE SAUVETAGE : Pour l’utilisation de ce matériel et des sous-systèmes de connexion, l’employeur doit avoir

un plan de sauvetage et les moyens de le mettre en œuvre et de le communiquer aux utilisateurs6, aux personnes

autorisées7 et aux sauveteurs8. Il est conseillé d’avoir une équipe de sauvetage formée présente sur place. Les membres

de l’équipe doivent disposer du matériel et de l’équipement, ainsi que des connaissances techniques nécessaires pour

accomplir un sauvetage réussi. La formation doit être répétée régulièrement an d’assurer l’efcacité des sauveteurs.

1.6 APRÈS UNE CHUTE : Si le produit a été soumis à une force d’arrêt de chute ou d’impact, le mettre hors service

immédiatement. Indiquer clairement « NE PAS UTILISER » sur le produit. Consulter la section 5 pour obtenir de plus

amples renseignements.

2.0 EXIGENCES DU SYSTÈME

2.1 ANCRAGE : Les exigences de structure d’ancrage varient selon l’application du système et le fait qu’il s’agisse d’un

ancrage homologué9 ou d’un ancrage non homologué10. La structure à laquelle est xé le système antichute, de restriction

du déplacement, de positionnement pour le travail ou de sauvetage doit supporter des charges statiques appliquées dans

les directions autorisées, comme l’indique le tableau suivant. Les exigences de résistance d’ancrage, de même que les

applications du système, sont détaillées ci-dessous, sauf si elles sont notées ou dénies dans le tableau 1 :

Systèmes de protection

Ancrage homologué

9

Ancrage non homologué

contre les chutes

Système antichute Deux fois la force d’arrêt maximale 22,2 kN (5 000 lbf) OSHA, ANSI

Dispositif de retenue/

restriction du déplacement

Deux fois la force d’arrêt prévisible

4,4 kN (1 000 lb) selon l’ANSI

22,2 kN (5 000 lb) selon l’OSHA

Positionnement de travail Deux fois la force d’arrêt prévisible 13,3 kN (3 000 lbf) OSHA, ANSI

Sauvetage Cinq fois la charge appliquée 13,3 kN (3 000 lbf) ANSI

Lorsque plusieurs équipements sont xés à un ancrage, les forces indiquées ci-dessus doivent être multipliées par le nombre

d’équipements de sauvetage xés à l’ancrage. Consultez la norme Z359.2 de l’ANSI pour de plus amples informations.

1 Système antichute : Ensemble de matériel de protection contre les chutes conguré pour arrêter une chute libre. Protège l’utilisateur en cas de chute. La distance

en chute libre admissible se limite à celle permise par le dispositif de raccordement (qu’il s’agisse d’une longe amortisseur de choc ou d’un dispositif autorétractable).

2 Système de restriction du déplacement : Ensemble de matériel de protection contre les chutes conguré pour empêcher que le centre de gravité de

la personne se retrouve en danger de chute. Empêche l’utilisateur de se retrouver en danger de chute. Aucune chute libre verticale n’est possible.

3 Système de positionnement pour le travail : En ensemble de matériel de protection contre les chutes conguré pour supporter un utilisateur dans

une position de travail. Doit comporter un système antichute individuel. La distance en chute libre maximale autorisée est de 2 pieds.

4 Système de sauvetage : Ensemble de matériel de protection contre les chutes conguré pour extraire une personne d’une situation dangereuse, lui éviter

des blessures ou la conner dans un endroit sûr. Aucune chute libre verticale n’est possible.

5 Personne compétente : Personne capable de reconnaître les dangers existants et prévisibles au sein du milieu de travail ou les conditions de travail

insalubres, risquées ou dangereuses pour les employés, et qui possède l’autorisation d’apporter des mesures correctives pour les éliminer.

6 Utilisateur : Une personne qui réalise des activités tout en étant protégée par un système de protection contre les chutes.

7 Personne autorisée : Une personne affectée par l’employeur et chargée d’exécuter des travaux à un emplacement qui l’expose à un danger de chute.

8 Sauveteur : Toute personne autre que la personne secourue effectuant un sauvetage assisté à l’aide d’un système de sauvetage.

9 Ancrage homologué : Un ancrage pour les systèmes antichute, de positionnement, de restriction du déplacement ou de sauvetage qu’une personne qualiée

juge capable de satisfaire aux critères en matière d’ancrage homologué conformément à la section 2.1.

10 Ancrage non homologué : Un ancrage pour un système antichute qu’une personne compétente peut juger capable de supporter les forces d’ancrage

prédéterminées énumérées à la section 2.1.

10

Déni par

OSHA, ANSI

16

Page 17

2.2 SYSTÈME ANTICHUTE INDIVIDUEL : La gure 1 illustre l’utilisation de ce connecteur d’ancrage. Les systèmes

antichute individuels utilisés avec ce système doivent être conformes aux normes, aux codes et aux exigences applicables

en matière de protection contre les chutes. Le système antichute individuel devra comporter un harnais de sécurité

complet et limiter la force d’arrêt conformément aux valeurs suivantes :

Force d’arrêt maximale Chute libre

Système antichute individuel avec

longe amortisseur de choc

Système antichute individuel avec

dispositif autorétractable

8 kN (1800 lbf)

8 kN (1800 lbf)

Consulter les directives incluses avec la longe

ou le dispositif autorétractable pour obtenir

de plus amples renseignements sur les limites

associées aux chutes libres.

2.3 TRAJECTOIRE DE CHUTE ET VITESSE DE BLOCAGE DU DISPOSITIF AUTORÉTRACTABLE : Une trajectoire de chute

non obstruée est nécessaire pour que le dispositif autorétractable se bloque normalement. Les situations sans trajectoire

de chute non obstruée doivent être évitées. Lorsqu’une personne travaille dans un espace réduit ou étroit, il est possible

qu’en cas de chute, le corps ne puisse pas atteindre une vitesse suffisante pour que le dispositif autorétractable se bloque.

De même, il est possible qu’une personne travaillant sur un matériau instable, comme du sable ou du grain, ne puisse pas

chuter à une vitesse suffisante pour bloquer le dispositif autorétractable.

2.4 DANGERS : L’utilisation de ce matériel dans des zones de dangers environnementaux peut exiger de prendre des

précautions additionnelles an d’éviter que l’utilisateur ne se blesse ou que le matériel ne subisse des dommages.

Les dangers peuvent comprendre, notamment et sans limitation : la chaleur, les produits chimiques, les environnements

corrosifs, les lignes électriques à haute tension, les gaz explosifs ou toxiques, de la machinerie en mouvement, les bords

acérés ou les matériaux suspendus pouvant tomber et entrer en contact avec l’utilisateur ou le système antichute individuel.

2.5 DÉGAGEMENT DE CHUTE : La gure 3 illustre les composants du dispositif antichute. Le dégagement de chute (DC)

sous l’utilisateur doit être sufsant pour arrêter la chute avant qu’il n’entre en contact avec le sol ou tout autre obstacle.

Le dégagement est affecté par un certain nombre de facteurs, notamment : emplacement de l’ancrage, (A) longueur de

la longe, (B) distance de décélération de la longe ou distance d’arrêt maximale du dispositif autorétractable (C) étirement

du harnais et affaissement et longueur de l’anneau en D/du connecteur. Se reporter aux directives fournies avec le soussystème antichute pour de plus amples détails sur le calcul du dégagement de chute.

2.6 CHUTES AVEC MOUVEMENT DE BALANCIER : Les chutes avec mouvement de balancier se produisent lorsque le point

d’ancrage ne se trouve pas directement au-dessus du point où une chute se produit (voir la gure 4). Si un objet est heurté

pendant le mouvement de balancier, la force peut être importante et causer des blessures graves ou la mort. Minimiser les

risques de chutes avec mouvement de balancier en travaillant le plus directement possible sous le point d’ancrage. Éviter

toute chute avec mouvement de balancier s’il y a un risque de blessure. Les chutes avec mouvement de balancier requièrent

une plus grande distance d’arrêt lors de l’utilisation d’un dispositif autorétractable ou de tout autre sous-système de

connexion à longueurs variables.

2.7 COMPATIBILITÉ DES COMPOSANTS : Le matériel 3M est destiné à être utilisé uniquement avec des composants et des

sous-systèmes approuvés par 3M. Les substitutions ou les remplacements effectués avec des composants ou des soussystèmes non approuvés peuvent affecter la compatibilité du matériel ainsi que la sécurité et la abilité du système dans

son ensemble.

2.8 COMPATIBILITÉ DES CONNECTEURS : les connecteurs sont jugés compatibles avec les éléments de connexion lorsqu’ils

ont été conçus pour travailler conjointement et de telle manière que leurs tailles et formes n’entraînent pas l’ouverture des

mécanismes, quelle que soit leur orientation. Communiquer avec 3M pour toute question sur la compatibilité.

Les connecteurs (crochets, mousquetons et anneaux en D) doivent pouvoir supporter une charge minimale de 22,2 kN

(5 000 lbf). Ils doivent être compatibles avec l’ancrage ou d’autres composants du système. Ne pas utiliser de matériel

non compatible. Les connecteurs non compatibles peuvent se désengager accidentellement (voir la gure 5). La taille, la

forme et la résistance des connecteurs doivent être compatibles. Si le connecteur sur lequel se xe le crochet à ressort ou

le mousqueton est trop petit ou de forme irrégulière, celui-ci risque d’exercer une force sur la clavette du crochet à ressort

ou du mousqueton (A). Cette force peut entraîner l’ouverture de la clavette (B), permettant ainsi au crochet à ressort ou

au mousqueton de se désengager du point d’attache (C).

La norme Z359 de l’ANSI et l’OSHA exigent l’utilisation de crochets à ressort et de mousquetons autoverrouillables.

2.9 RACCORDEMENTS : Les crochets à ressort et les mousquetons utilisés avec ce matériel doivent être autoverrouillables.

S’assurer que la taille, la forme et la résistance de tous les raccords sont compatibles. Ne pas utiliser de matériel non

compatible. S’assurer que tous les connecteurs sont complètement fermés et verrouillés.

Les connecteurs 3M (crochets à ressort et mousquetons) sont conçus pour être utilisés uniquement selon les directives

propres à chacun des produits. Consulter la gure 6 pour obtenir des exemples de raccordements inappropriés. Ne pas

connecter de crochet à ressort et de mousqueton :

A. À un anneau en D sur lequel un autre connecteur est raccordé.

B. D’une manière qui entraînerait une charge sur la clavette. Les crochets à ressort à ouverture large ne doivent pas

être connectés à des anneaux en D de taille standard ou à d’autres objets semblables, au risque d’entraîner une

charge sur la clavette si le crochet ou l’anneau en D se déforme ou pivote, sauf si le crochet à ressort est équipé

d’une clavette de 16 kN (3 600 lb) de capacité. Vérier les directives sur le crochet à ressort an d’assurer qu’il

convient à l’application.

C. En cas de xation défectueuse, où certains éléments qui dépassent du crochet à ressort ou du mousqueton se prennent

dans le point d’ancrage et semblent être totalement pris dans le point d’ancrage sans pouvoir le vérier visuellement.

D. L’un à l’autre.

E. Directement à une sangle, une longe en corde ou à un nœud coulant (sauf s’il est indiqué dans les directives du

fabricant de la longe et du connecteur qu’un tel raccord est permis).

F. À un objet dont la forme ou la dimension bloque la fermeture et le verrouillage du crochet à ressort ou du

mousqueton ou pourrait provoquer leur décrochage.

G. S’ils ne permettent pas au connecteur de s’aligner correctement alors qu’il est sous tension.

17

Page 18

3.0 INSTALLATION

Le propriétaire de ce matériel peut communiquer avec le Service technique de 3M en cas de questions concernant son

;

installation, son utilisation ou son inspection.

L’installation de l’ancrage à chariot DBI-SALA doit être faite ou supervisée par une personne compétente1.

;

1

2

3.1 PLANIFICATION : Planier la conguration du système de protection contre les chutes avant l’installation de l’ancrage

à chariot. Prendre en compte tous les facteurs qui pourraient affecter la sécurité avant, pendant et après une chute.

Tenir compte de toutes les exigences, restrictions et spécications indiquées dans la section 2 et le tableau 1.

3M rendra accessible sur demande les renseignements nécessaires à la conception et à la planication des systèmes.

;

3.2 CHOISIR UNE POUTRE D’ANCRAGE : Il est possible d’installer un ancrage à chariot sur des poutres horizontales et à

niveau répondant aux exigences d’ancrage indiquées dans le tableau 1. La poutre doit comporter des butées (A) à chaque

extrémité pour empêcher que le chariot ne se décroche. Voir la gure 10 aux ns de référence. Les butées doivent être

dimensionnées et placées de manière a être en mesure d’arrêter le chariot de façon sécuritaire. Le chariot ne doit pas rester

pris ou accroché sur la butée; il doit pouvoir retourner librement dans la direction opposée après avoir touché la butée.

Les joints entre les sections de poutre doivent être à plat pour permettre à l’ancrage à chariot de passer dessus

;

sans heurt.

3.3 INSTALLATION DE L’ANCRAGE À CHARIOT : Il est possible d’installer l’ancrage à chariot sur des poutres répondant

aux exigences d’ancrage indiquées dans le tableau 1. Voir la gure 1 pour connaître les mesures du chariot pour poutre.

La gure 7 illustre l’installation appropriée de l’ancrage à chariot. Pour installer l’ancrage à chariot :

1. Mesurer la largeur de la bride de poutre an de déterminer les paramètres des trous de réglage sur le chariot.

La gure 7.1 et le tableau 2 montrent la position des trous sur les boutons de réglage gauche et droit ainsi que la

traverse support correspondant au tableau 2. Garder en mémoire ces paramètres des trous de réglage et les utiliser

pour les étapes 3 et 4.

2. Pour ouvrir un côté du chariot, enlever l’anneau de traction de l’axe à épaulement et pousser l’axe à épaulement vers

le haut pour le retirer du bouton de réglage. Faire glisser la plaque latérale hors de la traverse support.

3. Sur le côté toujours assemblé du chariot, enlever l’anneau de traction et l’axe à épaulement de la plaque latérale et

régler la largeur au paramètre des trous de réglage déterminé à l’étape 1 et dans le tableau 2. Verrouiller le réglage

en place en réinstallant l’axe à épaulement à la verticale, avec la tête de l’axe à épaulement sur le dessus dans les

trous appropriés du bouton de réglage et de la traverse support, puis installer l’anneau de traction.

4. Placer la plaque latérale et la traverse support partiellement assemblées sur la bride inférieure de la poutre à l’aide

de l’anneau connecteur suspendu. Faire glisser la plaque latérale non assemblée sur la traverse support et l’aligner

sur le bouton de réglage et les trous de la traverse support déterminés à l’étape 1. Installer l’axe à épaulement à

la verticale, avec la tête de l’axe à épaulement sur le dessus dans le bouton de réglage et les trous de la traverse

support appropriés, puis xer avec l’anneau de traction.

Les paramètres de largeur du chariot indiqués dans le tableau 2 doivent être respectés. Les réglages de la

;

traverse support doivent utiliser les mêmes paramètres des deux côtés (c.-à-d. A - A, B - B, etc.). Les réglages

du bouton doivent se situer dans la limite d’une unité. L’utilisation des mauvais paramètres risque de charger le

chariot incorrectement. Si la bride de poutre est trop large pour faire passer l’axe à épaulement à travers les bons

trous, régler le chariot à la taille supérieure suivante de bride de poutre comme indiqué dans le tableau 2. L’anneau

en D doit toujours être centré entre les deux plaques latérales.

5. Vérier que la distance entre la face de la roue du chariot (C) et le bord de la bride de poutre (D) ne dépasse pas

1,6 mm (1/16 po). Si la distance est supérieure à 1,6 mm (1/16 po), placer les boutons de réglage au paramètre

inférieur suivant dans le tableau 2. S’assurer également que, visuellement, les axes à épaulement (A) sont installés

avec la tête au-dessus des boutons de réglage et que les anneaux de traction (B) sont entièrement insérés dans les

trous des axes à épaulement.

Si le chariot est déplacé vers une autre poutre ou si les anneaux de traction sont retirés, les anneaux de

;

traction en forme de cercle peuvent être réutilisés. Si une goupille fendue est utilisée, il faut en utiliser une neuve

à chaque nouvelle installation. Utiliser des anneaux de traction de 5/64 x 3/4 po en acier inoxydable 18-8 ou des

pinces Pivot Point bow-tieMC. Si des pinces Pivot Point bow-tieMC sont utilisées, elles sont également réutilisables.

N’utiliser que les axes à épaulement d’origine. Ne pas utiliser de produits de substitution.

4.0 UTILISATION

4.1 AVANT CHAQUE UTILISATION : Vérier que la zone de travail et le système antichute répondent à tous les critères

dénis dans les présentes directives. S’assurer qu’un plan de sauvetage est en place. Inspecter le produit en suivant

les points d’inspection « Utilisateur » dénis dans le « Registre d’inspection et d’entretien ». Si l’inspection révèle des

conditions dangereuses ou un état défectueux, ou s’il y a un doute relativement à son état en vue d’une utilisation

sécuritaire, mettre immédiatement le produit hors service. Indiquer clairement « NE PAS UTILISER » sur le produit.

Consulter la section 5 pour obtenir de plus amples renseignements.

4.2 CONNEXIONS POUR SYSTÈME ANTICHUTE : L’ancrage à chariot est utilisé avec un harnais de sécurité complet et une

longe amortisseur de choc ou un dispositif autorétractable. La gure 9 illustre la connexion de la longe (A) ou du dispositif

autorétractable (B) entre le harnais et l’ancrage à chariot. Raccorder la longe ou le dispositif autorétractable entre

1 Personne qualiée : Une personne possédant un diplôme ou un certicat professionnel et une expérience approfondie en protection contre les chutes.

Cette personne doit être en mesure de concevoir, d’analyser, d’évaluer et de spécier des systèmes de protection contre les chutes.

2 Personne compétente : Personne capable de reconnaître les dangers existants et prévisibles au sein du milieu de travail ou les conditions de travail insalu-

bres, risquées ou dangereuses pour les employés, et qui possède l’autorisation d’apporter des mesures correctives pour les éliminer.

18

Page 19

l’anneau en D de l’ancrage à chariot et l’anneau en D dorsal à l’arrière du harnais, comme indiqué dans les directives

comprises avec la longe ou le dispositif autorétractable.

Raccordement de la ligne de vie horizontale : L’ancrage à chariot pour poutre ne peut pas être utilisé en tant

;

que point d’ancrage d’extrémité pour une ligne de vie horizontale.

5.0 INSPECTION

Une fois que le matériel a été mis hors service, il ne peut pas être remis en service avant qu’une personne compétente

;

conrme par écrit qu’il est acceptable de le faire.

5.1 FRÉQUENCE D’INSPECTION : Le produit doit être inspecté par une personne autorisée avant chaque utilisation,

puis, en plus, par une personne compétente autre que l’utilisateur à un intervalle n’excédant pas une fois par année.

Une fréquence d’utilisation élevée du matériel et une utilisation dans des conditions plus difciles peuvent exiger des

inspections plus fréquentes par une personne compétente. La fréquence de ces inspections doit être déterminée par la

personne compétente en fonction des conditions particulières du chantier.

5.2 PROCÉDURES D’INSPECTION : Inspecter le produit selon les procédures énumérées dans le « Registre d’inspection

et d’entretien ». Le propriétaire de ce matériel doit conserver la documentation de chaque inspection. Un registre

d’inspection et d’entretien doit être placé à proximité du produit ou être facilement accessible aux utilisateurs. Il est

recommandé d’indiquer la date de la prochaine ou de la dernière inspection sur le produit.

Le propriétaire de ce matériel peut établir d’autres critères d’inspection. Ces autres critères doivent être équivalents

;

ou supérieurs à ceux établis par 3M dans le « Registre d’inspection et d’entretien » et dans les autres documents ofciels.

5.3 DÉFAUTS : Si le produit ne peut pas être remis en service en raison d’un défaut existant ou d’une condition dangereuse,

ou parce qu’il a été soumis à un arrêt de chute, détruire le produit ou communiquer avec 3M pour un remplacement ou

une réparation possible.

5.4 DURÉE UTILE DU PRODUIT : La durée utile du produit est déterminée par les conditions de travail et l’entretien.

Tant que le produit satisfait aux critères d’inspection, il peut être utilisé.

6.0 ENTRETIEN, SERVICE et ENTREPOSAGE

L’équipement qui nécessite un entretien ou dont l’entretien est prévu doit porter une étiquette indiquant « NE PAS UTILISER ».

;

Ces étiquettes ne doivent pas être retirées avant que l’entretien du matériel soit effectué.

6.1 NETTOYAGE : Nettoyer régulièrement les composants métalliques de l’ancrage à chariot avec une brosse douce, de l’eau

chaude et une solution savonneuse douce. Veiller à rincer les pièces minutieusement avec de l’eau propre.

6.2 SERVICE : Seules 3M ou les parties autorisées par écrit par 3M peuvent réparer ce matériel.

6.3 ENTREPOSAGE ET TRANSPORT : Lorsqu’il n’est pas utilisé, entreposer et transporter l’ancrage à chariot avec le matériel

de protection contre les chutes connexe dans un endroit frais, sec et propre à l’abri de la lumière directe du soleil. Éviter les

zones présentant des vapeurs chimiques. Procéder à un examen minutieux après un entreposage prolongé.

7.0 ÉTIQUETTE À IRF

7.1 EMPLACEMENT : Le produit 3M présenté dans ces directives d’utilisation est doté d’une étiquette d’identication par

radiofréquences (IRF). Les étiquettes à IRF peuvent être utilisées en combinaison avec un lecteur d’étiquettes à IRF pour

enregistrer les résultats des inspections du produit. Voir la gure 11 pour connaître l’emplacement de l’étiquette à IRF du

produit.

7.2 MISE AU REBUT : Avant de mettre ce produit au rebut, retirer l’étiquette à IRF et la mettre au rebut ou la recycler

conformément aux réglementations locales. Pour obtenir de plus amples renseignements, consulter notre site Web :

http://www.3M.com/FallProtection/RFID

8.0 ÉTIQUETTES et MARQUAGES

8.1 ÉTIQUETTES : La gure 12 illustre les étiquettes sur l’ancrage à chariot. Toutes les étiquettes doivent être présentes et

parfaitement lisibles. Les informations apparaissant sur chaque étiquette sont les suivantes :

1) Site Web de l’entreprise

2) Énoncé de mise en garde

3) Date de fabrication (année/mois) et numéro de lot

A

4) Numéro de modèle

5) Spécications du produit

6) Normes applicables

1) Site Web de l’entreprise

2) Exigences d’inspection – Voir la section 5 pour obtenir plus de renseignements.

B

3) Force de rupture minimale et température de service minimale

4) Registre d’inspection

1) Site Web de l’entreprise

2) Énoncé de mise en garde

C

3) Date de fabrication (année/mois) et numéro de lot

4) Numéro de modèle

5) Spécications du produit

19

Page 20

Tableau 2 – Réglage de la largeur du chariot

Largeur de la bride de

poutre en mm (po)

De

76,2 (3,0) 79,38 (3,13) D 1 1

79,38 (3,13) 82,55 (3,25) D 1 2

82,55 (3,25) 85,73 (3,38) D 2 2

85,73 (3,38) 88,90 (3,50) D 2 3

88,90 (3,50) 92,08 (3,63) D 3 3

92,08 (3,63) 95,25 (3,75) D 3 4

95,25 (3,75) 98,43 (3,88) D 4 4

98,43 (3,88) 101,40 (4,0) D 4 5

101,40 (4,0) 104,78 (4,13) D 5 5

104,78 (4,13) 107,95 (4,25) D 5 6

107,95 (4,25) 111,13 (4,38) C 1 1

111,13 (4,38) 114,3 (4,5) C 1 2

114,3 (4,5) 117,48 (4,63) C 2 2

117,48 (4,63) 120,65 (4,75) C 2 3

120,65 (4,75) 123,83 (4,88) C 3 3

123,83 (4,88) 127,0 (5,0) C 3 4

127,0 (5,0) 130,18 (5,13) C 4 4

130,18 (5,13) 133,35 (5,25) C 4 5

133,35 (5,25) 136,53 (5,38) C 5 5

136,53 (5,38) 139,7 (5,5) C 5 6

139,7 (5,5) 142,88 (5,63) B 1 1

142,88 (5,63) 146,05 (5,75) B 1 2

146,05 (5,75) 149,23 (5,88) B 2 2

149,23 (5,88) 152,4 (6,0) B 2 3

152,4 (6,0) 155,58 (6,13) B 3 3

155,58 (6,13) 158,75 (6,25) B 3 4

158,75 (6,25) 161,93 (6,38) B 4 4

161,93 (6,38) 165,1 (6,5) B 4 5

165,1 (6,5) 168,28 (6,63) B 5 5

168,28 (6,63) 171,45 (6,75) B 5 6

171,45 (6,75) 174,63 (6,88) A 1 1

174,63 (6,88) 177,8 (7,0) A 1 2

177,8 (7,0) 180,98 (7,13) A 2 2

180,98 (7,13) 184,15 (7,25) A 2 3

184,15 (7,25) 187,33 (7,38) A 3 3

187,33 (7,38) 190,5 (7,5) A 3 4

190,5 (7,5) 193,68 (7,63) A 4 4

193,68 (7,63) 196,85 (7,75) A 4 5

196,85 (7,75) 200,03 (7,88) A 5 5

200,03 (7,88) 203,2 (8,0) A 5 6

203,2 (8,0) --- A 6 6

Jusqu’à, mais non

inclus

Trous de la

traverse support

(deux côtés)

Trou du bouton de

réglage gauche

Trou du bouton de

réglage droit

20

Page 21

Tableau 3 – Registre d’inspection et d’entretien

Date d’inspection : Inspecté par :

Composants : Inspection : (Voir la section 1 : Fréquence d’inspection) Utilisateur

Ancrage à chariot

(Figure 2)

Structure S’assurer que la structure répond aux exigences du tableau 2, qu’une butée

Étiquettes

(gure 12)

Matériel de

protection contre

les chutes

Inspecter le chariot pour déceler les dommages. Rechercher toute ssure

ou déformation. Rechercher les signes d’usure excessive ou les dommages

sur le point de raccordement d’ancrage. Tous les systèmes d’attache doivent

être solidement fermés.

Inspecter les roues du chariot. Toutes les roues doivent tourner sans entrave

et être en bon état.

Inspecter toute l’unité an de détecter toute trace de corrosion.

S’assurer que les axes à épaulement (G) s’insèrent dans les trous du tube de

support (A). S’assurer que les deux axes à épaulement sont installés dans le

tube de support et que les deux anneaux en spire sont bien xés. N’utiliser

que les axes à épaulement fournis avec l’ancrage à chariot.

Inspecter les ancrages à chariot déjà installés et s’assurer qu’ils sont

installés conformément à la Section 3.

est présente à chaque extrémité de la poutre et que cette dernière n’est pas

endommagée.

Vérier que toutes les étiquettes sont présentes et bien lisibles.

Le matériel de protection contre les chutes supplémentaire utilisé avec

le système doit être installé et inspecté conformément aux directives du

fabricant.

Personne

compétente

Numéro(s) de série : Date d’achat :

Numéro de modèle : Date de première utilisation :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :

Mesures correctives/entretien : Approuvé par : Prochaine inspection

Date :