Page 1

3M Purification Inc.

AER

Water Filtration

System

Automated Endoscope Reprocessor Water Filtration

The Automated Endoscope Reprocessor Water Filtration system is designed

to provide high-quality water to AER’s by reducing sediment, particulate, and

bacteria that may be found in typical hospital water supply. Innovative pleating,

along with advanced design and construction technologies, effectively combine

two distinct areas of filtration in a single disposable cartridge to maximize water

throughput and filter life. The Sanitary Quick Change cartridge design enables

filter change-outs in a fraction of the time vs. traditional two-piece filter housings, providing a filter that is economical, easy to use and reduces the total cost

of filtration for your department.

The AER Water Filtration System is available in two configurations (left or right

inlet connection port) in order to be installed within a variety of locations including AER cart mounted and wall mounted. When installing, the manifold can be

easily configured for the water outlet to be opposite of the inlet by changing the

location of the outlet port (see ordering guide).

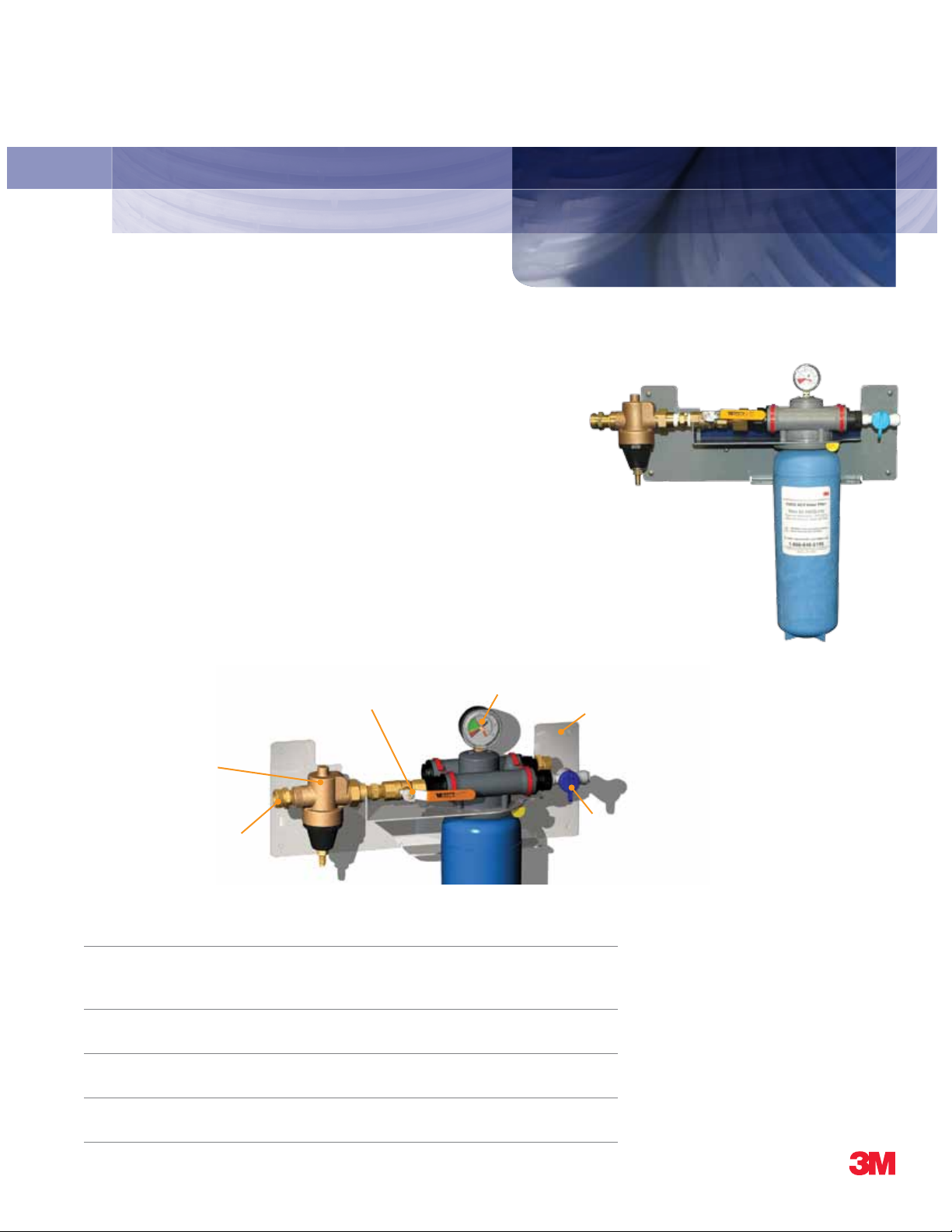

Integral shut-off valve isolates water flow

to minimize leakage during filter change

Pressure regulator minimizes

damage from spikes in

water pressure

3/4” male threaded hose

connectors for inlet and outlet

Color-coded gauge

indicates filter life

Mounting bracket designed for in-place replacement of

common two-stage water filtration manifolds

Integrated vent valve provides easy system pressure release

Features & Benefits

Sanitary Quick Change encapsulated cartridge.

n Two levels of filtration in one sanitary, disposable cartridge.

n

Fast and easy change outs in a fraction of the time with a 1/4 turn.

0.2 micron absolute-rated bacteria retentive final membrane.

n Helps protect & prolong the life of downstream sterile filters.

Multi-stage pre-filtration layer.

n Significantly increases the dirt/particulate holding capacity vs. traditional filters.

Advanced Pleat Technology (APT).

n Significantly longer life than conventional two-stage filters.

Innovative Water Manifold.

n Multiple mounting holes allow for easy replacement of existing manifolds in a variety of locations.

Page 2

Simple As 1-2-3:

1. Push the cartridge release

button.

2. Twi s t the cartridge clock-

wise.

Easier to use than conventional two-stage water filters

The AER Water Filtration System offers a variety of features that simplify the way filters

are used in hospital departments and reduce the costs associated with operation and maintenance of conventional two-stage filters (see Figure 1).

Figure 1 — Conventional Two-Filter System and the AER System

3. P ull the cartridge down,

remove and discard.

Faster filter changes:

The Sanitary Quick Change cartridge allows for fast and easy filter changes in three easy

steps after shutting off the water and venting the pressure1. As compared to a conventional

filter system requiring the labor intensive change-out of 2 filter housings (see photo), the

Sanitary Quick Change cartridge requires only minutes (see Figure 2).

AER Water Filter

Competitive A & B Filter Set

Figure 2 — Time Required for Change-out

2

1 Please refer to the in stallation and operat ion instructions pr ior to installing this product.

Page 3

Significantly longer life than existing two-stage water filtration systems.

The AER Water Filter cartridge is designed to last significantly longer than existing AER

water filters. APT membrane pleating combined with innovative filter design results in a

long life filter that reduces the number and frequency of filter changes required, lowering

the overall cost of filtration associated with endoscope reprocessing. Two levels of filtration are provided in one sanitary, disposable filter cartridge that eliminates the need for

filter housings.

Advanced Pleat Technology (APT)

Maximizes the useful surface area of the filter while maintaining open flow paths

between media pleats. As shown in Figure 3, by employing APT design, the AER Water

Filter provides over twice the service life, significantly reducing overall filtration costs.

Pre-filtration Zone

Pre-filtration Zone

Glass micro-fiber co-pleated with 0.6 micron

polyethersulfone membrane provide for high

dirt holding capacity and sub-micron particulate

filtration

AER

Water Filtration

System

Bacteria Retention Zone:

0.2 micron absolute-rated polyethersulfone mem-

Bacteria

Retention

Zone

brane captures >99.99% of common water-borne

bacteria2 and helps prolong the life of downstream

sterile filters.

AER Water Filtration Specifications

The AER Water Filtration System includes a single cartridge manifold with built-in

pressure gauge, inlet shut off valve, cartridge vent valve, mounting bracket, and one filter

cartridge.

Specifications

Inlet and outlet connections 3/4” hose fittings

Maximum operating pressure 125 psi (862 kPa)

Maximum operating temperature 140°F (60°C)

Flow Rate 5.0 gpm

Capsule material High-impact, high-temperature polyphenylene oxide (PPO)

Shipping weight 15 lbs

Figure 3 — One Cartridge vs. Six

Competitive Cartridges

2 including Pseudomonas aeruginosa (ATCC #14503) and Brevundimonas diminuta (ATCC #14756).

3

Page 4

Automated Endoscope Reprocessor (AER) Water Filtration System Ordering Guide

Manifold Configurations and Part Number

Part Number

HWB01 Left side

HWB02 Right side

5 Includes one manifold and one filter cartridge

5

Inlet Connection Ports

Cartridge Part Number/Packaging

HW SL0102 Hospital/AER Water Filter Cartridge

To Order Call: 1-866-646-5196

5

AER Water Filtration System General Dimensions

(HWB01 Shown)

18 1/4”

3” clearance (minimum)

for inlet/outlet tubing

3” clearance (minimum)

for cartridge removal

18”

Important Notice

The information described in this literature is accurate to the best of our knowledge. A variety of factors, however, can affect the performance of the Product(s) in a particular

application, some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE SAME

WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABILITY FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES OF

ANY NATURE WHATSOEVER RESULTING FROM THE USE OF OR RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fit for a particular purpose and suitable in your specific application.

3M PURIFICATION INC. MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH

INFORMATION REFERS.

Limitation of Liability

3M Purification Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential, regardless of

the legal theory asserted, including warranty, contract, negligence or strict liability. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation may not apply to you.

Your Local 3M Purification Inc. Distributor:

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450 3M is a trademark of 3M Company.

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (230) 630-4530 © 2011 3M Company. All rights reserved.

www.3Mpurification.com 70-0202-0837-0 0611PB

Loading...

Loading...