Page 1

9925 Premium Welding

Fume Respirator

Data Sheet

Main Features

The 3M 9925 respirator provides lightweight, effective, comfortable

and hygienic respiratory protection against dusts, mists and metal

fumes. Its convex shape enhances wearer comfort and allows a

good fit over a wide range of face sizes; the 3M™ Cool Flow™

exhalation valve reduces moisture build-up, particularly in hot and

humid work conditions.

The 4-point adjustable straps and adjustable nose clip to help

provide a proper fit.

The 3M 9925 Premium Welding Fume Respirator has been designed

specifically for welding applications to provide protection against

Ozone and welding fume, plus relief from nuisance odours.

The 3M 9925 does not require costly and time-consuming

maintenance.

Applications

• Iron Foundries • Potteries

• Steel Foundries • Powdered Chemicals

•

Ship Building/Ship Repairing

• Metal Manufacture

• Battery Manufacture • Paint Manufacture

• Welding and Soldering • Construction

Approvals

The 3M 9925 has been shown to meet the Basic Safety

Requirements under Article 10 and 11B of the European Community

Directive 89/686. An EC-type examination certificate is in force

issued by the British Standards Institute. The product is CE marked.

Materials

The following materials are used in the production of this product:

• Straps - Polyisoprene/Cotton fibre

• Nose-clip - Aluminium

• Filter - Polypropylene

• Nose foam - PVC

• Valve - Polypropylene

Weight: 13 g

Standards

The product has been tested to the European Norm EN149: 2001

and has met the requirements of category FFP2 in this standard.

Warnings:

• As with the use of any respiratory device, the wearer must first be

trained in the proper use of the product.

• This product does not protect the wearer against gases, vapours,

solvents from paint spray operations or atmospheres containing less

than 19.5% oxygen.

• 3M suggests the 9925 respirator for use up to 10 times the

Workplace Exposure Limit (WEL) of Ozone, and relief from nuisance

levels of organic vapours (i.e. levels below the WEL).

• Use only in adequately ventilated areas containing sufficient

oxygen to support life.

• Do not use when concentrations of contaminants are immediately

dangerous to life or health.

• Leave the area immediately if:

* breathing becomes difficult

* dizziness or other distress occurs

• Discard and replace respirator if it becomes damaged, breathing

resistance becomes excessive, or at the end of one shift.

• Never alter or modify this device.

Correct use

The respirator may be used in concentrations of solid, water based

and non-volatile liquid based aerosols up to 10 times the Workplace

Exposure Limit (WEL). Assigned Protection Factor= 10.

It can also be used to protect the wearer against Ozone gas

generated in welding applications in concentrations up to 10 times

the WEL and provide relief from nuisance levels (concentration

below the WEL) of organic vapours.

Page 2

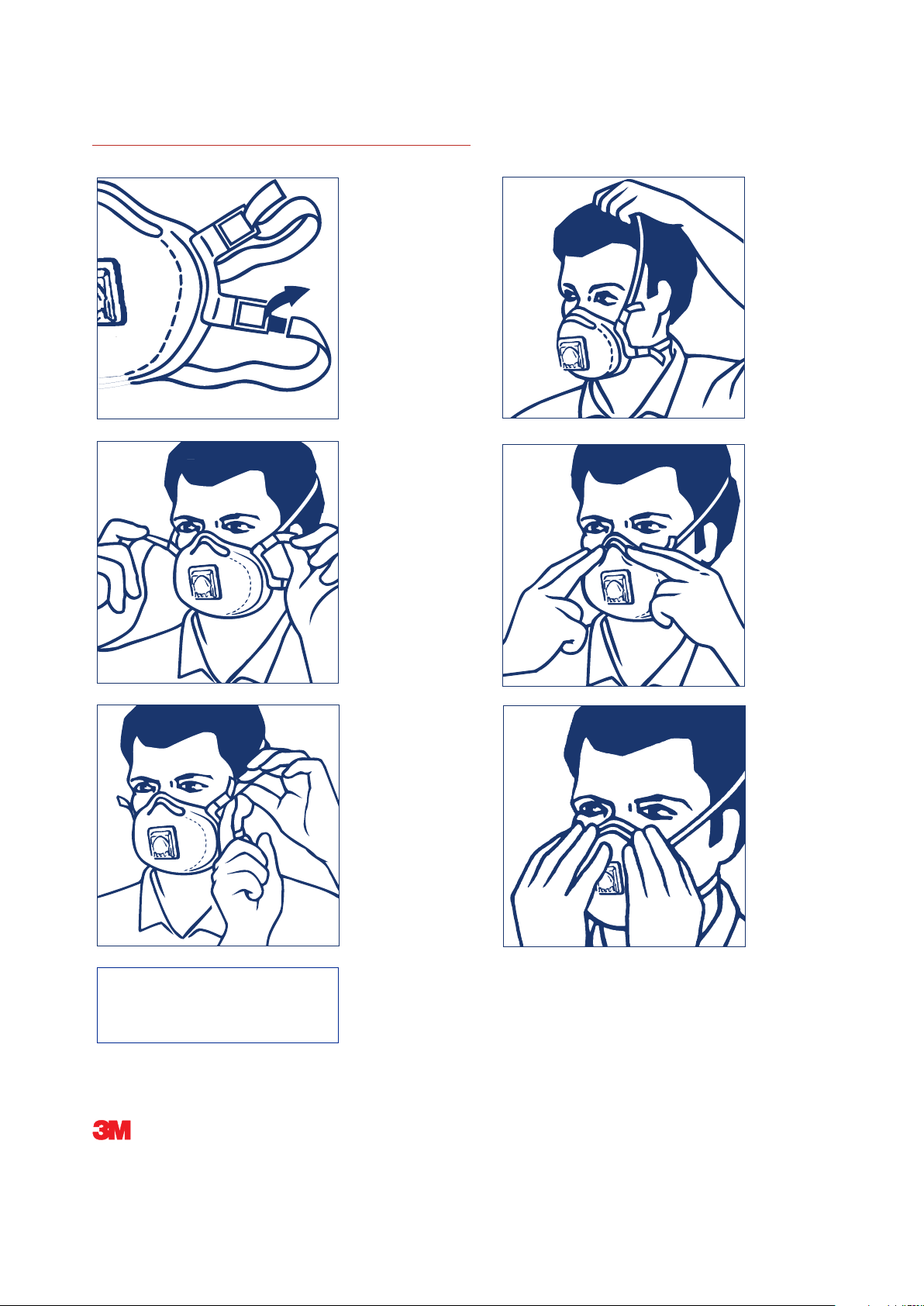

9925 Respirator

Fitting Instructions

Respiratory protection is only effective if it is correctly selected,

fitted and worn throughout the time when the wearer is exposed to

hazards.

3M offers advice on the selection of products and training in the

correct fitting and usage.

For help with selecting the most appropriate forms of PPE and

relevant Health and Safety legislation, or for more detailed product

information, please contact the 3M Health and Safety Helpline on:

0870 60 800 60 (UK).

For callers within the Republic of Ireland 1800 320500.

Occupational Health Group

3M United Kingdom PLC

3M Centre,

Cain Road, Bracknell,

Berkshire RG12 8HT

Tel: 0870 60 800 60

www.3M.com/uk/ohes

3M Ireland

3M House,

Adelphi Centre

Upper Georges St

Dun Laoghaire

Co. Dublin

Tel: 1 800 320 500

Note: do not use with beards or other facial hair

that may inhibit contact between the face and the

edge of the respirator

05/2007 CH9925DS

2. Place the top elastic strap

around the head, above the

ears. Untwist the strap.

1. Thread top elastic strap through

top buckles. Repeat for bottom

strap and buckles. Place the

bottom elastic strap around the

head just below the ears. Untwist

the strap.

3. Adjust tension by pulling tabs of

each strap, as shown.

4. Using both hands, mould

metal nosepiece

comfortably to shape of

nose.

5. Strap tension may be

decreased without removing

respirator from the head by

pushing out on the back of the

buckles. If you cannot achieve a

proper fit do not enter

contaminated area. See your

supervisor.

6. The seal of respirator on the

face should be fit-checked prior

to wearing in the work area.

a) Cover the front of the respirator

with both hands, being careful not

to disturb the position of

respirator.

b) Inhale sharply. A negative

pressure should be felt inside

respirator. If any leakage is

detected, adjust position of

respirator and/or tension of strap.

Retest the seal. Repeat the

procedure until the respirator is

sealed properly.

Loading...

Loading...