Page 1

3M™ Multi-Touch

Chassis Display

User Guide

Model C3266PW

Read and understand all safety information

contained in this document before using this product.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 2

2 3M™ Multi-Touch Chassis Display User Guide

The information in this document is subject to change without notice. No part of this document may be reproduced

or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written

permission of 3M Touch Systems, Inc. 3M may have patents or pending patent applications, trademarks, copyrights,

or other intellectual property rights covering subject matter in this document. The furnishing of this document does

not give you license to these patents, trademarks, copyrights, or other intellectual property except as expressly

provided in any written license agreement from 3M Touch Systems, Inc.

The information provided in this document is intended as a guide only. For the latest detailed engineering

specifications, please contact your 3M Touch Systems, Inc. Application Engineer. 3M Touch Systems, Inc. is

committed to continually improving product designs, as a result, product specifications may be subject to change

without notification.

"RoHS 2011/65/EU" means that the product or part does not contain any of the substances in excess of the

maximum concentration values (“MCVs”) in EU RoHS Directive 2011/65/EU, unless the substance is in an

application that is exempt under EU RoHS. The MCVs are by weight in homogeneous materials. This information

represents 3M's knowledge and belief, which may be based in whole or in part on information provided by third

party suppliers to 3M.

NOTICE: Given the variety of factors that can affect the use and performance of a 3M Touch Systems, Inc. Product

(the “Product”), including that solid state equipment has operation characteristics different from electromechanical

equipment, some of which factors are uniquely within User’s knowledge and control, it is essential that User evaluate

the 3M Touch Systems, Inc. Product and software to determine whether it is suitable for User’s particular purpose

and suitable for User’s method of application. 3M Touch Systems, Inc. statements, engineering/technical

information, and recommendations are provided for User’s convenience, but their accuracy or completeness is not

warranted. 3M Touch Systems, Inc. products and software are not specifically designed for use in medical devices as

defined by United States federal law. 3M Touch Systems, Inc. products and software should not be used in such

applications without 3M Touch Systems, Inc. express written consent. User should contact its sales representative if

User’s opportunity involves a medical device application.

IMPORTANT NOTICE TO PURCHASER: Specifications are subject to change without notice. These 3M Touch Systems,

Inc. Products and software are warranted to meet their published specifications from the date of shipment and for the period

stated in the specification. 3M Touch Systems, Inc. makes no additional warranties, express or implied, including but not

limited to any implied warranties of merchantability or fitness for a particular purpose. User is responsible for determining

whether the 3M Touch Systems, Inc. Products and software are fit for User’s particular purpose and suitable for its method of

production, including intellectual property liability for User's application. If the Product, software or software media is proven

not to have met 3M Touch Systems, Inc. warranty, then 3M Touch Systems, Inc. sole obligation and User’s and Purchaser’s

exclusive remedy, will be, at 3M Touch Systems, Inc. option, to repair or replace that Product quantity or software media or to

refund its purchase price. 3M Touch Systems, Inc. has no obligation under 3M Touch Systems, Inc. warranty for any Product,

software or software media that has been modified or damaged through misuse, accident, neglect, or subsequent manufacturing

operations or assemblies by anyone other than 3M Touch Systems, Inc. 3M Touch Systems, Inc. shall not be liable in any

action against it in any way related to the Products or software for any loss or damages, whether non-specified direct,

indirect, special, incidental or consequential (including downtime, loss of profits or goodwill) regardless of the legal theory

asserted.

Copyright © 2011-2012 3M All rights reserved.

Document Title: 3M Multi-Touch Chassis Display User Guide

Document Number: TSD-39373, Revision E

3M, the 3M logo, MicroTouch, and the MicroTouch logo are either registered trademarks or trademarks of 3M in the United

States and/or other countries.

Windows and/or other Microsoft products referenced herein are either registered trademarks or trademarks of Microsoft

Corporation in the U.S. and/or other countries.

Linux is a registered trademark of Linus Torvalds in the U.S. and/or other countries

All other trademarks are the property of their respective owners.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 3

3M™ Multi-Touch Chassis Display User Guide 3

Contents

Introduction

Overview .................................................................................................................... 5

Important Safety Information ..................................................................................... 6

Important Notes .......................................................................................................... 8

Service and Repair Indicators .................................................................................... 9

Touch Sensor Care and Cleaning ............................................................................... 9

3M Touch Systems Support Services ........................................................................ 9

Contact 3M Touch Systems ..................................................................................... 10

Chapter 1 Setting Up Your Multi-Touch Chassis Display

System Requirements ............................................................................................... 11

Unpacking Your Touch Display .............................................................................. 11

Connecting the Touch Display ................................................................................. 13

Multimedia Features................................................................................................. 13

Testing the Multi-Touch Chassis Display ................................................................ 13

Mounting the Multi-Touch Chassis Display ............................................................ 14

Articulating Arm Mounting Option ......................................................................... 14

Access to the Video Controls ................................................................................... 15

Clearance and Ventilation ........................................................................................ 15

Video Card Requirements ........................................................................................ 15

Using the Standard Controls for the Video Card ..................................................... 15

Supported Video Display Modes and Refresh Rates ............................................... 16

Configuring the Display Settings ............................................................................. 16

Adjusting the Multi-Touch Chassis Video Display ................................................. 16

On Screen Display .................................................................................................... 17

Menu Navigation ...................................................................................................... 17

Image Menu .............................................................................................................. 18

Display Menu ........................................................................................................... 20

Audio Menu ............................................................................................................. 22

System Menu ............................................................................................................ 23

Chapter 2 Enabling Your Multi-Touch Chassis Display

Windows® 7 USB Compatibility ............................................................................ 29

All Other Platforms .................................................................................................. 29

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 4

4 3M™ Multi-Touch Chassis Display User Guide

Multi-Touch Application Support ............................................................................ 29

Installing 3M™ MicroTouch™ Software ................................................................ 29

Video Alignment ...................................................................................................... 30

Appendix A 3M™ PX USB Controller Communications

Overview of USB Firmware Communications ........................................................ 33

Communication Basics ............................................................................................. 33

Receiving Reports from the Controller .................................................................... 34

Command Set ........................................................................................................... 34

Set Feature - Calibration .......................................................................................... 34

Get Feature - GetStatus ............................................................................................ 36

Get Feature - GetMaxCount ..................................................................................... 37

Set Feature - Reset ................................................................................................... 38

Set Feature –Restore Defaults .................................................................................. 38

Asynchronous Reports ............................................................................................. 39

Appendix B 3M™ PX Serial Controller Communications

Overview of Firmware Commands .......................................................................... 41

Controller Default Settings ...................................................................................... 42

Communicating with the Controller ......................................................................... 43

Firmware Commands ............................................................................................... 45

Calibrate ................................................................................................................... 46

Get Copyright ........................................................................................................... 48

Mode Down Up ........................................................................................................ 48

Mode Inactive ........................................................................................................... 48

Mode Stream ............................................................................................................ 48

Name Command ....................................................................................................... 49

Null Command ......................................................................................................... 49

Output Identity ......................................................................................................... 49

Restore Defaults ....................................................................................................... 49

Soft Reset ................................................................................................................. 50

Unit Type ................................................................................................................. 50

Appendix C Troubleshooting & Maintenance

Display Installation Problems .................................................................................. 52

Troubleshooting the Touch Sensor .......................................................................... 53

Power Management .................................................................................................. 54

Appendix D Regulatory Information

Regulatory Agency Approvals ................................................................................. 55

FCC Warning ........................................................................................................... 56

CE Conformity for Europe ....................................................................................... 56

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 5

3M™ Multi-Touch Chassis Display User Guide 5

Introduction

Overview

Congratulations on the purchase of your 3M™ Touch Systems Multi-Touch Chassis

Display. This guide describes how to set up your 3M™ Multi-Touch Chassis Display.

The 3M Touch Systems product line of chassis displays deliver true multi-touch

functionality in a versatile form factor. Perfect for interactive digital signage, interactive

tables and kiosk solutions, the 3M Multi-Touch Chassis provides system architects with

a high performance, easy to integrate professional display to enable innovative multitouch solutions.

The combination of 3M’s Projected Capacitive Technology (3M PCT) delivering fast,

accurate and precise multi-touch response, with a top-of-the-line full high definition LED

display, creates an immersive user experience for your next generation interactive

applications.

The design of the projected capacitive sensor has more than 6,000 touch sensing points

in close proximity, making it precise and extremely accurate across the entire touch

screen. The 3M PCT's durable chemically strengthened glass surface has unique antistiction properties that greatly reduces surface friction and allows users’ fingers to glide

effortlessly across the display for easy gesture functions.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 6

6 3M™ Multi-Touch Chassis Display User Guide

Important Safety Information

Read and understand all safety information before using this product. Follow all

instructions marked on the product and described in this document. Pay close attention to

the following installation warnings and safety precautions.

Intended Use

The 3M Touch Systems Multi-Touch Chassis Display was designed for touch input and

tested to replace an existing display. These displays are intended for indoor use only

and are not designed for use in hazardous locations.

Explanation of Signal Word Consequences

DANGER: Indicates a potentially hazardous situation, which, if not avoided, will

result in death or serious injury and/or property damage.

WARNING: Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury and/or property damage.

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury and/or property damage.

NOTICE: Indicates a potentially hazardous situation, which, if not avoided, may result

in property damage.

DANGER

To avoid the risk of fire and/or explosion which will result in serious injury or

death:

• Do not install or use this product in a hazardous location.

WARNING

To avoid the risk of electric shock which could result in serious injury or death:

• Do not remove the cover or back of the display. The power supply AC line should

be avoided.

• Plug power cord into appropriate grounded power source.

• Do not use a power cord that is frayed or otherwise damaged.

• Do not service the display yourself. There are no user serviceable parts inside.

Refer all servicing to qualified service personnel. Any change or modification to

the equipment not expressly approved by the party responsible for compliance

could void your authority to operate such equipment.

• Do not use a damaged display.

• Do not use non-conforming replacement parts.

• Do not place wet or damp objects on the display.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 7

3M™ Multi-Touch Chassis Display User Guide 7

WARNING

To avoid the risk of electric shock which could result in serious injury or death:

• Do not expose the display to rain or other sources of water, steam, or moisture.

• Do not place foreign objects on the display or its cables.

• Do not remove the cover or back of the display.

• Ensure that connecting the unit to the power source will not overload the power

source.

CAUTION

To avoid the risk of glass breakage which may result in minor or moderate injury:

• To avoid risk of injury when handling the display be aware that the sensor edges

may be sharp.

• Handle the display with care to avoid breaking the touch sensor. The display

contains glass parts. Dropping the display may cause the glass parts to break.

• Ensure mounting screws are tightened fully to prevent instability.

• Do not place foreign objects on the display.

• Do not use a visibly damaged or broken sensor.

• Ensure that mounting the unit will not adversely affect the stability of the end

equipment when installing in free standing equipment or using the VESA mount.

To avoid the potentially hazardous situations associated with the use of alcohol or

other solvents which may result in minor or moderate injury or property damage:

• Follow all instructions and recommendations in the manufacturer's Material Safety

Data Sheet and product label.

• Be sure to follow solvent manufacturer's precautions and directions for use when

using any solvents

• It is important to avoid using any caustic chemicals on the touch sensor.

To avoid possible environmental contamination which may result in minor or

moderate injury:

•

Dispose of the flat panel display according to applicable governmental regulations.

NOTICE

To avoid the risk of potential damage to the display electronics:

• Always use the VESA 200 mm mounting holes when using an arm attachment. Do

not drill additional holes in the unit to mount plates other locations

• Do not use longer screws as they could potentially damage electronics inside the

display.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 8

8 3M™ Multi-Touch Chassis Display User Guide

Important Notes

• In extreme temperature and humidity situations, you may observe condensation

between the sensor and the display. To minimize this condition, place the unit where

it will be used and allow a 24-hour environmental stabilization period prior to

powering on the display. Any noticeable condensation is temporary and will have no

long term affect on the operation of the display.

• You are cautioned that any change or modification to the equipment not expressly

approved by the party responsible for compliance could void your warranty.

• When unplugging the power supply cord, hold the plug, do not pull by the cord.

• Do not connect or disconnect this product during an electrical storm.

• Remember to take into account that the operating temperature of the installation may

be greater than the room ambient, and consideration should be given to installing the

unit in an environment compatible with the maximum rated operating temperature.

Specifications can be found in the product data sheet on the 3M Touch Systems

website at http://www.3m.com/touch/.

• When installing the unit, ensure that it does not restrict the flow of air to any other

equipment within the installation required for safe operation.

• The 3M Multi-Touch Chassis Display may not function as expected at altitudes

higher than 2000 meters.

• 3M Touch Systems recommends vacuuming the fan filter at least every six months or

if a noticeable rise in surface temperature occurs.

• An inherent characteristic of the PCT sensor is a fine grid pattern that may be visible

under certain lighting conditions.

• Install the display in a well-ventilated area. Always maintain adequate ventilation to

protect the display from overheating and to ensure reliable and continued operation.

• Do not expose this display to direct sunlight or heat. Passive heat may cause damage

to the housing and other parts.

• Do not install this display in areas where extreme vibrations may be generated. For

example, nearby manufacturing equipment may produce strong vibrations. The

vibrations may cause the display to exhibit picture discoloration or poor video

quality.

• Ensure the metal enclosure does not contact the touch sensor.

• Be sure to gasket the display to its enclosure properly to prevent damage to the touch

sensor. Refer to the 3M Multi-Touch PCT2000PX System Integration Guide (TSD-

39954) for more information.

• To avoid ergonomic concerns:

Do not install the display in a manner or location with awkward accessibility.

Extended use may result in muscle, tendon, or fixed posture strains. It is

recommended you take periodic breaks from continuous use.

• The 3M touch controllers mentioned in this document are USB compatible full speed

devices.

• 3M does not warrant that we are USB compliant pursuant to USB specifications.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 9

3M™ Multi-Touch Chassis Display User Guide 9

Service and Repair Indicators

Do not attempt to service this unit yourself. Removing the display cover may expose you

to dangerous voltages or other risks. Unplug the display from the power outlet and refer

servicing to qualified service personnel in the event that:

• Liquid is spilled into the product or the product is exposed to rain or water.

• The product does not operate properly when the operating instructions are followed.

• The product has been dropped or the metal case has been damaged.

• The product exhibits a distinct change in performance, indicating a need for service.

• The power cable or plug is damaged or frayed.

Touch Sensor Care and Cleaning

The touch sensor requires very little maintenance. 3M Touch Systems recommends that

you periodically clean the glass touch sensor surface. Be sure to turn off your display

before cleaning.

Typically, an isopropyl alcohol and water solution ratio of 50:50 is the best cleaning

agent for your touch sensor.

CAUTION

To avoid the potentially hazardous situations associated with the use of alcohol

or other solvents which may result in minor or moderate injury or property

damage:

• Follow all instructions and recommendations in the manufacturer's Material Safety

Data Sheet and product label.

• Be sure to follow solvent manufacturer's precautions and directions for use when

using any solvents

• It is important to avoid using any caustic chemicals on the touch sensor.

• Apply the cleaner with a soft, lint-free cloth. Avoid using gritty cloths.

• Always dampen the cloth and then clean the sensor. Be sure to spray the cleaning

liquid onto the cloth, not the sensor, so that drips do not seep inside the display or

stain the bezel.

3M Touch Systems Support Services

3M Touch Systems, Inc. provides extensive support services through our website and

technical support organization. Visit the 3M Touch Systems website at

http://www.3m.com/touch/, where you can download MT 7 software and drivers, obtain

regularly updated technical documentation on 3M Touch Systems products, and learn

more about our company.

Whenever you contact Technical Support, please provide the following information:

• Touch display size, part number and serial number

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 10

10 3M™ Multi-Touch Chassis Display User Guide

• Current driver version

• Operating system used

• Information on additional peripherals

Technical Support is available Monday through Friday 8:30 a.m. to 5:30 p.m. with

limited call back service after 5:30 p.m. until 8:00 p.m. US Eastern Standard Time – 9

a.m. to 5 p.m. throughout Europe.

You can contact 3M Touch Systems, Inc. Technical Support (US only -- Eastern

Standard Time) by calling the hot line, sending email or a fax.

• Technical Support Hot Line: 978-659-9200

• Technical Support Fax: 978-659-9400

• Toll Free: 1-866-407-6666 (Option 3)

• Email: US-TS-techsupport@mmm.com

Contact 3M Touch Systems

Contact information for all offices can be found on our website at:

http://www.3m.com/touch/

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 11

3M™ Multi-Touch Chassis Display User Guide 11

CHAPTER 1

Setting Up Your Multi-Touch Chassis Display

This chapter describes how to set up your 3M Touch Systems Multi-Touch Chassis

Display. You need to complete the following tasks:

• Unpack the components

• Connect the video cable, touch display cables, and power cable

• Power on the display and test your setup

• If you are not running Windows® 7 (or Tablet PC), install MT7 software from the

enclosed CD.

System Requirements

The Multi-Touch Chassis Display requires a personal computer (PC). The requirements

for your PC are as follows:

• Your PC must have an available USB or RS-232 serial communication (COM) port.

You connect the touch sensor cable to this communications port.

• Your PC must have a video card and video driver already installed for the display. If

you need to install a video card or a video driver, refer to your computer

documentation for instructions.

Note: Before setting up your Multi-Touch Chassis Display, refer to the “Important

Safety Information” section at the beginning of this document.

Unpacking Your Touch Display

Carefully unpack the carton and inspect the contents. Your Multi-Touch Chassis Display

includes the following cables and accessories:

• USB and RS-232 serial communication cables

• DVI, HDMI, and VGA video cables

• US, UK or EU power cables (as needed)

• Hardware Kit -- 4 mounting brackets and (12) 8-32 screws

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 12

12 3M™ Multi-Touch Chassis Display User Guide

• Use the cables supplied -- do not substitute different cables.

Cables Included with Your Multi-Touch Chassis Display

USB Cable

VGA Cable

US Power Cable

9-pin RS-232 serial cable

DVI Cable

HDMI Cable

EU power cable (optional)

Audio Cable

UK power cable (optional)

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 13

3M™ Multi-Touch Chassis Display User Guide 13

Connecting the Touch Display

Note: You are cautioned that any change or modification to the equipment not expressly

approved by the party responsible for compliance could void your warranty.

To connect the Multi-Touch Chassis Display:

1. Turn off your computer. You should always turn off the computer before connecting

or disconnecting a device.

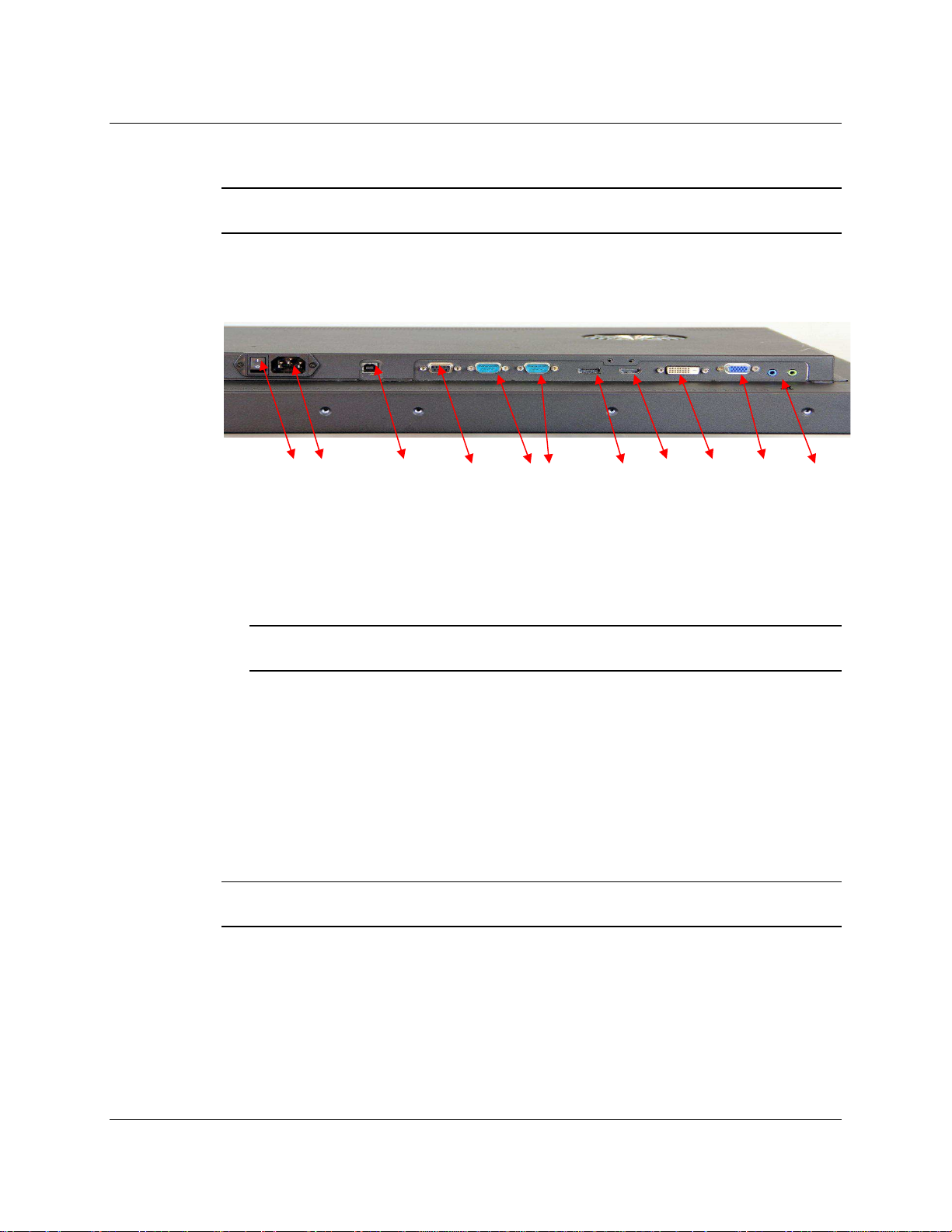

On/Off AC Input USB Serial Serial Display HDMI DVI VGA Audio

touch touch Out & In Port In & Out

2. Select either the DVI or VGA or HDMI cable. Connect one end of the video cable to

the video connector on the display. Connect the other end to the video card in your

computer.

3. Connect one end of the touch sensor cable (either USB or serial) to the LCD.

Connect the other end to an available port on your computer.

Note: Do not connect both USB and serial cables to the display. Choose one or the

other.

4. Connect the power cable to an appropriate grounded power source.

Multimedia Features

The C3266PW Multi-Touch Display comes with speakers built into the back of the

display housing and includes audio cables. These cables can be connected underneath the

display.

Testing the Multi-Touch Chassis Display

Note: The Multi-Touch Chassis Display has a power status light and video controls

located on the side of the display.

Before testing your touch display, make sure all cables are connected properly. Be sure

to tighten all cable screws. After connection, turn on the power switch located on the

back of the display.

To test that the display is working properly:

1. Turn on your computer.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 14

14 3M™ Multi-Touch Chassis Display User Guide

2. Make sure the video image is displayed. If it is not, check the LED to ensure that the

display is not in power save mode (amber)

3. Make sure the video image is centered within the screen area. Use the display

controls to adjust the image, if necessary.

You can adjust the horizontal and vertical position, contrast, and brightness to better suit

your video card and your personal preference. For additional details, refer to the

Adjusting the Video Display later in this chapter.

Mounting the Multi-Touch Chassis Display

The Multi-Touch Chassis Display is designed to fit any type of enclosure. All 3M Touch

Systems chassis displays are encased in rugged metal instead of plastic, making them

easy to integrate.

CAUTION

To avoid the risk of glass breakage which may result in minor or moderate injury:

To avoid risk of injury when handling the display be aware that the sensor edges may

be sharp.

The Multi-Touch Chassis Display includes a hardware accessory kit for mounting the

unit into an enclosure. The hardware accessory kit includes 4 mounting brackets and (12)

8-32 screws. The mounting holes are located on all 4 sides of the display. Always use the

supplied screws.

Note: Always use the mounting holes when attaching to the brackets. Do not drill

additional holes in the unit to mount brackets to other locations.

To remove the bezel, simply remove the screws along the edge.

Once you remove the bezel, you can attach the brackets to the edges of the chassis. The

brackets are slotted, allowing the chassis to slide in and out. You can also rotate the

brackets to various positions.

Note: Given the variety of factors that can affect the use and performance of any

product, some of which are uniquely within the user’s knowledge and control, it is

essential that the user evaluate the specific gasket to determine whether it is suitable for a

particular purpose and suitable for the user’s intended application.

Articulating Arm Mounting Option

The unit has a 200 mm VESA mounting pattern on the back to allow for arm mount

capability. Use 3/8 inch (9mm) screws to secure the VESA mount stand for use only with

UL listed wall mount bracket with minimum weight load capability of 33 lbs (15 kg).

Follow the manufacturer's instructions included with the mounting device to properly

attach your display.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 15

3M™ Multi-Touch Chassis Display User Guide 15

NOTICE

To avoid the risk of potential damage to the display electronics:

• Always use the VESA 200 mm mounting holes when using an arm attachment. Do

not drill additional holes in the unit to mount plates other locations

• Do not use longer screws as they could potentially damage electronics inside the

display.

Access to the Video Controls

The Multi-Touch Chassis Display has seven buttons for using the on-screen menu and

adjusting the video display. These controls are located on the side of the Multi-Touch

Chassis Display. These buttons let you display the on-screen menu and adjust the phase,

image position, contrast, and brightness. Make sure you will be able to access the video

controls once the Multi-Touch Chassis Display is installed.

Clearance and Ventilation

Leave at least two inches of clearance space behind the Multi-Touch Chassis Display for

proper ventilation. Units have vent holes at the top and bottom on the back of the chassis

-- ensure these holes are not blocked during installation. Always maintain adequate

ventilation to protect the display from overheating and to ensure reliable and continued

operation.

Refer to the published specifications for the maximum and minimum operating

temperature and humidity conditions. Refer to the product data sheet on the 3M Touch

Systems website at http://www.3m.com/touch/.

Video Card Requirements

Before you connect your touch display, make sure our computer has a video card

installed that supports the native video resolution of 1920 x 1080 for the Multi-Touch

Chassis Display. If you need information on installing a video card or video driver, refer

to the manual that came with your video card.

Using the Standard Controls for the Video Card

In addition to the standard controls on the display, each video card has several controls

that let you adjust the display settings. The software and driver for each video card is

unique. In most cases, you adjust these settings by using a program or utility provided by

the manufacturer of the video card.

For example, you can use the Windows Display Properties control panel to adjust the

desktop area (resolution), color depth, and refresh rate. Whenever you change these

settings, the image size, position, or shape may change. This behavior is normal. You can

readjust the image using the display controls described in this chapter.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 16

16 3M™ Multi-Touch Chassis Display User Guide

For more information on adjusting the desktop area/resolution, color depth, or refresh

rate, refer to the user manual that came with your video card. If you change the

resolution, it is a good idea to calibrate your sensor.

Supported Video Display Modes and Refresh Rates

Your video card should support one of the display modes specified below. If you select

an unsupported video mode, the display may stop working or display unsatisfactory

picture quality.

Display Mode Refresh Rate (Hz)

640 x 480 60

800 x 600 60

1024 x 768 60

1152 x 864 70

1280 x 720 60

1280 x 768 60

1280 x 960 60

1280 x 1024 60

1360 x 768 60

1366 x 768 60

1600 x 1200 60

1680 x 1050 60

1920 x 1080 60

Configuring the Display Settings

After you connect your Multi-Touch Chassis Display and turn on your computer, you

may need to configure one or more of these display settings. The ideal setting for the

Multi-Touch Chassis Display is as follows:

• Display mode (also called desktop area or video native resolution) 1920 x 1080

• Refresh rate (also called vertical scan rate or vertical sync) 60 Hz

• Color depth (also called color palette or number of colors) at least 16-bit (high color)

Adjusting the Multi-Touch Chassis Video Display

This section provides guidelines for adjusting the video display and using the display

controls to adjust the image to your liking. The controls for adjusting the video display

are located on the back of the Multi-Touch Chassis Display. These buttons let you

display the on-screen menu and adjust the phase, image position, contrast, and

brightness. Before you make any adjustments:

• Be sure to adjust the controls in your normal lighting conditions.

• Display a test image or pattern whenever you adjust the video.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 17

3M™ Multi-Touch Chassis Display User Guide 17

On Screen Display

Your Multi-Touch Chassis Display has the following controls for adjusting the video

display.

POWER SOURCE UP DOWN

Your Multi-Touch Chassis Display has seven controls to adjust the video display.

• Power -- Turns the display on and off.

• Source -- Selects the applicable input source: VGA, HDMI, or DVI. Settings are

saved automatically.

• Up -- Press to move among the menus and from the menu selection to specific

choices. (HOT KEY: Auto Configure)

• Down -- Press to move among the menus and from the menu selection to specific

choices. (HOT KEY: Adjust Aspect Ratio)

• + (plus sign) – (HOT KEY) Press to Mute or Un-mute sounds. Also to increase the

volume.

• - (minus sign) -- Press to decrease the volume.

• Menu -- Shows or hides the onscreen display menu and acts as the Select key when

scrolling through menu options. Refer to Menu Navigation below for additional

information.

If you do not press any buttons, the display adjustment program times out (you can adjust

this time -- up to 12 seconds) and hides the menu options. You can press the Menu

button at any time to display the options again.

+ -

MENU

Pressing Menu will pull up the On Screen Display (OSD) menus to control the Picture,

Color, Display, OSD Settings, and Setup, as shown below.

Menu Navigation

• To adjust the On-Screen Display:

• Select the Menu button to bring up the on-screen display (OSD)

• Use the Up and Down buttons to scroll through the various Menu choices:

• Image Menu

• Display Menu

• Audio Menu

• System Menu

• Once the Menu you want is highlighted, hit the Menu button again to select that

Menu.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 18

18 3M™ Multi-Touch Chassis Display User Guide

• Use the Up and Down buttons to scroll through the various Menu options. For

example, once you have chosen the Picture Menu, use the Up/Down buttons to select

Brightness, Contrast or Sharpness.

• Once the option you want is highlighted, hit the Menu button again to select that

option.

• Use the Up and Down buttons to increase or decrease the value of the option.

• Your selection will be automatically saved.

Image Menu

Includes choices for Brightness, Contrast, and Sharpness.

Brightness

Selecting the Brightness option will allow you to adjust the luminescence of the display.

Settings are saved automatically.

Contrast

Selecting the Contrast option increases or decreases the strength (lightness or dimness)

of the image. Settings are saved automatically.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 19

3M™ Multi-Touch Chassis Display User Guide 19

Sharpness

Adjusts the video quality to be sharp or blurry (special for text mode). Settings are saved

automatically.

Color Settings

Includes choices for 9300k, 6500k, and User Defined Color.

User Defined Settings

Adjust the Red, Green and Blue channels to your preference. Settings are saved

automatically.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 20

20 3M™ Multi-Touch Chassis Display User Guide

Display Menu

Includes choices for Auto Configure, Horizontal Position, Vertical Position, Clock and

Phase.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 21

3M™ Multi-Touch Chassis Display User Guide 21

Auto Configure

Performs automatic configuration of the Clock, Phase, Vertical and Horizontal positions.

If you do an Auto Configure, the display will try to find the best setting. If you are not

satisfied with the auto adjustment, fine-tune the settings manually as described below.

Settings are saved automatically.

Phase

Adjust this setting so that either the vertical bars of video noise are replaced by an even

amount of noise across the whole screen, or the noise disappears completely. Settings are

saved automatically.

Clock

If the clock setting is not fine-tuned, you may observe periodic vertical bars of video

noise on your image. These bars of noise are usually adjusted out when an Auto Adjust

is performed. If the bars of noise are still present, this setting can be adjusted manually.

Settings are saved automatically.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 22

22 3M™ Multi-Touch Chassis Display User Guide

H Position (Horizontal Position)

Moves image horizontally on screen either left or right. Settings are saved automatically.

V Position (Vertical Position)

Moves images vertically on screen either up or down. Settings are saved automatically.

Audio Menu

Volume

Mute

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 23

3M™ Multi-Touch Chassis Display User Guide 23

Audio Select

Digital video signal inputs, HDMI and Display Port, provide audio inputs. They will be a

priority unless external audio input is selected.

System Menu

Includes choices for Input Source, Menu Settings, Languages, Aspect Ratio, Dynamic

Contrast Ratio, Factory Reset, and DCR.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 24

24 3M™ Multi-Touch Chassis Display User Guide

Source

Source sets the input mode for the display either VGA, DVI, HDMI, or DP.

Menu Settings

Includes choices for OSD Timer, OSD Horizontal position, OSD Vertical Position, and

OSD Transparency.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 25

3M™ Multi-Touch Chassis Display User Guide 25

OSD Timer

Adjust how long the menu remains on the screen. Settings are saved automatically.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 26

26 3M™ Multi-Touch Chassis Display User Guide

OSD H Position

Adjusts the horizontal placement of the OSD display on your screen. Settings are saved

automatically.

OSD V Position

Adjusts the vertical placement of the OSD display on your screen. Settings are saved

automatically.

Transparency

Adjusts the transparency of the OSD screen on your display. Settings are saved

automatically.

Language

Sets the language for the OSD -- the choices are English, French, German, Italian,

Spanish, and Chinese. Settings are saved automatically.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 27

3M™ Multi-Touch Chassis Display User Guide 27

Aspect Ratio

Set the preferred aspect ratio for your display -- either Full, 16:10, or 4:3

DCR (Dynamic Contrast Ratio)

Turn the Dynamic Contrast Ratio on or off.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 28

28 3M™ Multi-Touch Chassis Display User Guide

Factory Reset

Resets the control functions back to the original factory preset values. Settings are saved

automatically.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 29

3M™ Multi-Touch Chassis Display User Guide 29

CHAPTER 2

Enabling Your Multi-Touch Chassis Display

Windows® 7 USB Compatibility

3M Multi-Touch technology works seamlessly with the Windows® 7 operating system.

The Multi-Touch display supports USB HID for direct communication. The Multi-Touch

Chassis Display leverages all the multi-touch functionality that is native to Windows® 7.

Plug the display into a system running Windows® 7 and you’ll quickly enter the world

of true multi-touch functionality.

The Multi-Touch Chassis Display is compatible with Windows® 7 with no additional

software. Refer to Microsoft's Windows® 7 documentation for additional information.

All Other Platforms

When using a Windows® 7 serial connection or for Windows® XP, Vista or Linux

operating systems (either USB or serial), 3M provides MicroTouch™ MT 7 Software for

multi-touch drivers. This guide includes information for writing your own drivers to

interface with the 3M Multi-Touch Technology.

Multi-Touch Application Support

Remember not all applications are multi-touch ready – Multi-touch behavior is a function

of YOUR application. Check with your application vendor to determine if your software

has multi-touch capability.

Installing 3M™ MicroTouch™ Software

Remember that Windows® 7 does not require any additional software to enable multitouch functionality.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 30

30 3M™ Multi-Touch Chassis Display User Guide

However, for Windows® XP, Vista or Linux® operating systems, 3M™ MicroTouch™

Software enables your Multi-Touch Chassis Display to work with your computer. 3M™

MicroTouch™ Software includes a control panel for setting your touch sensor

preferences and a diagnostic utility. If you are experiencing problems with the touch

sensor, you can use the diagnostic utilities provided to test the system.

For more information on installing this software and using the control panel, refer to the

3M™ MicroTouch™ Software User Guide on the accompanying CD or on the corporate

website at www.3m.com/touch.

Video Alignment

The Multi-Touch Chassis has been calibrated prior to shipment and the display as

delivered does not require video alignment. You should be able to accurately touch icons

on the sensor. If for some reason, you cannot do this, the touch sensor’s active area may

not be aligned to the underlying video.

Regardless of the operating system, after you connect your touch display:

• If you are using Windows® 7, you may calibrate by accessing the Software

Diagnostic Utility (SDU) found on the enclosed CD.

Launch the SDU from the CD. Select the Tools menu and highlight Calibration. The

screen below appears and you should touch the 2 targets as they appear. Press

Escape to cancel Calibration.

• If you are using 3M™ MicroTouch™ MT 7 Software, launch the MT 7 Control

Panel and follow the instructions on the Main tab. You'll be asked to touch 3 targets.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 31

3M™ Multi-Touch Chassis Display User Guide 31

• If you are writing your own drivers, you should provide your own video alignment

tool.

Use the Paint program (Start→ Programs→ Accessories→ Paint) to determine if you

have multi-touch operation. Retest the accuracy after you perform a calibration.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 32

Page 33

3M™ Multi-Touch Chassis Display User Guide 33

APPENDIX A

3M™ PX USB Controller Communications

This appendix is intended for software developers only and discusses the fundamentals

of communicating with the 3M™ PX controller. The firmware commands, which are

usually issued by a driver or utility program on the host system, control the operation of

the controller. This appendix lists the recommended firmware commands and describes

how to use each of these commands.

Overview of USB Firmware Communications

Developers may use this information when writing touch applications, developing

custom drivers or touch configurations, or testing their touch systems. Developers can

issue commands to initialize the controller, select operating modes, and execute

diagnostic functions.

Note: This document assumes you are familiar with USB standards and modes of

communication with USB devices, as well as firmware commands and how to use them.

Executing some commands may alter the performance of your sensor and render it

inoperable. You should be aware of the results before executing any firmware

commands.

To optimize the performance of the PX controller and simplify the development of

custom drivers, 3M Touch Systems recommends you use the commands listed in this

appendix for current development.

Communication Basics

This section provides information on sending firmware commands to the controller and

interpreting the responses that the controller returns. The default operation of the PX

controller is USB Rev 2.0 full speed.

The USB command set is implemented by using vendor requests and vendor reports, i.e.,

vendor specific transactions. The controller issues some reports without prompting the

computer. The computer can also send requests to the controller to change how it

operates or receives information about the controller. The controller issues a

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 34

34 3M™ Multi-Touch Chassis Display User Guide

synchronous report in response to some of these requests.

You need to know product ID (0506H) and the vendor ID (0596H) to write your own

driver. These values are required for identifying the controller.

Receiving Reports from the Controller

The controller sends a variety of reports to the computer. The first byte of each report is

the Report ID that defines the structure and content of the report. The controller sends

some reports as a direct response to a computer request (synchronous). The controller

will also send some reports as the result of an external event, such as a touch

(asynchronous).

Command Set

The USB command set is implemented by using HID Get Feature and Set Feature

commands. The various requests and reports are grouped together by report size under a

common feature ID.

The following table summarizes the available HID class requests.

Table 1. HID Class Requests Summary

HID Report Command

Name

bmRequest

Type

bRequest Feature

Report ID

Report

Subtype

Get Feature GetStatus 0xA1 (D2H) 0x01 0x06 -- 8

Set Feature Calibrate 0x21 (H2D) 0x09 0x03 4 8

Set Feature Reset 0x21 (H2D) 0x09 0x03 7 8

Set Feature Restore Defaults 0x21 (H2D) 0x09 0x03 8 8

Get Feature GetMaxCount 0xA1 (D2H) 0x01 0x12 -- 2

Set Feature - Calibration

This is a command to do a Calibrate Extended style calibration. The controller will autoorient on this 2 point calibration.

Table 2. Calibration Setup Stage

Offset Field Size Value Description

0 bmRequestType 1 0x21 Class,H2D,Interface

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 Msb 03 = Feature

Lsb 03 = Feature Report ID

Data

Stage

Bytes

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 35

3M™ Multi-Touch Chassis Display User Guide 35

Table 3. Data Stage

Offset Field Size Value Description

0 Report ID 1 0x03 Feature report ID

1 Report Subtype 1 0x04 Indicates a calibration request

2 bCalType 1 0x01 0x01 = Extended cal (CX)

3--7 Not used 5 0 Not used

The device stalls endpoint 0 if the command cannot be processed successfully. The

request cannot be processed if an invalid calibration type is given in the wValue field.

The request will also fail if the 2 calibration points do not fall within certain bounds

established by the firmware. These bounds require that the 2 calibration points be in

opposite quadrants of the sensor.

The host should issue a GetStatus request to determine the status of this request. The

status report includes a command status byte which will be set as shown below.

Table 4. Calibration Response

Command Status Byte Description

0 Calibration Failed

1 Controller is waiting for a touch in the lower left corner.

Calibration software paints a target in the lower left corner.

2 Controller is waiting for a touch in the upper right corner.

Calibration software paints a target in the upper right corner.

3 Calibration completed successfully.

The controller does not timeout waiting for touch. Use the Soft Reset command to abort

the calibration.

Determining Target Areas

The default calibration targets (points) are located 12.5% (1/8) inward from the corners

of the video image. For example, suppose the resolution of your Windows-based display

is 1680 x 1050. The Calibrate Extended command calculates the amount to move inward

as follows:

•

Amount to move inward in the X direction: 1680 x 1/8 = 210

•

Amount to move inward in the Y direction: 1050 x 1/8 = 131

The Calibrate Extended command then positions the first calibration target inward from

the lower left corner (0,1049) and the second calibration target inward from the upper

right corner (1679,0). The following illustration shows how the calibration targets are

calculated for a Windows-based system. Your operating system may be different.

The illustration below shows the coordinates of the calibration targets and display

corners. The corners show the video coordinates in parentheses and the touch screen

coordinates in brackets.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 36

36 3M™ Multi-Touch Chassis Display User Guide

X = 1679

(0, 0) [0, 0]

Lower Left Calibration Target

X = 0 + (1680 x 1/8) = 0 + 210 = 210

Y = 1049 - (1050 x 1/8) = 1049 - 131 = 918

(0, 1049) [0, 32767] (1679, 1049) [32767, 32767]

Note: Other screen resolutions will scale proportionally. The touch coordinates will not

change.

Get Feature - GetStatus

This is a request to send information that indicates the status of the controller. Among

the uses for this request are determining whether there were any power on check errors

and determining whether the last request was completed successfully.

Table 5. Controller Status Setup Stage

Offset Field Size Value Description

0 bmRequestType 1 0xA1 Class,D2H,Interface

1 bRequest 1 0x01 Get Report

2 wValue 2 0x0306 msb=03=Feature

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

(210, 918)

(

1679, 0) [32767, 0]

(1469, 131)

Upper Right Calibration Target

– (1680 x 1/8) = 1679 – 210 = 1469

Y = 0 + (1050 x 1/8) = 0 + 131 = 131

lsb=06= Feature Report ID

Table 6. Controller Status Data Stage (controller response)

Offset Field Size Value Description

0 Report ID 1 0x06 Feature Report ID

1 POC Status 1 0xXX Power On Check Status

2 Cmd Status 1 0xXX Status of last command

3 Touch Status 1 0 Not used

4 Async Reports 1 0xXX 0x00 = async touch output off

5-7 Not used 3 0 Not used

POC Status – The status of the Power-on Checks. Various controller systems are

checked at power-up. If any failures in these systems are detected, a POC flag is set. The

POC status field reports the state of these flags.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

0x01 = async touch output on

Page 37

3M™ Multi-Touch Chassis Display User Guide 37

Table 7. Power On Check Bit Fields

Bit Number Description Notes

0 Not used

1 ROM_ERROR Code area checksum error

2 PWM Error Touch screen not connected or potential problem

3 NOV_ERROR Parameter blocks checksum error

4 HDW_ERROR Problem with ADCs

5--7 Not used

Command Status – The status for the last command request. This field is used to

determine whether the last request was processed successfully. It is also used to track the

progress of a multi-stage request, such as 2 point calibration. The Status Request does

not affect the contents of this field, i.e., successful or unsuccessful processing of a

previous status request does not cause the command status field to be updated.

Table 8. Valid Command Status Field Entries

Response Description

0 Failure in command processing

1 Command being processed

2 Stage 1 processing complete (for multi-stage commands)

3 Command complete

4 Soft Reset Occurred

5 Hard Reset Occurred

6 -- 7 Not used

Get Feature - GetMaxCount

This is a request to send information that indicates the maximum number of

simultaneous touches supported by the controller.

Table 9. Setup Stage

Offset Field Size Value Description

0 bmRequestType 1 0xA1 Class,D2H,Interface

1 bRequest 1 0x01 Get Report

2 wValue 2 0x0312 msb=03=Feature

4 wIndex 2 0 Always 0

6 wLength 2 2 Always 2

Table 10. Data Stage (controller response)

Offset Field Size Value Description

0 Report ID 1 0x12 Feature Report ID

1 Max Count 1 0x1E Number of actual fingers supported

Note: The number of actual contacts reported may exceed this number.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

lsb=12 Feature Report ID

Page 38

38 3M™ Multi-Touch Chassis Display User Guide

Set Feature - Reset

This is a request to perform a controller reset. Soft resets are automatic after any block

parameter changes.

Table 11. Reset - Setup Stage

Offset Field Size Value Description

0 bmRequestType 1 0x21 Class,H2D,Interface

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 msb=03=Feature

lsb=03= Feature Report ID

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

Table 12. Reset – Data Stage

Offset Field Size Value Description

0 Report ID 1 0x03 Feature Report ID

1 Report Subtype 1 0x07 Indicates a reset request

2 bResetType 1 0x01

0x02

3--7 5 0 Not used

Soft Reset

Hard Reset

A Hard Reset will cause the controller to re-enumerate.

In the case of a Soft Reset, after sending the command, the controller will acknowledge

(ACK) the transfer, but the command will not yet be completed. Before sending any

other commands, the host should poll with GetStatus until the command status field

returns “Soft Reset Occurred,” “Command Complete,” or “Fail”. Any timeout for this

status polling should be 2 seconds minimum.

Set Feature –Restore Defaults

This is a request to restore parameter defaults.

Table 13. Restore Defaults -- Setup Stage

Offset Field Size Value Description

0 bmRequestType 1 0x21 Class,H2D,Interface

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 msb=03=Feature

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

lsb=03= Feature Report ID

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 39

3M™ Multi-Touch Chassis Display User Guide 39

Table 14. Restore Defaults - Data Stage

Offset Field Size Value Description

0 Report ID 1 0x03 Feature Report ID

1 Report Subtype 1 0x08 Restore Defaults

2-7 6 0 Not used

After sending this command, the controller will acknowledge (ACK) the transfer, but the

command will not yet be completed. Before sending any other commands, the host

should poll with GetStatus until the command status field returns “Command Complete”

or “Fail”. Any timeout for this status polling should be 2 seconds minimum.

Asynchronous Reports

Coordinate Data – Multi-Touch Digitizer mode Async Report 0x13

This is used to transfer the coordinate data to the host. This report, when activated, is

sent to the host whenever new data is available or scheduled for transmission. It is an

asynchronous report that is activated by default at power up.

The report shown supports up to 6 simultaneous touches. Note that if more than 6

touches were to be supported, Report 0x13 would be sent as many times as necessary to

accommodate the number of fingers touching. Only the first Report 0x13 will have a

non-zero actual count. Each valid touch is marked with an ID number that remains the

same from touchdown through liftoff. The ID number can be any value from 0 to 255.

Ignore all other data within a touch report structure with a status marked “not valid”.

The coordinate system is Upper Left origin.

Table 15. Coordinate Data Report 0x13 --Data Stage

Offset Field Size Value Description

0 Report ID 1 0x13 Report ID

1 Touch Report 10 See table 16 Touch Report Structure

11 Touch Report 10 See table 16 Touch Report Structure

21 Touch Report 10 See table 16 Touch Report Structure

31 Touch Report 10 See table 16 Touch Report Structure

41 Touch Report 10 See table 16 Touch Report Structure

51 Touch Report 10 See table 16 Touch Report Structure

61 Actual Count 1 1 to 60 Number of valid touch reports

62 Not used 1 0

63 Not used 1 0

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 40

40 3M™ Multi-Touch Chassis Display User Guide

Table 16. Touch Report Structure

Offset Field Size Value Description

0 Status 6 0xXX 0x00 Report not valid

0x04 Not touching

0x07 Touching

1 Touch ID 1 0-255 Touch thread ID number

2 X lsb 1 0xXX X ( 0-7FFF)

3 X msb 1 0xXX

4 Y lsb 1 0xXX Y ( 0-7FFF)

5 Y msb 1 0xXX

6 Width lsb 1 0xXX Width ( 0-7FFF)

7 Width msb 1 0xXX

8 Height lsb 1 0xXX Height ( 0-7FFF)

9 Height msb 1 0xXX

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 41

3M™ Multi-Touch Chassis Display User Guide 41

APPENDIX B

3M™ PX Serial Controller Communications

This appendix is intended for software developers only and discusses the fundamentals

of communicating with the 3M™ PX serial controller. The firmware commands, which

are usually issued by a driver or utility program on the host system, control the operation

of the controller; however developers can enter these commands directly. This appendix:

•

Describes the controller default settings.

•

Lists the recommended firmware commands for current development.

•

Describes how to use each of these commands.

•

References additional commands developers may need to use.

The description of each command includes the command syntax, the default value, how

the command works, and the expected response from the controller.

Overview of Firmware Commands

Developers may use these commands when writing touch applications, developing

custom drivers or touch configurations, or testing their touch systems. Developers can

issue commands to initialize the controller, select operating modes, and execute

diagnostic functions.

Note: This document assumes you are familiar with standards and modes of

communication with serial devices, as well as firmware commands and how to use them.

Executing some commands may alter the performance of your sensor and render it

inoperable. You should be aware of the results before executing any firmware

commands.

To optimize the performance of the 3M™ PX controller and simplify the development of

custom drivers, 3M Touch Systems recommends you use the commands listed in this

appendix for current development.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 42

42 3M™ Multi-Touch Chassis Display User Guide

1

0

0

Controller Default Settings

Communication Parameters

The operation of the PX serial controllers is N81 (no parity, 8 data bits, and 1 stop bits)

at 115,200 baud (nonadjustable).

Data Format

Data format refers to the type of packet the controller uses to send the X/Y touch

coordinates to the host system. Format Tablet Multi-Touch is the default format for the

3M™ PX serial controller. In Format Tablet Multi-Touch, the controller sends 6 bytes

per point and provides the most rapid response time to a touch.

Note that 3M MicroTouch Software automatically sets communications parameters to

N81.

The format is a six byte packet that includes one status byte, four bytes of binary X,Y

position data and a touch ID. The X,Y coordinates are 14 bits, providing a range of 0 to

16,383. The data is sent in the following format:

Table 17. Touch Data Format Settings

Data Sequence Bits

7 6 5 4 3 2 1 0

Status - Byte 1 1 P

0 0 0 0

X - Byte 2 0 X6 X5 X4 X3 X2 X1 X0

X - Byte 3 0 X13 X12 X11 X10 X9 X8 X7

Y - Byte 4 0 Y6 Y5 Y4 Y3 Y2 Y1 Y0

Y - Byte 5 0 Y13 Y12 Y11 Y10 Y9 Y8 Y7

ID – Byte 6 0 N6 N5 N4 N3 N2 N1 N0

Note 1: P is the proximity bit. It is set to 1 when there is a touch, 0 for a liftoff.

The ID is associated with a touch stream from one finger. The ID, in the range of 0-127,

is assigned on a rotating basis at touchdown. A finger touch stream consists of a

touchdown, maybe some continuing touch points, ending with a liftoff. The ID is

released on liftoff, and becomes available to be reassigned.

When multiple fingers are down, the packets from the touch streams are sent interleaved.

There is no order imposed on the interleave.

Operating Mode

The operating mode specifies the conditions under which the controller sends the X/Y

touch coordinates (input data packet) to the host system.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 43

3M™ Multi-Touch Chassis Display User Guide 43

Mode Stream is the default operating mode for the 3M™ PX serial controller. In Mode

Stream, the controller sends a continuous stream of data packets when the sensor is

touched. The controller sends the data as long as a touch continues on the sensor.

Because Mode Stream sends touch data continually, it is the most versatile mode, and it

provides the best response time and overall feel.

3M Touch Systems recommends that the touch driver generate an interrupt as each

packet in the data stream arrives. Because touchdown and liftoff events are specially

coded, your software can generate mouse events that correspond to what the user is

doing. This enables instant feedback and prevents data loss.

Communicating with the Controller

This section provides information on sending firmware commands to the controller and

interpreting the responses that the controller returns.

The commands listed in Table 18 are those that 3M Touch Systems currently uses for

development. 3M Touch Systems recommends that you use only these commands for

3M™ PX serial controller development.

Commands to the controller are sent on the signal Receive Data (RXD) line as a serial

data stream. For each command it receives, the controller sends a response to the host on

the signal Transmit Data (TXD) line also as a serial data stream.

Sending Commands to the Controller

When you send a command to the controller, you must use the correct command format.

The general format of a command is as follows:

<Header>Command<Terminator>

Note: The following descriptions of header, command, and terminator, use 3M Touch

Systems terminal emulator key sequences. You may need to enter the sequence in a

different format, depending on your emulator.

The header is the first character in the command string and is the ASCII start-of-header

control character SOH. The hexadecimal code for the ASCII SOH control character is

01. To start the command sequence, use the key combination Ctrl A (^A). If you are

working with an IBM PC compatible system, the Ctrl A key combination immediately

returns an ASCII ☺ character.

The command, which always follows the header, consists of ASCII uppercase letters and

numbers only (printable characters).

The terminator is the last character of each command string and is an ASCII carriage

return CR. An ASCII CR control character is 0D hexadecimal. To enter a carriage return,

ending the command sequence, use Enter or the key combination Ctrl M (^M).

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 44

44 3M™ Multi-Touch Chassis Display User Guide

This appendix lists each command as a string of ASCII control characters and printable

characters consisting of a header, the command, and a terminator as follows:

<SOH>Command<CR>

Receiving Responses from the Controller

After executing a command, the controller returns a response or acknowledgment to the

host system. Each controller response consists of a header, the command response, and a

terminator in the following format:

<Header>Command Response<Terminator>

Note: The following descriptions of header, response, and terminator, use 3M Touch

Systems terminal emulator key sequences. The format of controller responses varies

depending on the terminal emulation mode you are using.

The header is the first character in the response string and is the ASCII start-of-header

control character SOH. The hexadecimal code for the ASCII SOH control character is

01. If you are working with an IBM PC compatible system in terminal mode, the SOH

control character returns a ☺ character to the sensor.

The command response, which always follows the header, is a range of ASCII characters

depending on the type of command sent. Responses can be in many forms. For example,

one standard response is 0 (ASCII character ‘zero’ or 30 hexadecimal). This response

indicates a successful command completion for most commands, while it indicates a

failed completion for other commands. Refer to the firmware command section for a

description of what the response indicates for each particular command.

Another standard response is 1 (ASCII character ‘one’ or 31 hexadecimal). In most

cases, this response indicates the command failed. The controller received an invalid

command that it could not execute.

Some possible reasons for a command failure include:

•

The command was not formatted correctly.

•

The system parameters were not set up to allow command execution.

•

The controller does not support the command.

The terminator is the last character of each response string and is an ASCII carriage

return CR. The hexadecimal code for the ASCII CR control character is 0D hexadecimal.

The value returned in the response will be the ASCII control character for a carriage

return, displayed on the screen as the cursor moving to the next line.

In this appendix, responses are shown as a string of ASCII characters consisting of a

header, the response, and a terminator as follows:

<SOH>Response<CR>

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 45

3M™ Multi-Touch Chassis Display User Guide 45

Controller Initialization

To initialize the 3M™ PX serial controller for new development, 3M Touch Systems

recommends that the host system issue a Reset command whenever the host system is

powered on and is attempting to establish communication with the controller.

Firmware Commands

Developers may use this information when writing touch applications, developing

custom drivers or touch configurations, or testing their touch systems. Developers can

use firmware commands to initialize the controller, select operating modes, specify data

formats, and execute diagnostic functions.

Caution: This document assumes you are familiar with firmware commands and how to

use them. Executing some commands may alter the performance of your touch system

and render it inoperable. You should be aware of the results before executing any

firmware commands.

To optimize the performance of the touch controller and simplify the development of

custom drivers, 3M Touch Systems recommends you use the commands listed in Table

18 for current development. Using these commands ensures compatibility with all 3M™

controllers.

Note: When you enter commands in terminal mode, precede each command with

<CTRL> A to enter the start of header.

Table 18. Firmware Commands for PX Serial Controller Development

Command Code Description

Calibrate CX Initiates an interactive 2-point calibration.

Get Copyright Q101 Returns the copyright string.

Mode Down Up MDU Reports touchdowns and liftoffs only.

Mode Inactive MI Turns off touch reports.

Mode Stream MS Default mode. Streaming touch reports.

Name Command NM Returns a controller identifier string.

Null Command Z Returns an ACK. No effect.

Output Identity OI Returns Identity string: ADxxxx

Soft Reset R Resets certain modes and gets a new baseline.

Restore Defaults RD Restores default settings.

Unit Type UT Returns the Status string: AD****ss.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 46

46 3M™ Multi-Touch Chassis Display User Guide

Calibrate

Syntax: <SOH>CX<CR>

Response: <SOH>1<CR> Valid point response.

A Valid Point Response (‘1’) signifies that a touch coordinate was detected and is in

range of the expected screen target area. Two valid point responses indicate successful

calibration.

<SOH>0<CR> Invalid point response

An Invalid Point Response (‘0’) is returned if the touch coordinate is out of range. If

either calibration point is invalid, the touch coordinates are discarded and the calibration

points remain unchanged from their previous values.

<SOH>2<CR> Invalid point response

An Invalid Point Response (‘2’) is returned if the user did not touch the target long

enough to provide an accurate point.

Description: Initiates an interactive 2-point calibration.

During the calibration process, you define the active area of the touch sensor by mapping

locations to an absolute X/Y coordinate system. You touch two target areas on the

sensor. Touching the target areas sends the X/Y coordinates for those touch points to the

controller. The controller calculates all other touch points based on these two points.

The Calibrate command sets the calibration targets (points) 12½ percent inward from the

corner of the video image. Setting the targets inward makes the calibration process easier

and more accurate.

It also establishes screen orientation.

Calibrate Procedure

To use the CX command:

1. Enter the Calibrate (CX) command. The controller sends an initial acknowledgment

of <SOH>0<CR>.

2. Touch the sensor at a lower left target, which is located 12.5% (1/8) in from the

corner of the video image. The controller returns an acknowledgment of

<SOH>1<CR>. This is a positive response. If you receive a negative response

<SOH>0<CR>, you can cancel the calibration by issuing a Reset command and then

start over again.

3. Touch the sensor at an upper right target, which is located 12.5% (1/8) in from the

corner of the video image. The controller returns an acknowledgment of

<SOH>1<CR>. This is a positive response. If you receive a negative response, you

must start over again.

3M Touch Systems, Inc. Proprietary Information – TSD-39373 REV E

Page 47

3M™ Multi-Touch Chassis Display User Guide 47

Touching the two valid calibration points results in a successful calibration. If either

calibration point is invalid, the calibration fails. The PX controller restores the previous

calibration values. If Calibrate fails, repeat the CX process.

Guidelines for Calibrate Command

Here are several guidelines for using the Calibrate commands:

• The controller uses the data immediately before liftoff to register a calibration touch.

Therefore, you can touch the coordinate target, hold for a few seconds, and then lift

off. Instructing users to touch this way results in a more accurate calibration.

• The controller stores the data in non-volatile memory (NOVRAM). Therefore, you

do not have to calibrate the sensor each time you power on the system. You should,

however, recalibrate the touch sensor any time the video display changes size or

resolution.

• You can cancel calibration at any time during this sequence by issuing a Reset

command.

Determining Target Areas

The default calibration targets (points) are located 12.5% (1/8) inward from the corners