Page 1

3

Dynatel™

Advanced Modular System

965AMS

Version 4.01.17 User’s Guide

November 2010

78-8135-5011-4-D

Future-Proof Testing Platform

Page 2

Page 3

Contents

Introduction .....................................................................................5

Getting Started ..........................................................................................5

Welcome Screen ........................................................................................7

Help ...........................................................................................................7

High Voltage .............................................................................................8

System Setup ................................................................................... 9

Country .....................................................................................................9

Language .................................................................................................10

Module ....................................................................................................11

Network Setup ........................................................................................11

Units ........................................................................................................12

User Info .................................................................................................14

Clock Settings .........................................................................................15

Set Beep Volume .....................................................................................18

Power Down Timeout .............................................................................19

Custom Cable ..........................................................................................20

Voltage Termination ................................................................................24

Measurement Functions ................................................................ 26

Volts-DC or AC .......................................................................................27

Loop Current ...........................................................................................29

Ohms Measurements ...............................................................................32

Toolbox ...................................................................................................38

Internet Explorer .....................................................................................44

Opens ......................................................................................................48

Tone .........................................................................................................53

RFL (Resistance Fault Locate) ...............................................................58

DSL (Digital Subscriber Line) ................................................................99

TDR.......................................................................................................117

POTS .....................................................................................................137

Auto Test ...............................................................................................163

Talk Set .................................................................................................185

Care & Maintenance .................................................................... 191

3

Page 4

System Modes .......................................................................................191

AC Charger ...........................................................................................192

DC Charger ...........................................................................................192

Level of Charge .....................................................................................193

System Reset .........................................................................................193

Battery Pack ..........................................................................................194

Battery Holder .......................................................................................196

Test Leads .............................................................................................196

Self-Test Board ............................................................................197

Specifications .............................................................................. 199

Electrical Specications ........................................................................199

General Specications ..........................................................................202

Contact 3M ................................................................................... 203

4

Page 5

3M™ Dynatel™ Advanced Modular System 965AMS Introduction

Introduction

Getting Started

1. Press the red key to power up the unit or to power

down the unit.

2. Press the

key to change the contrast. Use the or

keys to adjust the contrast on the screen.

3. F1 through F5 are the soft

keys. Their function is

displayed in the box above

the key.

Example: To use the AC

Volts, press F5.

4. At the beginning of each

chapter there will be a

wiring diagram showing

the test lead hook-up. The

screen will also show the

test lead hook-up.

RED

GRN

BLK

YEL

BLU

Ring (B) 1Ring (B) 1

Ground

Ground

Tip (A) 1

Tip (A) 1

Ring (B) 2

Ring (B) 2

Tip (A) 2

Tip (A) 2

5

Page 6

Introduction 3M™ Dynatel™ Advanced Modular System 965AMS

Getting Started

5. Some screens require you

to choose from a list of

possible choices.

Use the up and down arrow

keys to make your choice.

6. Other screens may allow

you to enter information

such as telephone numbers.

You can position the cursor

by using the Left and Right

arrow keys.

7. This symbol indicates you

should use the blue keys

to enter numeric values or

numbers.

6

Page 7

3M™ Dynatel™ Advanced Modular System 965AMS Introduction

Getting Started

8. Use the (escape) key to quit the current screen

without making any changes. Use multiple escapes to return

to the Welcome screen.

9. The battery symbol in the upper right-hand corner of

the display gives an indication of the approximate battery

capacity. Each bar represents one-quarter of the full

capacity.

10. The unit is powered by a rechargeable NiMH battery pack.

The unit will also work with the “AA” battery pack. Six

“AA” batteries are required. Dispose of the batteries per

your company procedures. See Care & Maintenance for

more information on using the rechargeable battery pack.

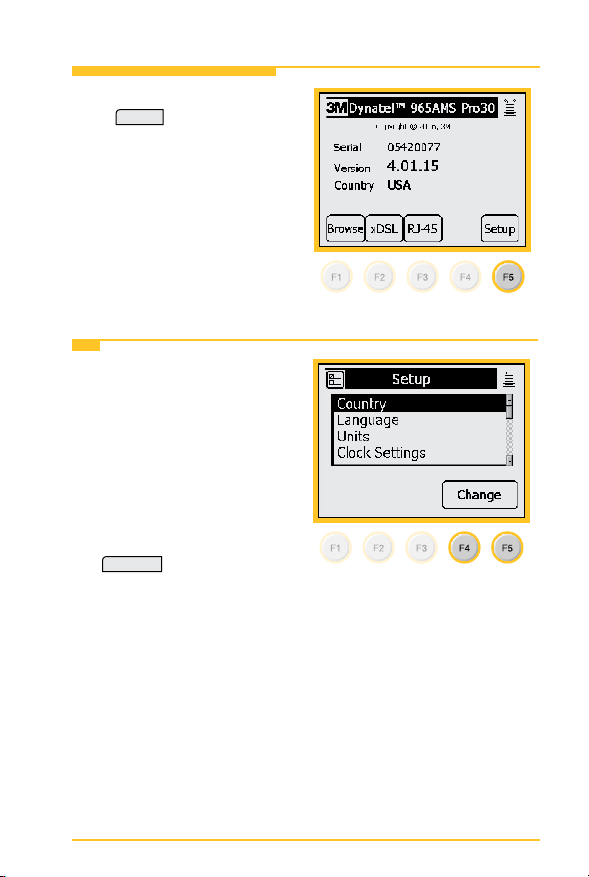

Welcome Screen

This is the screen that you see

when you rst turn on the tester.

It shows the model name, serial

number, software version, and

selected country.

Help

Press the key at any time in any screen to get help with the

current function. Press

screen.

7

OK

or to return to the previous

Page 8

Introduction 3M™ Dynatel™ Advanced Modular System 965AMS

High Voltage

This screen indicates a high

voltage (120 VAC/VDC or

greater) has been detected

between the test leads when not

in the Voltage Mode. The tester

has opened an internal relay

to protect itself from damage.

Use standard safety practices

for disconnecting the test leads

since high voltage may be

present. Press

the 965AMS tester.

OK

to restart

8

Page 9

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

System Setup

Start with the Welcome Screen.

Setup

Press

global settings or to make

changes.

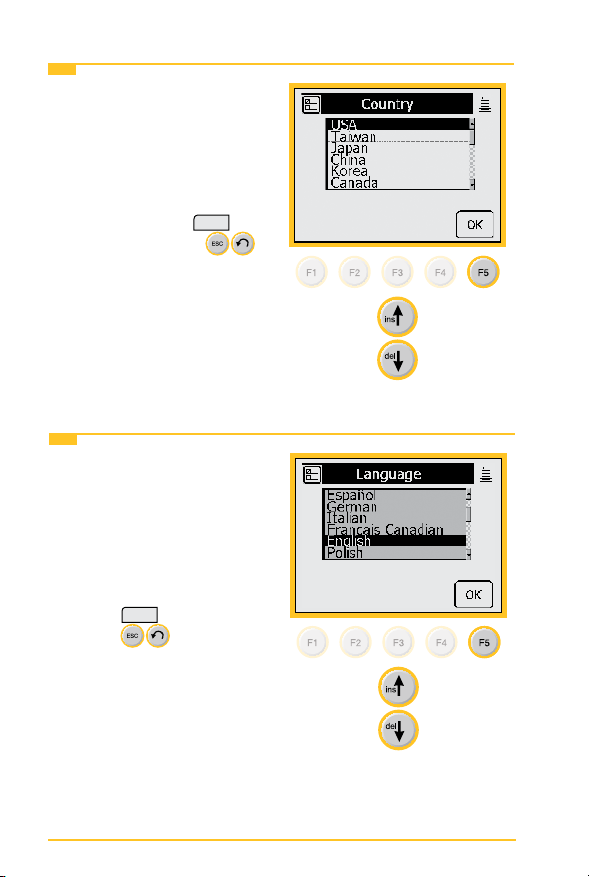

Country

1. Use the Country setup to

congure the tester for a

specic country. Selecting a

new country will congure

the tester with the setups

for language, units, clock

format, wire gauges,

and cable types for that

particular country. Press

or to review the current

settings.

to review the

Change

to make changes

9

Page 10

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

Country

2. Use the up and down arrow

keys to highlight a country.

You will be warned about

changing country-specic

default values and asked

to conrm or cancel your

selection. Press

continue or press

OK

to

to quit without making

changes.

Language

1. Use the Language setup to

change only the language

in the tester. Country-

specic default values are

not affected. Use the up

and down arrow keys to

highlight a new language.

OK

Press

press

making changes.

to continue or

to quit without

10

Page 11

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

Module

1. Use the Module setup to

select the type of module

that is installed in your

tester. The module type is

listed on the label on the

module.

Use the up and down arrow

keys to highlight Module.

Change

Press

to make

changes or to review the

current settings.

Network Setup

1. Use Network Setup

to change network

options used to connect

to computers or ADSL

circuits.

Use the up and down arrow

keys to highlight Network

Setup. Press

make changes or to review

the current settings.

Change

to

11

Page 12

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

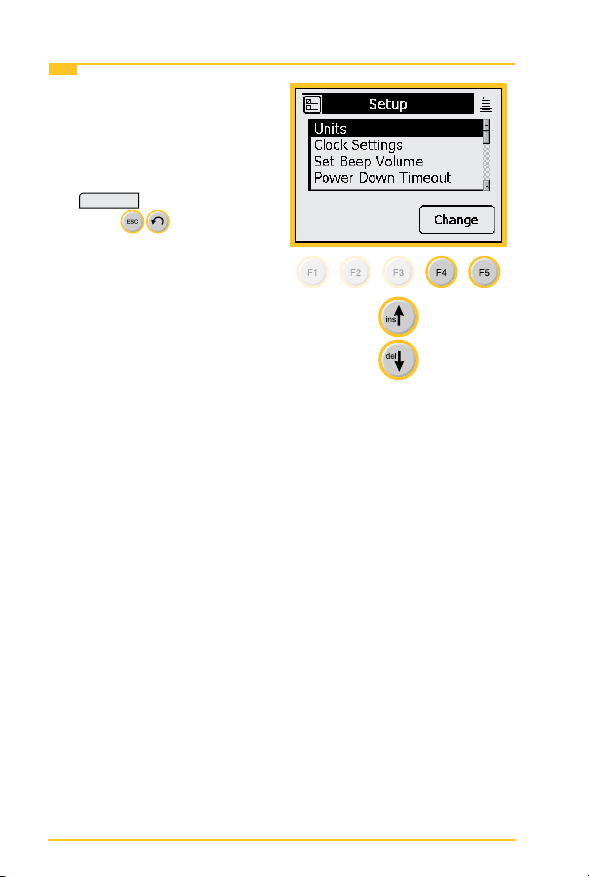

Units

1. Use the Units menu

to change the Units of

Measure. Use the up

and down arrow keys to

highlight Units. Press

Change

to continue or

press

making changes.

to quit without

12

Page 13

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

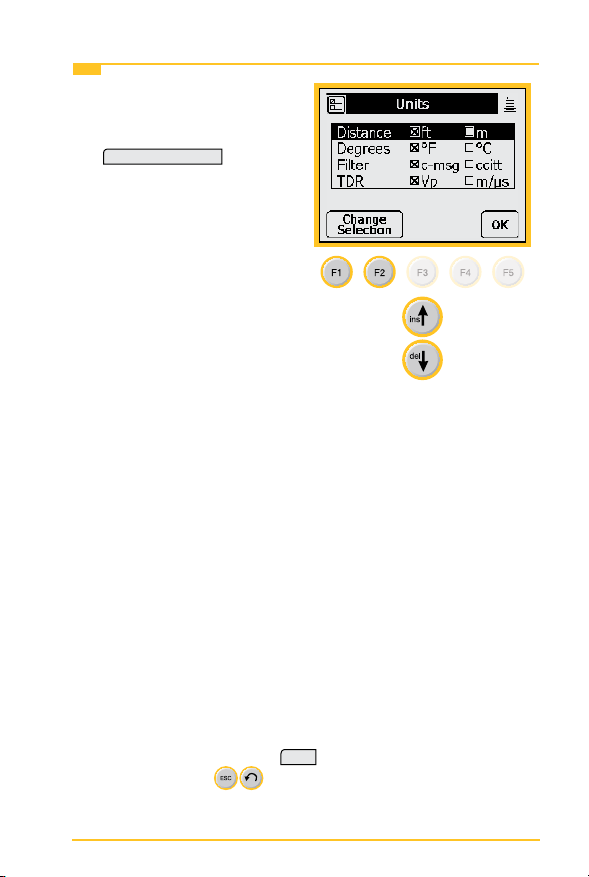

Units

2. Use the up and down arrow

keys to select the units

you want to change. Press

Change Selection

the units of measure. An

“X” in a box indicates your

choice.

Distance: Feet or Meters:

This affects all distances

displayed in the 965AMS

tester.

Degrees: Fahrenheit or

Centigrade: This affects all

temperatures used in the

965AMS tester.

Filter: C-Message or CCITT: This affects the lter

used in the POTS Noise function. Use the C-Message

lter in the US and Canada. Use the CCITT (also called

“Psophometric”) lter in all other countries.

The 965AMS tester features a dBrnP lter for noise tests

in New Zealand. To set the default noise lter to dBrnP, set

Filter option to CCITT. This lter is used only in units sold

in New Zealand; for all other countries, the CCITT option

uses a dBrnOp lter. Noise test results will be displayed

as dBrnP.

to change

TDR: Vp (Velocity Propagation) or m/µS (meters

per microsecond): This affects the TDR “velocity of

propagation.” Use “Vp” in the US and Canada. Use “m/µS”

in other countries. Press

return. Use the

OK

to accept any changes and

key to return to the Welcome Screen

without making changes.

13

Page 14

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

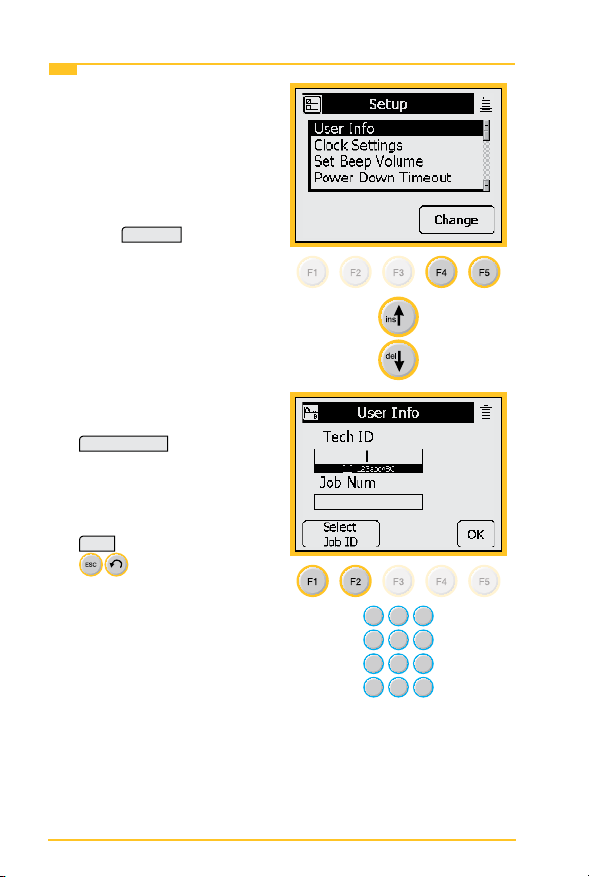

User Info

1. Select User Info to add

your Tech ID and job

number to be added to

saved test results.

Use the up and down arrow

keys to highlight User Info.

Change

Press

changes or to review the

current settings.

2. Use the blue keys to enter

your ID, name, etc. Press

Select Job ID

the Job Num eld.

Use the blue keys to enter

a job number or ID. Press

OK

to continue or press

making changes.

to make

to highlight

to quit without

14

Page 15

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

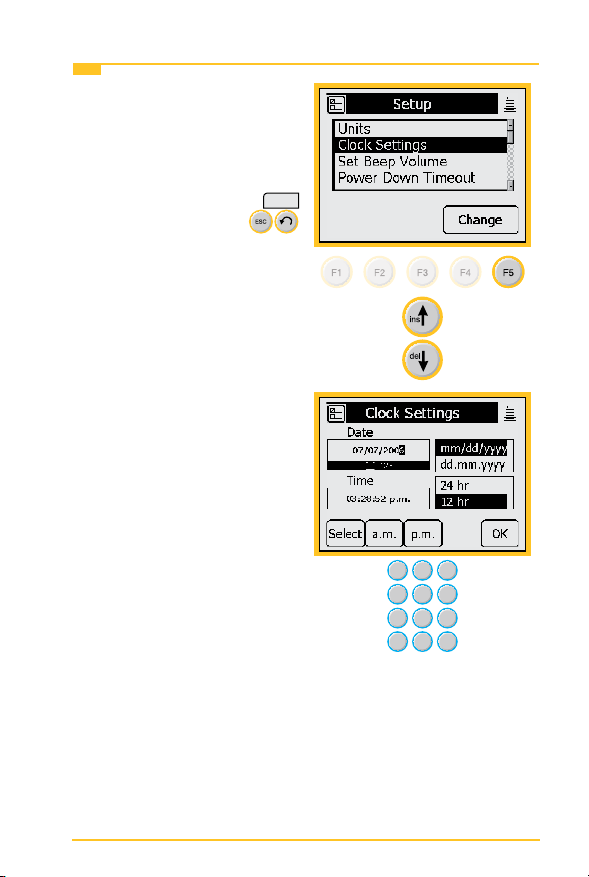

Clock Settings

1. Use the Clock Settings

menu to select the clock

format and to set the

correct time. Use the up

and down arrow keys to

highlight Units. Press

to continue or press

to quit without making

changes.

2. Use the blue keys to enter

the correct date.

OK

15

Page 16

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

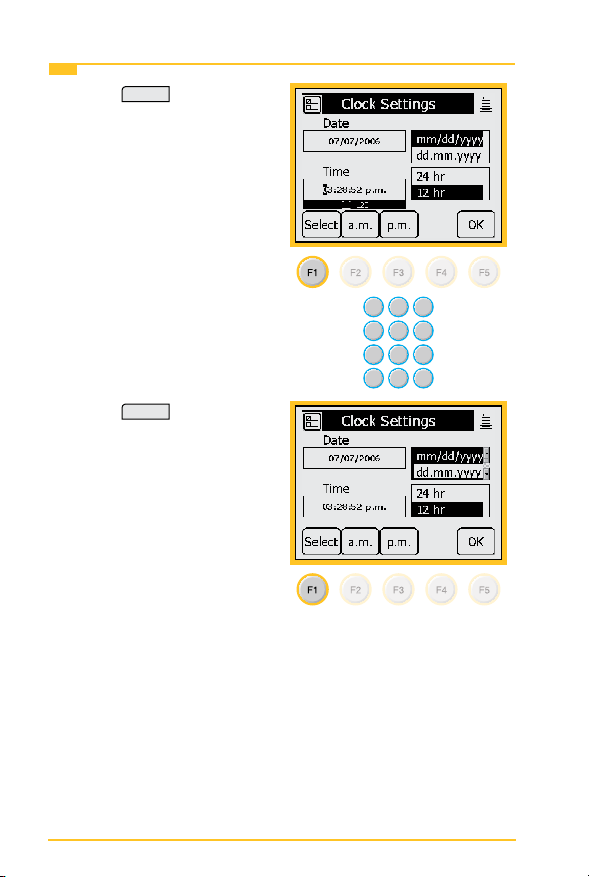

Clock Settings

3. Press

Select

, then enter the

correct time using the blue

keys.

4. Press

Select

to enter the

date format. Choose month,

day, year or day, month,

year.

16

Page 17

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

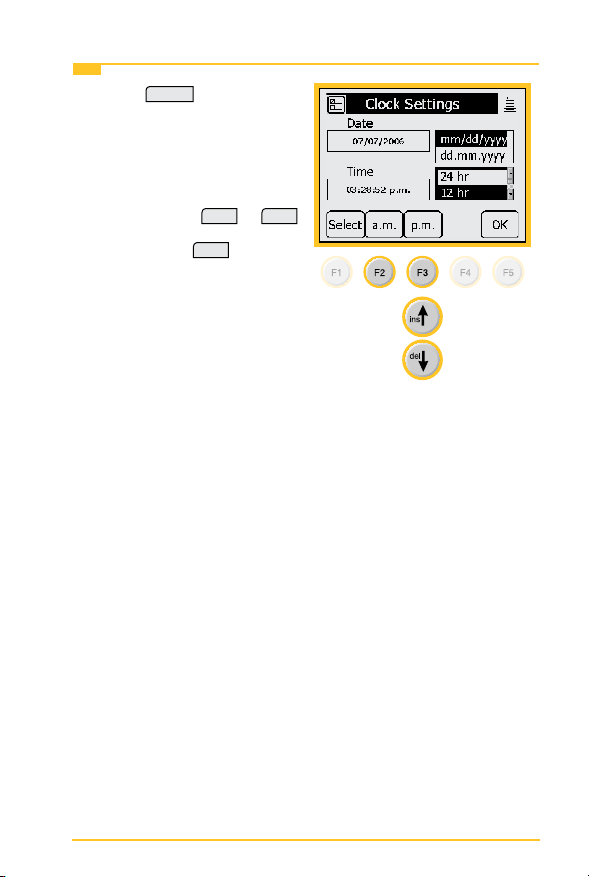

Clock Settings

5. Press

Select

to choose the

12-hour or 24-hour format.

Use the up and down arrow

keys to select the format.

If you choose the 12-hour

a.m.

at

or

p.m.

format, press

Note: Press

OK

any time that you have

completed your updates.

.

17

Page 18

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

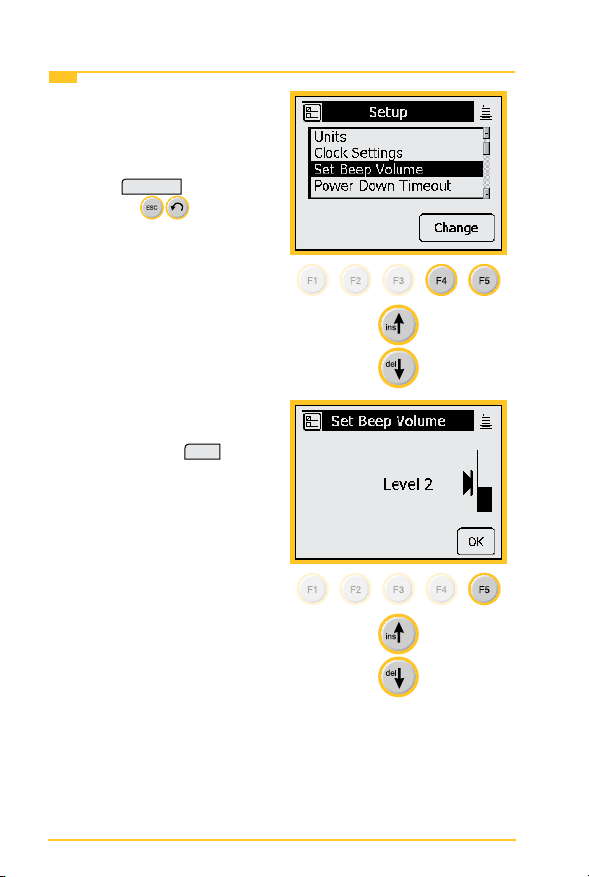

Set Beep Volume

1. Use this menu to change the

Set Beep Volume. Use the

up and down arrow keys to

highlight Set Beep Volume.

Change

Press

or press

without making changes.

2. Use the up and down arrow

keys to change the beep

volume. Press

this volume setting.

to continue

to quit

OK

to save

18

Page 19

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

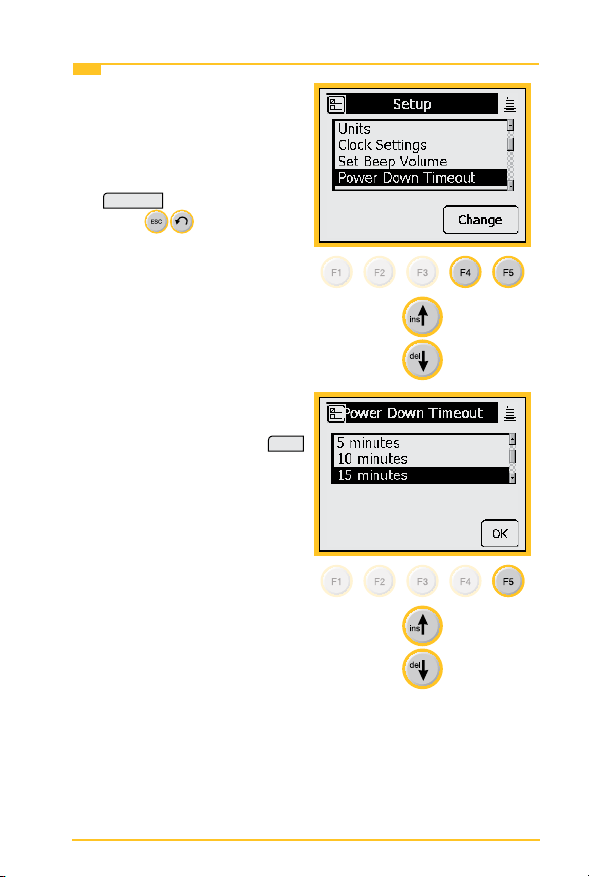

Power Down Timeout

1. Use this menu to change

the Power Down Timeout.

Use the up and down arrow

keys to highlight Power

Down Timeout. Press

Change

to continue or

press

making changes.

2. Use the up and down arrow

keys to select the timeout

you want to use. Press

to save your choice.

to quit without

OK

19

Page 20

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

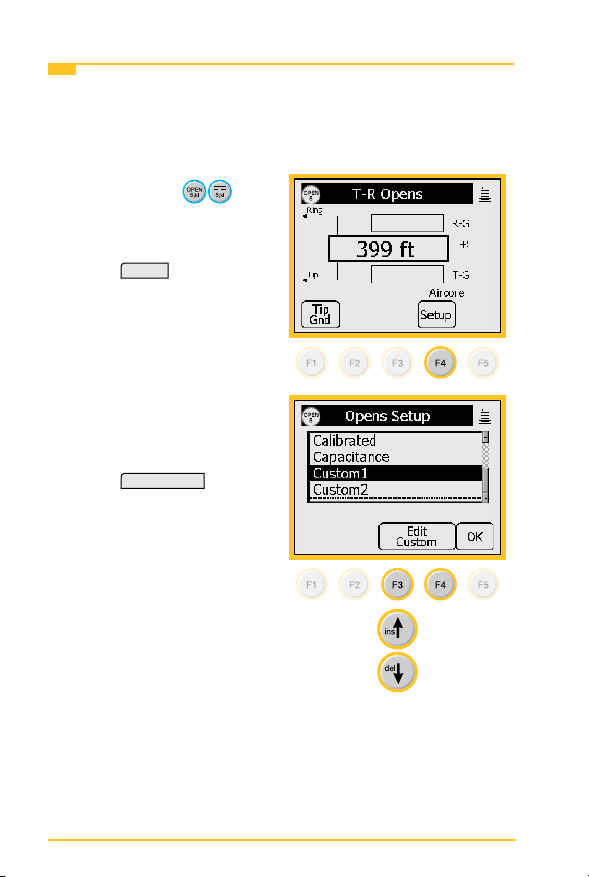

Custom Cable

Use Custom Cable 1 or Custom Cable 2 to create a special

cable you are using on a regular basis that has capacitance

values that are different from existing cables. You can also

access this function in the Opens Setup menu.

1. Press the blue

key to enter the Opens

measurement function.

2. Press

Setup

to enter the

Setup menu.

3. Use the up and down arrow

keys to select Custom 1 or

Custom 2.

Press

Edit Custom

.

20

Page 21

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

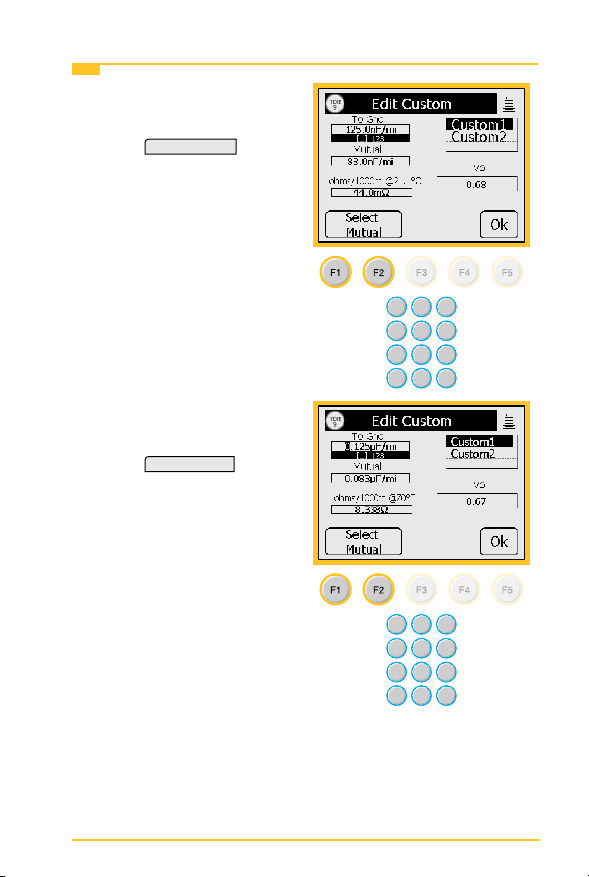

Custom Cable

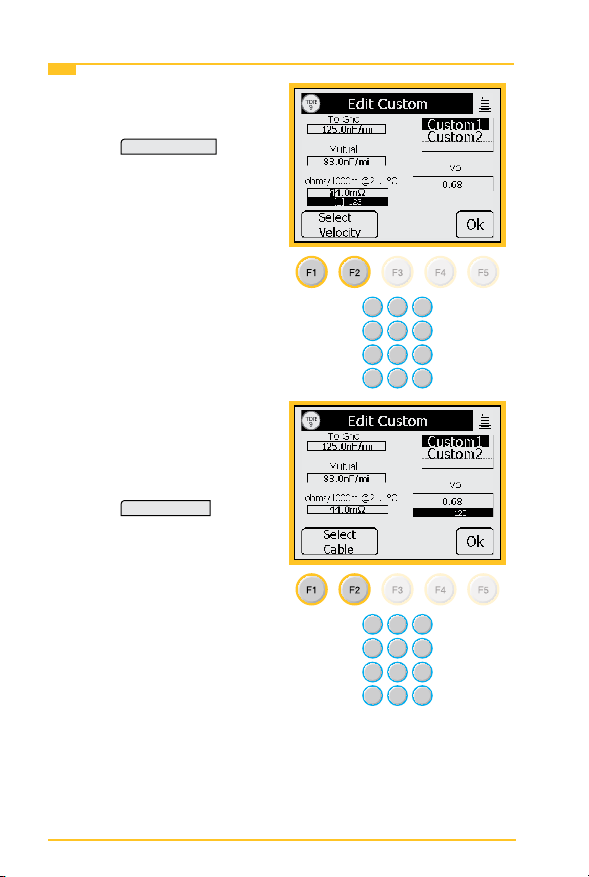

4. Use the blue keys to enter

the capacitance to ground.

Press

5. Use the blue keys to enter

Press

Select Mutual

.

the mutual capacitance.

Select Ohms

.

21

Page 22

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

Custom Cable

6. Use the blue keys to enter

ohms per thousand feet.

Press

7. Use the blue keys to enter

Press

Select Velocity

.

the velocity propagation. If

you do not know this value,

use 0.68.

Select Cable

.

22

Page 23

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

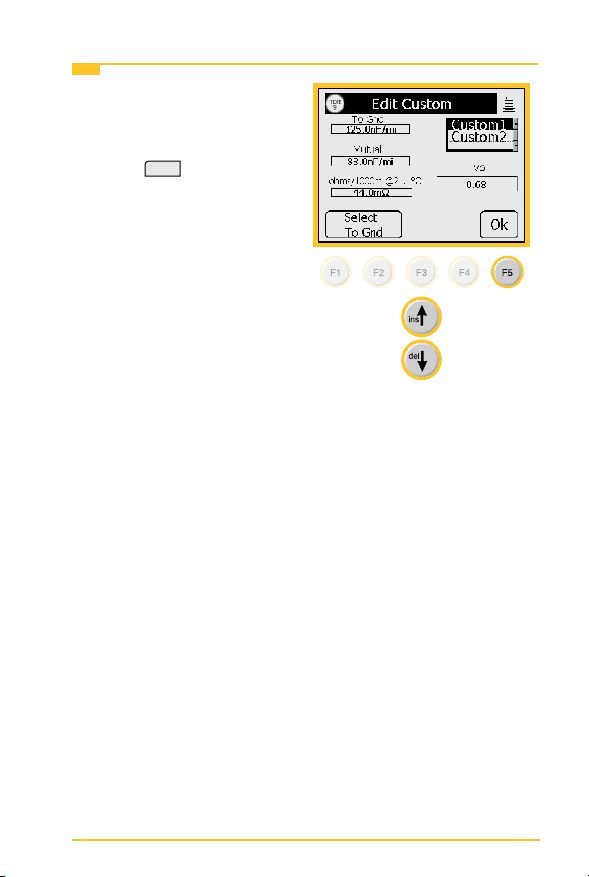

Custom Cable

8. Use the up and down arrow

keys to select Custom 1 or

Custom 2.

Press

OK

to save the

custom cable.

23

Page 24

System Setup 3M™ Dynatel™ Advanced Modular System 965AMS

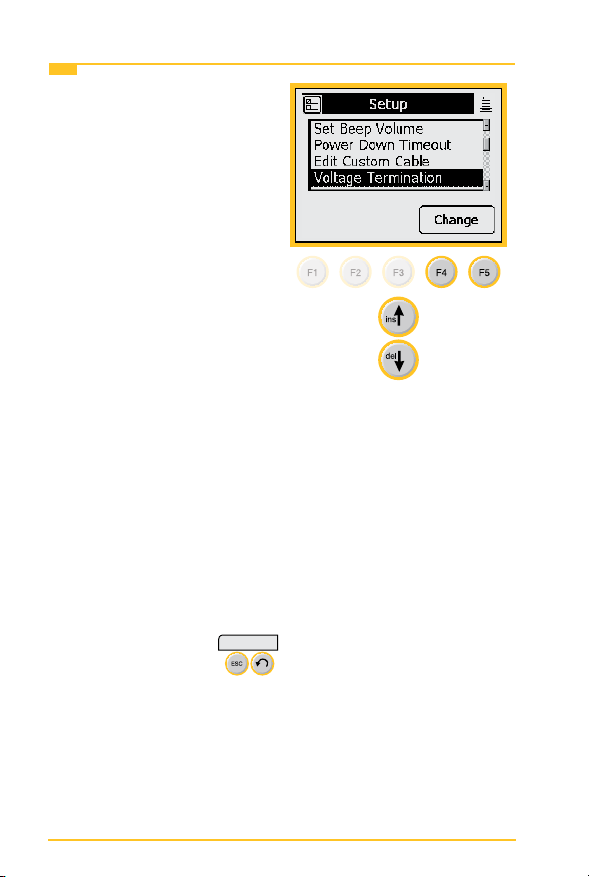

Voltage Termination

1. The Voltage Termination

option allows you to select

the input impedance of the

965AMS digital voltmeter

(in supported countries

only). The input impedance

of the internal 965AMS

voltmeter is normally

1Mohm. However, some

legacy systems use voltage

measurement systems

with input impedances of

100Kohms. This option

is provided to maintain

measurement compatibility

with those systems.

If 100Kohm termination is

selected, the 965AMS tester

will display ‘100K’ on the

voltage measurement.

Use this menu to change

the Voltage Termination.

Use the up and down arrow

keys to highlight Voltage

Termination. Press

to continue or press

to quit without making

changes.

Change

24

Page 25

3M™ Dynatel™ Advanced Modular System 965AMS System Setup

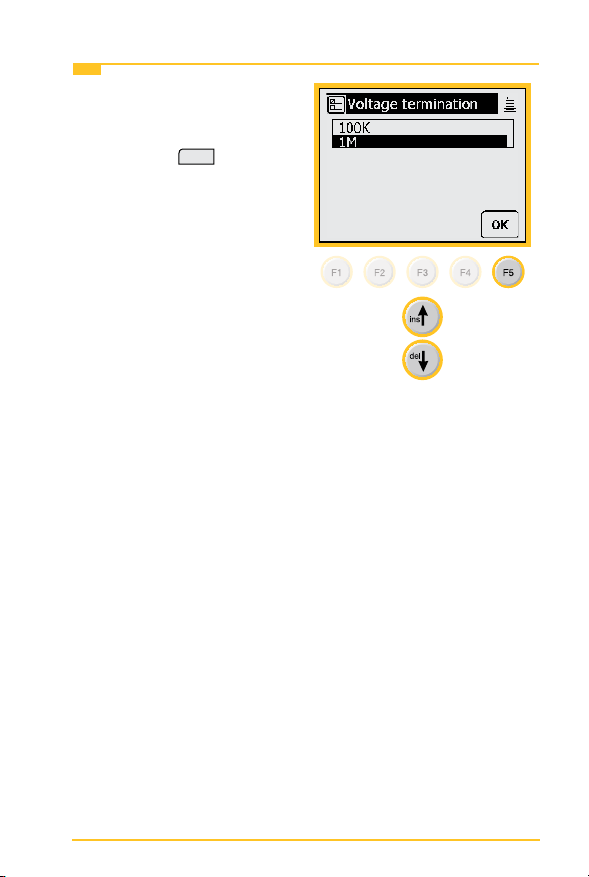

Voltage Termination

2. Use the up and down arrow

keys to select the Voltage

Termination you want to

use. Press

your choice.

OK

to save

25

Page 26

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Measurement Functions

The 12 measurement functions include:

DC and AC voltage measurements

milliAmps and ground resistance measurements

Ohms measurement and Soak Test

Self-Calibrate, Stored Results and Ohms-to-Distance

Calculator

Opens distance measurement

Send Tones

Resistance Fault Locate: Distance measurement to a

resistive fault

DSL Loss and Noise plus the Spectrum Analyzer and

Resistance Balance

Time Domain Reectrometer (TDR)

POTS Loss, Noise, Longitudenal Balance, Load Coil

Counter and Caller ID

Automatic testing of circuits using “Expert Pair Tests”

Talk Set

#

26

Page 27

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Volts-DC or AC

The Volts function measures the DC voltage or AC voltage

between Tip, Ring and Ground.

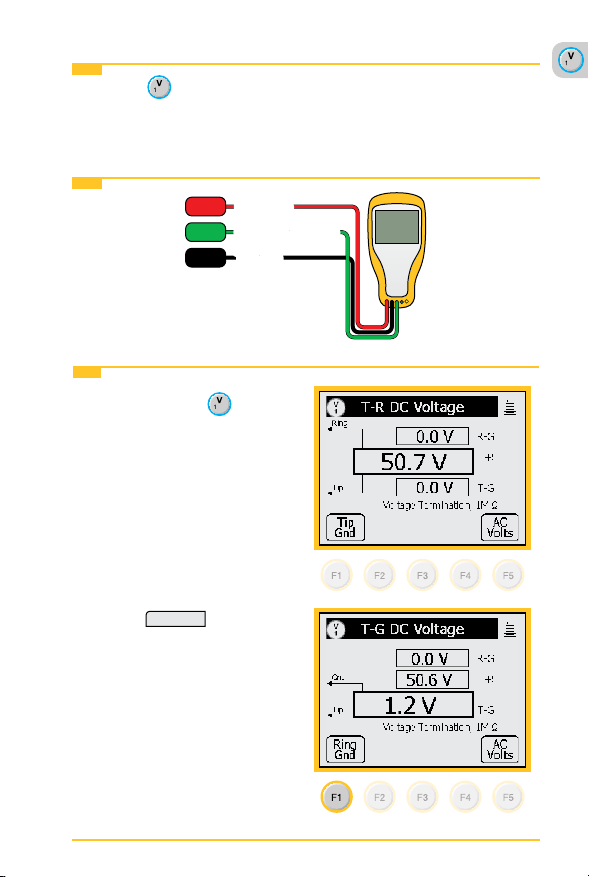

Volts-DC or AC>Hook-Up

RED

Ring (B)Ring (B)

GRN

Ground (Earth)

Ground (Earth)

BLK

Tip (A)

Tip (A)

Volts-DC or AC>Operation

1. Press the blue

key

to start the voltage

measurement function.

2. This screen displays the

T-R voltage in the larger

active measurement box.

3. Press

Tip Gnd

to display

the T-G voltage. The T-R

measurement will be

saved on the screen in a

smaller box until a new

measurement updates the

screen.

27

Page 28

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

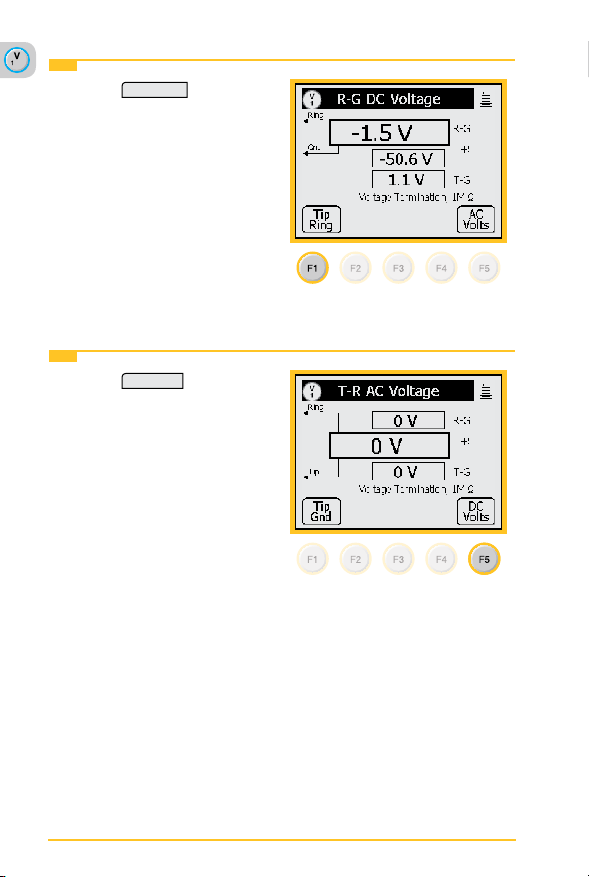

Volts-DC or AC>Operation

4. Press

Ring Gnd

to display

the R-G voltage. The

T-G measurement will be

saved on the screen in a

smaller box until a new

measurement updates the

screen.

5. All measurements are erased when you exit this function.

Volts-DC or AC>AC Volts

1. Press

AC Volts

to measure

AC volts.

AC Normal Range—Active Line:

1. R-G and T-G should have the same AC voltage. If they are

not equal the pair will probably have noise.

2. T-R should be 0 volts

Note: Maximum voltage = 300 volts DC, 250 volts AC

28

Page 29

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

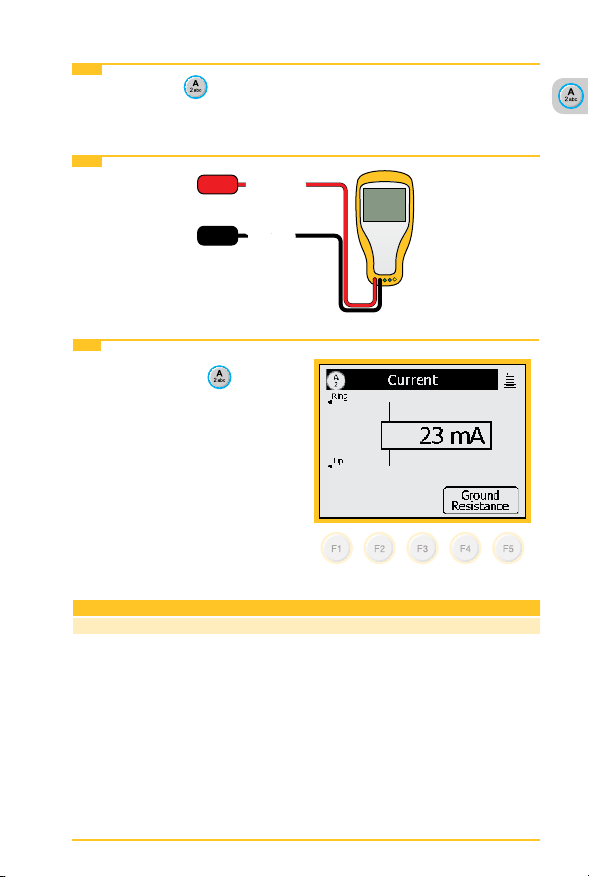

Loop Current

Loop Current measures the loop current in an active line.

Loop Current>Hook-Up

RED

Ring (A)Ring (A)

BLK

Tip (B)

Tip (B)

Loop Current>Operation

1. Press the blue

key to

start this test.

2. This is a continuous

measurement until you

disconnect the test leads or

choose another function.

Normal Measurements

Current >23mA 20-23mA <20mA

29

OK Marginal Not OK

Page 30

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Loop Current>Operation

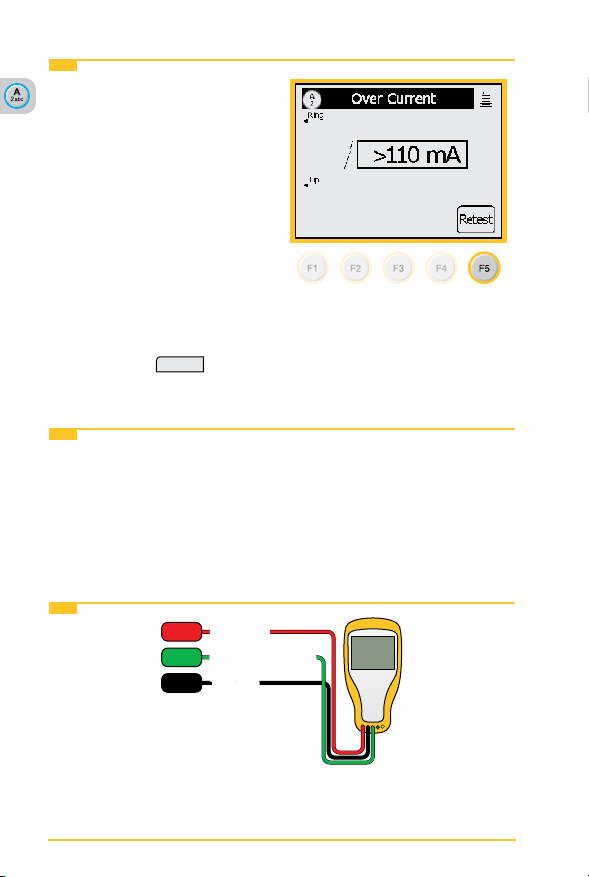

3. Over Current Warning

The tester has detected

a current greater than

110 mA.

Over current can damage

the test set. Use standard

safety practices for

disconnecting the test leads

and eliminating the source

of the over current.

Disconnect all test leads

then press

Retest

to

continue.

Loop Current>Ground Resistance

The Ground Resistance function compares the customer

protector ground resistance to an active central ofce pair.

Note: The Ground Resistance function only works with central

ofces with the Tip connected to ground.

Loop Current>Ground Resistance>Hook-Up

RED

Ring (B)Ring (B)

GRN

Ground (Earth)

Ground (Earth)

BLK

Tip (A)

Tip (A)

30

Page 31

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Loop Current>Ground Resistance>Operation

1. Press the blue

key to

start this test.

Press

Gnd Resistance

to access the Ground

Resistance function.

2. Press

Test

to start the

test. The results will be

displayed in the box in the

center of the screen.

3. This is not a continuous

test. Press

Test

to see an

updated result.

Normal Measurements

0 Ω to 25 Ω

31

Page 32

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Ohms Measurements

The Ohms Measurement function measures the insulation

resistance between the Tip, Ring and Ground. This function

can also measure the resistance of the Tip and Ring loop or

individual wires.

Ohms Measurements>Hook-Up

RED

Ring (B)Ring (B)

GRN

Ground (Earth)

Ground (Earth)

BLK

Tip (A)

Tip (A)

Ohms Measurements>Operation

1. Press the blue

key to

start the ohms measurement

function.

2. This screen displays the

T-R resistance in the larger

active measurement box.

32

Page 33

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Ohms Measurements>Operation

3. Press

Tip Gnd

to display

the Tip-Ground resistance.

The T-R measurement will

be saved on the screen in

a smaller box until a new

measurement updates the

screen.

4. Press

Ring Gnd

to display the

Ring-Ground resistance.

The T-G measurement will

be saved on the screen in

a smaller box until a new

measurement updates the

screen.

5. All measurements are erased when you exit this function.

Normal Range: POTS Insulation Resistance

Insulation Resistance >3.3 MΩ 80 kΩ to 3.3 MΩ <80 kΩ

OK Marginal Not OK

33

Page 34

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Ohms Measurements>Voltage Compensation

The Voltage Compensation

feature compensates for

crossed battery on the line.

Use “compensated” for most

measurements.

Press

V Comp

to turn voltage

compensation off and on. The

screen displays “Compensated”

or “Not Compensated.”

Ohms Measurements>Soak Test

The Soak Test function can

determine if the source of a

resistive fault is caused by

moisture, corrosion or pure

resistance by applying a current

to the circuit and measuring a

change in resistance.

Soak Test

Press

to access the

Soak Test menu.

NOTE: The Soak Test function

will not work properly if there

is voltage on the line. Voltage

Compensation does not apply

to the Soak Test.

34

Page 35

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

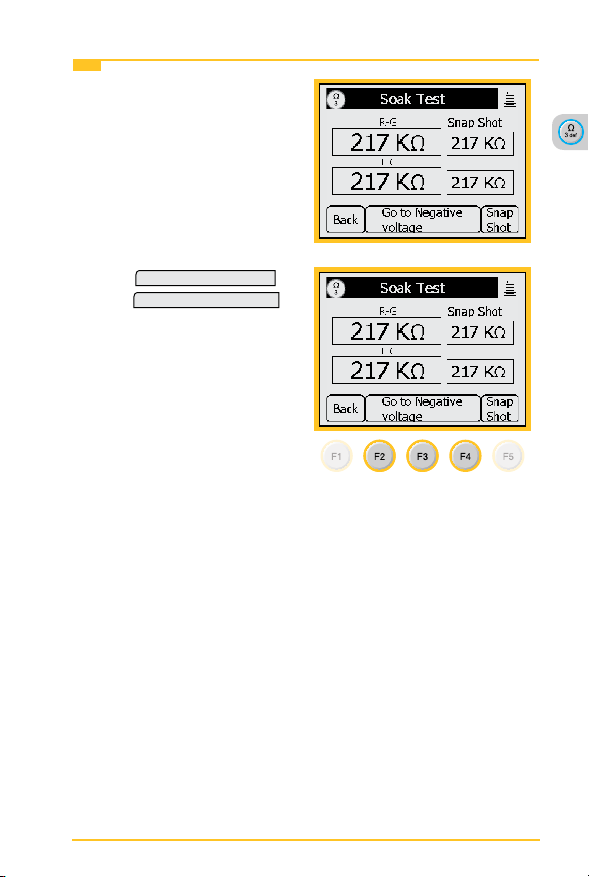

Ohms Measurements>Soak Test

1. Take an initial resistance

measurement by pressing

Snap Shot

the

key.

2. You will compare this to

other active measurements

to determine the source of

the fault.

3. One of the properties of

moisture in a circuit is that

the current from the tester

can “dry out” the moisture.

The display will rst show

a lower resistance, then

after one or two minutes the

resistance will increase to a

higher reading.

Initial Reading

This indicates the fault is

caused by moisture.

Note: This is not an

acceptable procedure to

“dry” a fault.

Reading After 1 or 2 Minutes

35

Page 36

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Ohms Measurements>Soak Test

4. A property of corrosion

is that a current owing

through the corrosion will

cause the corrosion to

become a better conductor.

The display will show a

lower resistance reading if

corrosion is the cause.

Initial Reading

Reading After 1 or 2 Minutes

36

Page 37

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Ohms Measurements>Soak Test

5. If the resistance value does

not change, the fault is a

pure resistive fault.

and

Go To Positive Voltage

Go To Negative Voltage

to

6. Use

reverse the voltage polarity.

Use the lowest resistance

reading of the two numbers

for your measurements.

37

Page 38

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Toolbox

Use the Toolbox to: (1) view saved test results,

(2) perform a self calibrate, (3) use the Ohms to Distance

calculator, (4) use Internet Explorer and (5) Upload results to the

965AMS Results Manager.

Toolbox>Stored Results

The Stored Results function allows you to review the results of

previously saved tests.

Toolbox>Stored Results>Operation

1. Press the blue

key to

enter the Toolbox function.

Use the up and down arrow

keys to select the Stored

Results function. Press

OK

to save your choice.

38

Page 39

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Toolbox>Stored Results>Operation

2. If one or more test results

have been stored, the ID

number for each will be

displayed.

The ID number is like a le

folder and each test result

is like a le. The name of

the le is the time and date

stamp that is generated by

the tester.

Press

View

to see the list

of les.

3. This screen shows the

contents of the le.

Press

Delete Result

to

delete one le or press

Delete Folder

to delete all

les in the folder.

39

Page 40

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Toolbox>Self-Calibrate

The Self-Calibrate function will verify that all of the internal

circuits and test leads are operating properly. Use self-calibrate:

• After the rst full battery charge before you put the tester in

service for the rst time.

• Anytime the working temperature changes by more than

35°F (20°C). Calibrate the 965AMS tester at the same

temperature at which it will be used.

• After changing the batteries, or anytime the battery pack

completely discharges.

Toolbox>Self-Calibrate>Hook-Up

RED

GRN

BLK

YEL

BLU

All five leads are shorted together.

40

Page 41

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Toolbox>Self-Calibrate>Operation

1. Press the blue

key to

enter the Toolbox function.

2. Use the up and down arrow

keys to select the SelfCalibrate function. Press

OK

to save your choice.

3. The calibration may take up

to 1 minute to complete.

41

Page 42

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

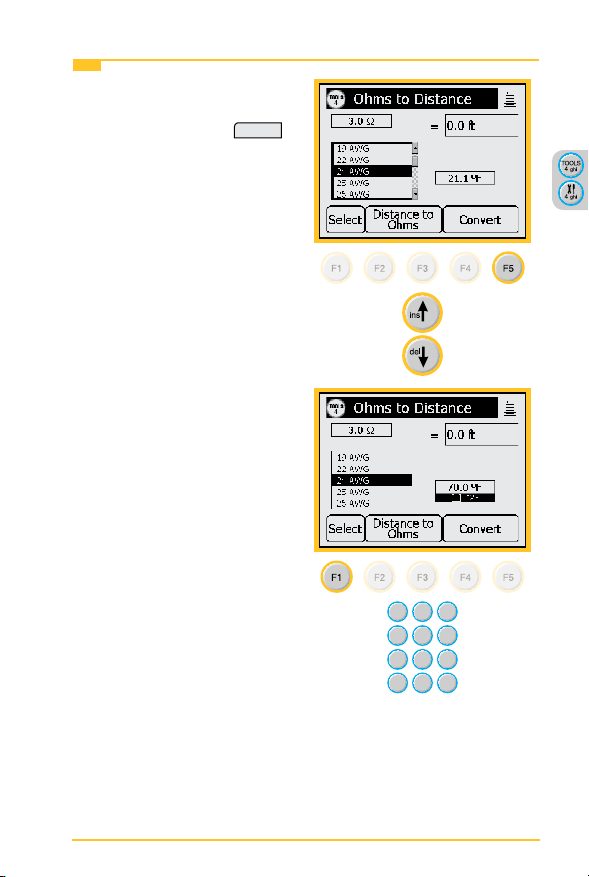

Toolbox>Ohms-to-Distance Calculator

Use this function to convert from Ohms to Distance or Distance

to Ohms based on temperature and wire gauge.

Toolbox>Ohms-to-Distance Calculator>Operation

1. Press the blue

key to

enter the Toolbox function.

2. Use the up and down arrow

keys to select the Ohms-toDistance Calculator. Press

OK

to save your choice.

3. Use the blue keys to enter

the Ohms value. Press

Select

to save and highlight

the wire gauge selection.

42

Page 43

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Toolbox>Ohms-to-Distance Calculator>Operation

4. Use the up and down

arrow keys to select the

wire gauge. Press

Select

to save and highlight the

temperature eld.

5. Use the blue keys to enter

the temperature.

43

Page 44

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Toolbox>Ohms-to-Distance Calculator>Operation

6. Press

Convert

to nd the

distance.

7. Select

Distance to Ohms

if you want to convert a

distance to an Ohms value.

Internet Explorer

1. Internet Explorer is

available on the VDSL2

module.

2. Use the up and down arrow

keys to select Internet

Explorer. Press

save your choice.

OK

to

44

Page 45

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Toolbox>965AMS Results Manager

The 965AMS tester uses the 965AMS Results Manager to

upload and convert les from the tester. The following les are

supported by the 965AMS Results Manager:

• Single Trace TDR

• Active POTS Autotests

• Vacant POTS Autotests

• Wideband Autotests

• xDSL Link Metrics

• xDSL Bin Graphs

Note: Only results listed above will be converted using the

965AMS Results Manager.

Toolbox>965AMS Results Manager>Software Installation

Visit www.3m.com/dynatel to nd the latest 965AMS Results

Manager.

You will need to install the following software before using the

Results Manager:

1. The following Microsoft software:

a. DotNetFX 2.0 or higher

b. Activesync 4.2 or higher

Note: Visit www.microsoft.com and search for each le

download.

2. The following 3M software will be needed.

a. 3M_Usb_Driver

b. 965AMS Results Manager

Note: Visit www.3m.com/dynatel to download the les.

45

Page 46

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

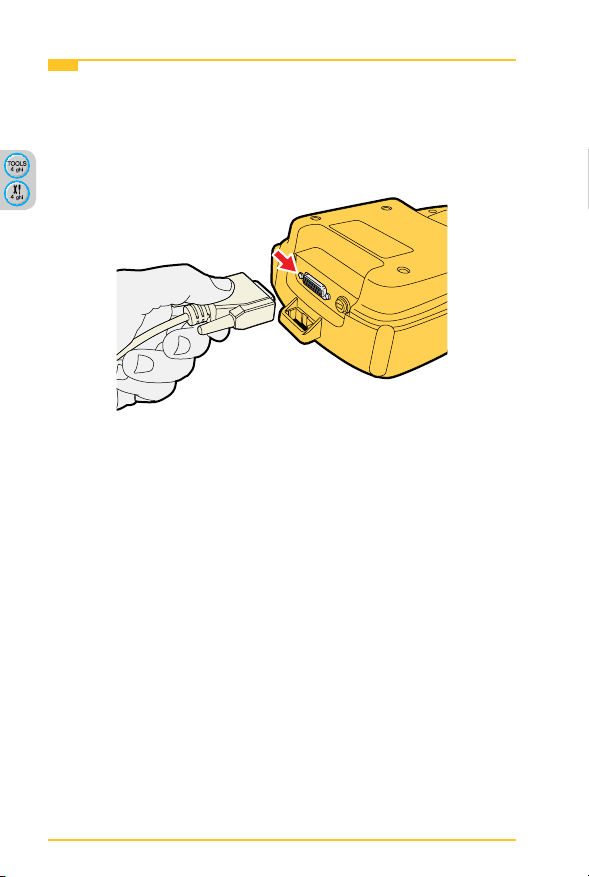

Toolbox>965AMS Results Manager>Connections

1. Turn on the 965AMS tester and allow the unit to boot up.

2. Connect the 965AMS tester to power.

3. Connect the 965AMS tester to the PC via the USB to 15-pin

cable.

Note: If the “Welcome to Found New Hardware Wizard”

window appears then select “No, not this time” when asked

about connecting to Windows Update.

4. Select “No” when prompted to Set Up a Partnership.

46

Page 47

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Toolbox>965AMS Results Manager>Copying Files

To copy les that are saved in a 3M Dynatel 965AMS:

1. Click on the le labelled 965AMS_Results_Manager.exe.

2. Press the Copy All XML_Results Files From 965AMS

to PC.

3. You can also delete all the les on the PC.

Note: Wait until you have veried that you are nished with

the les before deleting.

4. After you have selected a directory to save the les you

will see a progress bar and a notication of completion

when nished.

Toolbox>965AMS Results Manager>Converting Upgraded Files

To convert your saved les to HTML:

1. Start the 965AMS Results Manager.

2. Click on the tab labeled “Files on PC.”

3. Press the “Convert XML Results Files on PC to HTML for

viewing.”

47

Page 48

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Opens

Opens measures the distance to an “open” circuit. This

could be a broken wire, a cut pair or the end of the circuit.

Opens>Hook Up

RED

Ring (B)Ring (B)

GRN

Ground (Earth)

Ground (Earth)

BLK

Tip (A)

Tip (A)

Opens>Operation

1. Press the blue

key to enter the Opens

measurement function.

2. Press

Setup

Setup menu.

48

to enter the

Page 49

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Opens>Operation

3. Use the up and down arrow

keys to choose the type of

cable that best describes

your cable. Press

OK

to

save your choice.

4. This screen displays the

T-R distance in the larger

active measurement box.

Press

Tip Gnd

to display

the T-G distance.

5. The T-R measurement will

be saved on the screen in

a smaller box until a new

measurement updates the

screen.

Press

Ring Gnd

to display

the R-G distance.

49

Page 50

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Opens>Operation

6. The T-G measurement will

be saved on the screen in

a smaller box until a new

measurement updates the

screen.

7. All measurements are erased when you exit this function.

Normal Range: A good pair should have the T-G and R-G

within about 2% of each other. If they are not within 2%, the

shortest distance will be the location of the fault and the other

distances will not provide accurate distances. Typically this will

be an open ground bond or a broken Tip or Ring.

Note: “Opens” is more accurate if other cable pairs are active.

If other pairs are not active, short at least 30% of the inactive

pairs to the cable shield.

50

Page 51

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Opens>Calibrate Cable

Use this function to measure the capacitance of a known good

pair within a cable of known length. This value can be used as

a ‘Calibrated Cable’(or ‘reference’) to nd the distance to an

‘open’ on the same or similar cable.

1. Press

2. Press

Setup

.

Calibrate Cable

.

51

Page 52

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Opens>Calibrate Cable

3. Use the blue keys to enter

the known distance.

Measure

Press

.

4. The screen will display the

measured capacitance per

distance for the reference

pair.

52

Page 53

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Tone

Use Tone to send a tone on a pair.

Tone>Set-Up

RED

Ring (B)Ring (B)

GRN

Ground (Earth)

Ground (Earth)

BLK

Tip (A)

Tip (A)

Tone>Operation

1. Press the blue

key to

enter the Tone function.

2. Use the up and down

arrow keys to highlight the

frequency that you want to

use.

53

Page 54

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Tone>Operation

3. Press

tone.

4. Press

tone.

Send Tone

Stop Tone

to send the

to stop the

54

Page 55

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Tone>Edit The Frequency Of A Tone

There are 10 frequencies that can be stored in memory. If you

need a different frequency you can edit any of the displayed

frequencies and change to a new frequency.

1. Use the up and down arrow

keys to select one of the

frequencies to change.

2. Press Setup to adjust the

highlighted selection with

the following frequency

range:

ID - 200 Hz and 1,000 Hz

Precision - 200 Hz and

19,999 Hz

Wideband (965AMS Pro

tester 2) - 20 kHz and 2200

kHz.

(965AMS Pro 30 tester) -

20 kHz and 30 MHz.

3. For this example we will

replace 196 kHz with

138 kHz. Use the up and

down arrow keys to select

Wideband Tone.

55

Page 56

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

Tone>Edit The Frequency Of A Tone

4. Use the blue keys to enter

the frequency in kHz.

OK

5. Press

.

Tone>Applications

The Tone function can be used for three applications: ID Tone,

Precision Tone and Wideband Tone.

Tone>Applications>ID Tone

1. Use the ID Tone for pair identication and tone coiling.

2. The ID tone is always an interrupted tone.

3. The frequency is adjustable between 200 Hz and 1,000 Hz.

4. The 965AMS tester automatically goes off-hook when an ID

tone is sent.

5. The volume control on the 965AMS tester controls the

volume you hear, but the output to the far end is set at a

xed level.

56

Page 57

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

Tone>Applications>Precision Tone

1. Use the Precision Tone to send a tone.

2. Use another 965AMS tester to receive the tone. Press the

blue key, then select

Loss

.

3. The output frequency of the Precision tone is adjustable

between 200Hz and 19,999Hz.

4. The output level range is –20dBm to +1dBm.

5. The most common frequencies for POTS lines are 404Hz,

1004Hz and 2804Hz.

6. The impedance is xed at 600Ω.

7. Press

8. Press

Send Tone

Stop Tone

to send the Precision tone.

to stop the Precision tone.

Tone>Application>Wideband Tone

1. Use the Wideband Tone to send a tone to the other end of a

wideband circuit to measure the signal loss.

2. Use another 965AMS tester to receive the tone.

3. Press the blue

key, then select

DSL Loss

.

4. The output frequency of the Wideband tone is adjustable

between 20kHz and 2200kHz.

5. The output level is xed at 0dBm.

6. The impedance can be set to 100Ω or 135Ω.

7. Press

8. Press

57

Send Tone

Stop Tone

to send the wideband tone.

to stop the wideband tone.

Page 58

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL (Resistance Fault Locate)

Use RFL to nd the distance to a short or ground.

Important Note: You must rst use the Auto test

Ohmmeter

, to determine the type of fault.

1. There are two types of hook-ups, Separate Pair and Single

Pair. Separate Pair is more accurate, but it requires hooking

up more wires. The “Good” wires can be any gauge and any

length. As an example, the Good wires can be jumper wire.

Separate Pair is recommended for applications where you

have a short or ground in an aerial cable or a direct buried

cable and you want to nd the fault the rst measurement.

2. Single Pair requires that the “Good” wire is the same gauge

and length as the faulted wire. Single Pair is appropriate for

situations where you are looking for the fault to be in the

nearest pedestal.

3. RFL has the ability to nd the distance to a short or ground

using a single section of cable or a section with multiple

gauges. Select Single- or Multi-section for your situation.

RFL>Hook-Up

There are ten possible scenarios for connecting a 965AMS tester

to use the RFL function:

Tip-Ground Separate Pair

, or the

GRN

Ground (Earth)Ground (Earth)

BLK

Tip (A) 1/Fault

Tip (A) 1/Fault

YEL

Ring (B) 2/Good

Ring (B) 2/Good

BLU

Tip (A) 2/Good

Tip (A) 2/Good

58

Fault

Strap

Page 59

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

BLK

Tip (A) 1/FaultTip (A) 1/Fault

GRN

YEL

BLU

Strap

Ground (Earth)Ground (Earth)

Ring (B) 2/Good

Ring (B) 2/Good

Tip (A) 2/Good

Tip (A) 2/Good

Fault

RFL>Hook-Up

Ring-Ground Separate Pair

RED

GRN

YEL

BLU

Short Separate Pair

RED

BLK

YEL

BLU

Tip-Cross Separate Pair

Ring (B) 1/FaultRing (B) 1/Fault

Ground (Earth)

Ground (Earth)

Ring (B) 2/Good

Ring (B) 2/Good

Tip (A) 2/Good

Tip (A) 2/Good

Ring (B) 1/FaultRing (B) 1/Fault

Tip (A) 1/Fault

Tip (A) 1/Fault

Ring (B) 2/Good

Ring (B) 2/Good

Tip (A) 2/Good

Tip (A) 2/Good

Fault

Fault

Strap

Strap

59

Page 60

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Hook-Up

Ring-Cross Separate Pair

RED

GRN

YEL

BLU

Tip-Ground Single Pair

RED

GRN

BLK

Ring-Ground Single Pair

RED

GRN

BLK

Ring (B) 1/FaultRing (B) 1/Fault

Ground (Earth)Ground (Earth)

Ring (B) 2/Good

Ring (B) 2/Good

Tip (A) 2/Good

Tip (A) 2/Good

Ring (B)/GoodRing (B)/Good

Ground/Earth

Ground/Earth

Tip (A)/Fault

Tip (A)/Fault

Ring (B)/FaultRing (B)/Fault

Ground (Earth)

Ground (Earth)

Tip (A)/Good

Tip (A)/Good

Fault

Fault

Fault

Strap

Strap

Strap

60

Page 61

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Hook-Up

Short Single Pair

RED

Ring (B)/FaultRing (B)/Fault

BLK

BLU

Tip-Cross Single Pair

Ring-Cross Single Pair

Tip (A)/Fault

Tip (A)/Fault

Good

Good

RED

Ring (B)1/GoodRing (B)1/Good

GRN

Ground/Earth

Ground/Earth

BLK

Tip (A)1/Fault

Tip (A)1/Fault

RED

Ring (B)1Ring (B)1

GRN

Ground/Earth

Ground/Earth

BLK

Tip (A)1

Tip (A)1

Fault

Fault

Fault

Strap

Strap

Strap

RFL>Separate-Pair, Single-Section Operation

, to

, or

1. Use the Auto test

the Ohmmeter

determine the type of fault.

61

Page 62

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Single-Section Operation

2. Press the blue

key to

enter the RFL function.

Press

Select

until the Fault

section is highlighted. Use

the up and down arrow keys

to select the type of fault

that you have. The options

include:

Tip Cross, Ring Cross, Wet

Pulp, T-G, R-G, Short

This example will show a

Ring-Ground fault.

Press

Select

to move to

the Pair section.

3. Use the up and down arrow

keys to select Separate Pair.

Press

Select

to move to

the Multiple-Single section.

62

Page 63

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Single-Section Operation

4. Use the up and down

arrow keys to select Single

Section.

5. Press

Setup

to choose the

measurement parameters.

6. The rst parameter is

the gauge. Use the Up

and Down arrow keys to

highlight the gauge of your

cable.

Press

Select

to choose the

cable length.

63

Page 64

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

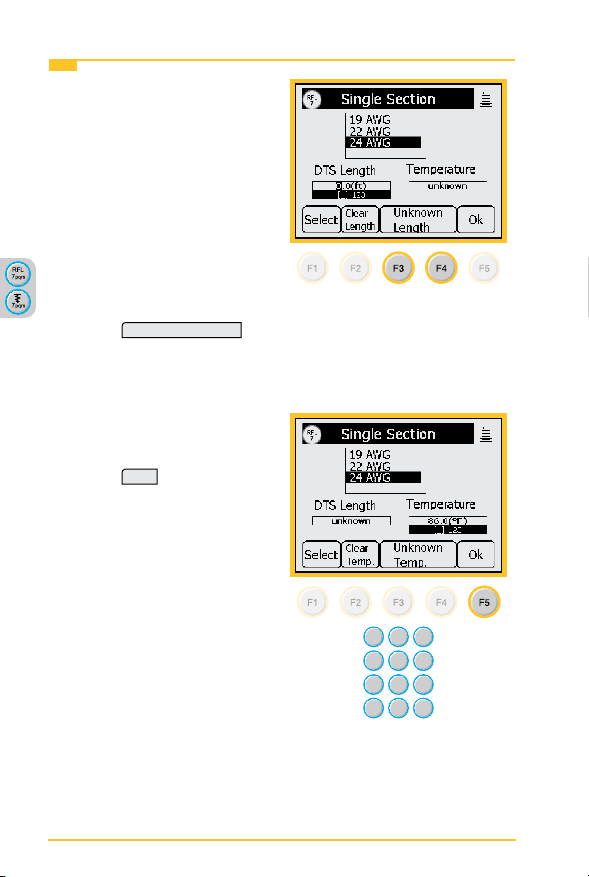

RFL>Separate-Pair, Single-Section Operation

Special Requirement: Enter

the cable temperature or the

length, but not both. Only one

parameter can be entered.

There must be one unknown to

solve the calculation.

For this example, we will use

the cable temperature as the

known value and the length

will not be entered.

7. Press

Unknown Length

to enter an unknown

length and highlight the

Temperature section.

8. Enter the temperature using

the blue keys.

Press

OK

to return to the

main RFL screen.

64

Page 65

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Single-Section Operation

9. Press

to review the

Test

settings.

10. This screen shows the

test lead hook-ups and the

settings you have selected.

Start

Press

to begin the

test.

11. If the hook-up is not

correct, you will see an

error message on the wiring

diagram at the point of the

error.

65

Page 66

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Single-Section Operation

12. During the measurement

process, a bar graph of the

null voltage for DTS and

then for DTF will be visible

on the screen.

13. The results of the

measurements are displayed

on the screen.

DTS is the distance to the

strap.

DTF is the distance to the

fault.

DSTF is the distance from

the strap to the fault.

This screen also displays

the value of the fault.

In some situations it may

be more helpful to use the

resistance values instead of

the distance values. Press

Convert to ohms

to use the

resistance values.

66

Page 67

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Single-Section Operation

14. Press

Convert to distance

to

convert the resistance back

to distance.

RFL>Separate-Pair, Multi-Section Operation

1. Use the Auto test

the Ohmmeter

, or

, to

determine the type of fault.

2. Press the blue key to

enter the RFL function.

Press

Select

until the Fault

section is highlighted. Use

the up and down arrow keys

to select the type of fault

that you have. The options

include:

Tip Cross, Ring Cross, Wet

Pulp, T-G, R-G, Short

This example will show a

Ring-Ground fault.

Press

Select

to move to

the Pair section.

67

Page 68

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Multi-Section Operation

3. Use the up and down arrow

keys to select Separate Pair.

Select

Press

to move to

the Multiple-Single section.

4. Use the up and down arrow

keys to select Multiple

sections of cable that have

more than one gauge.

5. Press

Setup

to dene the

sections.

68

Page 69

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Multi-Section Operation

6. Use the up and down

arrow keys to select a

section. Press

Edit Section

to choose the measurement

parameters.

7. The rst parameter is

the gauge. Use the Up

and Down arrow keys to

highlight the gauge of your

cable.

Press

Select

to highlight

the section length section.

69

Page 70

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Multi-Section Operation

8. Use the blue keys to enter

the section length.

Select

Press

to move to

the Temp section.

9. Use the blue keys to enter

the cable temperature.

Press

OK

to return to the

Multiple Gauge screen.

70

Page 71

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Multi-Section Operation

10. Use the up and down arrow

keys to select the next

section. Press

Edit Section

to choose the measurement

parameters.

11. You can add a load coil

to the calculations. Press

Load Coil

to add the H88

load coil to the section.

You can add as many load

coils as you need, but each

one must be in a different

section on the screen.

12. Press OK to store the

load coil and return to the

Multiple Gauge screen.

71

Page 72

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Multi-Section Operation

13. Use the up and down arrow

keys to select the next

section. Press

Edit Section

to choose the measurement

parameters.

14. Use the Up and Down

arrow keys to highlight the

gauge of your cable.

Press

Select

to highlight

the section length section.

72

Page 73

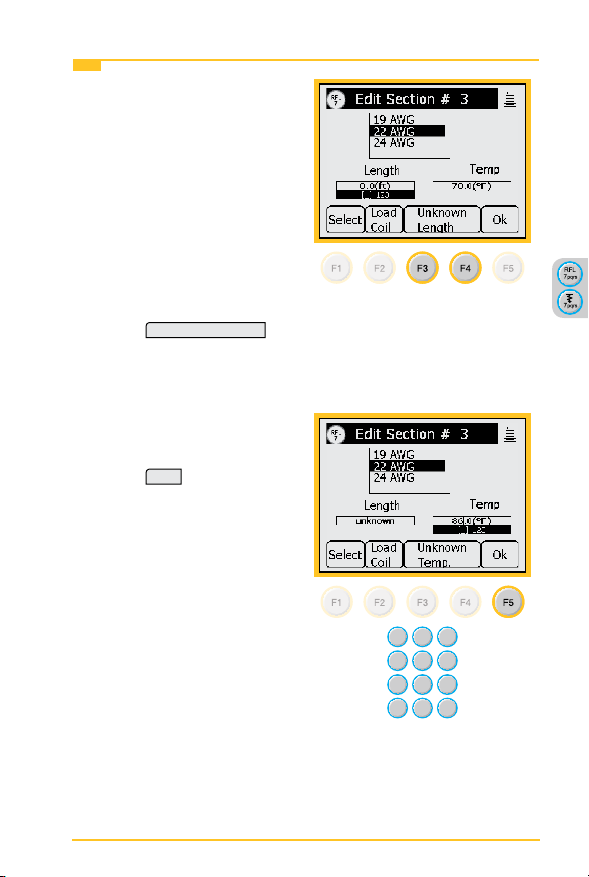

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Multi-Section Operation

Special Requirement: Enter

the cable temperature or the

length, but not both. Only one

parameter can be entered.

There must be one unknown to

solve the calculation.

For this example, we will use

the cable temperature as the

known value and the length

will not be entered.

15. Press

Unknown Length

to

enter an unknown length

and move to the Temp

section.

16. Use the blue keys to enter

the cable temperature.

Press

OK

to return to the

Multiple Gauge screen.

73

Page 74

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Multi-Section Operation

17. Press

OK

again to return

to the main RFL screen.

18. Press

to review the

Test

settings.

19. This screen shows the

test lead hook-ups and the

settings you have selected.

Start

Press

to begin the

test.

74

Page 75

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Separate-Pair, Multi-Section Operation

20. If the hook-up is not

correct, you will see an

error message on the wiring

diagram at the point of the

error.

21. During the measurement

process, a bar graph of the

null voltage for DTS and

then for DTF will be visible

on the screen.

75

Page 76

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Separate-Pair, Multi-Section Operation

22. The results of the

measurements are displayed

on the screen.

DTS is the distance to the

strap.

DTF is the distance to the

fault.

DSTF is the distance from

the strap to the fault.

This screen also displays

the value of the fault.

In some situations it may

be more helpful to use the

resistance values instead of

the distance values. Press

Convert to ohms

to use the

resistance values.

23. Press

Convert to distance

to

convert the resistance back

to distance.

76

Page 77

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single-Pair, Single-Section Operation

1. Use the Auto test

the Ohmmeter

, or

, to

determine the type of fault.

2. Press the blue key to

enter the RFL function.

Press

Select

until the Fault

section is highlighted. Use

the up and down arrow keys

to select the type of fault

that you have. The options

include:

Tip Cross, Ring Cross, Wet

Pulp, T-G, R-G, Short

This example will show a

Ring-Ground fault.

Press

Select

to move to

the Pair section.

77

Page 78

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single-Pair, Single-Section Operation

3. Use the up and down arrow

keys to select Single Pair.

Select

Press

to move to

the Multiple-Single section.

4. Use the up and down

arrow keys to select Single

Section.

5. Press

Setup

to choose the

measurement parameters.

78

Page 79

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single-Pair, Single-Section Operation

6. The rst parameter is

the gauge. Use the Up

and Down arrow keys to

highlight the gauge of your

cable.

Press

Select

to choose the

cable length.

Special Requirement: Enter

the cable temperature or the

length, but not both. Only one

parameter can be entered.

There must be one unknown to

solve the calculation.

For this example, we will use

the cable temperature as the

known value and the length

will not be entered.

7. Press

Unknown Length

to

enter an unknown length

and move to the Temp

section.

79

Page 80

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single-Pair, Single-Section Operation

8. Enter the temperature using

the blue keys.

OK

Press

to return to the

main RFL screen.

9. Press

settings.

80

to review the

Test

Page 81

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single-Pair, Single-Section Operation

10. This screen shows the

test lead hook-ups and the

settings you have selected.

Start

Press

to begin the

test.

11. If the hook-up is not

correct, you will see an

error message on the wiring

diagram at the point of the

error.

12. During the measurement

process, a bar graph of the

null voltage for DTS and

then for DTF will be visible

on the screen.

81

Page 82

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single-Pair, Single-Section Operation

13. The results of the

measurements are displayed

on the screen.

DTS is the distance to the

strap.

DTF is the distance to the

fault.

DSTF is the distance from

the strap to the fault.

This screen also displays

the value of the fault.

In some situations it may

be more helpful to use the

resistance values instead of

the distance values. Press

Convert to ohms

to use the

resistance values.

14. Press

Convert to distance

to

convert the resistance back

to distance.

82

Page 83

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single Pair, Multi-Section Operation

1. Use the Auto test

the Ohmmeter

, or

, to

determine the type of fault.

2. Press the blue key to

enter the RFL function.

Press

Select

until the up

and down arrow keys are in

the Fault section. Use the

up and down arrow keys

to select the type of fault

that you have. The options

include:

Tip Cross, Ring Cross, Wet

Pulp, T-G, R-G, Short

This example will show a

Ring-Ground fault.

Press

Select

to move to

the Pair section.

83

Page 84

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single Pair, Multi-Section Operation

3. Use the up and down arrow

keys to select Single Pair.

Select

Press

to move to

the Multiple-Single section.

4. Use the up and down arrow

keys to select Multiple

sections of cable that have

more that one gauge.

5. Press

Setup

to choose the

measurement parameters.

84

Page 85

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single Pair, Multi-Section Operation

6. Use the up and down

arrow keys to select a

section. Press

Edit Section

to choose the measurement

parameters.

7. The rst parameter is

the gauge. Use the Up

and Down arrow keys to

highlight the gauge of your

cable.

Press

Select

to highlight

the section length section.

85

Page 86

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single Pair, Multi-Section Operation

8. Use the blue keys to enter

the section length.

Select

Press

to move to

the Temp section.

9. Use the blue keys to enter

the cable temperature.

Press

OK

to return to the

Multiple Gauge screen.

86

Page 87

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single Pair, Multi-Section Operation

10. Use the up and down arrow

keys to select the next

section. Press

Edit Section

to choose the measurement

parameters.

11. You can add a load coil

to the calculations. Press

Load Coil

to add the load

coil to the section. You

can add as many load

coils as you need, but each

one must be in a different

section on the screen.

12. Press OK to store the

load coil and return to the

Multiple Gauge screen.

87

Page 88

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single Pair, Multi-Section Operation

13. Use the up and down arrow

keys to select the next

section. Press

Edit Section

to choose the measurement

parameters.

14. Use the Up and Down

arrow keys to highlight the

gauge of your cable.

Press

Select

to highlight

the section length section.

88

Page 89

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single Pair, Multi-Section Operation

Special Requirement: Enter

the cable temperature or the

length, but not both. Only one

parameter can be entered.

There must be one unknown to

solve the calculation.

For this example, we will use

the cable temperature as the

known value and the length

will not be entered.

15. Press

Unknown Length

to

enter an unknown length

and move to the Temp

section.

16. Use the blue keys to enter

the cable temperature.

Press

OK

to return to the

Multiple Gauge screen.

89

Page 90

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single Pair, Multi-Section Operation

17. Press

OK

again to return

to the main RFL screen.

18. Press

Test

to review the

settings.

19. This screen shows the

test lead hook-ups and the

settings you have selected.

Start

Press

to begin the

test.

90

Page 91

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Single Pair, Multi-Section Operation

20. If the hook-up is not

correct, you will see an

error message on the wiring

diagram at the point of the

error.

21. During the measurement

process, a bar graph of the

null voltage for DTS and

then for DTF will be visible

on the screen.

91

Page 92

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Single Pair, Multi-Section Operation

22. The results of the

measurements are displayed

on the screen.

DTS is the distance to the

strap.

DTF is the distance to the

fault.

DSTF is the distance from

the strap to the fault.

This screen also displays

the value of the fault.

In some situations it may

be more helpful to use the

resistance values instead of

the distance values. Press

Convert to ohms

to use the

resistance values.

23. Press

Convert to distance

to

convert the resistance back

to distance.

92

Page 93

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Wet Pulp

Use this function to nd the approximate distance to a resistance

fault when both wires in a pair are faulted at the same place

and a separate good pair or a single common conductor is not

available.

RFL>Wet Pulp>Hook-Up

RED

Wire With Lower Resistance ValueWire With Lower Resistance Value

GRN

Common/Ground

Common/Ground

BLK

Wire With Higher Resistance Value

Wire With Higher Resistance Value

1. The resistance faults must be common to the reference

(Green) conductor. Use the ohmmeter function to measure

the resistance on each side of the pair to the reference

conductor.

2. The lower value fault should be connected to the Red test

lead.

3. The higher value fault should be connected to the Black test

lead.

4. The Green test lead should be connected to the reference

conductor, usually the shield or ground.

93

Page 94

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Wet Pulp> Requirements

Note: All of the following conditions must be met or this

function does not apply:

1. One fault must be at least twice the ohms value of the other

fault. For example, a 5 kΩfault has twice the value of a

10 kΩfault.

2. The sum of both faults must be at least 100 times the loop

resistance of the pair. For example, if the loop resistance is

50 Ω, the sum of the faults must be 5 kΩor greater. You may

continue with the test, but the results may have a reduced

accuracy.

3. The 965AMS checks to see if the resistance of the loop

is less than 7 kΩ. If the resistance is greater than 7 kΩ,

the distance to strap may be too long or the strap is not

connected,

RFL>Wet Pulp>Operation

1. Press the blue

key to

enter the RFL function.

Use the up and down keys

to select Wet Pulp.

Press

Setup

to select the

gauge of the pair.

94

Page 95

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Wet Pulp>Operation

2. Use the up and down arrow

keys to select the gauge of

the pair.

Press

Select

Unknown Temp.

or

to highlight

the temperature eld.

3. Use the blue keypad to

enter the cable temperature.

Press

OK

to continue.

95

Page 96

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Wet Pulp>Operation

4. The Wet Pulp test rst

makes a measurement with

the far-end open.

Press

Start

to start the test.

5. Strap the pair at the far end,

then press

Continue

.

Note: The “Opens Ratio” value

displayed on the screen is the

ratio of R1/(R2+R1) times

100. This value is used by

some companies as part of the

measurement. It is not needed

to calculate the distance to the

fault.

6. The test results are shown

in ohms.

Press

Dist.

to convert the

ohms to the distance to the

fault.

96

Page 97

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

RFL>Wet Pulp>Operation

7. DTS—Distance to the strap

(far end).

DTF—Distance to the fault.

DSTF—Distance from the

strap to the fault.

Press

Avg. Result

to view a

summary of test results.

8. Use the results of this test

to nd the distance or run

the test multiple times and

the tester will average the

distances.

RFL>Wet Pulp>Error Screens

1. Swap the Red and Black

test leads.

97

Page 98

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

RFL>Wet Pulp>Error Screens

2. The strap at the far-end is

open. There should be a

solid short at the far-end.

3. The tester checks to see

that the sum of the faults

is more than 100 times the

loop resistance. You may

Continue

press

with the

test, but the results may

have a reduced accuracy.

98

Page 99

3M™ Dynatel™ Advanced Modular System 965AMS Measurement Functions

DSL (Digital Subscriber Line)

The DSL functions include: DSL Loss, DSL Noise, DSL

Spectrum Analyzer, Resistive Balance, and DSL Impulse Noise.

DSL>DSL Loss

Use DSL Loss function to measure the amount of loss in a

circuit at a specic frequency. This is typically accomplished by

sending tone with another 965AMS tester, a 3M

End Device (FED), or test equipment that is capable of sending

wideband tone from 20 kHz to 30 MHz.

DSL>DSL Loss>Hook-Up

RED

Ring (A)Ring (A)

BLK

Tip (B)

Tip (B)

™

Dynatel™ Far

99

Page 100

Measurement Functions 3M™ Dynatel™ Advanced Modular System 965AMS

DSL>DSL Loss>Operation

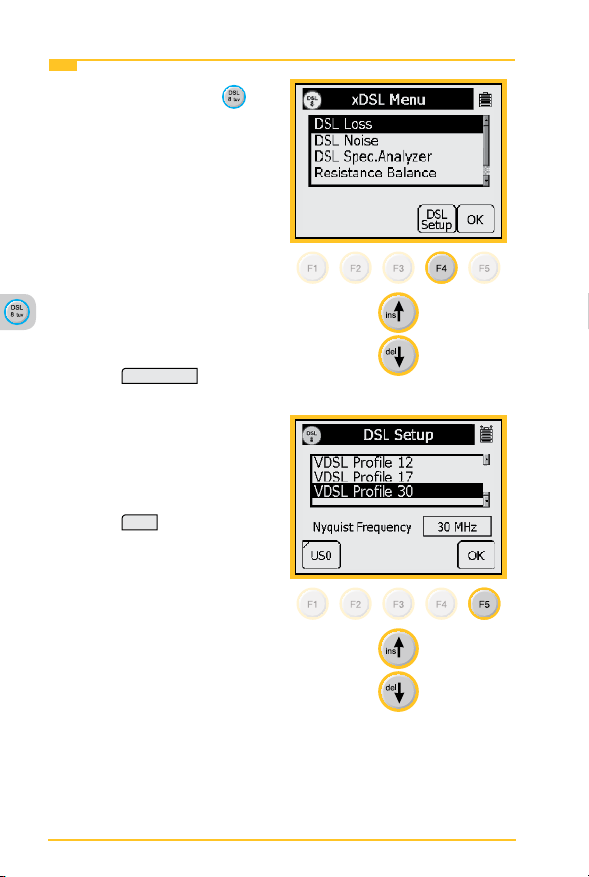

1. Press the blue DSL

key

to enter the DSL function.

Use the up and down arrow

keys to select DSL Loss.

Use a tone source at the

far end that is capable of

sending a known output

level such as a 965AMS

tester. Use 0dBm as the

output level or follow your

method of test.

2. Press

DSL Setup

to select

the type of service.

3. Use the up and down

arrow keys to select the

type of service that you are

measuring.

4. Press

OK

when nished.

100

Loading...

Loading...