Page 1

3

Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9461PC, 9462P

Construction

Technical Data November, 2006

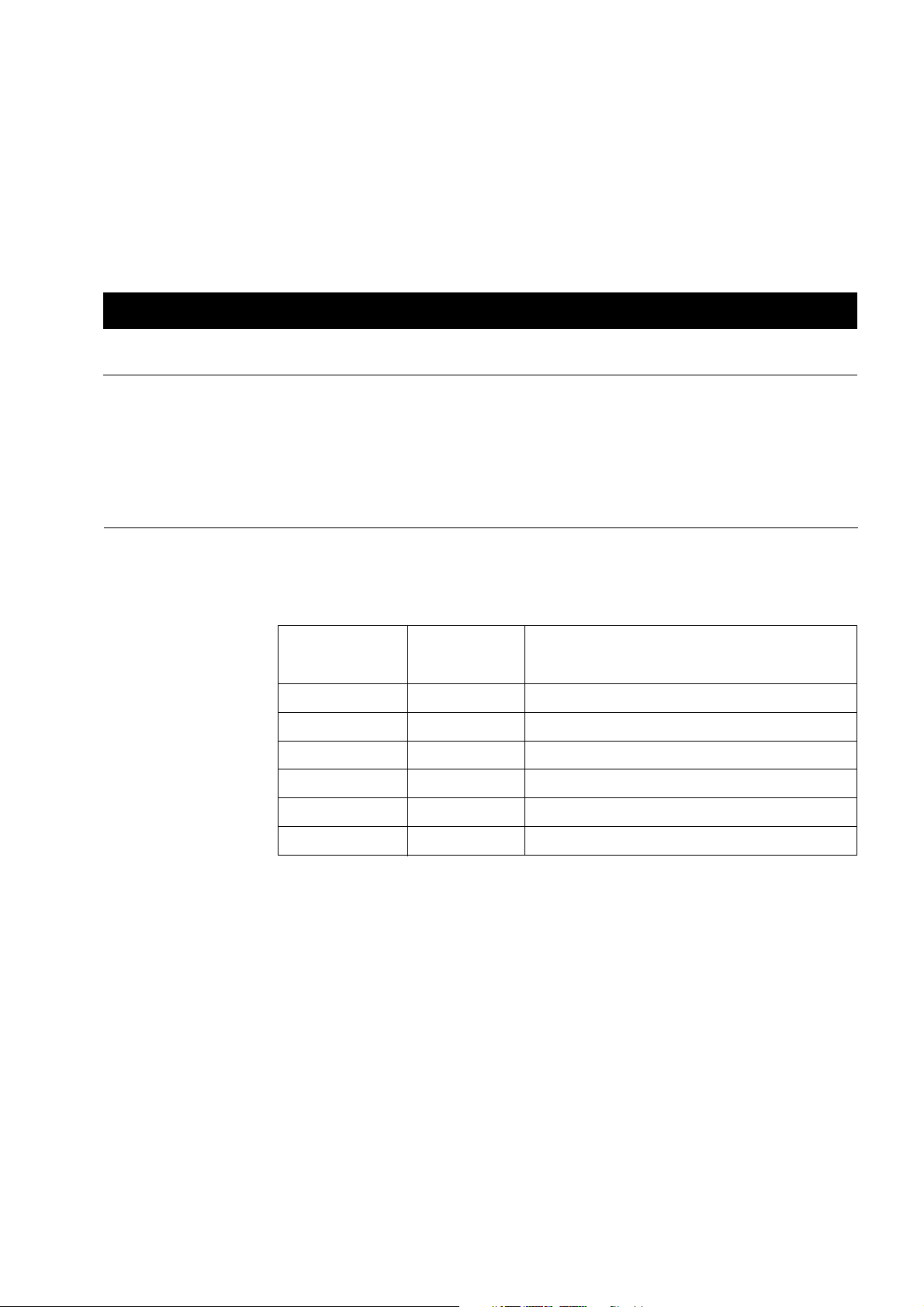

Adhesive

3M™ Adhesive Thickness

Transfer (mils) Liner Material - Thickness

Tape 941 2.3 (.06 mm) 58# Polycoated Kraft - 4.0 mils thick

Tape 966 2.3 (.06 mm) 62# Densified Kraft - 3.8 mils thick with printed liner

Tape 9461P 1.16 (.03 mm) 55# Densified Kraft - 3.2 mils thick with printed liner

Tape 9461PC 1.16 (.03 mm) 58# Polycoated Kraft - 4.0 mils thick

Tape 9462P 2.3 (.06 mm) 55# Densified Kraft - 3.2 mils thick with printed liner

Tape 965 2.3 (.06 mm) 55# Densified Kraft - 3.2 mils thick with printed liner

3M™ Adhesive Transfer Tapes 941, 966, 9461P, 9461PC and 9462P use the same 3M

adhesive 100 and come with different liners for a variety of die cutting applications.

3M™ Adhesive Transfer Tape 965 uses a slightly modified 3M adhesive 100 to provide

excellent resistance to jet fuel and other chemicals for identification lables on aircraft.

Product Description

These 3M™ Adhesive Transfer Tapes with 3M™ Adhesive 100 are designed for

temperature exposure to 450°F (232°C) for short periods of time and/or solvent

resistance. They have exceptional shear values even at elevated temperatures. They

also offer low “outgassing” properties, which is an important consideration for the

aerospace, automotive and electronic industries.

*Note: The caliper listed is based on a calculation from manufacturing controlled adhesive coat

weights using a density of 1.012 g/cc. While past data pages have listed nominal thicknesses

of 1 mil and 2 mils, the coat weight (and theoretical caliper) has not changed.

Page 2

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

Typical Physical

Properties and

Performance

Characteristics

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

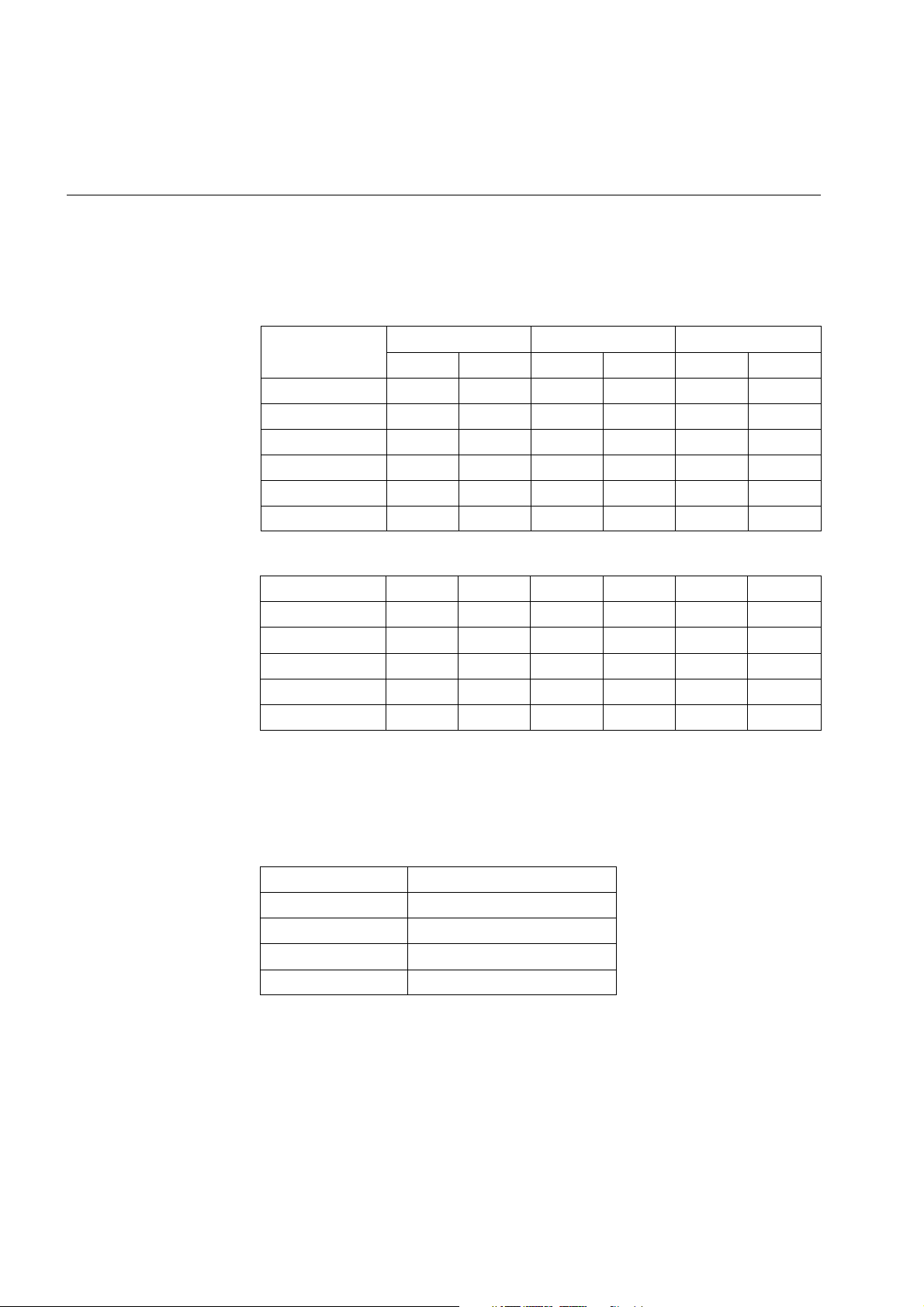

Adhesion Peel: ASTM D-3330 (modified) (90 degree peel, 12"/min. [305 mm/min.]

2 mil aluminum)

Metal (Stainless Steel)

- 2 -

3M™ Adhesive

20 minute dwell 72 hr. dwell Ultimate bond

Transfer oz./in. N/100mm oz./in. N/100mm oz./in. N/100mm

Tape 941 53 58 78 85 145 159

Tape 965 45 49 72 79 116 127

Tape 966 53 58 78 85 145 159

Tape 9461P 48 53 85 93 119 130

Tape 9461PC 48 53 85 93 119 130

Tape 9462P 53 58 78 85 145 159

Adhesive Static Shear

Values for all 3M™ Adhesive 100 family of tapes on Stainless Steel

(1 x 1 inch test samples)

Room temperature 2000 gms for 10,000 minutes

158°F (70°C) 1000 gms for 10,000 minutes

200°F (93°C) 1000 gms for 10,000 minutes

350°F (177°C) 500 gms for 10,000 minutes

450°F (232°C) 400 gms for 10,000 minutes

3M tape 941 44 48 54 59 40 44

3M tape 965 – – 69 75 45 49

3M tape 966 44 48 54 59 40 44

3M tape 9461P – – 36 39 18 20

3M tape 9461PC – – 36 39 18 20

3M tape 9462P 44 48 54 59 40 44

High Surface Energy Plastic (ABS)

Use on “Low Surface Energy Plastics” such as Polypropylene is not recommended. Consider

other 3M™ Adhesive Transfer Tapes with 3M™ Adhesive 300, 300MP, 350 or 300LSE.

Note: 3M tape 965 showed some slippage at evaluated temperatures above 200°F (93°C).

Page 3

- 3 -

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

Typical Physical

Properties and

Performance

Characteristics

(continued)

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

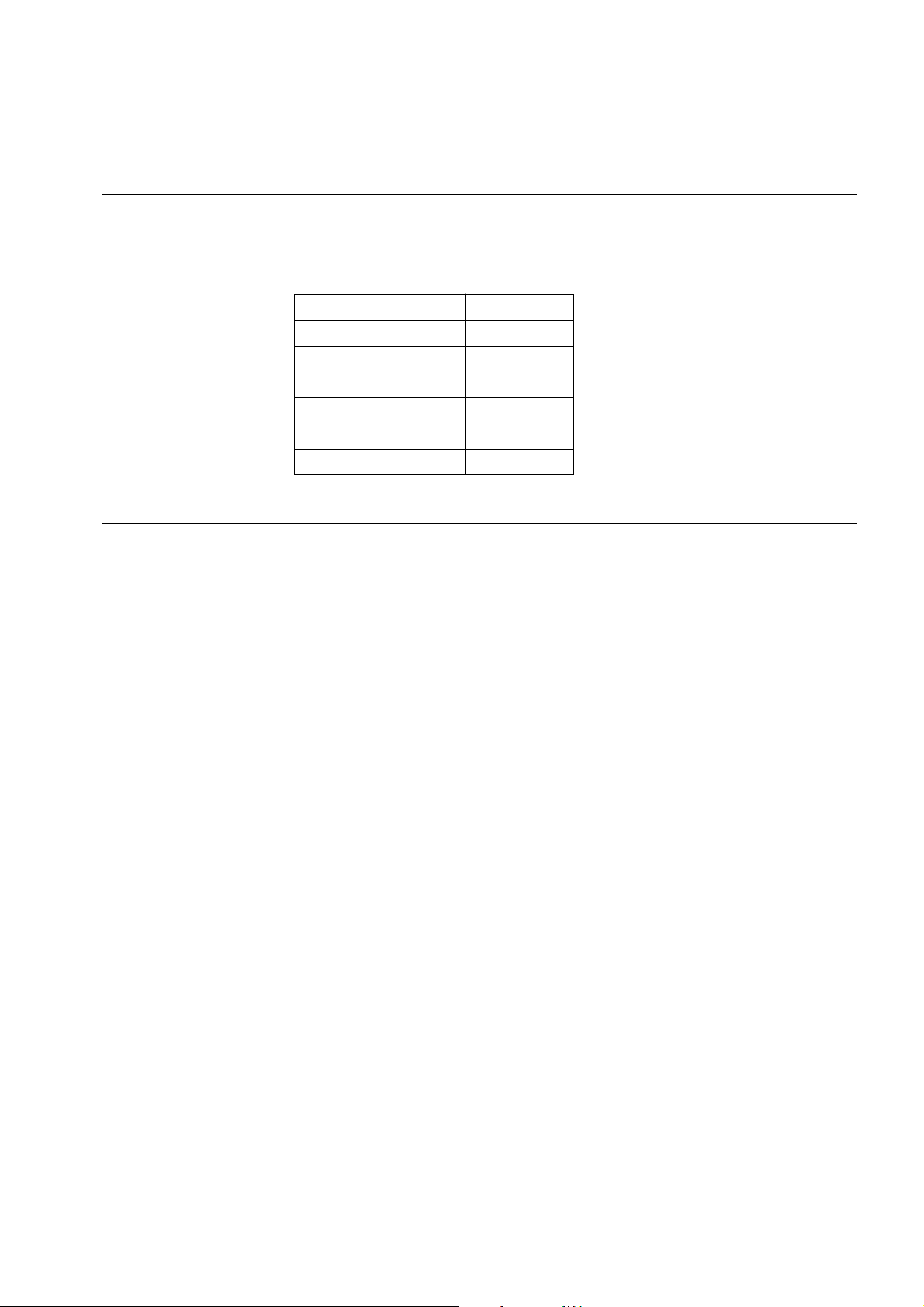

Typical Liner Release Values: Liner release values may vary from lot to lot. Values

stated are only typical or average values based on lots tested.

3M™ Adhesive Transfer

Tape 941 23 gms/inch

Tape 965 22 gms/inch

Tape 966 39 gms/inch

Tape 9461P 29 gms/inch

Tape 9461PC 35 gms/inch

Tape 9462P 30 gms/inch

Environmental

Performance

The properties defined are based on the attachment of impervious faceplate materials

(such as aluminum) to an aluminum test surface.

Bond Build-up: The bond strength of 3M™ Adhesive 100 increases as a

function of time and temperature.

Humidity Resistance: High humidity has a minimal effect on adhesive

performance. Bond strengths are generally higher after

exposure for 7 days at 90°F (32°C) and 90% relative

humidity.

U.V. Resistance: When properly applied, nameplates and decorative trim

parts are not adversely affected by outdoor exposure.

Water Resistance: Immersion in water has no appreciable effect on the bond

strength. After 100 hours in room temperature, the bond

actually shows an increase in strength.

Temperature Cycling Bond strength generally increases after cycling four times

Resistance: through: 4 hours at 158°F (70°C)

4 hours at -20°F (-29°C)

16 hours at room temperature

Chemical Resistance: When properly applied, nameplate and decorative trim

parts will hold securely after exposure to numerous

chemicals including gasoline, oil, Freon™ TF, sodium

chloride solution, mild acids and alkalis.

Heat Resistance: The 3M adhesive 100 is usable for short periods (minutes,

hours) at temperatures up to 450°F (232°C) and for longer

periods (days, weeks) up to 300°F (149°C).

Low Temperature -40°F (-40°C). Parts should be tested for low temperature

Service: shock service.

Page 4

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

Available Size

Core size: 3M™ Adhesive Transfer Tapes are offered on a three inch paper core.

Minimum width: 1 inch

3 inch for 3M™ Adhesive Transfer Tape 9462P

Maximum width: 48 inches

Standard length: 180 yards

For other than standard sizes contact your 3M sales representative.

Features

• Excellent bond to metal and high surface energy plastics.

• Outstanding temperature and chemical resistance.

• Two adhesive thicknesses: 1 mil for thin profile labels and 2 mil for rougher surfaces.

• Low outgassing and low leachable chloride, important considerations for electronic

and aerospace industries.

• Available on various liners for specialized processing:

– 60# Densified Kraft for die-cutting metal nameplates

– 55# Densified Kraft for rotary die-cutting specialty labels

– 58# Polycoated Kraft for polycarbonate graphics

– 86# Polycoated Kraft for polycarbonate end tabs and plastic nameplates on

a common sheet

- 4 -

Page 5

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

- 5 -

Chemical and

Environmental

Exposure

The 3M™ Adhesive 100 is well known in industry for environmental and chemical

resistance. For many applications, any one of the products in this grouping will perform

satisfactorily when exposed to different chemicals or temperatures. Jet fuels, however, are a

challenge for pressure sensitive products. More specifically, the Aviation Turbine Fuel,

Grade JP-4 (MIL H-T-5624), will attack many of the best adhesives within 72 hours. In

response to the demands of this market and the corresponding military specification MIL-T9906C, 3M™ Adhesive Transfer Tape 965 was developed as it differs slightly in chemistry

from the rest of the 3M adhesive 100 family to provide the extra chemical resistance.

In addition to the added fuel resistance, 3M tape 965 retains all of the notable features of the

adhesive 100: excellent adhesion to metals, good adhesion to high surface energy plastics,

low outgassing, and excellent static shear values for room temperature and heated conditions.

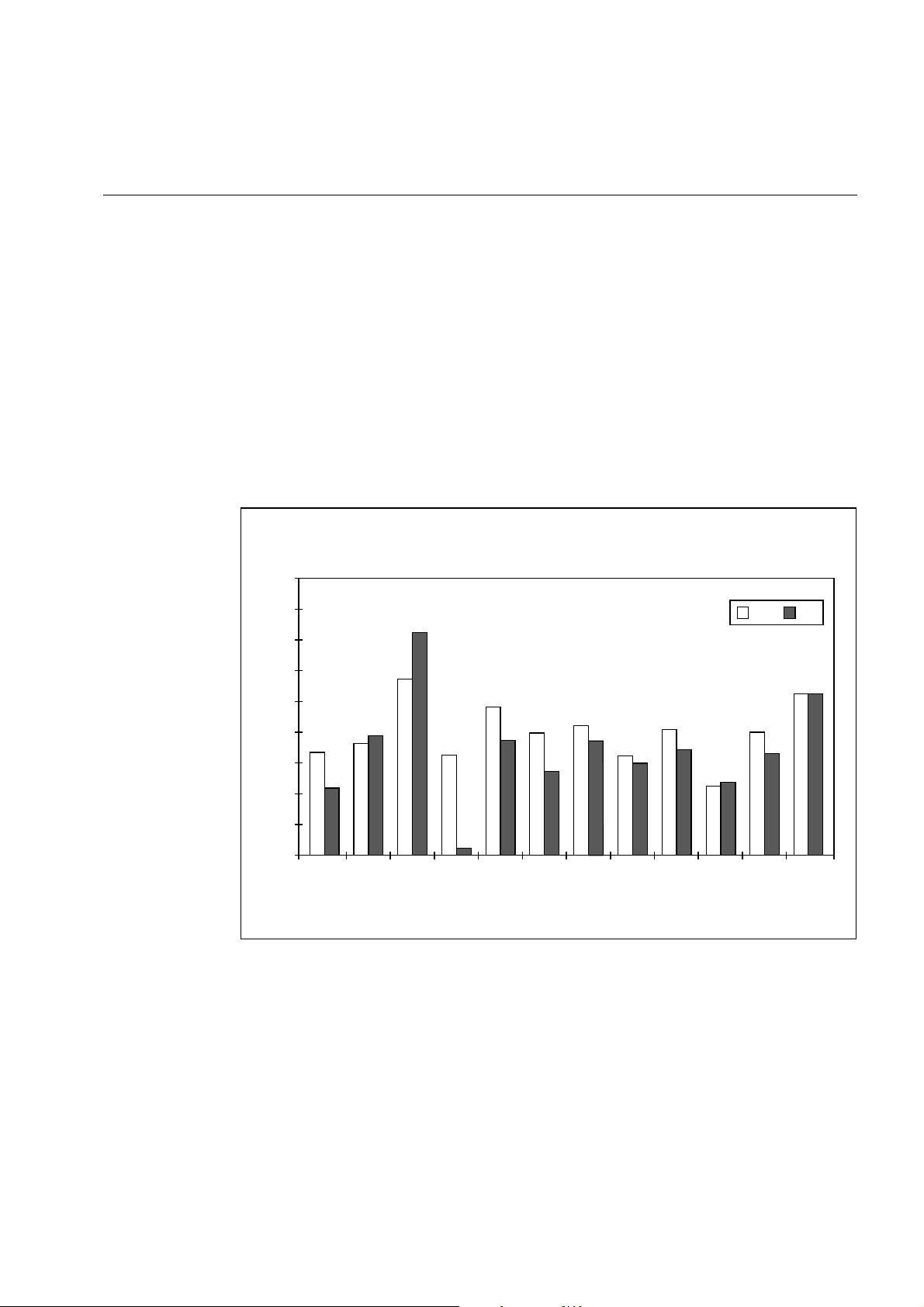

The chart below shows adhesion values (to stainless steel) of 3M™ Adhesive Transfer Tapes

965 and 966, with an emphasis on fuel and oil exposure. The data represents representative

or typical values and should not be used for specification purposes.

180

160

140

120

100

80

60

40

20

0

67

43

72

78

116

145

66

5

76

97

55

79

74

84

65

60

69

82

45

48

67

79

105

105

Initial

RT

158°F

JP-4 Fuel

Lube Oil

Kerosene

Hydr. Fluid

Gas

NaCl Sol’n

MEK

Water

Temp Cycle

Adhesion to Stainless Steel (oz/in)

Environmental Exposure

965

966

3M tape 965 vs. 3M tape 966

Chemical and Environmental Exposure

Page 6

- 6 -

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

Thermal and

Electrical Properties

for 3M tape 966

Thermal Conductivity (ASTM C518) .103 BTU-ft/ft2-hr-°F (@105°F)

.106 BTU-ft/ft2-hr-°F (@160°F)

.108 BTU-ft/ft2-hr-°F (@214°F)

.178 Watt/m-K (@41°C)

.183 Watt/m-K (@71°C)

.187 Watt/m-K (@101°C)

Coefficient of Thermal Expansion (ASTM-D696)

First heat (125-175°C) 19.9 x 10-5m/m/°C

Second heat (25-175°C) 58.4 x 10-5m/m/°C

Insulation Resistance

(test voltage = 100 VDC, MIL-I-46058C)

Before moisture resistance >1.0 x 1015ohms

Cycle #4 1.5 x 1011ohms

Cycle #10 9.4 x 1010ohms

24 hr after moisture resistance 9.7 x 1012ohms

Surface Resistance >1.0 x 1015ohms

Surface Resistivity >5.6 x 1016ohms

Volume Resistance 3.9 x 1011ohms

Volume Resistivity (ASTM D257-92) 4.0 x 1015ohm-cm

Dissipation Factor 0.025 (@1 kHz)

Dielectric Constant (ASTM D-150-92) 2.92 (@1 kHz)

Dielectric Strength (500 vac, rms. [60 Hz]/sec.) 1100 volts/mil

(ASTM D149-92)

3M™ Adhesive Transfer Tape 966 was tested for the following properties; however,

the results should be very similar for the other 3M™ Adhesive Transfer Tapes with

3M™ Adhesive 100.

Application

Techniques

For maximum bond strength the surface should be thoroughly cleaned and dried.

Typical cleaning solvents are heptane or isopropyl alcohol.*

Bond strength can also be improved with firm application pressure and moderate heat,

(for metal surfaces only), from 100°F (38°C) to 130°F (54°C), causing the adhesive to

develop intimate contact with the bonding surface.

*Note: Carefully read and follow the manufacturer’s precautions and directions for use

when working with solvents. These cleaning recommendations may not be

compliant with the rules of certain Air Quality Management Districts in

California; consult applicable rules before use.

Page 7

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

- 7 -

Dispenser Selection

For assistance in helping you determine the best dispenser for your application,

contact your local 3M sales representative, or the toll free 3M sales assistance

number at 1-800-362-3550.

Application Ideas

Ideal tape application temperature range is 70°F to 100°F (21°C to 38°C) and

application to surfaces at temperatures below 50°F (10°C) is not recommended for

most pressure sensitive adhesives because the adhesive becomes too firm to adhere

readily. However, once properly applied, low temperature holding is satisfactory. For

more specific information, contact Customer Service at 1-800-223-7427.

The liner used for 3M™ Adhesive Transfer Tapes 9461P, 9461PC and 9462P is not

intended to provide premium release characteristics. Testing is urged for

applications where liner release is critical. These products are not recommended for

use with non-transferable facestocks such as 3M™ Label Material 8070, 8071 or

8074 because of the potential for liner caused pre-destruct.

3M™ Adhesive Transfer Tape 965 has been specially modified to provide

outstanding performance for fuel line identification labels, bar code labels for harsh

environments and specially performance-engineered labels for automotive, aerospace

and industrial markets. It also meets MIL-T-9906C specification requirements.

Storage

Store at room temperature conditions of 72°F (22°C) and 50% R.H. and in a plastic

bag.

Shelf Life

Product retains its performance and properties for two years from date of manufacture.

Page 8

3M™Adhesive Transfer Tapes with Adhesive 100

941, 965, 966, 9461P, 9641PC, 9462P

3M is a trademark of 3M Company.

Printed in U.S.A.

©3M 2006 70-0709-3907-2 (11/06)

Recycled Paper

40% pre-consumer

10% post-consumer

- 8 -

TSCA: These products are defined as articles under the Toxic Substances Control Act and therefore,

are exempt from inventory listing requirements.

MSDS: 3M has not prepared a MSDS for these products which are not subject to the MSDS requirements

of the Occupational Safety and Health Administration’s Hazard Communication Standard, 29 C.F.R.

1910.1200(b)(6)(v). When used under reasonable conditions or in accordance with the 3M directions

for use, the products should not present a health and safety hazard. However, use or processing of the

products in a manner not in accordance with the directions for use may affect their performance and

present potential health and safety hazards.

UL: 3M™ Adhesive Transfer Tapes 941, 966 and 9462P have been recognized by Underwriters

Laboratories Inc. under Standard UL 969 Marking and Labeling in File MH26206. For more information

on the UL Certification, please visit the website at http://www

.3m.com/converter, select UL Recognized

Materials, and then select the specific product area.

Certification/

Recognition

All statements, technical information and recommendations contained in this document are based upon

tests or experience that 3M believes are reliable. However, many factors beyond 3M’s control can affect

the use and performance of a 3M product in a particular application, including the conditions under

which the product is used and the time and environmental conditions in which the product is expected to

perform. Since these factors are uniquely within the user’s knowledge and control, it is essential that the

user evaluate the 3M product to determine whether it is fit for a particular purpose and suitable for the

user’s method of application.

Product Use

Unless stated otherwise in 3M’s product literature, packaging inserts or product packaging for individual

products, 3M warrants that each 3M product meets the applicable specifications at the time 3M ships the

product. Individual products may have additional or different warranties as stated on product literature,

package inserts or product packages. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF

DEALING, CUSTOM OR USAGE OF TRADE. User is responsible for determining whether the 3M product

is fit for a particular purpose and suitable for user’s application. If the 3M product is defective within the

warranty period, your exclusive remedy and 3M’s and seller’s sole obligation will be, at 3M’s option, to

replace the product or refund the purchase price.

Warranty and

Limited Remedy

Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising from the

3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory

asserted, including warranty, contract, negligence or strict liability.

Limitation of Liability

This Industrial Adhesives and Tapes Division product was manufactured under a 3M quality system registered to ISO 9001: 2000 standards.

ISO 9001:2000

3

Industrial Business

Converters Markets

Industrial Adhesives and Tapes Division

3M Center, Building 21-1W-10, 900 Bush Avenue

St. Paul, MN 55144-1000

800-223-7427 • 651-778-4244 (fax)

www.3M.com/converter

Loading...

Loading...