3M 8810 Service Manual

Technical

Datasheet

3M™ 8000 Series

Particulate Respirators

Product Description

The 3M™ 8000 Series Particulate Respirators provide eective

respiratory protection for use in industries where workers will be

exposed to dust particles and/or non-volatile liquid particles.

• Tested and CE Approved to EN 149:2001+A1:2009.

• Traditional convex shape, with nose clip and twin strap design.

• Durable, collapse resistant inner shell.

• Reliable, eective protection against fine particles.

• 3M™ Advanced Electret Filter Material gives eective filtration

with low breathing resistance for consistent high quality

performance.

• 3M™ Cool Flow™ exhalation valve oers improved comfortin

hot humid environments and/or where work is hard and

physical*.

• Coloured headbands for easy identification: yellow for FFP1

and blue for FFP2.

* 8812 and 8822 models only

Approvals

Standards

These products meet the requirements of recently amended

European Standard EN 149:2001 + A1:2009, filtering facepiece

respirators for use against particles. They should be used to

protect the wearer from solid and non-volatile liquid particles only.

Products are classified by filtering efficiency and maximum total

inward leakage performance (FFP1, FFP2 and FFP3), also by

usability and clogging resistance.

Performance tests in this standard include filter penetration;

extended exposure (loading) test; flammability; breathing

resistance and total inward leakage. Reusable products are also

subjected to cleaning, storage and mandatory clogging resistance

tests (clogging is optional for non reusable products). A full copy

of EN 149:2001+A1:2009 can be purchased from your national

standards body.

Designations:

R = Reusable

NR = Non reusable (single shift use only)

D = Meets the clogging resistance requirements

These products meet the requirements of the European

Community Directive 89/686/EEC (Personal Protective Equipment

Directive) and are thus CE marked. Certification under Article

10, EC Type-Examination, has been issued for these products

by INSPEC International Limited, 56 Leslie Hough Way, Salford,

Greater Manchester M6 6AJ, UK (Notified Body number 0194).

Certification under Article 11, EC quality control, has been issued

by BSI Product Services (Notified Body number 0086).

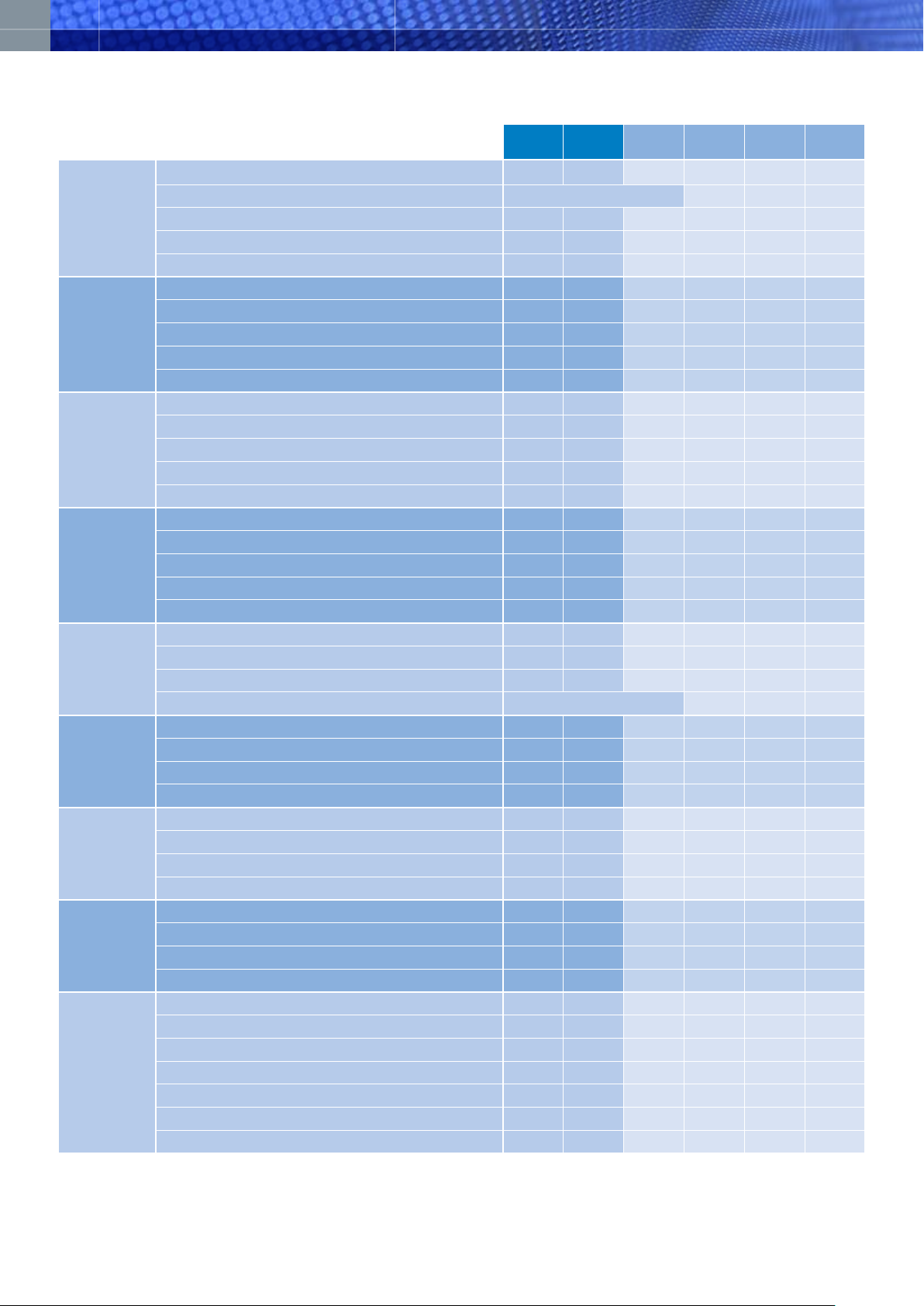

Applications

These respirators are suitable for use in concentrations of solid

and non-volatile liquid particles up to the following limits:

Model EN 14 9+ A1

Classification

8710 E / 8710S FFP1 NR D Unvalved 4

8812 FFP1 NR D Valved 4

8810 FFP2 NR D Unvalved 12

8822 FFP2 NR D Valved 12

Respiratory protection is only effective if it is correctly selected,

fitted and worn throughout the time when the wearer is exposed

to hazards.

Exhalation

Valve

Threshold Limit

Value, TLV

Selection Guide

Painting,

Varnishing,

Spraying,

Coating,

Mixing

Sanding,

Stripping,

Grinding,

Cutting,

Drilling

Construction /

Maintenance

Metal working /

Foundries

Cleaning /

Waste Removal

Allergens /

Biohazards

Agriculture /

Forestry

Mining /

Quarrying

Other

Industrial

Applications

This selection guide is only an outline designed to focus on products which may be appropriate for typical applications - it should not be used as the only means of selecting a product. Selection

of the most appropriate personal protective equipment (PPE) will depend on the particular situation and should be made only by a competent person knowledgeable of the assessed risks, actual

working conditions and limitations of PPE. Details regarding performance and limitations are set out on the product packaging and user information. If in doubt, contact a safety professional or 3M.

For respiratory training and advice please contact your local 3M representative.

Solvent-Based - brush / roller applied • •

Solvent-Based - spray applied Ask 3M

Water-Based - brush / roller / spray applied • •

Wood Preservatives • •

Powder Coating •

Rust, most Metals, Filler, Concrete, Stone •

Cement, Wood, Steel, •

Paints, Varnish, Anti-rust coating •

Stainless Steel, Anti-fouling varnish •

Resins, Reinforced plastics (carbon / glass fibre) • •

Scabbling, Shot-creting (concrete dust) • • •

Plastering, Rendering, Cement mixing • • •

Demolition • • •

Groundwork, Ear th moving, Piling, Underpinning • •

Spray foam, Loft Insulation • •

Welding, Soldering • • •

Electro-plating • • •

Finishing, Slotting, Drilling, Riveting, Machining • •

Oxyacetylene cutting • •

Molten metal handling, Smelting • • •

Disinfection, Cleaning • • • •

Waste removal • • •

Asbestos handling •

Asbestos removal Ask 3M

Pollen, Animal dander •

Mould / Fungus, Bacteria**, Viruses • •

**Tuberculosis •

Diesel exhaust / Smoke •

Handling infected animals, Culling • • •

Feeding livestock, Cleaning sheds / harvesters • • •

Straw chopping, Composting, Harvesting • •

Pesticides, Insecticides (crop spraying) • • •

Tunnelling, Drilling, Grinding, E xcavation • •

Pumping, Dredging, Washing • •

Cutting, Sawing • •

Changing Filters • •

Inks, Dyes, Solvents, Chemicals • • •

Powdered Additives / Chemicals • • •

Pharmaceuticals • • •

Rubber / Plastics processing • • •

Oil and Gas Extraction / Processing • • • • •

Pottery, Ceramics •

Wood / Paper Mills • •

FFP1 FFP2 FFP3

Organic

Vapour

Acid

Gas

Welding

Loading...

Loading...