3M 8560010, 8517715, 8517719, 8530140, 8517716 Assembly & Instruction Manual

...

CE Type Test

No. 0086

BSI Product Services

P.O. Box 6221, Kitemark Court

Davy Avenue

Milton Keynes

MK1 9EP UK

CE Production Quality Control

P.O. Box 6221, Kitemark Court

User must read and understand these instructions

before assembling or using this equipment.

EN795: 1996

Class B

No. 0086

BSI Product Services

Davy Avenue

Milton Keynes

MK1 9EP UK

Ladder Fall Arrest System

Model Numbers:

8517714

8517715

8517716

8517717

8517718

8517719

8530140

8560010

Assembly Instruction Manual

IMPORTANT: This instruction

manual is intended for assembly

of the product only. The “Ladder

Fall Arrest System User Instruction

Manual” (5902345) describes use,

operation, and maintenance of this

product. The owner’s organization

must provide the User Instruction

Manual to any user of this equipment

or rescuer.

IMPORTANT: If you have questions

on the use, care, application, or

suitability for use of this safety

equipment, contact Capital Safety.

IMPORTANT: These assembly instructions must be provided to the assembler of this equipment. The assembler must

read and understand these manufacturer’s instructions before starting the assembly procedure. The assembler must

follow the instructions for each component of the complete system. Alterations or misuse of this product, or failure to

follow these assembly instructions, may result in serious injury or death.

FORM NO: 5902369

REV: C

© Copyright 2018, Capital Safety

1.0 Assembly

1.1 PROCEDURE: It is the responsibility of the owner’s

organization to read this assembly manual and to train

assemblers before they start assembling the equipment.

Untrained assemblers are not qualifi ed to assemble the

equipment.

1.2 OPERATION: The FlexiGuard™ Ladder Fall Arrest

System (Ladder FAS) User Instruction Manual describes

equipment use, operation and maintenance procedures.

The owner’s orgainzation must provide the User

Instruction Manual to any user of this equipment or to

any rescuer.

2

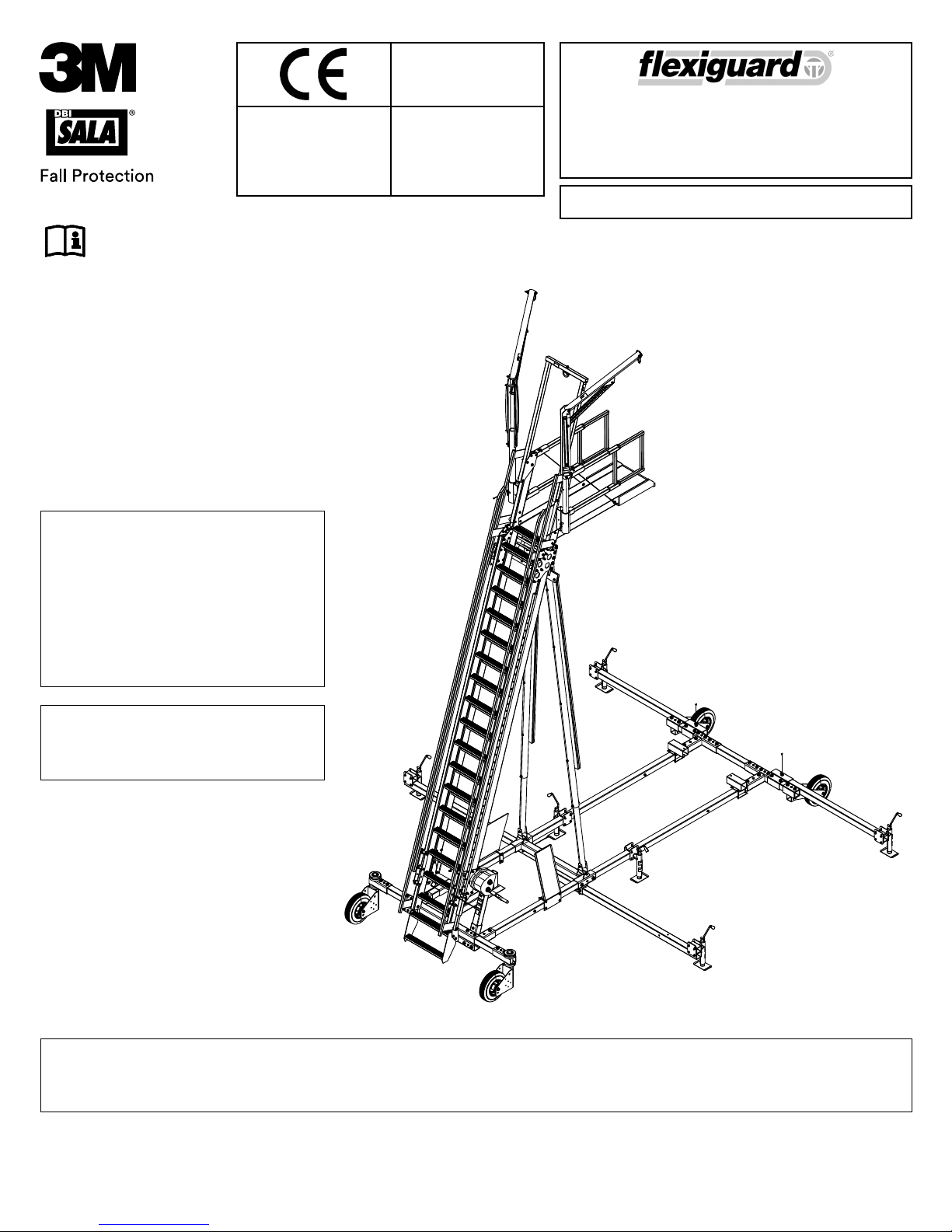

2.0 Ladder System Component Identifi cation

12

10

5

12

9

8

11

3

Back

7

4

3

2

Front

14

1. Jack

2. Swivel Wheel

3. Fixed Wheel

4. Outrigger (long)

5. Outrigger

6. Winch Post

7. Lifting Kit

8. Platform

1

5

13

6

2

9. Handrail (2)

10. Overhead Anchor Point Post

11. Ladder Support Tubes

12. Davit

13. Operators Setup and Use

Decal Plate

14. Step

4

3

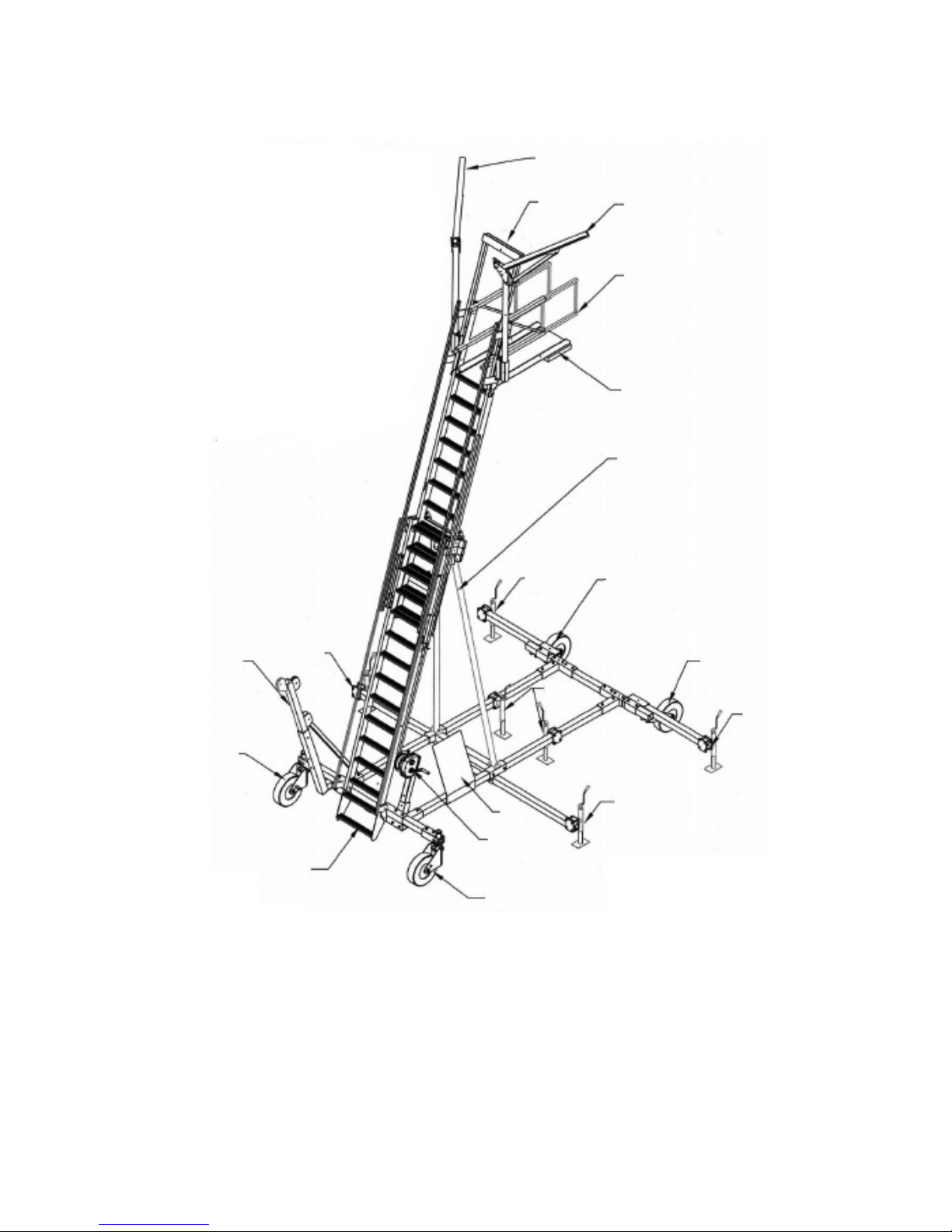

3.0 Ladder System Assembly

Figure 1 - Shipping Layout

The unit comes shipped on its side to keep the majority

of the unit assembled. Remove all loose packages and

place them out of the way at this stage of assembly.

Remove the strapping

holding the ladder to the

shipping pallet.

Aluminum shipping

stands.

The strap that is

secured from the

base to ladder

should stay secured

until the unit is

rested on the

ground.

4

3.0 Ladder System Assembly - Continued

Figure 2 - Remove from Pallet

After packages are removed, the base and ladder

assembly must be removed from the pallet.

Remove screws

and nails from the

aluminum stands to

separate the unit from

the pallet.

Place forklift under the

base as shown here.

Cut all strapping. Lift unit slowly to make certain it is

balanced on the forks. Reposition forks if necessary.

After the unit is off the pallet, slowly lower the unit to

the ground. Then, using the forklift, slowly back up while

rotating the unit fl at to the ground.

Using a 3/4”

wrench, loosen

all bolts that

secure the three

aluminum stands.

5

3.0 Ladder System Assembly - Continued

Figure 3 - Position for Assembly

Using the forklift,

lift the unit up to

assemble all four

wheels to the base.

Shipping stand.

Remove the center

aluminum shipping

stand.

6

3.0 Ladder System Assembly - Continued

Figure 3 Continued - Position for Assembly

Remove the front

aluminum shipping

stand.

Remove detent pins.

Rotate the middle

jacks down to help

support the base

while assembling the

wheels and outriggers

in the following steps.

Replace detent pins.

7

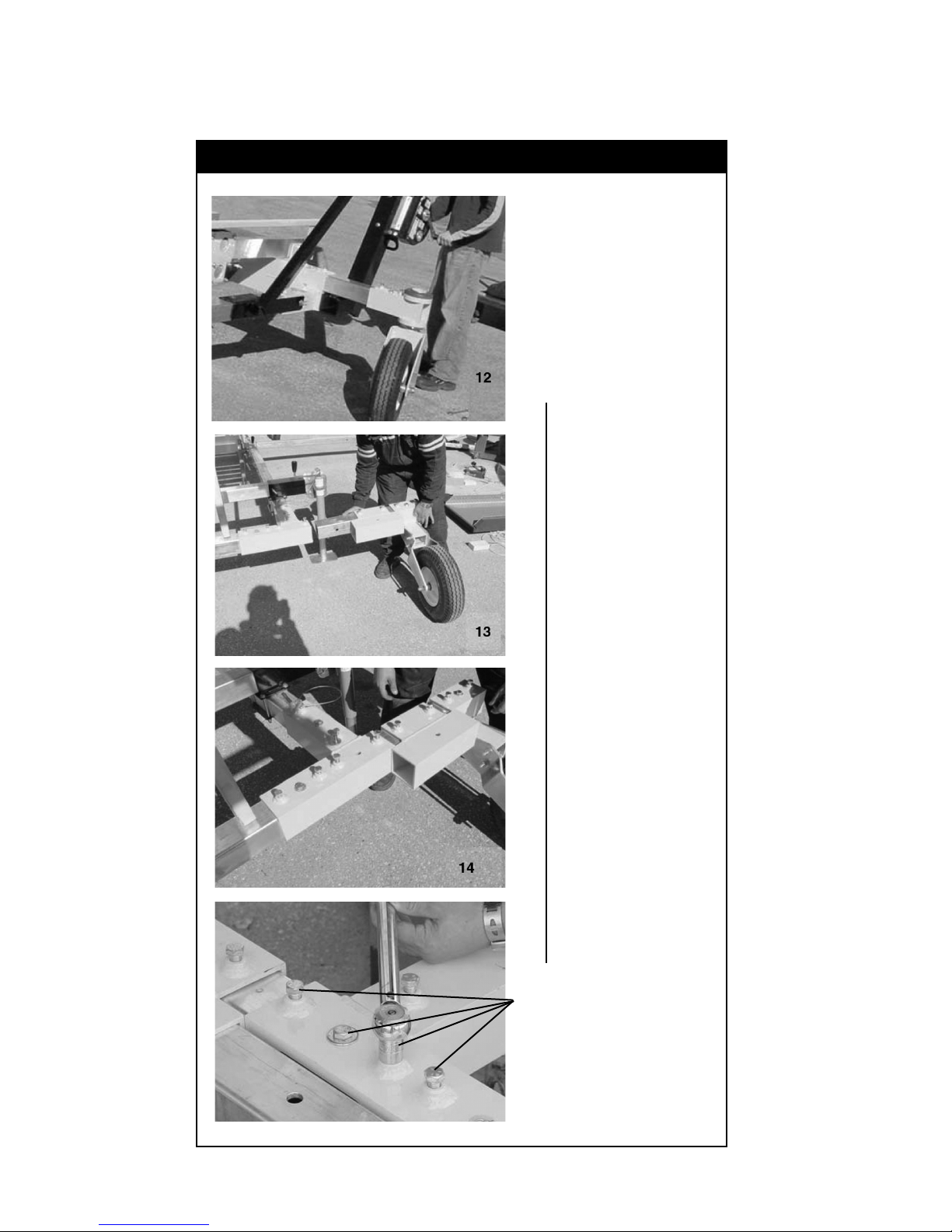

3.0 Ladder System Assembly - Continued

Figure 4 - Add Wheels

Add all four wheels

to the base. Swivel

casters are used

at the front. Fixed

casters are used at

the back.

Secure all bolts to

25 ft lbs (33.9 N.m).

Secure all bolts to

25 ft lbs (33.9 N.m).

8

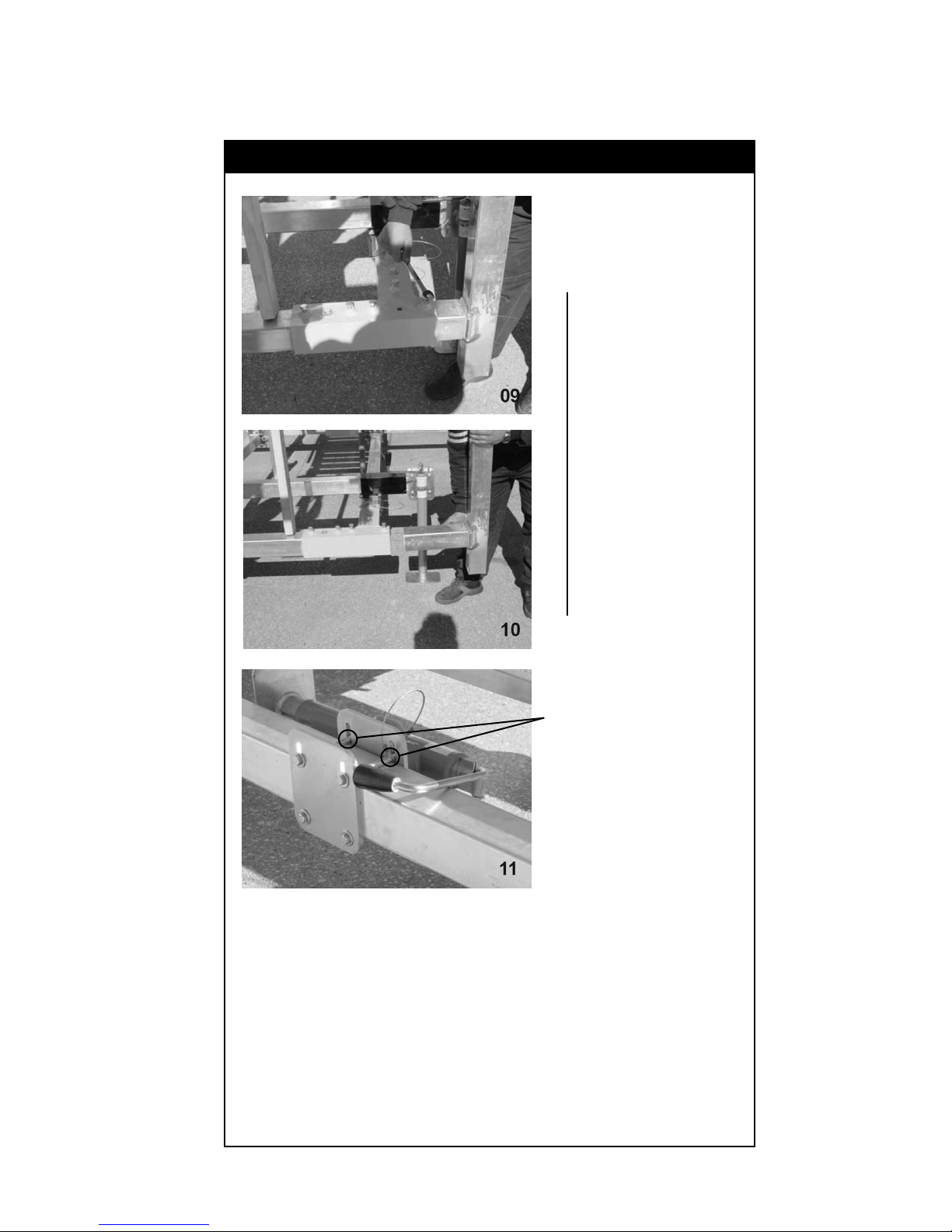

3.0 Ladder System Assembly - Continued

Figure 5 - Insert Outriggers

Insert all outriggers

into their appropriate

sockets.

Longer outriggers are

used with the center

base section.

Orient jacks toward

fi xed wheels (back).

Make sure all detent

pins are fully inserted

and secure.

9

3.0 Ladder System Assembly - Continued

Figure 6 - Add Ladder Winch

Add the ladder

winch to the socket

on the right side of

the ladder.

Bolt the winch post

so it is at its tallest

position.

10

3.0 Ladder System Assembly - Continued

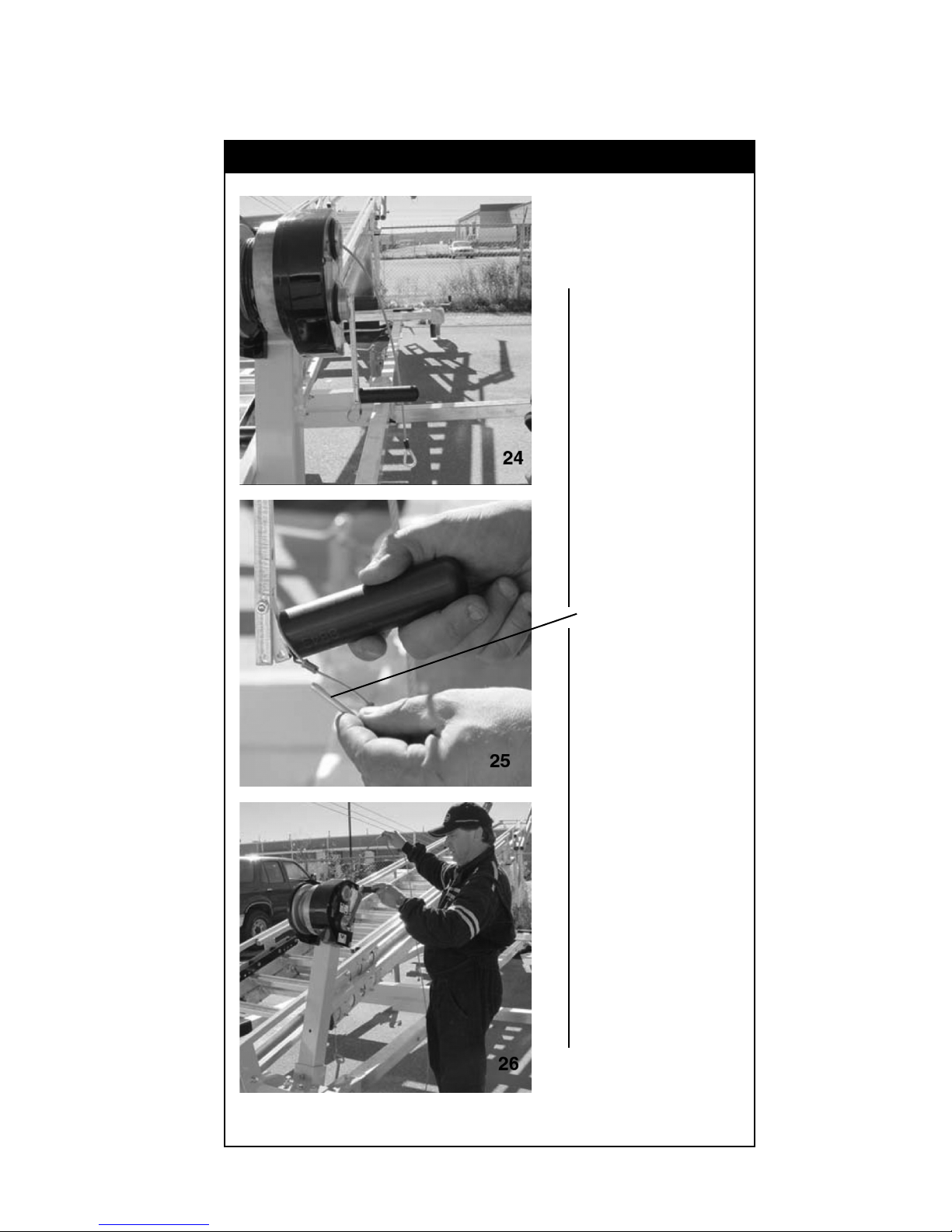

Figure 6 Continued - Add Ladder Winch

Unwind the cable,

leaving only 3 to 5

wraps.

Secure the handle

in operating

position with

detent pin.

11

3.0 Ladder System Assembly - Continued

Figure 6 Continued - Add Ladder Winch

Feed the cable

through the fi rst

pulley as shown

here. Next, feed

the cable across

to the next pulley

and feed it through

as shown.

Cable

Cable

12

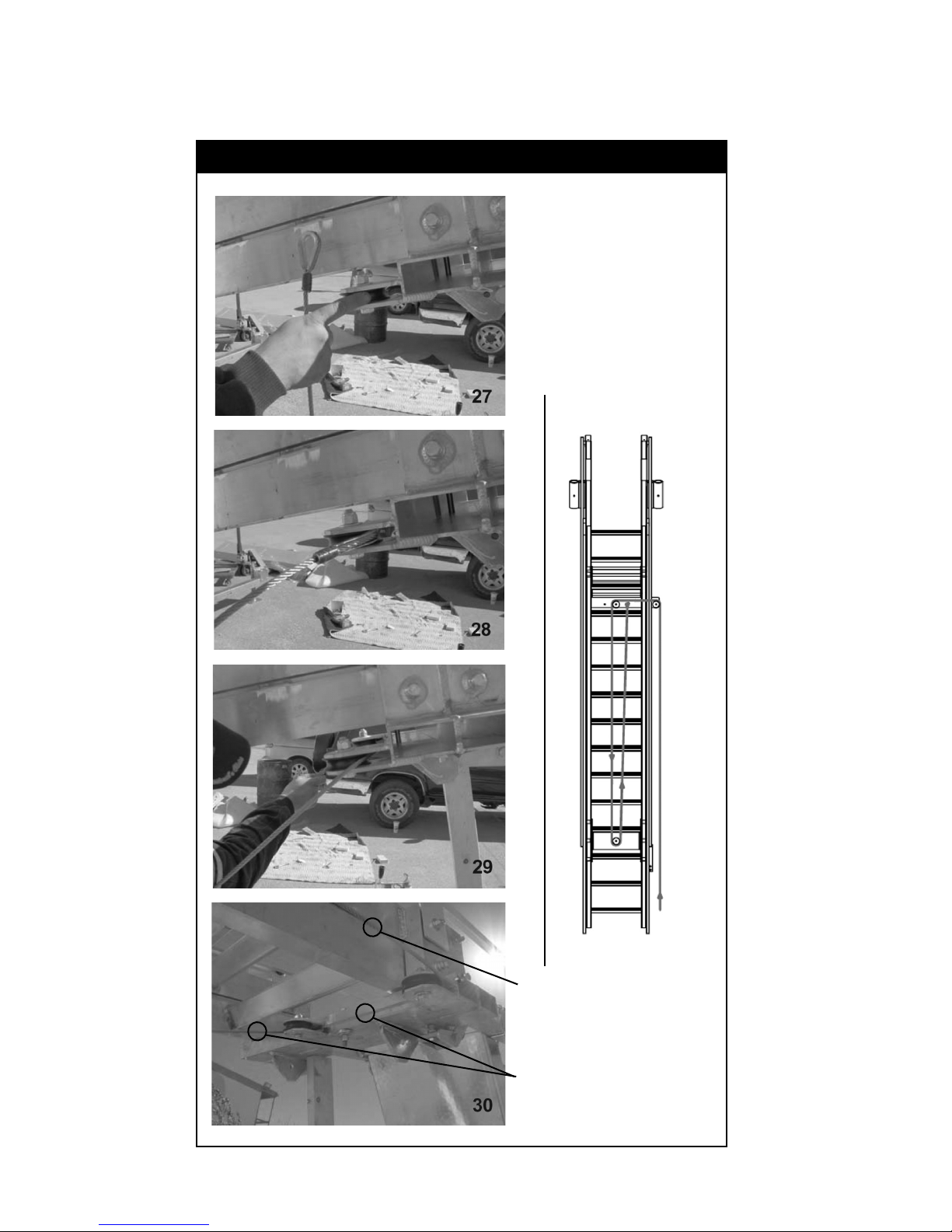

3.0 Ladder System Assembly - Continued

Figure 6 Continued - Add Ladder Winch

Feed the cable down

the pulley at the

bottom of the ladder

and back through the

other side as shown.

13

3.0 Ladder System Assembly - Continued

Figure 6 Continued - Add Ladder Winch

Next, pull the cable

back up to pulleys at

the top of the ladder

and attach to the bolt

located between the

two pulleys as shown

in illustrations 34 - 36.

Mounting

bolt

Nut

Washer

Washer

Cable Thimble

Washer

14

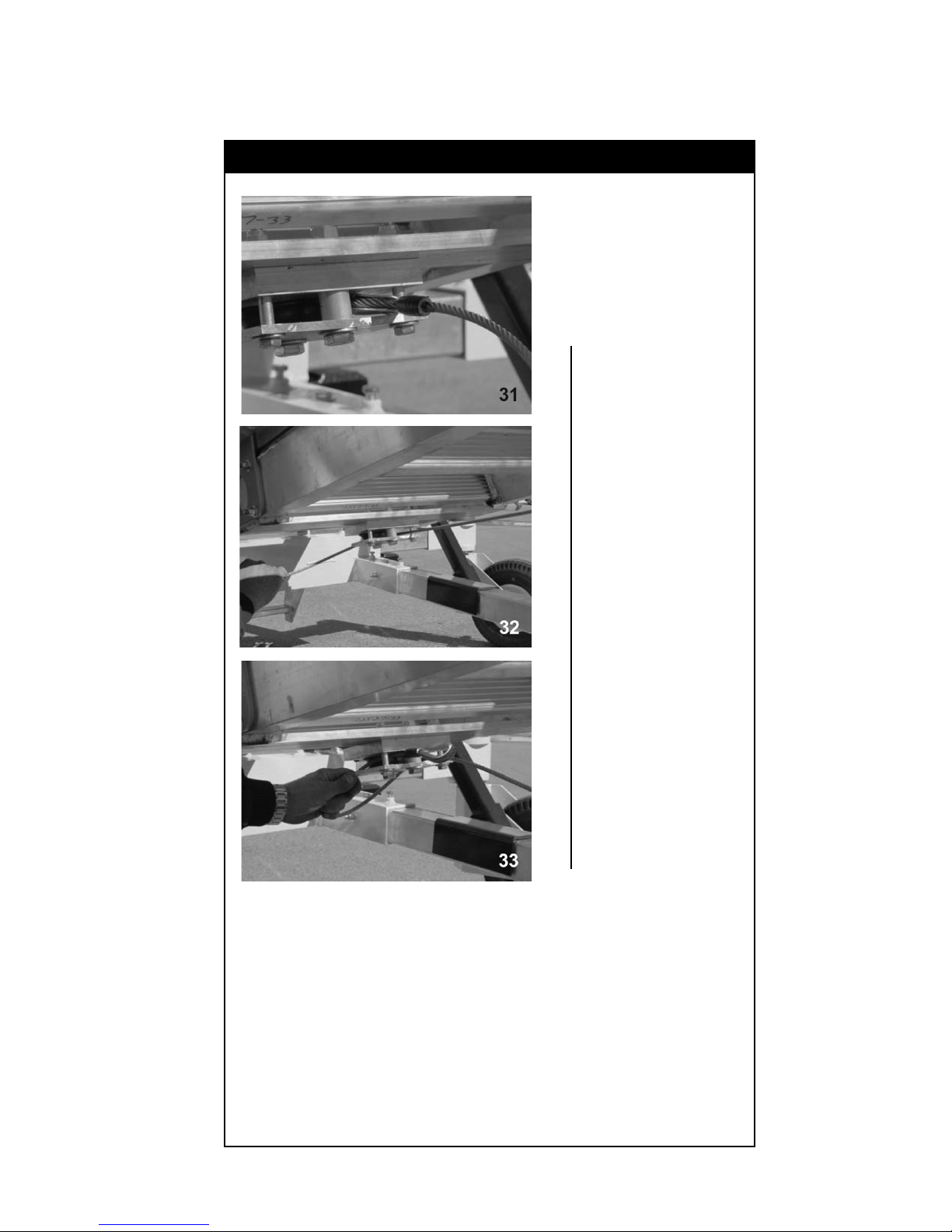

3.0 Ladder System Assembly - Continued

Figure 7 - Lifting Kit

(Skip this section if Lifting Kit was not ordered)

Skip this section if

no lifting kit was

ordered.

Substitute a crane or

forklift to erect the

ladder on the base.

WARNING

Do not stand under

the ladder while

assembling.

Add the lifting kit

to the base of the

ladder. First add the

post, making certain

it is angled away

from the unit. Tighten

the bolts to secure

the post as shown in

illustration 38.

Lift Kit

Section

15

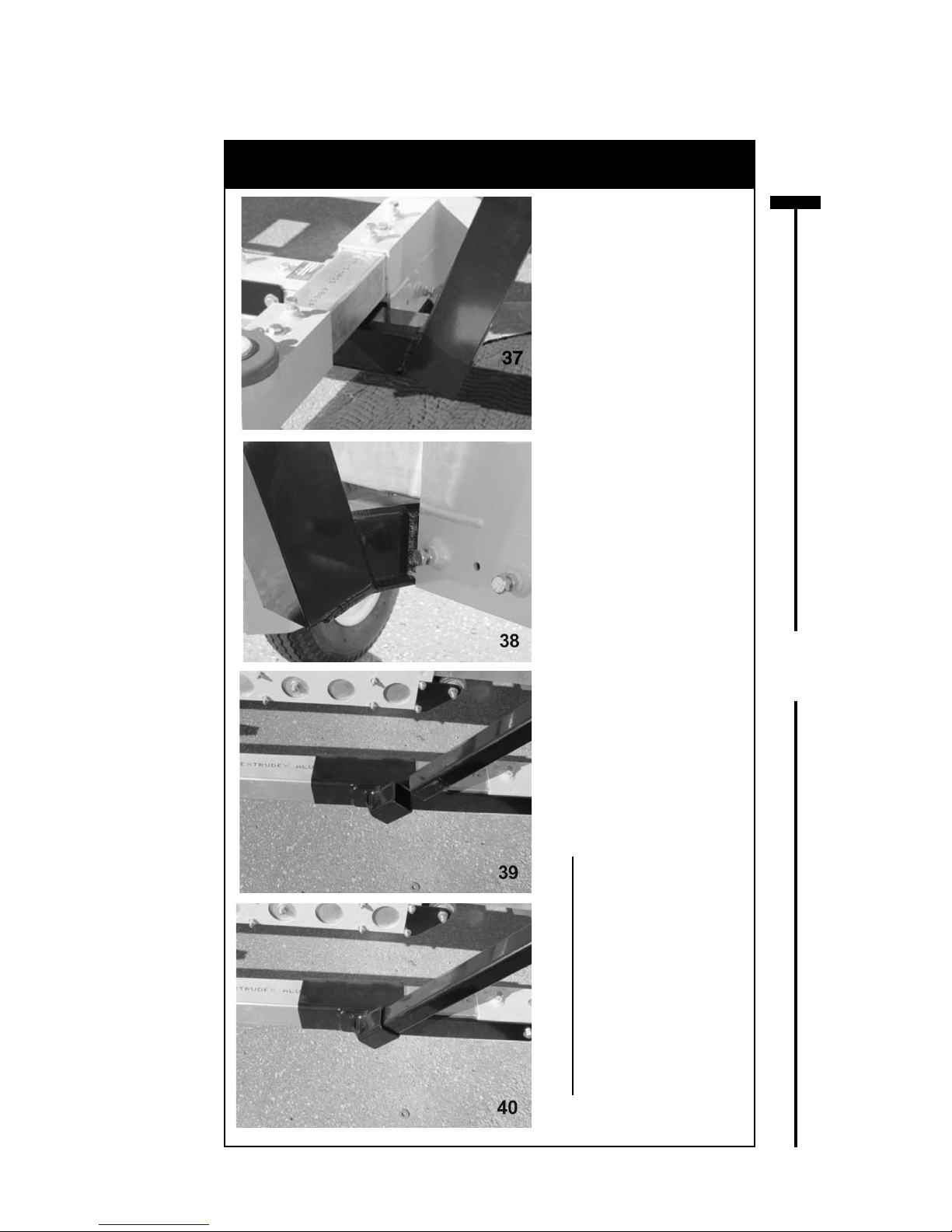

Second, add the

support tube by

fi rst inserting it into

the receiver pocket

mounted on the

base, as shown in

39 and 40.

3.0 Ladder System Assembly - Continued

Figure 7 Continued - Lifting Kit

Third, bolt the

support tube

between the ears

located on the

lifting kit post as

shown in 41.

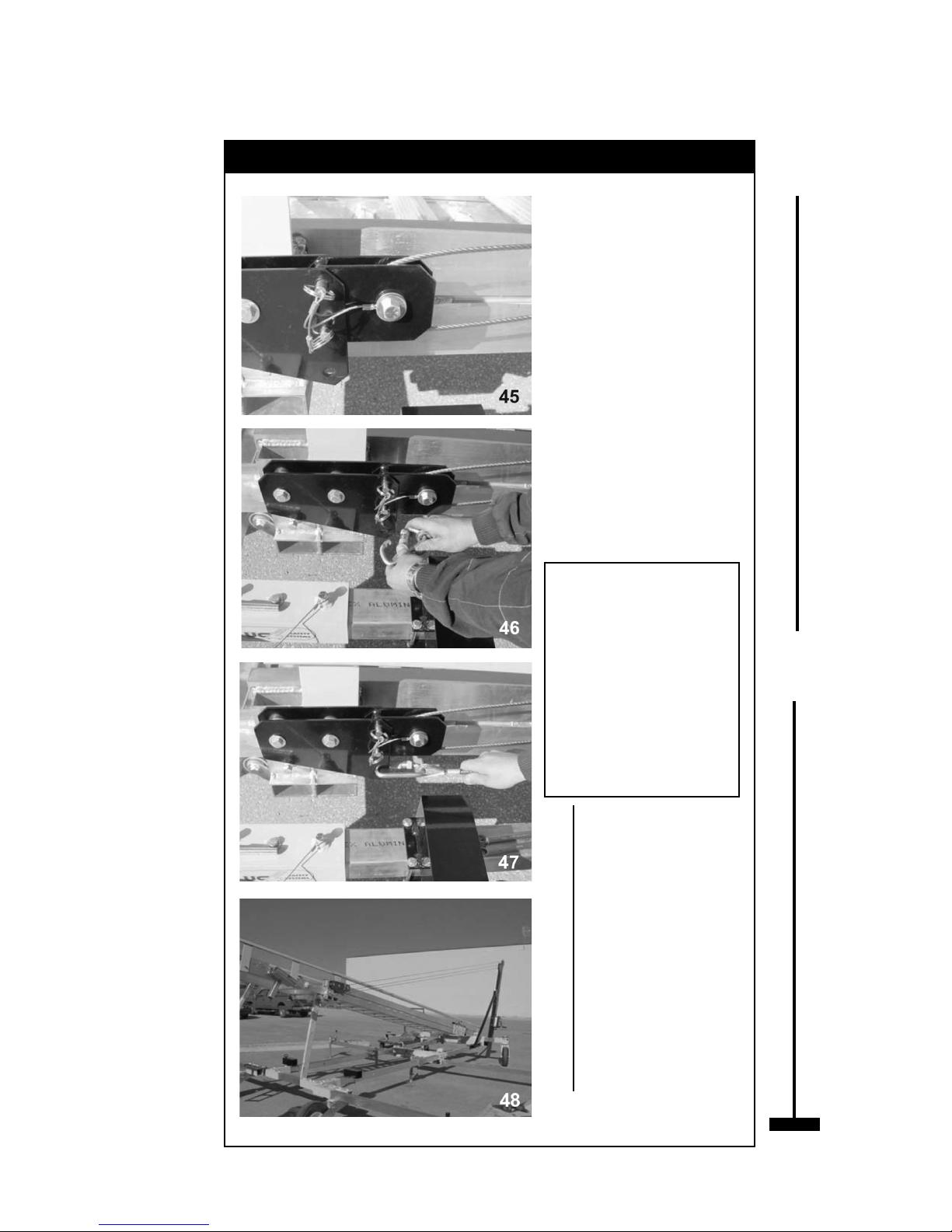

Unwind the cable

by holding both the

redirect pulley and

the carabiner as

shown in 42 and 43.

When the cable is

long enough, attach

both the redirect

pulley and the

carabiner to the

attachment at the

top of the ladder

as shown in 44

through 47.

Lift Kit

Section

16

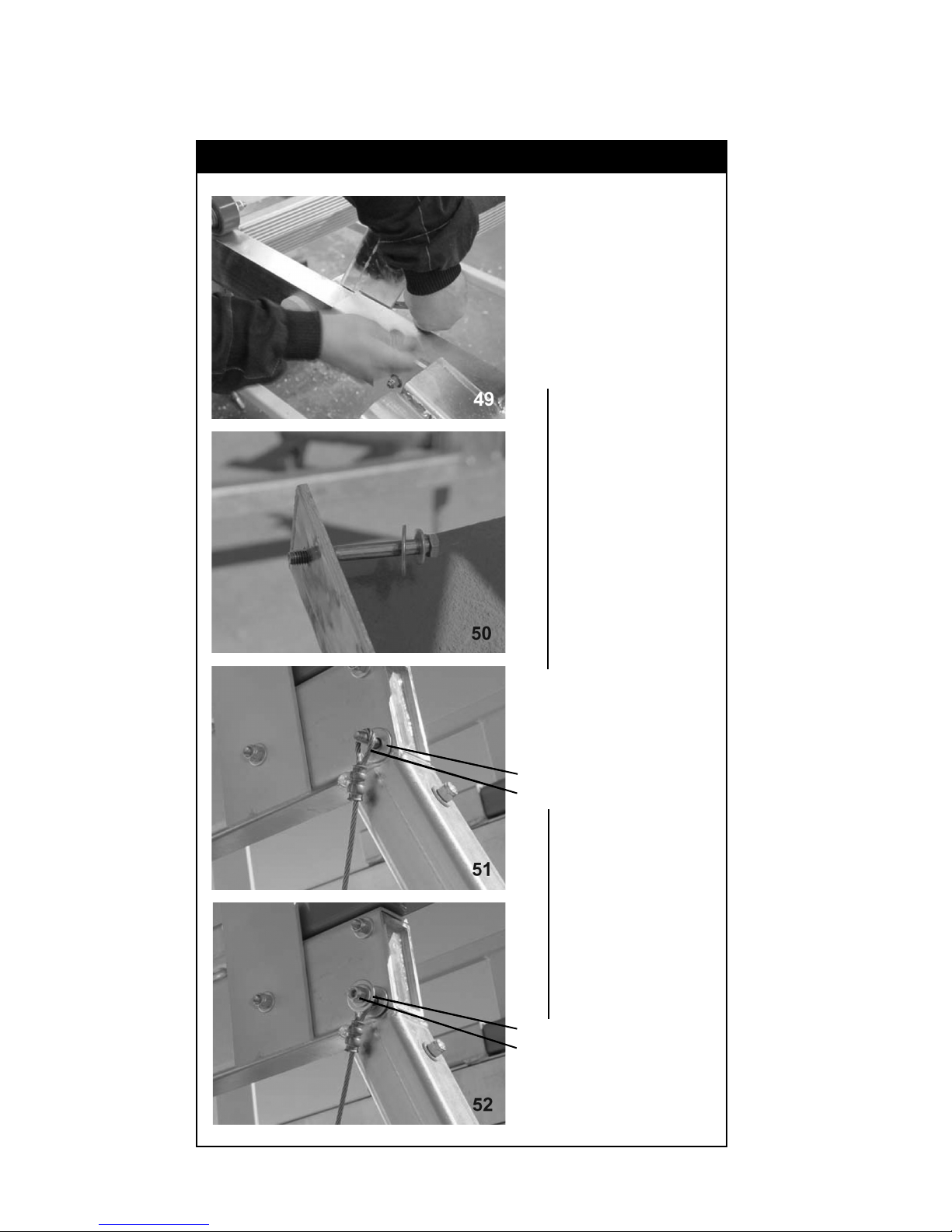

3.0 Ladder System Assembly - Continued

Figure 7 Continued - Lifting Kit

Before using the

lifting kit, ensure

that all connections

are secured. Unwind

the remaining cable

from the winch drum

and respool neatly to

avoid cable damage

sudden cable

jumping.

Do not raise the

ladder until the

ladder support tubes

are assembled (see

illustration 63).

WARNING

Once the ladder is

upright, secured and

ready to use, this

lifting device must

be disconnected

(remove carabiner)

to ensure that no

improper use occurs

while operating the

ladder.

Lift Kit

Section

End of Lift Kit

section.

17

3.0 Ladder System Assembly - Continued

Figure 8 - Attach Platform to Ladder

Assemble the

platform to the

ladder. Remove the

nuts and washers

from both bolts

where the platform

mounts and the

cables attach.

Attach cables to

both sides.

Assemble hardware.

Washer

Cable

Washer

Nut

18

3.0 Ladder System Assembly - Continued

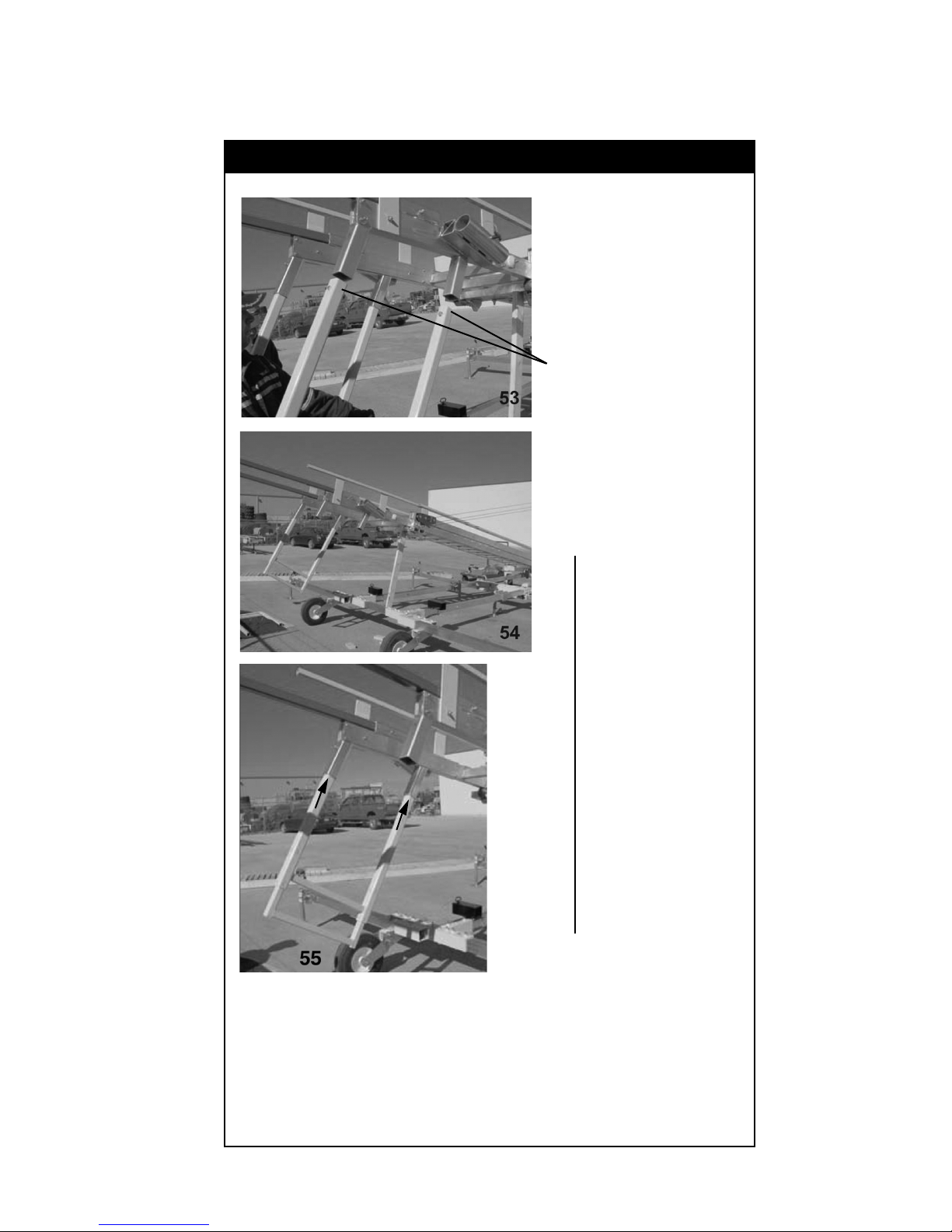

Figure 9 - Assemble Handrails

Assemble the

adjustable handrails

to the unit.

Insert the hand rails

to the steel sleeve

section handrail

pockets as shown in

54 and 55.

19

3.0 Ladder System Assembly - Continued

Figure 9 Continued - Assemble Handrails

Add bolts to secure

the handrails. Make

certain the cables

inside the tubing are

also secured by the

bolts by going through

the cable eyes.

20

3.0 Ladder System Assembly - Continued

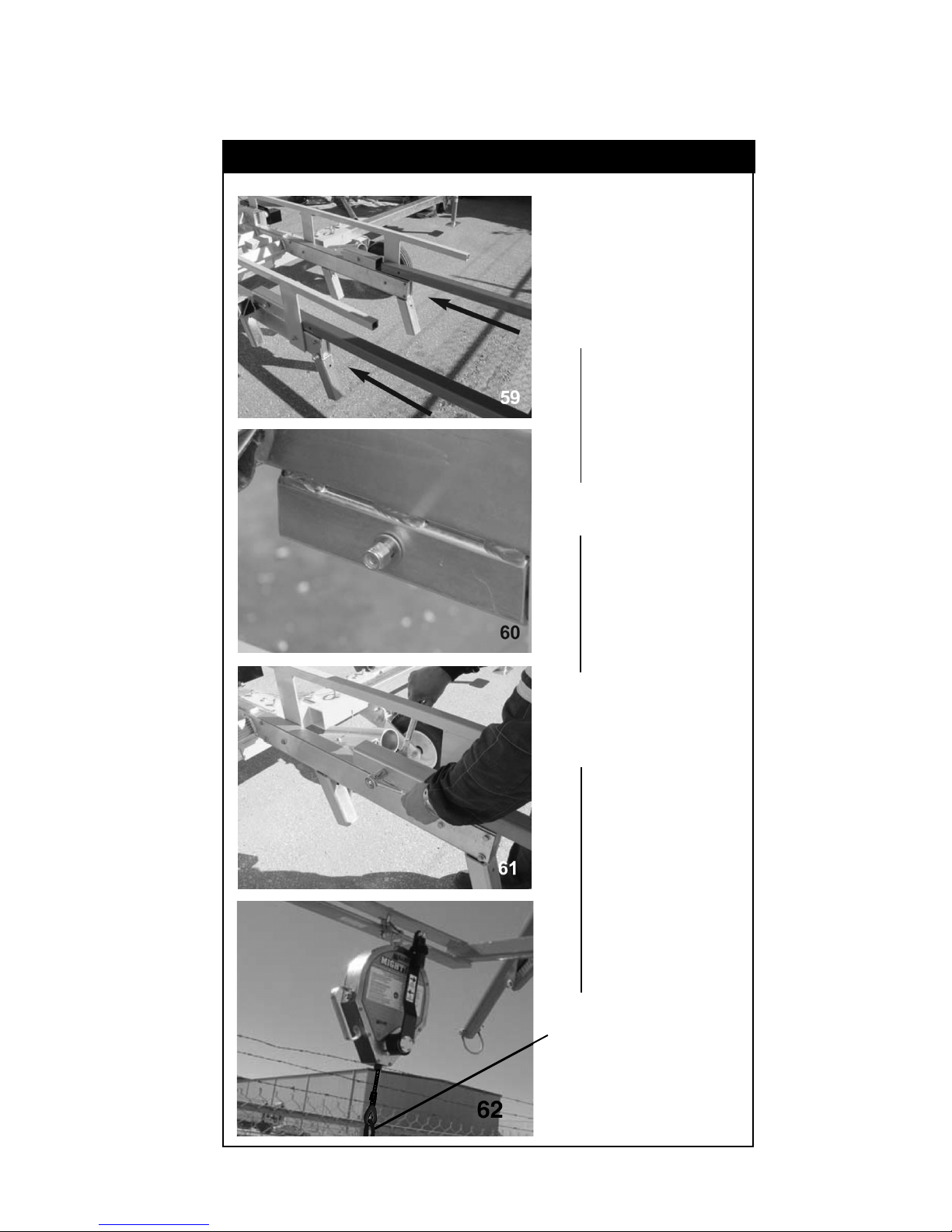

Figure 10 - Assemble Overhead Anchor Post

Assemble the

overhead anchor

point post by

inserting the post into

the pockets on the

steel sleeve section.

Align holes and

bolt into place.

Attach an SRL that

will secure the

operator climbing up

and down the ladder.

Make certain a

tag line is

attached to pull

the retractable

cable down the

ladder before

climbing the unit.

21

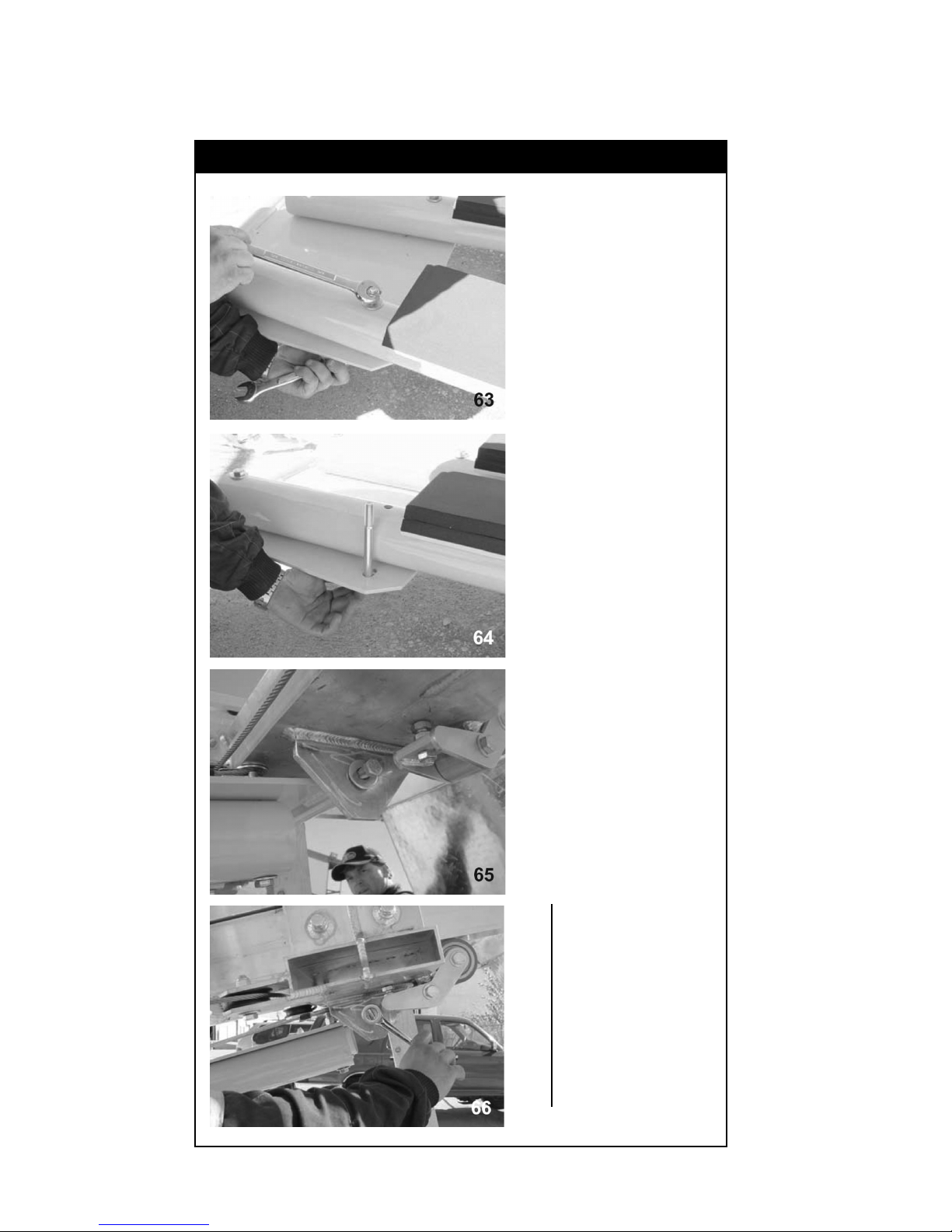

3.0 Ladder System Assembly - Continued

Figure 11 - Assemble Ladder Support Tubes

Assemble the ladder

support tubes.

Mount the support

tube assembly to the

ladder unit:

First, raise the ladder

using the lifting

device by about 4 to

5 feet.

Second, remove the

inner tubes from the

support tubes to be

able to align the holes

in the ears.

22

Third, slide the

support tube

assembly under the

raised ladder while

aligning the threaded

holes with the holes

in the ears under the

ladder, as shown in

65 and 66.

3.0 Ladder System Assembly - Continued

Figure 11 Continued - Assemble Ladder Support Tubes

Slowly lift the ladder

with attach support

tubes (using lift kit,

forklift or overhead

crane) until it is

possible to insert the

inner tubes of the

support tube assembly

and bolt into place.

23

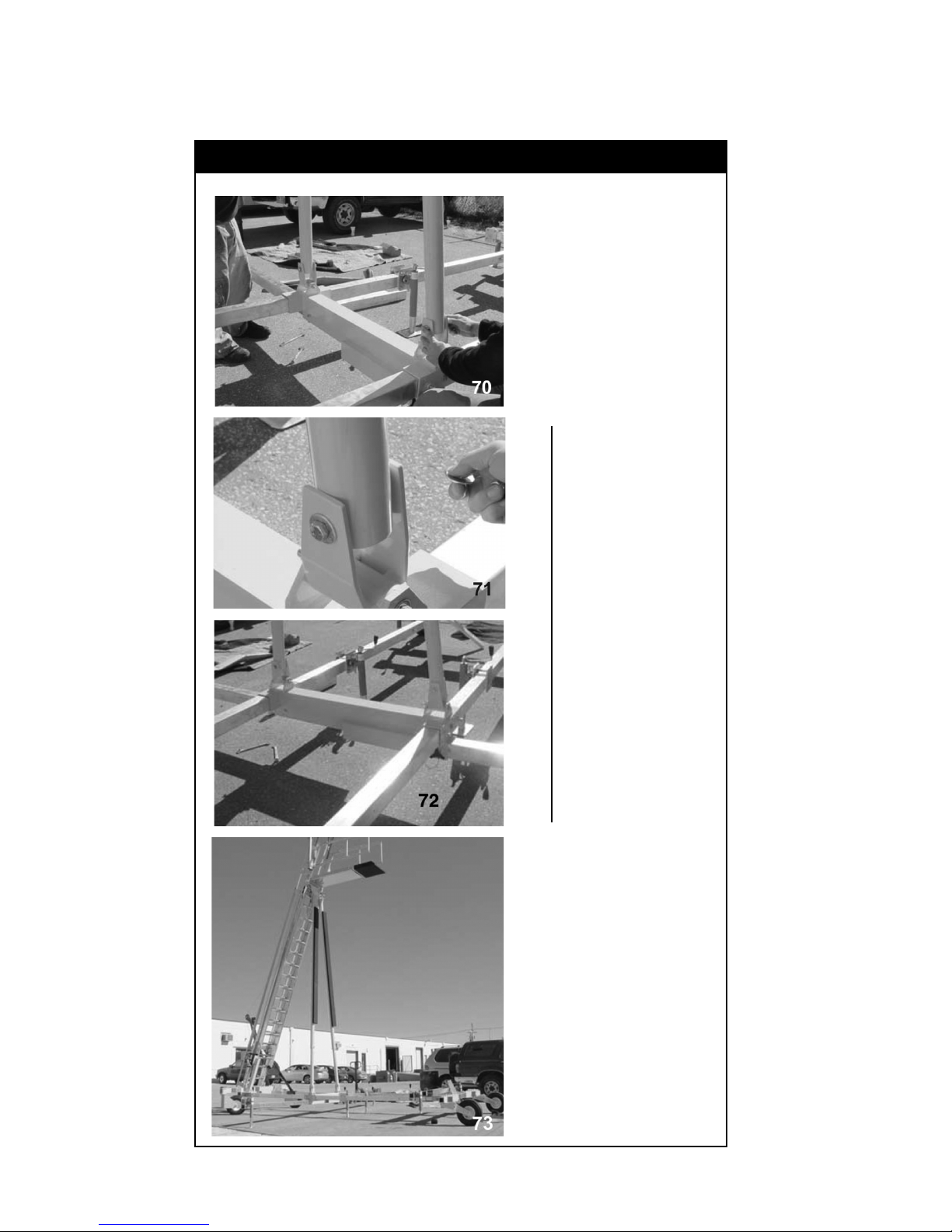

3.0 Ladder System Assembly - Continued

Figure 11 Continued - Assemble Ladder Support Tubes

Continue to lift

the ladder into its

operating position.

Mount the support

tubes into the U

channels attached

to the center

section of the base,

as shown in 70

through 72.

24

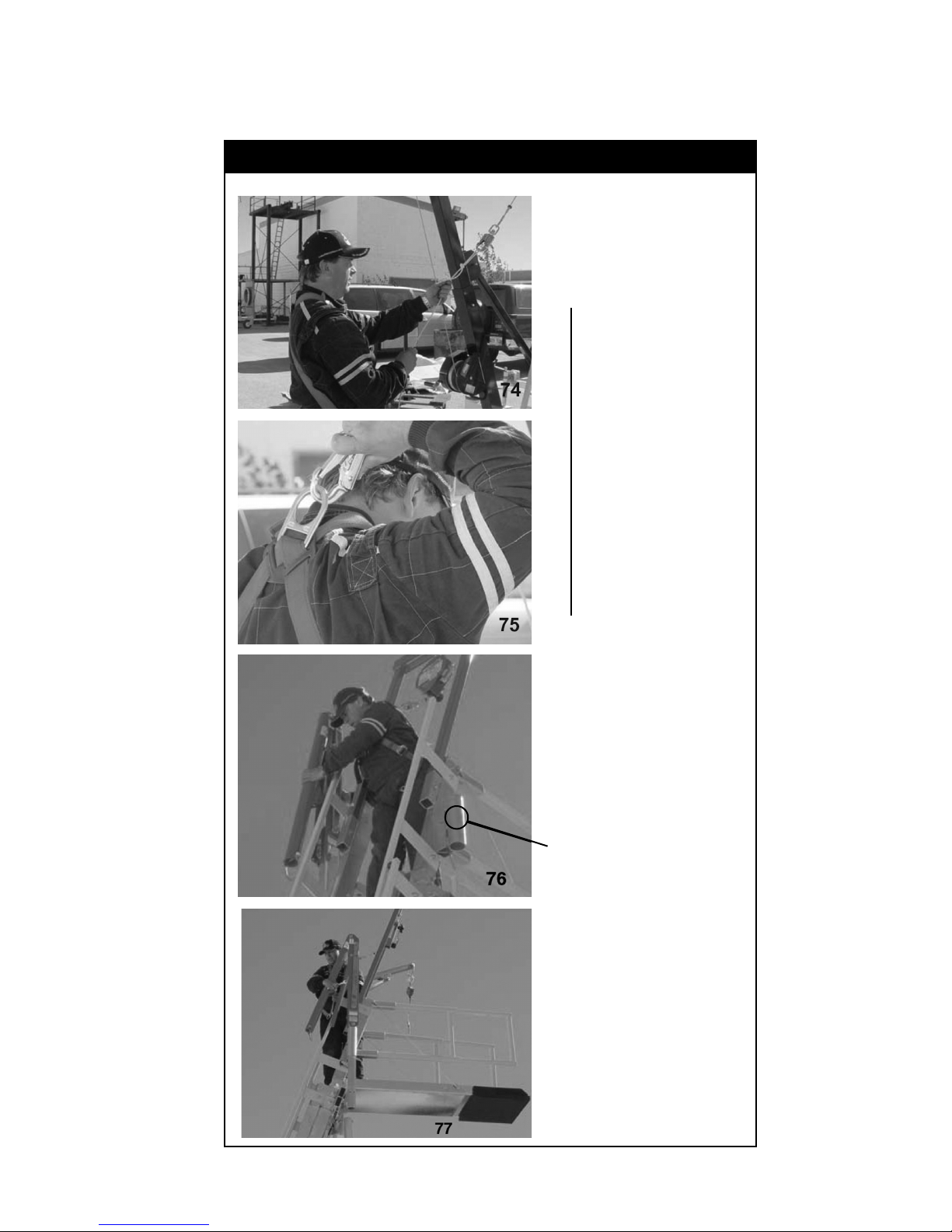

3.0 Ladder System Assembly - Continued

Figure 12 - Final Assembly Steps

Pull your tag line down

to attach the SRL

to your harness, as

shown in 74 and 75.

Depending on

available equipment,

you may want to use

a forklift or crane to

lift the davits up to

the steel sleeve and

insert them.

Sleeve

25

3.0 Ladder System Assembly - Continued

Figure 12 Continued - Final Assembly Steps

Next, pin the davits

into place as shown

in 78. Set up the

davits by removing

the hardware at the

end of the gusset and

attach the gusset to

the davit.

The davits will point

out and away from

the ladder. This gives

the operators a larger

working area with

approximately a 6

foot (1.8 m) radius.

(See User Instruction

Manual.)

Attach your SRLs,

not provided, to the

anchor point at the

end of each davit, as

shown in 79

through 81.

26

3.0 Ladder System Assembly - Continued

Figure 12 Continued - Final Assembly Steps

Attach the operators

setup and use decal

plate on the base of

the unit, as shown.

This should be on

the same side as

the winch.

27

Last, assemble the

step to the base of

the ladder. Assemble

the step between the

ears shown in 85.

Align and bolt.

4.0 Ladder System Maintenance and Inspection

4.1 Visual inspection after assembly

A complete visual inspection should be performed on the FPALS

equipment prior to operation. The following items should be checked;

and the results recorded on the “Maintenance and Inspection Log”

sheet found in the Operators Manual.

4.1 Labels

Check that all labels are clean and legible. Clean the labels if any are

dirty using a mild soap and a damp cloth. Replace if any are illegible.

4.2 Fasteners

Check that all ladder screws and other fasteners are tight. Tighten

ladder fasteners hand tight only. Base fasteners must be checked

using 15 ft. lbs (20.3 N.m) of torque. If any are loose, tighten to 20

ft. lbs (27.1 N.m).

Contact your local dealer or DBI-SALA for any replacement fasteners

that may be required

Check the components for cracks, dents, bends, or breaks.

Minor cosmetic damage in the component body will not affect the

function of the FPALS System. However, if there are major dents or

any other structural damage, the unit should not be used and should

be returned to the manufacturer for service.

28

Essai de type CE

N° 0086

BSI Product Services

B.P. 6221, Kitemark Court

Davy Avenue

Milton Keynes

MK1 9EP Royaume-Uni

L’utilisateur doit lire et comprendre ces instructions

avant d’assembler ou d’utiliser ce matériel.

IMPORTANT : ce manuel

d’instructions concerne uniquement

l’assemblage du produit. Le « manuel

d’instructions de l’utilisateur du

dispositif d'échelle antichute »

(5902345) décrit l’utilisation, le

fonctionnement et l’entretien de ce

produit. Il incombe à l’employeur de

remettre le manuel d’instructions

de l’utilisateur à tout utilisateur de

l’équipement ou sauveteur.

EN795: 1996

Classe B

Contrôle qualité

production CE

N° 0086

BSI Product Services

B.P. 6221, Kitemark Court

Davy Avenue

Milton Keynes

MK1 9EP Royaume-Uni

Dispositif d'échelle antichute

Numéros de modèles :

8517714

8517715

8517716

8517717

8517718

8517719

8530140

8560010

Instructions d’assemblage

IMPORTANT : pour toute question

relative à l’utilisation, l’entretien ou

la compatibilité de cet équipement de

sécurité à une utilisation particulière,

adressez-vous à Capital Safety.

IMPORTANT : ces instructions d’assemblage doivent être mises à la disposition de la personne chargée d’assembler

l’équipement. Celle-ci doit lire et comprendre ces instructions du fabricant avant de commencer la procédure

d’assemblage. Elle doit respecter les instructions relatives à chaque composant du système. Toute modifi cation ou

utilisation inappropriée de ce produit, ou le non-respect de ces instructions d’assemblage, peut provoquer des blessures

graves voire la mort.

Nº DE FORMULAIRE : 5902369

RÉV. : C

© Copyright 2013, Capital Safety

Loading...

Loading...