Page 1

Cold Shrink QS-III

Three-Conductor Splice Kit for use on

Armor and Non-Armor Cables

Instructions

IEEE Std. 404

35 kV Class

250 kV BIL

* Splices (including size transitions) can be made to smaller or larger conductors, provided

both cables are within the Insulation O.D. Range and the connector meets the dimensional

requirements shown below.

Connector Dimensional Requirements

Minimum Maximum

inches (mm) inches (mm)

Outside Diameter 0.51" (13,0 mm) 1.70" (43,2 mm)

Length

Aluminum (Al/Cu) ------ 6.00" (152 mm)

Length

Copper (Cu) ------ 6.50" (165 mm)

Cable Range Requirements

Kit Number Cable Insulation Conductor

O.D. Range Size Range

5797A-MT 1.07" to 1.70" 1/0 AWG - 350 kcmil*

(27,2 mm to 43,2 mm) (60 - 185 mm

2

)

3M™Cold Shrink

QS-III Splicing Kit

5797A-MT

78-8126-0432-6-A

CAUTION

Working around energized high-voltage systems may cause serious

injury or death. Installation should be performed by personnel familiar

with good safety practice in handling high-voltage electrical equipment.

De-energize and ground all electrical systems before installing product.

Page 2

2

78-8126-0432-6-A

Contents

1.0 Kit Contents ............................................................................................................................................3

2.0 Prepare Cable ..........................................................................................................................................3

3.0 Place Components on Cable ..................................................................................................................5

4.0 Install Splice ............................................................................................................................................6

5.0 Install Armor Continuity (if cable is armored) ......................................................................................8

6.0 Install Splice Jacket ................................................................................................................................9

Page 3

3

78-8126-0432-6-A

1.0 Kit Contents:

1.1 Kit Contents are as follows:

3 ..............Cold Shrink 5467A QS-III Silicone Splice Bodies

6 ..............Tubes, P55/R Red Compound

3 ..............Metallic Shield Sleeves

6 ..............Constant Force Spring Shield Connectors (1.31" I.D.)

2 ..............Constant Force Spring Shield Connectors (1.54" I.D.)

1 ..............Armor to Armor Continuity Braid

2 ..............Cold Shrink Jacket Tubes

1 ..............3M

™

CC-2 Cable Preparation Kit

1 ..............Roll, Scotch

™

33+ Vinyl Electrical Tape (3/4" x 66')

5 ..............Rolls, Scotch

™

Super 88 Vinyl Electrical Tape (1 1/2" x 44')

4 ..............Rolls, Scotch-Seal

™

2229 Mastic Tape (3 3/4" x 10')

1 ..............Roll, Scotch

™

24 Electrical Shielding Tape (1" x 15')

1 ..............Roll, Scotch

™

2228 Rubber Mastic Tape (2" x 10')

6 ..............Rolls, Armorcast

™

Structural Material (4" x 15')

6 ..............Cold Shrink Adapter Tubes (3 white core and 3 red core)

1 ..............Instruction Sheet

6 ..............Copper Foil Tape (1/2" x 10")

12 ............Gloves

2.0 Prepare Cable

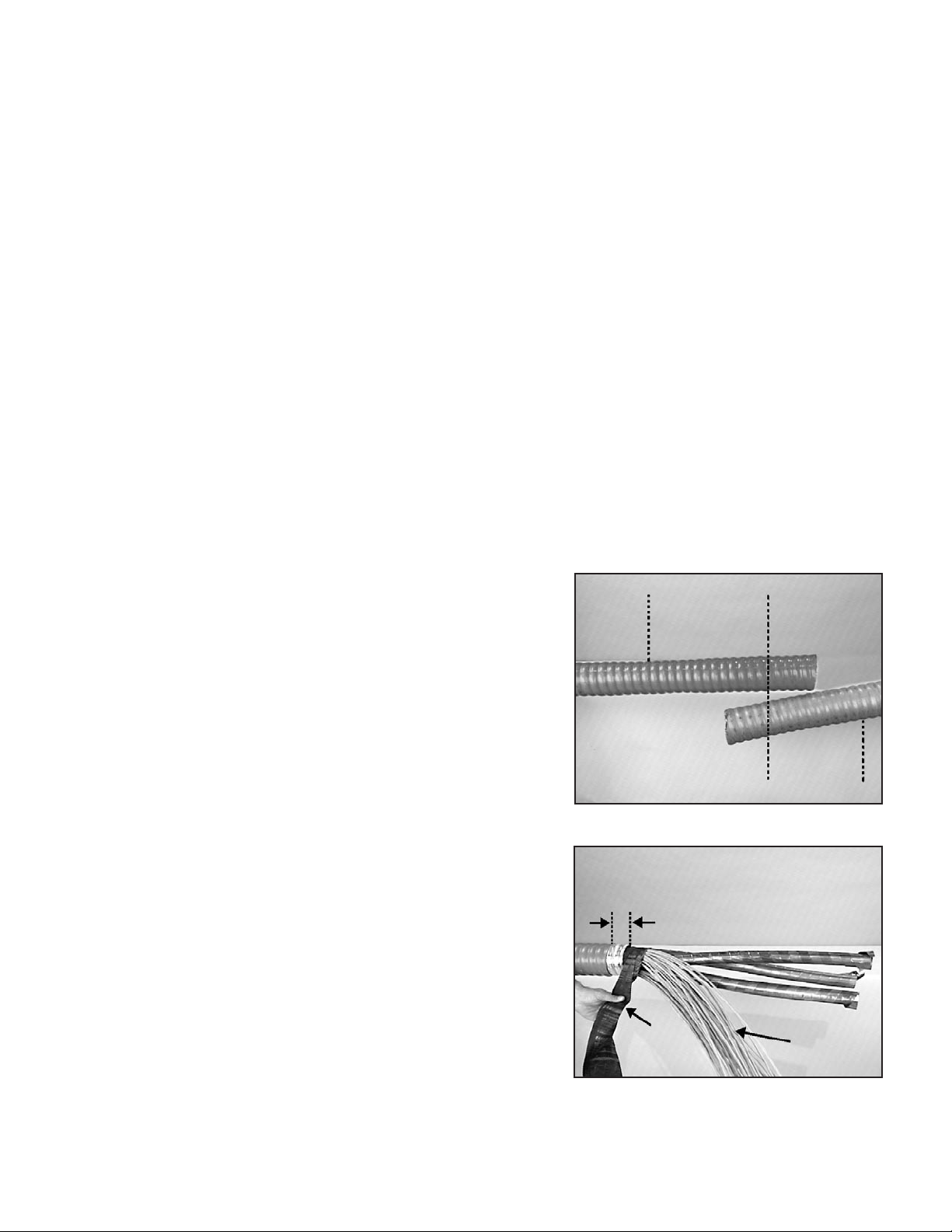

2.1 Prepare the cable according to your company's

standard procedures. Allow cable ends to overlap as

much as 10" (254 mm).

Remove 33" (838 mm) of cable jacket, plus half of

the overlap from Cable X.

Remove 25" (635 mm) of cable jacket, plus half of

the overlap from Cable Y.

Keep a 22" (559 mm) piece of cable jacket removed

from Cable X and a 14" (356 mm) piece of jacket

from Cable Y for use later in these instructions.

2.2 If cable is armored, remove cable armor leaving

1 1/2" (37 mm) armor exposed beyond jacket end.

Remove cable binder , if present, at the end of the

jacket or armor and discard.

Fold cable fillers and ground wire(s) back over

cable jacket end. Do not cut off.

Temporarily hold the fillers and ground wire(s) back

by banding them to the cable jacket using Scotch

™

33+ vinyl tape.

Cable Y

25" (635 mm)

Cable X

33" (838 mm)

remove

binder

fold fillers back

DO NOT CUT OFF

1 1/2"

(37 mm)

Page 4

4

78-8126-0432-6-A

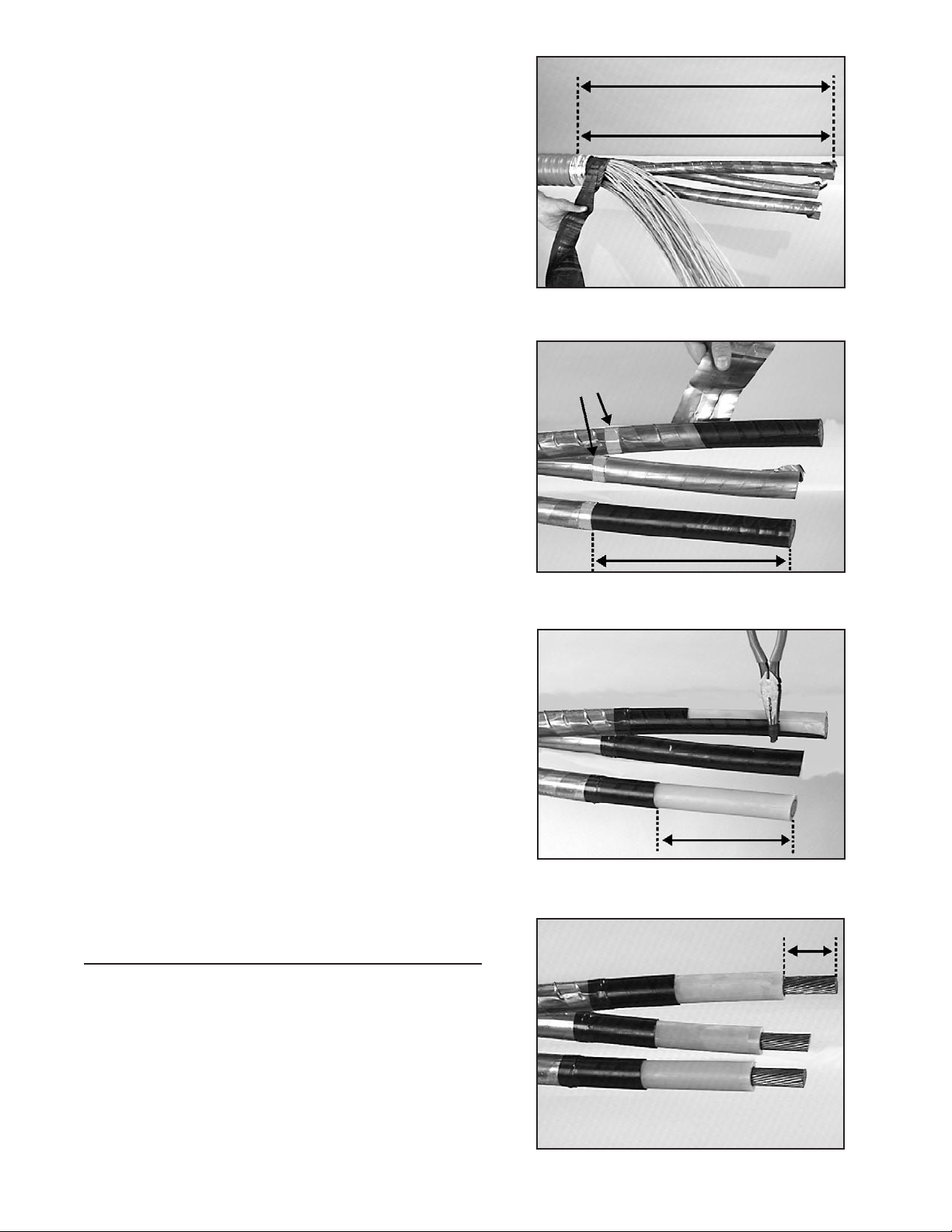

2.3 Cut the phase cores to the appropriate length.

Cores of Cable X should be 33" (838 mm) when

measured from the cable jacket end or 31 1/2"

(800 mm) when measured from end of the armor.

Cores of Cable Y should be 25" (635 mm) when

measured from the cable jacket end or 23 1/2"

(597 mm) when measured from end of the armor.

2.4 Bind the metallic shields of both Cable X and

Cable Y cores with a copper tape strip at a point

11 1/2" (292 mm) from the end of each conductor.

Remove the metallic shields to the copper tape

binding.

If the phase cores are individually jacketed, remove

the individual jackets a distance of 15" (381 mm)

from the end of each conductor.

Cable X 33" (838 mm)

Cable Y 25" (635 mm)

copper

tape strips

8 1/2" (216 mm)

11 1/2" (292 mm)

field determine

2.5 Remove cable semi-conductive insulation screen

from cores of both Cable X and Cable Y for

a distance of 8 1/2" (216 mm) from the end of each

conductor.

Note: Cables must be within Insulation O.D. range of

the splice kit.

2.6 Remove cable insulation from conductors ends of

both Cable X and Cable Y.

Remove cable insulation for 1/2 connector length plus

an allowance * for increases in connector length due

to crimping. Insulation removal length shall not

exceed 3 1/4" (83 mm) from conductor end.

Do not install connectors now.

*Note: This assumes that the installer has determined

the increased length of an aluminum connector

crimped with a specific tool and die.

Aluminum Typical Growth

Connector Size allowance per end

1/0 AWG 1/8" (3 mm)

2/0 AWG 1/8" (3 mm)

3/0 AWG 1/8" (3 mm)

4/0 AWG 1/4" (6 mm)

250 kcmil 1/4" (6 mm)

350 kcmil 1/4" (6 mm)

Notes: 1. Copper connectors do not require a length

change allowance.

2. Maximum aluminum connector crimped length

allowed is 6.50" (165 mm).

Page 5

5

78-8126-0432-6-A

3.0 Place Components on Cable

3.1 Slide one large cold shrink jacket tube onto

Cable X and one onto Cable Y with the loose

core ribbon ends going on the cable last, extending

toward the cable ends.

3.2 Slide a 3M

™

cold shrink splice body onto each

core of Cable X with the loose core ribbon

end going on the cable first, away from cable end.

3.3 Expand metallic shield sleeves and slide one onto

each core of Cable Y. Compress the ends of each

shield sleeve together next to the cable armor or

jacket, away from the prepared conductor ends.

3.4 For 1/0 through 3/0 AWG connectors, or

connectors with an O.D. between 0.51–0.76"

(13,0–19,3 mm): Slide the cold shrink adapter tube

with the WHITE CORE onto the insulation with the

loose core ribbon end going on first, away from the

cable end.

For 4/0 AWG through 350 kcmil connectors or

connectors with an O.D. between 0.68–1.07"

(17,3–27,2 mm): Slide the cold shrink adapter tube

with the RED CORE onto the insulation with the

loose core ribbon end going on first, away from the

cable end.

loose core ribbon end

splice body

loose core ribbon end

shield

sleeve

adapter tube

large jacket tube

loose core

ribbon end

Page 6

6

78-8126-0432-6-A

4.0 Install Splice

4.1 Install connectors. See Table on front cover of

this instruction for proper connector dimensions.

Crimp connectors per recommendations from

connector manufacturer. For standard 3M

™

connectors, refer to the table at the end of this

instruction for crimping information.

4.2 Apply a tape marker to core semi-con insulation

screens of Cable Y (cable side which does not

contain splice body) at a distance of 10"

(254 mm) measured from the CENTER of

connectors.

4.3 Position cold shrink copper connector adapter over

CENTER of connector. Shrink the adapter near

center of connector by pulling and unwinding the

loose core ribbon end in a counter-clockwise

direction.

4.4 Remove any excess oxidation inhibitor from

connector ends if aluminum connectors are used.

Clean cable using standard practice:

a. Do not use solvent or abrasive on cable

semi-conductive insulation shield.

b. If abrasive is used on cable insulation, do not

reduce diameter below the 1.07" (27,2 mm)

minimum specified for the splice.

10" (254 mm)

Page 7

7

78-8126-0432-6-A

4.5 Apply red compund on cable insulation, making

certain to fill in edges of cable semi-cons.

Note: DO NOT use silicone grease.

4.6 Position each splice body over the connector and

align the leading end of the rubber part with the

center of the marker tape.

Slowly begin to remove the inner support core by

pulling, while unwinding, the loose ribbon end in a

counterclockwise direction. Allow only 1/4"

(6 mm) of the splice to shrink onto the marker tape.

Carefully slide the splice body off the marker tape

until its leading edge is aligned with the marker tape

edge. Continue removing the core to complete splice

body installation.

Note: The splice body ends must overlap onto the

semi-conducting layer of each cable by at least

1/2" (12,7 mm).

Note: DO NOT push the splice body towards the tape

marker, as this may cause the end to roll under. If

the end does roll under, DO NOT use sharp edged

tools to pull it out as this could cut and damage

the splice.

4.7 Apply copper shield sleeves:

a) Center one shield sleeve over each splice body.

b) Starting at center, form sleeves to splice bodies

using vinyl tape bands.

4.8 Connect sleeve ends to the cable metallic shield

with constant force springs.

Install each spring by unwrapping and rewrapping

the spring around itself over the shield sleeve end and

cable metallic shield.

Trim off excess shield sleeve braid material.

Cover springs and trimmed shield sleeve ends with

one half-lapped layer of vinyl tape.

Red P55/R

compound

vinyl tape bands

align end of splice body to

marker tape

trim off excess sleeve

Page 8

8

78-8126-0432-6-A

5.0 Install Armor Continuity (If Cable is Armored)

4.10 Unfold the cable fillers and reestablish their lay

between the cable phase cores. Hold the fillers in

place with a band of 33+ vinyl tape.

4.9 Connect the ground wire(s) from Cable X to the

ground wire(s) from Cable Y. Make the connection

away from the splice bodies.

33+ vinyl tape

connect ground wire(s)

5.1 Apply multiple wraps of Scotch™24 shielding tape

around the exposed armor on both Cable X and

Cable Y to fill a valley in the corrugated armor. Half

hitch to tie off.

5.2 Wrap an end of the ground continuity braid around

exposed armor and applied 24 tape on one cable end.

Wrap one wrap only and fold the braid at 90°with

the long braid end extending toward splice opening.

Install a large constant force spring around the

braid wrapped on the armor. Spiral wrap the braid

around the splice opening to the other cable armor.

Fold the braid 90°and wrap braid end around armor.

Wrap braid end for one wrap only. Cut off and

discard excess braid.

Connect braid by installing other constant force

spring. Overwrap each spring with 33+ tape.

constant

force

spring

Page 9

9

78-8126-0432-6-A

6.0 Install Splice Jacket

6.1 Over wrap the exposed conductors on each side of

splice bodies with jacket pieces saved from step 2.1.

Bind the cable jacket pieces in place with one

half-lapped layer of Scotch

™

88, 1 1/2" wide tape.

6.2 At both ends of splice, apply four wraps of 2228

rubber mastic, around the cable jacket 1/2" from

jacket ends.

Stretch the rubber mastic to three-fourth original

width when applying.

6.3 Install a Cold Shrink jacket tube on each cable with

the leading end just covering the 2228 mastic and the

tube extending toward the splice bodies.

Pull while unwinding the loose core ribbon end in

a counterclockwise direction to install jacket tubes.

6.4 Apply one half lapped layer of 88 tape over the

unjacketed area in splice center. Do not overlap the

Cold Shrink jacket tubes.

overwrap jacket piece

with vinyl tape

2228 rubber

mastic

88 vinyl

tape

Cold Shrink jacket

tube

Page 10

10

78-8126-0432-6-A

88 vinyl

tape

Armorcast

™

wrap

2229 mastic

tape

6.5 Apply two half-lapped layers of 4" wide 2229 tape

over applied vinyl tape in splice center. Overlap ends

of Cold Shrink jacket tubes 2" (51 mm).

6.6 Cover the applied 2229 mastic with two half lapped

layers of 88 tape.

6.7 Overwrap the entire splice with a minimum of two

half lapped layers of Armorcast

™

wrap.

Tear open the top end of the foil Armorcast material

container and fill foil container half full with water.

Squeeze the container four or five times allowing the

water to penetrate the roll. Pour out water, remove

roll from foil container and immediately apply to

splice area.

Bind the final wrap in place with vinyl tape.

Note: Wear rubber gloves provided when handling

Armorcast

™

Wrap. The resin contains a

black die that will stain human skin.

Armorcast™Wrap can be applied first and then

sprayed with water to activate the curing system

It will also cure from moisture in the air in

humid conditions.

6.8 Splice is complete.

Page 11

11

78-8126-0432-6-A

™M3

rotcennoC

rebmuN

rotcudnoC

eziS

roGWA(

)limck

ydnruBproCstteB&samohT

.oCDerauqS

.viDnosrednA

yenraeK

6DM92YMA43Y

93Y,53Y

*64Y,*54Y

**0001Y5MBT8MBT21MBT51MBT

**3-6CV

**TF-6CV

OepyT

)uC(500010/1)2(361W)1(0/1)1(R52A)1(TR52U—)2(kniP)2(kniP — )2(24)1( —

)uC/lA(500020/1)2(142W)1(0/1)1(RA52A)1(TRA52U)1()2(naT)2(naT — )1(05)1()3(1-8/5

)uC/lA(0/1-IC0/1)3(GB — )1(342U)1(TRA52U —— )2(evilO — )1(05)1()3(1-8/5

)uC(600010/2)2(142W)1(0/2)1(R62A)2(TR62U — )2(kcalB)2(kcalB — )1(54)1( —

)uC/lA(600020/2)4(GB)1(0/2)2(RA62A)2(TRA62U)1()2(evilO)2(evilO — )2(H45)2()3(1-8/5

)uC(600110/2)3(142W)2(0/2)2(R62A)2(TR62U — )3(kcalB)3(kcalB — )2(54)2( —

)uC/lA(0/2-IC0/2)3(942W —— )2(TRA82U —— )4(eulB — )2(67)2()4(048

)uC(700010/3)2(342W)1(0/3)1(R72A)2(TR72U — )2(egnarO)2(egnarO — )1(05)1( —

)uC/lA(700020/3)4(661W)1(0/3 — )2(TRA72U)1()2(ybuR)2(ybuR — )2(06)2()3(737

)uC(700110/3)3(342W)2(0/3)2(R72A)3(TR72U — )3(egnarO)3(egnarO — )2(05)2( —

)uC/lA(0/3-IC0/3)3(942W —— )2(TRA82U —— )4(eulB — )2(67)2()4(048

)uC(800010/4)3(GB)1(0/4)2(R82A)2(TR82U — )2(elpruP)2(elpruP — )2(H45)2(

)uC/lA(800020/4)4(066W)2(0/4)2(RA82A)2(TRA82U)1( — )4(etihW — )4(66)2()4(048

)uC(800110/4)4(GB)2(0/4)3(R82A)3(TR82U — )3(elpruP)3(elpruP — )3(H45)3( —

)uC/lA(0/4-IC0/4)3(942W —— )2(TRA82U —— )4(eulB — )2(67)2()4(048

)uC(90001052)3(661W)1(052)2(R92A)2(TR92U — )2(wolleY)2(wolleY — )2(26)2( —

)uC/lA(90002052)3(942W — )2(RA92A)2(TRA92U)1( —— )2(H17)2(H17)3( —

)uC(90011052)4(661W)2(052)3(R92A)3(TR92U — )3(wolleY)3(wolleY — )3(26)3( —

)uC/lA(052-IC052 —— — )2(TRA13U ——— )2(H78)2(H78)2( —

)uC(01001003 —— )3(R03A)2(TR03U —— )2(etihW — )2(66)2( —

)uC/lA(01002003 —— )2(RA03A)2(TRA03U)1( —— )3(H67)1(67)2( —

)uC(01011003 —— )3(R03A)3(TR03U —— )3(etihW — )3(66)3( —

)uC/lA(003-IC003 —— — )2(TRA13U ——— )2(H78)2(H78)2( —

)uC(11001053 —— )2(R13A)2(TR13U —— )3(deR — )3(H17)2( —

)uC/lA(11002053 —— — )2(TRA13U)1( —— )3(H78)3(H78)2( —

)uC(11011053 —— )3(R13A)3(TR13U —— )4(deR — )4(H17)3( —

)uC/lA(053-IC053 —— — )2(TRA13U ——— )2(H78)2(H78)3

( —

Crimping Tool - Die Sets (number of crimps/end)

*Y45 and Y46 accept all Y35 dies (“U Series”). For Y45, use PT6515 adapter. For Y46, use PUADP adapter.

**Anderson VC6-3, VC6-FT and Burndy Y1000 require no die set.

Page 12

IMPORTANT NOTICE

Before using this product, you must evaluate it and determine if it is suitable for your intended application. You assume all risks and liability

associated with such use.

Warranty; Limited Remedy; Limited Liability. This product will be free from defects in material and manufacture as of the date of

purchase. 3M MAKES NO OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within the warranty period stated above,

your exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product or refund the purchase price of the 3M product. Except

where prohibited by law, 3M will not be liable for any loss or damage arising from this 3M product, whether direct, indirect, special,

incidental or consequential regardless of the legal theory asserted.

Electrical Products Division

6801 River Place Blvd.

Austin, TX 78726-9000

800/245-3573

http://www.3M.com/electrical

Armorcast™, Scotch™, Scotch-Seal™and 3M™are trademarks of 3M Company.

Note: The core material being removed from the Splice Body, Jacket Tubes

and adapter are mixed polymers and can be recycled with other waste.

Printed in USA

© 3M IPC 2002 78-8126-0432-6-A

Printed on 50% recycled paper

with 10% post-consumer

Loading...

Loading...