Page 1

3

Model 724 Work Station Monitor

Instructions

Page 2

2

Index

Section Page

Safety Information..................................................................................................3

1. Theory of Operation......................................................................................4

2. Installation of 3M™ Model 724 Monitor

with Work Surface Ground Monitoring.........................................................8

3. Installation of Model 724 Monitor

without Work Surface Ground Monitoring ...................................................9

4. Selection of Test Voltage and Resistance Limit ..........................................12

5. Mounting the 724 Monitor and 3M™ Model 732 Remote.........................12

6. Wrist Strap Connection...............................................................................13

7. Fault Conditions..........................................................................................14

8. 3M™ Model 3057 Standby Jack.................................................................15

9. 3M™ Model 733 Dual Conductor Remote Input Jack ...............................15

10. Installation of Model 733 Remote...............................................................15

11. Verification Procedure for the Model 724 Monitor.....................................16

12. Specifications ..............................................................................................19

13. Parts Included..............................................................................................19

14. Required Accessories and Optional Available Parts....................................20

15. Additional Wrist Strap Monitoring Information.........................................20

16. Warranty ......................................................................................................21

Page 3

3

Safety Information

Intended Use

The 3M™Model 724 Work Station Monitor

is designed to monitor the operation of two

wrist strap grounding systems and two

work surfaces. This product has been

designed and tested for use with 3M

™

Dual

Conductor Wrist Straps and 3M Work

Surfaces Grounding Systems. For North

America this unit is designed for use with

an AC adapter included. Outside North

America, obtain an appropriate AC adapter

meeting the specifications as stated in the

user instruction manual (Section 12). Use

of other components may cause improper

performances and/or unsafe conditions. For

use outside of North America, grounding of

the Model 724 Monitor is recommended

through a separate ground wire with ring

terminal supplied (Sections 2 and 3).

CAUTION

• Incorrect grounding of an operator may cause electrostatic discharge (ESD) damage to

components or assemblies being handled. For proper grounding of the operator when

using the 3M 724 Work Station Monitor, use of the three-prong AC adapter specified

in the user instruction manual or supplied ground wire with ring terminal is required.

• Verify that the electrical ground point is suitable. If you are not sure what a suitable

ground is, contact a licensed electrician before installation.

Explanation of Symbols

– Caution: refer to user instruction manual.

– Operator(s) Wrist Strap Assembly Ground.

– W ork Surface Ground.

– Electrical ground.

– Power input connector polarity (center negative).

– See user instruction manual for explanation of the indicator lamps.

Read and understand all safety information before

operating this equipment.

Page 4

4

Section 1.

Theory of Operation

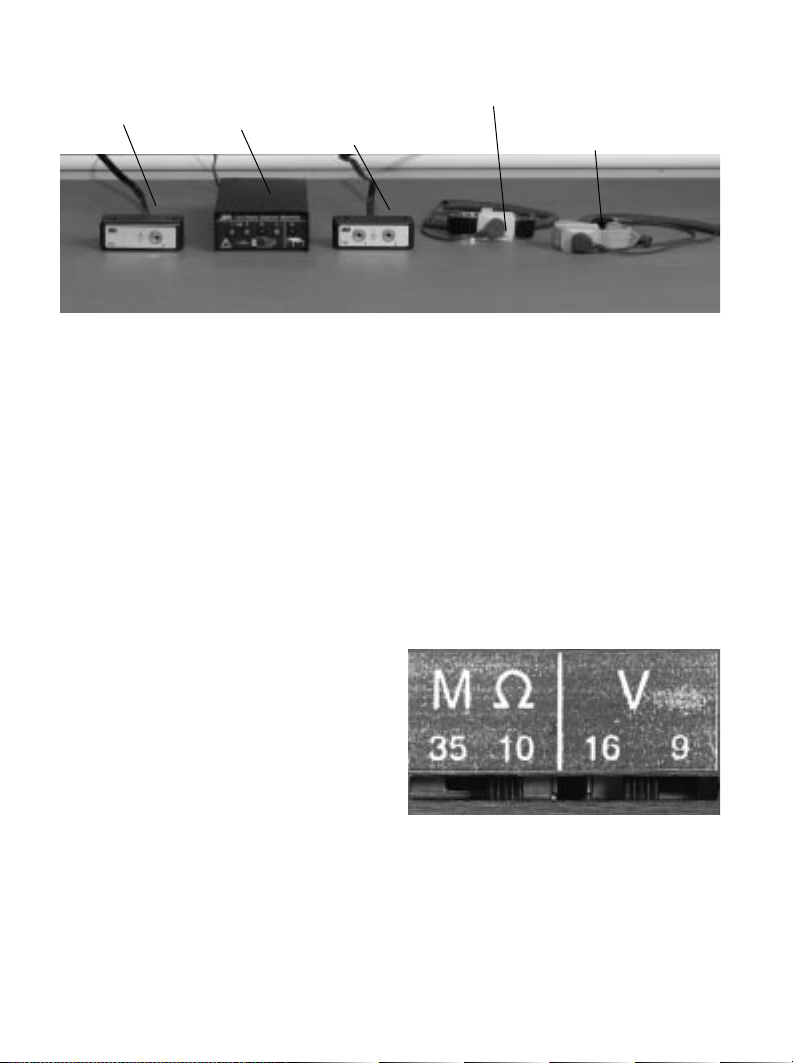

The 3M Model 724 Work Station

Monitor (Fig. 1) is designed to

monitor the operation of the wrist

strap grounding systems of two

operators. To accomplish this, it uses a

DC current source to measure a loop

electrical resistance. The system uses

a special wrist band and ground cord

that contain two independent

elements.* The 724 monitor employs

two selectable test voltages (9 and 16

volts) and resistance limits

(10 Megohms and 35 Megohms).**

It also monitors the grounding of up to

two 3M work surfaces.

The Model 724 monitor performs a

resistance measurement by applying

an electrical current of less than 3 µA

approximately every 2.0 seconds for

0.2 of a second in duration. The path

for the current is through one

conductor of the ground cord that

contains a current-limiting resistor,

through one side of the wrist band,

through the skin of the wearer under

the band, through the second side of

the wrist band, through the second

conductor of the ground cord that

contains a current-limiting resistor,

and finally back to the monitor.

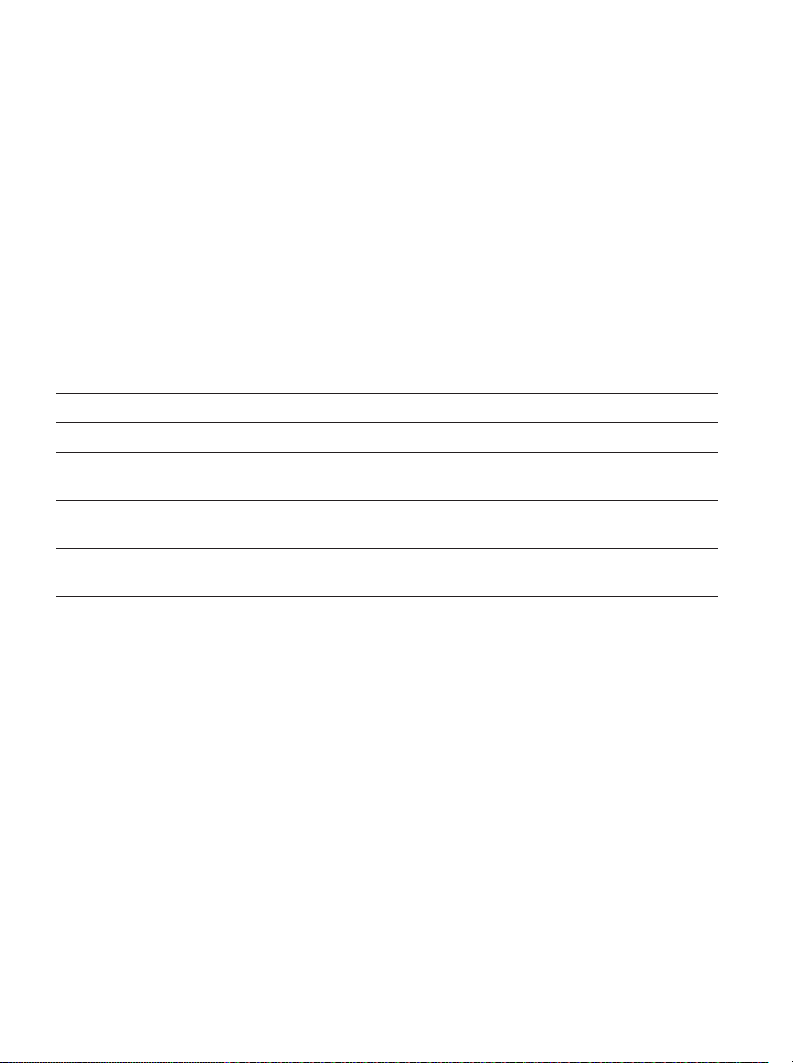

Selection of Test Voltage and

Resistance Limit

Fig. 2 - Resistance/Voltage switch selection.

Fig. 1 - Model 724 Work Station with dual conductor wrist strap assemblies and remote input jacks.

Model 724

Work Station

Monitor

Model 732

Remote

Input Jack

Model 733

Remote

Splitter Kit

Dual Conductor

Metal Wrist Strap*

Dual Conductor

Fabric Wrist Strap*

*Resistance values are ±15%

Page 5

5

The Model 724 monitor allows for the

selection of test voltages (9v or 16v)

and resistance limits (10 Megohms or

35 Megohms). The additional ranges

have been added to accommodate

global Electrical Static Discharge

requirements. Selection of the

operating parameters are left up to the

user’s discretion (See Section 4).

Operator Monitoring Single and Dual

Fig. 3 - Face of Model 724

The wrist strap monitoring function

is activated by plugging a wrist strap

dual conductor ground cord into either

one of the jacks on the 3M™Models

732/733 Dual Conductor Remote

Input Jack. If the resistance of the

wrist strap loop is within the limits of

the selected range (1.5 Megohms to

10 Megohms or 1.5 Megohms to 35

Megohms)* on the Model 724

Monitor, the cord, the wrist band, and

the contact to the arm of the wearer, it

is considered to be functioning

correctly. At this time, one of the

(OK) green lamps (1 or 2) will be

illuminated on the front of

the monitor.

If the resistance of the wrist strap

loop is higher than the selected range

(10 Megohms or 35 Megohms)* on the

724 monitor, an (OK) wrist strap green

lamp (1 or 2) extinguishes, and

a high wrist strap red lamp (H)

illuminates with an audible alarm. This

is an indication of a high resistance in

the cord band, or poor contact between

arm and band. If the resistance in the

loop is under 1.5 Megohms,* it is an

indication of a low resistance meaning

one or both current-limiting resistors

are bypassed. The low yellow lamp (L)

will flash and an (OK) green lamp

(1 or 2) will remain illuminated.

Caution

A low resistance condition can also

be caused by touching a grounded

object or by standing on a

conductive surface.

The wrist strap of a second operator

is measured in the same way. Operators

are identified by the two (OK) green

lamps (1 & 2). However, the same high

wrist strap red lamp (H) and low

yellow (L) lamps illuminate when a

fault is detected. The green lamp that

extinguishes identifies the operator that

is experiencing the fault condition.

* Resistance values are ±15%

3M 733 Remote Splitter Kit purchased separately.

OK #1

Operator

OK #2

Operator

Resistance High Operator

Resistance Low Operator

Resistance High

Work Surface

Page 6

6

Voltage on Operator

When Connected to the

Model 724 Monitor

There is a concern about the voltage

that is applied to an operator while

they are connected to a monitor. Some

of today’s electronic components are

extremely sensitive to electrostatic

discharge from a person (less than

10 volts). The following chart for

the Model 724 monitor illustrates the

level of voltage that will appear on the

operator under various resistance

conditions.

Note:

For more information about wrist strap

monitoring see Additional Wrist Strap

Monitoring Information (Section 15).

Voltage on Operator when connected to the Model 724 monitor

Condition 9V-10 Megohms 9V-35 Megohms 16V-10 Megohms 16V-35 Megohms

No Skin Resistance 0.9V 0.9V 1.6V 1.6V

200K Ohm Skin

Resistance 1.0V 1.0V 1.8V 1.8V

Likely Case Before

Alarm 2.5V 3.6V 4.4V 6.4V

Worst Case Before

Alarm 4.5V 7.1V 8.0V 12.6V

Absolute Worst Case 9.0V 9.0V 16.0V 16.0V

Page 7

7

Audible Alarm T ones

For wrist strap malfunctions the

Model 724 monitor indicates a

different tone for each operator-a

continuous tone for #1 operator and a

fast chirping beep for #2 operator. The

volume of the wrist strap alarm is

adjusted by selection of the internal

DIP switch #1. For work surface

malfunctions, a slow chirping beep is

made. This alarm sound is turned on

or off by selection of DIP switch #2.

Switch #1 and #2 are accessible

through a slot located in the bottom of

the chassis.

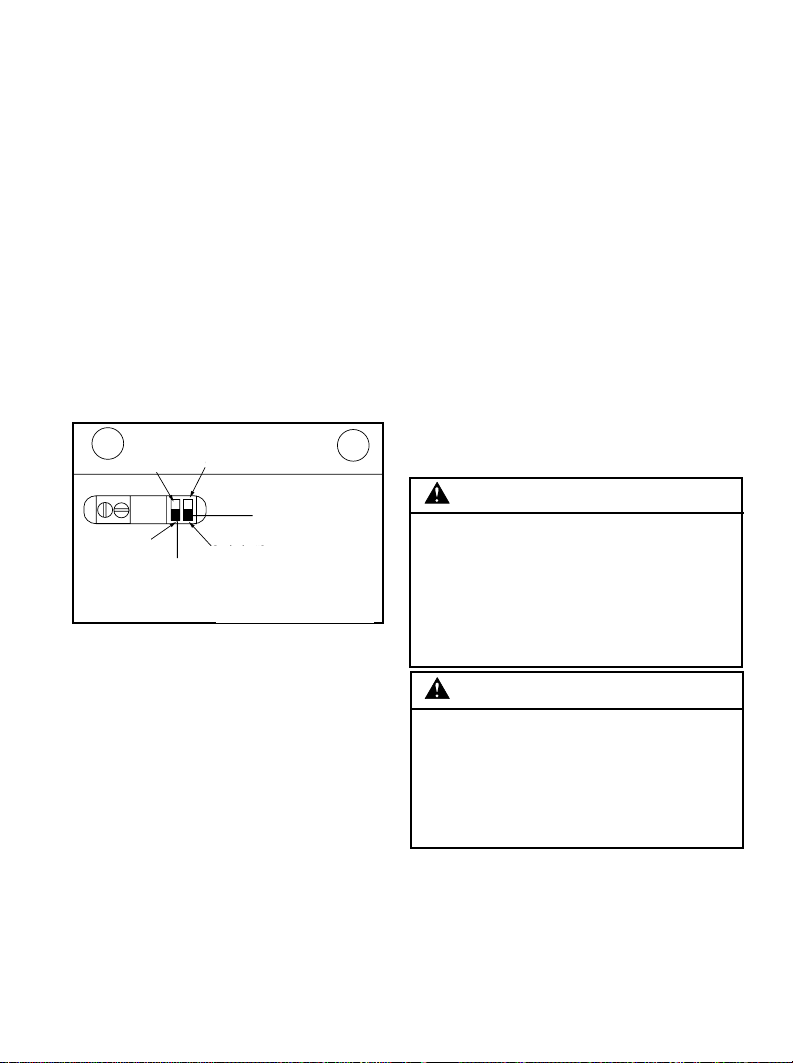

Fig. 4 - Selected desired alarm options

Work Surface Monitoring

The Model 724 monitors its

connection to ground and the

grounding of a 3M ESD work surface.

A loop resistance is measured from

the monitor, through a 3M™2380

Monitor/Table Mat Cord to the work

surface (Section 2), across the

conductive layer of the work surface,

through the grounding wire of the

work surface to an electrical ground

and finally back to the monitor through

the 724 grounding wire. If the

resistance of the loop exceeds

3.7 Megohms* the work surface high

red lamp (M) will illuminate and all

green lamps will be extinguished. If

DIP switch #2 is in the ON position

(Fig. 4) the audible alarm will activate.

If no ESD work surface is to be

monitored, the 3M 2380 Monitor/Table

Mat Cord and the ground wire of the

724 must be connected to an electrical

ground (Section 3). This is done to

ensure that the 724 is providing a

ground connection for the operators.

Again, if the loop resistance exceeds

3.7 Megohms the work surface high

red lamp (M) will illuminate and the

alarm will activate if selected.

Caution

The grounding wire from the work

surface and the ground wire from

the Model 724 monitor must be

attached to separate electrical grounds.

The work surface monitoring function

is active any time that the power supply

for the monitor is plugged in.

Caution

Disconnect the 3M 2380 Monitor/

Table Mat Cord to prevent possible

damage to the Model 724 monitor

before testing the resistance of the

work surface with a high voltage

megohmmeter.

* Resistance values are ±15%

DIP Switch

Switch #1

Loud

Switch #2

On

Model 724 Bottom View

Soft

Model 724 bottom view

DIP switch

Off

On

Loud

Switch #2

Switch #1

Page 8

8

Section 2.

Installation of 3M™724

Monitor with Work Surface

Ground Monitoring

Wire Attachments and Grounding See Fig. 12 for complete drawing of

the Model 724 monitor wire

connections.

Tools required - Small blade,

screwdriver and wire cutter.

Note:

Two snap fasteners or appropriate

connectors must be installed at

opposite corners of the work surface to

use this feature. Recommended

surfaces are 3M™8200, 8300, and

8800. Use of a 3M™Female Snap

Fastener 3034 or 3050 (depending on

the type of surface) is recommended

for connection to the 3M™2380

Monitor/Table Mat Cord that is

supplied with the Model 724 monitor.

If you are using the 3M 8300

Dissipative Hard Laminate Material,

attach the 3M™2380 cord to suitable

hardware used to make an electrical

connection to the ground layer of the

work surface. This may require you to

cut off the plastic cap end of the

2380 cord.

a) Connect the work surface to

an electrical ground with the

appropriate one megohm ground

cord you received at time of

purchase.

b) Using a small screwdriver move the

DIP switch #2 on the Model 724

monitor to the ON position to

activate the work surface audible

alarm (Fig. 4).

c) Locate the accessory package that

contains a 3M™2380 Monitor/Table

Mat Cord, Model 724 ground wire

(with ring terminal), and the twowire connector plug.

d) Attach the 3M 2380 (tinned wire

end) to the work surface terminal of

the two-wire connector by inserting

it into opening and securing with the

screwdriver (Fig. 5A or 5B). Attach

the plastic cap end to the snap on

the work surface.

Note:

If for any reason a snap fastener

cannot be used on the work surface,

the plastic cap on the end of the 2380

cord can be cut off and replaced with a

ring terminal not supplied (Fig. 6).

e) Determine how you want to ground

the Model 724 monitor:

• If you are grounding through the AC

adapter perform step (2f).

• If you are grounding through the

724 ground wire perform step (2g).

f) Attach the tinned ground wire of the

AC adapter to the ground terminal

of the two-wire connector by

inserting it into opening and

securing with screwdriver (Fig. 5B).

Continue with step (2h).

Page 9

9

g) Attach the tinned Model 724

ground wire to the ground terminal

of the two-wire connector by

inserting the tinned end into

opening and securing with

screwdriver (Fig. 5A). Attach the

ring terminal end with a screw (not

supplied) to an electrical ground

(Fig. 7B). Continue with step (2h).

h) Plug the two wire connector

into the jack at the rear of the

724 monitor (Fig. 8).

i) Insert the plug connector of the 3M

732 Dual Conductor Remote Input

Jack cable into the 732 jack at the

rear of the Model 724 monitor

(Fig. 9).

j) Insert the round connector from the

AC adapter into the jack at the rear

of the 724 monitor

Note:

Disconnect the 3M™2380 cord to

check for visual and audible high

work surface alarm condition and

reconnect. If the high work surface

lamp (M) is on before removing the

2380 cord, check for loose

connections or high resistance to

ground (>3.7 Megohms). Disconnect

the 3M 2380 cord from the work

surface and check the resistance to

ground by attaching one lead of an

ohmmeter to the connector on the

work surface and the other lead

to ground.

Section 3.

Installation of Model 724

Monitor without Work

Surface Ground Monitoring

Wire Attachments and Grounding - See

Fig. 12 for complete drawing of 724

monitor wire connections.

Tools required - Small blade,

screwdriver, and wire cutter.

a) Using a screwdriver move DIP

switch #2 on the Model 724 monitor

to the OFF position to deactivate the

work surface audible alarm (Fig. 4).

b) Locate the accessory package that

contains a 3M™2380 Monitor/Table

Mat Cord, Model 724 ground wire

(with ring terminal), and the twowire connector plug.

c) Attach the 3M™2380 (tinned wire

end) to the work surface terminal of

the two-wire connector plug by

inserting into opening and securing

with screwdriver (Fig. 5A or 5B).

d) Cut off the plastic cap on the

end of the 3M™2380 cord and strip

off approximately 1/2 inch of

insulation and twist the stranded

wire together (Fig. 6). Attach this

end to an electrical ground using a

ring terminal (not supplied) or by

wrapping the wire around the head

of a screw (Fig. 7A).

Page 10

10

e) Determine how you want to ground

the Model 724 monitor:

• If you are grounding through the AC

adapter, perform Step (3f.)

• If you are grounding through the

Model 724 ground wire, perform

Step (3g.)

f) Attach the tinned ground wire of the

AC adapter to the ground terminal of

the two-wire connector by inserting

into opening and securing with

screwdriver (Fig. 5B). Continue with

Step (3h.)

g) Attach the tinned Model 724 ground

wire to the ground terminal of the twowire connector by inserting the tinned

end into opening and securing with

screwdriver (Fig. 5A). Attach the ring

terminal end with a screw (not supplied)

to an electrical ground (Fig. 7B).

Continue with Step (3h.)

h) Plug the two wire connector into the

jack at the rear of the Model 724

monitor (Fig. 8).

Caution

Do not physically connect the 3M

2380 Monitor/Table Mat Cord and the

Model 724 ground wire together. The

ground wire for the work surface and

the ground wire from the 724 monitor

must be attached to separate electrical

grounds. However, by attaching the

wires to the same ground but at a

different physical location, the Model

724 monitor can check for loose or

lost connections to ground. This would

be indicated by the high red work

surface lamp (M) illuminating.

i) Insert the plug connector of the

Model 732 remote cable into the

732 jack at the rear of the Model

724 monitor (Fig. 9).

j) Insert the round connector from the

AC adapter into the jack at the rear

of the Model 724 monitor.

Fig. 5A & 5B - Attaching ground wire/cord and work surface cord to two-wire connector.

Fig. 5A Fig. 5B

Two-Wire Connector

2380

2380

DC Plug

724 Ground Cord

2380

AC Adapter

Ground Wire

AC Adapter

Attach 724 Ground Cord or

AC Adapter Ground Wire

Page 11

11

Fig. 6 - Cutting off table mat ground snap.

Fig. 7A - Attaching system grounds. Note work

surface and unit are grounded at different

locations.

Fig. 7B - Grounding Model 724.

Fig. 8 - Inserting two-wire connector into rear of

Model 724.

Fig. 9 - Inserting 732 plug into rear of Model 724.

Page 12

12

Section 4.

Selection of Test Voltage

and Resistance Limit

Tools required - Small blade,

screwdriver.

The Model 724 monitor allows for the

selection of test voltages (9v or 16v)

and resistance limits (10 Megohms or

35 Megohms). The additional ranges

have been added to accommodate

global ESD requirements. Selection of

the operating parameters are left up to

the user’s discretion.

a) Select the desired resistance and

voltage limit by moving the

appropriate slide switch (with

screwdriver) on the side of the

Model 724 monitor to the desired

position (Fig. 2).

Section 5.

Mounting the 3M™Model 724

Monitor and 3M™Model 732

Remote

a) Mount or position the Model 724

monitor so that the lamps are easily

viewed by the operator (Figs. 10 and

11). Mount the Model 724 monitor

to the underside of a work bench top

or shelf through the two holes

located at the top rear of the case

using the two screws supplied. If

using the screws is not possible,

apply an appropriate amount of

durable, double-sided adhesive

foam tape to the case.

b) Locate the Model 732 Dual

Conductor Remote Input Jack so

that it is convenient for the

operators to attach their wrist strap

ground cord. Mount the remote

with the screws provided.

Fig. 10 - Model 724 mounted on bench top.

Fig. 11 - Model 724 mounted under shelf or bench.

Page 13

13

c) Plug the AC

adapter into a

3-prong grounded

outlet (North

American System).

Outside North

America use

appropriate AC

adapter (see

specifications

Section 11). The

724 monitor is

ready for use.

Section 6.

Wrist Strap Connection

a) Attach a 3M Dual Conductor

Ground Cord to a 3M Dual

Conductor Wrist Band (Fig.13).

Plug the cord into either of the two

jacks on the Model 732 Dual

Conductor Remote Input Jack

(Fig.14). Plugging into a jack

activates the monitor for that input.

b.) The high wrist strap red lamp

(H) should illuminate and the

corresponding audible alarm for

the input (1 or 2) should sound

indicating proper functioning of

the monitor.

c.) Slip the wrist band on your

wrist. The alarm should quiet

and the wrist strap high red lamp

(H) should slowly extinguish.

The corresponding OK wrist

strap green lamp (1 or 2)

should illuminate.

732 Remote

Ground

When not using work station

monitoring feature,connect

work surface wire to ground.

Conductive

Work Surface

Ground

AC

Adaptor

Rear

Ground

722 Monitor

Fig. 13 - Connecting ground cord to wrist band.

Fig. 14 - Connecting wrist snap ground cord to

Model 732.

Fig. 12 - Model 724 wire connection diagram for single

work station.

Ground

Rear

Ground

Ground

AC Adapter

732 Remote

732 Monitor

Conductive

Work Surface

When not using work

station monitoring

feature, connect

work surface wire

to ground.

Page 14

14

Section 7.

Fault Conditions

(Refer to Fig. 3)

Red Wrist Strap Lamp (H)

Accompanied by an A udible Alarm

This indicates that a high resistance

condition (greater than 10 Megohms

or 35 Megohms) exists for an operator

or wrist strap assembly. If two

operators are connected to the monitor

the high condition is with the operator

whose green lamp has extinguished.

Check the operator for good contact

between the wrist and band. Check the

ground cord and connections for

continuity. Some operators have

difficulty in providing sufficient

continuity to the wrist band due to dry

skin or arm hair. They

may need to use an approved skin

moisturizer or reposition the wrist

band on the arm.

Note:

The operators may complain that the

alarm is sounding too often until they

learn to adjust the wrist band to fit

securely or apply an approved skin

moisturizer on a frequent basis.

Please remember that the monitor

is informing you that the operator

is exceeding the established static

control requirement for resistance

to ground when wearing a static

protective wrist strap assembly. These

alarms alert the operator when

sensitive electronics are possibly

being exposed to static electricity.

Prior to incorporating the work

station monitor into your static

control process, the operator was

unaware of these events.

Yellow Wrist Strap Lamp (L) with

no Audible Alarm

Caution

This indicates that a low resistance

condition (less than 1.5 Megohms)

exists between the operator and

ground. One or both of the one

megohm current-limiting resistors are

being bypassed. A low resistance

condition can be caused by touching a

grounded object or by standing on a

conductive surface.

Red Work Surface Lamp (M)

This indicates that a high resistance

condition (greater than 3.7 Megohms)

exists across the conductive layer of

the work surface and/or the ground

connections. Check the work surface,

ground cords, and the connections for

continuity. Note the audible alarm

may also sound if selected.

Page 15

15

Section 8.

3M™Model 3057

Standby Jack

Since the activating switches are

located in the Models 732/733 Dual

Conductor Remote Input Jack, the

normal operating procedure is for the

operators to disconnect their cords

from the remotes when leaving the

work station. However, an optional

standby jack (3M™Model 3057) that

allows the wrist strap ground cord to

remain plugged into the remotes is

available. Simply attach it to any

convenient location then disconnect the

cord from the wrist band and attach it

to the standby jack (Fig. 15). The OK

green lamp (1 or 2) on the Model 724

monitor will illuminate upon

connection. The low yellow lamp (L)

will slowly flash if the standby jack is

grounded. It can be grounded by

attaching a ground wire to the screws

or back plate. It can also be grounded

if the plate is attached to a grounded

metal surface. The operator should

reconnect the wrist strap ground cord

to their wrist band upon returning to

the work station.

Fig. 15 - Attach cord to Model 3057 standby jack.

Section 9.

3M™Model 733 Dual

Conductor Remote

Input Jack

The Model 733 Dual Conductor

Remote Input Jack is used to separate

the two wrist strap jacks on the Model

732 that connect to a Model 724

Monitor. This provides a separation up

to approximately 10 feet apart. This is

done using a second remote input

module (Model 733) in conjunction

with the Model 732 remote input

module originally supplied with the

Model 724 monitor. Two separate work

stations can also be created using the

Model 733 and the 3M™Model 2389

(10 ft.) Monitor/Table Mat Interconnect

Cord. Instructions for creating two

separate work stations are included

with the purchase of the 3M™2389

cord (Fig. 17).

Section 10.

Installation of 733 Remote

a) Insert the plug connector of the

Model 733 Dual Conductor Remote

Input Jack cable into the Model 733

jack at the rear of the Model 724

monitor (Fig. 16).

b) Fully insert the small plastic plug

that comes with the kit into the #2

wrist strap input on the Model 732

Dual Conductor Remote Input Jack.

This disables the #2 input and

prevents a situation where two users

would simultaneously attempt to use

the input lines to the Model 724.

Page 16

16

c) Position and mount both remote

input jacks in convenient locations.

Fig. 16 - Inserting Model 733 plug into rear of

Model 724

Section 11.

Verification Procedure for

the Model 724 Monitor

The Model 724 Monitor cannot be

recalibrated after the initial factory

calibration. However, the following

steps can be used to determine if the

Model 724 is operating within its

specifications.

Equipment Needed:

• Small blade screwdriver.

• Resistance Substitution Box (RSB),

1 Ohm to 45 Megohms ±1%.

Fig. 17 - Model 724 wire connection diagram for two work stations.

™

Page 17

17

• One two-conductor cable with

standard 3.5 mm (miniature)

phone plug attached on one end

and appropriate connectors on the

other end to connect to RSB.

Note:

Two-conductor cable must have an

isolation resistance of >1 Gigohm

between conductors. Two separated

wires may also be used to obtain

higher isolation resistance.

• Two wires with alligator clips.

• Ohmmeter capable of measuring to

45 Megohms ±0.5%, to verify the

RSB.

Procedure:

Work Surface

a) Access the DIP switches SW1 and

SW2 through a slot located at the

bottom of the chassis. Adjust SW1

to the LOUD position and SW2 to

the ON position with a small

screwdriver (Fig 4).

b) Plug in the AC adapter. Note that

the red high work surface lamp

(M) is illuminated with an audible

alarm (slow chirping beep).

c) Adjust DIP switch SW1 to the

SOFT position. Note that the

loudness of the alarm decreases.

d) Adjust DIP switch SW2 to the

OFF position. Note that the audible

alarm is silenced.

e) Attach the 3M™2380 Monitor/Table

Mat Cord and the 724 ground wire

to the RSB using the two wires with

alligator clips. Set the resistance as

follows and observe Model 724

monitor output:

3.1 Megohms – Red work surface

lamp (M) OFF.

4.3 Megohms – Red work surface

lamp (M) ON.

f) Disconnect the cords from the RSB.

g) Connect the ring terminal end of the

Model 724 ground wire to the metal

snap of the 3M™2380 Monitor/Table

Mat Cord. The red work surface

lamp (M) should now be OFF.

Wrist Strap

Set Resistance Limit 10 Megohms and

Test Voltage 9v (Fig. 2).

h) Connect the two-wire cable with

3.5 mm phone plug into the #1 input

of the Model 732 Dual Conductor

Remote Input Jack and attach the

other end to the RSB. Set the

resistance as follows and observe the

Model 724 monitor output:

1.3 Megohms – Yellow low lamp (L)

flashing, green (OK) lamp (1) ON,

and audible alarm OFF.

1.7 Megohms - Yellow low lamp (L)

OFF, green (OK) lamp (1) ON, and

audible alarm OFF.

Page 18

18

8.5 Megohms – High red wrist

strap lamp (H) OFF, green (OK)

lamp (1) ON, and audible alarm

OFF.

11.5 Megohms – High red wrist

strap lamp (H) ON, audible alarm

ON (continuous tone), and green

(OK) lamp (1) OFF.

i) Repeat step (6h) for input #2 of the

732 Dual Conductor Remote Input

Jack. Audible alarm will be a fast

chirping beep.

Set Resistance Limit 35 Megohms and

Test Voltage 9v (Fig. 2).

j) Test as in step (6h) above.

However, set the resistance as

follows and observe the 724

monitor output:

1.3 Megohms – Yellow low lamp

(L) flashing, green (OK) lamp (1)

ON, and audible alarm OFF.

1.7 Megohms – Yellow low lamp

(L) OFF, green (OK) lamp (1) ON,

and audible alarm OFF.

29.8 Megohms – High red wrist

strap lamp (H) OFF, green (OK)

lamp (1) ON, and audible alarm

OFF.

40.2 Megohms – High red wrist

strap lamp (H) ON, audible alarm

ON (continuous tone), and green

(OK) lamp (1) OFF.

k) Repeat step (6j) for input #2 of the

732 Dual Conductor Remote Input

Jack. Audible alarm will be fast

chirping beep.

Set Resistance Limit 10 Megohms and

Test Voltage 16v (Fig. 2).

l) Connect the two-wire cable with

3.5 mm phone plug into the #1

input of the Model 732 Dual

Conductor Remote Input Jack and

attach the other end to the RSB. Set

the resistance as follows and

observe the 724 monitor output:

1.3 Megohms – Yellow low lamp

(L) flashing, green (OK) lamp (1)

ON, and audible alarm OFF.

1.7 Megohms – Yellow low lamp

(L) OFF, green (OK) lamp (1) ON,

and audible alarm OFF.

8.5 Megohms – High red wrist strap

lamp (H) OFF, green (OK) lamp (1)

ON, and audible alarm OFF.

11.5 Megohms – High red wrist

strap lamp (H) ON, audible alarm

ON (continuous tone), and green

(OK) lamp (1) OFF.

m)

Repeat step (6l) for input #2 of the

Model 732 Dual Conductor Remote

Input Jack. Audible alarm will be

fast chirping beep.

Set Resistance Limit 35 Megohms and

Test Voltage 16v (Fig. 2).

Page 19

19

n) Test as in step (6l) above. However,

set the resistance as follows and

observe the 724 Monitor output:

1.3 Megohms - Yellow low lamp

(L) flashing, green (OK) lamp (1)

ON, and audible alarm OFF.

1.7 Megohms - Yellow low lamp

(L) OFF, green (OK) lamp (1) ON,

and audible alarm OFF.

29.8 Megohms - High red wrist

strap lamp (H) OFF, green (OK)

lamp (1) ON, and audible alarm

OFF.

40.2 Megohms - High red wrist

strap lamp (H) ON, audible alarm

ON (continuous tone), and green

(OK) lamp (1) OFF.

o) Repeat step (6n) for input #2 of the

Model 732 Dual Conductor

Remote Input Jack. Audible alarm

will be fast chirping beep.

Section 12.

Specifications

724 Monitor Size:

6.5 x 3.125 x 1.375 in.

(16,5 x 7,9 x 3,5 cm)

732/733 Remote Input Jack Size:

2.75 x 1.0 x 1.0 in.

(7,0 x 2,5 x 2,5 cm)

Power Supply Requirements:

Input: 120 V ac +/-10%

(North America)

Output: 25 Vdc @ 50 mA

rated load

Output Plug Polarization:

Center Negative

Output Plug Dimensions: 5,5mm O.D.

x 2,1mm I.D. x 9,5mm Length

Accuracy: +/-15%

T est Voltage: 9 VDC / 16 VDC

Open circuit

Test Current: Less than 3 microamps

Environmental Operating Conditions:

Temperature:

Maximum 110°F / 43°C

Minimum 50°F / 10°C

Humidity:

Maximum 75% R.H.

Section 13.

Parts Included

1 ea. Model 724 Work Station

Monitor

1 ea. Model 732 Dual Conductor

Remote Input Jack

1 ea. AC Adapter (North America

Only for outside North America

see Power Supply

Requirements (Section 12)

1 ea. 724 Ground Cord

1 ea. 2380 Monitor/Table Mat Cord

1 ea. Two-Wire Connector

4 ea. Mounting Screws

2 ea. Wire Management Clips

1 ea. User Instruction Manual

Page 20

20

Section 14.

Section 15.

Additional Wrist Strap

Monitoring Information

Suggested reading on wrist strap

requirements and wrist strap

monitoring:

• EIA 625 - Requirements for

Handling Electrostatic-DischargeSensitive (ESDS) Devices.

• EN100015/1 - Protection of

Electrostatic Sensitive Devices.

• 3M Tech. Response #123 - Pulsed

Current vs. Constant Current in

Work Station Monitors.

• 3M Static Digest Issue No.1, 1998 Disc Drive Industry - Static Control

Considerations.

Note:

The 3M references are available by

calling 3M Electronic Handling &

Protection Division Customer Service

Department at 1-800-328-1368.

Industry standards (EIA & EN) are

available through Global Engineering

Documents at 1-800-854-7179.

Required Accessories and Optional Available Parts

Model No. Description Size

2361 Dual Conductor Fabric Wrist Strap* small

2362 Dual Conductor Fabric Wrist Strap* medium

2363 Dual Conductor Fabric Wrist Strap* large

2364 Dual Conductor Fabric Wrist Band small

2365 Dual Conductor Fabric Wrist Band medium

2366 Dual Conductor Fabric Wrist Band large

2368 Dual Conductor Fabric Wrist Band adjustable

2381 Dual Conductor Metal Wrist Strap* small

2382 Dual Conductor Metal Wrist Strap* medium

2383 Dual Conductor Metal Wrist Strap* large

2384 Dual Conductor Metal Wrist Band small

2385 Dual Conductor Metal Wrist Band medium

2386 Dual Conductor Metal Wrist Band large

2360 Dual Conductor Coil Cord 5 ft.(1,5 m.)

2370 Dual Conductor Coil Cord 10 ft.(3,0 m.)

2371 Dual Conductor Coil Cord 20 ft.(6,0 m.)

2380 Monitor-Table Mat Replacement Cord (No resistor) 6 ft.(1,8 m.)

2389 Monitor-Table Mat Replacement Cord (No resistor) 10 ft.(3,0 m.)

3057 Stand-By Jack 1.9 x 1.3 x 1.1 in. (4,8 x 3,3 x 2,8 cm)

732 Replacement Remote Input Jack 6.5 x 3.1 x 1.4 in.(16,5 x 7,9 x 3,5 cm)

733 Dual Remote Splitter Kit 6.5 x 3.1 x 1.4 in.(16,5 x 7,9 x 3,5 cm)

* Includes band & cord

Page 21

21

Section 16.

Warranty

Limited Warranty - 3M expressly

warrants that for a period of one year

from the date of purchase, 3M static

control products will be free of

defects in materials (parts) and

workmanship (labor).

Defects occuring during the warranty

period will be repaired or products will

be replaced at 3M’s option and expense

if 3M receives notice during the

warranty period. Defective products

must be returned to 3M with proof

of purchase date.

Warranty Exclusions -THE

FOREGOING EXPRESS WARRANTY

IS MADE IN LIEU OF ALL OTHER

PRODUCT WARRANTIES, EXPRESS

AND IMPLIED.

INCLUDING FITNESS AND

MERCHANT ABILITY. The express

warranty will not apply to defects of

damage due to accidents, neglect,

misuse, alterations, operator error,

or failure to properly maintain, clean,

or repair products.

Limit of Liability - In no event will

3M or Seller be responsible or liable for

special, incidental, or consequential

losses or damages, whether based in

tort or contract. Fulfillment of 3M’s

warranty obligations will be Customer’s

exclusive remedy and 3M’s and Seller’s

limit of liablity for any breach of

warranty or otherwise.

Loading...

Loading...