Page 1

3M-Matic

™

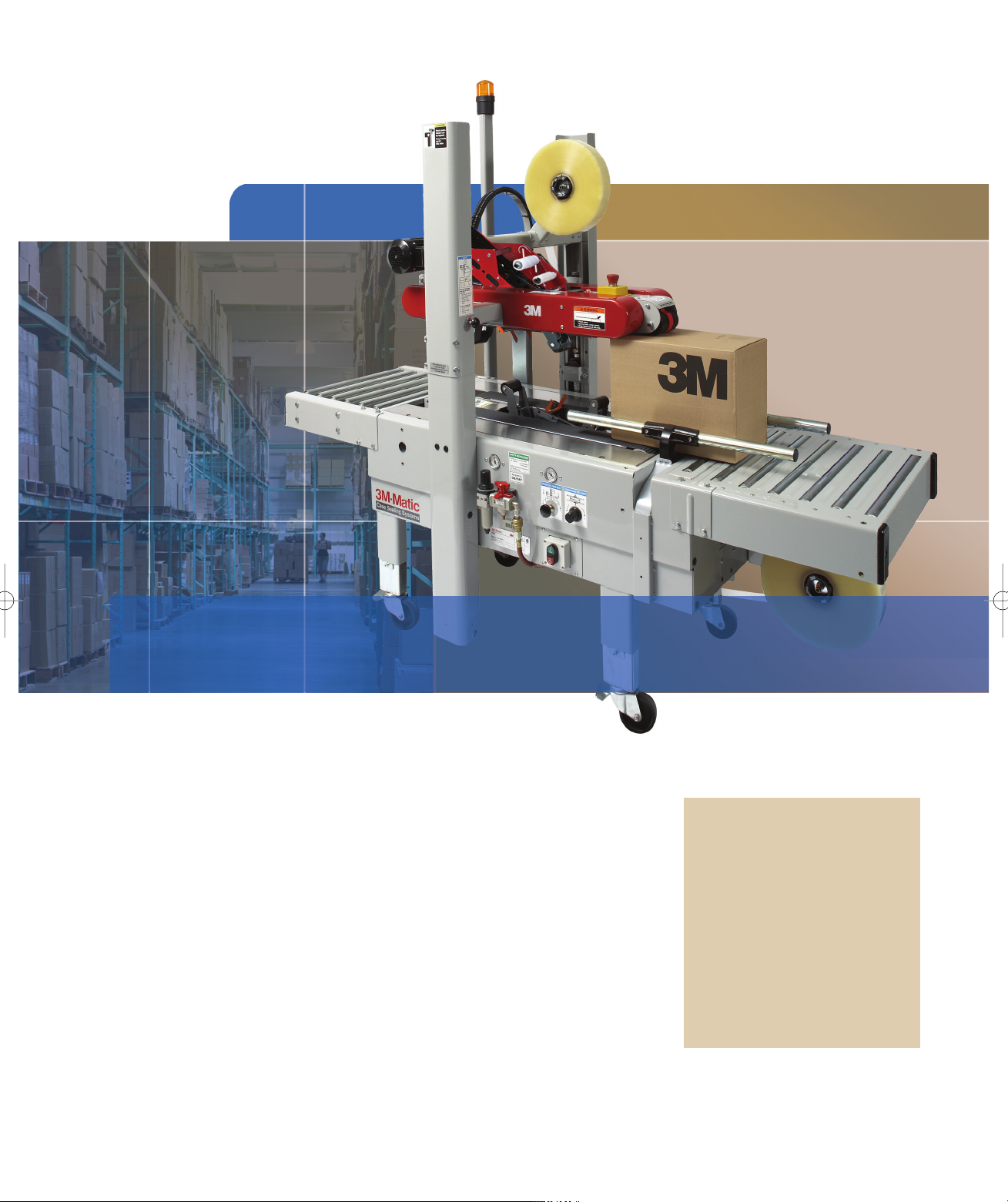

Random Case Sealers

700r/700r3

Reliable

tight

Choice of 2" or 3" 3M™AccuGlide™3

Taping Head for higher productivity

sealing

1

Up to 19 different case sizes per minute

Productivity and performance – bringing it all together in two

sturdy units for 2" or 3" tape application:

• Consistent top and bottom sealing of

random-sized RSCs with automatic

adjustment for case heights and widths

• Dual masts with air cylinders for

greater stability of taping head

• Top and bottom belts for positive

traction and gear motor drive for high

volume, heavy duty reliability shiftafter-shift with cases up to 85 pounds

• Pneumatic centering station to keep

case centered, automatically adjusting

for width

™

• 3M

• Emergency stop positioned for quick

• Rugged construction with 16-gauge

Options shown: Low tape indicator

light staff, infeed and exit conveyors,

locking casters

AccuGlide™3 Taping Head for

low impact sealing that protects cases

while providing greater throughput

and easy access

welded steel frame and epoxy

paint finish

Box capacities

Length: 6" to unlimited

Width*: 6" to 21.5"

Height: 4.75" to 24.5"

Weight: 5-85 lbs.

*See back for 700r3 width

1

(152mm to unlimited)

(152mm to 546mm)

(121mm to 622mm)

(3-38 kg)

3

Page 2

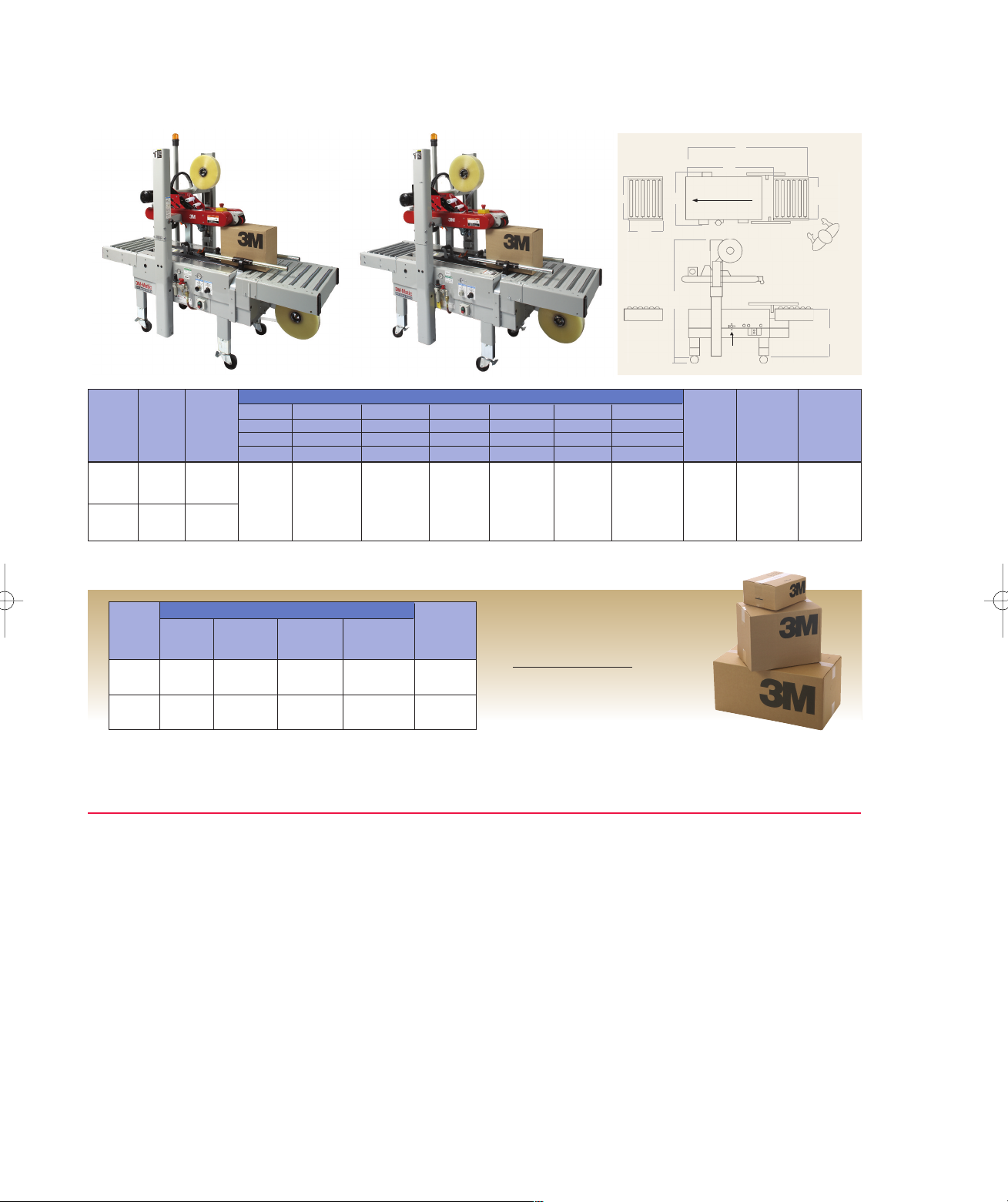

Specifications

3M-Matic™Case Sealer 700r 3M-Matic™Case Sealer 700r3 700r and 700r3 Footprint

Product Use: User is responsible for determining whether the product is fit for a particular purpose and suitable for user’s method of application.

Warranty and Limited Remedy: THE FOLLOWING WARRANTIES ARE MADE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A

COURSE OF DEALING, A CUSTOM OR USAGE OF TRADE: 3M sells its 3M-Matic

™

Case Sealers 700r/700r3 with the following warranties: 1) The Taping Head knife blades, springs

and rollers will be free from all defects for ninety (90) days after delivery. 2) All other Taping Head parts will be free from all defects for three (3) years after delivery. 3) All other

parts will be free from all defects for two (2) years after delivery. Please refer to individual data pages for additional details and exceptions. If any 3M-warrantied part is proved to be

defective within its warranty period, then the exclusive remedy and 3M’s and seller’s sole obligation shall be, at 3M’s option, to repair or replace the part, provided the defective part

is returned immediately to 3M’s factory or an authorized service station designated by 3M. A part will be presumed to have become defective after its warranty period unless the part

is received or 3M is notified of the problem no later than five (5) calendar days after the warranty period. If 3M is unable to repair or replace the part within a reasonable time, then

3M, at its option, will replace the equipment or refund the purchase price. 3M shall have no obligation to provide or pay for the labor required to install the repaired or replacement

part. 3M shall have no obligation to repair or replace (1) those parts failing due to operator misuse, carelessness, or due to any accidental cause other than equipment failure, or

(2) parts failing due to non-lubrication, inadequate cleaning, improper operating environment, improper utilities or operator error. Limitation of Liability: 3M and seller shall not be

liable for direct, indirect, special, incidental or consequential damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal theory. The

foregoing Warranty and Limited Remedy and Limitation of Liability may be changed only by a written agreement signed by authorized officers of 3M and seller.

Printed in U.S.A.

© 3M 2008

70-0710-0379-5

Industrial Adhesives and Tapes Division

Bldg. 21-1W-10

900 Bush Ave.

St. Paul, MN 55106

1-800-362-3550

www.3 M.com/packaging

3M, 3M-Matic and AccuGlide are

trademarks of 3M Company.

Scotch

®

is a registered trademark

of 3M Company.

3

3" Scotch®Box

Sealing Tapes

2" Scotch®Box

Sealing Tapes

* Optional infeed/exit conveyors ** 20 (521) min, 31 (780) max *** Optional casters

Use with clean dry boxes in dry, relatively clean environments at 40°F to 120°F (4.4°C to 48.9°C).

Note: The 3M-Matic™Adjustable Case Sealer

700r/r3 can accommodate most boxes within

the size range listed here.

However, if:

Box Length in Direction of Seal

Box Height

is less than .75

Boxes should be test run to ensure proper

machine performance.

Machine

Box Capacities Inches (mm)

Weight

Length Width Height Height Range

Min Min Min Range w/ Lbs. (kg)

Max Max Max Masts Raised

700r 6 (150) 6 (150) 4.75 (120)* 8.0 (203) 5 (3)

Unlimited 21.5 (123.4) 24.5 (625) 28.5 (725) 85 (38)

700r3 6 (150) 7 (175) 4.75 (120) 8.0 (203) 5 (3)

Unlimited 21.5 (123.4) 24.5 (625) 28.5 (725) 85 (38)

Contact your 3M representative for special modifications that may be available for sizes not listed.

* 3.75" (90mm) with taping heads adjusted to apply 2" (50mm) tape leg lengths and mast stops relocated.

Note: This technical information and data should be considered representative or typical only and should not be used for specification purposes.

A

F

B

BBooxx TTrraavveell

L

T

W

F

Infeed

Conveyor

Supplied

CCoonnttrrooll SSiiddee

H

C

Air Hose

Connection

32

4

Machine Tape Machine

Machine Dimensions Inches (mm)

Electrical Operating Drive Belt

Size Weight

W T H A* B C*** F

Rate at 70 Speed

Inches Lbs. Min Min PSIG 3.75

(mm) (kg) Max Max SCFM

Masts up Masts up**

700r 1.5-2 429 31 (787) 64.5 (1640) 53 (1346) 18 (457) 24 (610) 4 (102) 24.5 (622) 115V Up to 19 100 fpm

(36-48) (194.6) 86 (2184) 35 (889) 60Hz per minute (0.05 m/s)

90 (2290) 3.8A depending

700r3 2-3 431 440 watts on box

(48-72) (199) 8' cord dimensions

Loading...

Loading...