Page 1

Technical Data | July 2015

3M™ Bumpon™ Protective Products

Resilient Rollstock

SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Product Description

3M™ Bumpon™ Resilient Rollstock Products are opaque, colored polyurethane materials produced with aggressive

pressure-sensitive adhesives.

3M™ Bumpon™ Resilient Thickness Polyurethane Polyurethane

Rollstock Product Inches mm Hardness, Shore M Surface Finish Adhesive Type

SJ5216 1/16 1.6 36 (soft foam) R-25

SJ5208 1/8 3.2 29 (soft foam)

SJ5832 1/32 0.8 72

SJ5801 3/64 1.0 72

SJ5816 1/16 1.6 72

SJ5808 1/8 3.2 72

SJ5916 1/16 1.6 40 (medium foam)

SJ5908 1/8 3.2 36 (medium foam) matte

SJ5904 1/4 6.4 36 (medium foam)

SJ6032 1/32 0.8 72

SJ6016 1/16 1.6 72

SJ6008 1/8 3.2 72

SJ6005 1/5 5.0 72

SJ6232 1/32 0.8 72

SJ6216 1/16 1.6 72 matte

SJ6208 1/8 3.2 72

matte

(synthetic rubber)

matte

matte

(natural rubber)

(synthetic rubber)

R-30

A-20

(acrylic)

A-20

(acrylic)

R-25

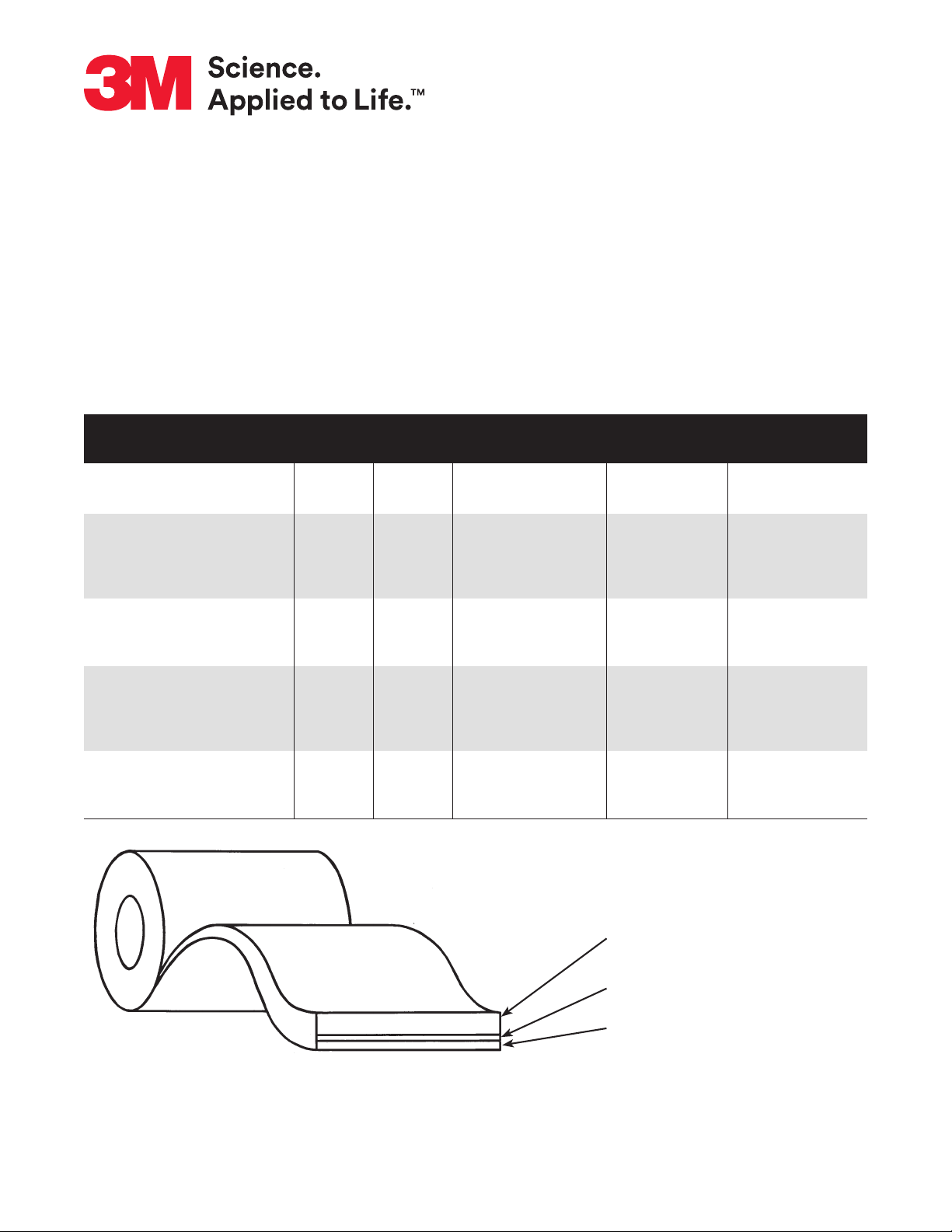

Polyurethane

Pressure Sensitive Adhesive

Polyester Release Liner

Page 2

3M™ Bumpon™ Protective Products

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Features

• Can be die cut to a variety of shapes and sizes.

• Excellent skid-resistance, high coefficient of friction.

• Excellent resistance to marring or staining.*

• Long aging resiliency – will not crack or harden.*

• Excellent cushioning properties.

• Excellent abrasion resistance.

• Vibration and shock dampening.

• Easy application – pressure-sensitive backing.

*Resulting from a urethane composition.

Application Ideas

• Die cut into circles or squares for use as skid-resistant feet on hand held or desktop computers, calculators,

electric housewares, electronic equipment, desk top items and medical devices.

• Die cut for gasket application.

• Skid-resistant surface on floor.

• Cushions or spacers within electronic devices.

• Selective masking for sandblast operation.

• Spacer or stop to prevent surface damage.

• Anti-rattle spacer to fill gaps, dampen noise and reduce vibration.

• Door kick pads.

• Corner protection strips.

• Roll covering for textile industry and other web feed machinery.

• Die cut cushioning stop for cabinetry (3M™ Bumpon™ Resilient Rollstock SJ5200 and SJ5900 Foam).

(2)

Page 3

3M™ Bumpon™ Protective Products

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Product Construction

3M™ Bumpon™ Resilient Rollstock Series

SJ5200 SJ5800 SJ5900 SJ6000 SJ6200

Elastomer Polyurethane (foam) Polyurethane (solid) Polyurethane (foam) Polyurethane (solid) Polyurethane (solid)

Elastomer Finish matte matte matte matte matte

4 mil, silicone coated, 4 mil, silicone coated, 4 mil, silicone coated, 4 mil, silicone coated, 4 mil, silicone coated,

Release Liner translucent polyester (PET), translucent polyester (PET), translucent polyester (PET), translucent polyester (PET), translucent polyester (PET),

with printed 3M logo with printed 3M logo with printed 3M logo with printed 3M logo with printed 3M logo

Adhesive R-25 (synthetic rubber) R-30 (natural rubber) A-20 (acrylic) A-20 (acrylic) R-25 (synthetic rubber)

3M™ Bumpon™ Resilient Rollstock Product

SJ5216 SJ5208 SJ5832 SJ5801 SJ5816 SJ5808 SJ5916 SJ5908 SJ5904 SJ6032 SJ6016 SJ6008 SJ6005 SJ6232 SJ6216 SJ6208

Color Light Light Black Black Black Black Black Black Black Black Black Black White Black Black Black

Brown Brown Brown Brown Brown Brown Brown Brown Black

Thickness* in. 1/16 1/8 1/32 3/64 1/16 1/8 1/16 1/8 1/4 1/32 1/16 1/8 1/5 1/32 1/16 1/8

in. 0.062 0.125 0.031 0.039 0.062 0.125 0.062 0.125 0.250 0.031 0.062 0.125 0.20 0.031 0.062 0.125

(mm) (1.6) (3.2) (0.8) (1.0) (1.6) (3.2) (1.6) (3.2) (6.4) (0.8) (1.6) (3.2) (5.0) (0.8) (1.6) (3.2)

Thickness ± in. 0.010 0.015 0.005 0.006 0.007 0.010 0.010 0.015 0.020 0.005 0.007 0.010 0.012 0.05 0.007 0.010

Tolerance ± (mm) (0.25) (0.38) (0.13) (0.15) (0.18) (0.25) (0.25) (0.38) (0.50) (0.13) (0.18) (0.25) (0.31) (0.13) (0.18) (0.25)

Roll Length yd. 36 36 72 72 36 36 36 36 18 72 36 36 24 72 36 36

Roll Width**

Standard in. 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5

(mm) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3) (114.3)

Minimum in. 0.5 0.5 0.5 – 0.5 1 0.5 0.5 1 0.5 0.5 1 – 0.5 0.5 1

(mm) (12.7) (12.7) (12.7) – (12.7) (25.4) (12.7) (12.7) (25.4) ((12.7) (12.7) (25.4) – (12.7) (12.7) (25.4)

Maximum in. 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9

(mm) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6) (228.6)

Slitting ± in. 1/32 1/32 1/32 1/32 1/32

Tolerance ± in. 0.031 0.031 0.031 0.031 0.031

± (mm) (0.8) (0.8) (0.8) (0.8) (0.8)

*Tested in accordance with ASTM D-3767 method, procedure A (3.2 psi) measured without liner.

**Non-standard sizes may be subject to minimum order requirements.

Custom Rollstock Products

Custom Thickness: 3M can customize thickness to your specifications.

Note: The capability range for 3M™ Bumpon™ Resilient Rollstock Series SJ5800, SJ6000, and

SJ6200 is 1/32 in. (0.031) minimum and 1/4 in. (0.250) maximum.

The capability range for 3M™ Bumpon™ Resilient Rollstock Series SJ5900 is 1/16 in. (0.062)

minimum and 5/16 in. (0.312) maximum.

Custom Color: 3M can match most colors to your specifications.

Note: Special products require a qualifying minimum order quantity, and one-time color matching charge. For more

information please contact your local 3M sales rep or distributor.

(3)

Page 4

3M™ Bumpon™ Protective Products

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

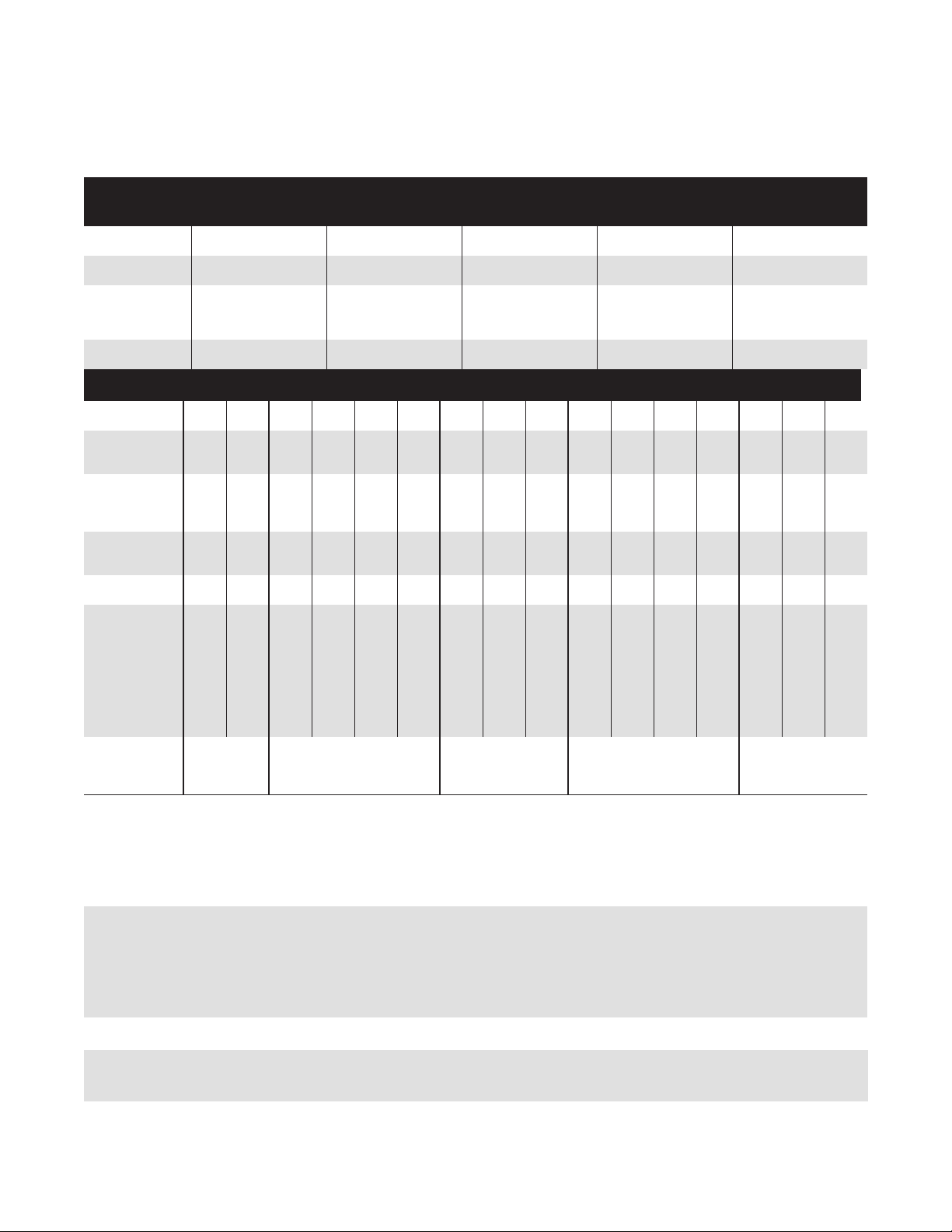

Typical Physical Properties and Performance Characteristics

Note: The following technical information and data should be considered representative or typical only and should

not be used for specification purposes.

3M™ Bumpon™ Resilient Rollstock Series

Property Test Method*** SJ5200 SJ5800 SJ5900 SJ6000 SJ6200

Hardness, Shore M ASTM-D-2240 36 (SJ5216) 72 40 (SJ5916) 72 72

29 (SJ5208) 36 (SJ5908,

SJ5904)

Approximate Density, lb/ft3 40 80 40 80 80

(g/cm3) (0.64) (1.3) (0.64) (1.3) (1.3)

Kinetic Coefficient of Friction* ASTM-D-1894

Stainless Steel * > 1 > 1 > 1 > 1

Glass * > 1 > 1 > 1 > 1

Formica® laminate * 0.9 - 1.4 0.8 - 1.4 0.9 - 1.4 0.9 - 1.4

Wood * 0.9 - 1.4 0.8 - 1.4 0.9 - 1.4 0.9 - 1.4

* Two important laws of friction applicable to 3M™ Bumpon™ Resilient Rollstock are: (1) Friction is independent of the area of contact

between solids. (2) Friction is proportional to the load between solid surfaces. Thus, if the load (weight) is doubled, the force required to

cause surface sliding is also doubled. This is expressed mathematically as follows:

Sliding force = (kinetic coefficient of friction) x (weight)

Abrasion Resistance ASTM-C-501 * 1.7 - 1.9 1.8 - 2.0 1.7 - 1.9 1.7 - 1.9

Taber H 18, 1 kg, g/1000 cycles

Tensile, lb/in2 ASTM-D-412, Die A * 600 120 600 600

(kPa) (4140) (830) (4140) (4140)

Elongation, % ASTM-D-412, Die A * 100 100 100 100

Compression Set, % ASTM-D-1056 8 – 12 – –

(50% deflection) 10 – 14 – –

ASTM-D-395 – 3 – 3 3

(25% deflection) – 4 – 4 4

Dielectric Strength, volts/mil ASTM-D-1000 * 200 140 200 200

Flammability Listing UL Classification * UL94HB UL94HBF UL94HB UL94HB

(except SJ5916)

Stain Resistance** 3M - 24 hrs. @ 158°F against No staining observed

white paint, 7 days exposed to UV

Ozone and Oxygen Resistance** 3M - 30 days @ 50 ppm ozone No visual deterioration

Solvent and Fuel Resistance** 3M - 24 hr. immersion

5% Detergent in water No apparent effect

25% Ammonia in water No apparent effect

Bleach No apparent effect

Hydrochloric Acid (1 normal solution) No apparent effect

Diesel Fuel No apparent effect

Auto Oil No apparent effect

Isopropyl Alcohol Slight effect (swelling)

Heptane Slight effect (swelling)

Toluene (Toluol) Considerable effect (swelling)

Lacquer Thinner Considerable effect (swelling)

Load Tolerance The recommended maximum load which Bumpon Resilient Rollstock series SJ5800, SJ6000

and SJ6200 will support is 100 psi (690 kPa) at 70°F (21°C) to 120°F (49°C).

Environmental Performance Bumpon Resilient Rollstock is intended for interior applications where resilience and all other

physical properties will remain unchanged. When exposed to UV light for extended periods,

some discoloration may occur. Bumpon resilient rollstock may be used outdoors in a protected

area with some discoloration and chalking possible.

* = Not tested for Bumpon SJ5200 Series (soft foam)

** = Reference test for time periods specified only.

Results may vary for different product application conditions.

*** = When ASTM method is listed, data was collected in accordance with ASTM test method.

(4)

Page 5

3M™ Bumpon™ Protective Products

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Relative Adhesive Performance Characteristics

Note: The following technical information and data should be considered representative or typical only and should

not be used for specification purposes.

3M™ Bumpon™ Resilient Rollstock

SJ5900 Series SJ5200 Series

SJ5800 Series SJ6000 Series SJ6200 Series

Adhesive:

R-30 A-20 R-25

Adhesion (Peel)

Low Surface Energy: Good Poor Excellent

High Surface Energy: Good Good Excellent

Static Shear

75°F (25°C): Excellent Excellent Excellent

120°F (49°C): Fair Excellent Good

158°F (70°C): Poor Excellent Fair

Initial Adhesion

Low Surface Energy: Good Poor Excellent

High Surface Energy: Good Fair Excellent

Solvent Resistance: Good Excellent Good

Age Life: Good Excellent Good

Natural Rubber Acrylic Synthetic Rubber

Adhesive Performance

Note: The following technical information and data should be considered representative or typical only and should

not be used for specification purposes.

The following table on peel adhesion provide representative performance characteristics of the adhesive

systems used in the construction of 3M™ Bumpon™ Resilient Rollstock SJ5200, SJ5800, SJ5900, SJ6000,

and SJ6200 series products.

90° Peel Adhesion Peel Force, oz. per 1/2 inch

3M™ Bumpon™ Resilient Rollstock

SJ5900 Series SJ5200 Series

SJ5800 Series SJ6000 Series SJ6200 Series

Substrate:

R-30 A-20 R-25

Polypropylene 25 3 52

Polystyrene 25 11 55

ABS 25 25 55

Stainless Steel 22 25 55

Aluminum 22 25 55

3M Test Method TM-2011; 72 hour dwell, 1/2 inch wide samples pulled at 12 inches per minute. Testing completed using Bumpon Resilient Rollstock

products SJ5816, SJ6016, and SJ6216.

Natural Rubber Acrylic Synthetic Rubber

(5)

Page 6

3M™ Bumpon™ Protective Products

Initial Contact (Minimal Contact)

After Rubdown (More Contact)

After Dwell Time (Excellent Contact)

Bonding

Surface

Adhesive

Bonding

Surface

Adhesive

Bonding

Surface

Adhesive

Low

Adhesion

High

Acrylic

Rubber

0

24 48 72

Dwell Time – Hours

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Adhesive Description

Natural Rubber (R-30) – Used in the construction of 3M™ Bumpon™ Resilient Rollstock SJ5800 Series products.

This high tack adhesive system provides excellent initial adhesion and is designed for providing excellent adhesion

to a wide variety of surfaces including many low surface energy surfaces such as polypropylene, polyethylene and

powder coated paints. This adhesive system shows reduced shear properties at elevated temperatures.

Acrylic (A-20) – Used in construction of 3M™ Bumpon™ Resilient Rollstock SJ5900 and SJ6000 Series products.

This high strength adhesive system provides excellent shear strength properties. The adhesive is designed for

providing excellent adhesion to many high surface energy substrates such as metals, ABS, polycarbonate and

acrylic. When adhesion is required on low surface energy substrates (ie, polypropylene, polyethylene, etc.)

acrylic-based adhesives do not perform as well as rubber-based adhesives.

Synthetic Rubber (R-25) – Used in the construction of 3M™ Bumpon™ Resilient Rollstock SJ6200 Series products.

This very high tack adhesive system provides excellent initial adhesion and is designed for providing excellent

adhesion to a wide variety of surfaces including many low surface energy surfaces such as polypropylene,

polyethylene and powder coated paints. Improved die-cutting performance with new polyester (PET) release liner.

This adhesive system shows reduced shear properties at elevated temperatures.

Application Techniques

Application Temperature: 40°F (5°C) to 125°F (52°C)

Service Temperature: -30°F (-34°C) to 150°F (66°C)

225°F (107°C) intermittent exposure

To obtain maximum adhesion, surfaces should be flat, dry, and free of contaminants. Surface contact is essential to

adhesive performance. To maximize contact on a substrate:

• Clean surfaces with low strength solvent such as isopropyl alcohol (rubbing alcohol) or heptane.

Note: Be sure to follow the solvent manufacturer’s precautions and directions for use when using solvents.

• Apply firm pressure to help increase the cold flow and contact of the adhesive with the substrate.

• Allow time (dwell) to increase the surface contact and adhesion (see illustration below).

Adhesive Surface Contact

Rubber Adhesive vs. Acrylic Adhesive Bond Build-up

Note: Product selection is ultimately the responsibility of the user and should conduct their own tests under actual use and

storage conditions to determine whether product is fit for a particular purpose and user’s method of application.

(6)

Page 7

3M™ Bumpon™ Protective Products

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Die Cut Considerations

• Very important that knives be sharp.

• Although rotary die cutting can be used for thicker materials (≥ 1/16 inches), distortion in the die cut shape is

possible using this die cutting method. Flat bed die cutting is recommended for thicker materials.

• The R-25 (synthetic rubber) adhesive system is very firm (tough). It can be more difficult to die cut versus the

R-30 and A-20 adhesive systems. Also, the R-25 adhesive system is inherently stringy; as a result, if the adhesive

is not thoroughly cut, the adhesive may have a tendency to string-out when the die cut parts are removed from

the release liner quickly or by using a snapping motion. The adhesive string-out will not diminish the performance

of the product.

• Some re-welding (tendency of the adhesive system to flow back together after die cutting) is possible with the

R-25 adhesive system. Exposure to high temperature (greater than the recommended storage temperature of

60° to 80°F [16° to 27°C]) in combination with time and pressure will increase the tendency of re-welding.

Die Cut Examples

3M™ Bumpon™ Resilient Rollstock Products can be die cut to a variety of shapes and sizes.

The following examples illustrate just a few of the possibilities.

Storage and Shelf Life

The shelf life of 3M™ Bumpon™ Protective Products is 18 months from the date of manufacture when stored in the

original packaging materials and stored at 16-27°C (60-80°F) and 50% relative humidity.

(7)

Page 8

3M™ Bumpon™ Protective Products

Resilient Rollstock SJ5200 • SJ5800 • SJ5900 • SJ6000 • SJ6200 Series

Regulatory: For regulatory information about this product, contact your 3M representative.

Technical Information: The technical information, recommendations and other statements contained in this document are based upon

tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance

of a 3M product in a particular application. Given the variety of factors that can affect the use and performance of a 3M product, user

is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s

method of application.

Warranty, Limited Remedy, and Disclaimer: Unless an additional warranty is specifically stated on the applicable 3M product

packaging or product literature, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships

the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED

WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does

not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the

purchase price.

Limitation of Liability: Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product,

whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract,

negligence or strict liability.

Electronics Materials Solutions Division

3M Center, Building 224-3N-11

St. Paul, MN 55144-1000

1-800-251-8634 phone

651-778-4244 fax

www.3M.com/electronics

3M and Bumpon are trademarks of 3M Company.

Formica is a registered trademark of the Formica Corporation.

Please recycle.

©3M 2015. All rights reserved.

60-5002-0523-6

(8)

Loading...

Loading...