Page 1

Instructions and Parts List

TM

3M-Matic

P/N 78-8069-3971-2

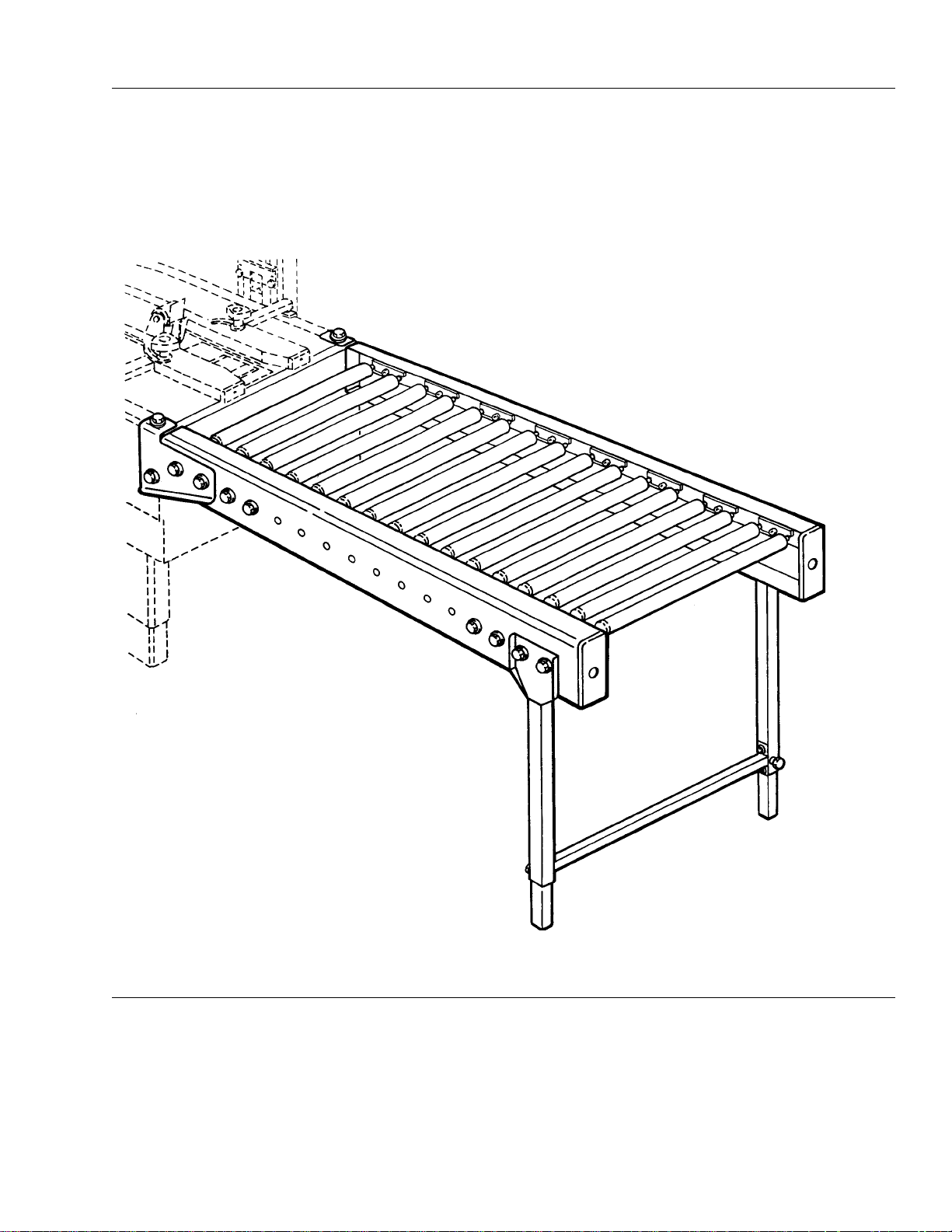

Infeed/Exit Conveyor Attachment, 1.2 Meter Type 19100

The Infeed/Exit Conveyor, 1.2 Meter, has been

designed and tested to be used only with

3M-Matic:

100a, 200a, 700a, 800a, 800a3, 800ab, 800af,

800af3 Adjustable Case Sealers

700r Random Case Sealer

Infeed/Exit Conveyor Attachment, 1.2 Meter

Shown installed on 200a Adjustable Case Sealer

Purpose of Attachment

The Infeed/Exit Conveyor Attachment, 1.2 Meter, when installed on the infeed or discharge end of a case sealer

provides additional conveyor platform surface. Use of this product for other purposes may lead to unsafe

conditions.

Page 2

Specifications

Overall Dimensions:

Length 1210 mm [47-11/16 in.]

Height 90 mm [3-1/2 in.]

Width 655 mm [25-3/4 in.]

Weight:

Packaged 31.8 kg [70 lbs.] approximate

Unpackaged 31.3 kg [69 lbs] approximate

Installation

See Figure 1

WARNINGS

1. Turn off and disconnect electrical

and air supply to case sealer before

beginning conveyor installation.

Failure to do so could result in injury

to personnel or damage to machine.

2. Safe installation of this product

requires two people to prevent

personal injury.

Important: 700r Case Sealer Do not

remove existing infeed conveyor on 700r

prior to installing this conveyor attachment.

Contents:

(1) Conveyor Roller Assembly

(2) Leg Assembly W/Mounting Hardware

(1) Leg Crossbrace

(1) Package includes:

Bracket R/H, L/H (All except 800af/af3)

Bracket R/H, L/H (800af/af3 only)

(8) M8 x 16 Hex Screws

(8) M8 Plain Washers

(4) M8 Hex Nuts

Hardware for mounting optional

Box Hold Down Attachment

P/N 78-8052-6553-1

3. Measure height from floor to case sealer

machine bed and adjust legs on conveyor to

this approximate dimension. (Loosen height

adjustment lock bolt on both legs, adjust inner

legs in or out and tighten height adjustment lock

bolt.)

4. Attach right and left-hand conveyor brackets to

conveyor with M8 x 16 bolts, plain washers and

nuts as shown. Do not tighten nuts.

5. Attach conveyor assembly to case sealer with

M8 x 16 bolts and plain washers as shown. Do

not tighten bolts.

6. Adjust conveyor legs if necessary to level

conveyor.

1. Remove M6 nuts and plain washers from leg

crossbar mounting studs on lower end of each

leg and attach crossbar as shown.

2. Remove M8 nuts, plain washers and bolts from

top mounting flange of both legs and attach legs

to conveyor as shown. Note Legs may be

attached in alternate location if desired.

7. Tighten all nuts/bolts on both conveyor brackets

(four each bracket).

Note: Bracket (Item 29) and related hardware

shown on parts drawing is used for mounting

optional Box Hold Down Attachment

(P/N 78-8052-6553-1) on conveyor.

Page 3

Figure 1 Installation

Page 4

Figure 2 Parts Drawing

Page 5

Replacement Parts List

Ref Part

No. Number Description

1 78-8094-6000-5 Conveyor Assembly

2 78-8094-6001-3 Frame R/H

3 78-8094-6002-1 Frame L/H

4 78-8076-4511-0 Cap Front, R/H

5 78-8076-4512-8 Cap Front, L/H

6 78-8032-0375-7 Screw Hex Hd, M6 x 16

7 78-8010-7418-4 Nut Hex, M6

8 78-8094-6003-9 Crossbrace Conveyor

9 26-1003-5842-8 Screw Hex Hd, M8 x 20

10 78-8017-9318-9 Washer Plain, 8 mm

11 78-8076-4579-7 Roller

12 78-8076-4507-8 Plate Infeed

13 78-8010-7157-8 Screw Hex Hd, M4 x 10

14 78-8005-5740-3 Washer Plain, 4 mm

15 78-8094-6004-7 Bracket R/H

(All except 800af)

16 78-8094-6005-4 Bracket L/H

(All except 800af)

Ref Part

No. Number Description

17 78-8094-6006-2 Bracket R/H (800af only)

18 78-8094-6007-0 Bracket L/H (800af only)

19 26-1003-5841-0 Screw M8 x 16

20 26-1003-6904-5 Nut Hex, M8

21 78-8094-6008-8 Leg

22 26-1002-4189-7 Screw Hex Hd, M10 x 20

23 78-8094-6009-6 Leg Inner

24 78-8094-6010-4 Cap

25 78-8094-6011-2 Crossbrace Leg

26 78-8094-6012-0 Screw Special, M6 x 16

27 26-1000-0010-3 Washer Flat, M6

28 26-1004-5507-5 Washer M8

29 78-8119-8958-7 Bracket

30 26-1002-5836-2 Screw Hex Hd, M6 x 40

31 26-1001-9843-6 Screw Flat Soc Hd,

M6 x 16

32 26-1003-6916-9 Nut Locking Plastic

Insert, M6

How To Order Replacement Parts

1. Refer to Parts Illustration Figure 3 to find part

needed and reference number.

2. Refer to parts list for correct part number.

3. Order by part number, description, attachment

part number and name.

Minimum billing on parts orders will be $25.00. Replacement part prices available on request.

$10.00 restocking charge per invoice on returned parts.

4. Replacement parts and part prices available

direct from:

3M/Tape Dispenser Parts

241 Venture Drive 800/344 9883

Amery, WI 54001-1325 FAX #715/268 8153

Page 6

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF

DEALING, A CUSTOM OR USAGE OF TRADE:

3M warrants that its 3M-Matic P/N 78-8069-3971-2 Infeed/Exit Conveyor Attachment, 1.2 Meter, Type 19100 will be free from defects

for ninety (90) days after delivery. If any part is proved to be defective within the warranty period, then the exclusive remedy and 3Ms and

sellers sole obligation shall be, at 3Ms option, to repair or replace the part, provided the defective part is returned immediately to 3Ms

factory or an authorized service station designated by 3M. A part will be presumed to have become defective after the warranty period

unless the part is received or 3M is notified of the problem no later than five (5) calendar days after the warranty period. If 3M is unable to

repair or replace the part within a reasonable time, then 3M, at its option, will replace the equipment or refund the purchase price. 3M shall

have no obligation to provide or pay for the labor required to install the repaired or replacement part. 3M shall have no obligation to repair

or replace (1) those parts failing due to operator misuse, carelessness, or due to any accidental cause other than equipment failure, or (2)

parts failing due to non-lubrication, inadequate cleaning, improper operating environment, improper utilities or operator error.

Limitation of Liability: 3M and seller shall not be liable for direct, indirect, special, incidental or consequential damages based upon

breach of warranty, breach of contract, negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a written agreement signed by

authorized officers of 3M and seller.

3

"Scotch" and 3M-Matic are trademarks of 3M,

3M Packaging Systems Division

3M Center, Building 220-8W-01

St. Paul, MN 55144-1000

St. Paul, Minnesota 55144-1000

Litho in U.S.A.

©3M 2001 44-0009-1938-9(B21.0)

Loading...

Loading...